Patents

Literature

136results about How to "Even heat absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

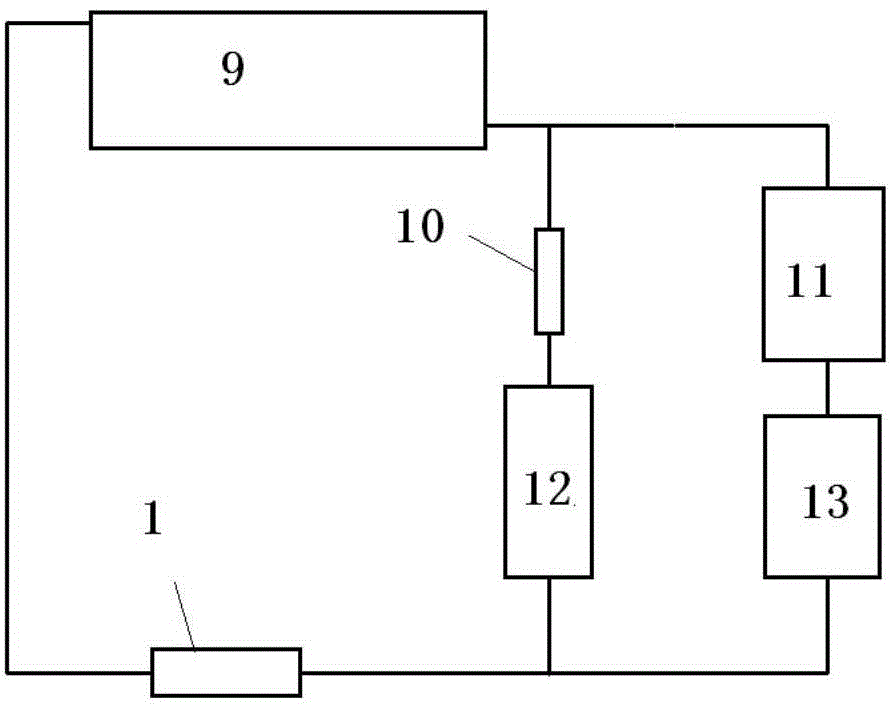

Solar heat storage system

InactiveCN104819579AAvoid wastingEven heat absorptionSolar heating energySolar heat devicesEngineeringSolar heat

The invention provides a solar heat storage system. The solar heat storage system comprises a heat collector, a water tank and a heat storage drive, wherein water in the heat collector is heated, and then input into the water tank, the water tank is connected with the heat storage drive, the heated water in the water tank enters the heat storage drive, and an insulating layer is arranged on the exterior of the heat storage device. The solar heat storage system saves energy, and improves heat utilization ability of solar energy.

Owner:SHANDONG UNIV

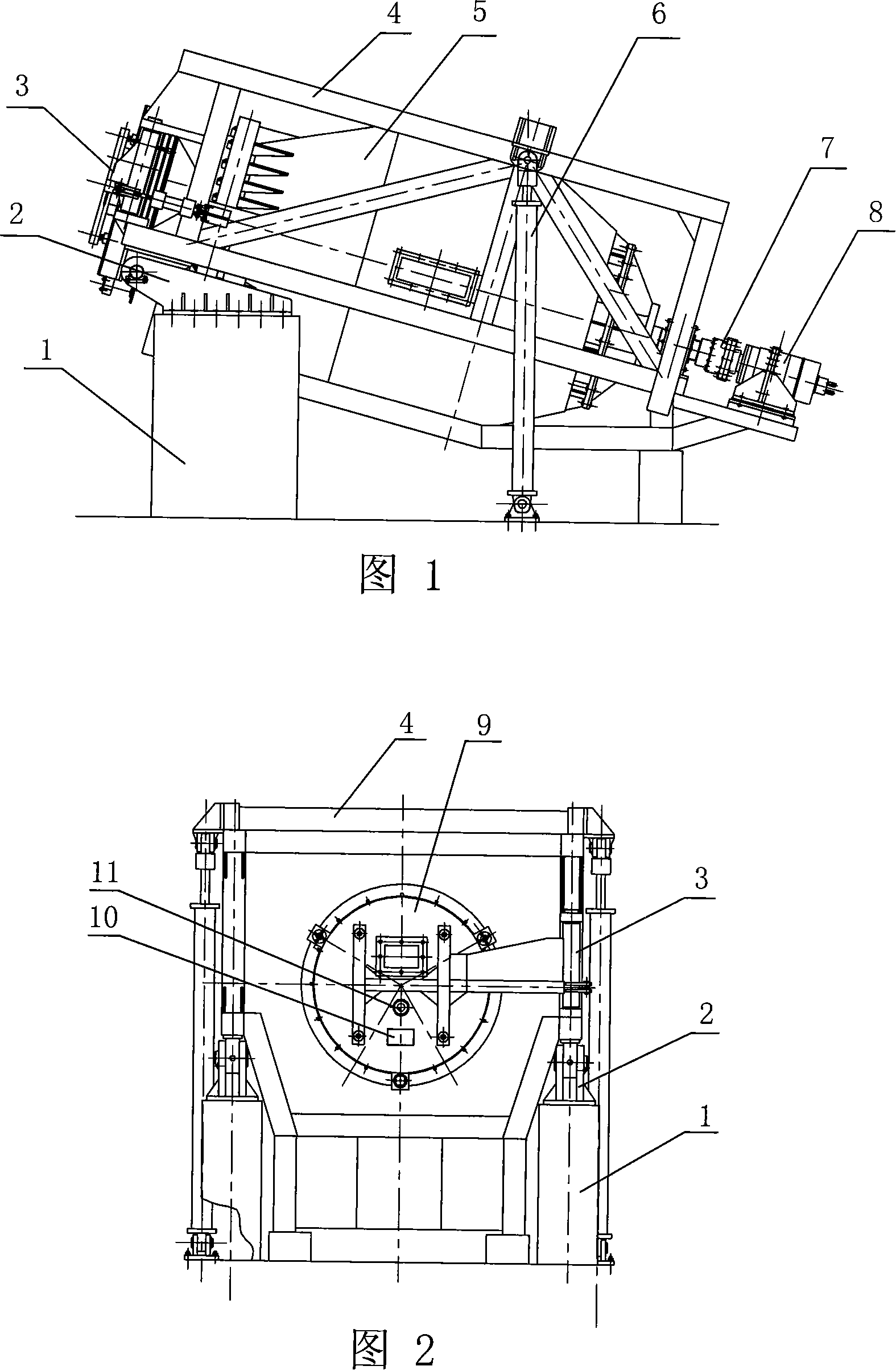

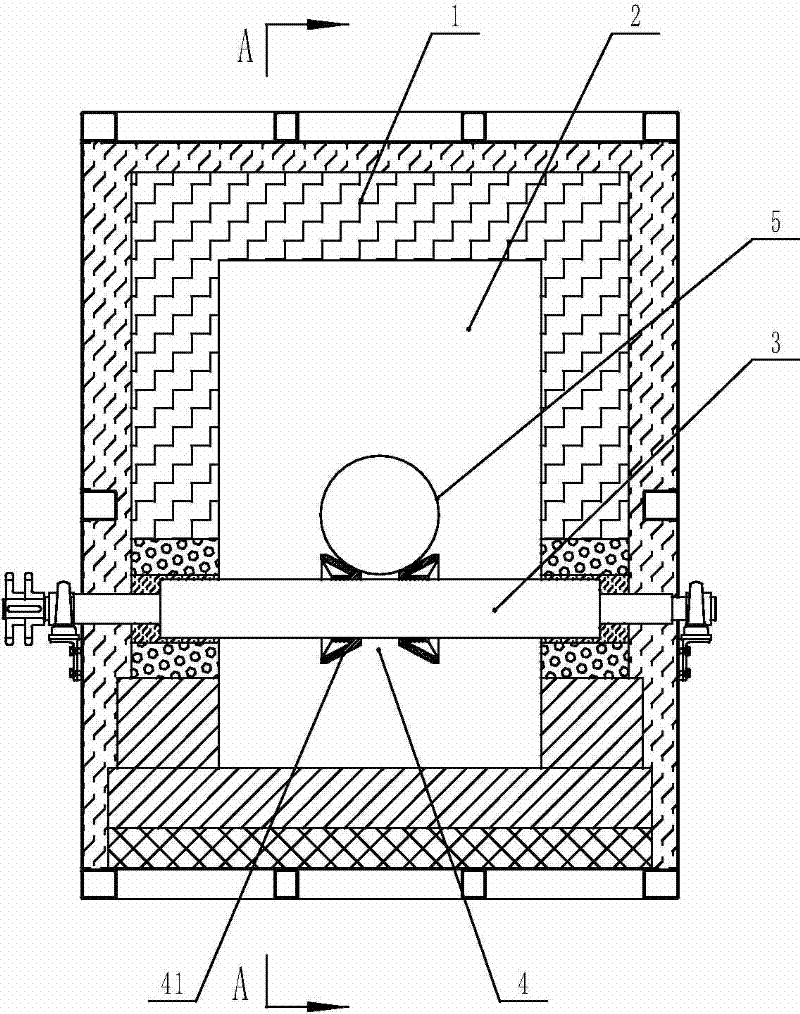

Tiltable rotary secondary aluminum smelting furnace

InactiveCN101131304AImprove performanceIncrease production capacityRotary drum furnacesClinker productionCombustorRotary furnace

This invention relates to a tilting rotary secondary aluminum smelting furnace. It includes roller type rotary furnace body, which is supported on the steel support. The anterior end of rotary furnace is arranged in the sleeve. The anterior end face of the rotary furnace has round furnace opening. The posterior end of rotary furnace connects to power device. The steel support corresponding to the rotary furnace posterior end parts connects to lifting cylinder. The steel support corresponding to the rotary furnace anterior end part connects to supporting shaft. There is round furnace door corresponding to the round furnace opening. There is sealing ring between the round furnace opening and door. The round furnace door is arranged on the roll-over shaft and connects to controlling oil cylinder. The round furnace door has fuel gas combustor and waste air discharging opening. The structure is simple. This invention is convenient. It has low energy dissipation and high producing efficiency.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

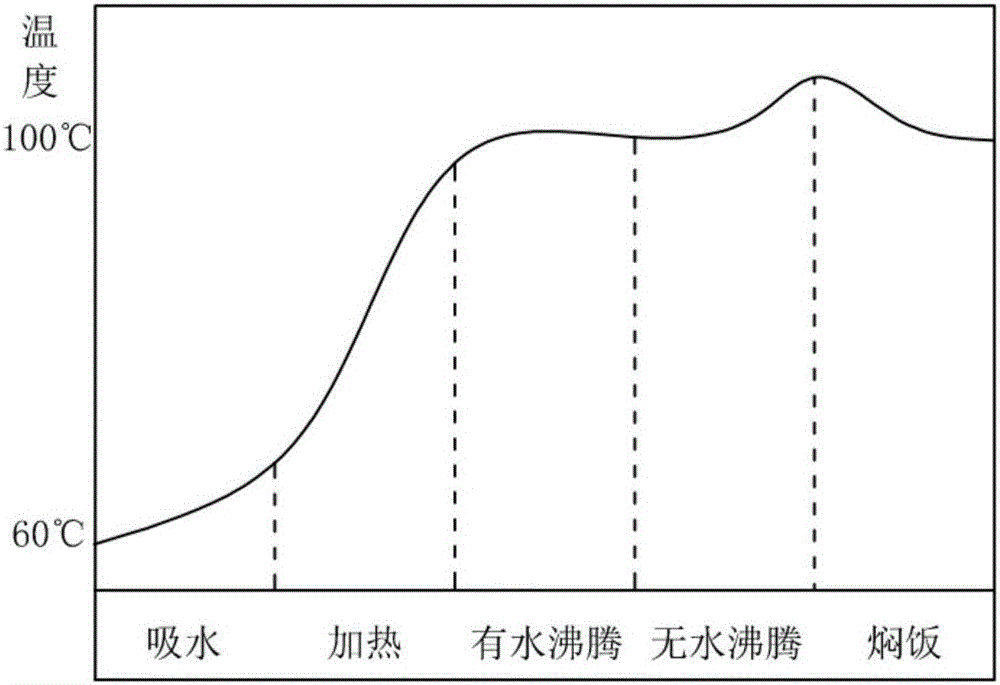

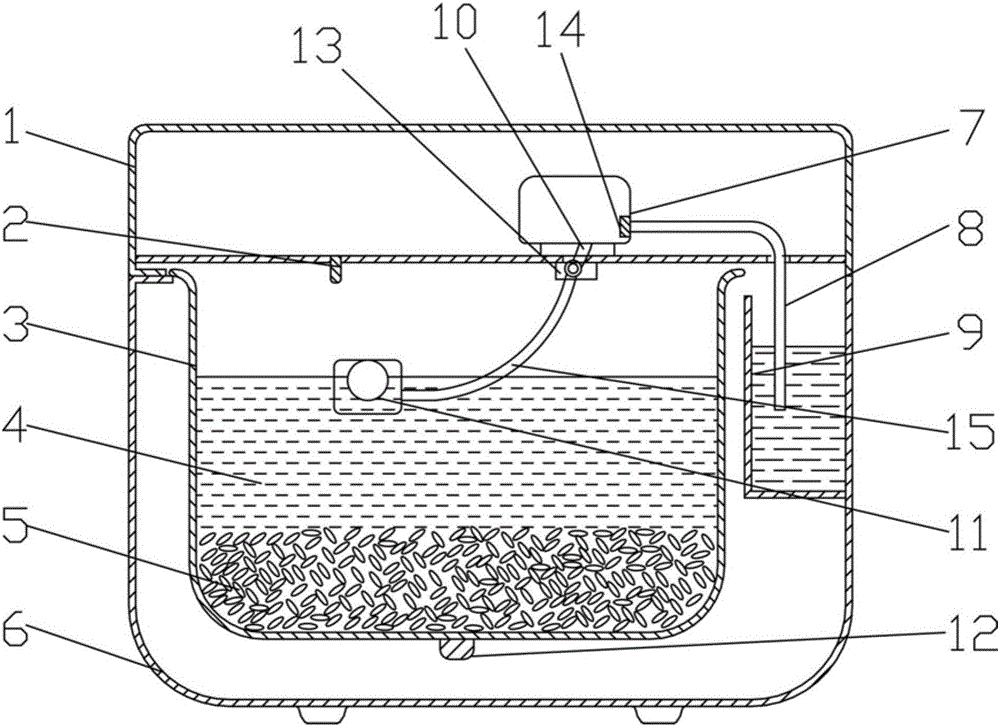

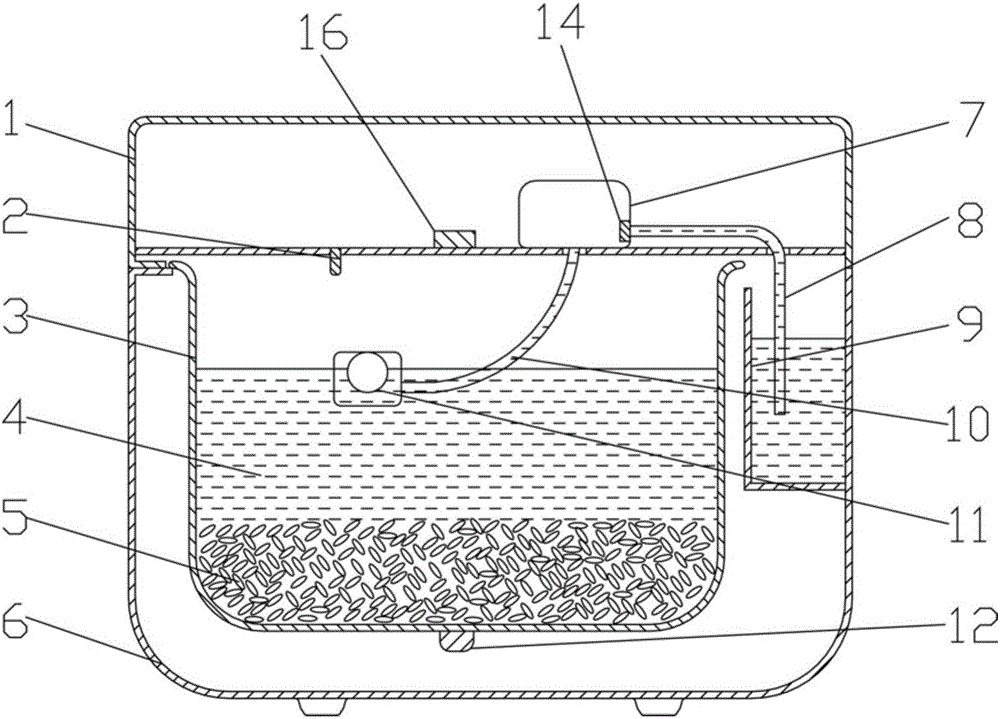

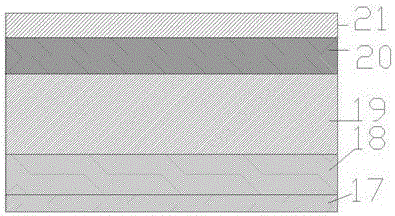

Intelligent electric rice cooker and rice cooking method thereof

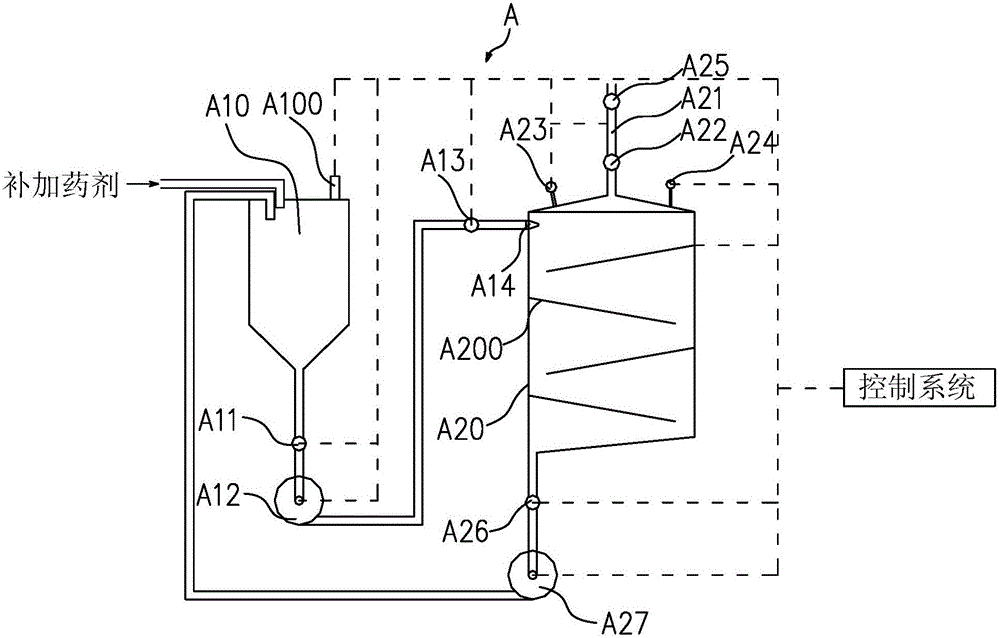

ActiveCN105852626AEven heat absorptionGood taste consistencySteam cooking vesselsWarming devicesControl systemEngineering

The invention relates to the field of electric rice cookers, and discloses a rice cooking method of an intelligent electric rice cooker. The rice cooking method comprises the following steps of heating, water boiling and water-lack boiling; in the heating step, enabling a control system of the electric rice cooker to calculate the amounts of water and rice in the electric rice cooker, continuing to heat, and entering the water boiling step; in the water boiling step, boiling the rice in the water after setting time, enabling the control system of the electric rice cooker to calculate the amount of to-be-remained water according to the amount of rice, starting a water suction device to drain water, drain the water out of the electric rice cooker until the amount of water in the electric rice cooker is equal to the amount of to-be-remained water, closing the water suction device, continuing to heat, evaporating the water in the electric rice cooker, and entering the water-lack boiling step. The rice cooking method solves the technical problem of nonuniform heat absorbing of rice in the water boiling step when the electric rice cooker of the prior art is used for cooking rice. The invention provides the intelligent electric rice cooker with the rice cooking method.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

