Patents

Literature

74results about How to "Does not cause corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tableware detergent with anti-bacterial function

InactiveCN105441219AReduce poisonLess irritatingInorganic/elemental detergent compounding agentsDetergent mixture composition preparationHydroxypropylmethyl celluloseChemistry

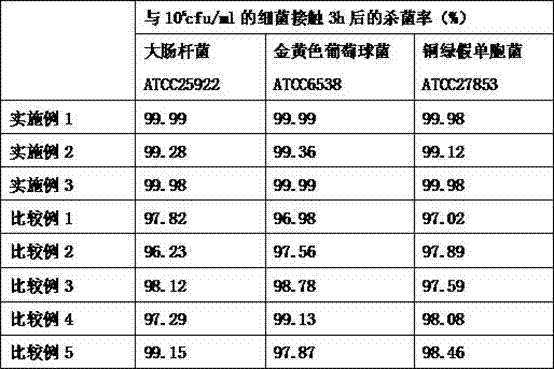

The invention relates to a tableware detergent with an anti-bacterial function. The tableware detergent is prepared by the following raw materials in parts by weight: 5 to 10 parts of sucrose palmitate, 5 to 10 parts of alkyl glycoside, 5 to 10 parts of dodecyl dimethyl betaine, 5 to 10 parts of chitosan, 1 to 5 parts of seconary alkane sulphonate sodium, 0.5 to 2 parts of sodium alginate, 0.5 to 3 parts of sodium sulfate, 0.5 to 3 parts of sodium perborate, 1 to 3 parts of lemon acid, 1 to 3 parts of sodium chloride, 1 to 5 parts of hydroxypropyl methylcellulose sodium, 1 to 5 parts of xanthan gum, 1 to 5 parts of lipase, 0.5 to 1 parts of tea saponin, 0.5 to 2 parts of bactericide, 0.5 to 2 parts of chelating agent, 0.1 to 0.5 part of essence, 5 to 10 parts of glycerin, 5 to 10 parts of ethanol, and 20 to 50 parts of deionized water. The tableware detergent with the anti-bacterial function has the advantages that the detergency is strong, the irritation to skins is avoided, the environment-friendly effect is realized, the inhibition function on various pathogenic bacteria is realized, various food residues and oils can be quickly removed, and the spots of the tableware are avoided after cleaning.

Owner:王玉芹

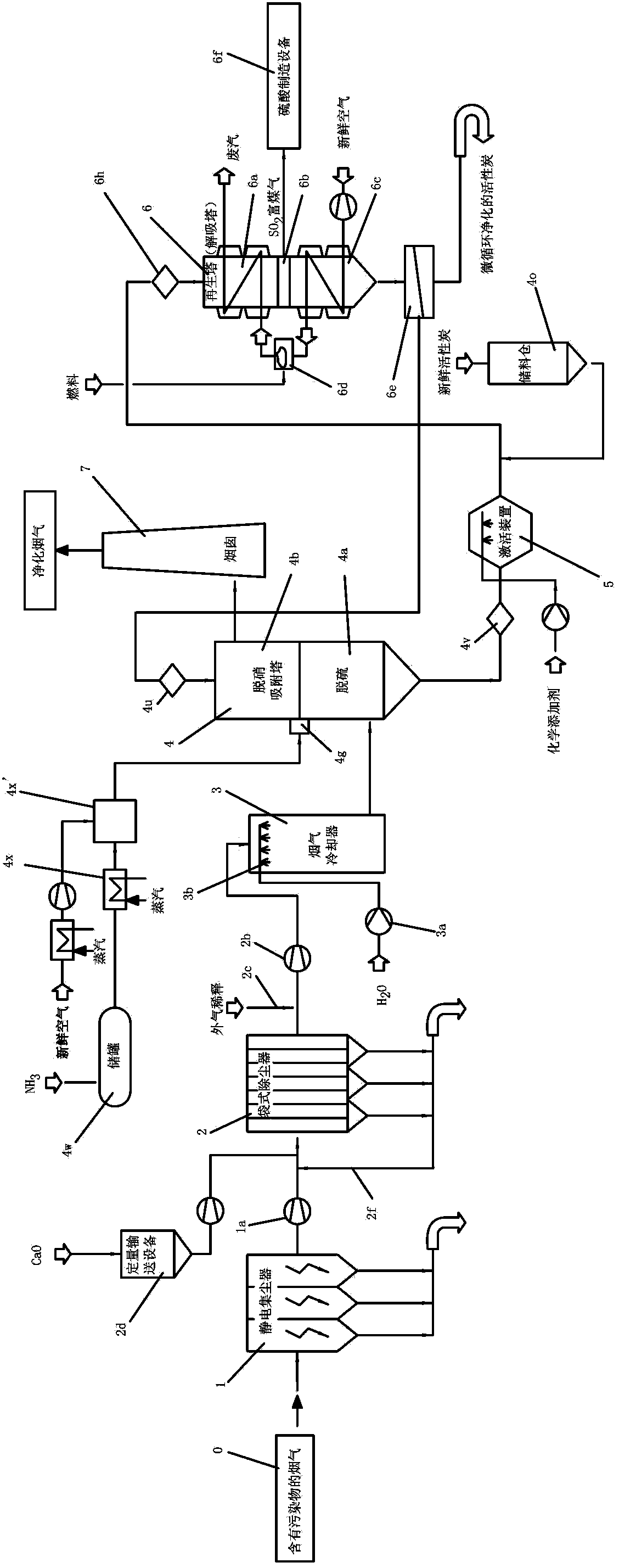

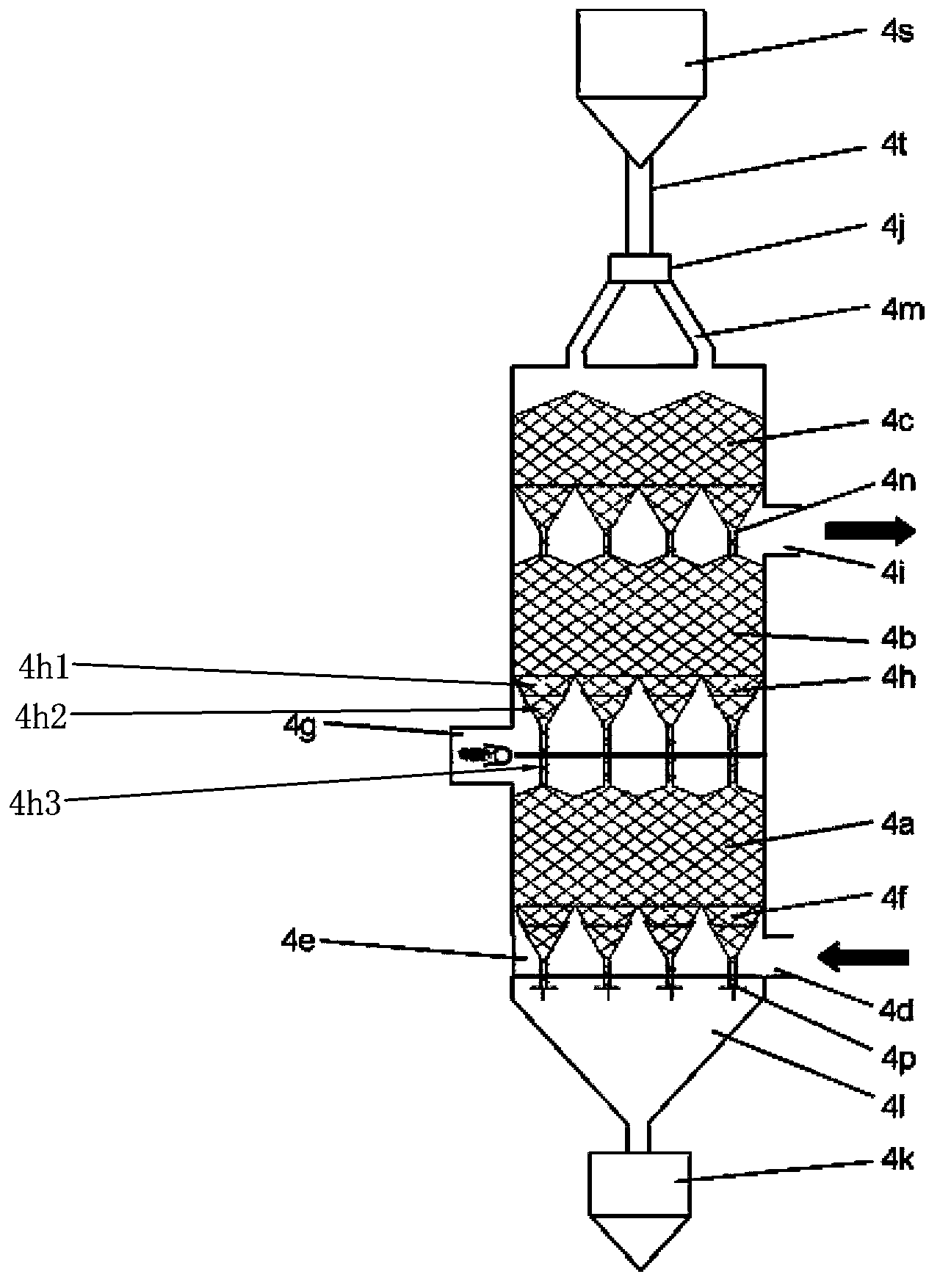

Flue gas purifying system

The invention relates to a flue gas purifying system which comprises a pretreatment system, a flue gas cooling system and an adsorbing tower, wherein flue gas enters the adsorbing tower through the pretreatment system by a pipeline and then is purified, the flue gas cooling system is arranged on a pipeline between the pretreatment system and the adsorbing tower, the flue gas cooling system comprises a flue gas cooler, an external gas diluter, a first temperature sensor, a second temperature sensor and a first flue gas pipe; one end of the first flue gas pipe is fixedly arranged on a gas inlet of the adsorbing tower, a gas inlet baffle plate is arranged on the gas inlet of the adsorbing tower, the other end of the first flue gas pipe is connected with the pretreatment system, the external gas diluter and the flue gas cooler are respectively arranged on the first flue gas pipe, the flue gas cooler is positioned between the external air cooler and the adsorbing tower, the first temperature sensor is positioned between the external gas diluter and the flue gas cooler, the second temperature sensor is positioned between the flue gas cooler and the adsorbing tower, and a baffle plate capable of regulating the gas inflow is arranged on the external gas cooler. According to the flue gas purifying system, local hot spots of active carbon or active coke in the adsorbing tower can be prevented.

Owner:HONGKONG NOROTAEIL ENVIROMENTAL PROTECTION TECH CO +1

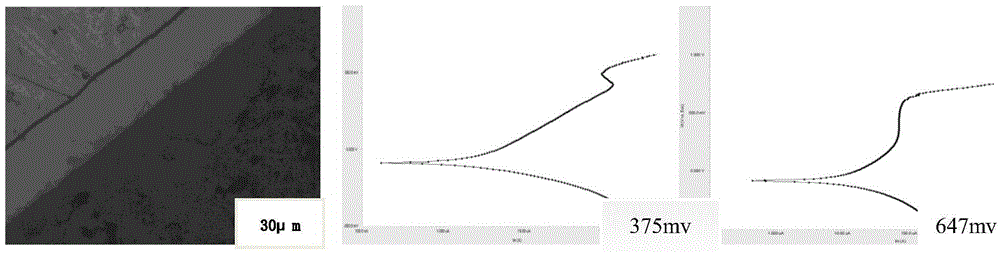

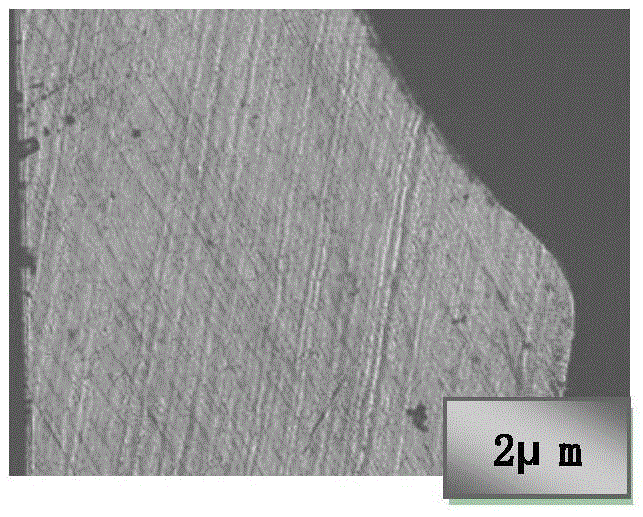

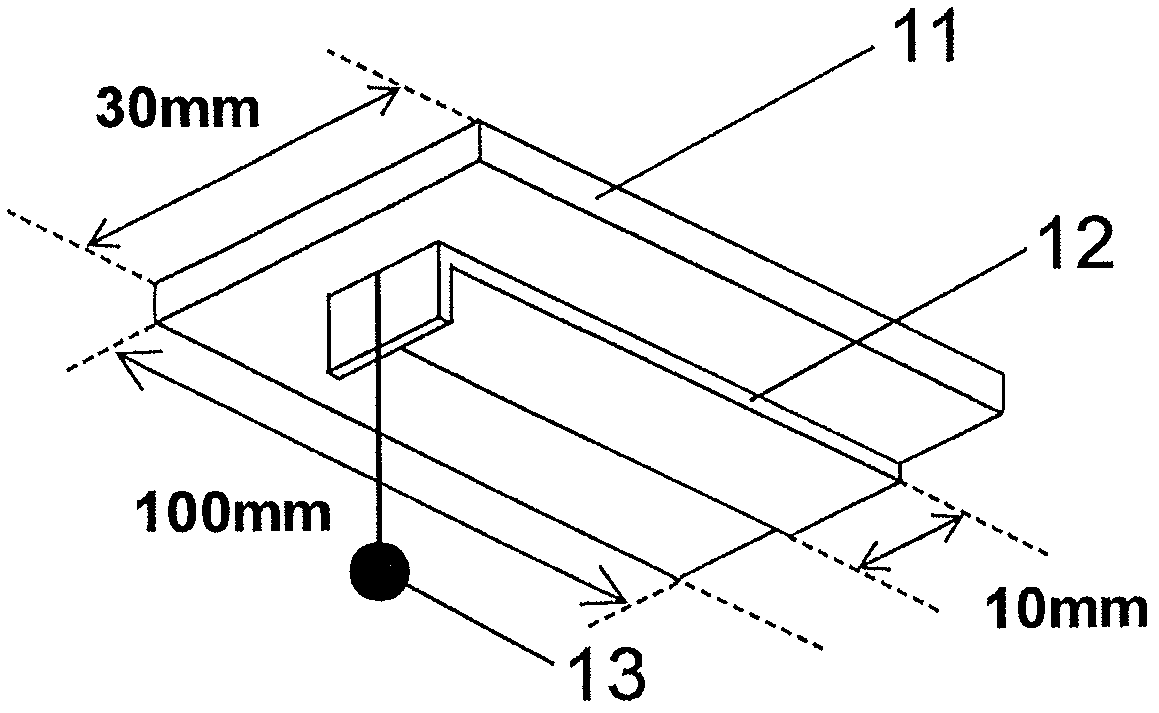

Glow ion carbonization method for enhancing surface hardness and corrosion resistance of stainless steel

InactiveCN105603359AAdd depthGuaranteed corrosion resistanceSolid state diffusion coatingHydrogenCarbonization

The invention discloses a glow ion carbonization method for enhancing surface hardness and corrosion resistance of stainless steel. The method comprises the following steps: putting an austenitic stainless steel part with clean and dry surface in a glow ion nitriding furnace; evacuating air in the furnace, cleaning the hearth with high-purity hydrogen, charging argon under high voltage, and carrying out glow discharge to remove the passivating film on the stainless steel surface, thereby obtaining the activated surface. In the glow discharge process, under the plasma bombarding action, the temperature of the stainless steel rises; when the temperature rises to the carburizing temperature, the argon is shut down, and a carbon-containing reducing atmosphere is introduced to a certain pressure to perform carburization; and after the carburization is finished, the stainless steel is immersed in an etching solution to remove the non-corrosion-resistant layer on the workpiece surface, thereby enhancing the hardness and corrosion resistance of the austenitic stainless steel. The treated stainless steel has the advantages of uniform surface carburized layer, high safety and reliability, no pollution and the like.

Owner:FUJIAN WIDE PLUS PRECISION INSTR

Pressure-sensitive adhesive composition and pressure-sensitive adhesive sheet

InactiveCN102757752ANo corrosionDoes not cause corrosionFilm/foil adhesivesEster polymer adhesivesTemperature stressVitrification

The present invention provides a pressure-sensitive adhesive composition excellent in the anti-foaming release property and high-temperature stress relaxation property, and a pressure-sensitive adhesive layer composed of the pressure-sensitive adhesive composition. The invention relates to a pressure-sensitive adhesive composition including an acrylic polymer which is formed from a monomer component including methyl methacrylate and has a glass transition temperature (Tg) of -40 DEG C or more, wherein the pressure-sensitive adhesive composition has a shear storage elastic modulus at 85 DEG C as measured by a dynamic viscoelasticity measurement of from 110 4 to 310 5 Pa.

