Movable type storage battery curing and drying device, and sealant curing and drying method

A technology for curing and drying batteries, which is applied in the direction of lead-acid batteries, lead-acid battery construction, and devices for coating liquid on the surface. It can solve the problems of reduced heating effect and curing efficiency, labor and time consumption, and inconvenient operation. Improve the effect of electric heating and curing efficiency, small site area, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] Air tightness measurement:

[0065] Put the battery at an ambient temperature of 25°C for 24 hours, inflate or pump air into the battery through the safety valve hole, when the internal and external pressure difference is 50kpa, the pressure pointer is stable for 3-5s, which means the airtightness is qualified, if it is lower than 3 seconds The airtightness is unqualified.

Embodiment 1

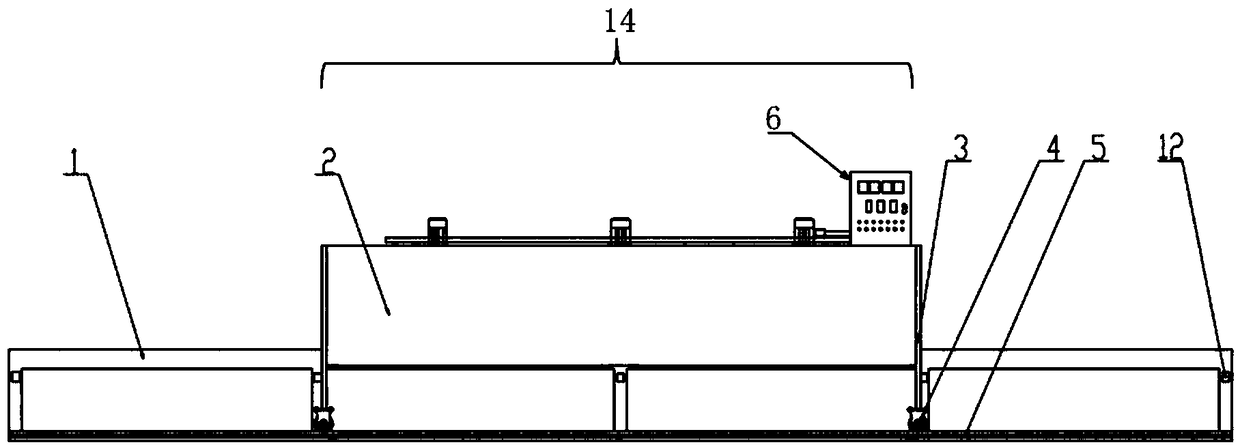

[0067] This embodiment provides a mobile battery curing and drying device, figure 1 What is shown is a schematic diagram of its external structure placed on the console 1 . The mobile storage battery curing and drying device includes an oven 14 and a roller guide 5 .

