Scavenger for clearing away PVC (polyvinyl chloride) polymer in top condenser of polymerization kettle

A scavenger, condenser technology, applied in detergent compositions, soap detergent compositions, non-surface-active detergent compositions, etc. Ease of use, great social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

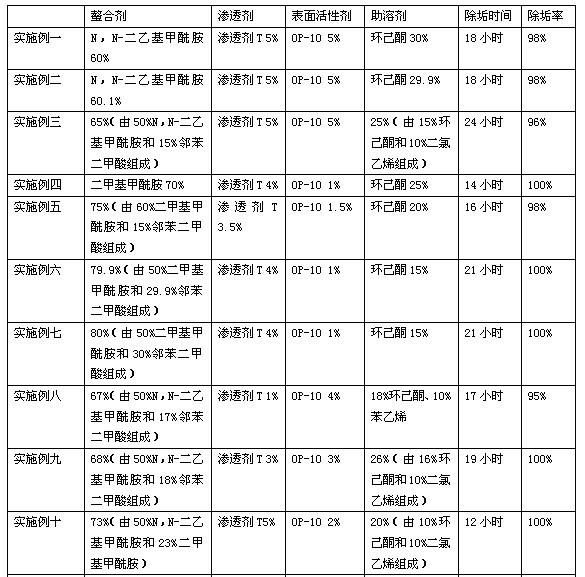

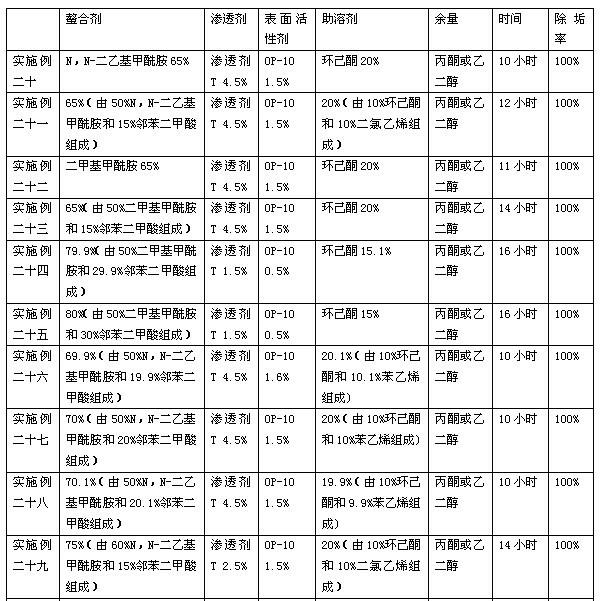

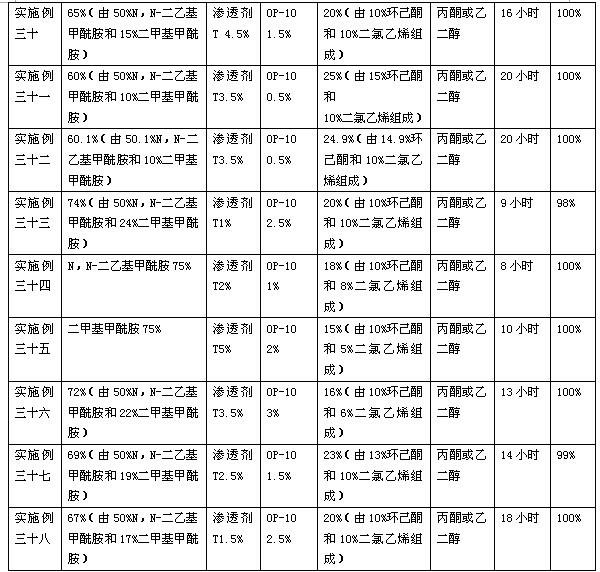

Examples

Embodiment 1

[0026] Embodiment one: a PVC polymer scavenger in the condenser on the top of the polymerization kettle, the scavenger is composed of the following components by weight percentage: chelating agent N, N-diethylformamide 60%, penetrant T 5% , Surfactant OP-10 5%, cosolvent cyclohexanone 30%.

[0027] The preparation method of the product PVC polymer scavenger of the present invention: take by weighing various raw materials according to the raw material composition of above-mentioned PVC polymer scavenger, add raw materials such as chelating agent, penetrant, surfactant, co-solvent in the reaction vessel and stir, After fully dissolving, stir evenly, and finally fill.

[0028] The application test of the above-mentioned product: take a certain amount of the product PVC polymer scavenger of the present invention and put it into a container, put a certain amount of white PVC polymer block into the product scavenger of the present invention, and heat it in a water bath to control it...

Embodiment 2

[0029] Embodiment two: basically the same as embodiment one, the difference is: the PVC polymer scavenger in the condenser on the top of the polymerization tank is made up of the following components by weight percentage: chelating agent N, N-diethylformazan Amide 60.1%, penetrant T 5%, surfactant OP-10 5%, cosolvent cyclohexanone 29.9%.

[0030] The application test of the above-mentioned product: take a certain amount of the product PVC polymer scavenger of the present invention and put it into a container, put a certain amount of white PVC polymer block into the product scavenger of the present invention, and heat it in a water bath to control its temperature at 60 to 85 ℃, after about 18 hours, the white blocky PVC polymer has completely dissolved and turned into a transparent viscous liquid. The PVC polymer is completely dissolved, and the removal rate of PVC polymer reaches 98%.

Embodiment 3

[0031] Embodiment three: basically identical with embodiment one, difference is: PVC polymer scavenger is made up of the following components by weight percentage in the condenser on the top of polymerization kettle: chelating agent 65% (from 50%N, N-two ethyl formamide and 15% phthalic acid), penetrant T 5%, surfactant OP-10 5%, cosolvent 25% (composed of 15% cyclohexanone and 10% dichloroethylene).

[0032] The application test of the above-mentioned product: take a certain amount of the product PVC polymer scavenger of the present invention and put it into a container, put a certain amount of white PVC polymer block into the product scavenger of the present invention, and heat it in a water bath to control its temperature at 60 to 85 ℃, after about 24 hours, the white blocky PVC polymer has completely dissolved and turned into a transparent viscous liquid. The PVC polymer is completely dissolved, and the removal rate of PVC polymer reaches 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com