Owner:NITTO DENKO CORP

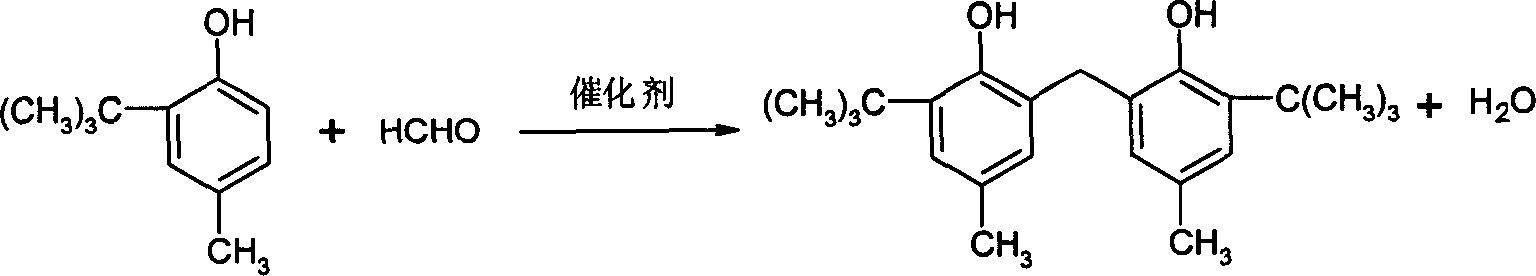

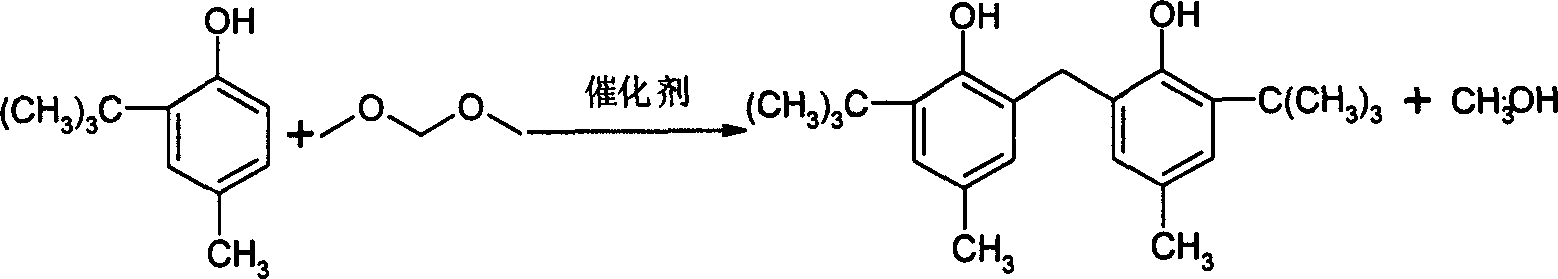

Prepn process of 2,2'-methylene bis (4-methyl-6-tert-butyl phenol)

InactiveCN1506345AImprove stabilityEasy to separateOrganic chemistryOrganic compound preparationTert butyl phenolCresol

The present invention relates to the preparation process of 2,2'-mehtylene bis(4-methyl-6-tert-butyl phenol). The present invention adopts macroporous strong acid cationic exchange resin, zeolite with SiO2 / Al2O3 molar ratio of 15-100, or heteropolyacid or other solid acid as catalyst; and formal and 2-tert-butyl-4-cresol as material, with the catalyst amount being 10-80 wt% of 2-tert-butyl-4-cresol. The reaction is performed at the temperature of 40-100 deg.c for 1-5 hr, and the reaction resultant is filtered, distilled and refined to obtain the product. The process of the present invention has the features of simple post-reaction treatment, high product yield, high product quality, no corrosion to the apparatus and high catalyst stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

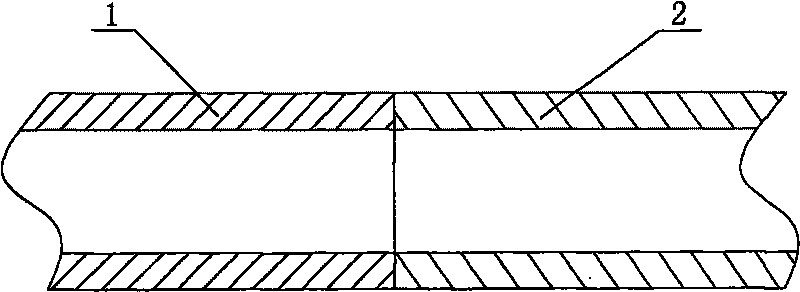

Copper-aluminum joint pressure welding technique

ActiveCN101274389AReduce production processReduce manufacturing costNon-electric welding apparatusPneumatic pressurePure metals

The invention relates to a pressure welding technique of a copper and aluminum joint, which is characterized by steps of: the blanking of a copper pipe and an aluminum pipe, the removal of burr and the washing of the surface of the copper pipe with acid; welding: a welding machine, an upper clamping mould and a lower clamping mould are adjusted; the copper pipe and the aluminum pipe are respectively clamped between the upper clamping mould and the lower clamping mould, the two ports for welding are extruded out of the clamping mould, the ends of the copper pipe and the aluminum pipe to be welded are heated to the temperature of about 420 to 540 DEG C and applied with the upsetting force of 0.4 to 0.8Mpa so as to cause the close contact of the welding surface of the copper pipe and the welding surface of the aluminum pipe, radial plastic deformation is generated by pressure, metal flashes are formed and a welding line is formed by the closely contacted pure metals, therefore, the welding process is finished; detecting welding beadings, removing residues and external burr; leak-checking: detecting whether the welded pipe has leakage by an air pressure test; drying and leak-checking with helium. The invention has simple technique and can reduce production cost and enhance production efficiency; since the oxidized film of the contact surface of the copper pipe and the aluminum pipe are damaged and extruded during pressure-increasing and deforming, the welded joint can be purified with good welding quality, no leakage, no deformation and long service life.

Owner:SHUNDE SANSHENG ELECTRICAL MFG CO LTD

Nonionic water base amphiphilic engine cleansing agent

The invention discloses a nonionic water base amphiphilic engine cleansing agent, comprising the following components by weight percent: 10-15% of washing foaming agent, 18-22% of ether-type nonionic surfactant, 4-6% of colloid, 0.1-0.5% of demulsifier, 0.05-0.10% of engine abstergent, 4-6% of activating agent and the balance of water. The nonionic water base amphiphilic engine cleansing agent provided by the invention belongs to a special engine washing additive of a vegetable biological preparation, and has the properties of biodegradation, low toxicity and extremely less pollution to environment; the engine can be washed more thoroughly and cleanly by utilizing the engine cleansing agent, the rust corrosion drawback can not be caused, and the engine oil cost and the fuel cost are saved compared with those of the existing methods; and the vehicle power is preferably utilized, thus achieving the effects of emission reduction ( the emissions of waste lubricating oil, a flammable liquid and waste gas are reduced), energy conservation (the lubricating oil, the flammable liquid and power fuels are saved), environment friendliness ( the production, transportation, storage and use processes conform to a safety environment conservation standard) and the like.

