Copper-aluminum joint pressure welding technique

A copper-aluminum joint, pressure welding technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of high production cost, low production efficiency, removal, etc., to reduce production processes, stable welding quality, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] It is a copper-aluminum joint pressure welding process, the steps are as follows:

[0026] ① Cutting copper and aluminum tubes, deburring, and pickling the surface of copper tubes; the copper tubes are made of TP2 oxygen-free copper tubes, and the aluminum tubes are made of 1060 pure aluminum tubes or 3003 alloy aluminum tubes.

[0027] ② Welding:

[0028] a. Adjust the welding machine and the upper and lower clamping molds;

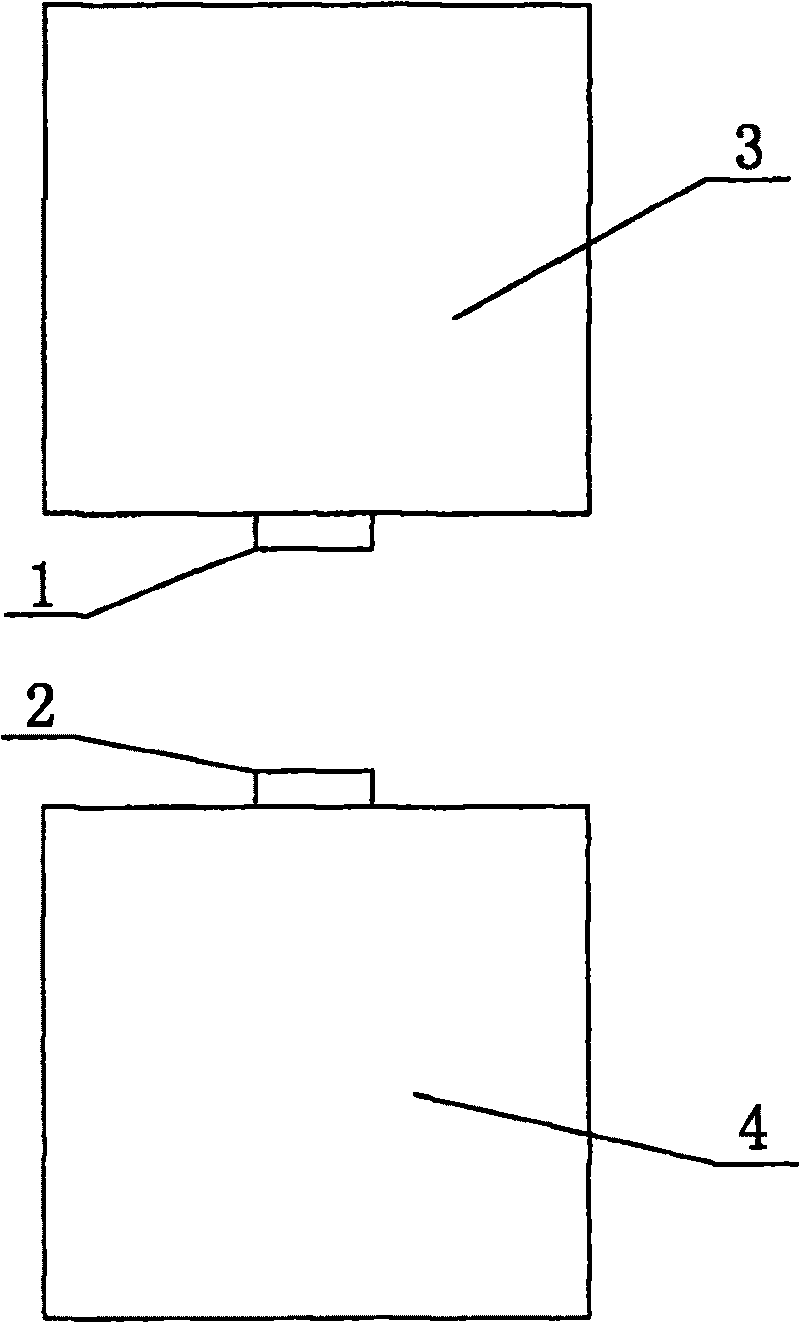

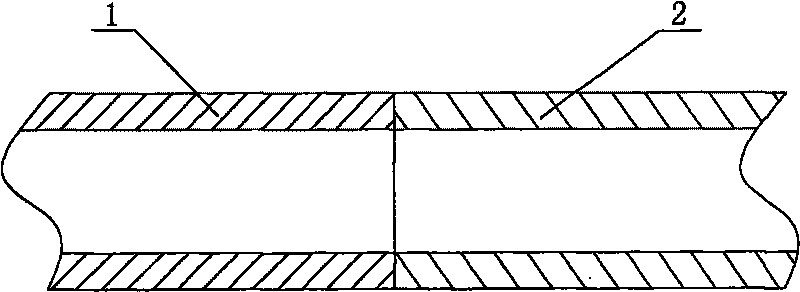

[0029] b. If figure 1 , 2 As shown, the copper tube 1 and the aluminum tube 2 are respectively clamped in the upper and lower clamping molds 3 and 4, and the two welded ports extend out of the clamping mold, and the surfaces of the ports are flat and connected, and the copper tube and the aluminum tube are Heat the welding end to about 420°C, and then apply an upsetting pressure of 0.8MPa to make the welding surface of the copper tube and the welding surface of the aluminum tube come into close contact, and produce radial plastic deformation th...