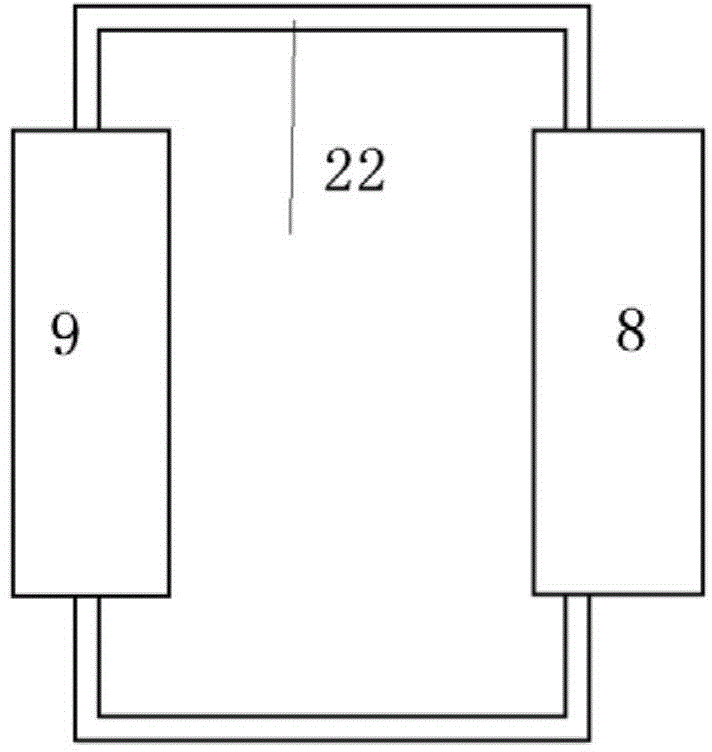

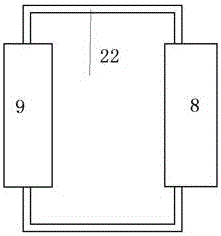

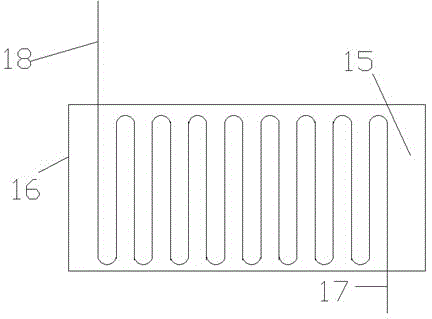

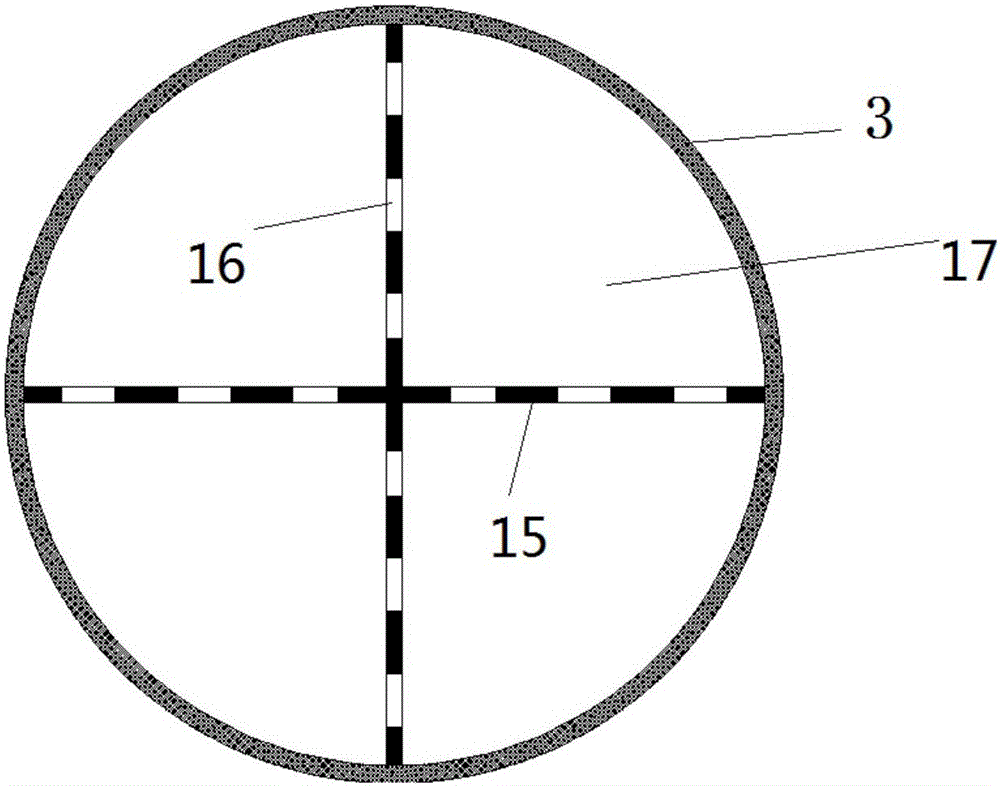

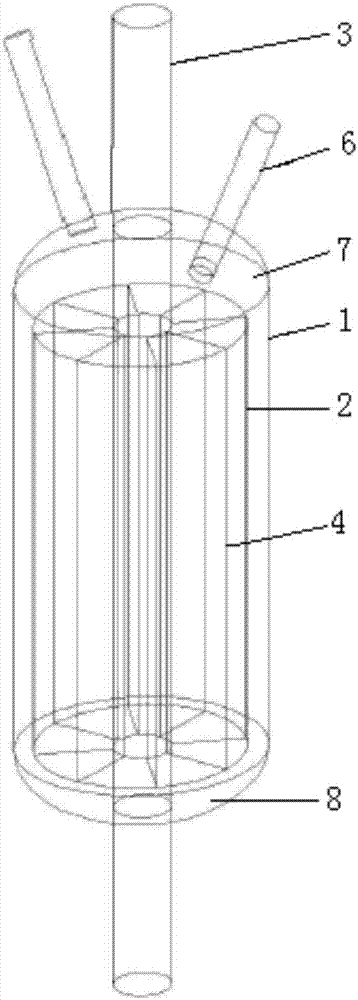

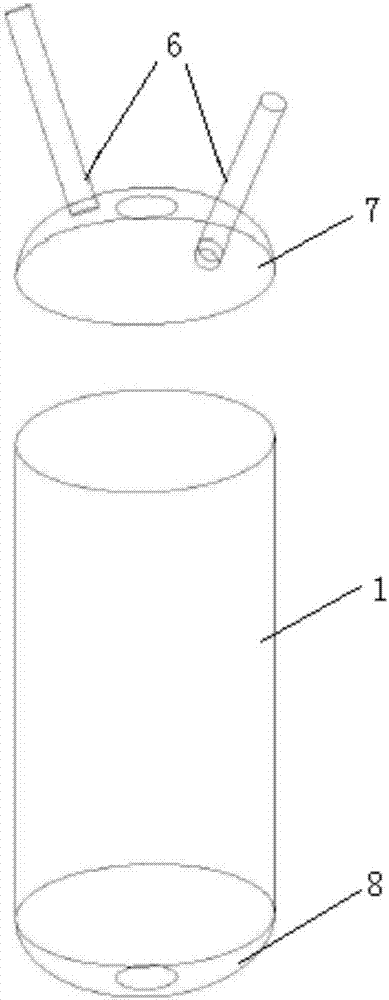

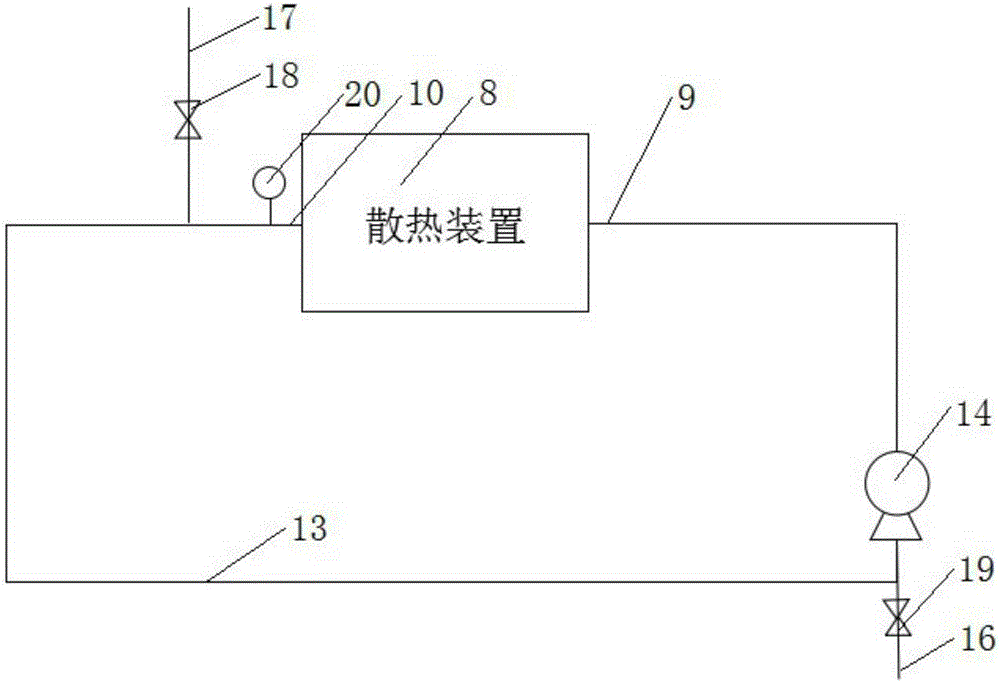

Solar heat storage system of loop heat pipe

InactiveCN105737399AAvoid wastingEven heat absorptionSolar heating energySolar heat devicesMicro-loop heat pipeEvaporation

The invention provides a solar heat storage system of a loop heat pipe. The solar heat storage system comprises a heat collector, a water tank, a heat storage device and the loop heat pipe; the condensation end of the loop heat pipe is arranged in the water tank, and the heat collector absorbs heat of solar energy to heat the evaporation end of the loop heat pipe; working liquid at the evaporation end is circulated to enter the condensation end of the loop heat pipe, and heat releasing is carried out at the condensation end to heat water in the water tank; and after heat releasing is completed at the condensation end, the working liquid is recirculated to enter the evaporation end of the loop heat pipe to conduct heating, and the water tank is connected with the heat storage device. According to the loop heat pipe solar heat storage system, by means of the loop heat pipe, the heat using capacity of solar energy is improved.

Owner:SHANDONG UNIV

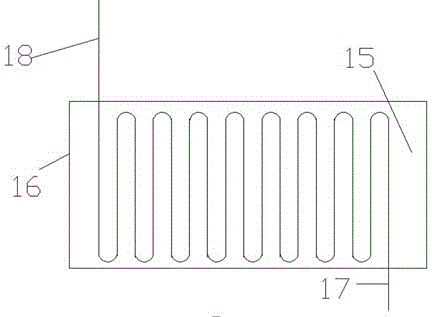

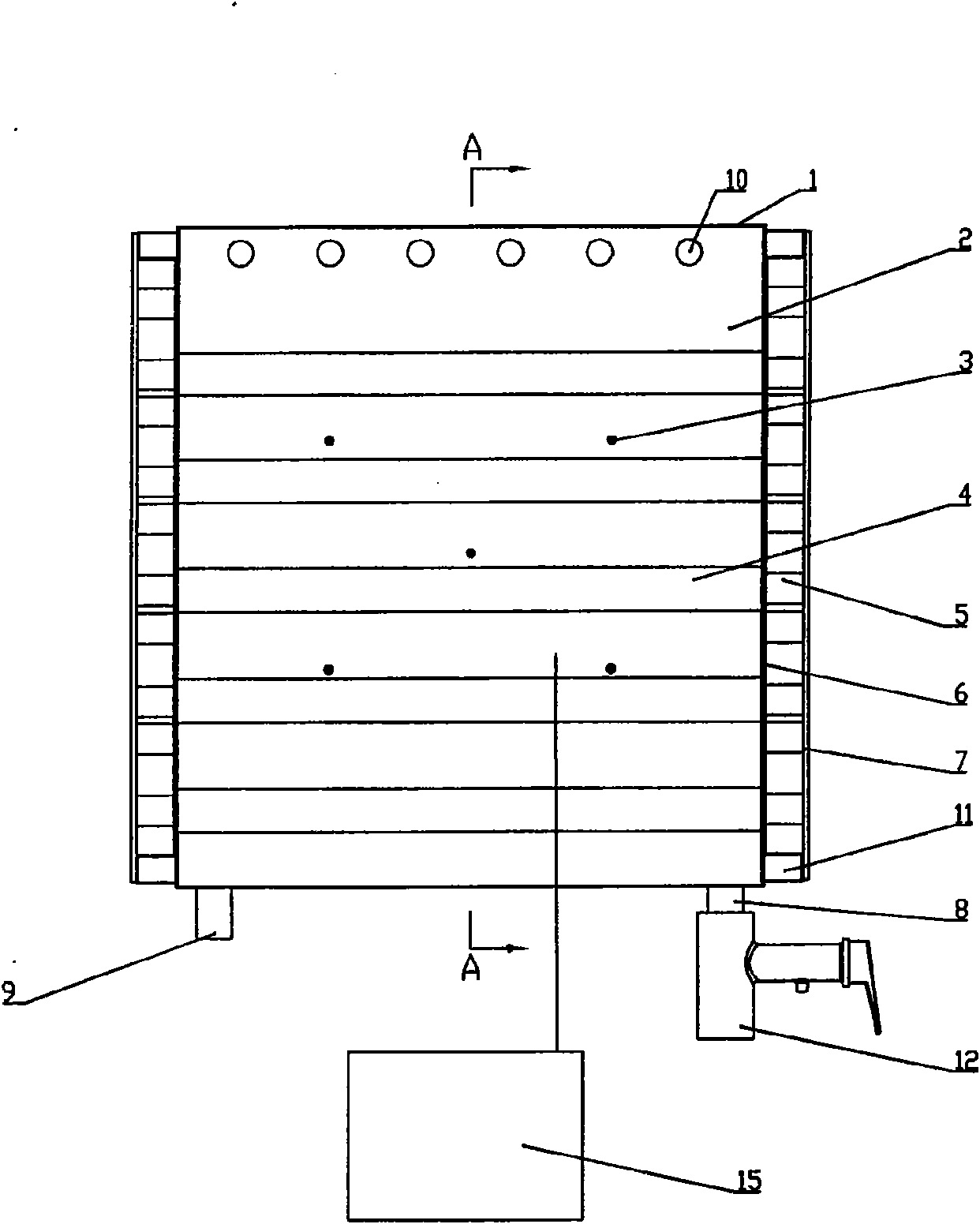

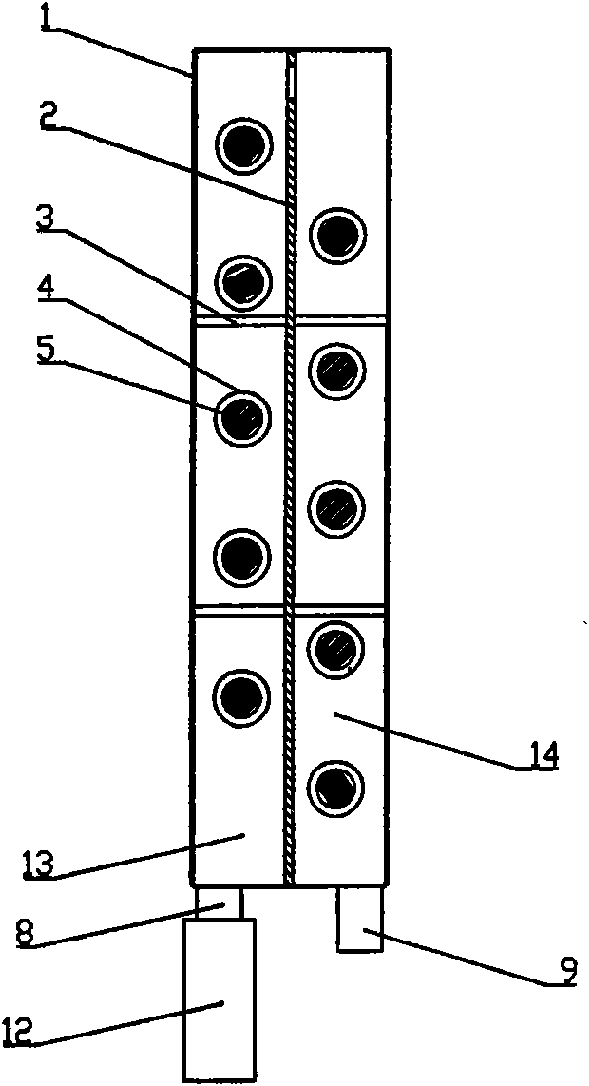

Heat storage heat exchanger and fresh air system thereof

ActiveCN104807355AEven heat absorptionAvoid uneven heat absorptionHeat storage plantsSpace heating and ventilation detailsEngineeringRecuperator

The invention relates to a heat storage heat exchanger and an air supply system comprising same. The heat exchanger comprises a shell, a heat storage medium and a fluid passage, wherein the heat storage medium is arranged in the shell, the fluid passage is arranged in the heat storage medium, the fluid passage is provided with a fluid inlet and a fluid outlet, the heat storage capacity of the heat storage heat exchanger is S, the heat storage capacity S is set as a function which is x away from the fluid inlet, i.e. S=f(x), in the heat storage heat exchanger, f(x) is more than 0, and f(x) is a first derivative of f(x). The heat storage medium integrally and uniformly absorbs the heat in the flowing direction of the fluid, and the situation such as non-uniformity in heat absorption can be avoided.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

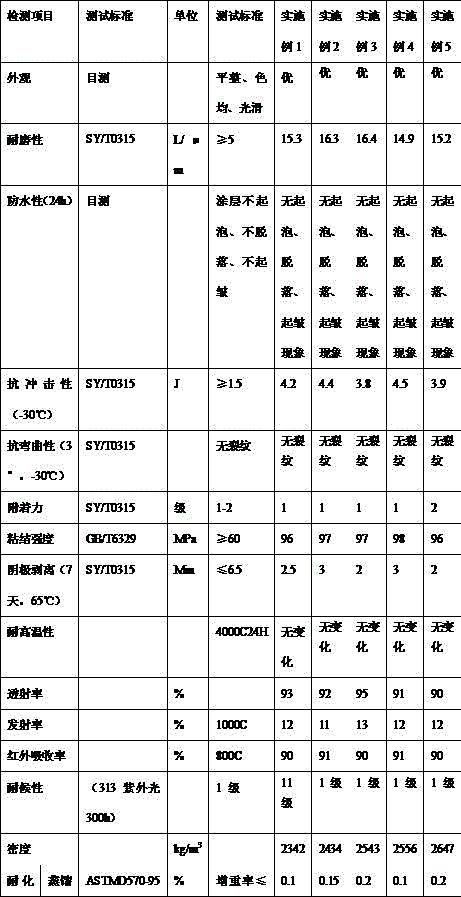

Solar heat-absorbing paint

InactiveCN106010241AImprove stabilityGood weather resistanceFireproof paintsAntifouling/underwater paintsPolyethylene glycolSolvent

The invention discloses solar heat-absorbing paint which is prepared from the following components in parts by weight: 25-35 parts of an acrylate-modified composite emulsion, 2-6 parts of a fluorocarbon surfactant, 35-55 parts of a nano carbon powder and manganese dioxide mixture, 7-12 parts of a curing agent, 50-35 parts of a film forming agent, 1-3 parts of an absorption enhancer, 10-20 parts of a solvent, 5-10 parts of dispersants, and 0.5 to 0.7 part of a thickening agent, wherein the dispersants are sodium dodecyl sulfate and polyethylene glycol / polyvinyl pyrrolidone; the film forming agent is modified fibroin-gelatin; nano carbon powder is 10-20 nm in particle size, 150-180 m<2> / g in specific surface area and 90-95% in carbon content. The prepared solar heat-absorbing paint has excellent weather resistance and water resistance under the outdoor condition, the preparation process is simple and easy to understand, and the heat absorption efficiency of the heat-absorbing paint is further ensured.

