Flue gas purifying system

A flue gas purification system and flue gas technology, applied in the direction of chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of adsorption tower damage, combustion, activated carbon or activated coke failure, etc., to avoid failure and avoid partial hotspot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

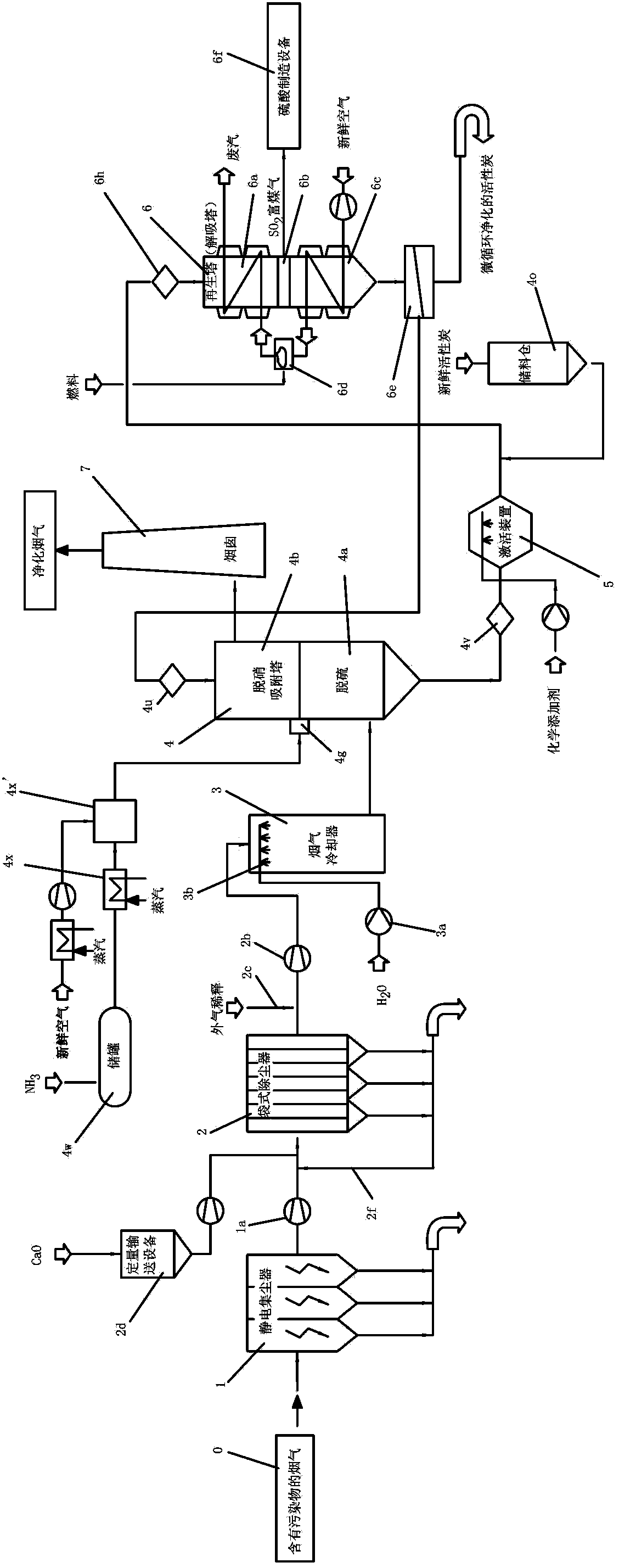

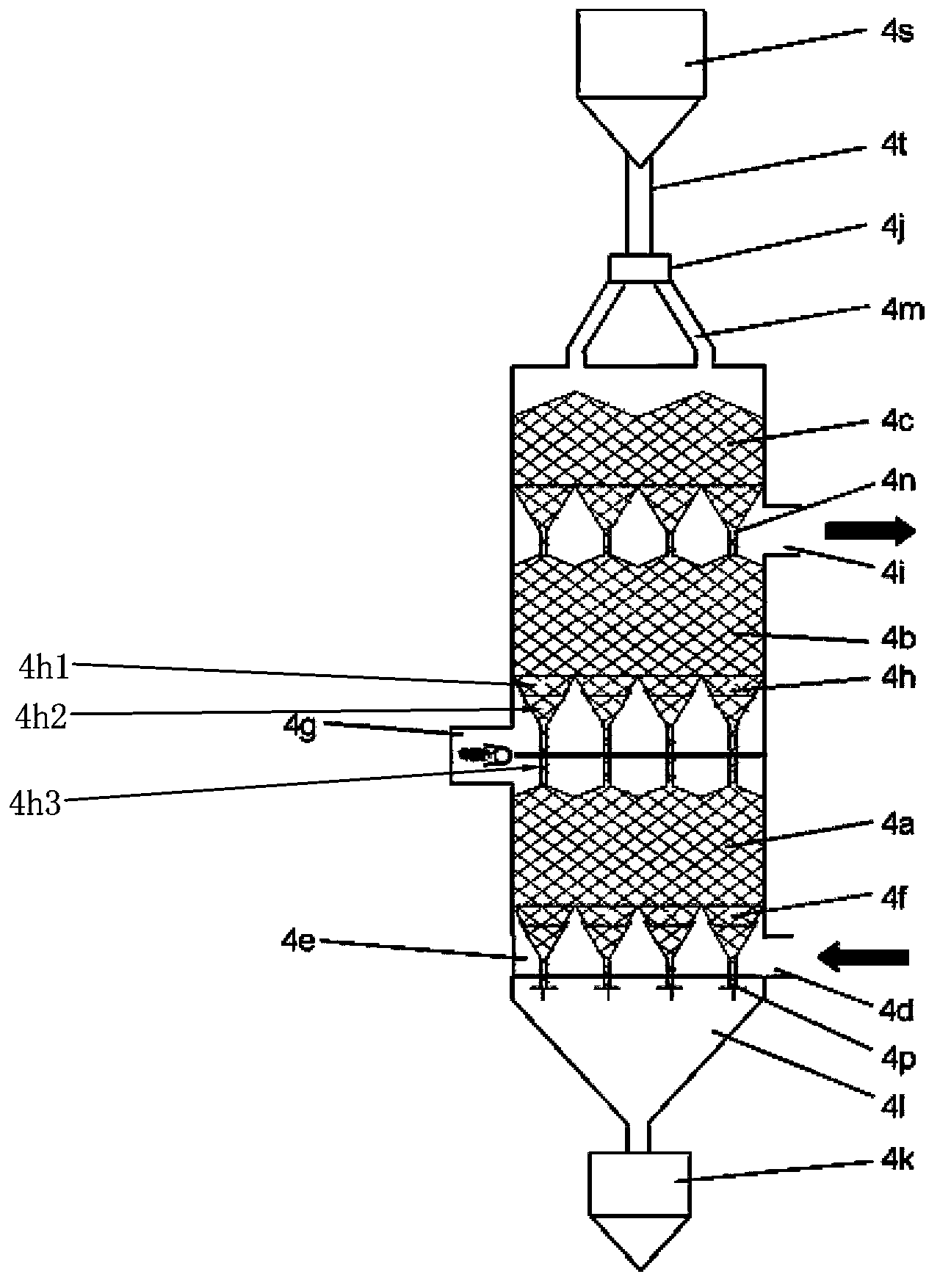

[0034] The flue gas purification system is to remove the sulfur oxides and nitrogen oxides contained in the flue gas produced by the sintering process of ironworks or the combustion of fossil fuels and their compounds in coal-fired power plants, or the flue gas emitted by incinerators. , tribute, dioxin / furan and integrated systems for dust capture and removal, such as figure 1 As shown, the flue gas purification system of the present invention includes a pretreatment system, a flue gas cooling system, an adsorption tower, a regeneration tower 6, an activation device 5, a dust removal system, and a fresh activated carbon storage bin 4o. The flue gas enters the adsorption system through a pipeline through the pretreatment system After the tower 4 is purified, the purified flue gas is discharged from the chimney 7.

[0035] The pretreatment system of the present invention includes an electrostatic precipitator 1 and a first bag filter 2, the electrostatic precipitator 1 is a pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com