Autonomous propulsion type soft robot main body

A robotic and propulsive technology, applied in the field of medical devices, can solve the problems of patients' cavity scratches, perforations, and increased safety hazards, and achieve the effect of improving human comfort and operational safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

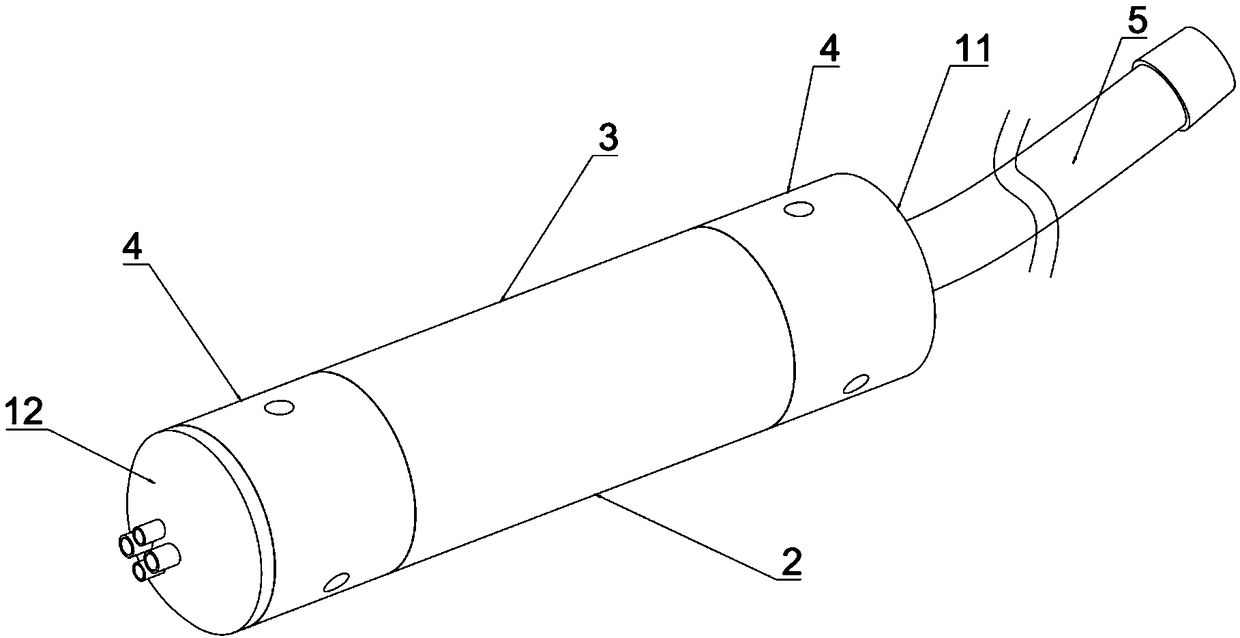

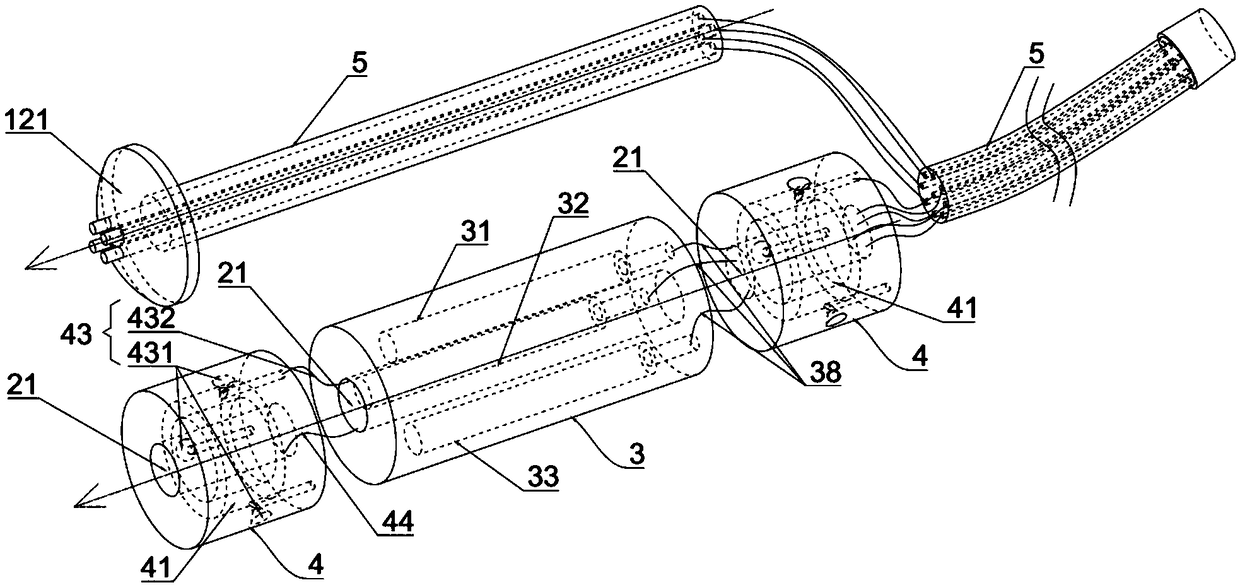

[0055] This embodiment provides a soft robot main body, its structure is as follows: Figure 1 to Figure 11 As shown, it is suitable for automatic walking in the cavity, which includes a tube body 2, a propulsion structure 3, and a support structure 4. The inside of the tube body 2 is provided with a tube body cavity 21 along the axial direction, such as figure 2 The propulsion structure 3 shown includes a first drive unit 31 , a second drive unit 32 and a third drive unit 33 that are uniformly fixed on the peripheral wall of the tube body cavity 21 relative to the axis of the tube body cavity 21 along the axial direction of the tube body 2 , The first driving unit 31 , the second driving unit 32 and the third driving unit 33 can be extended or contracted along the axial direction of the pipe body 2 . Such as Figure 8 As shown, when the second driving unit 32 and the third driving unit 33 distributed uniformly in the axial direction in the tubular body 2 are respectively ex...

Embodiment 2

[0085] This embodiment provides a main body of an autonomously propelled soft robot. The difference between it and Embodiment 1 is that the first constraining layer 34 in this embodiment is along the first driving unit 31, the second driving unit 32 and the third driving unit respectively. 33 surrounds the outside of the first drive unit 31, the second drive unit 32 and the third drive unit 33, and is suitable for defining the first drive unit 31, the second drive unit 32 and the third drive unit 33 along the pipe body 2. Axial elongation or contraction. Such as Figure 11 As shown, the first constraining layer 34 is respectively wrapped on the outside of the drive unit, so that the confinement effect on each drive unit is more precise. At the same time, the first constraining layer 34 of different winding methods can also be configured for each drive unit, so that the propulsion The combination of various actions such as elongation, shortening or twisting of the structure 3 ...