Owner:NANNING KEYU ENERGY TECH CO LTD

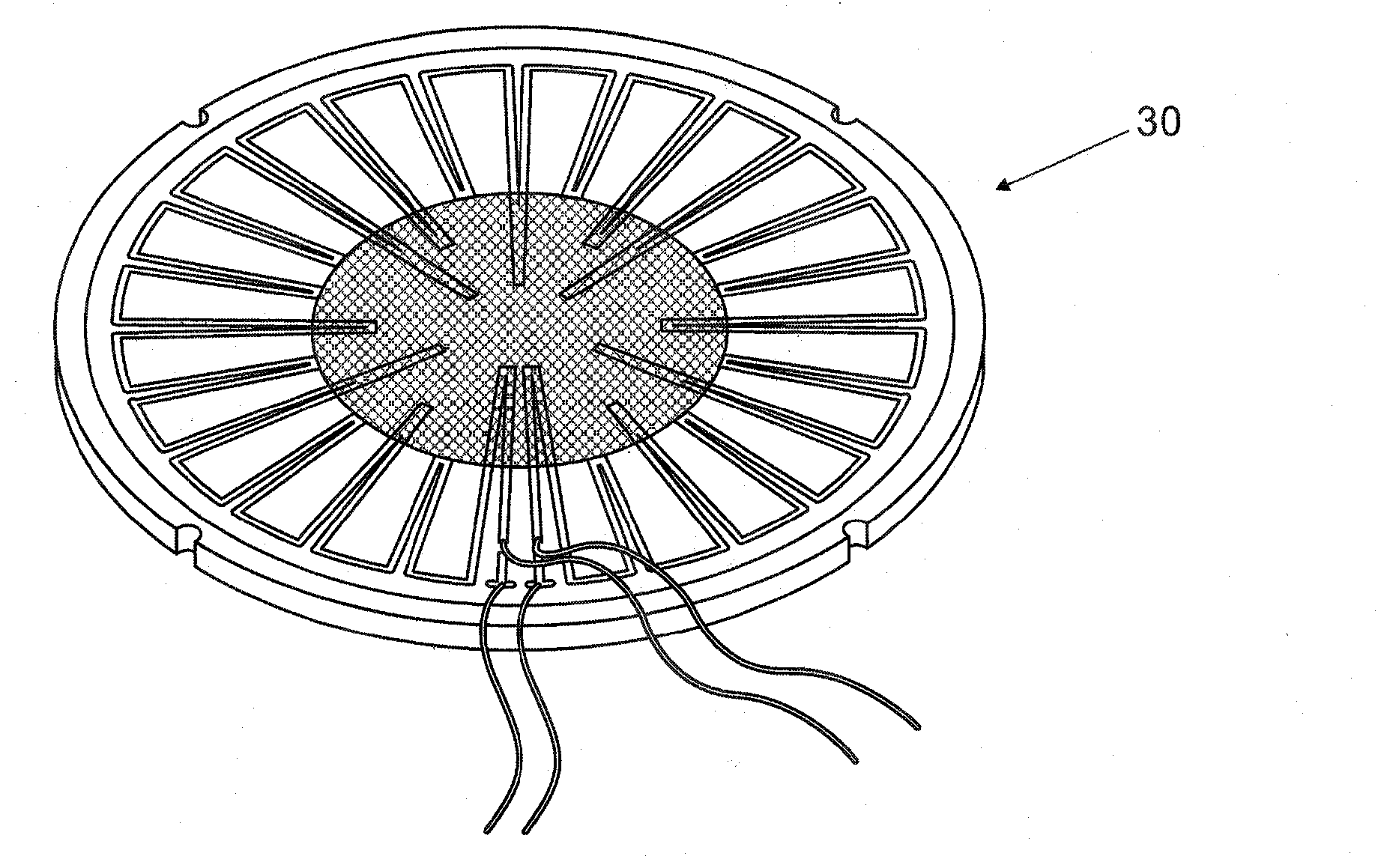

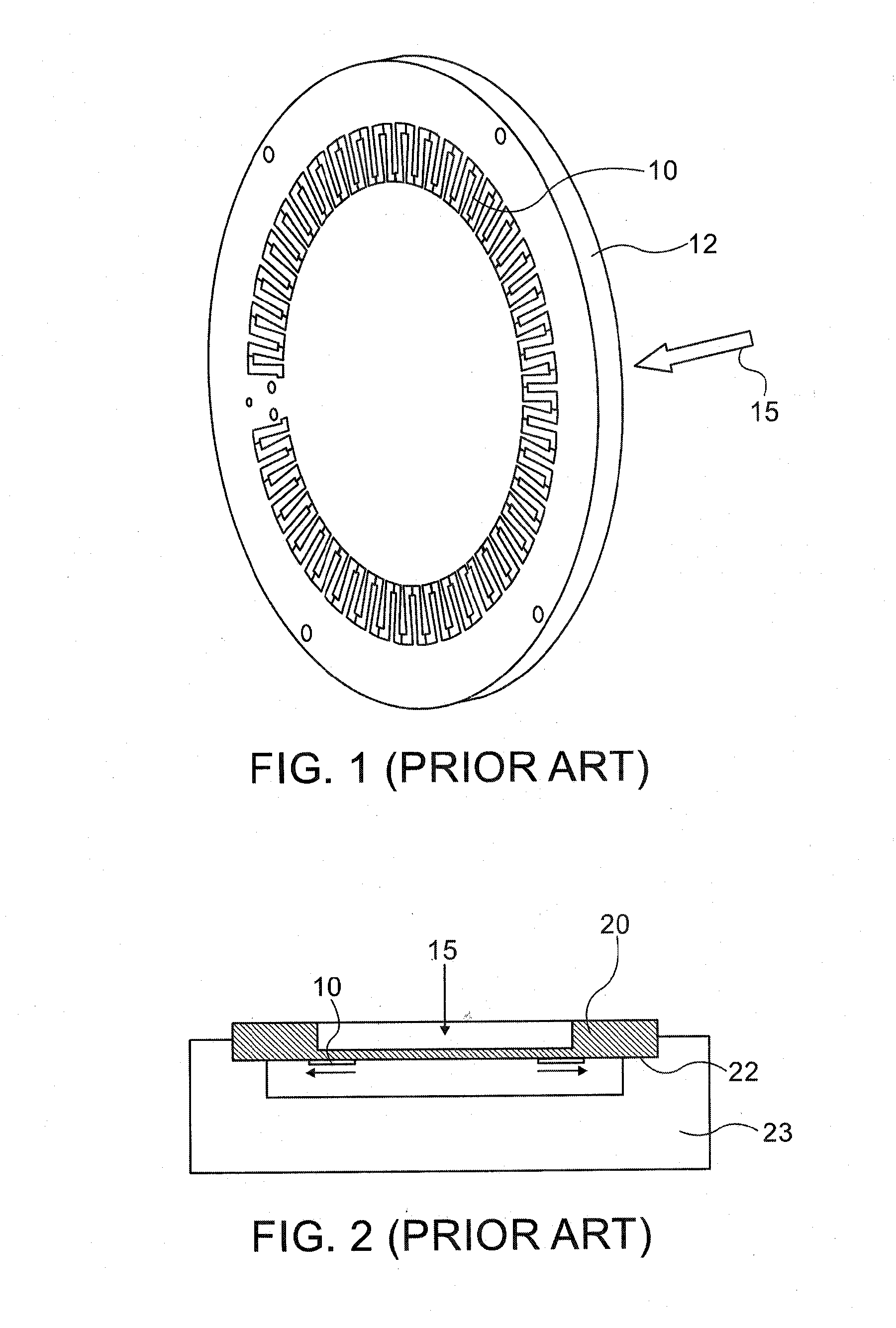

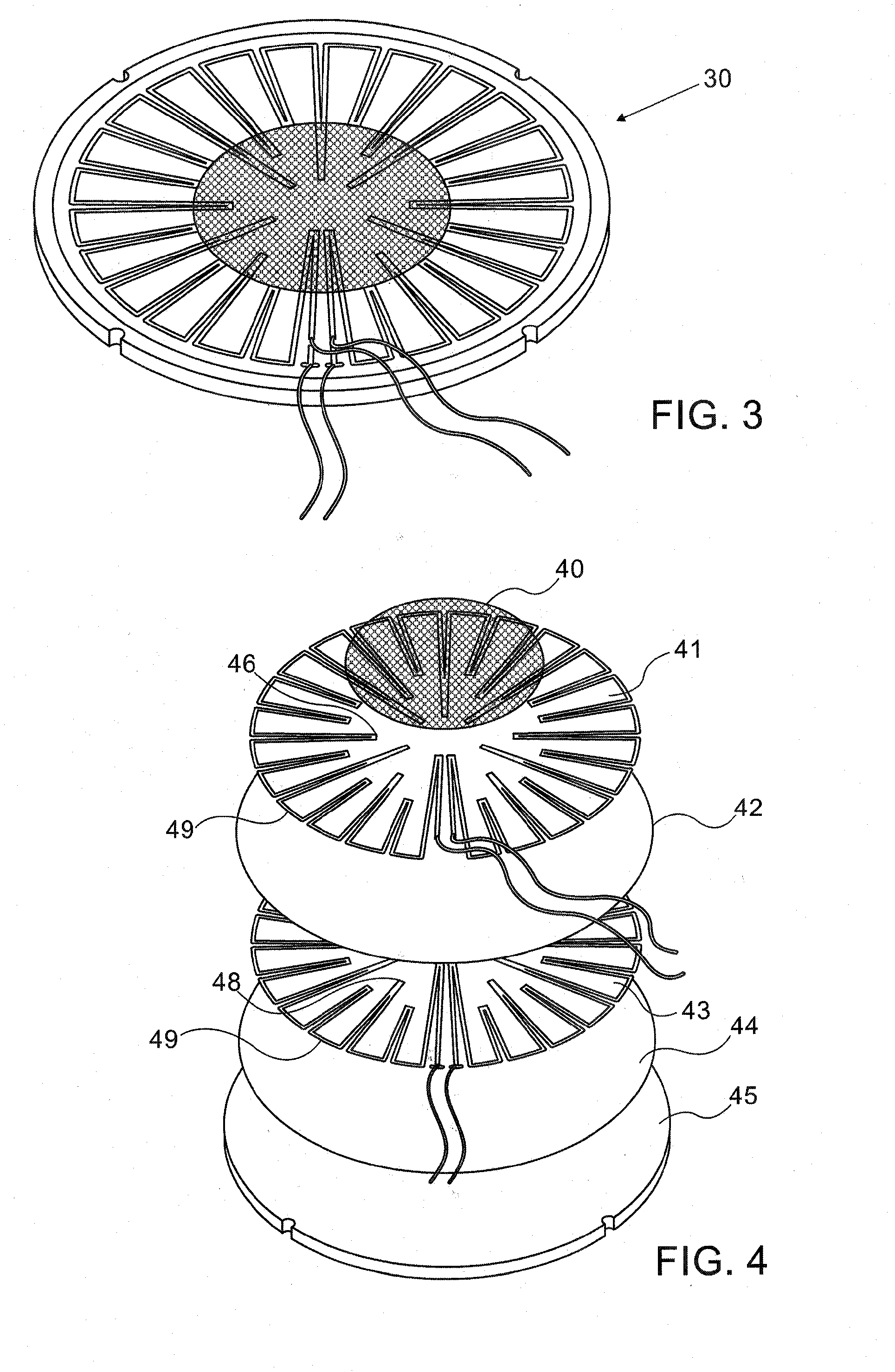

Fast response thermopile power sensor

ActiveUS20130250997A1Rapid responseReduce distanceThermometers using physical/chemical changesCalorimeterPower sensorThermopile

A power measuring sensor for an optical beam which utilizes the temperature difference across a thin layer of heat insulating material, generated by the axial flow of the absorbed beam, from an absorber layer on which the beam impinges, to a cooled heat sink which dissipates the heat after passage through the sensor. The axial heat flow is measured by means of a continuous matrix of adjacent thermocouple junctions over the heat flow region of the sensor disc, with the thermal insulating layer, which generates the temperature drop, having thicker and thinner regions at alternate junctions. The junctions on the thicker regions of the insulator thus become the hot junctions, and those on the thinner regions of the insulating layer become the cold junctions, and the sum of the voltages generated by the thermocouples is proportional to the flow of heat, and thus to the incident optical power.

Owner:OPHIR OPTRONICS SOLUTIONS LTD

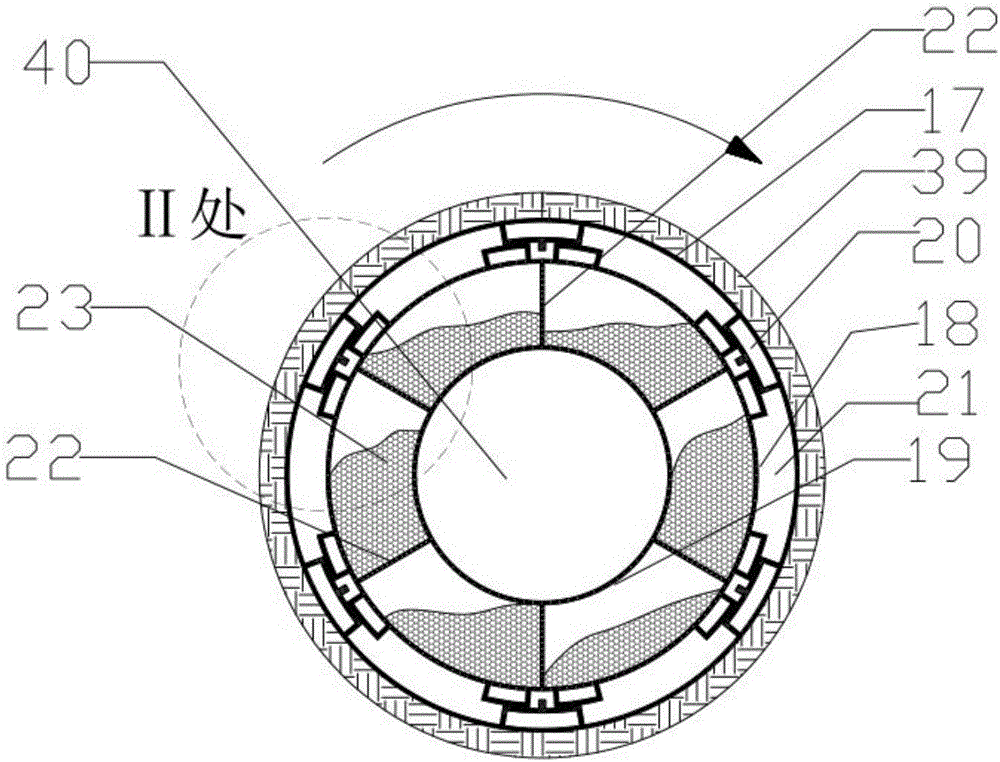

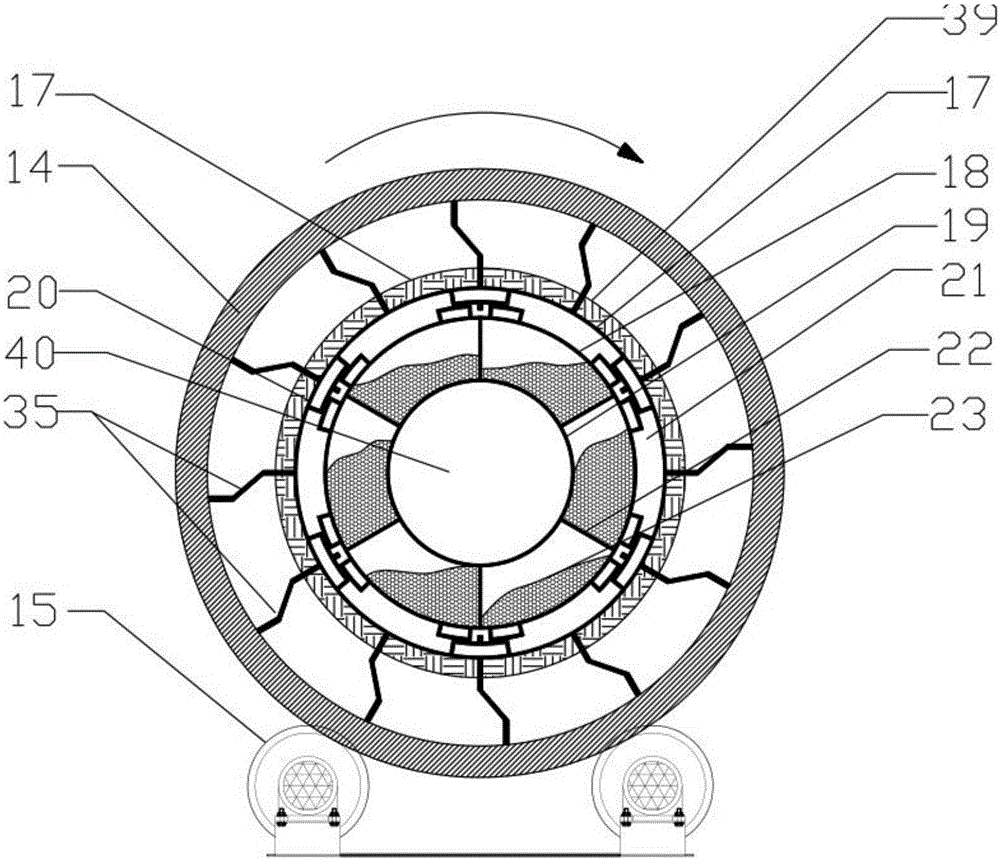

Roller type drying and sintering or roasting device

InactiveCN106679366AAutomatic separationEven heat absorptionRotary drum furnacesDrying gas arrangementsEngineeringNet shape

The invention relates to a roller type drying and sintering or roasting device which comprises a kiln body and a drive device. A drying roller comprises a kiln body outer shell, a net-shaped outer sleeve and a net-shaped inner sleeve from outside to inside in the radial direction of the drying roller. The inner wall of the kiln body outer shell and the outer wall of the net-shaped outer sleeve are connected through a plurality of sliding drive shifting blocks evenly distributed in the circumferential direction, and rotary drive is carried out. A powder chamber is formed by a space between the kiln body outer shell and the net-shaped outer sleeve. The net-shaped outer sleeve and the net-shaped inner sleeve are connected through a plurality of net-shaped partitions spirally extending in the length direction of the kiln body. A space between the net-shaped outer sleeve and the net-shaped inner sleeve is divided by the partitions into a plurality of drying or roasting (sintering) material chambers distributed in the circumferential direction. An inner sleeve air chamber is formed by a space in the inner sleeve. The device has the beneficial effects that material drying is even, thorough and fast; the manmade pellet (spherical block) damage rate is low; the device investment is reduced; the productivity is greatly improved; and energy saving and emission reduction are realized.

Owner:唐竹胜

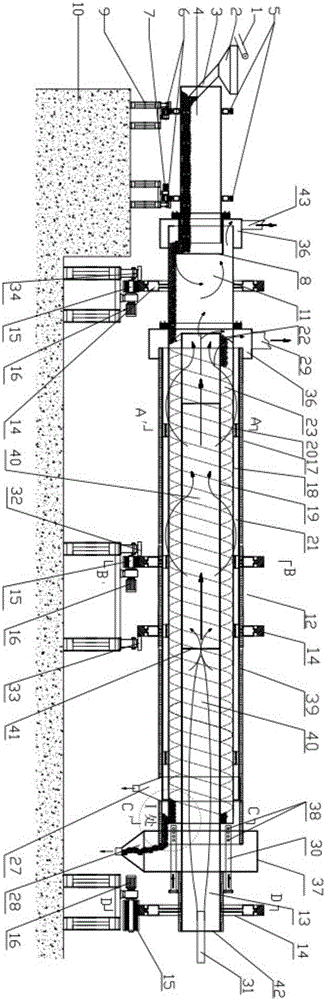

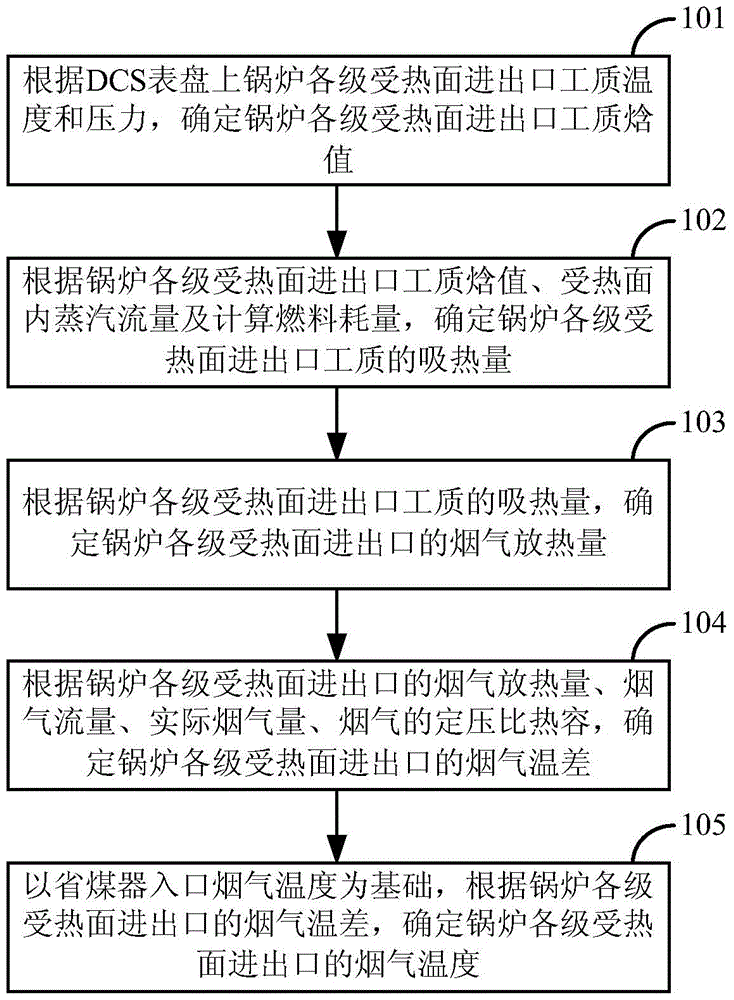

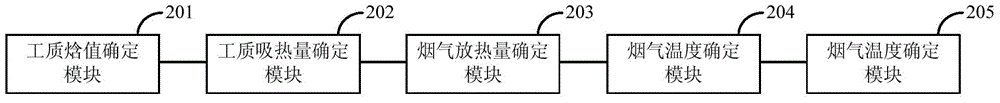

All-level boiler heating surface flue-gas temperature determination method and device

InactiveCN104896457AJudging the operationJudging whether the layout of heating surfaces at all levels of the boiler is reasonable and operatingBoiler controlFlue gasDistributed control system

The invention discloses an all-level boiler heating surface flue-gas temperature determination method and device. The method includes: determining enthalpy values of all-level boiler heating surface inlet-outlet working media according to temperature and pressure of the all-level boiler heating surface inlet-outlet working media on a DCS (distributed controls system) dial; determining heat absorption capacity of the all-level boiler heating surface inlet-outlet working media according to the enthalpy values of the all-level boiler heating surface inlet-outlet working media, steam flow in the heating surfaces and calculated fuel consumption; determining flue-gas heat release of all-level boiler heating surface inlets and outlets according to the heat absorption capacity of the all-level boiler heating surface inlet-outlet working media; determining flue-gas temperature difference of the all-level boiler heating surface inlets and outlets according to the flue-gas heat release of the all-level boiler heating surface inlets and outlets, flue gas flow, actual flue gas volume and specific heat at constant pressure of flue gas; based on flue gas temperature of a coal economizer inlet, and determining flue gas temperature of the all-level boiler heating surface inlets and outlets according to the flue gas temperature difference of the all-level boiler heating surface inlets and outlets. By the method and device, the flue-gas temperature of the all-level boiler heating surfaces can be acquired accurately.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