Owner:黄显扬

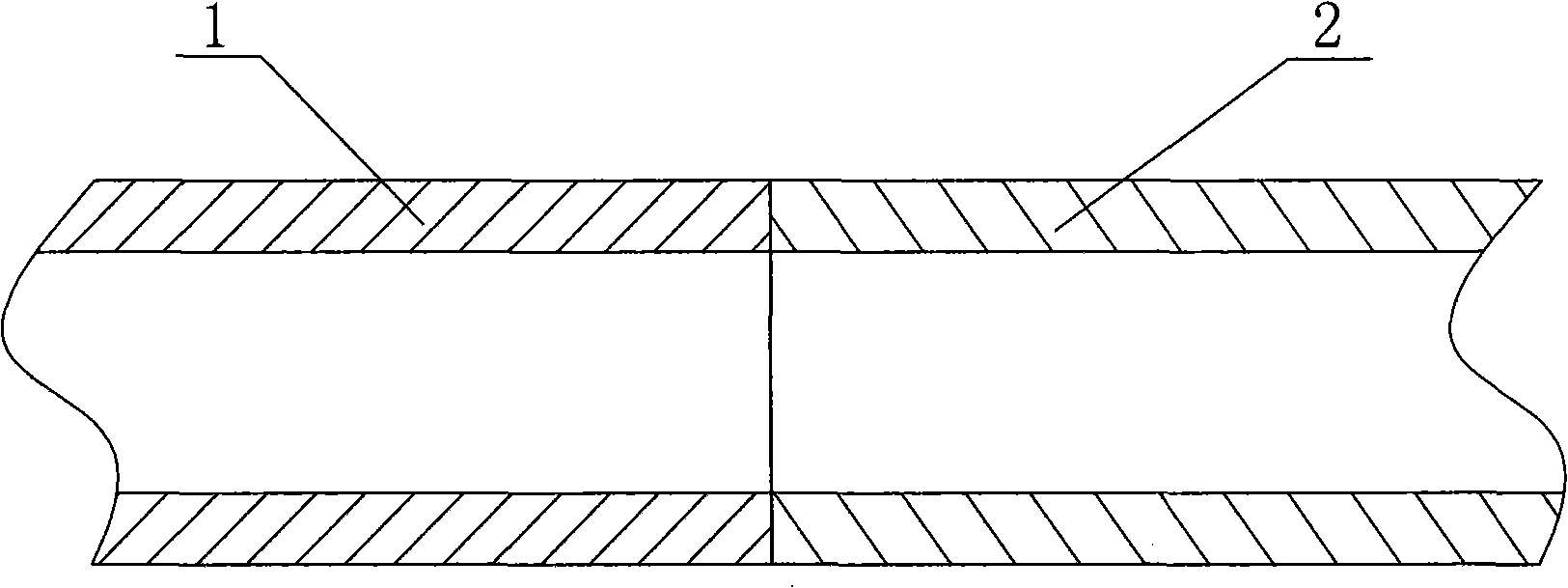

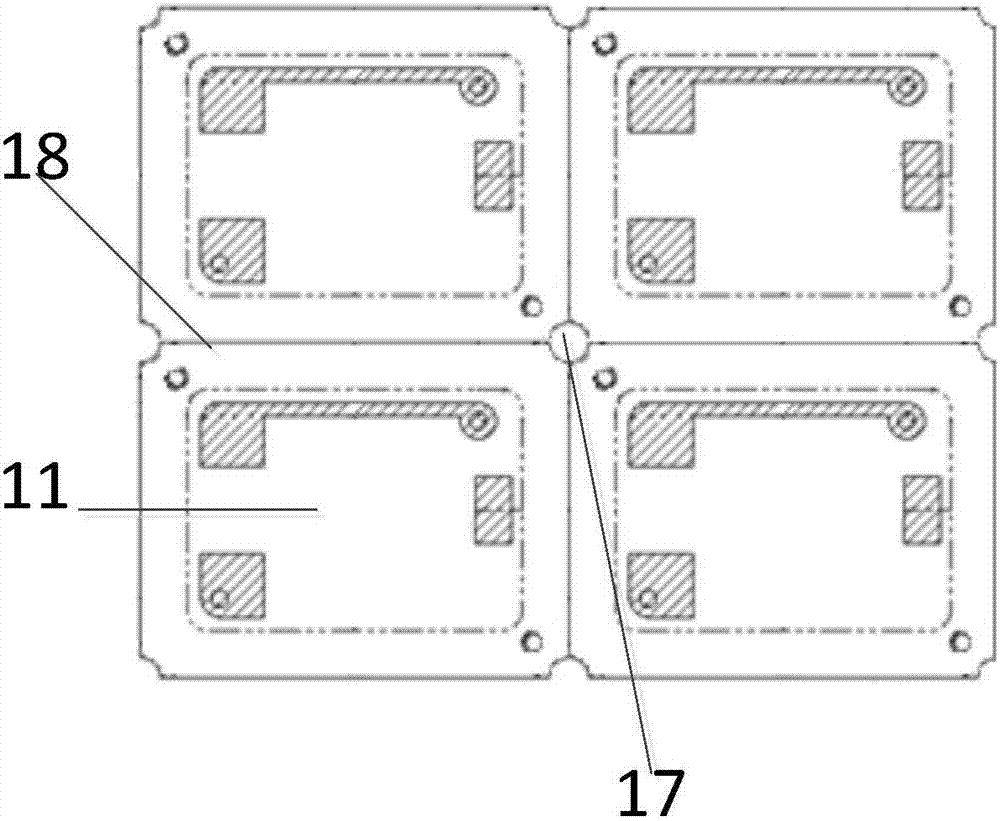

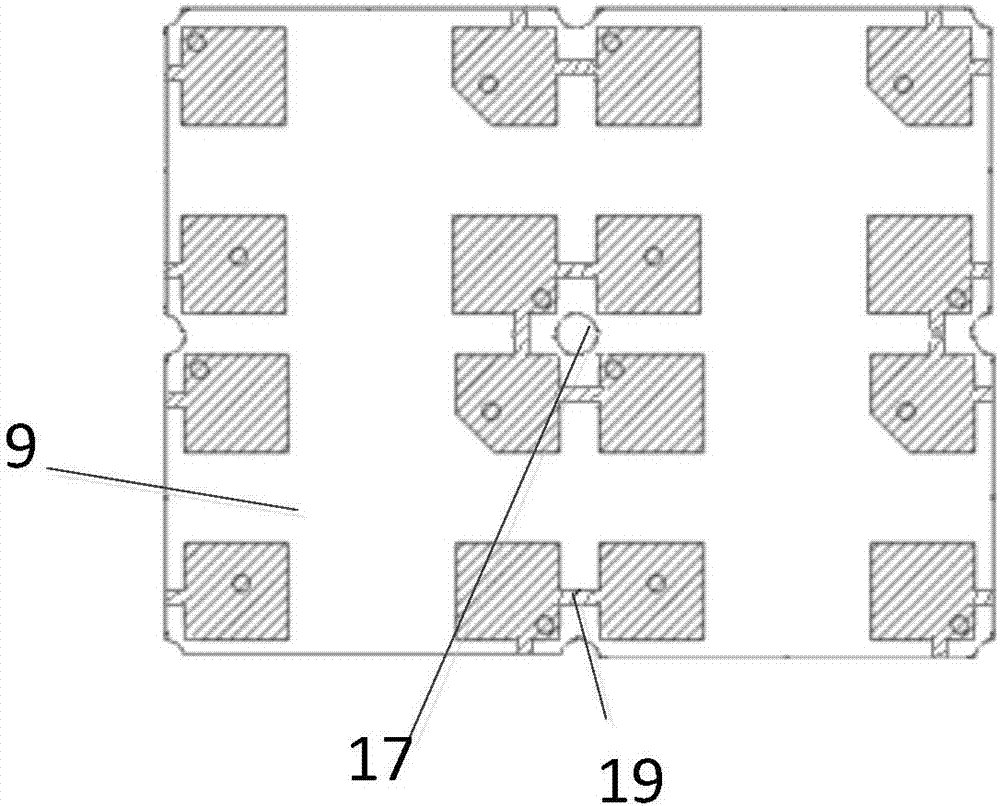

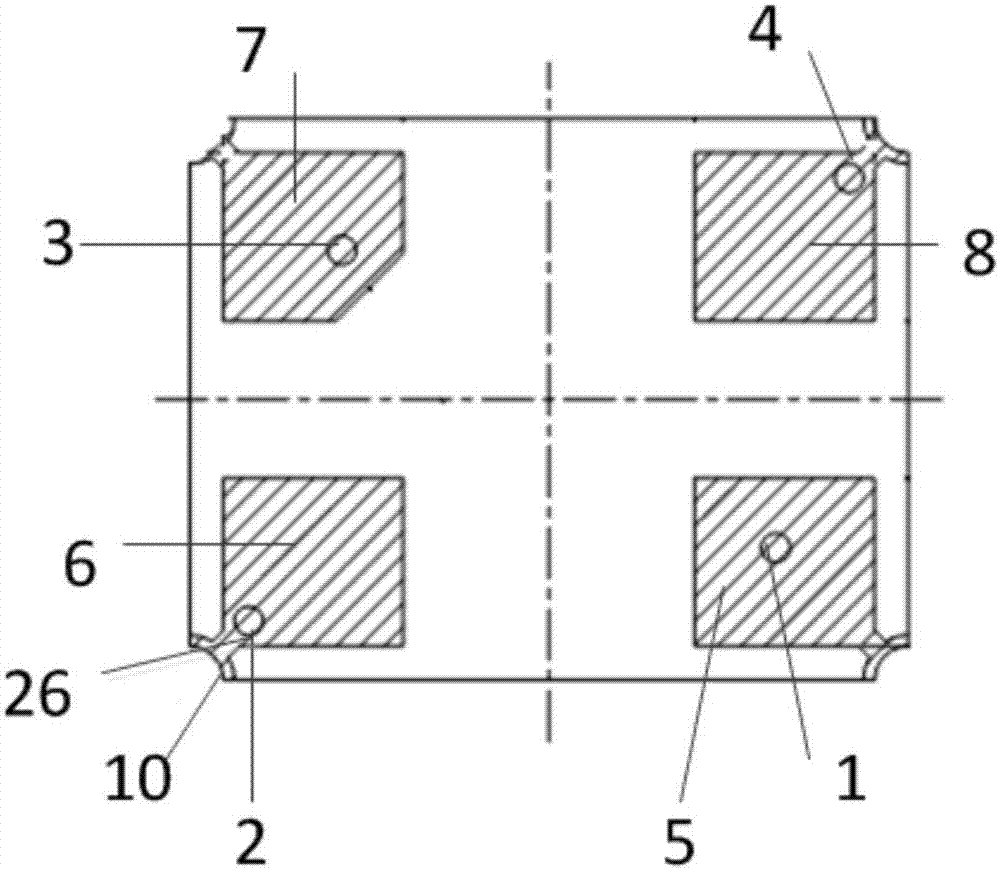

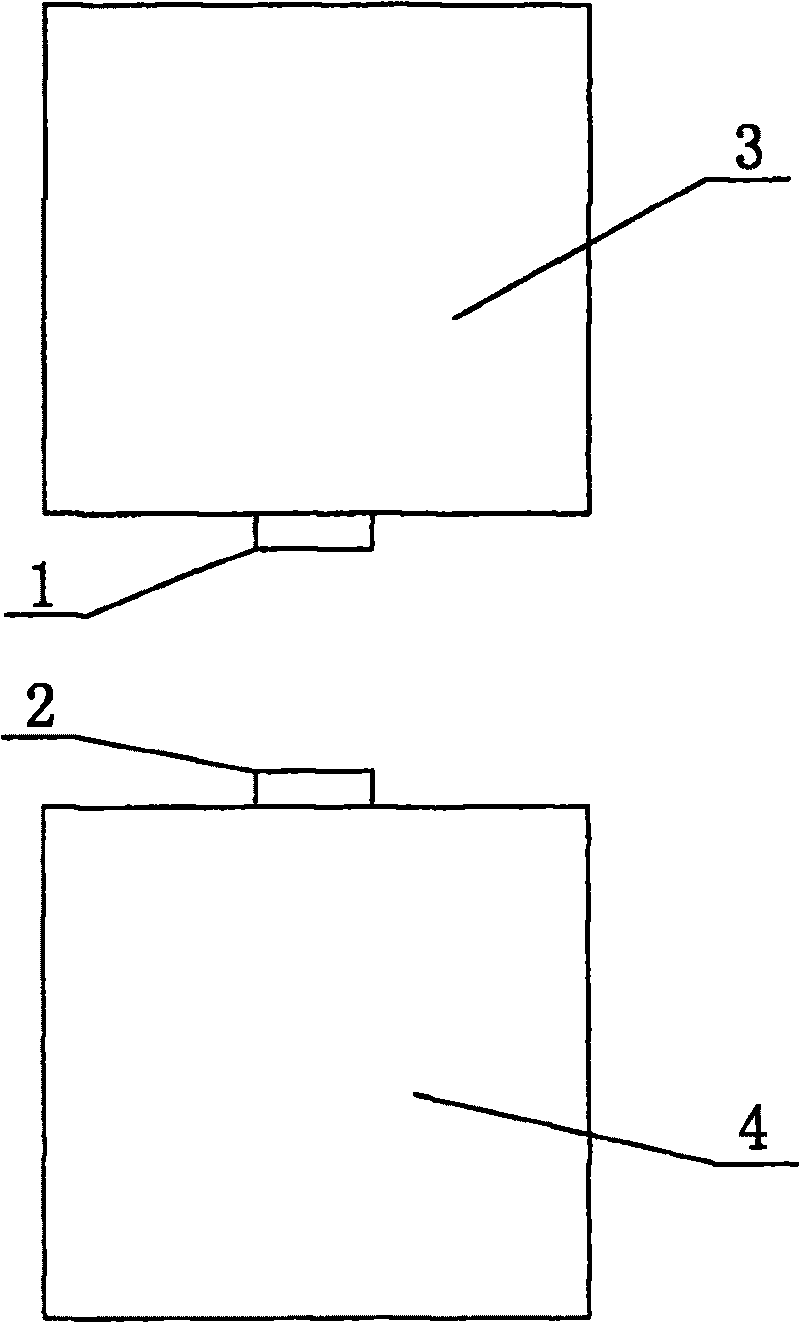

SMD quartz crystal resonator processing method and resonator thereof

The invention relates to a processing method of a SMD quartz crystal resonator. The processing method comprises the following steps: firstly providing a complete board resonator semi-finished product, wherein the complete board resonator semi-finished product comprises a base complete board and a cover complete board covered on the base complete board; and then cutting the cover complete board on the complete board resonator to form single base cover boards, and spraying and coating protective layers on the upper surface and sections of each cover board, wherein the method for spraying and coating the protective layer comprises pretreatment process and spraying and coating process; the pretreatment process comprises cleaning, washing, air showering and drying; the spraying and coating process comprises the following steps: firstly spraying and coating the spraying and coating material on the upper surface and section of each base cover board of the resonator complete board by using an electrostatic spraying and coating process to form the coatings, and then performing curing treatment on the coatings to form the protective layers on the upper surface and the section of each base cover board. The processing method disclosed by the invention aims at improving the salt mist resistance and high temperature and high humidity resistance of the SMD quartz crystal resonator under the severe environment. The invention further relates to a resonator prepared by adopting the above-mentioned method.

Owner:SICHUAN MDH TECH CO LTD

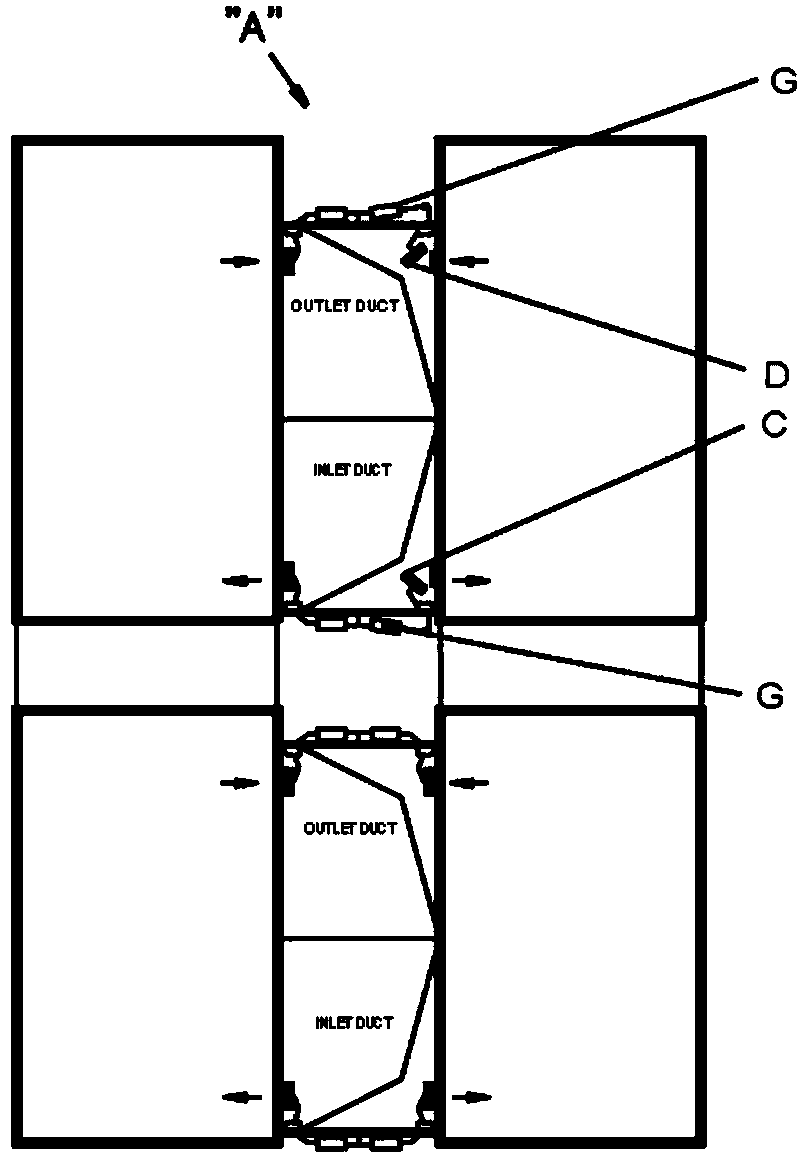

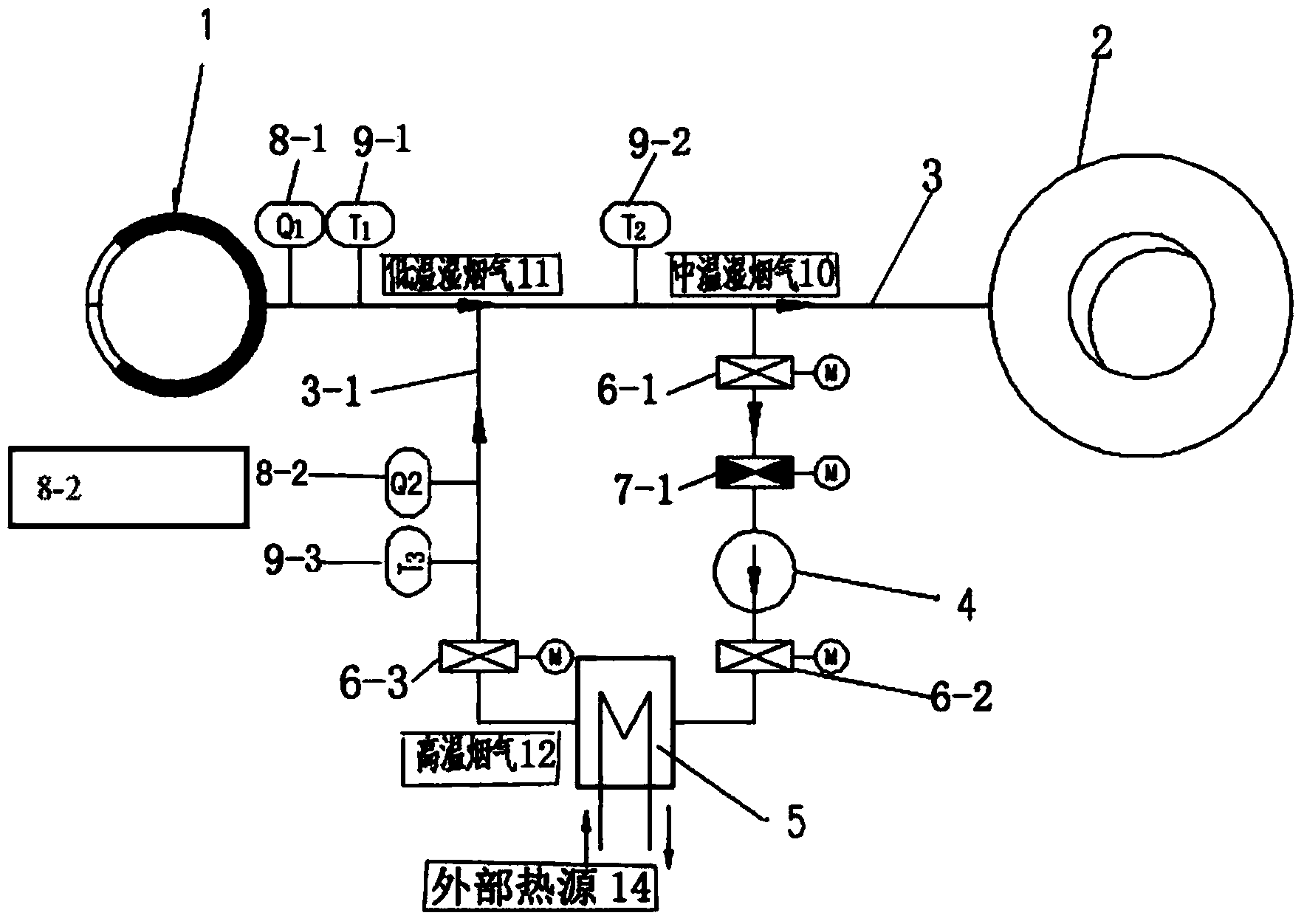

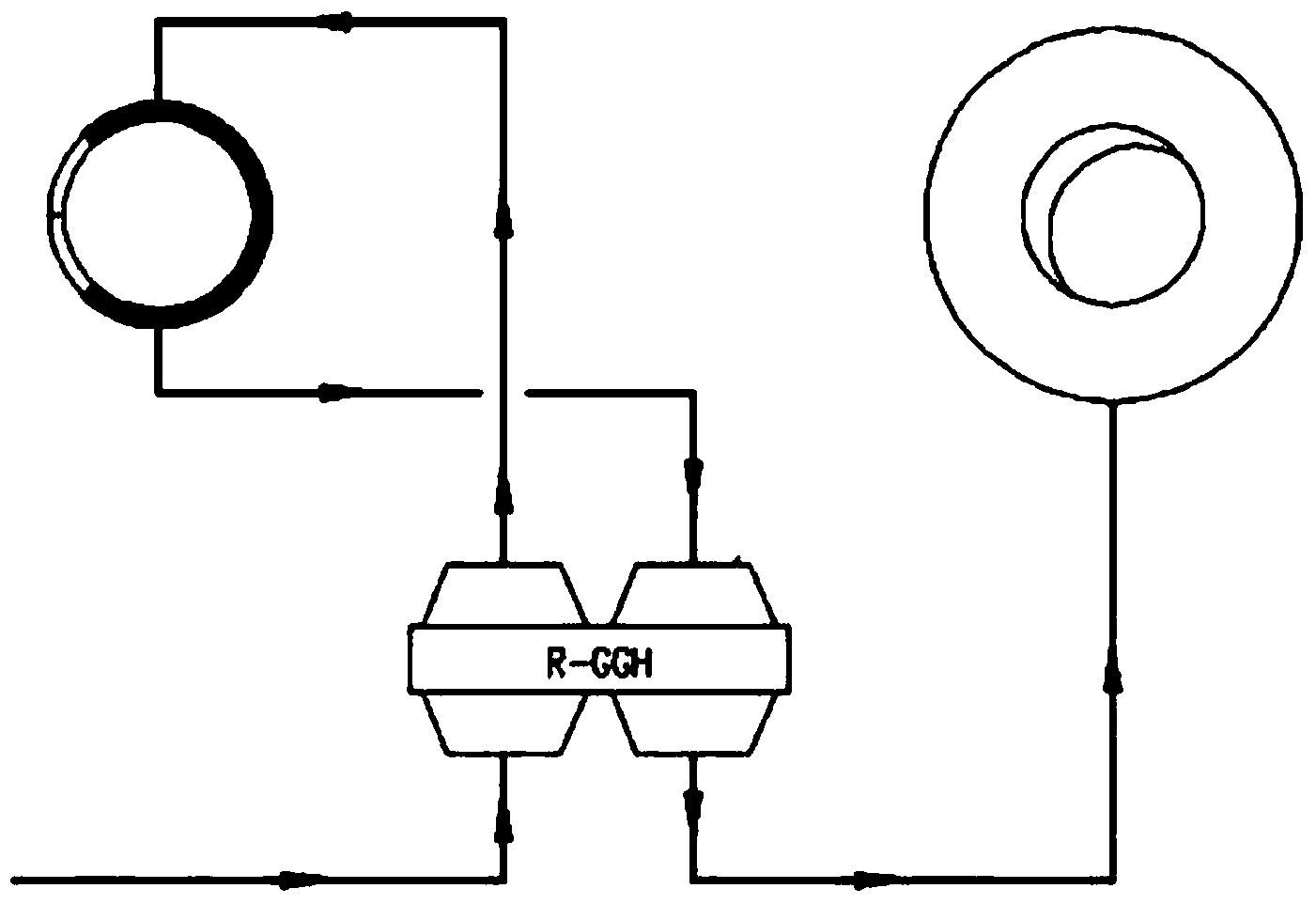

Externally heating type wet flue gas dehumidifying method and system

ActiveCN103638784AExtended service lifeSolve the problem of "white smoke" when dischargingDispersed particle separationFlue gasSmall footprint

The invention relates to an externally heating type wet flue gas dehumidifying method and system. The externally heating type wet flue gas dehumidifying method is characterized in that the externally heating type wet flue gas system is arranged, part of wet flue gas is extracted and reheated, and the heated wet flue gas is changed into high-temperature flue gas and is refilled into low-temperature wet flue gas to increase the final exhaust temperature of the flue gas; part of medium-temperature flue gas is extracted from the inlet of a chimney and is fed into an external steam heat exchanger of the externally heating type wet flue gas system, the heating steam is from auxiliary steam of a thermal power plant or other heat sources of heat supply systems, the medium-temperature flue gas is heated to high-temperature flue gas of 160 DEG C by the externally heating type wet flue gas system and then is fed into low-temperature wet flue gas after being boosted by a booster fan, and all the low-temperature wet flue gas is heated into the medium-temperature flue gas and is exhausted into the chimney to realize dehumidification of the wet flue gas. The externally heating type wet flue gas dehumidifying method can eliminate 'white smoke' phenomenon when the flue gas is exhausted from the chimney, and has the characteristics of having small occupied area and capability of operating continuously and safely.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Adhesive sheet for metal surface bonding

ActiveCN103492507ADoes not cause corrosionAvoid corrosionFilm/foil adhesivesEster polymer adhesivesChemistrySurface bonding

An adhesive sheet to be bonded to a metal surface, which comprises an adhesive layer that is formed of an acrylic adhesive that uses a (meth)acrylic acid ester copolymer. The content of a (meth)acrylic acid alkoxyalkyl ester monomer (A) is 50% by mass or more and the content of a (meth)acrylic acid alkyl ester (B) having an acryl group with 1-4 carbon atoms is 5-45% by mass in the monomer components constituting the (meth)acrylic acid ester copolymer, while the content of a carboxyl group-containing monomer is 1% or less in the monomer components constituting the (meth)acrylic acid ester copolymer. Consequently, the adhesive sheet for metal surface bonding is capable of reducing white turbidity and metal corrosion under high temperature high humidity conditions.

Owner:DIC CORP

Photoresist reworking liquid composition for CF process

ActiveCN111638632AImprove solubilityGood dispersionPhotosensitive material processingActive agentOrganosolv

The invention discloses a photoresist reworking liquid composition for a CF process, and belongs to the field of wet electronic chemicals. The composition comprises the following components in percentage by weight: 0.5 to 40 percent of an inorganic alkaline substance, 0.5 to 45 percent of organic amine, 0.1 to 50 percent of a protic polar organic solvent, 0.1 to 50 percent of an aprotic polar organic solvent, 0.1 to 30 percent of a cyclic alcohol compound, 0.01 to 10 percent of a chemical formula A-Gemini type surfactant and the balance of water. The composition provided by the invention can be used for effectively removing bad photoresist on a glass substrate in the CF process, has the advantages of strong stripping performance, short stripping time, low operating temperature and the like, does not corrode substrate glass, has good dispersity on the photoresist, can reduce the blockage condition of a filter element to the greatest extent, and is small in volatility, low in foam, easyto rinse and free of environmental pollution.