Embodiment 3

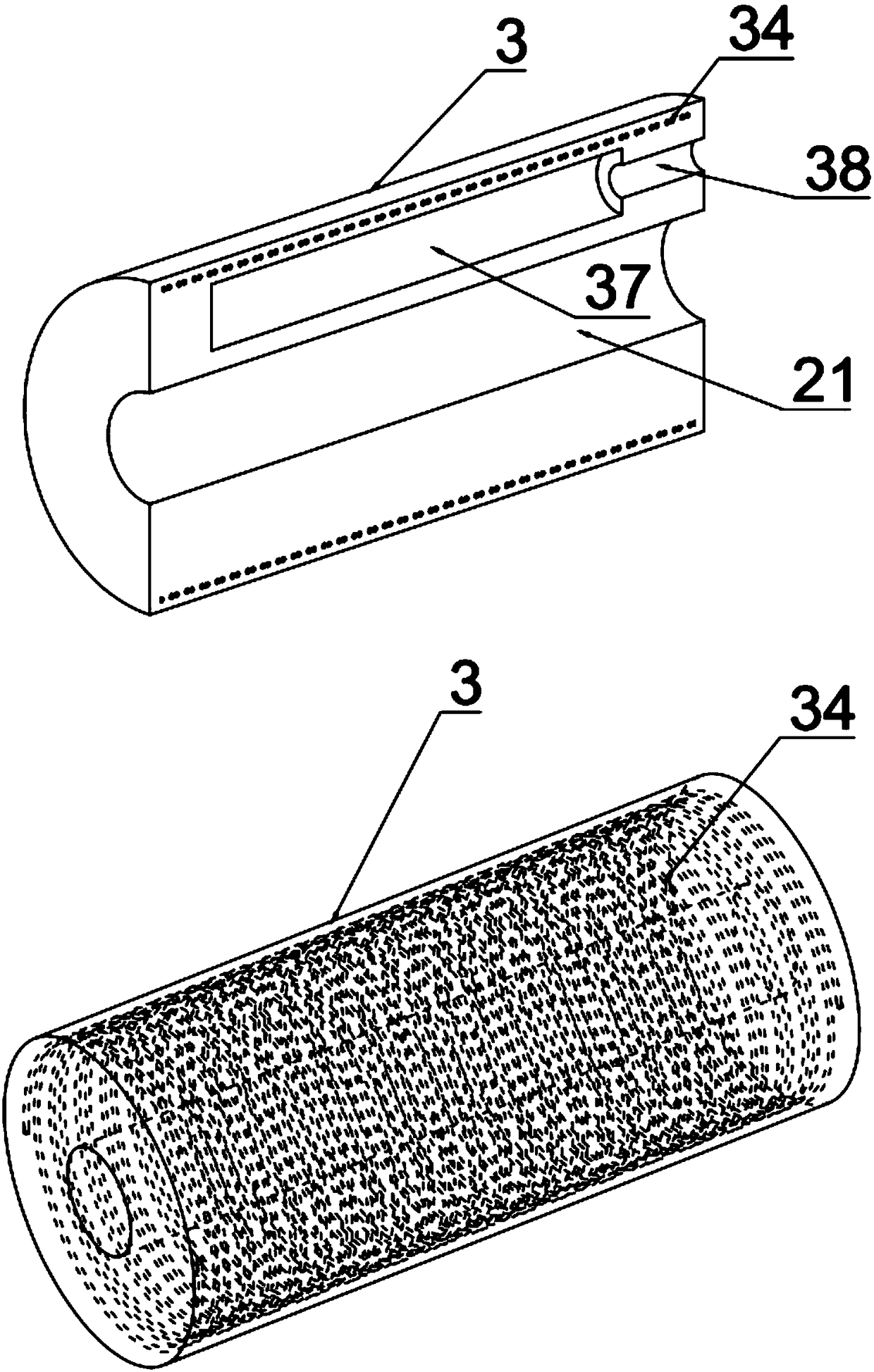

[0087] Such as Figure 13 As shown, the present embodiment provides a self-propelled soft robot main body, which is different from the main propulsion soft robot main body in Embodiment 1 in that the first drive unit 31, the second drive unit 32 and the third drive unit 33 Each has a first expansion body 35 , and a first fluid accommodating cavity 37 is formed in the first expansion body 35 . Specifically, such as Figure 12 As shown, three expansion cavities 36 are evenly opened on the peripheral wall of the tubular body 2 along the circumferential direction, and three first expansion bodies 35 are placed in each expansion cavity 36 respectively, and the shape of each first expansion body 35 is similar to that of the expansion cavity 36 By matching, the first driving unit 31 , the second driving unit 32 and the third driving unit 33 are formed. A first fluid accommodating chamber 37 is opened inside each first expansion body 35 , and one end of the first fluid accommodating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com