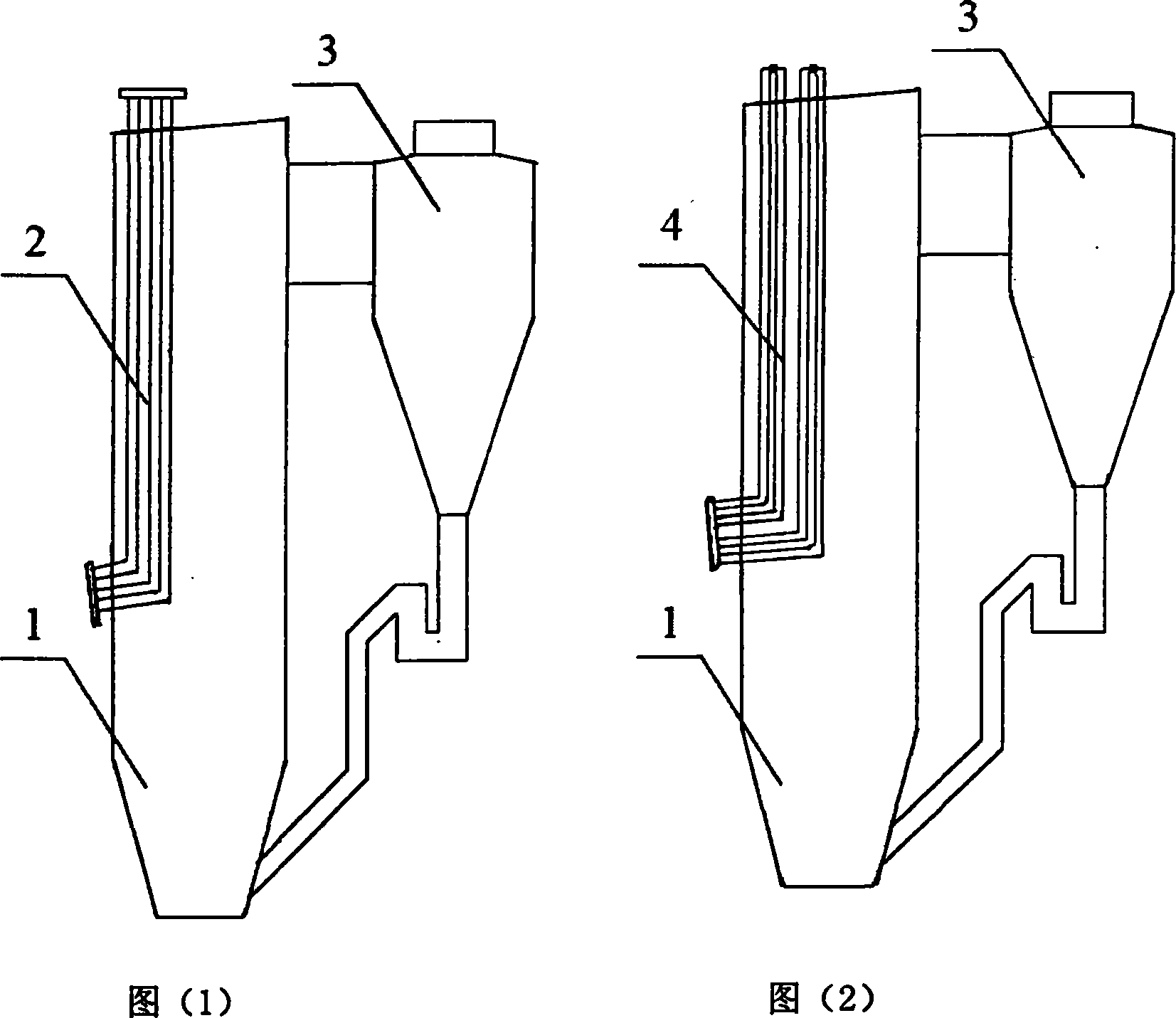

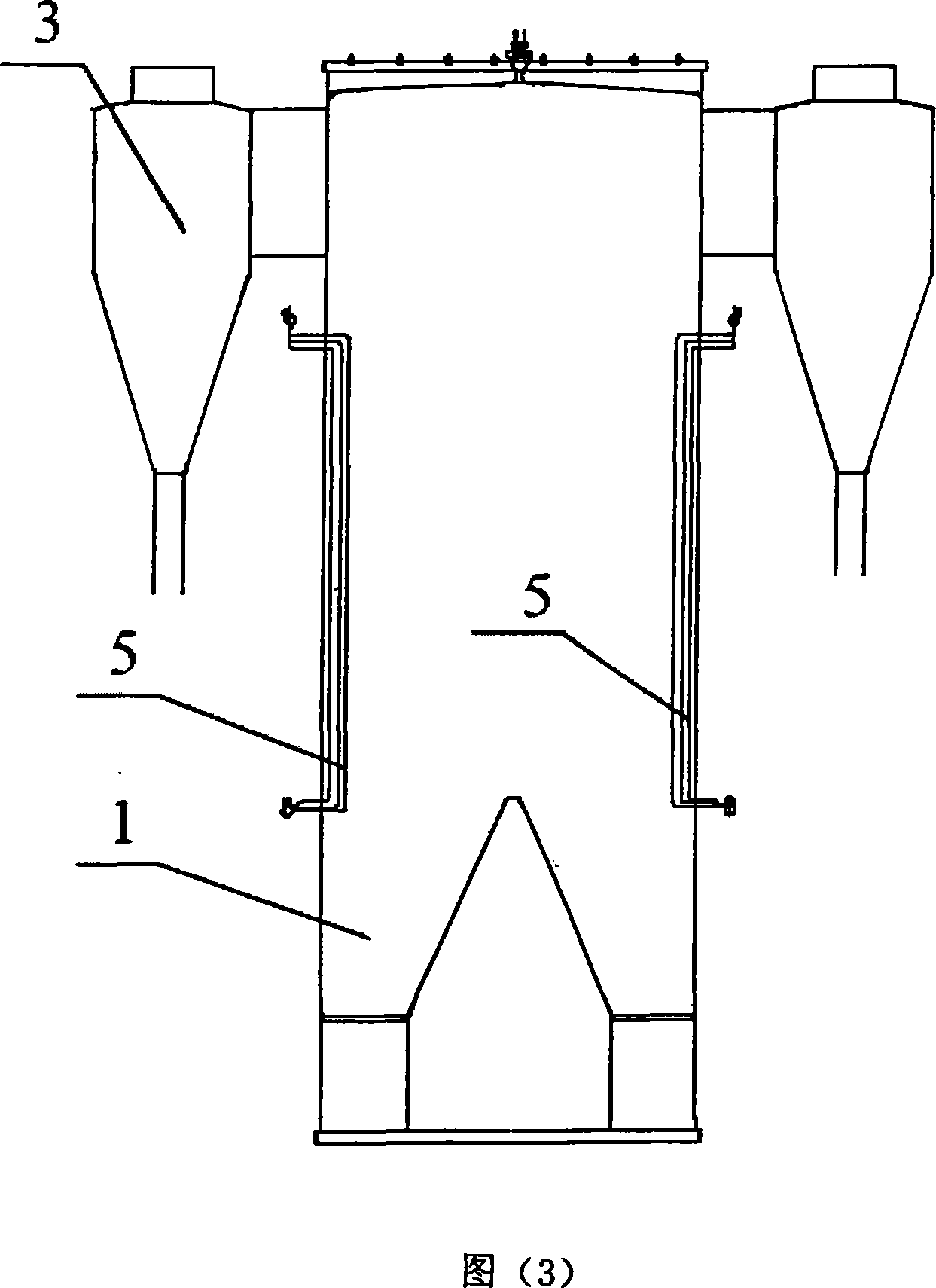

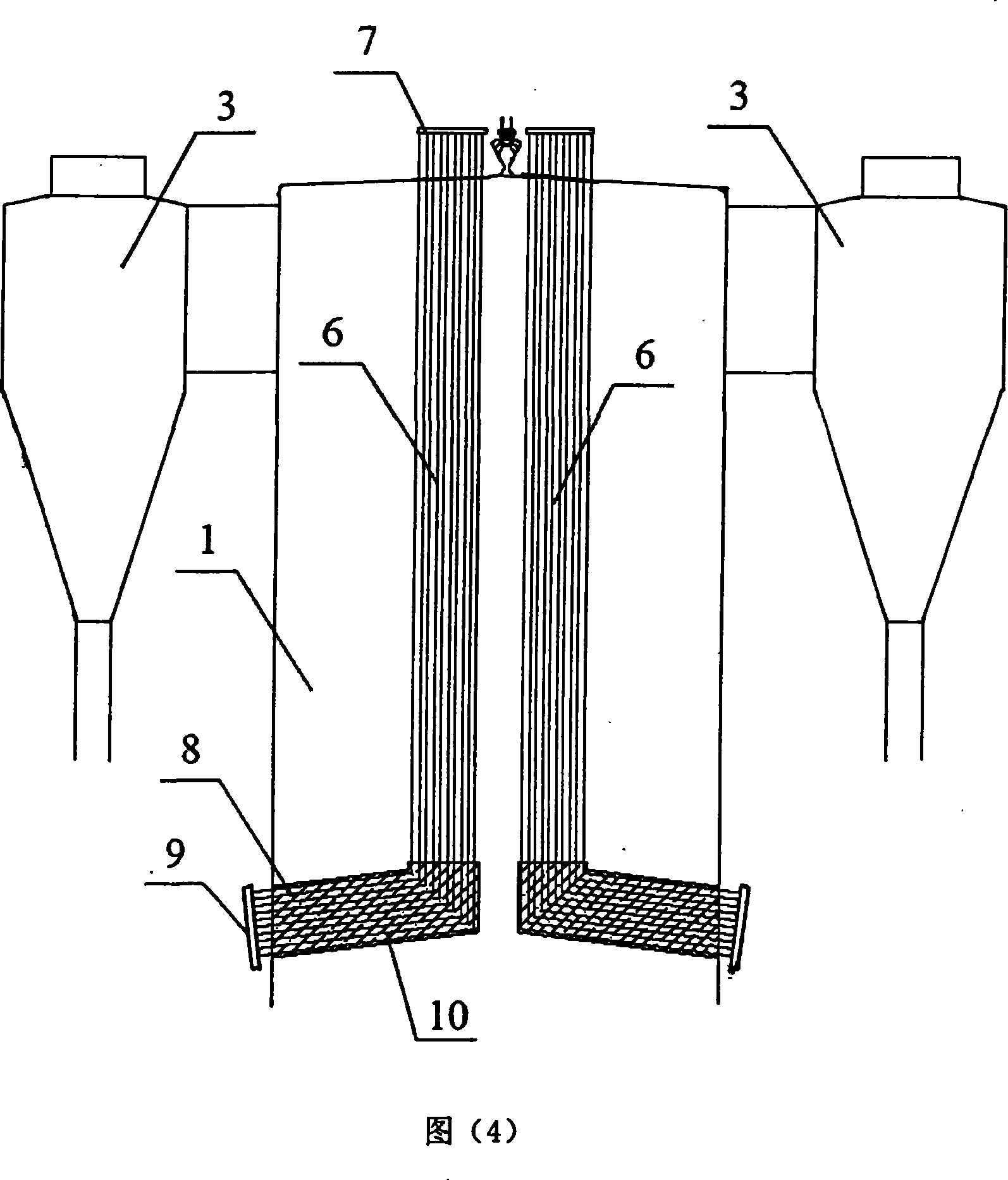

Screen type heated surface arrangement method for fluid bed boiler furnace

InactiveCN101105287ANot affected by quantityOptimize layoutBoiler water tubesWater-tube boilersBoiler furnaceFluidized bed

The invention relates to a layout method for screen heating surface of furnace tank of a fluidized bed boiler, which comprises a boiler and at least a separator respectively provided at two sides of the boiler. The invention is characterized in that the screen heating surface is vertically disposed in the middle of the boiler, the upper end of the screen heating surface passes out of the top of the boiler and connected with an outlet header, and the lower end of the screen heating surface passes out from the water cooling wall at the side wall of boiler through pin and abrasion-proof casting material and connected with an inlet header. The invention is easy to be laid out, and is not influenced by volume, parameters and the number of separators.

Owner:SHANGHAI BOILER WORKS

Flat plate solar energy heat absorption coating

InactiveCN105482603AReduce hydrophilicityImprove waterproof performanceRadiation-absorbing paintsUltraviolet lightsEngineering

The invention discloses a flat plate solar energy heat absorption coating. A light absorption agent, a film forming agent, a solvent and an addition agent are evenly scattered in a ball milling mode, then a film forming addition agent is added into the mixture to be mixed to be uniform, and therefore the flat plate solar energy heat absorption coating is obtained. The flat plate solar energy heat absorption coating is prepared from, by weight, 50-100 parts of the film forming agent, 10-30 parts of the film forming addition agent, 35-55 parts of the light absorption agent, 20-50 parts of the solvent and 10-30 part of the addition agent. The film forming addition agent is ethylene glycol monobutyl ether, triethylene glycol monomethyl and the like. A preparation method of the film forming agent comprises the steps that casein and gelatin are mixed according to the weight ratio of 5-10:2-3, water is added into the mixture, the mixture is soaked at the temperature of 15-22 DEG C and then transferred to a plate under the normal temperature, a mixture solution with methyl methacrylate and polysiloxane quaternary ammonium sodium with the ratio of parts by weight of 1-2:1-3, the mixture is stirred and then irradiated by ultraviolet light for 10-15 min, and then modified casein-gelatin is obtained. The film forming agent is modified and then used as the important raw material of the coating, so that the prepared coating has the good weather resistance and water resistance under the outdoor conditions, the preparation technology is simple and easy to understand, and the heat absorption efficiency of the heat absorption coating is ensured.

Owner:GUANGXI CHAOXING SOLAR ENERGY TECH

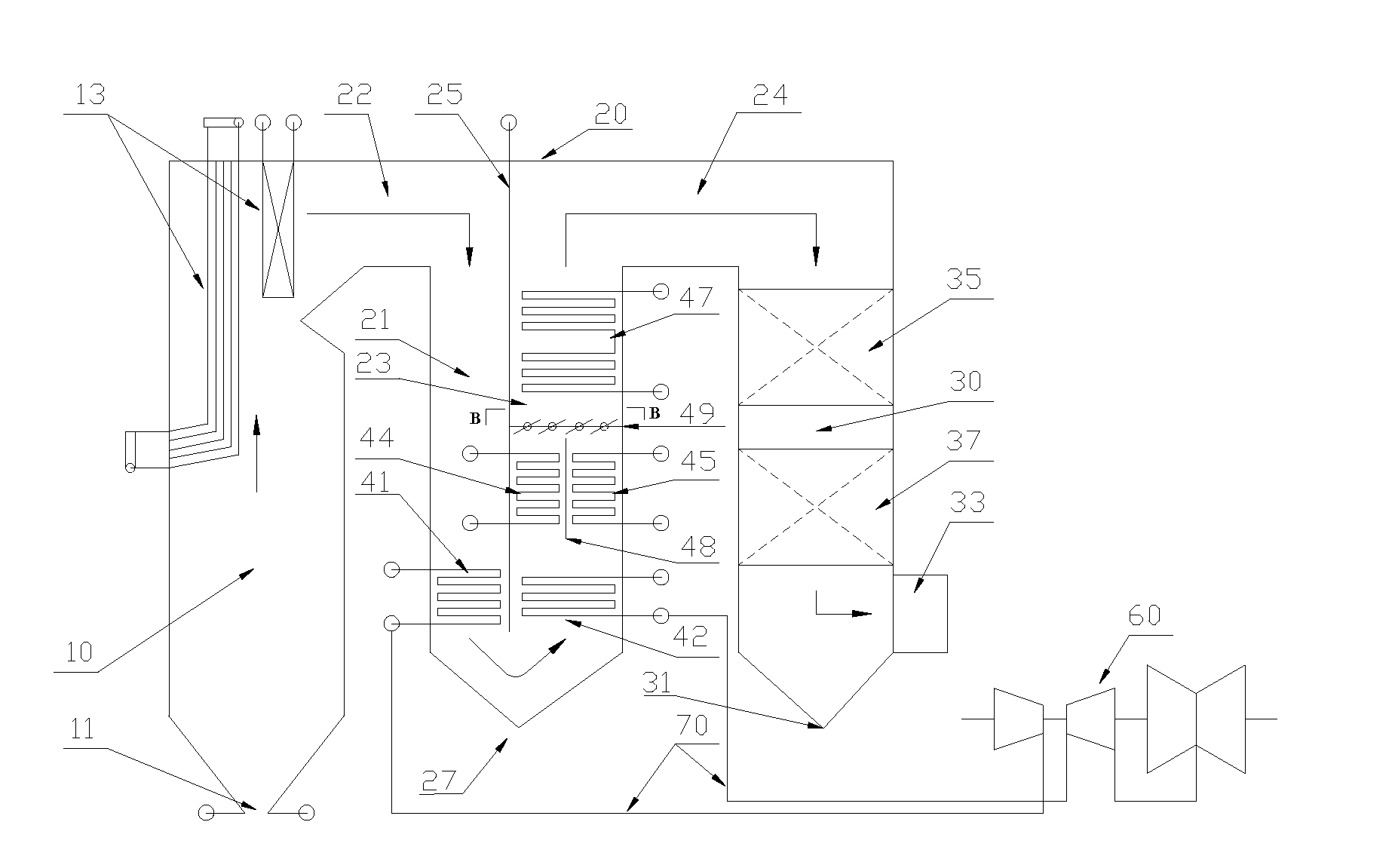

M-type pulverized coal boiler suitable for ultrahigh steam temperature

ActiveUS20140033712A1Increase manufacturing costSteam turbine can be greatly reducedWater circulationFuel injection apparatusSlagFlue gas

The disclosure provides an M-type pulverized coal boiler suitable for ultrahigh steam temperature. The pulverized coal boiler comprises a hearth of which the bottom is provided with a slag hole and a tail downward flue of which the lower part is provided with a flue gas outlet. The pulverized coal boiler further comprises a middle flue communicated between the hearth and the tail downward flue, wherein the middle flue comprises an upward flue and a hearth outlet downward flue of which the bottoms are mutually communicated and the upper ends are respectively communicated with the upper end of the hearth and the upper end of the tail downward flue to form a U-shaped circulation channel. In the pulverized coal boiler provided by the disclosure, the middle flue which extends downwards and can make flue gas flow along the U-shaped circulation channel is arranged between the outlet of the hearth and the tail downward flue, so that high-temperature flue gas from the hearth can be introduced into a position with low elevation through the downward flue, and final-stage convection heating surfaces (such as a high-temperature superheater and a high-temperature reheater) can be arranged at positions with low height, and the length of ultrahigh-temperature steam pipelines between the high-temperature superheater and a steam turbine, and between the high-temperature reheater and the steam turbine can be greatly reduced. Therefore, the manufacturing cost of a boiler unit is obviously reduced.

Owner:HUANENG CLEAN ENERGY RES INST

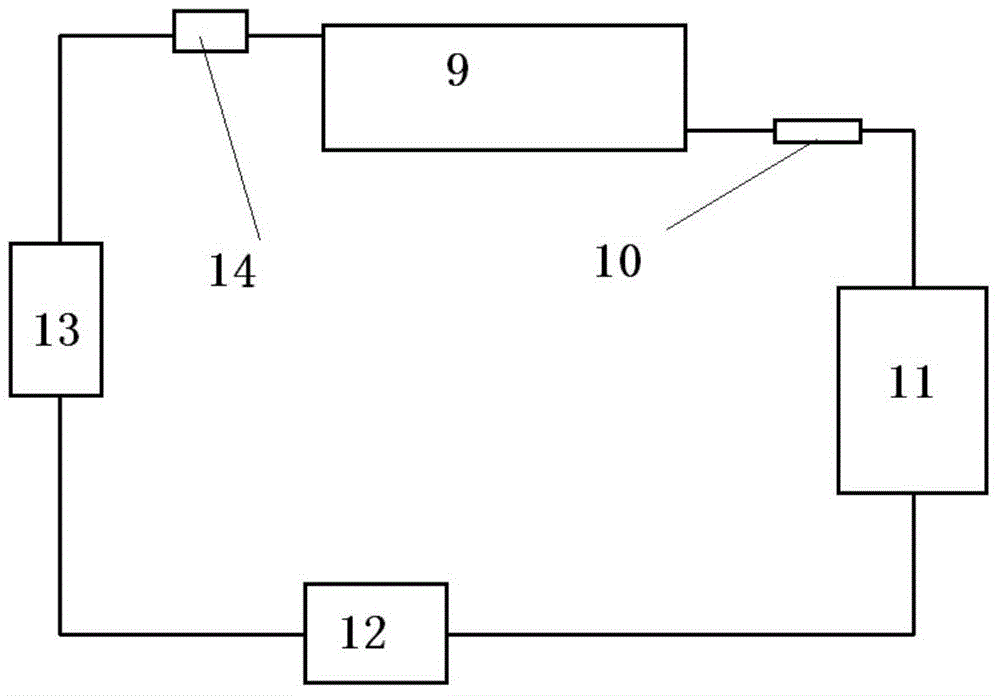

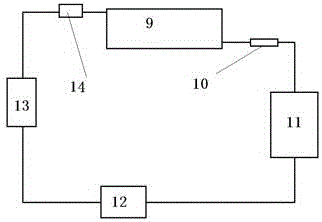

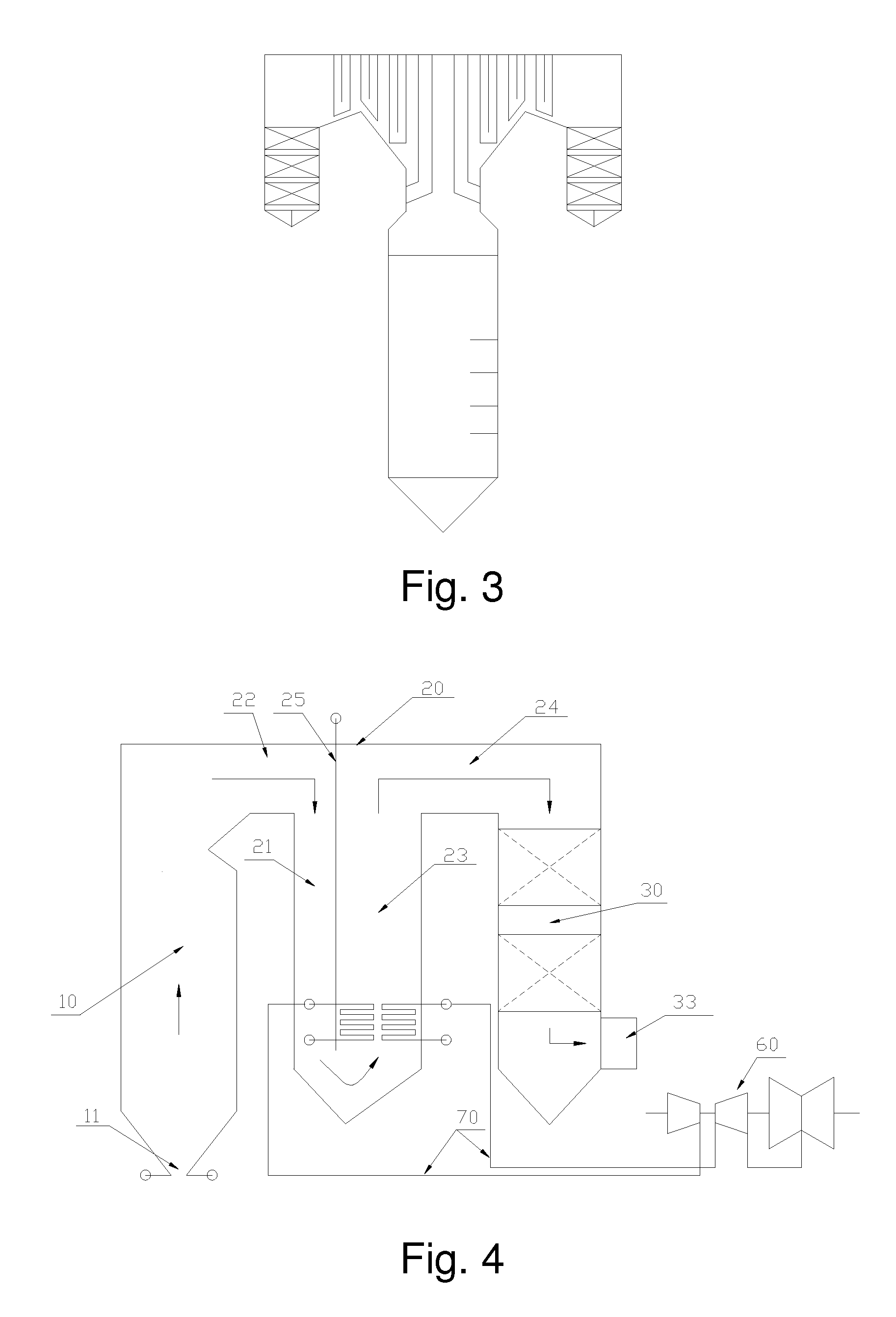

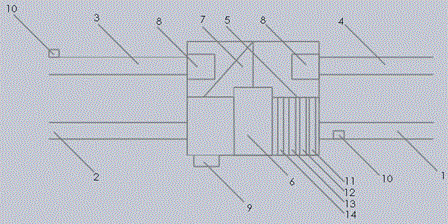

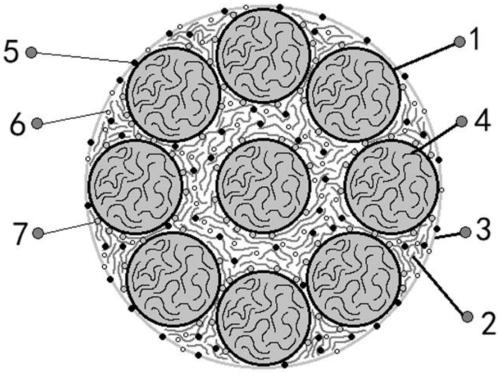

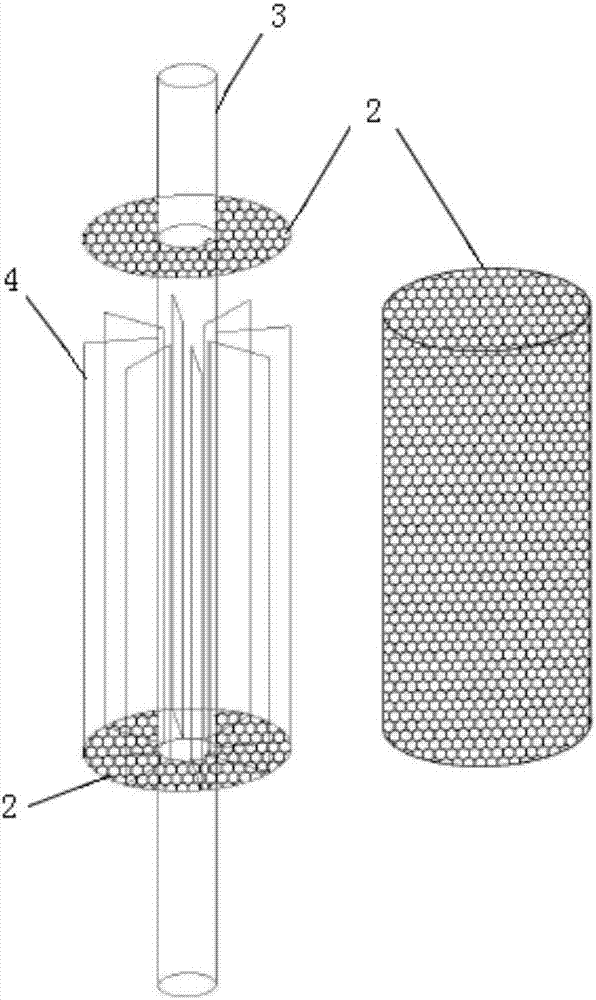

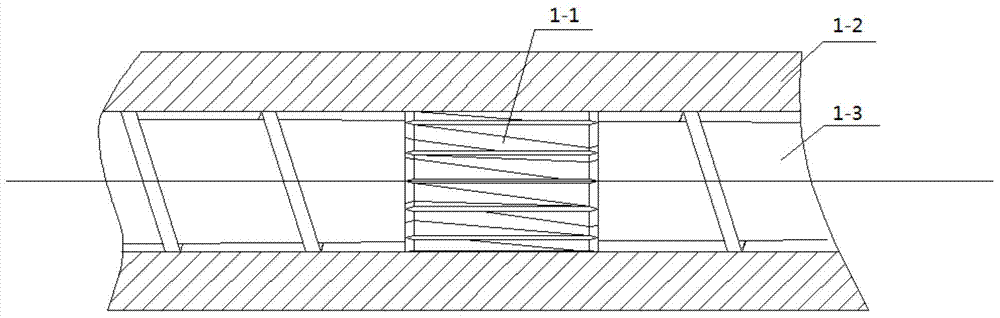

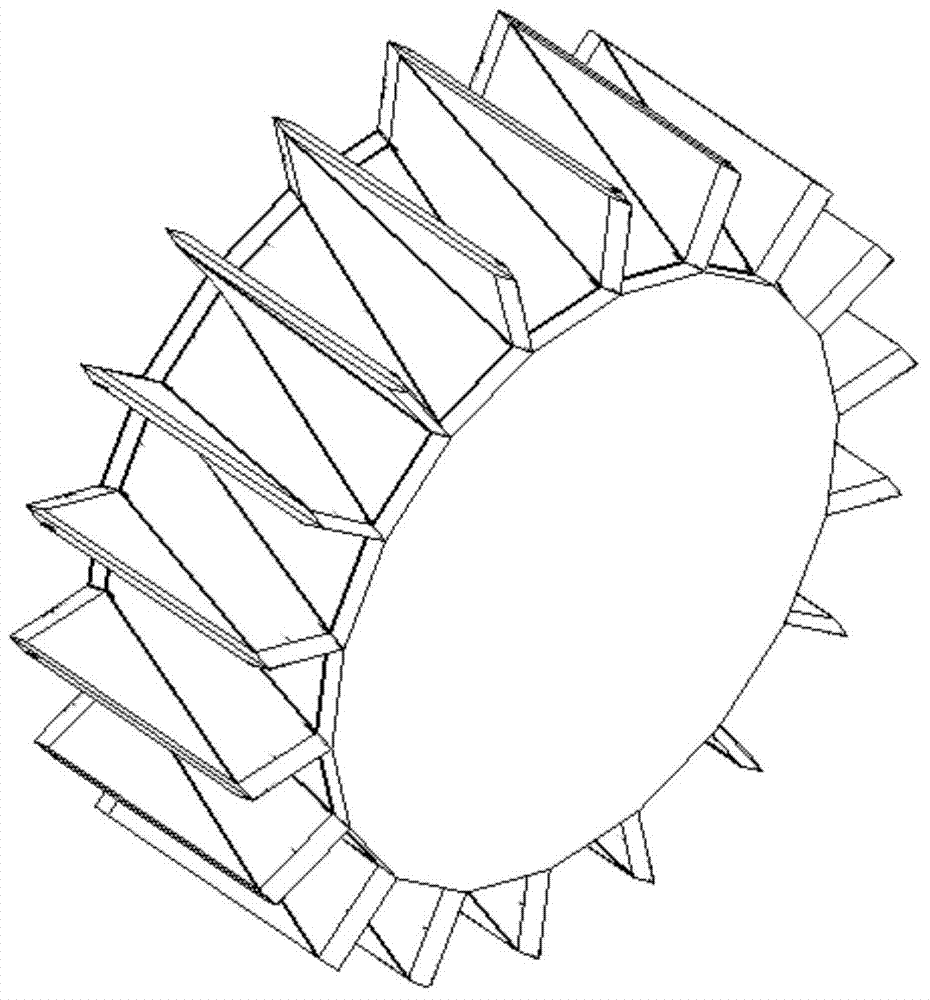

Loop heat pipe solar system with fins of different heights in heat collection pipes