Owner:福建省佑达环保材料有限公司

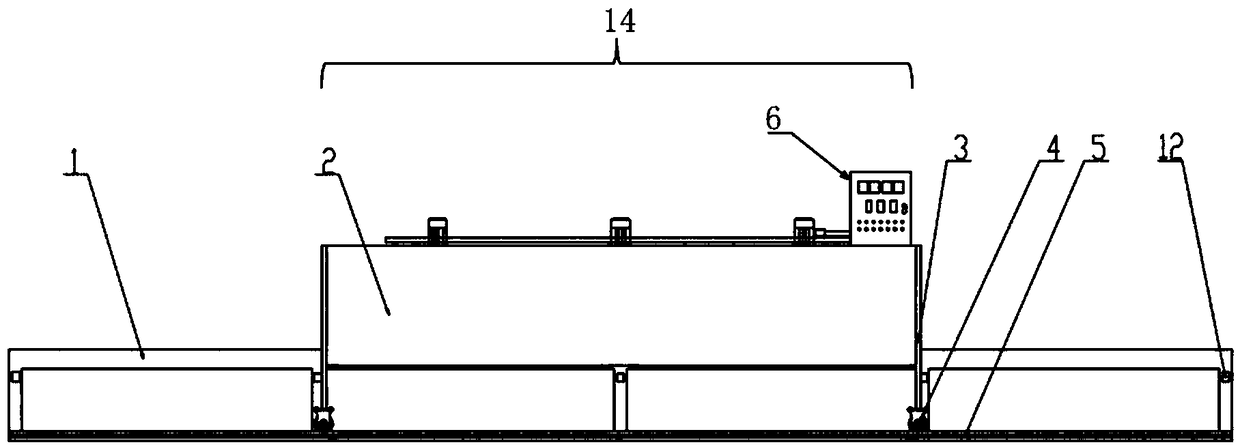

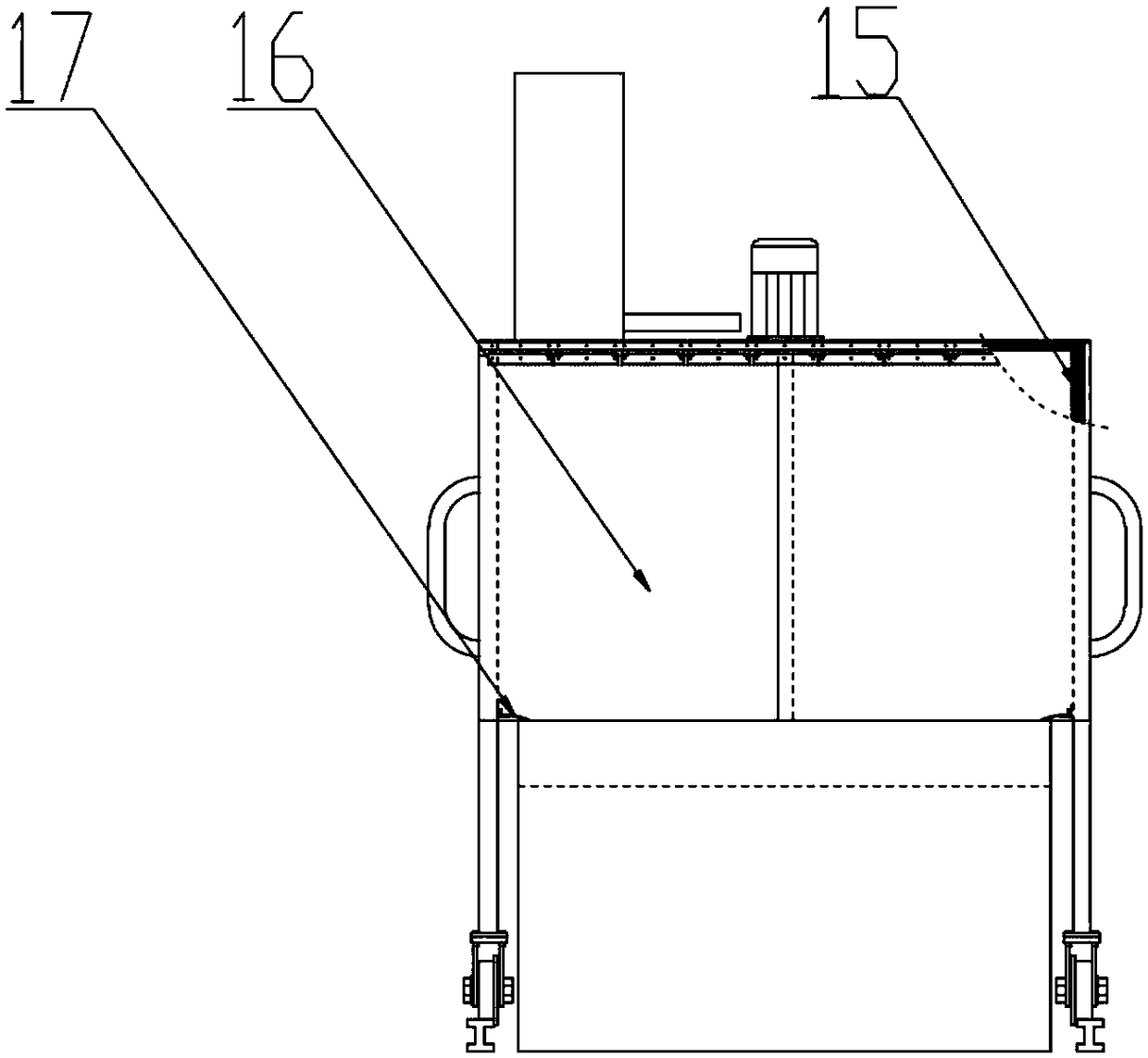

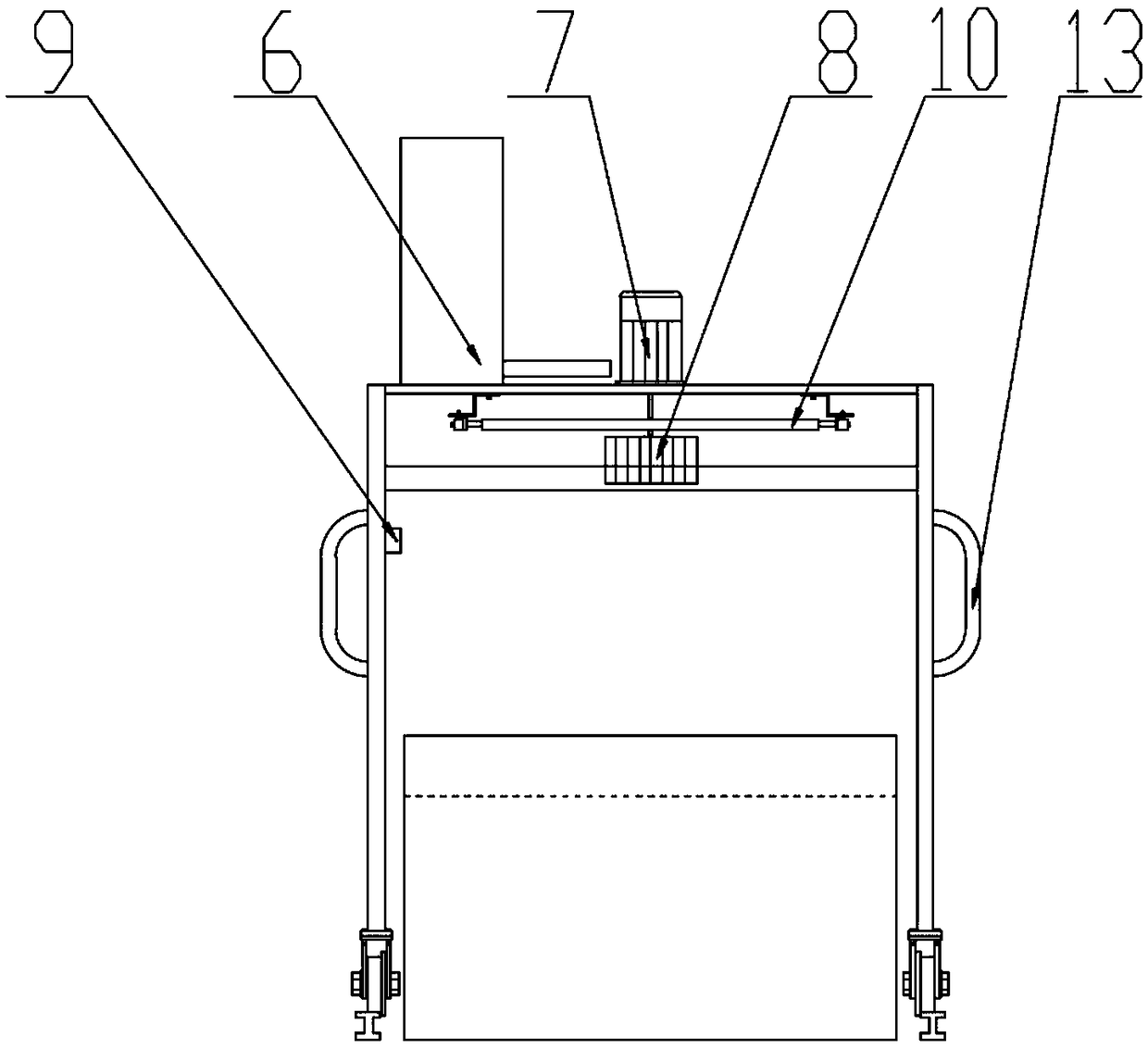

Movable type storage battery curing and drying device, and sealant curing and drying method

PendingCN108745823AAchieve freedom of movementReduces the possibility of acid osmosisFinal product manufacturePretreated surfacesMovable typeEngineering

The invention relates to a movable type storage battery curing and drying device, and a sealant curing and drying method. The movable type storage battery curing and drying device comprises a drying oven and roller guide rails, wherein the drying oven is provided with rollers so as to roll on the roller guide rails through the rollers; and the roller guide rails are flatly paved on the ground andare arranged on two sides of an operating table. The storage battery sealant curing and drying method provided by the invention adopts the movable type storage battery curing and drying device provided by the invention, so that a storage battery sealant can be cured on the operating table without moving a storage battery, the heat energy utilization ration is high, a curing effect is good, the possibility of storage battery acid seepage is reduced greatly, and the whole curing and drying device is small in occupied area, high in production efficiency, time and labor saving.

