High-efficiency reactor for hydrated salt chemical energy storage

A hydrated salt chemical and reactor technology, which is applied in the field of thermochemical energy storage, can solve the problems of poor heat and mass transfer, inability to use hydrated salt thermochemical energy storage, and low energy storage density. Accelerate the kinetic process of chemical reactions, increase the rate of adsorption and desorption reactions, and increase the effect of energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

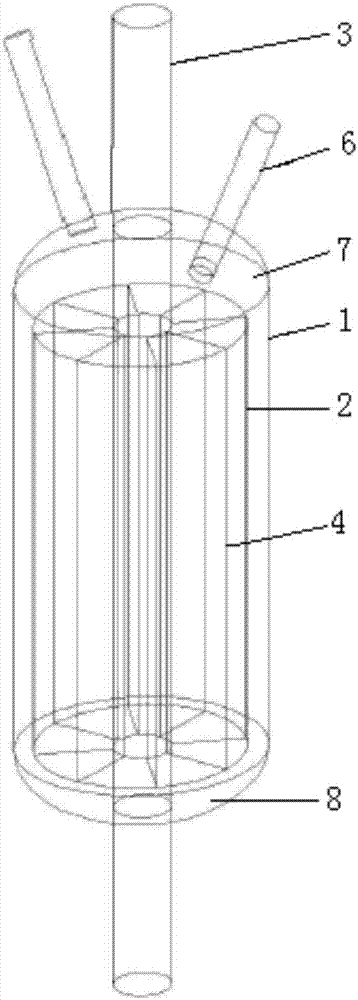

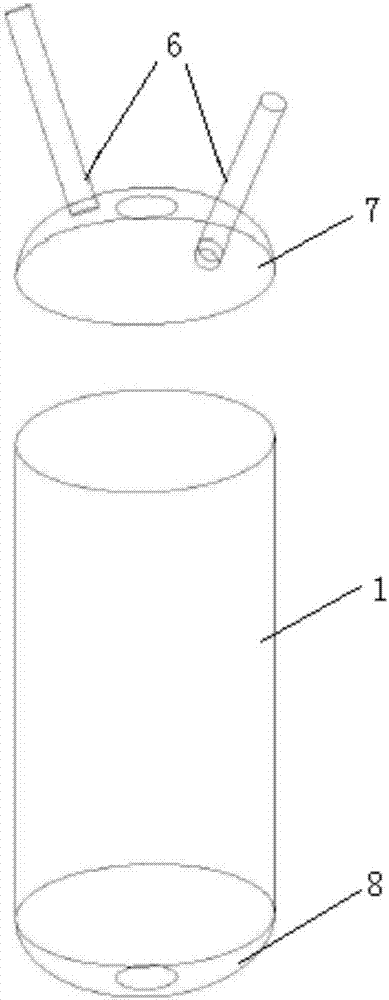

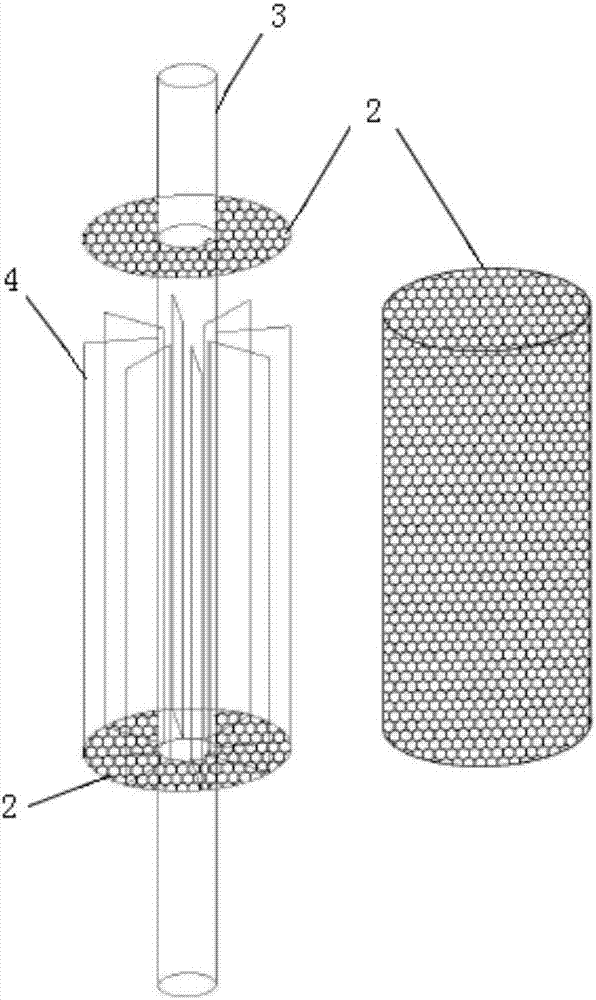

[0027] like Figure 1 to Figure 4As shown, a high-efficiency reactor for chemical energy storage of hydrated salts includes a thermally insulated container 1, a column 2 for wrapping hydrated salts, heat exchange tubes 3, fins 4, hydrated salts 5 and pipelines 6; The cross-section of the heat-insulating container 1 is ring-shaped, and the center of the heat-insulating container 1 is provided with a cylinder 2; the cylinder 2 is cylindrical, and the center of the cylinder 2 is provided with a heat exchange tube 3, and the cylinder 2 is made of foam The metal foam board has many fine-pore structures, which can prevent the hydrated salt 5 from slipping and allow the reaction steam to transmit effectively. The water vapor can conduct heat and mass transfer reactions with the hydrated salt in the radial and axial directions at the same time and can avoid Part of the hydrated salt in the traditional stacked bed absorbs water and liquefies excessively, while the other part cannot ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com