InactiveCN104633960AEfficient use ofEven heat absorptionSolar heating energySolar heat devicesEnvironmental resistanceMicro-loop heat pipe

The invention provides a loop heat pipe solar collector system, which comprises a solar collector, a water tank and a loop heat pipe, wherein the evaporation section of the loop heat pipe is the collector, and the condensation section of the loop heat pipe is arranged in the water tank; the collector absorbs heat of solar energy, and water in the collector is evaporated and then flows into the condensation section of the loop heat pipe; the heat is released in the condensation section to heat the water in the water tank, after heat release of the condensation section, the water enters the collector in a circulating way to be heated; the collector comprises heat collection pipes of which the inner walls are provided with fins, and the heights of the fins in different heat collection pipes are different. The heights of the fins are different, so that the solar collector plate uniformly absorbs heat to avoid local overheating, so that the solar energy is well utilized, and the environmental protection and energy-saving effects are achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Heat storage heat exchanger and fresh air system with automatic electrostatic precipitation control function

ActiveCN104930895AEven heat absorptionAvoid uneven heat absorptionSpace heating and ventilation safety systemsSpace heating and ventilation control systemsPlate heat exchangerAutomatic control

Disclosed is a heat storage heat exchanger. The heat exchanger comprises a shell, heat storage medium and a fluid passage, wherein the heat storage medium is located in the shell; the fluid passage is located in the heat storage medium and provided with a fluid inlet and a fluid outlet; the heat storage capacity of the heat storage heat exchanger is gradually increased in the flowing direction of fluid. The heat storage medium is uniform in overall heat absorption in the flowing direction of fluid, and therefore the phenomenon of uneven heat absorption is avoided.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

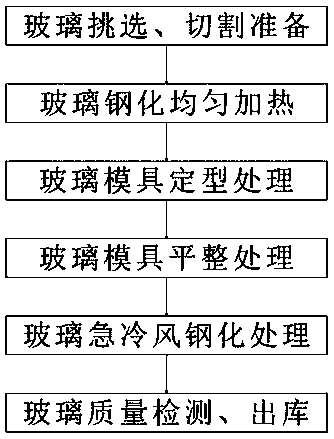

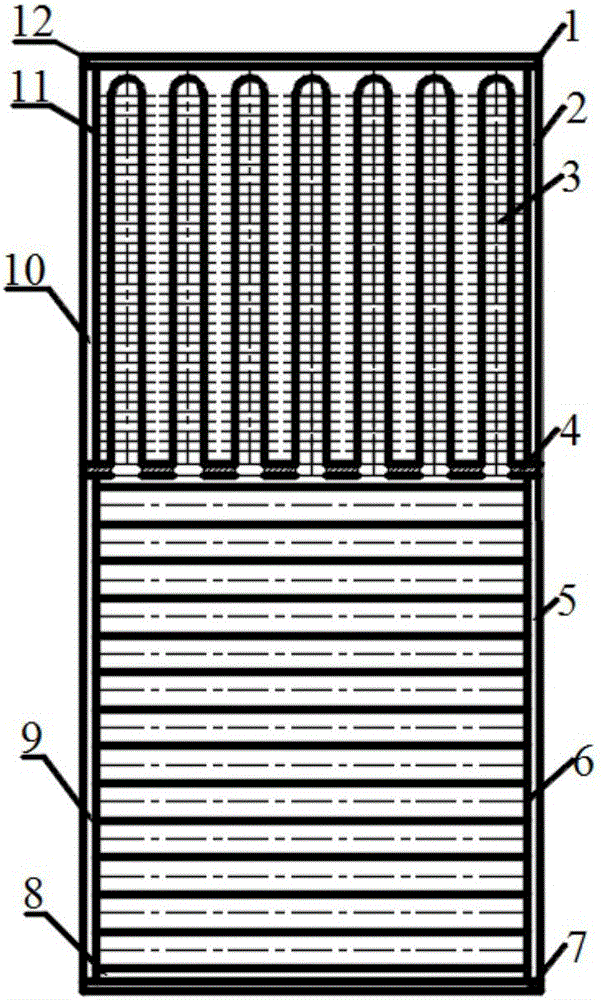

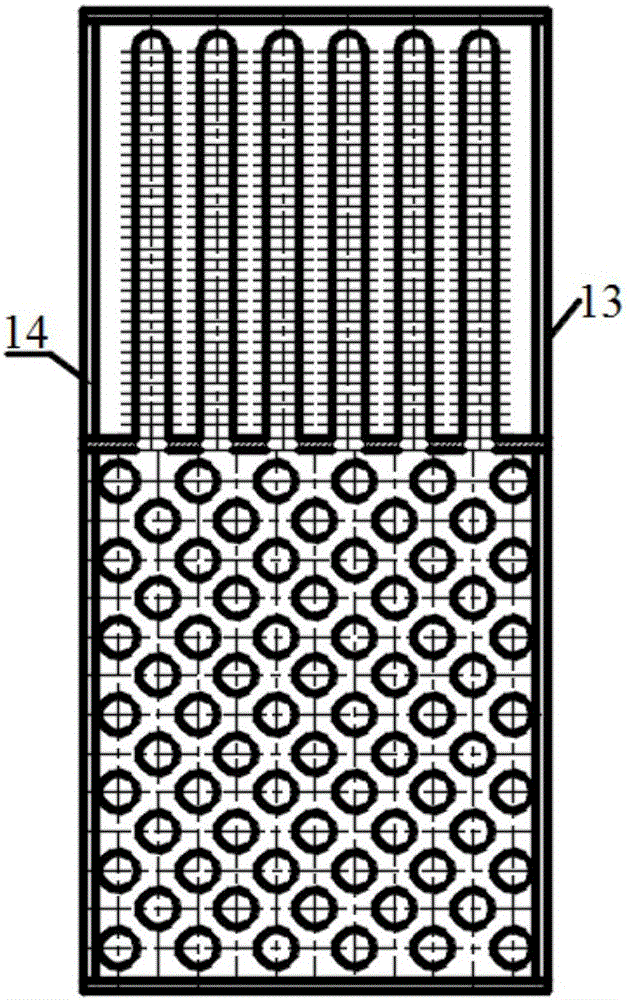

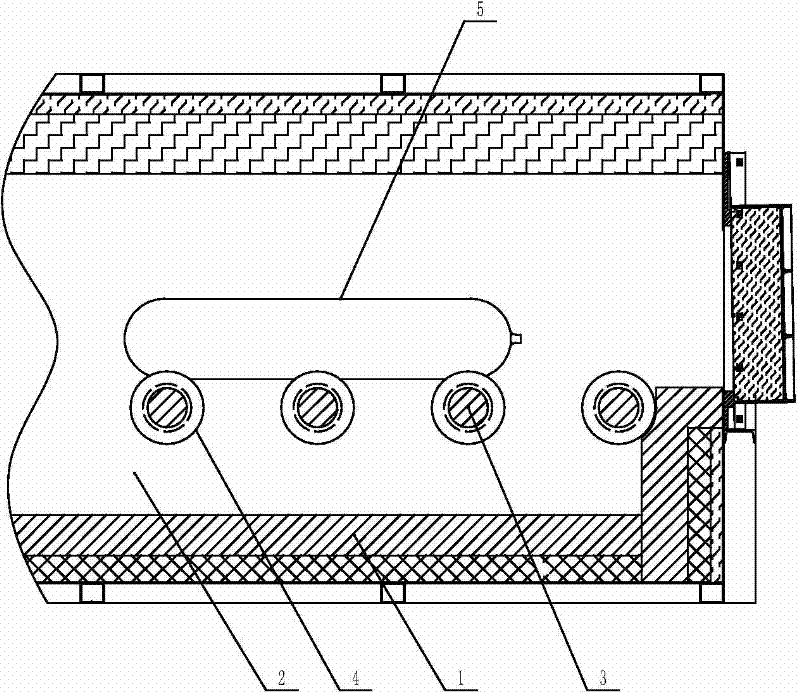

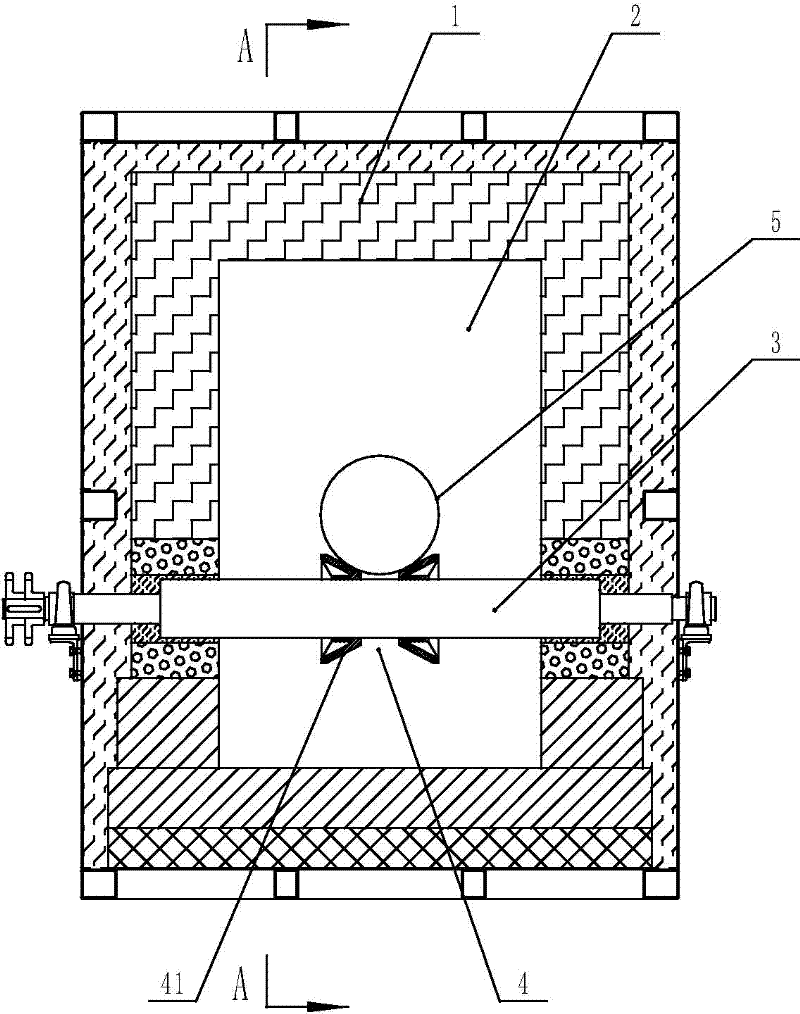

Horizontal roller way type dinner plate toughening furnace and production technology thereof

PendingCN110386755ARun smoothlyGood resistance to sudden temperature changesGlass transportation apparatusGlass reforming apparatusEngineeringHeating furnace

The invention provides a horizontal roller way type dinner plate toughening furnace and a production technology thereof, and relates to a toughening furnace. The toughening furnace comprises an upperpiece table, a conveying device, a heating furnace body, a die molding device, a die leveling device, a toughening blowing device, a toughening cooling device, a lower piece table and a supporting frame. The production technology of the horizontal roller way type dinner plate toughening furnace comprises the steps of glass preparation, uniform heating of toughening glass, sizing treatment of a glass die, leveling treatment of the glass die, cold air cooling and toughening treatment of the glass die and detection and measurement of the glass die. Main drive of the horizontal roller way type dinner plate toughening furnace is composed of an upper piece segment, a heating segment, a passing segment and a cooling segment, the technological process is continuous and disconnected, unbounded power and temperature are adopted to control and reduce temperature field stage change, so that heat absorption of same glass and different areas is more uniform, levelness of the glass is improved, the glass has a good toughening effect and good quality, the whole toughened glass yield is improved, and the working efficiency is high.

Owner:王德海

Waste gas afterheat recovery heat exchanger

ActiveCN106017164AContamination in timeContaminated in timeCorrosion preventionIndirect heat exchangersLight pipeEvaporation

The invention discloses a waste gas afterheat recovery heat exchanger. The waste gas afterheat recovery heat exchanger mainly consists of a heat end cavity, a cold end cavity, a sealing separation plate, an intensified heat exchange condensation pipe bundle and an evaporation light pipe bundle; an inner cavity of a cold end fin pipe is communicated with the upper wall of a heat evaporation cavity through welding; during working, smoke containing afterheat passes through the internal of a pipe at a hot end to heat liquid in the heat end cavity for gasification; steam enters from a small hole, communicated with the internal of an intensified heat exchange pipe, on the sealing separation plate; heated gas flows out of an intensified heat exchange pipe bundle, so that the steam in the pipe is condensed; the heat is transferred to the heated gas; and the condensed liquid flows back into the heat end cavity under the effect of gravity for recycling. Compared with the prior art, the waste gas afterheat recovery heat exchanger effectively solves the problems of blockage and difficult cleaning in the waste gas afterheat recovery process.

Owner:XI AN JIAOTONG UNIV

Heat storage heat exchanger and fresh air system with same

ActiveCN104807354AEven heat absorptionAvoid uneven heat absorptionHeat storage plantsSpace heating and ventilation detailsPlate heat exchangerFresh air

The invention relates to a heat storage heat exchanger. The heat exchanger comprises a shell, a heat storage medium and a fluid passage, wherein the heat storage medium is arranged in the shell, the fluid passage is arranged in the heat storage medium, the fluid passage is provided with a fluid inlet and a fluid outlet, and the heat storage medium is a phase-changing heat storage medium. By adopting the heat storage heat exchanger, the capacity of the phase-changing material for absorbing a great amount of potential heat and capable of being recycled for a long time is utilized, so that the consumption of unnecessary additional energy is avoided, and the temperature of fresh air is more comfortable; the system is high in heat exchanging efficiency, pollution-free, energy-saving and environment-friendly.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Graphene/phase-change microcapsule composite material and preparation method and application thereof

PendingCN109735306AClosely linkedImprove the heat absorption effectHeat-exchange elementsHeat conductingPhase change

An embodiment of the invention relates to a graphene / phase-change microcapsule composite material and a preparation method and application thereof. The composite material comprises multiple phase-change microcapsules, a heat conducting network and a shell structure wrapping the phase-change microcapsules and the heat conducting network, the heat conducting network wraps each phase-change microcapsule and mutually combines the phase-change microcapsules, and each of the heat conducting network and the shell structure is made of a graphene material. In the composite material, even the shell structure and the heat conducting network are damaged, a phase-change material wrapped in the phase-change microcapsules is less prone to leakage; the composite material is high in heat absorbing efficiency, and heat conducting among the phase-change microcapsules in the composite material is comparatively quick. The composite material can be used as a filling agent of phase-change materials, rubber or plastic. The preparation method is simple, quick and convenient for industrialization.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

Instant electric water heater

The invention discloses an instant electric water heater; a vertical shunting clapboard is arranged in the middle part between the front and back sides of a box body to form a first cavity and a second cavity, a group of stream guidance holes are arranged at top part of the shunting clapboard, a group of stainless steel thermal energy pipes are uniformly distributed in the first cavity and the second cavity horizontally or vertically, and ports of the stainless steel thermal energy pipes are welded with the corresponding side plates of a box body in a penetrating way, a group of carbon fiber far infrared heating tubes are respectively arranged in the group of the stainless steel thermal energy pipes and are fixed by fixed clamping plates, a power supply input end of each carbon fiber far infrared heating tube body is electrically connected with an automatic thermostat by a wiring groove circuit board. the instant electric water heater has rapid heating, low power consumption, high hotwater yield, high electric-heating conversion efficiency, good safety and long service life and is energy saving and environmental protection.