Owner:浙江天地之光电池制造有限公司

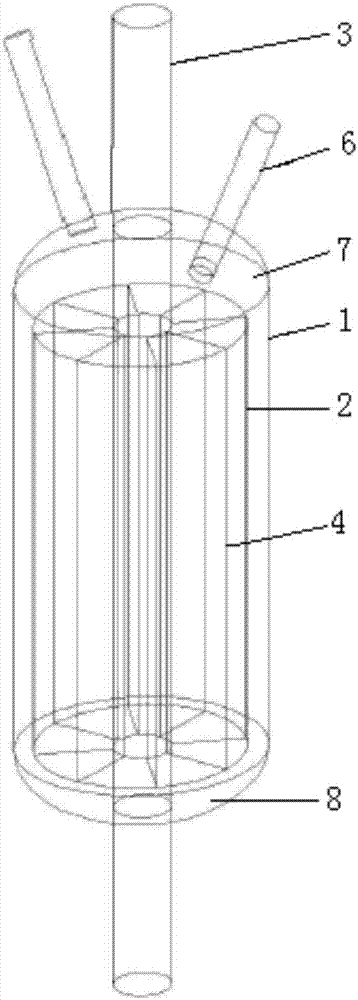

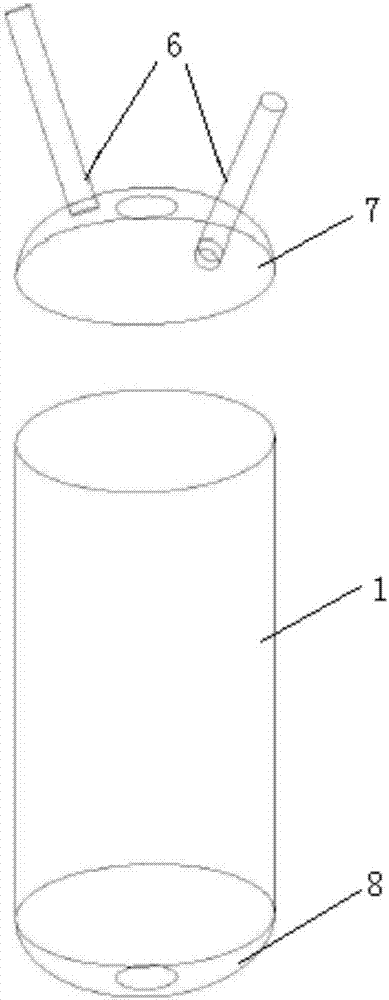

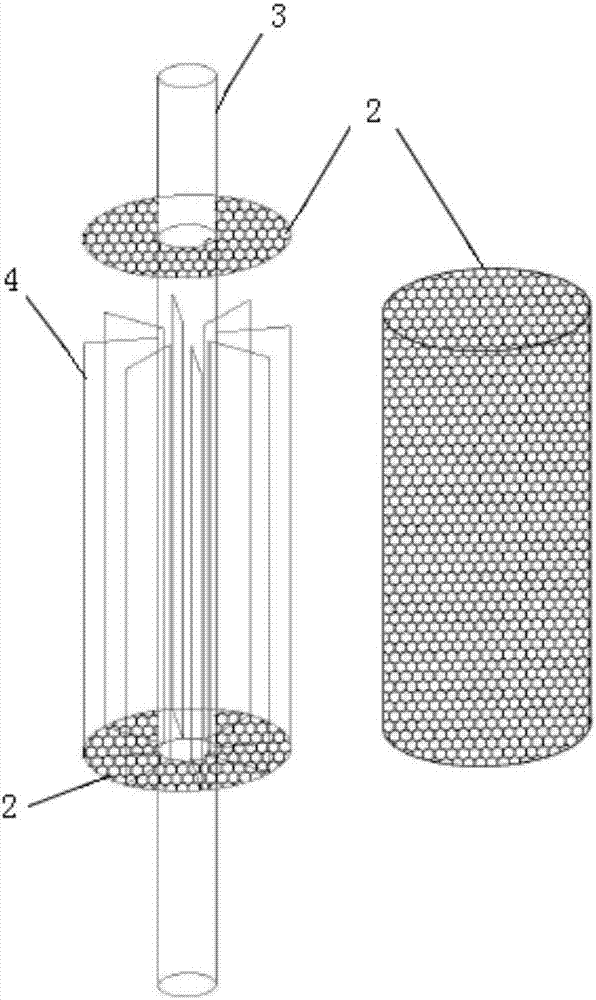

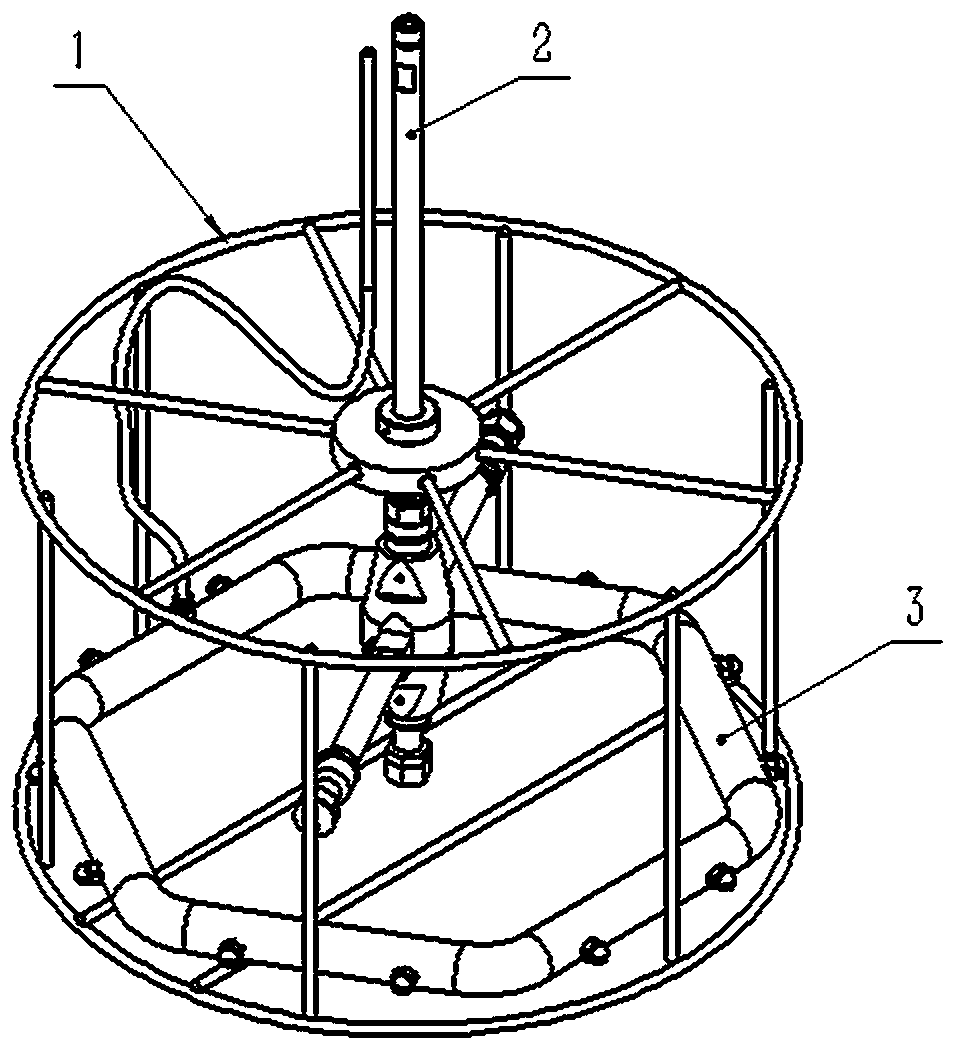

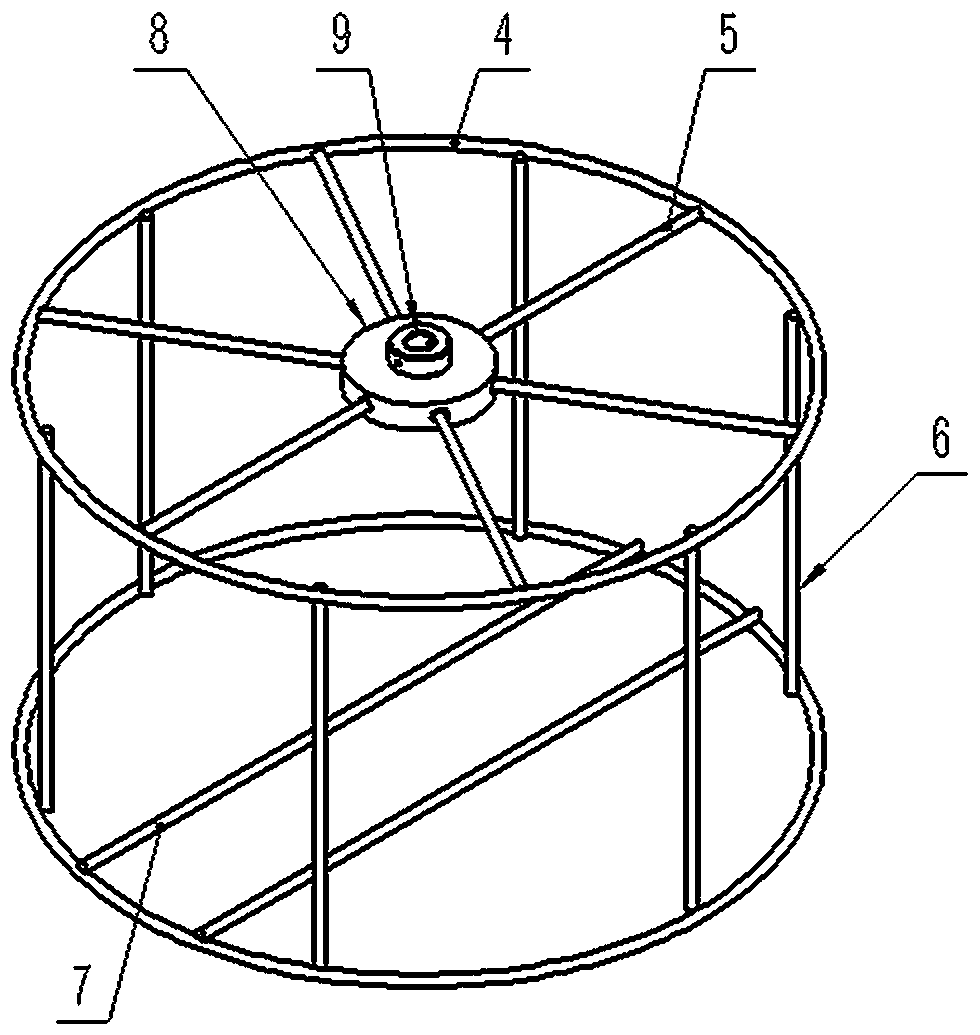

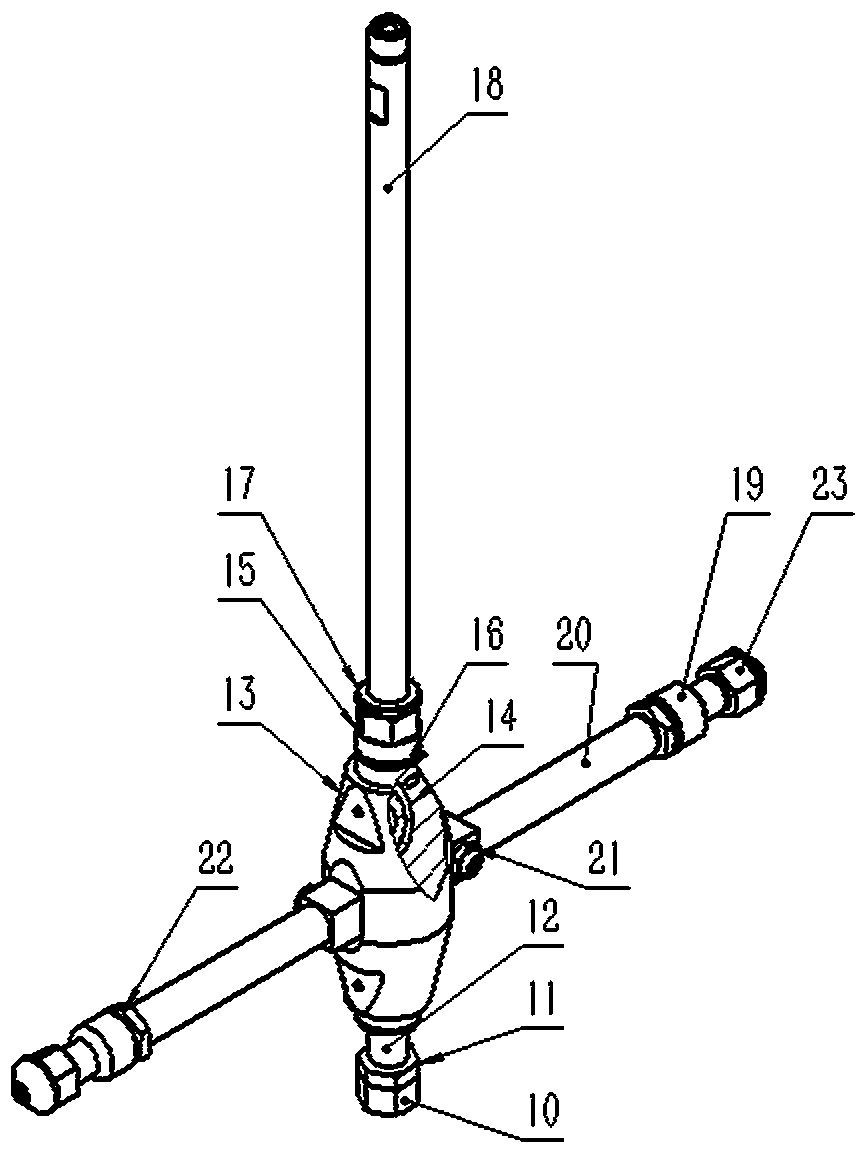

High-efficiency reactor for hydrated salt chemical energy storage

InactiveCN107289803AHigh reaction conversion rateHigh energy storage densityHeat storage plantsHydration reactionEngineering

The invention discloses a high-efficiency reactor for hydrated salt chemical energy storage. The high-efficiency reactor comprises a heat insulation container, a column body for wrapping hydrated salt, a heat exchange pipe, fins, hydrated salt and pipelines, wherein the column body is arranged in the heat insulation container; the heat exchange pipe is arranged at the center of the column body; the multiple fins are uniformly arranged between the heat exchange pipe and the column body; one end of each fin is connected with the outer wall of the heat exchange pipe, and the other end of the fin is connected with the inner wall of the column body; a space between the heat exchange pipe and the column body is filled with the hydrated salt; and the two pipelines are arranged on an upper end cover of the heat insulation container. The high-efficiency reactor for hydrated salt chemical energy storage disclosed by the invention can well enable reaction salt to react with steam; the reaction is faster and more thorough, and the heat transfer and mass transfer effect in a reaction process is obviously enhanced; irreversible loss caused by liquefaction of the hydrated salt due to excessive water absorption can be further effectively avoided, so that the number of times of recycling of an energy storage material is increased, and the service life of the material is prolonged; and meanwhile, the corrosion effect of the liquefied hydrated salt on the reactor is also avoided.

Owner:SHANGHAI MARITIME UNIVERSITY

Bridge type water filtering pipe cleaning device

PendingCN110153113ADoes not cause corrosionReduce resistanceHollow article cleaningDrinking water installationSpray nozzleJet flow

The invention relates to a bridge type water filtering pipe cleaning device. The bridge type water filtering pipe cleaning device comprises a cleaning protection device and a cleaning mechanism. A rotating spray nozzle mechanism and a high-pressure air blowing mechanism are further arranged below the protection device in sequence. The rotating spray nozzle mechanism comprises a rotating spray nozzle and cleaning nozzles. The bridge type water filtering pipe cleaning device has the advantages that the high-pressure water is utilized to wash and remove the dirt through the rotating spray nozzle,and the equipment corrosion phenomenon cannot happen. Meanwhile, a large number of bubbles are formed below the high-pressure water jet flow through the blowing of the high-pressure air, and therefore the resistance of the water is reduced, the impact force of the high-pressure water cannot be excessively attenuated, the hard dirt can be effectively cleaned away, and the bridge type water filtering pipe cleaning device can be suitable for removing the hard and thick dirt, is low in cost, light in dead weight, convenient to operate and easy to maintain, and can be suitable for various bridge type water filtering pipes. Meanwhile, the protection device fulfills the protection function and the locating function, and protects the rotating spray nozzle and the inner walls of the bridge type water filtering pipes.

Owner:SHENYANG ACAD OF INSTR SCI

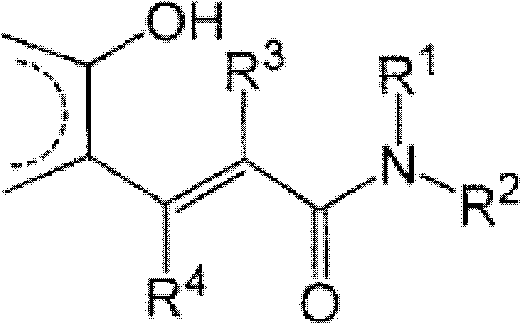

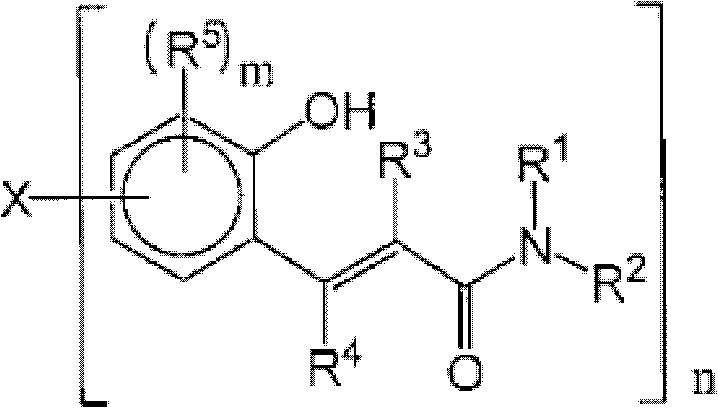

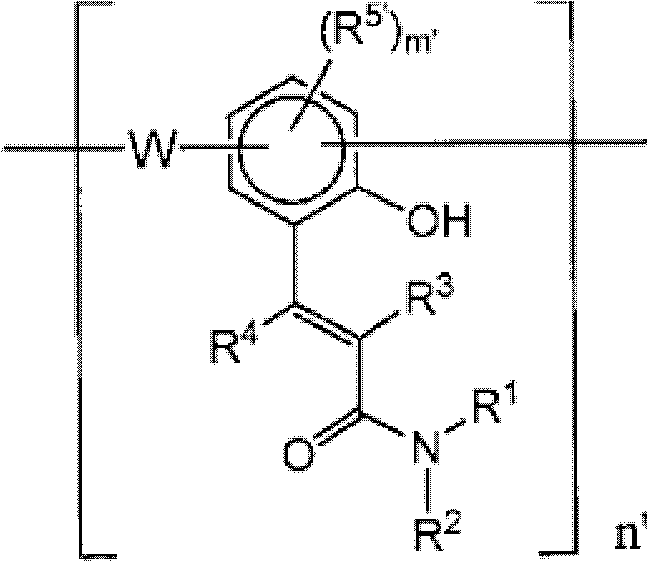

Base-generating agent, photosensitive resin composition, material for pattern-forming comprising said photosensitive resin composition, pattern-forming method using said photosensitive resin composition, and article

InactiveCN102575140AIncreased sensitivityImprove solubilityOrganic chemistryOther chemical processesPolymerPhotochemistry

Disclosed is a photosensitive resin composition that has excellent resolution, low cost, and wherein there is a wide range of structurally applicable options for a polymer precursor wherein the reaction towards an end product is promoted by means of a basic substance or by means of heating under the presence of a basic substance. Further disclosed is a base-generating agent that can be used in this type of photosensitive resin composition. The base-generating agent is characterized by having a specific structure and by generating a base by means of heating and being irradiated by electromagnetic waves, and the photosensitive resin composition is characterized by containing the polymer precursor that promotes the reaction towards an end product by means of said base-generating agent and a basic substance or by means of heating under the presence of a basic substance.