Embodiment 2

[0037] It is a copper-aluminum joint pressure welding process, the steps are as follows:

[0038] ① Cutting copper and aluminum tubes, deburring, and pickling the surface of copper tubes; the copper tubes are made of TP2 oxygen-free copper tubes, and the aluminum tubes are made of 1060 pure aluminum tubes or 3003 alloy aluminum tubes.

[0039] ② Welding:

[0040] a. Adjust the welding machine and the upper and lower clamping molds;

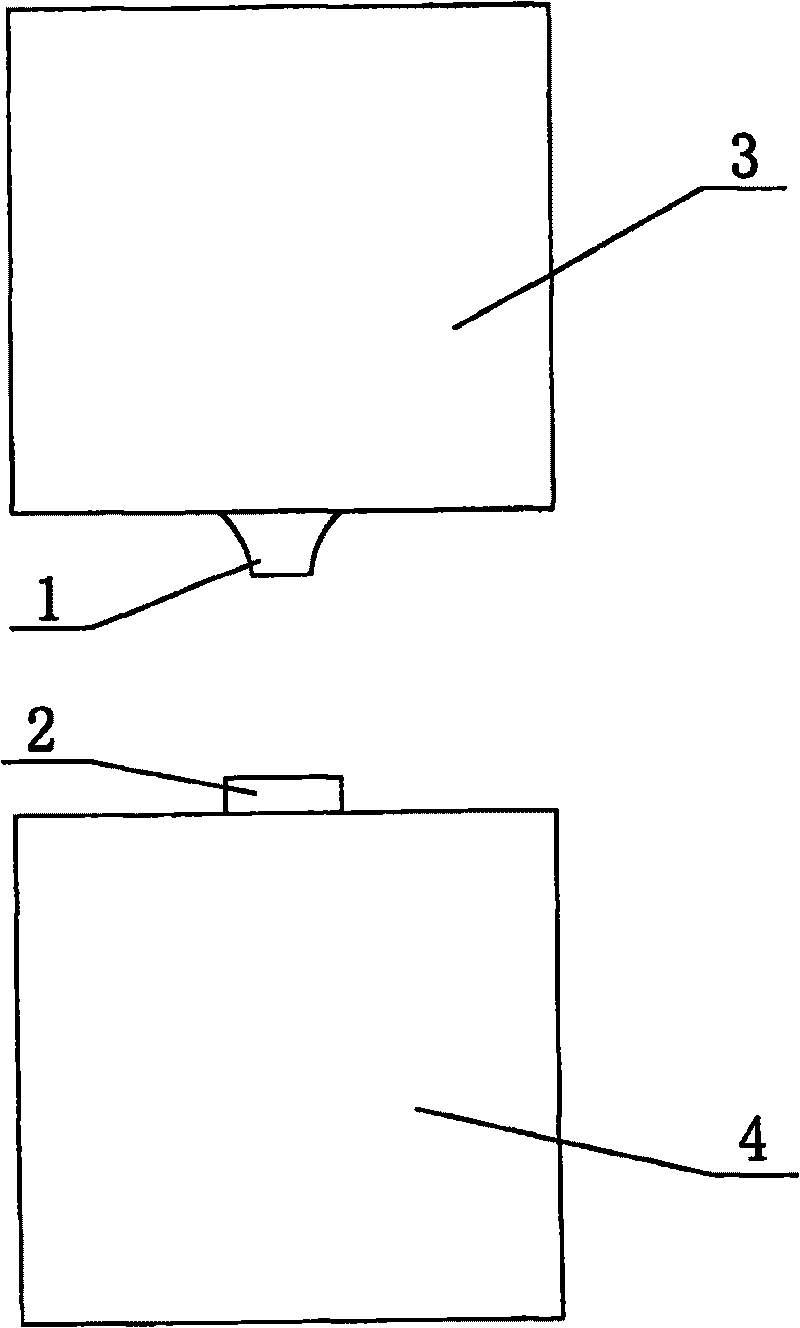

[0041] b. If image 3 , 4 As shown, the copper tube 1 and the aluminum tube 2 are respectively clamped in the upper and lower clamping molds 3 and 4, the two welded ports extend out of the clamping mold, and the ports of the copper and aluminum tubes are plugged and matched, and the copper tube and the aluminum tube are plugged together. The end of the pipe to be welded is heated to about 540°C, and then an upsetting pressure of 0.4MPa is applied to make the welding surface of the copper pipe and the welding surface of the aluminum pipe come in...

Embodiment 3

[0049] It is a copper-aluminum joint pressure welding process, the steps are as follows:

[0050] ①Unload copper and aluminum tubes, deburr them, and pickle the surface of the copper tubes; the copper tubes are made of TP2 oxygen-free copper tubes, and the aluminum tubes are made of 1060 pure aluminum tubes or 3003 alloy aluminum tubes.

[0051] ② Welding:

[0052] a. Adjust the welding machine and the upper and lower clamping molds;

[0053] b. If figure 1 , 2 As shown, the copper tube 1 and the aluminum tube 2 are respectively clamped in the upper and lower clamping molds 3 and 4, and the two welded ports extend out of the clamping mold, and the surfaces of the ports are flat and connected, and the copper tube and the aluminum tube After the welding end is heated to about 480°C, an upsetting pressure of 0.6 MPa is applied, so that the welding surface of the copper tube and the welding surface of the aluminum tube are in close contact, and the radial plastic deformation is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com