Owner:霍海凌

Light pipe evaporators and refrigerator

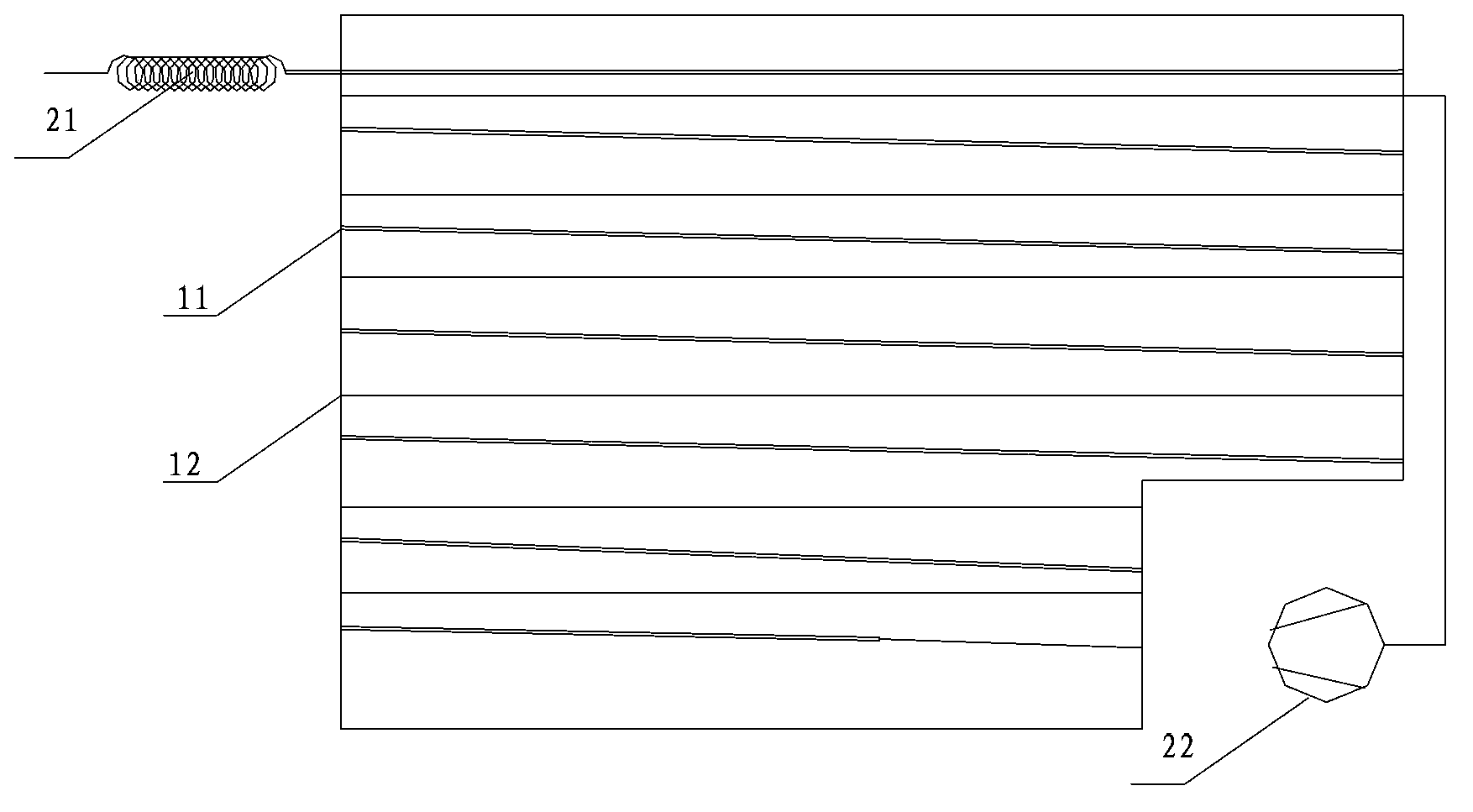

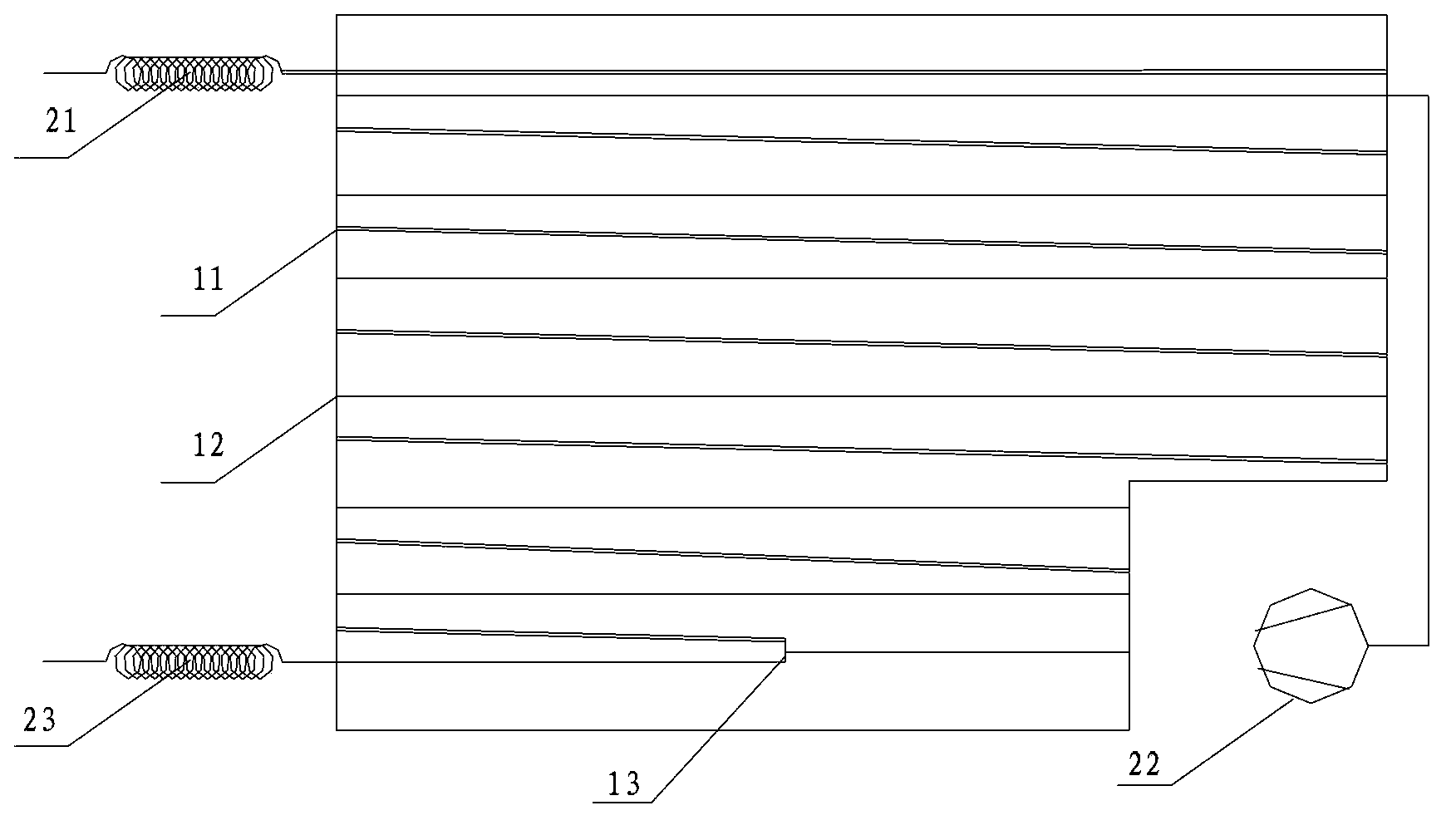

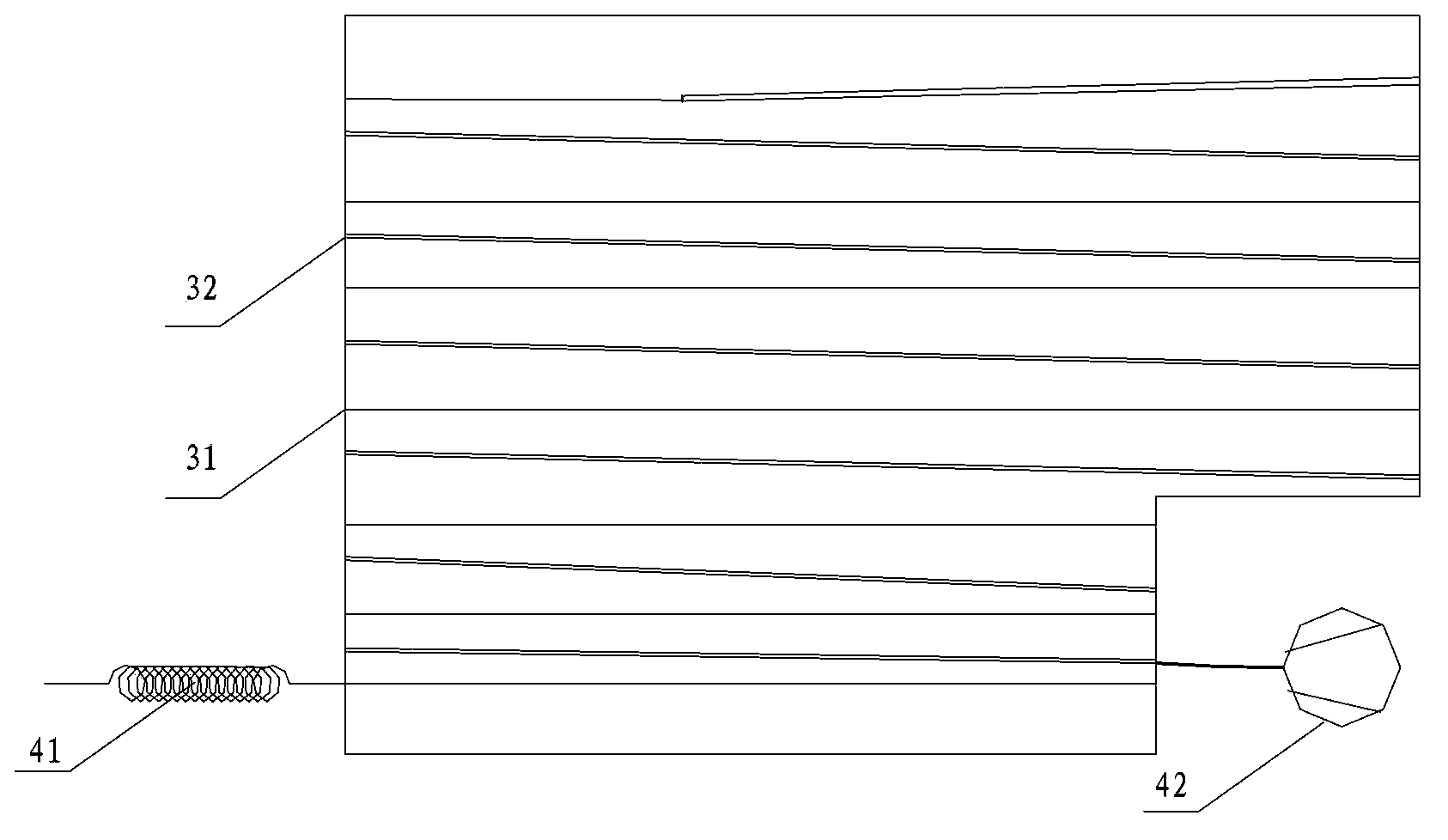

ActiveCN104101135AEven heat absorptionImprove utilization efficiencyEvaporators/condensersLight pipeEngineering

The invention provides a light pipe evaporator and a refrigerator. The light pipe evaporator is formed by intertwining an evaporating pipe on an inner container of refrigeration equipment; the evaporating pipe of the light pipe evaporator comprises a first partial evaporating pipe and a second partial evaporating pipe; the first partial evaporating pipe is intertwined from top to bottom along the wall of the inner container of the refrigeration equipment, and a first connecting port for connecting a first capillary tube is formed in the first partial evaporating pipe and is positioned at the position of the upper part of the wall of the inner container of the refrigeration equipment; the second partial evaporating pipe is intertwined from bottom to top along the wall of the inner container of the refrigeration equipment, and a second connecting port for connecting a compressor is formed in the second partial evaporating pipe and is positioned at the position of the upper part of the wall of the inner container of the refrigeration equipment. The invention further provides another light pipe evaporator and a refrigerator. According to the light pipe evaporators and the refrigerator provided by the invention, the heat absorption capacity of refrigerant can be balanced to the maximum degree, so that the temperatures of everywhere of the inner container of the refrigeration equipment are approximate, and a refrigeration effect can be played to the maximum degree.

Owner:HAIER GRP CORP +1

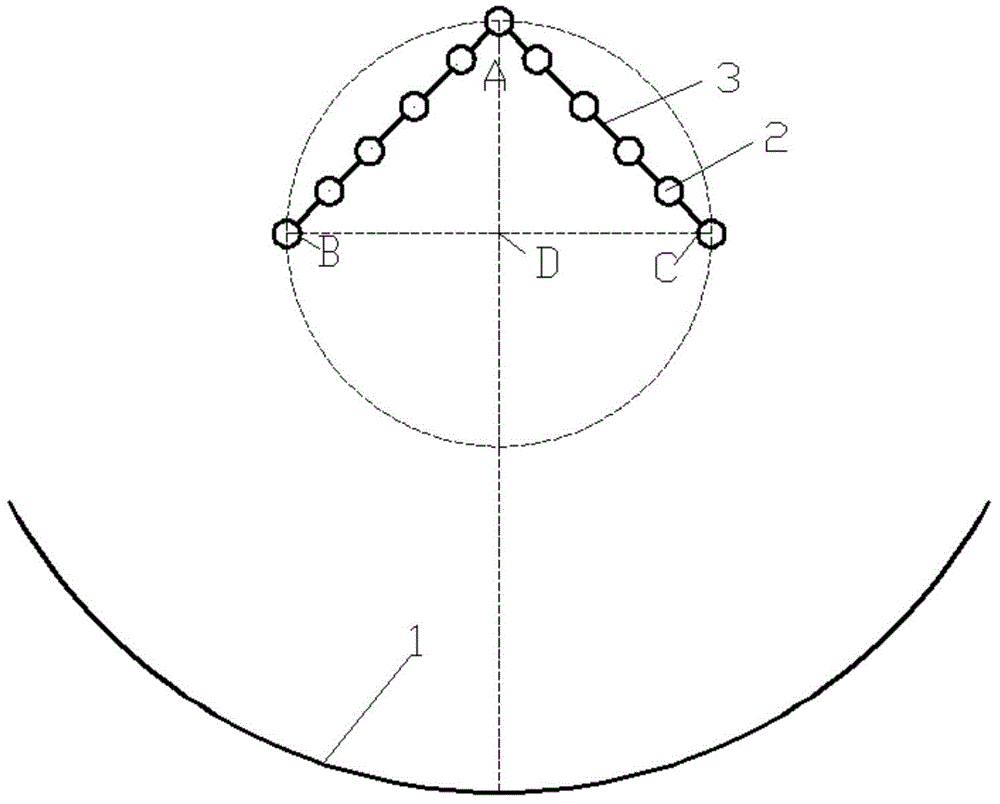

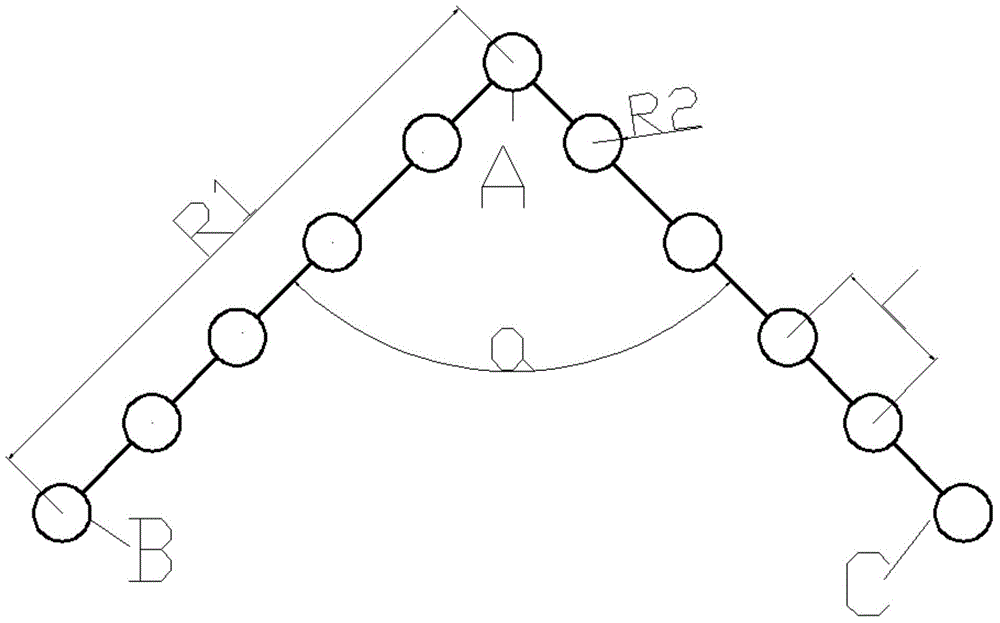

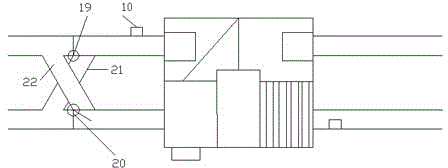

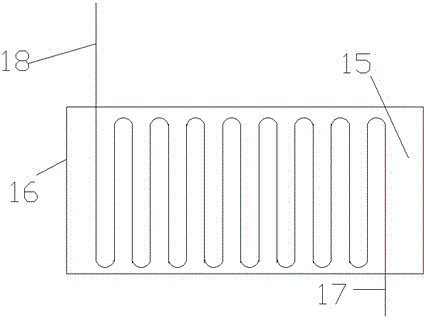

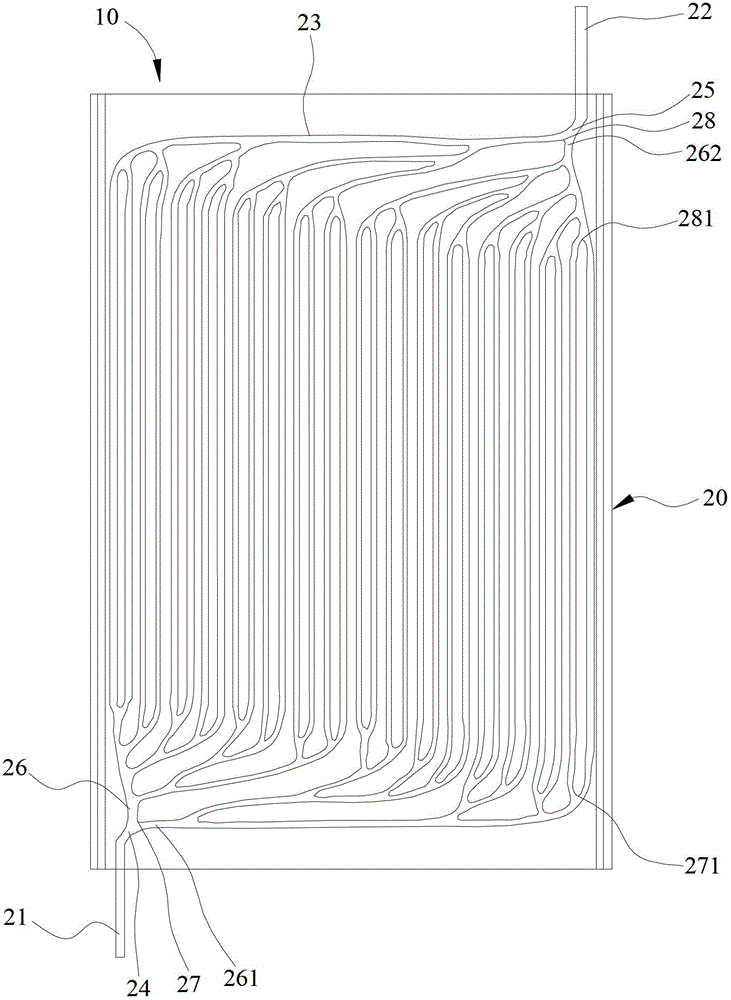

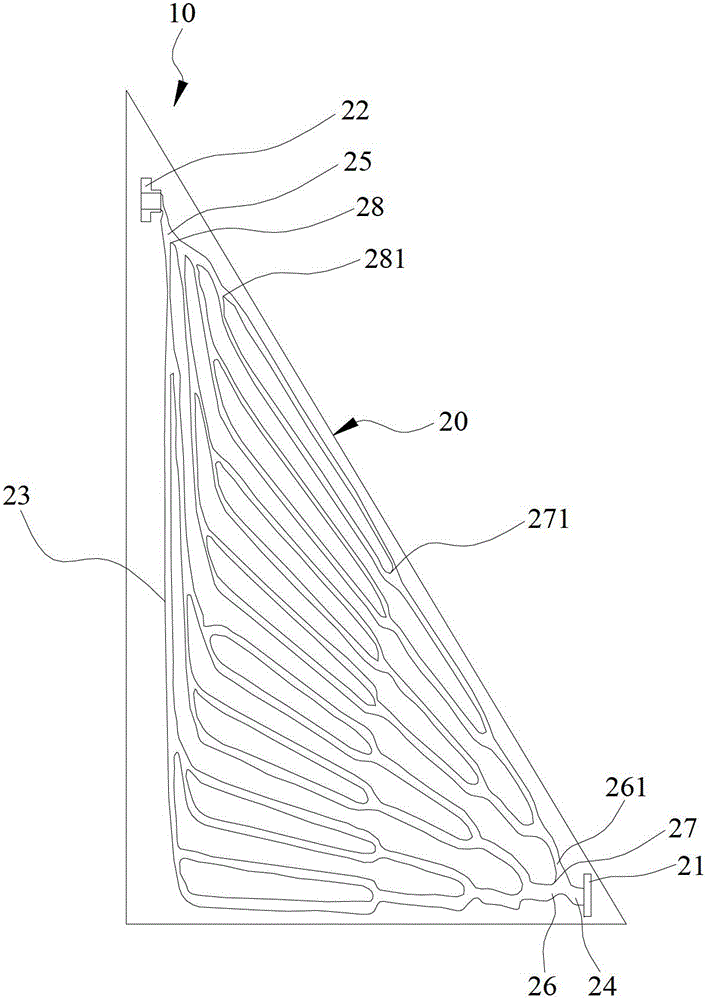

Flat plate heat collector with vein-shaped runners

InactiveCN104006549AEven heat absorptionGuaranteed Instantaneous EfficiencySolar heating energySolar heat devicesCollector deviceEngineering

The invention provides a flat plate heat collector with vein-shaped runners. The flat plate heat collector with the vein-shaped runners comprises a heat absorption body, wherein the heat absorption body comprises a first collection pipe, a second collection pipe and a branch pipe, the second collection pipe and the first collection pipe are arranged at an interval, the branch pipe is arranged between the first collection pipe and the second collection pipe in connection mode, the branch pipe is provided with a shunting area used to shunt heat absorption mediums and a converging area used to converge the heat absorption mediums, at least two shunting runners arranged in vane shape are arranged between the shunting area and the converging area, starting ends of the at least two shunting runners are arranged on the shunting area and arranged in intersection mode so as to form shunting points, and tail ends of the at least two shunting runners are arranged on the converging area and arranged in intersection mode so as to form intersection points. According to the flat plate heat collector with the vein-shaped runners, the heat absorption mediums can evenly absorb heat by arranging the at least two shunting runners arranged in vane shape on the branch pipe, and accordingly heat absorption efficiency of the flat plate heat collector with the vein-shaped runners can be improved, and furthermore the fact that instantaneous efficiency of the flat plate heat collector is larger than or equal to 0.8 is guaranteed well.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

High-efficiency reactor for hydrated salt chemical energy storage

InactiveCN107289803AHigh reaction conversion rateHigh energy storage densityHeat storage plantsHydration reactionEngineering

The invention discloses a high-efficiency reactor for hydrated salt chemical energy storage. The high-efficiency reactor comprises a heat insulation container, a column body for wrapping hydrated salt, a heat exchange pipe, fins, hydrated salt and pipelines, wherein the column body is arranged in the heat insulation container; the heat exchange pipe is arranged at the center of the column body; the multiple fins are uniformly arranged between the heat exchange pipe and the column body; one end of each fin is connected with the outer wall of the heat exchange pipe, and the other end of the fin is connected with the inner wall of the column body; a space between the heat exchange pipe and the column body is filled with the hydrated salt; and the two pipelines are arranged on an upper end cover of the heat insulation container. The high-efficiency reactor for hydrated salt chemical energy storage disclosed by the invention can well enable reaction salt to react with steam; the reaction is faster and more thorough, and the heat transfer and mass transfer effect in a reaction process is obviously enhanced; irreversible loss caused by liquefaction of the hydrated salt due to excessive water absorption can be further effectively avoided, so that the number of times of recycling of an energy storage material is increased, and the service life of the material is prolonged; and meanwhile, the corrosion effect of the liquefied hydrated salt on the reactor is also avoided.