Owner:DAI NIPPON PRINTING CO LTD

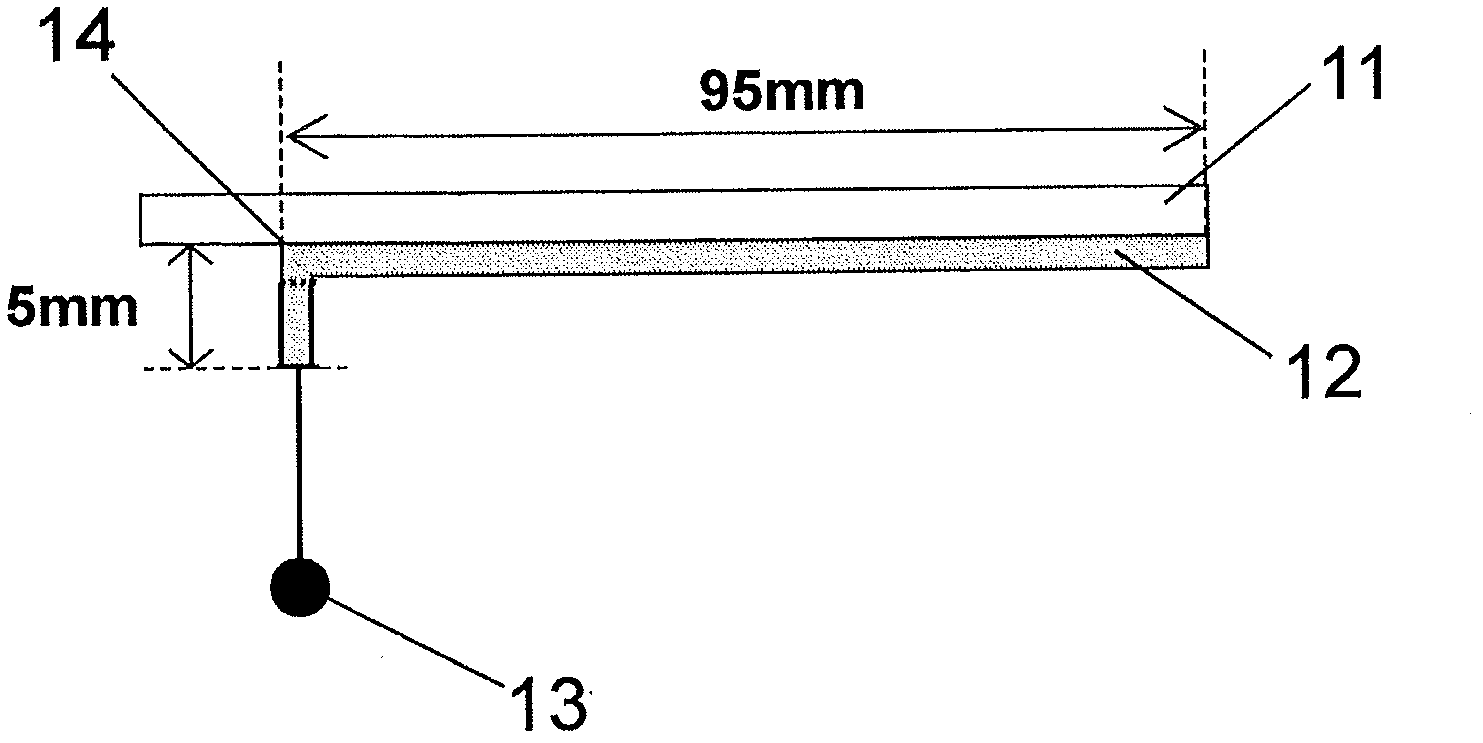

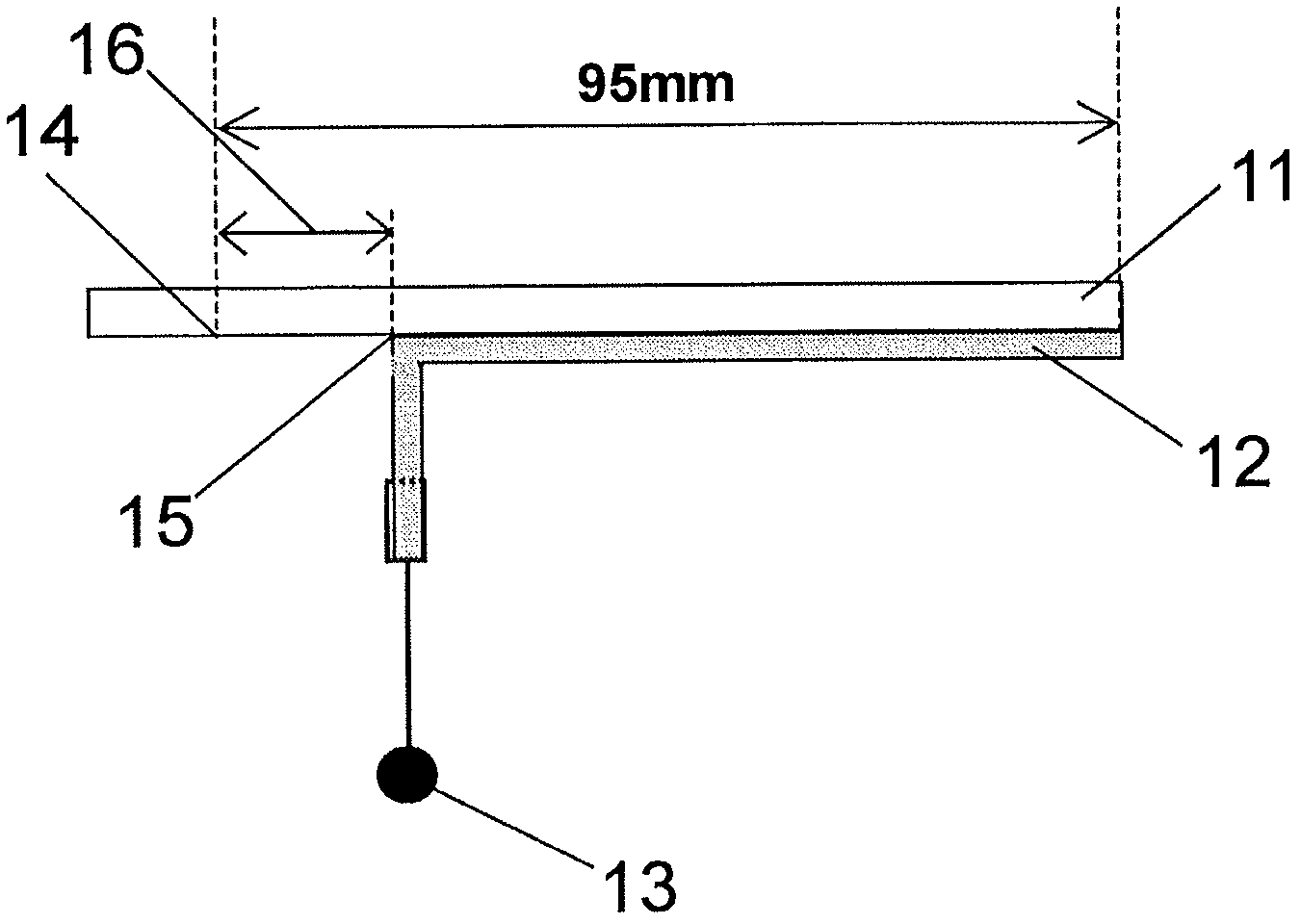

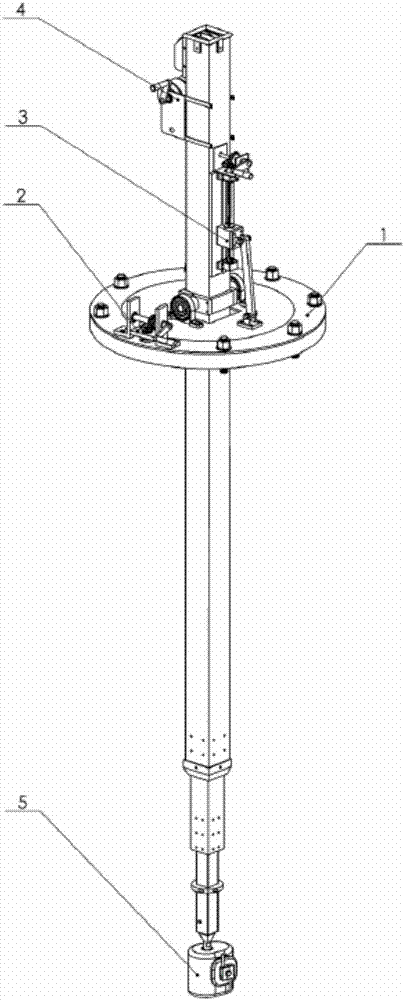

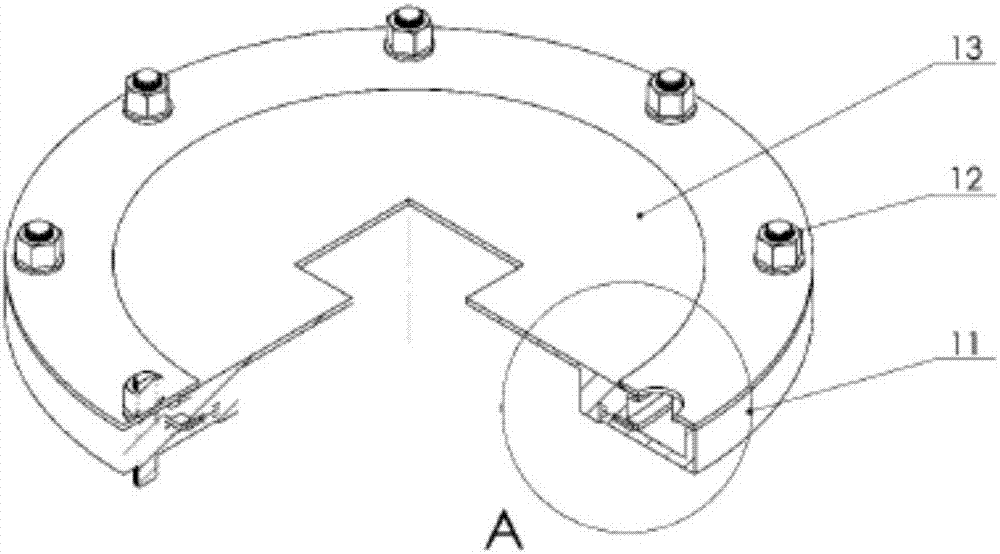

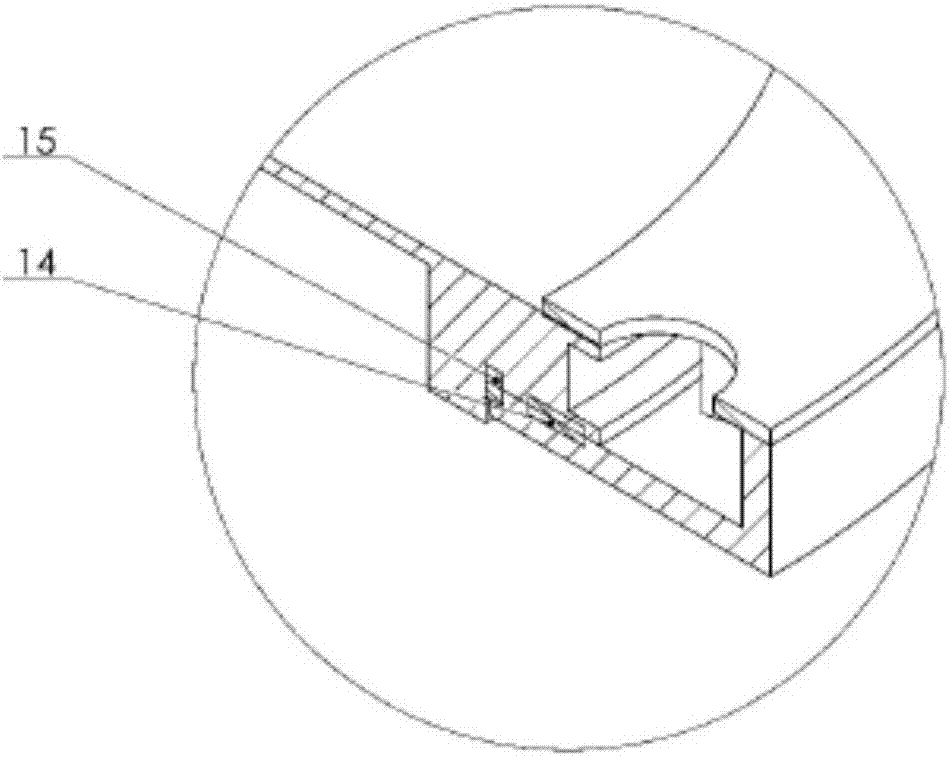

Positioning telescopic arm device used for reaction kettle cleaning

The invention discloses a positioning telescopic arm device used for reaction kettle cleaning. The positioning telescopic arm device comprises a connecting manhole flange and fixing mechanism thereof, a chain external engaging rotation mechanism, a swing mechanism and a rope sheave drive telescopic arm mechanism. The connecting manhole flange and fixing mechanism thereof comprise a fixing flange, a flange connection fixing device, an inner disk, a rolling bearing and an anti-attrition wearing ring. The chain external engaging rotation mechanism comprises a driving chain wheel mechanism, a manual driving bevel gear mechanism and an annular chain. The swing mechanism comprises a linear ball screw linear guideway sliding table device, a sliding block, a connecting rod, a swing shaft, a main swing arm and a rotating handle. The rope sheave drive telescopic arm mechanism comprises a first telescopic arm, a second telescopic arm and a rope sheave assembly. Telescopic, swing and rotating motion of the telescopic arms can be achieved, the phenomenon of making contact with reaction kettle stirring blades and the inner wall of a reaction kettle can be effectively avoided during cleaning operations, and using safety of the mechanical system is improved. Meanwhile, by the adoption of a simple and common mechanical structure, the mechanical structure is stable and economic efficiency is high.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Corrosion-resistant cleaning agent for solid-wood furniture

InactiveCN107955729AWill not corrodeDoes not cause corrosionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium BentoniteEngineering

An anti-corrosion cleaning agent for solid wood furniture, the components and the parts by weight are: 20-30 parts of trichlorethylene, 2-8 parts of high-grade essence, 5-10 parts of sodium citrate, and 10-parts of oxidized microcrystalline wax 18 parts, ethyl acetate 15‑27 parts, emulsifier 3‑8 parts, bentonite 2‑5 parts, plant essential oil 10‑20 parts, natural vegetable wax 2‑6 parts, bamboo charcoal extract 2‑10 parts, aloe vera extract 2‑5 parts, 15‑25 parts of triethanolamine, and the rest are deionized water. The cleaning agent obtained in the present invention, when applied on the surface of solid wood furniture, can obviously play a cleaning role, and will not cause corrosion of the solid wood on the surface of the furniture.

Owner:徐州隆邦家具有限公司

Water quality stabilizer for circular cooling water in condesing unit of power plant

InactiveCN1548387ADoes not cause corrosionReduce corrosionScale removal and water softeningIonPower station

The present invention relates to water quality stabilizer, and is especially one kind of water quality stabilizer for circular cooling water in condensing unit of power plant. The water quality stabilizer features that it contains SDF scale inhibitor in 1-10 mg / L and BTA corrosion inhibitor in 2-5 mg / L for use in the first three days and 0.5-1 mg / L for the later use. The practical use shows that SDF has few complexing effect on Cu, Fe and Zn ion and no corrosion on the copper tube of condensing unit, and BTA corrosion inhibitor can raise the corrosion resistance of copper tube. The quality stabilizer may be used in power plant to reach scale inhibiting and corrosion inhibiting effects.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

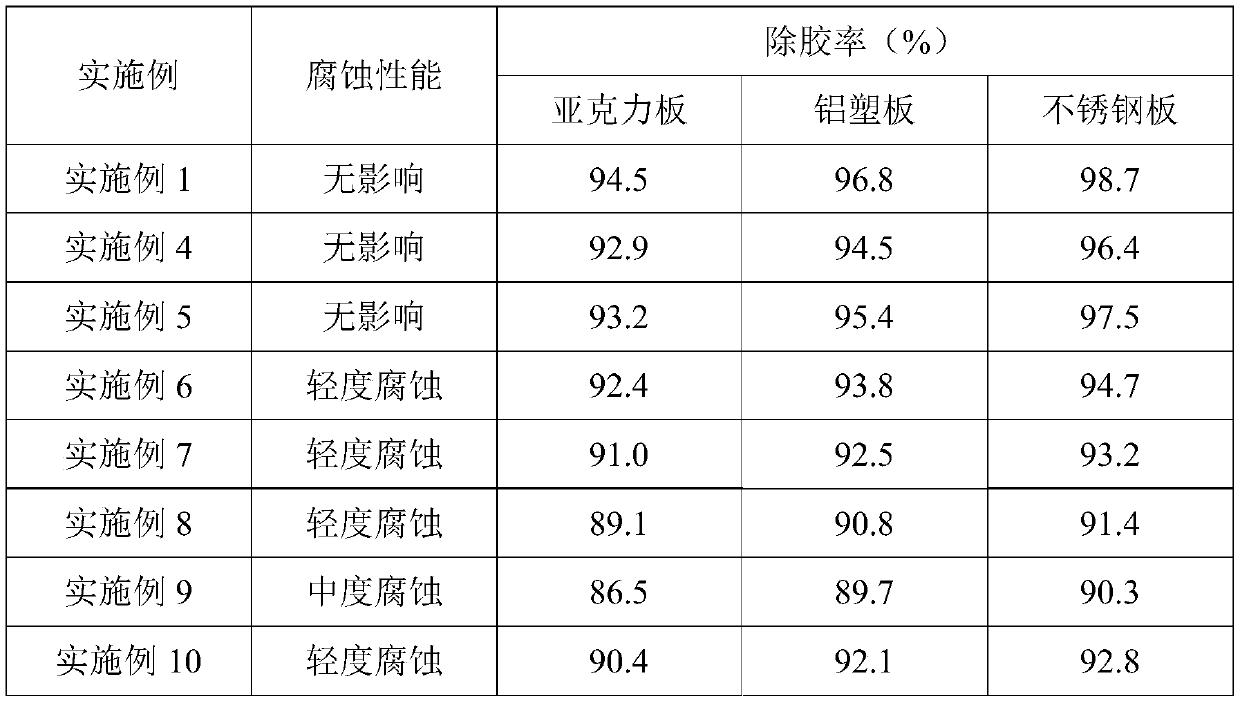

Environment-friendly degumming agent as well as preparation method and application thereof

ActiveCN110791389AHelp removeAids in surface removalNon-ionic surface-active compoundsOrganic detergent compounding agentsHydrocarbon solventsActive agent

The invention relates to the field of degumming agents, and provides an environment-friendly degumming agent which at least comprises the following raw materials in parts by weight: 55-75 parts of limonene, 25-45 parts of a deodorized hydrocarbon solvent, 5-20 parts of a penetrating agent, 5-10 parts of a surfactant, 5-15 parts of dibasic acid ester and 30-80 parts of water. The invention also provides a preparation method and application of the environment-friendly degumming agent.

Owner:义乌欧风汽车用品有限公司

Multifunctional polymer slurry powder and preparation method thereof

InactiveCN109762538AImprove construction efficiencyVersatileDrilling compositionSolventSpecific gravity

The invention relates to multifunctional polymer slurry powder and a preparation method thereof. The multifunctional polymer slurry powder is mainly prepared from 30 to 80 parts of slurry making agents, 1 to 20 parts of wall protection stabilizing agents, 1 to 20 parts of slag settling agents, 1 to 15 parts of dissolution promotion agents and 1 to 15 parts of regulating agents in parts by weight through compounding preparation. The multifunctional polymer slurry powder has the main characteristics that the technical flow process is reasonable and simple; the production efficiency is high; thepackaging and the transportation are convenient and fast; no contaminants are discharged; the cost is low. Compared with the prior art, the multifunctional polymer slurry powder produced by using themethod has the advantages of small specific weight, little addition, fast dissolution, high viscosity, low filter loss, little settled slag quantity, few circulation times, no pollution and the like,and has good application prospects in pile foundation construction.