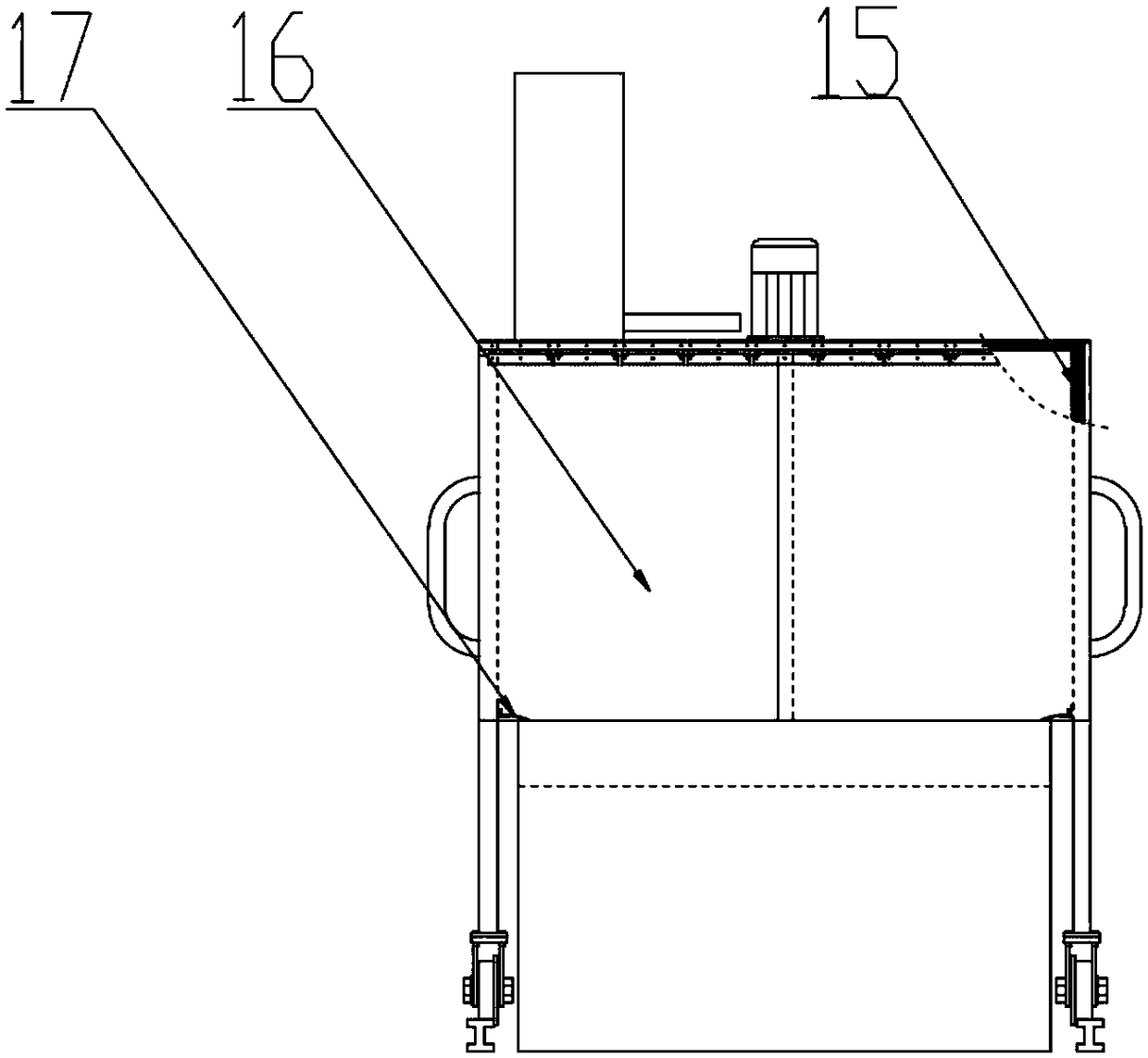

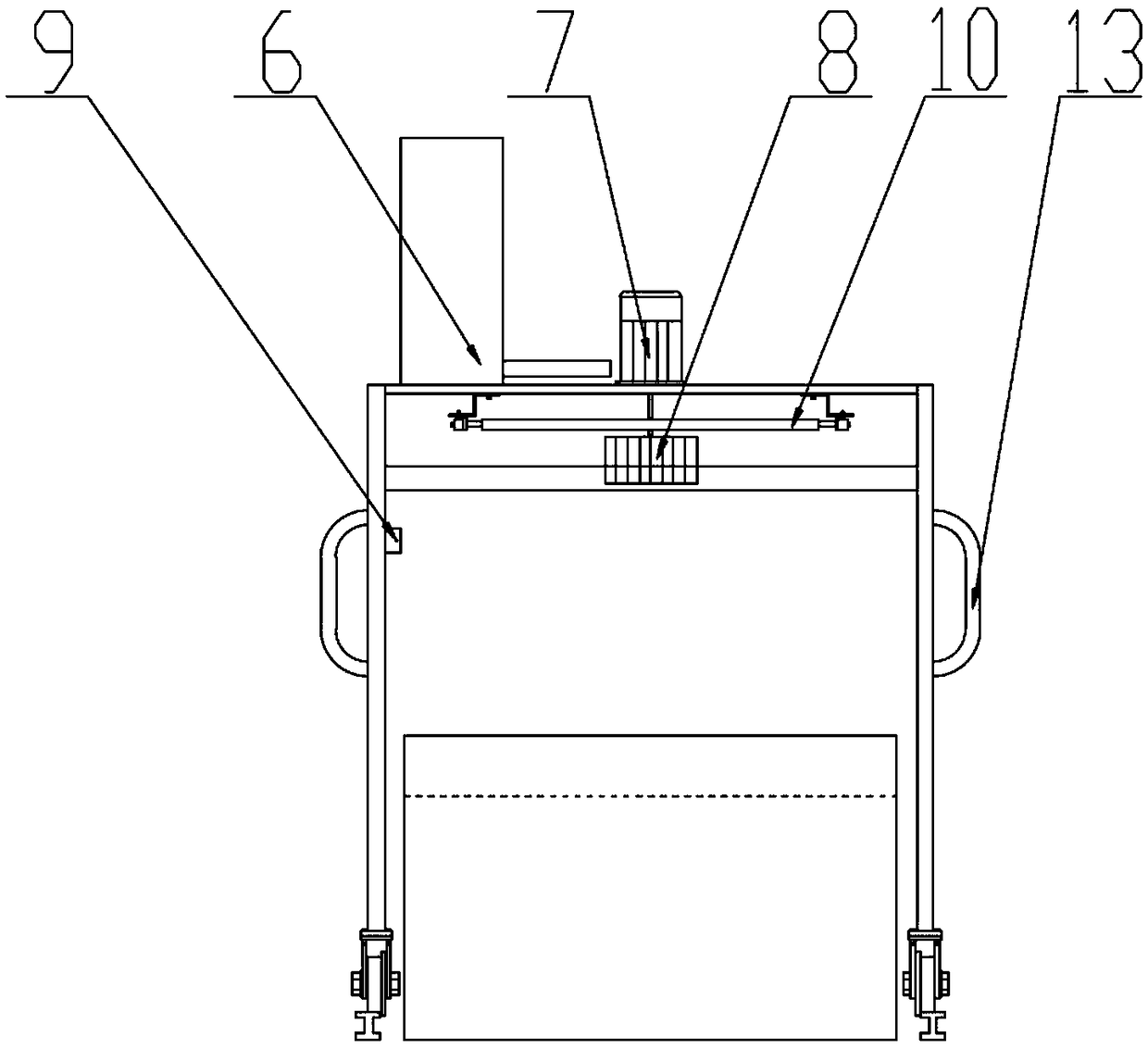

[0068] Oven 14 comprises the box body 2 that can be covered on the top of operating table 1, and the size of described operating table is long 14800mm, wide 1210mm, high 750mm, and the size of described box body 2 is long 5000mm, wide 1550mm, high 1640mm, box body The surface is made of stainless steel, made of figure 2 As can be seen, in the middle of the box body box wall, an insulating layer 15 is provided, and a windshield curtain 16 is used at the opening of the door on both sides, and a rubber plate 17 is used at the adjacent position of the box wall and the operating table to prevent heat energy from distributing. The inside of the box body 2 is provided with a heating system, the upper surface of the...

Embodiment 2

[0071] This embodiment provides a method for curing and drying battery sealant, which uses the mobile battery curing and drying device prepared in Embodiment 1.

[0072] Inject sealant into the battery on the console 1 to obtain a semi-finished battery after closing the cover. The sealant is CW-M-106H. Use a squeeze pot to squeeze the sealant into the glue groove of the battery tank and move it evenly. Let the sealant flow into the groove without leaving air holes to prevent acid leakage. The amount of glue should be 0.5-1mm lower than the plane of the glue groove, and then cover the middle cover to seal the battery; move the oven 14 along the roller guide rail 5 to the operation above table 1; connect the power plug 11 to the power switch box 12 on the console 1, turn on the power supply of the oven 14, set the drying temperature to 60°C, and the drying time to 2 hours; heat up to the specified temperature and specified Time makes the semi-finished battery sealant fully cured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com