Owner:SHANGHAI MARITIME UNIVERSITY

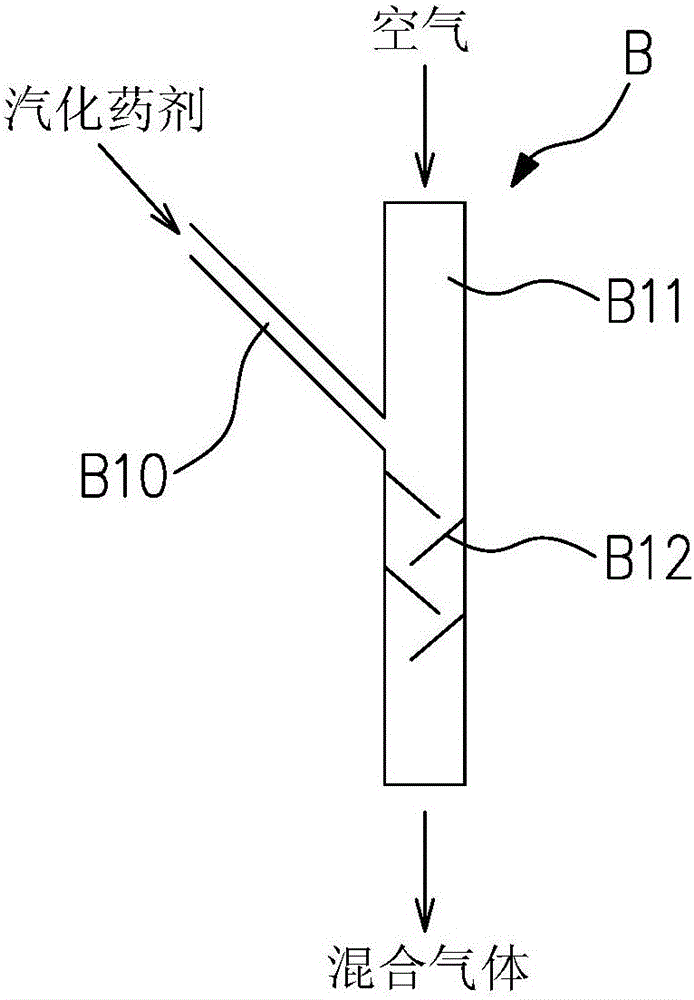

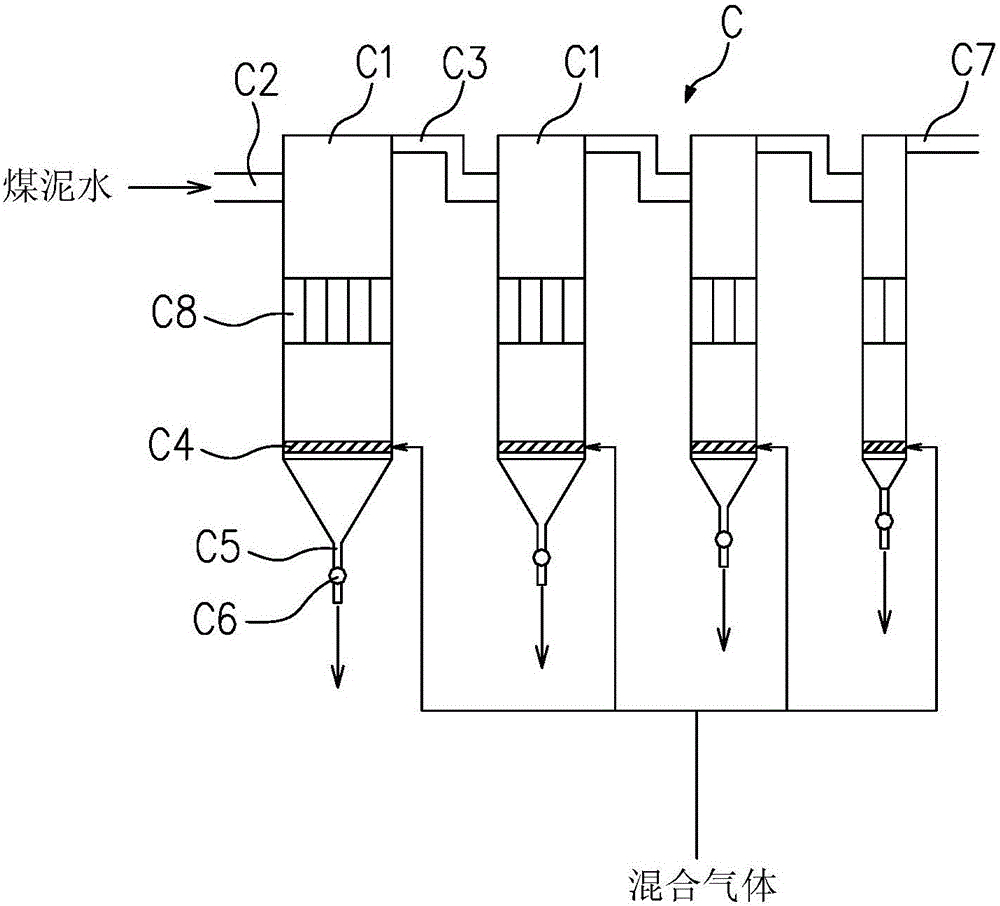

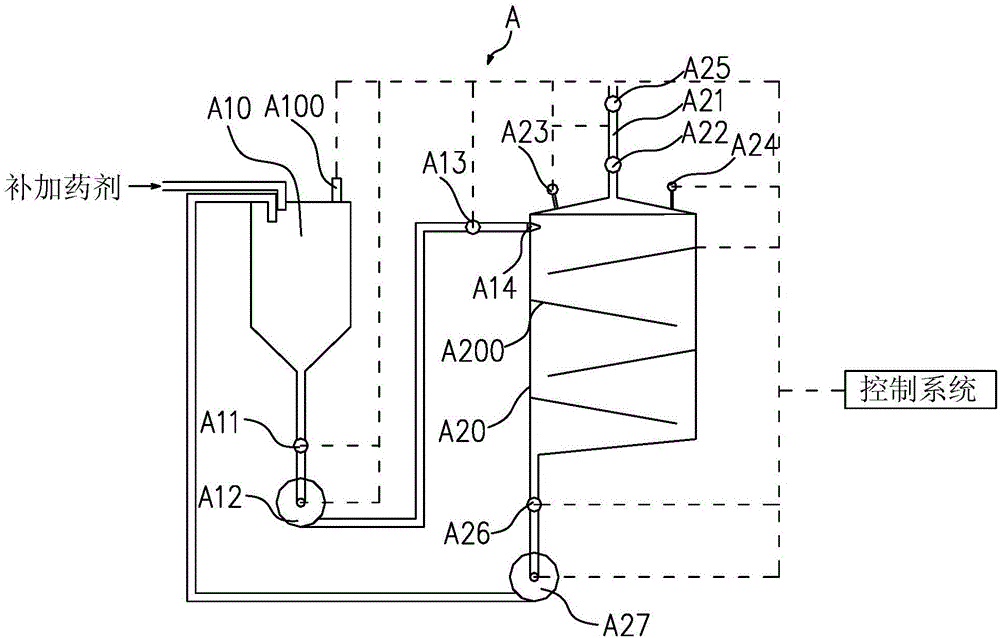

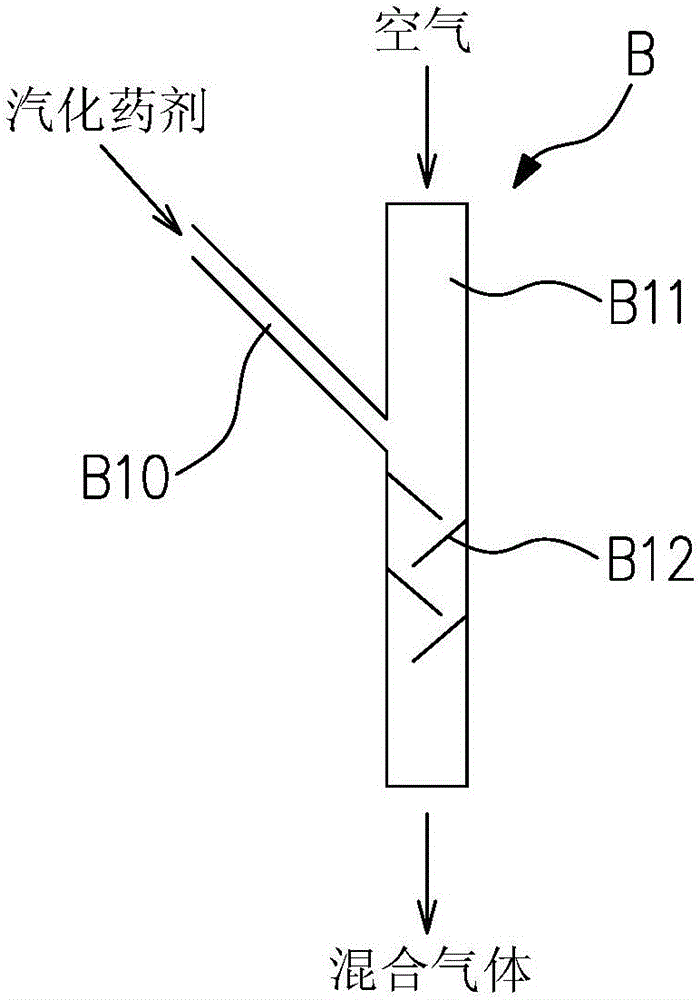

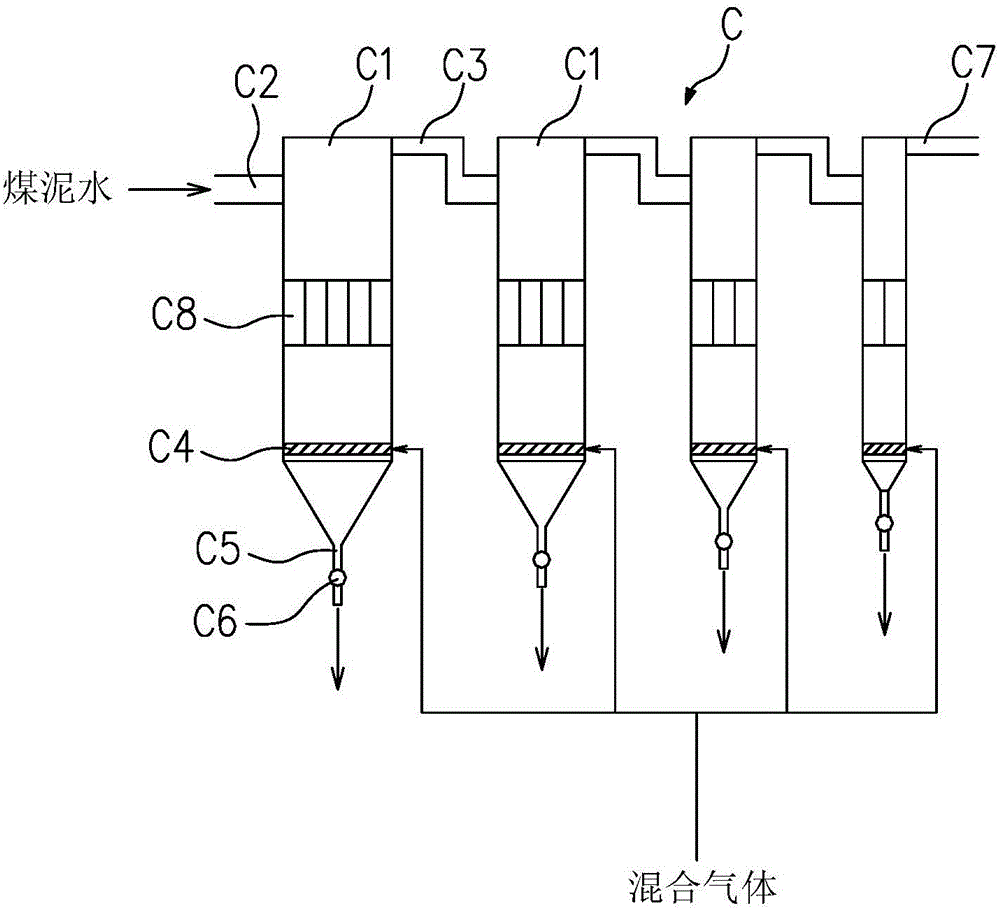

Slime water flotation device and technology

The invention discloses a slime water flotation device and technology. The slime water flotation device comprises a chemical pre-vaporization device, a chemical and air mixing device, a slime water pre-classifying device and flotation equipment. A vaporization chemical of the chemical pre-vaporization device is output to the chemical and air mixing device, the output end of the chemical and air mixing device communicates with the slime water pre-classifying device, and after being subjected to classifying flotation, the vaporization chemical flows into the flotation equipment. The flotation technology comprises the steps that firstly, the chemical is subjected to pre-vaporization and mixing, wherein a collecting agent and a foaming agent in a flotation chemical are subjected to pre-vaporization, and then the vaporization chemical and air are sufficiently mixed to form mixed gas; and secondly, slime water is subjected to pre-classifying and flotation, wherein the mixed gas is led into the slime water pre-classifying device to be subjected to classifying flotation. The slime water flotation device is simple in structure and stable in running, the contact area of the chemical and slime water is sufficiently increased, the slime water pretreatment effect is effectively improved, and the slime water classifying effect can be improved.

Owner:ANHUI UNIV OF SCI & TECH

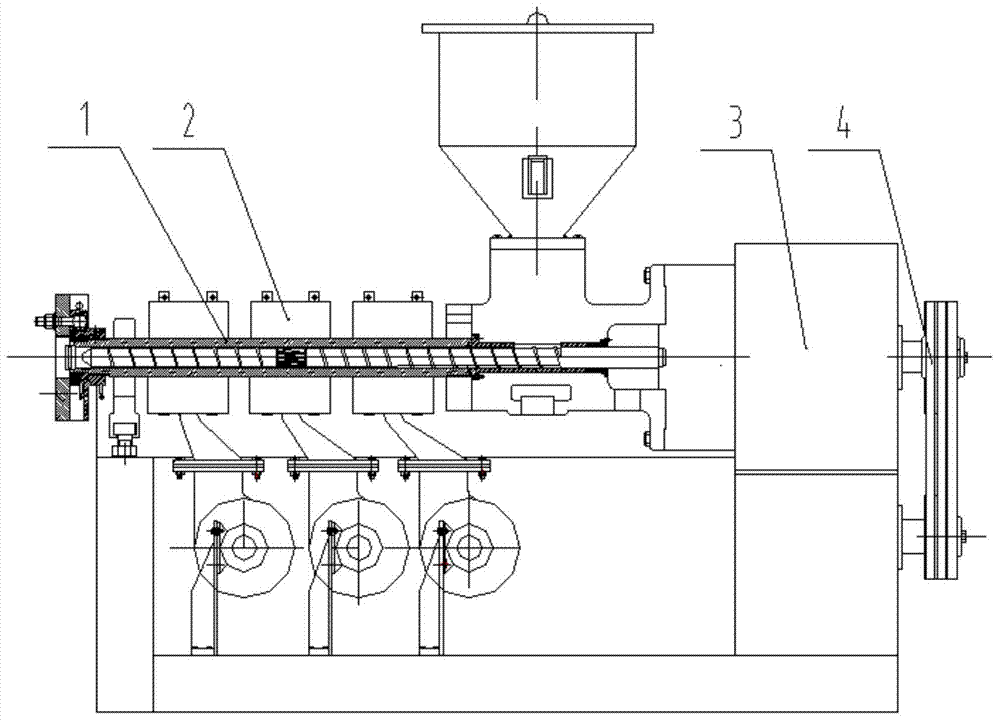

Polymer melt calculus heat transfer enhancement and mixing plasticization extruder

The invention discloses a polymer melt calculus heat transfer enhancement and mixing plasticization extruder. The polymer melt calculus heat transfer enhancement and mixing plasticization extruder mainly comprises a charged material plasticizing part, a heating and cooling part, a control system, a drive system and the like; the structures and the connection modes of the charged material plasticizing part, the heating and cooling part, the control system and the drive system are as the same as those of a common extruder; a screw rod of the charged material plasticizing part is provided with a mixing section which is provided with axial cutting edges (or forms an angle with the axial direction) with n equal divisions along the peripheral direction; adjacent cutting edges are parallel mutually; 90-degree torsional curve surfaces are additionally arranged in inner surfaces among the cutting edges, namely distributary torsion convergence sections. In the extruder provided by the invention, polymer melts rotate along with screws as well as twist by 90 degrees along the inner surfaces of the cutting grooves under the relative motion of the screws and machine barrels, so that the heat of the machine barrels is transmitted successively via each surface of the melts to enforce convection, and the heat transfer intensification and plasticization effects are achieved; additionally, the melts in the cutting grooves are subjected to distributary torsion convergence, and are mixed fully, so that the mixing effect is improved.