Owner:河北施奈德科技有限公司

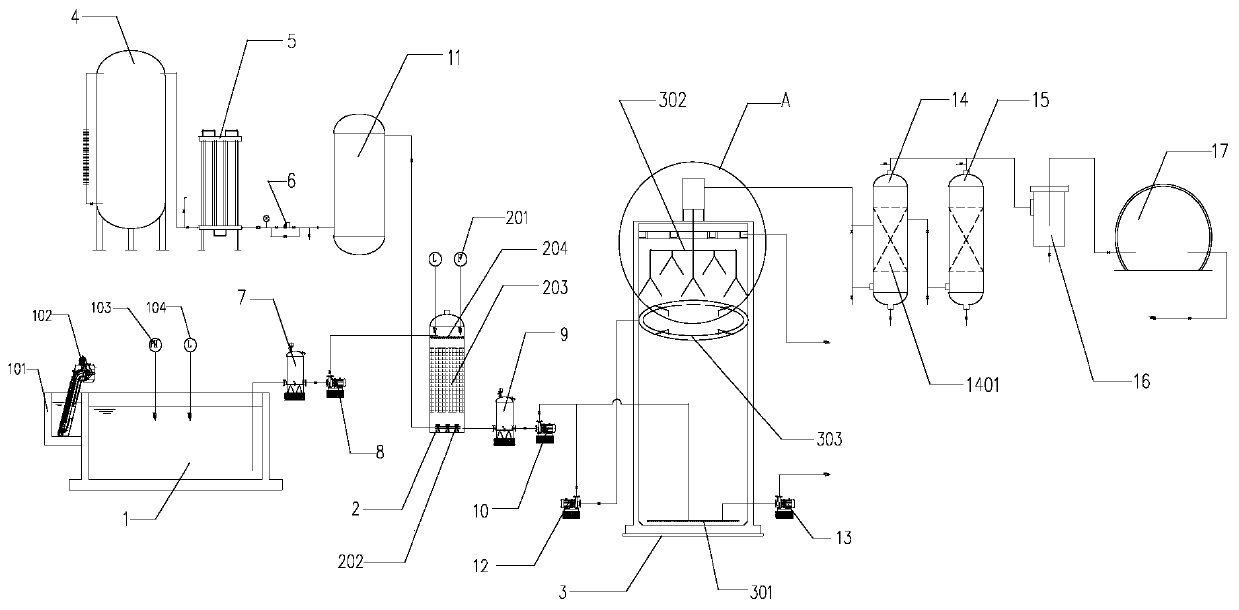

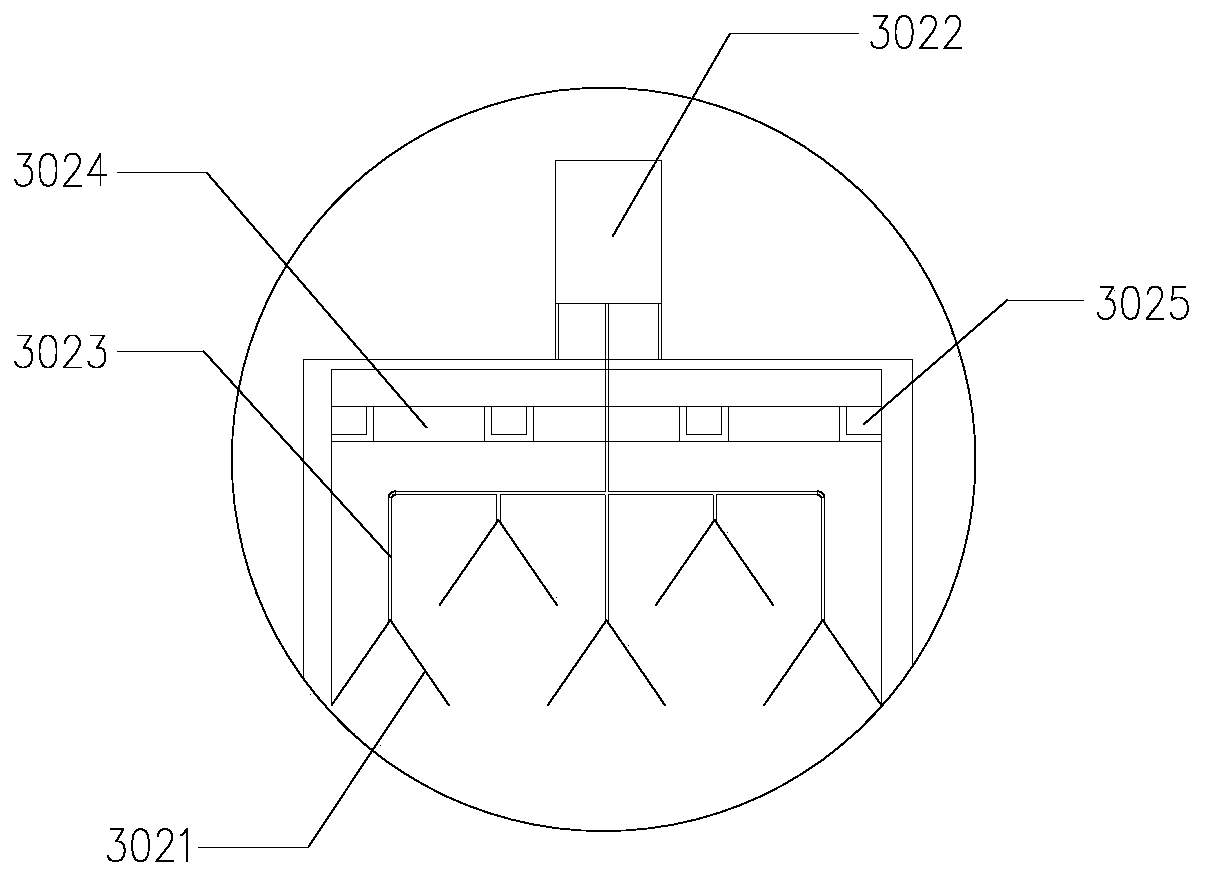

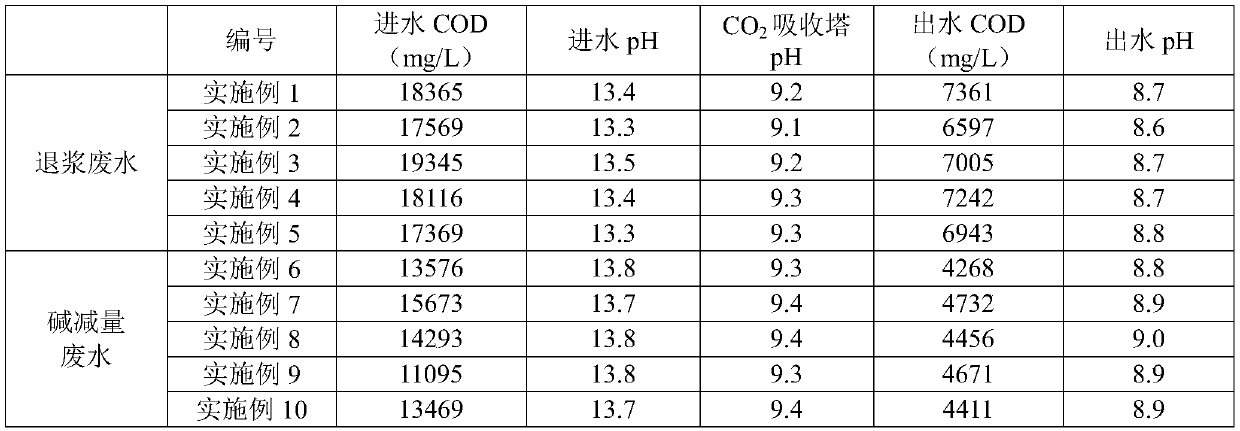

High-alkalinity high-concentration printing and dyeing wastewater anaerobic pretreatment system and process

ActiveCN110734192APH dropReduce alkalinityWater treatment parameter controlWater contaminantsSulfate-reducing bacteriaCo2 absorption

The invention relates to the technical field of sewage treatment, and discloses a high-alkalinity high-concentration printing and dyeing wastewater anaerobic pretreatment system and process. The system comprises a high-concentration wastewater regulating tank, a high-pressure microbubble CO2 absorption tower and an anaerobic reactor which are connected in sequence; the high-pressure microbubble CO2 absorption tower is connected with a CO2 storage system; the CO2 storage system comprises a liquid CO2 storage tank, a CO2 vaporizer and a gas pressure regulating device which are connected in sequence; a first water diversion tank and a first lift pump which are respectively connected with the high-concentration wastewater regulating tank and the high-pressure microbubble CO2 absorption tower are arranged between the high-concentration wastewater regulating tank and the high-pressure microbubble CO2 absorption tower, and a second water diversion tank and a second lift pump which are respectively connected with the high-pressure microbubble CO2 absorption tower and the anaerobic reactor are arranged between the high-pressure microbubble CO2 absorption tower and the anaerobic reactor. According to the method, CO2 is adopted to adjust the pH value of sewage, so that corrosion of the reactor is avoided, mass propagation of sulfate reducing bacteria is avoided, the COD removal effect isnot influenced, the alkalinity of the wastewater is not reduced, and alkali callback cost is avoided.

Owner:杭州乐升环保工程有限公司

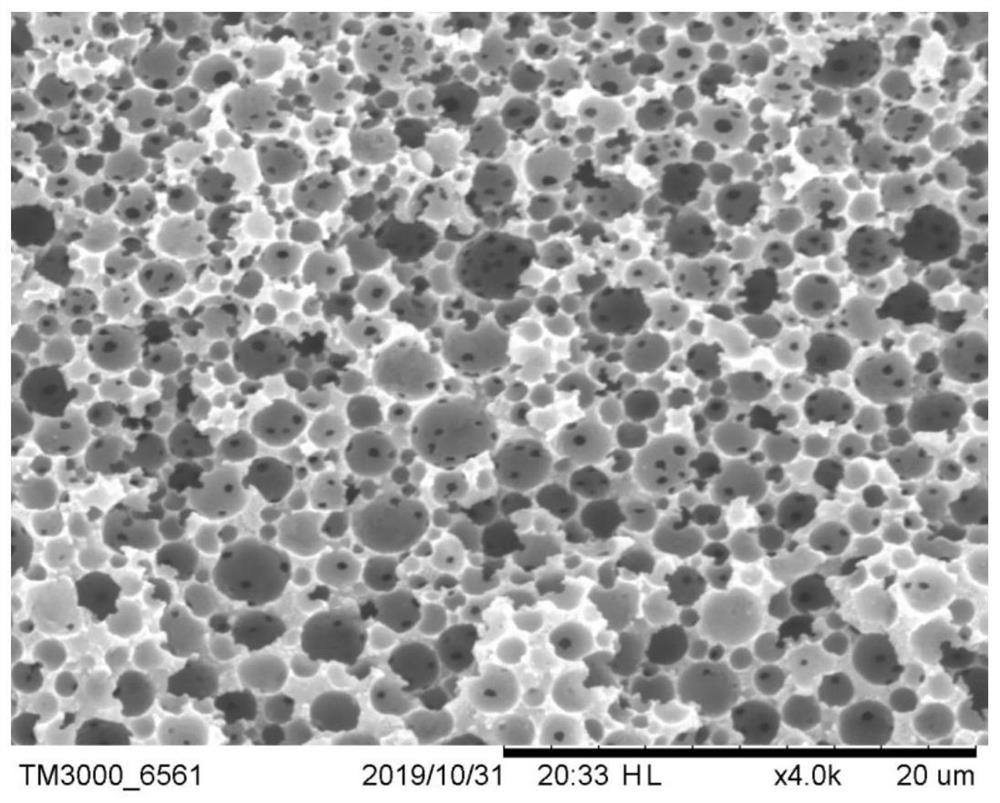

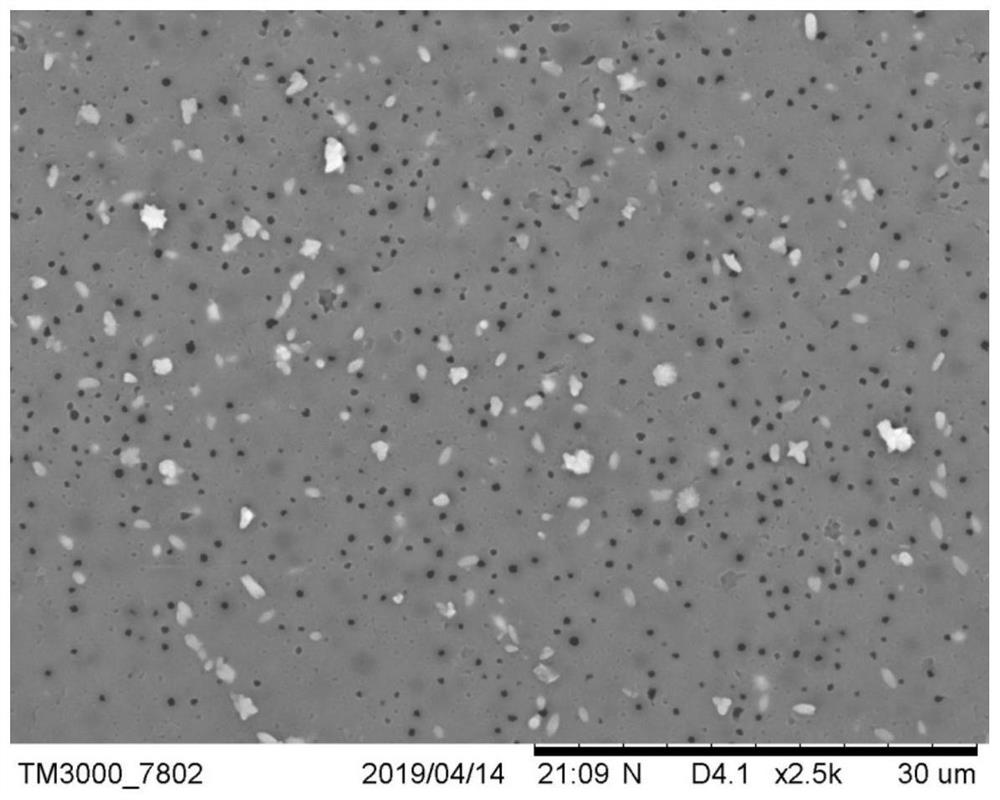

Polyacrylate composite material for CO2 adsorption and preparation method of polyacrylate composite material

The invention discloses a polyacrylate composite material for CO2 adsorption, which is prepared by the following steps of: carrying out amination grafting on porous polyacrylate, and carrying out epoxy resin surface end-capping treatment to obtain the polyacrylate composite material for CO2 adsorption. The invention has the following advantages: the synthesis process is simple, and the price is low; the three-stage interconnected pore structure meets the requirement for rapid adsorption / desorption of CO2, does not cause blockage of pores by moisture in flue gas, is uniform in particle size distribution and controllable in ball size, and can better meet the requirement of a fluidized bed.

Owner:武汉汇碳科技有限公司

Method for preparing aromatics

InactiveCN1369479ADoes not cause corrosionCarboxylic acid nitrile preparationAmino preparation from aminesHydrogen halideSide reaction

A method for preparing an aromatic compound is characterized in that the hydrolysis and decarboxylation reactions are carried out in multiple stages when an aromatic cyano compound is hydrolyzed and decarboxylated in the presence of an acidic substance and the corresponding aromatic compound is prepared. Especially when the aromatic cyano compound contains halogen, it can effectively prevent the corrosion of the reactor caused by the hydrogen halide generated by the side reaction, and at the same time, the target compound can be prepared in high yield.

Owner:NIPPON SHOKUBAI CO LTD

Pretreatment method for crude lube stock

ActiveCN103102953ALow acid valueDoes not cause corrosionTreatment with hydrotreatment processesLubricant compositionPtru catalystHydrogenation reaction

The invention relates to a pretreatment method for a crude lube stock. According to the invention, an acid-containning crude lube stock and hydrogen contact with hydrotreatment catalysts and undergo a hydrogenation reaction in a fixed bed reactor; reaction materials successively pass through a protective agent, a hydrotreatment catalyst A and a hydrotreatment catalyst B; a resultant of the reaction is subjected to gas-liquid separation, an obtained gas phase is recycled for the hydrogenation reaction, and an obtained liquid phase is used for production of lubricant base oil; the hydrotreatment catalyst A and the hydrotreatment catalyst B have proper pore distribution and composition. The method provided by the invention overcomes the disadvantage of poor pretreatment effect of a conventional hydrorefining method on a lubricating oil distillate raw material, and hydrofined oil is an excellent furfural refining raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

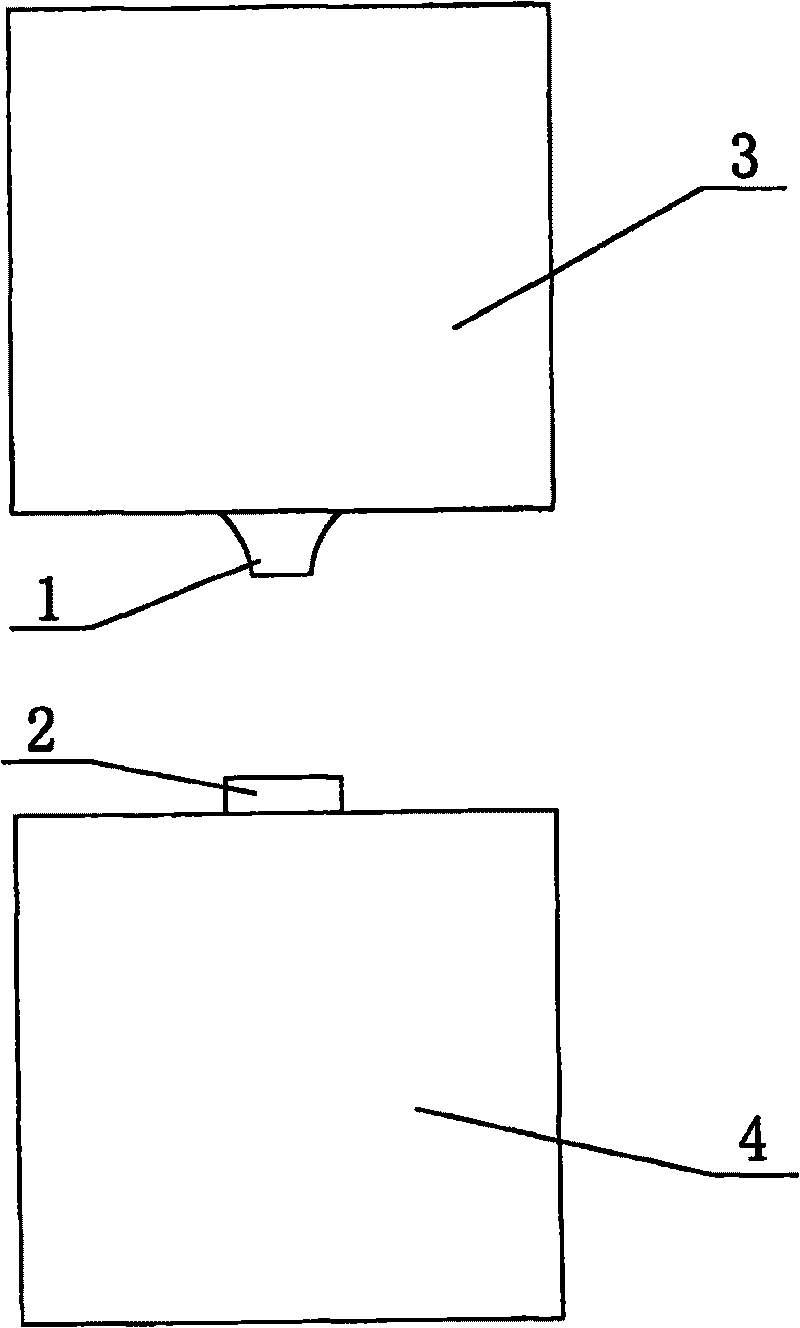

Copper-aluminum joint pressure welding technique

ActiveCN101274389BReduce production processReduce manufacturing costNon-electric welding apparatusAtmospheric pressureHelium

