Cold-state stainless steel band or plate descaling process

A technology of stainless steel and steel strip, applied in the field of iron and steel metallurgy, can solve the problems of affecting the surface quality of stainless steel, affecting the surface quality of strip steel, and not removing it cleanly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

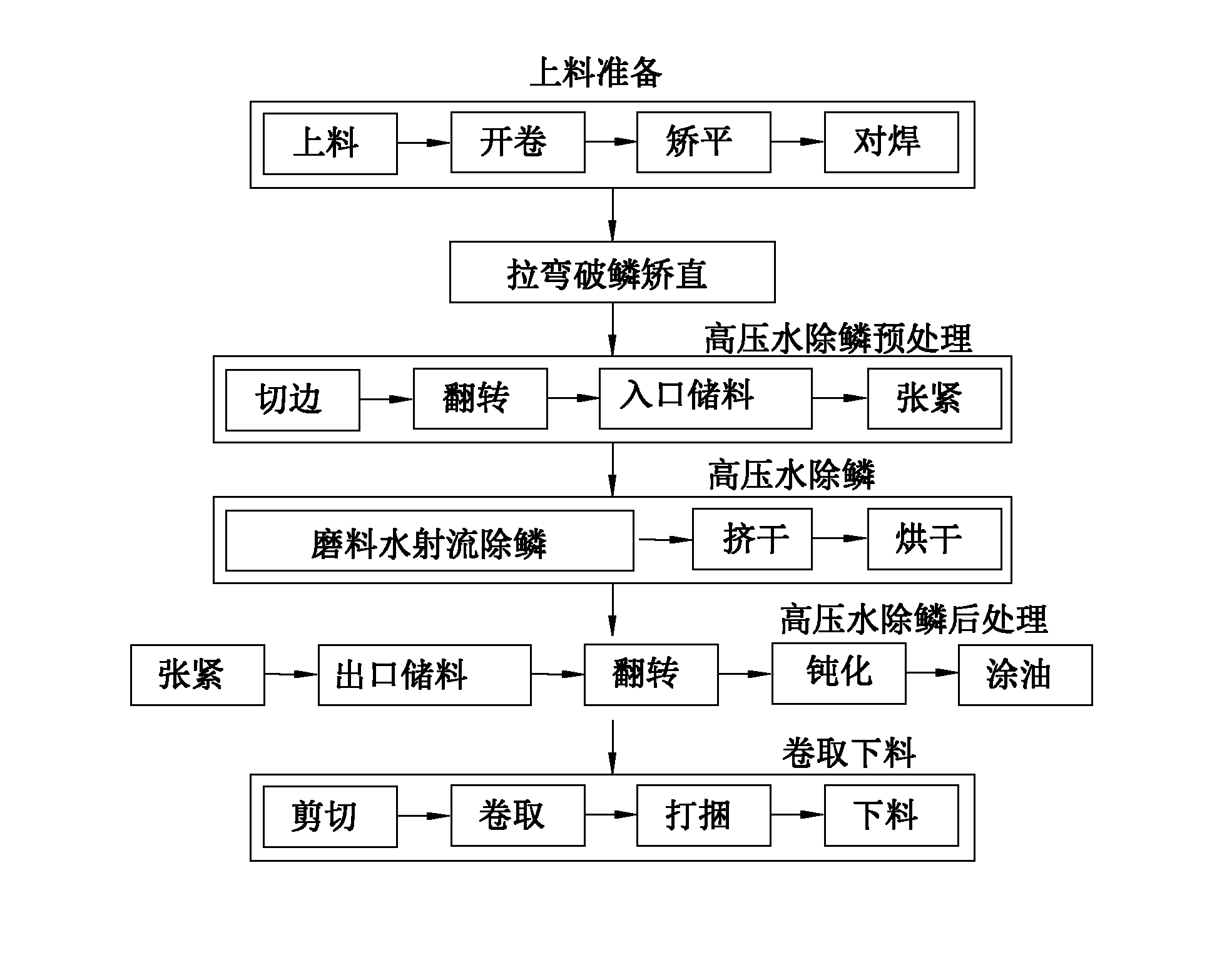

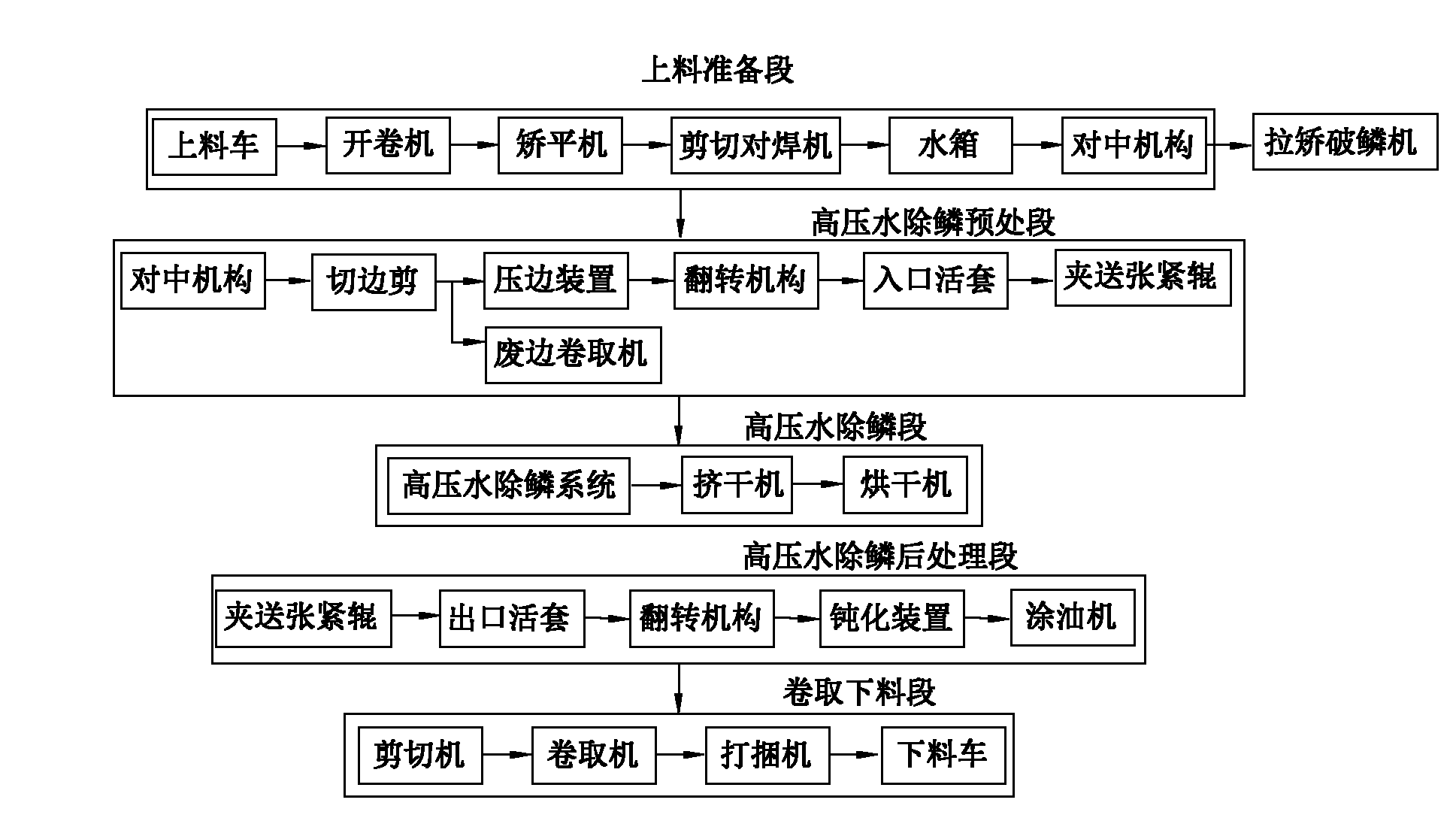

[0026] The cold-state stainless steel strip or plate descaling process provided by the present invention mainly includes feeding preparation, stretching and bending, descaling and straightening, high-pressure water descaling pretreatment, high-pressure water descaling, high-pressure water descaling post-treatment, coiling process steps. Specific process such as figure 1 As shown, the schematic flow chart of the equipment in this embodiment is as follows figure 2 shown.

[0027] Feeding preparation section: The steel coils of steel strips or plates are sequentially processed by feeding, uncoiling, leveling, shearing, and butt welding, and the discontinuous steel strips or plates are welded into a completely continuous form to ensure that the steel coils after welding Continuity of strip or sheet. can be used as figure 2 The feeding car shown sends the stainless steel strip or plate to the swing arm uncoiler for uncoiling, and after being leveled by the leveler, it is sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com