Owner:BEIJING UNIV OF CHEM TECH

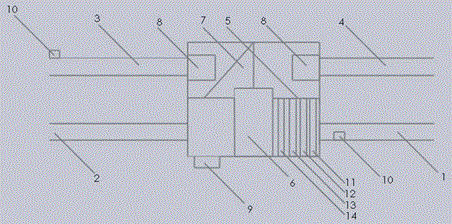

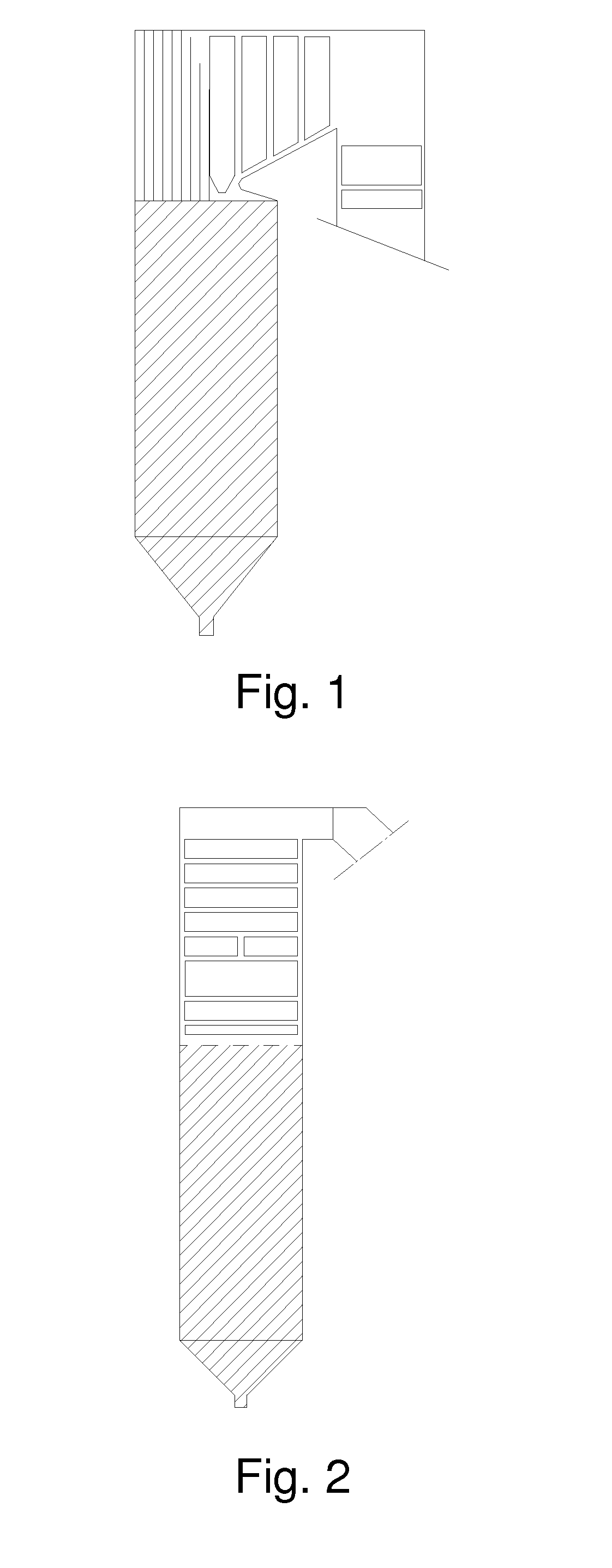

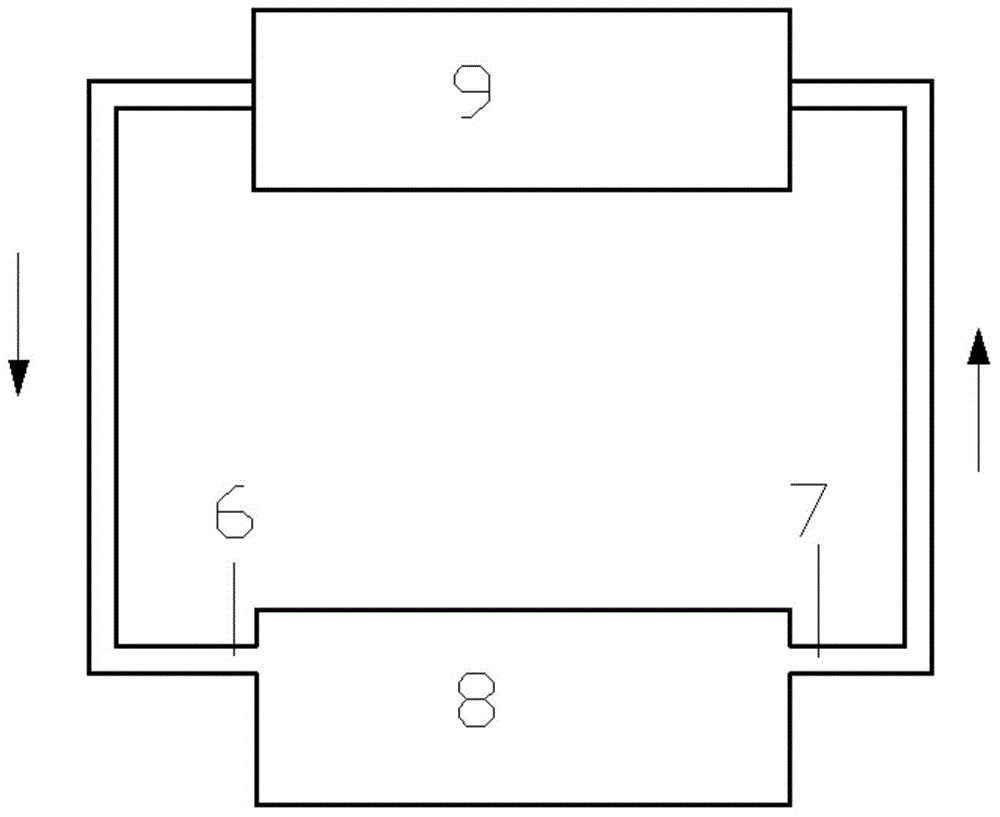

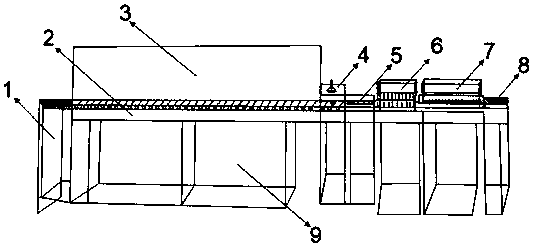

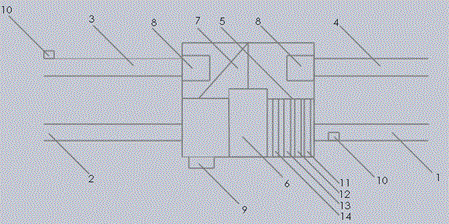

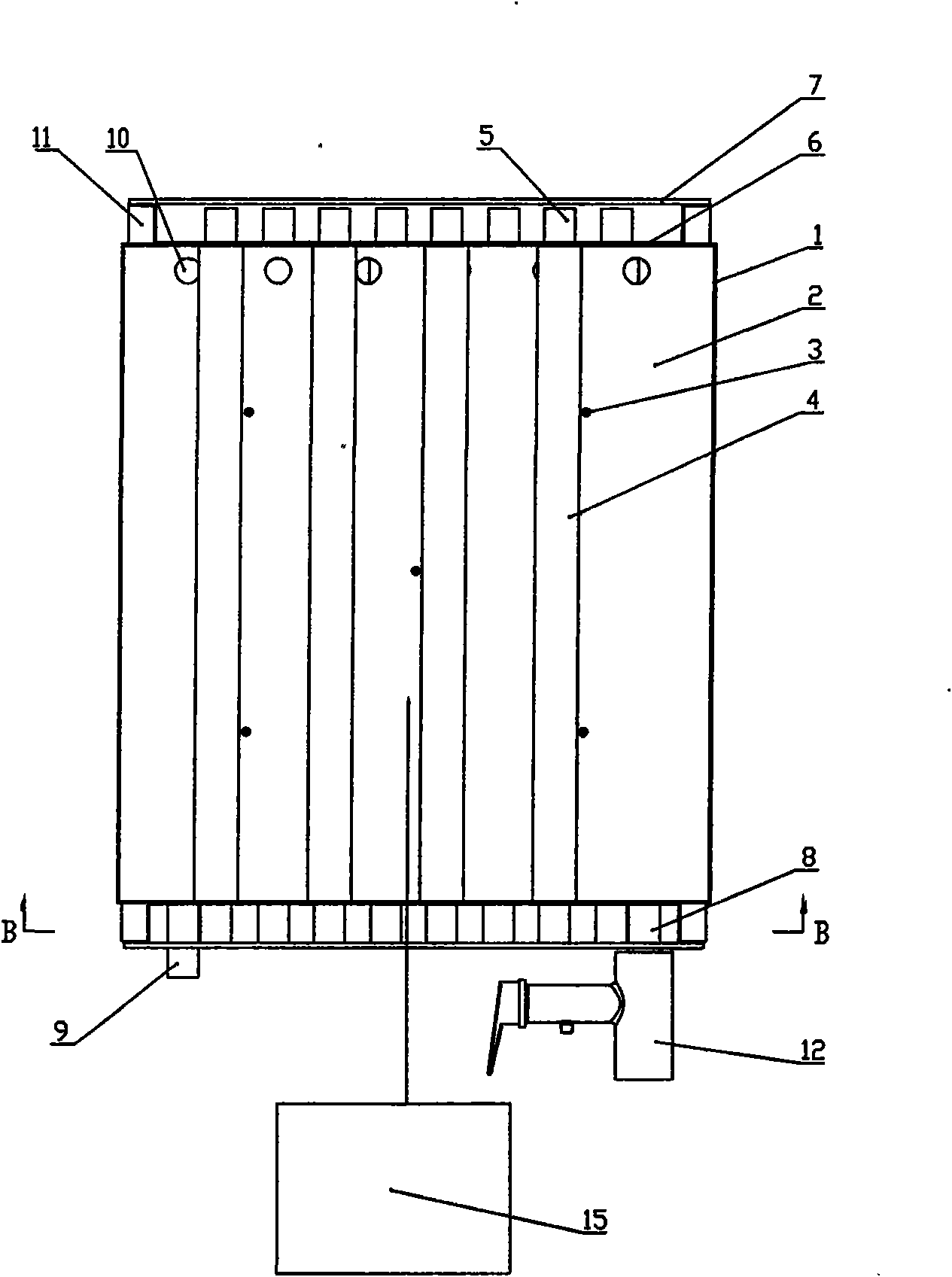

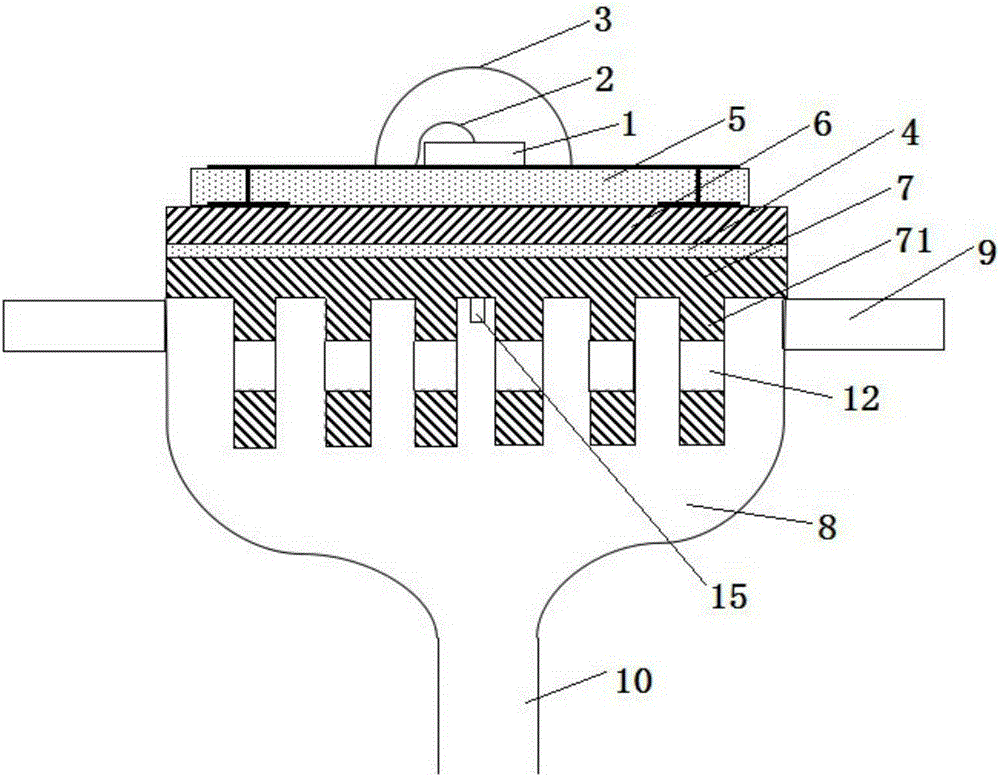

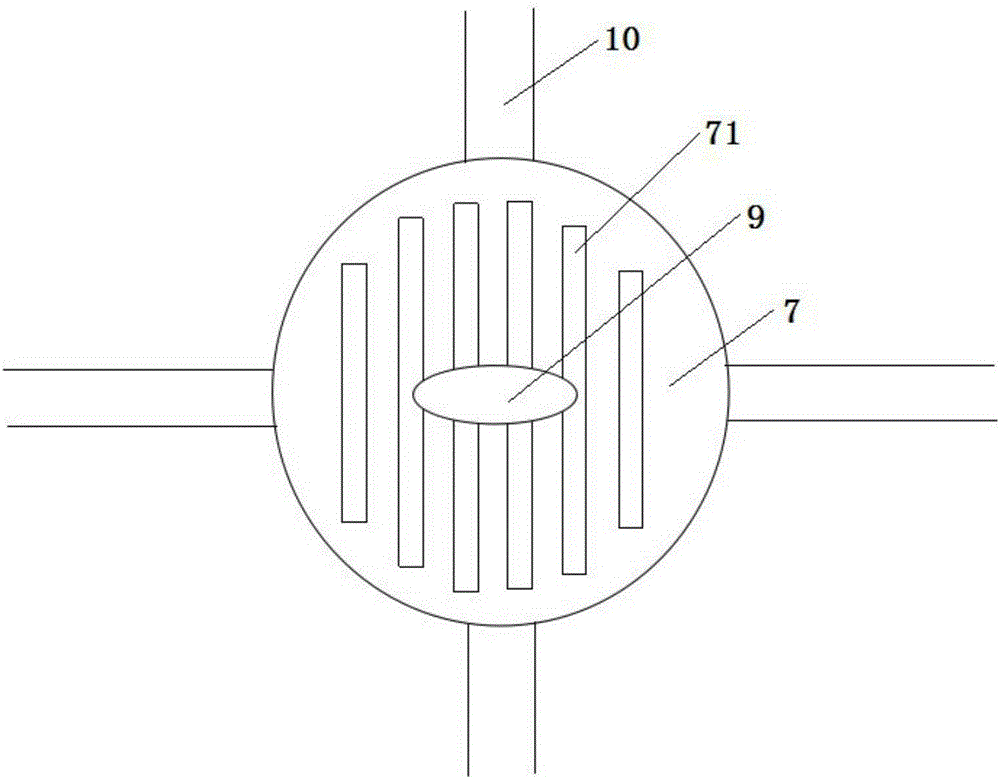

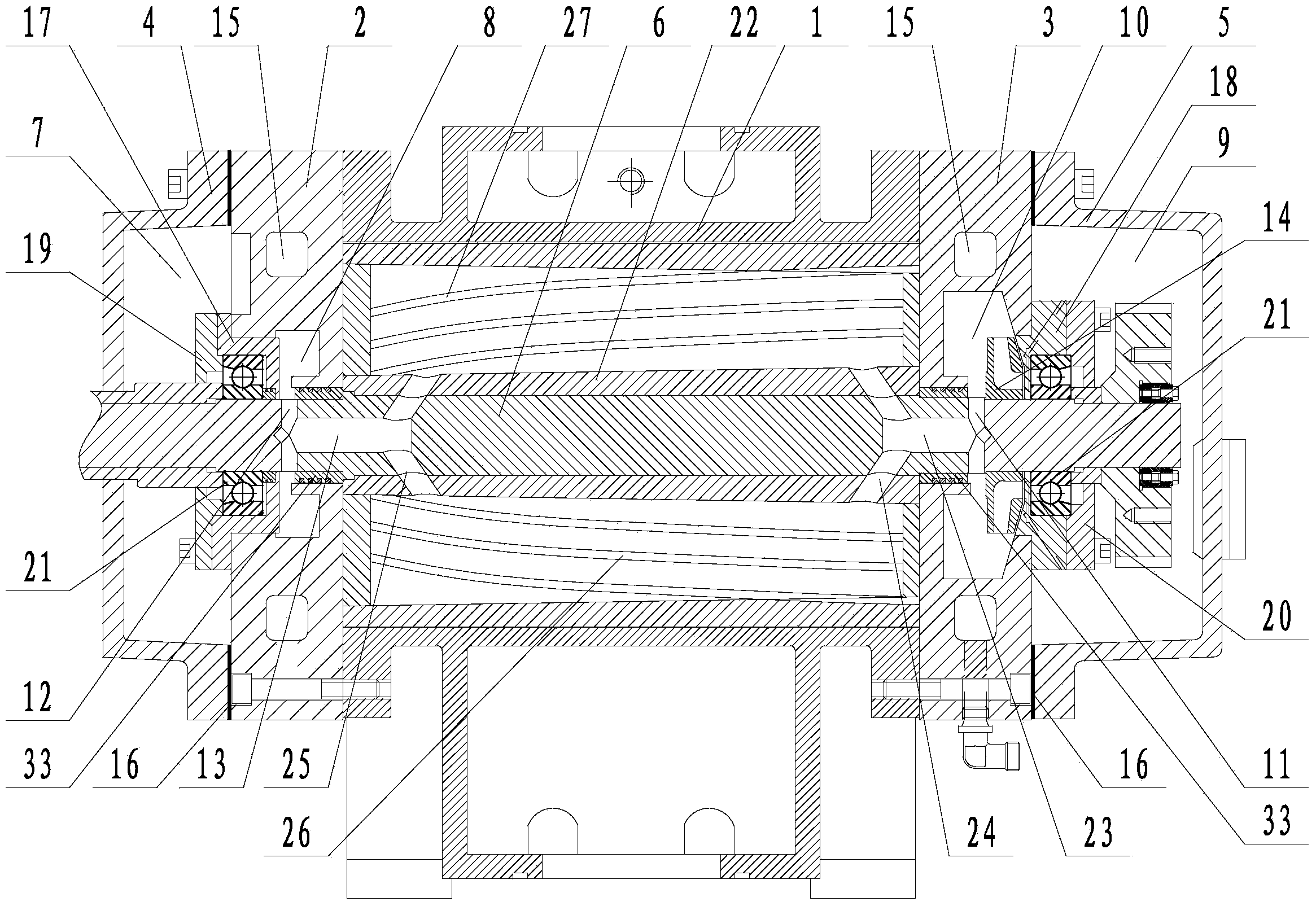

LED lamp with water-circulating heat dissipation function

ActiveCN105221970AImprove heat absorption efficiencyEven heat absorptionPoint-like light sourceLighting heating/cooling arrangementsHeat sinkEngineering

The invention discloses an LED lamp with a water-circulating heat dissipation function. The LED lamp comprises an LED wafer (1), a connecting wire (2), a lens (3), an LED wafer substrate (5), a system circuit board (6) and a heat dissipation fin (7), wherein a heat dissipation device (8) used for heat dissipation is arranged below the heat dissipation fin (7); the water inlet (9) of the heat dissipation device (8) is positioned under the heat dissipation device (8); and two or more water outlets (10) are arranged the heat dissipation device (8) and uniformly distributed on the side surface of the heat dissipation device (8). The LED lamp has the beneficial effects that the water inlet is arranged under the heat dissipation device and the water outlets are arranged on the side surface of the heat dissipation device, and water flows in from below and flows out from the surroundings, so that water flow of relative low temperature is formed from the middle to both sides of the heat dissipation fin, heat on the heat dissipation fin is brought away, uniform heat absorption of the water flow is achieved, heat absorption efficiency of the water flow is improved, and all regions of the heat dissipation fin can keep the same and stable temperature.

Owner:JIANGSU TIWIN OPTO ELECTRONICS TECH

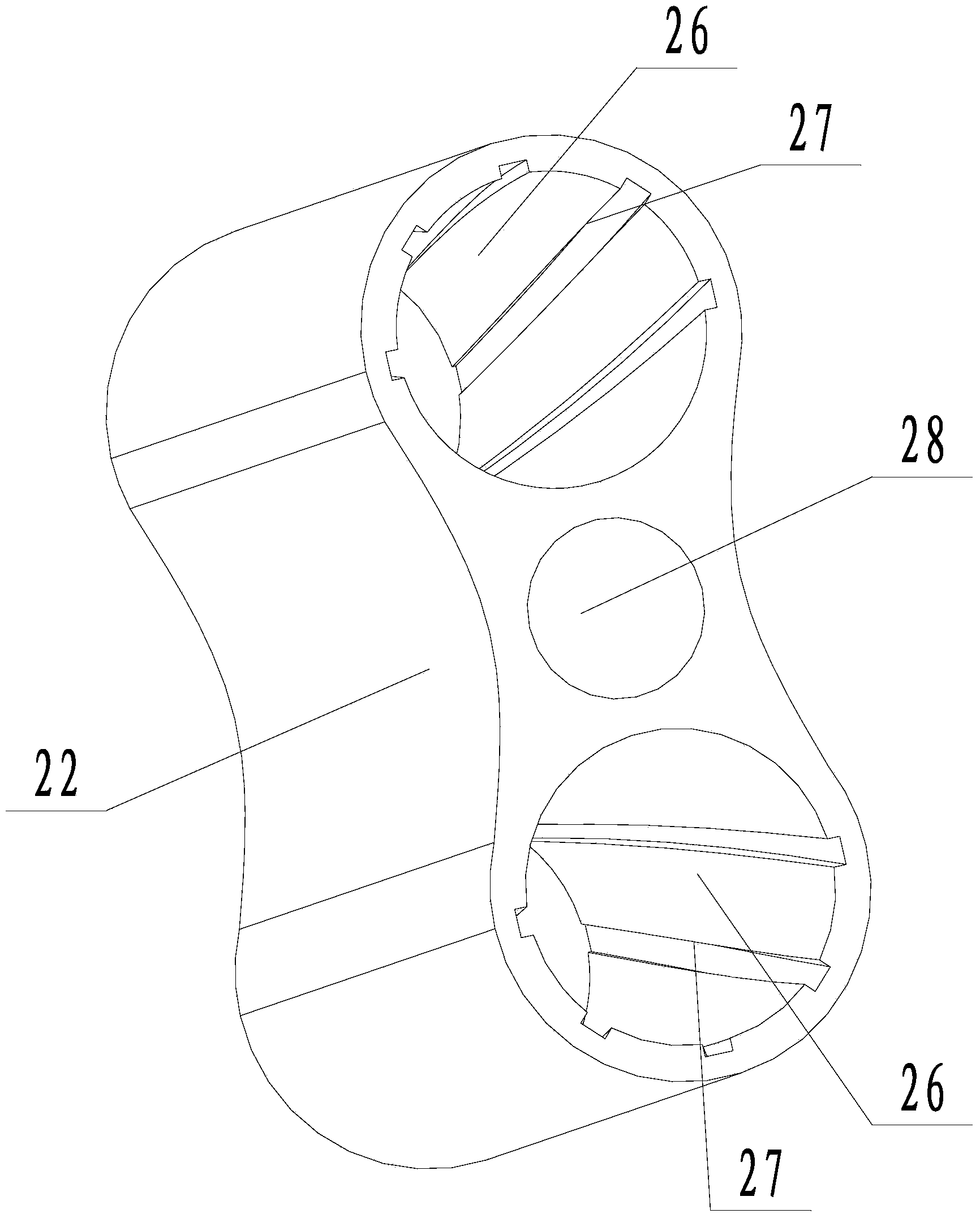

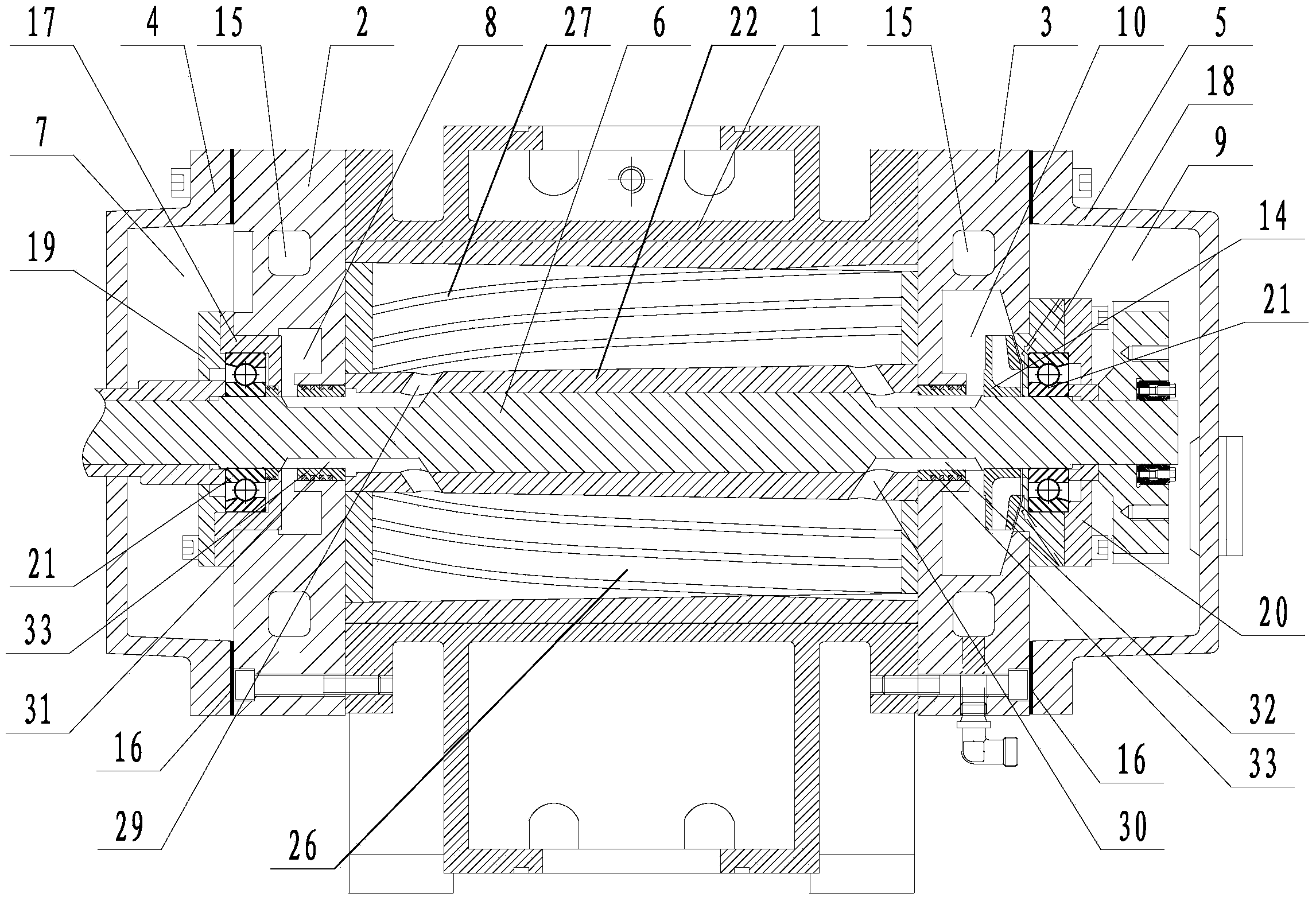

Roots pump with rotor cooling structure

ActiveCN103511282AFirmly connectedFast flowRotary/oscillating piston pump componentsLiquid fuel engine componentsImpellerCooling effect

The invention discloses a roots pump with a rotating shaft cooling structure, and aims to overcome the defects of weaker rotating shaft cooling effect and short service life in the existing roots pump. The roots pump comprises a pump body, wherein the front end and the back end of the pump body are respectively connected with a front side cover and a back side cover; the front side cover is connected with a front cover; the back side cover is connected with a back cover; a rotating shaft is connected between the front cover and the back cover, and is connected with a rotor; a front cover cavity is formed in the front cover; a front cooling cavity is formed in the front side cover; a back cover cavity is formed in the back cover; a back cooling cavity is formed in the back side cover; the front cover cavity is communicated with the front cooling cavity; the back cover cavity is communicated with the back cooling cavity; the rotor takes the shape of 8, and is provided with two closed rotor cooling cavities inside; two ends of the rotor cooling cavities are respectively communicated with the front cooling cavity and the back cooling cavity; the rotor is provided with a centrifugal impeller for driving cooling liquid near to a liquid inlet hole; the centrifugal impeller is arranged in the back cooling cavity; a liquid inlet pipe is arranged on the back cover; a liquid outlet pipe is arranged on the front cover.

Owner:杭州新安江工业泵有限公司

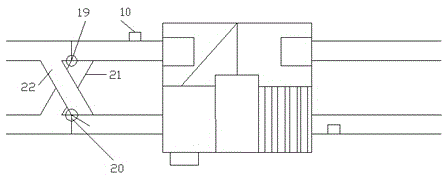

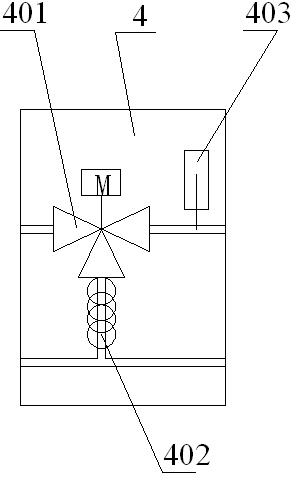

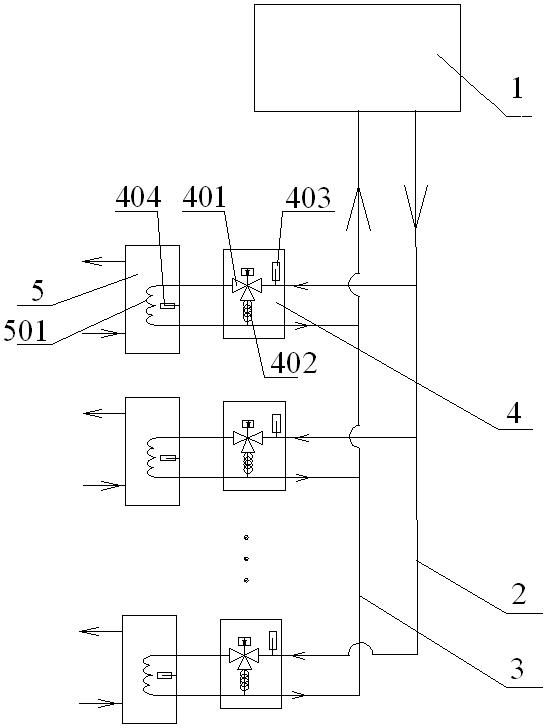

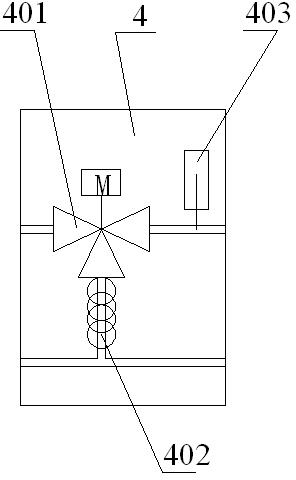

User work station of damper tube type central-household solar water heating system

ActiveCN102052708AEven heat absorptionPrevent back passLighting and heating apparatusSpace heating and ventilation detailsElectricitySolar water heating system

The invention discloses a user work station of a damper tube type central-household solar water heating system. The user work station comprises a three-way electronic control valve for controlling the flow direction of a heat medium, a fluid damper, a heat medium temperature sensor and a control device, wherein a liquid inlet of the three-way electronic control valve is communicated with a heat medium inlet; a first liquid outlet of the three-way electronic control valve is communicated with a heat medium outlet; a second liquid outlet of the three-way electronic control valve is communicated with one end of the fluid damper; and the other end of the fluid damper is communicated with a heat medium bypass inlet and a heat medium bypass outlet. The user work station also includes a hot water temperature sensor arranged in a temperature insert of a user hot water storage tank; the heat medium temperature sensor is arranged on the upstream of the liquid inlet of the three-way electronic control valve; and the hot water temperature sensor, the heat medium temperature sensor and the three-way electronic control valve are respectively electrically connected with the control device. The user work station can prevent heat of water in the user hot water storage tank from being transferred to the heat medium, and can ensure uniform heat absorption of each user hot water storage tank.

Owner:ZHEJIANG ZHONGXIN ENERGY SOURCE DEV

Heat treatment furnace for steel cylinders

InactiveCN102312070AStable deliveryEven heat absorptionFurnace typesHeat treatment furnacesEngineeringHeat treated

Owner:张家港市嘉华炉业有限公司

Coal slime water flotation reagent vaporizing device and vaporizing method thereof

ActiveCN105728201ASimple structural designIncrease contact areaFlotationElectric heatingControl system

The invention discloses a coal slime water flotation reagent vaporizing device and a vaporizing method thereof. The coal slime water flotation reagent vaporizing device comprises a reagent barrel, wherein the reagent barrel communicates with a vaporizing container through an electric control valve I, a high pressure pump, an electric control valve II and a spray nozzle; the part, at the upper end of the container, of the vaporizing container is connected to an electric heating tube; an electric control valve III used for collecting the vaporizing reagent is arranged on the electric heating tube; a temperature monitoring device and a pressure monitoring device for monitoring the temperature and the pressure of the inner part of the container are arranged on the vaporizing container; and the vaporizing container is further connected with a vacuum-pumping pipeline which communicates with the reagent barrel. The vaporizing container comprises a plurality of electric heating plates which are arranged on the inner part of the container, wherein the heating temperature of the electric heating plates is gradually increased from top to bottom; and the part, at the outlet of the electric control valve III, of the electric heating tube is further provided with a flow monitoring device. The device is further provided with a control system which is electrically connected to the monitoring devices, the electric control valve, the electric heating tube, the high pressure pump, the vacuum pump and the electric heating plate. The device is simple in structure, and is stable to operate, and the contact area of the reagent and coal slime water is sufficiently increased.

Owner:ANHUI UNIV OF SCI & TECH

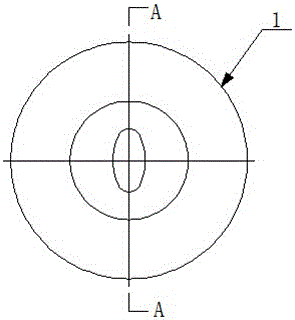

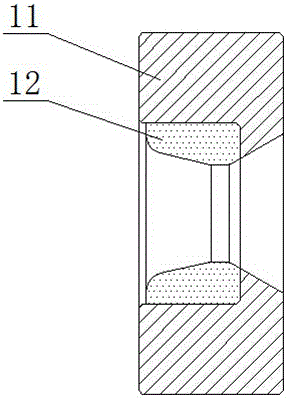

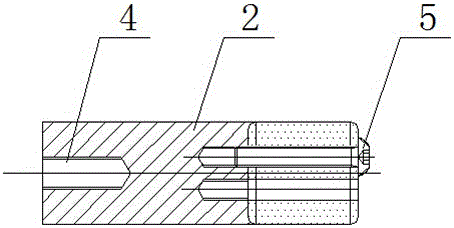

A special-shaped tube processing technology

ActiveCN104307899BImprove efficiencyImprove processing efficiencyDrawing diesMachining processProduct processing

The invention provides a process for machining a special pipe. The method comprises the following steps: 1) extrusion and preforming of a roller, to be specific, selecting a hard round-straight copper pipe with an appropriate dimension parameter as a special pipe blank to be machined, and extruding and preforming the special pipe blank by using the roller so as to obtain a primarily machined blank; 2) one-step drawing formation, to be specific, putting the primarily machined blank into a drawing mold and obtaining the formed pipe after one-time drawing. The drawing mold comprises an outer mold and a core print, wherein the outer mold comprises a mold sleeve and a mold core; a cavity is formed in the mold sleeve; the mold core is clamped in the mold sleeve; a cavity is formed in the mold core; the core print is arranged in the cavity of the mold core; a drawing passage for drawing the pipe is formed between the mold core and the core print. The process for machining the special pipe, provided by the invention, has the advantages of higher machining process efficiency, better product stability and better appearance effect of the formed copper pipe; meanwhile, the rate of finished products is also increased and the product machining difficulty is reduced.

Owner:CHONGQING LONGYU PRECISION COPPER TUBE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com