Owner:SHUNDE SANSHENG ELECTRICAL MFG CO LTD

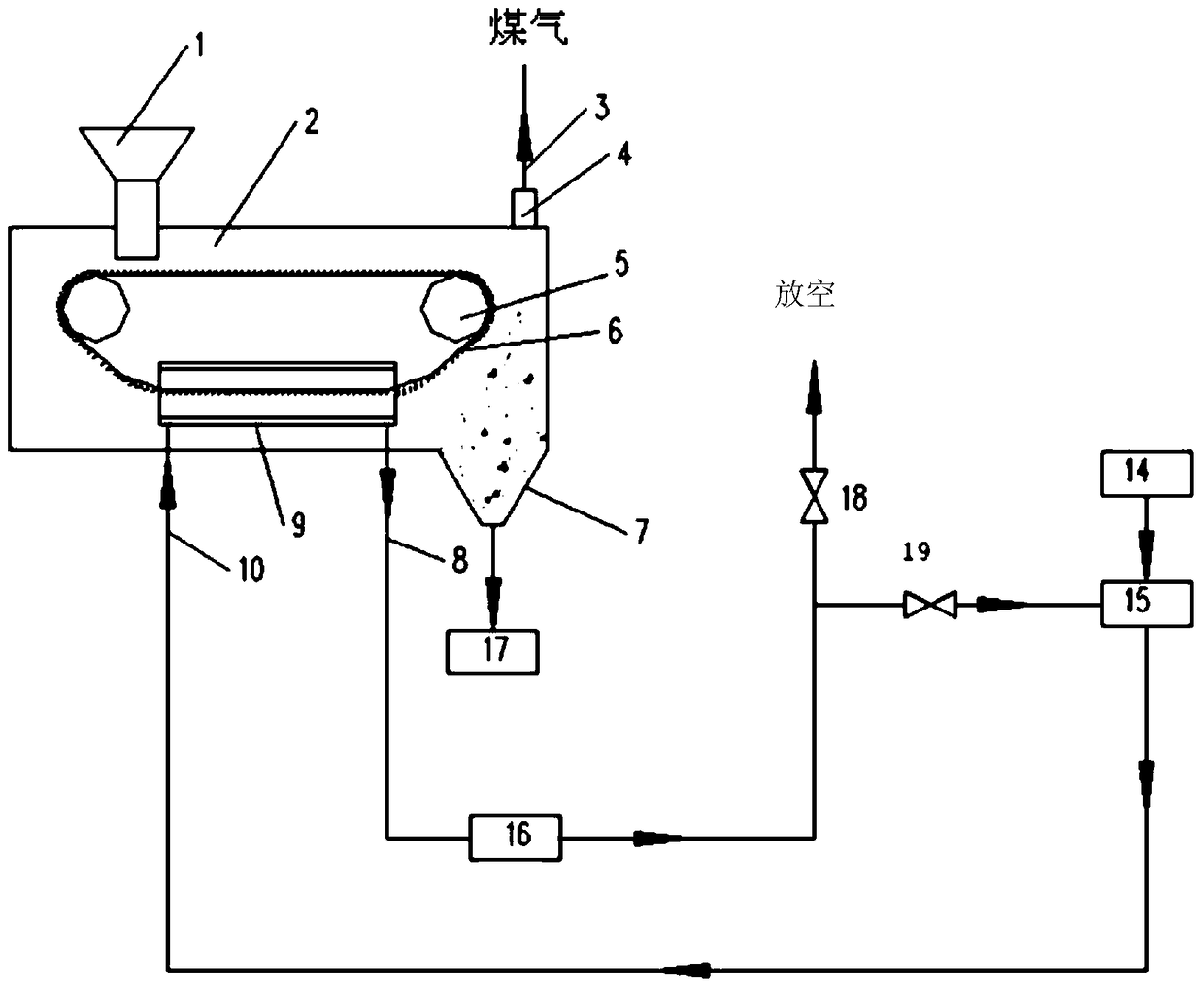

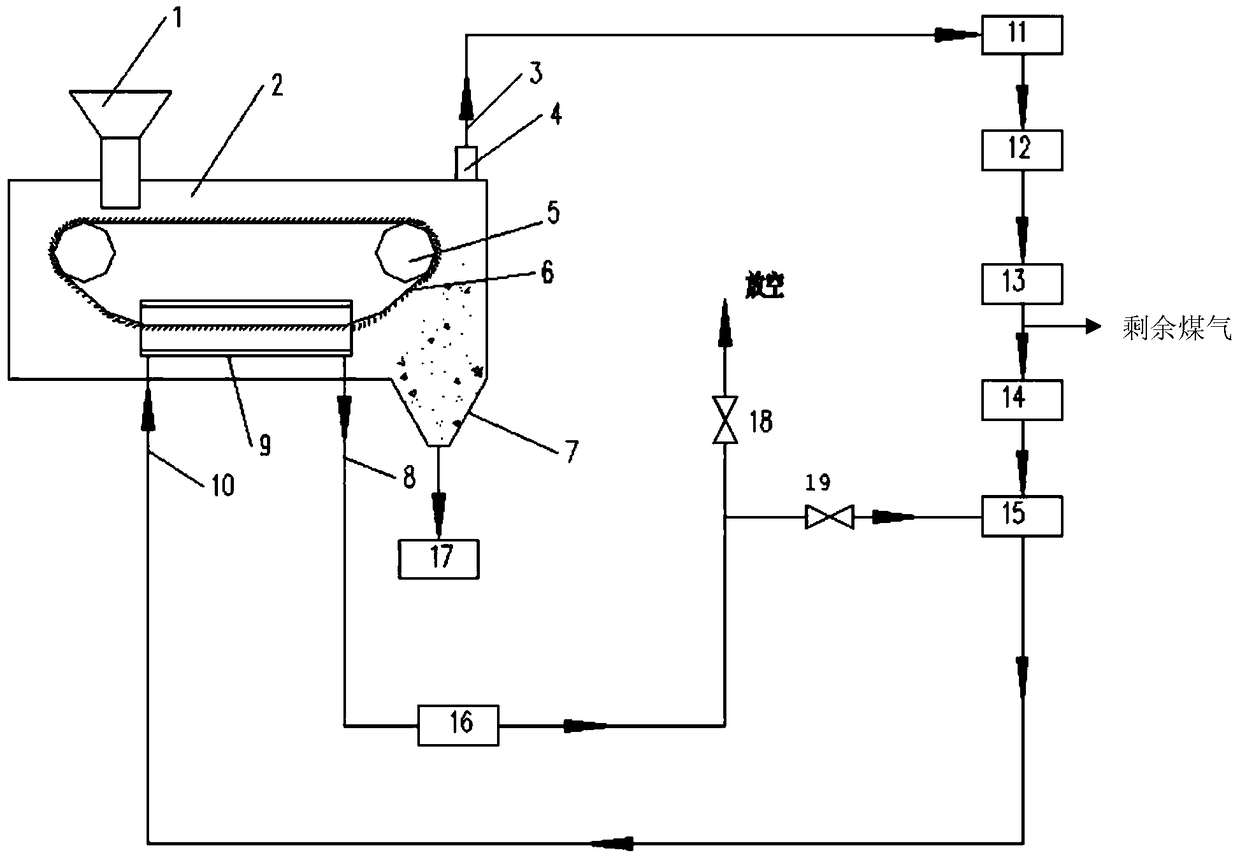

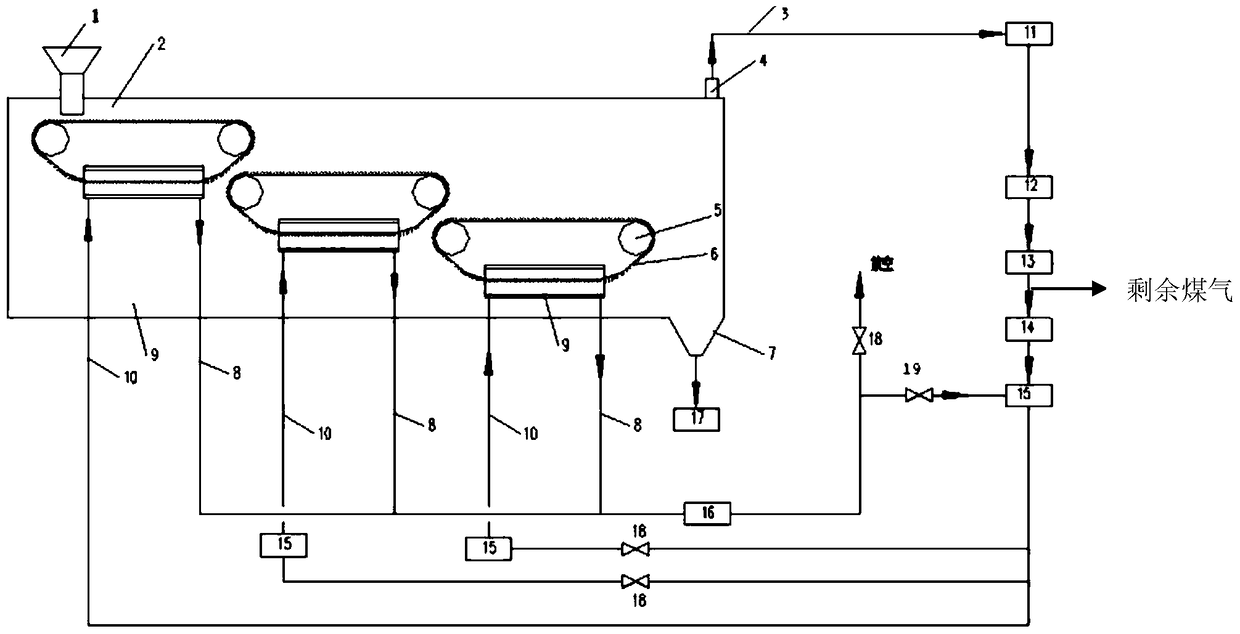

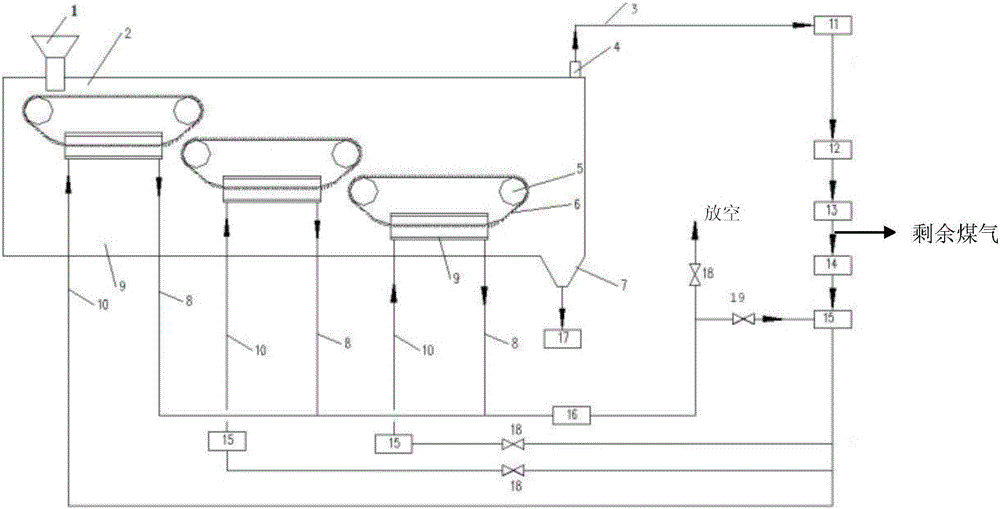

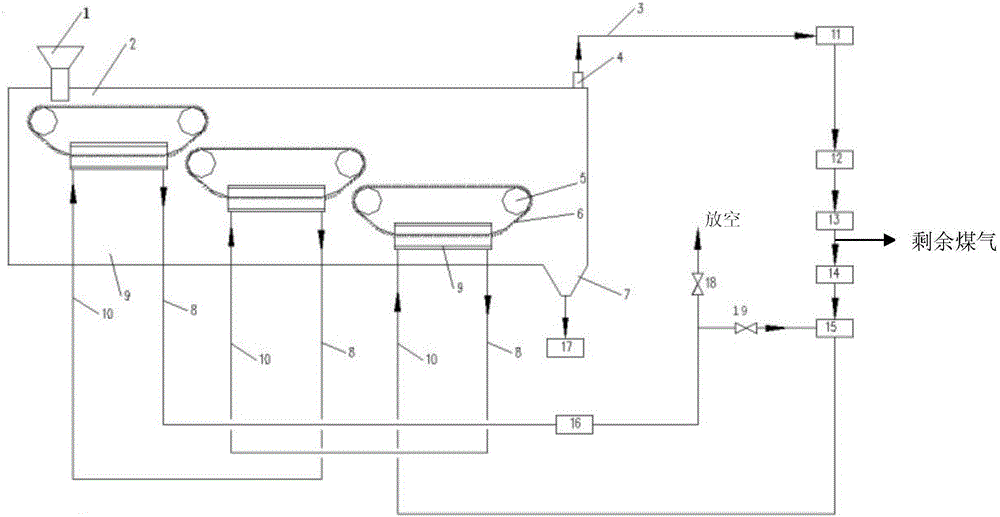

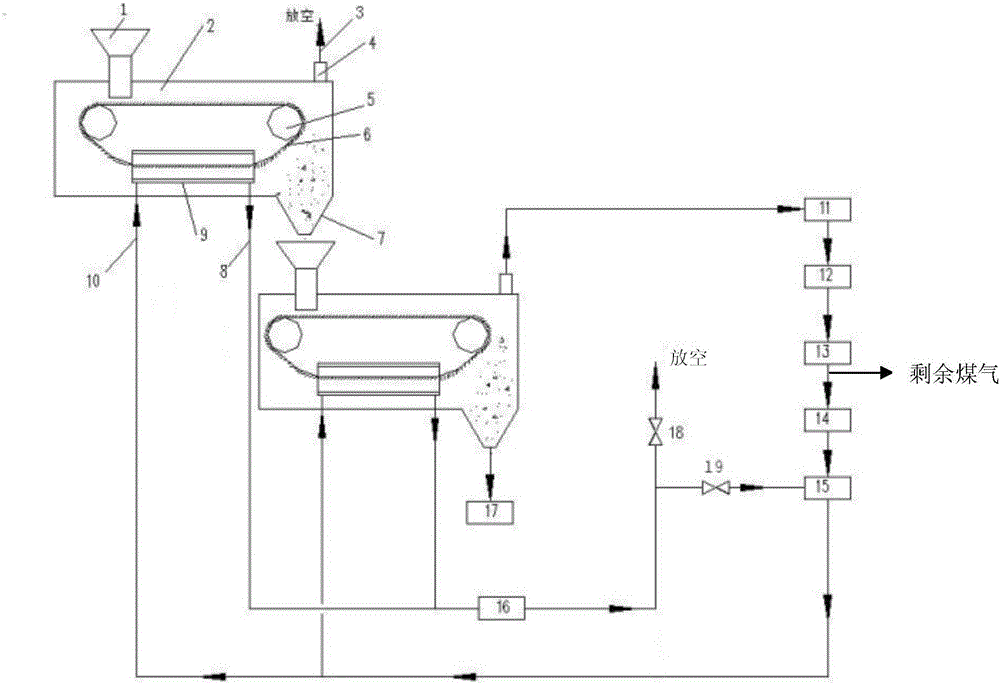

A pulverized coal upgrading pyrolysis device and upgrading pyrolysis process

ActiveCN105062523BImprove quality improvement efficiencyFull heat exchangeSpecial form destructive distillationThermodynamicsCombustion

The invention relates to the field of coal chemical industry, in particular to the field of energy utilization. The invention provides a pulverized coal quality upgrading pyrolysis device and a process using the device, which includes a coal drop port, including a coal drop port, a upgrading furnace body, a gas outlet pipeline, and a gas outlet. It is characterized in that the quality upgrading A toothed driving wheel and a toothed steel belt are arranged inside the furnace body, and the toothed steel belt is used as a heating medium; the pulverized coal enters the upgrading furnace body through the coal drop port and falls into the hot toothed steel belt. belt, and along with the movement of the toothed steel belt, is sent to the other end of the upgrade furnace body to realize the upgrade pyrolysis reaction of pulverized coal. The invention can solve the technical problems of low utilization efficiency, easy combustion and serious loss in the pulverized coal upgrading process.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

Dinnerware cleaning agent

InactiveCN101205507AReduce poisonLess irritatingCationic surface-active compoundsOrganic detergent compounding agentsEating UtensilsCleansing Agents

The invention discloses a tableware cleaning agent. The components of the invention by weight portion are as follows: 10 to 20 portions of sodium lauryl benzenesulfate, 2 to 5 portions of sodium dodecyl sulfate,1 to 4 portions of lauric diethanol amide,0.1 to 0.4 portion of sodium ethylenediamine tetraacetate, 2 to 5 portions of sodium xylenesulfonate, 0.1 to 0.4 portion of formaldehyde (water solution with weight concentration of 35 percent), 0.1 to 0.4 portion of essence, and 75 to 85 portions of distilled water. The invention has good decontamination effect, has extremely small toxicity to the human body, and can be used to clean daily life products such as tableware, eating utensils, cookers and so on.

Owner:曹月秀

Pulverized coal upgrading pyrolysis device and upgrading pyrolysis process

ActiveCN105062523AImprove quality improvement efficiencyFull heat exchangeSpecial form destructive distillationThermodynamicsCombustion

The invention relates to the field of coal chemical industry, in particular to the field of energy utilization. The invention provides a pulverized coal upgrading pyrolysis device and a process using the device. The device comprises a coal drop port, an upgrading furnace body, a gas outlet pipeline and a gas outlet. The device is characterized in that the upgrading furnace body is internally provided with toothed driving wheels and a toothed steel strip, and the toothed steel strip is a heating medium. Pulverized coal enters the upgrading furnace body through the coal drop port, drops onto the hot toothed steel strip, and is sent to the other end of the upgrading furnace body along with the movement of the toothed steel strip, thus realizing the upgrading pyrolysis reaction of pulverized coal. The device and the process provided by the invention can solve the technical problems of low utilization efficiency, easy combustion and serious loss in a pulverized coal upgrading process.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

Preparation method of positive current collector for lithium ion battery

ActiveCN105895889AReduce polarizationPolarization Reduction and Polarization ReductionElectrode carriers/collectorsSilanesInternal resistance

The invention discloses a preparation method of a positive current collector for a lithium ion battery. The preparation method comprises the following steps of immersing an aluminum foil in 3-amino propyl trimethyl silane; taking out the aluminum foil, immersing the aluminum foil in an HC1 solution, taking out the aluminum foil, immersing the aluminum foil in a sodium polystyrenesulfonate solution, taking out the aluminum foil, immersing the aluminum foil in a conductive polymer monomer solution, taking out the aluminum foil, immersing the aluminum foil in a polyoxometallic acid lithium salt solution, taking out the aluminum foil, washing and drying the aluminum foil, and fabricating to the positive current collector. With the positive current collector prepared according to the method, the defect that only the electron transmission speed can be increased by a traditional intaglio printing method is made up, the internal resistance and the polarization of a lithium iron phosphate system battery are favorably reduced, and the electrical performance of the lithium iron phosphate battery is further improved.

Owner:中国东方电气集团有限公司

Water-based pearlescent ink binder for decoration paper

InactiveCN110437670ANot prone to subsidence and delaminationDoes not cause corrosionInksDispersion stabilityWater based

The invention discloses a water-based pearlescent ink binder for decoration paper, wherein the preparation raw materials comprise, by weight, 9-12% of a water-soluble resin, 0.5-0.7% of a film-formingauxiliary agent, 0.05-0.2% of a color fixing agent, 0.2-0.5% of a wetting agent, 0.5-1.5% of an anti-settling agent, 0.1-0.3% of an antifoaming agent, 0.01-0.05% of a bactericide, and the balance ofdeionized water. According to the present invention, the pearl powder pigment paste prepared from the ink binder has good dispersion stability, can be stored for a long time, does not easily generatesedimentation, layering and other phenomena of pearl powder, and cannot affect the color developing caused by gloss loss due to corrosion on pearl powder; and the product has excellent characteristicsof good printing adaptability, easy operation, large powder loading, no shell forming during high temperature pressing plate, no edge warping during scratching, excellent water resistance and the like.

Owner:上海欧畅新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com