Patents

Literature

140results about How to "Reduce the chance of burns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

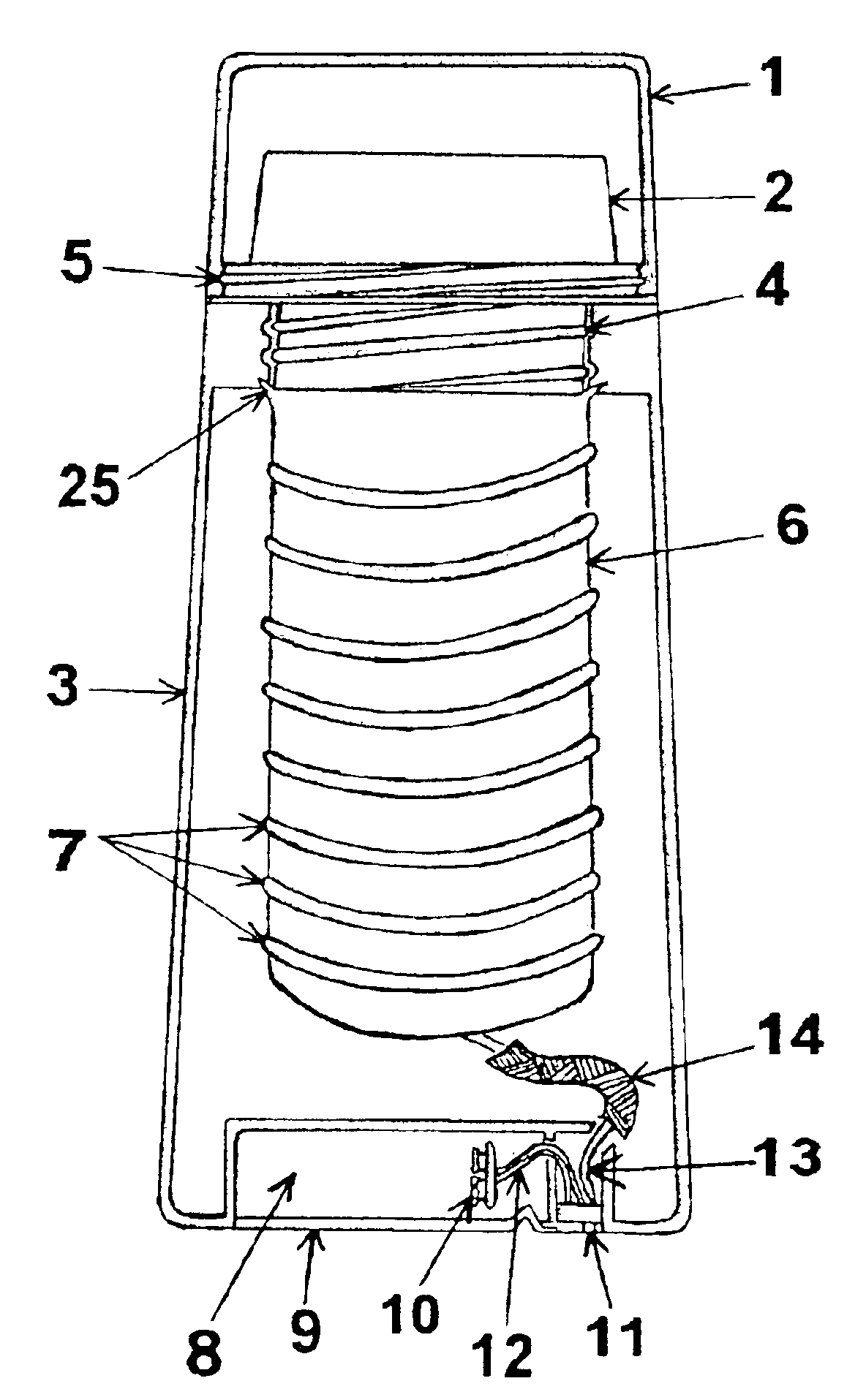

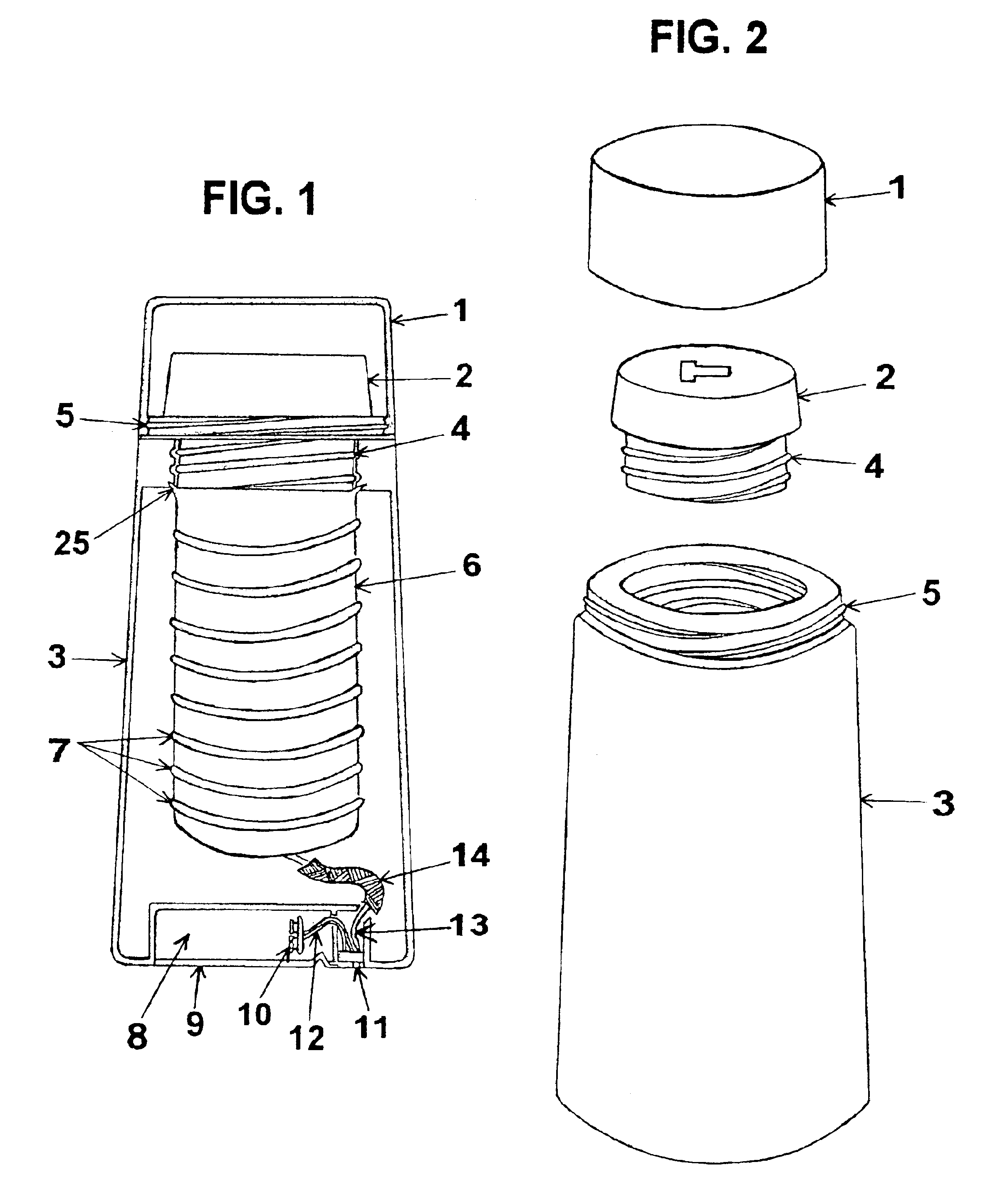

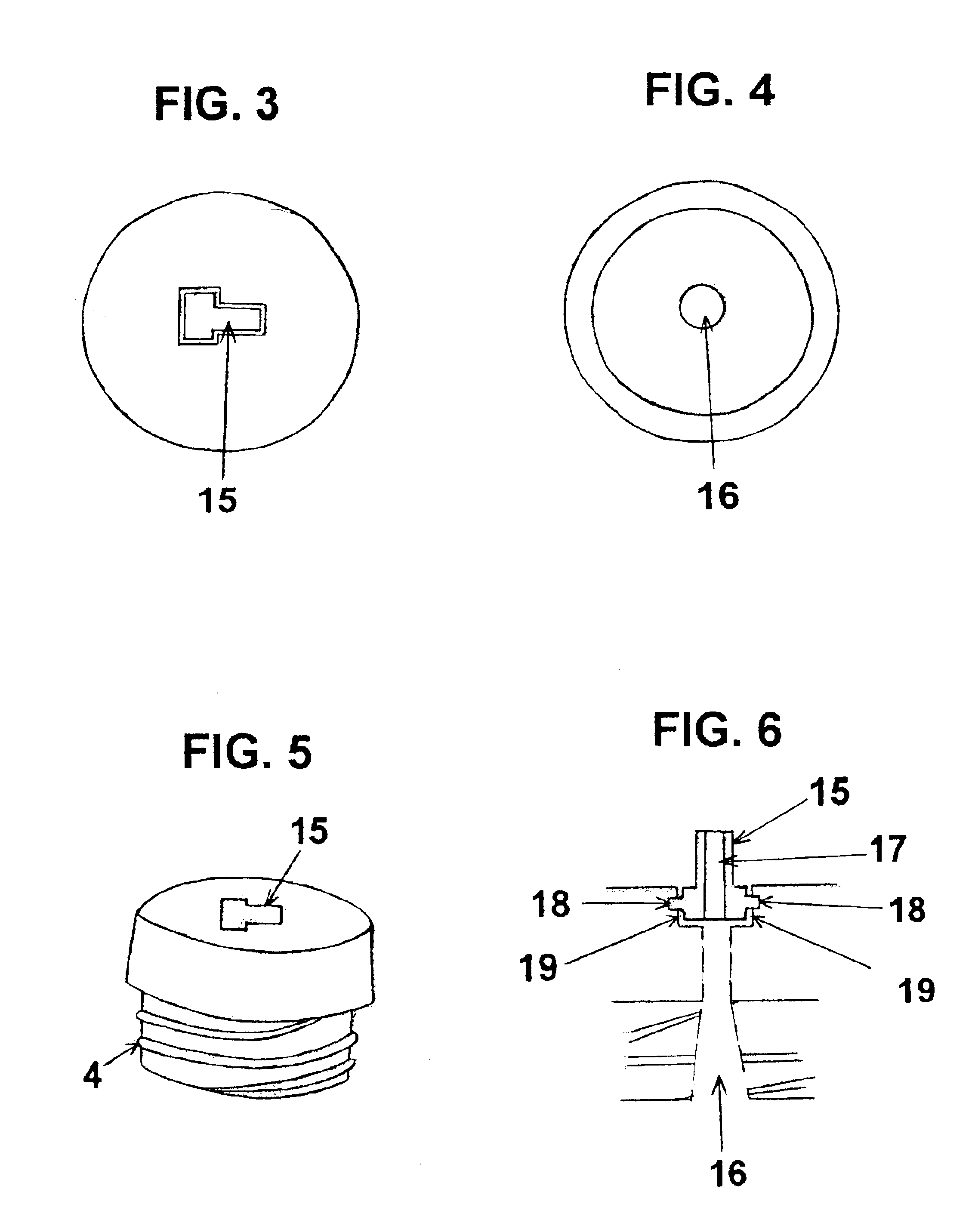

Battery operated self heating thermos container

InactiveUS6943323B2The process is simple and effectiveEasy to operateHeater elementsBaking ovenVacuum flaskElectrical battery

A thermos container with inner sealing cap and outer cap used to contain solid or liquid foods. Integral heating coils contained within the innermost compartment of the receptacle receives energy from the main power cord connected to the On / Off sliding switch power conductor. When the sliding switch is moved to the On position it activates the battery power to heat the integral coils to a certain temperature to warm the contents of the thermos container. With such applications the invention is a battery operated self heating thermos thus allowing for storage and heat to foods contained within the inner receptacle.

Owner:IANNUCCI CLAUDINE

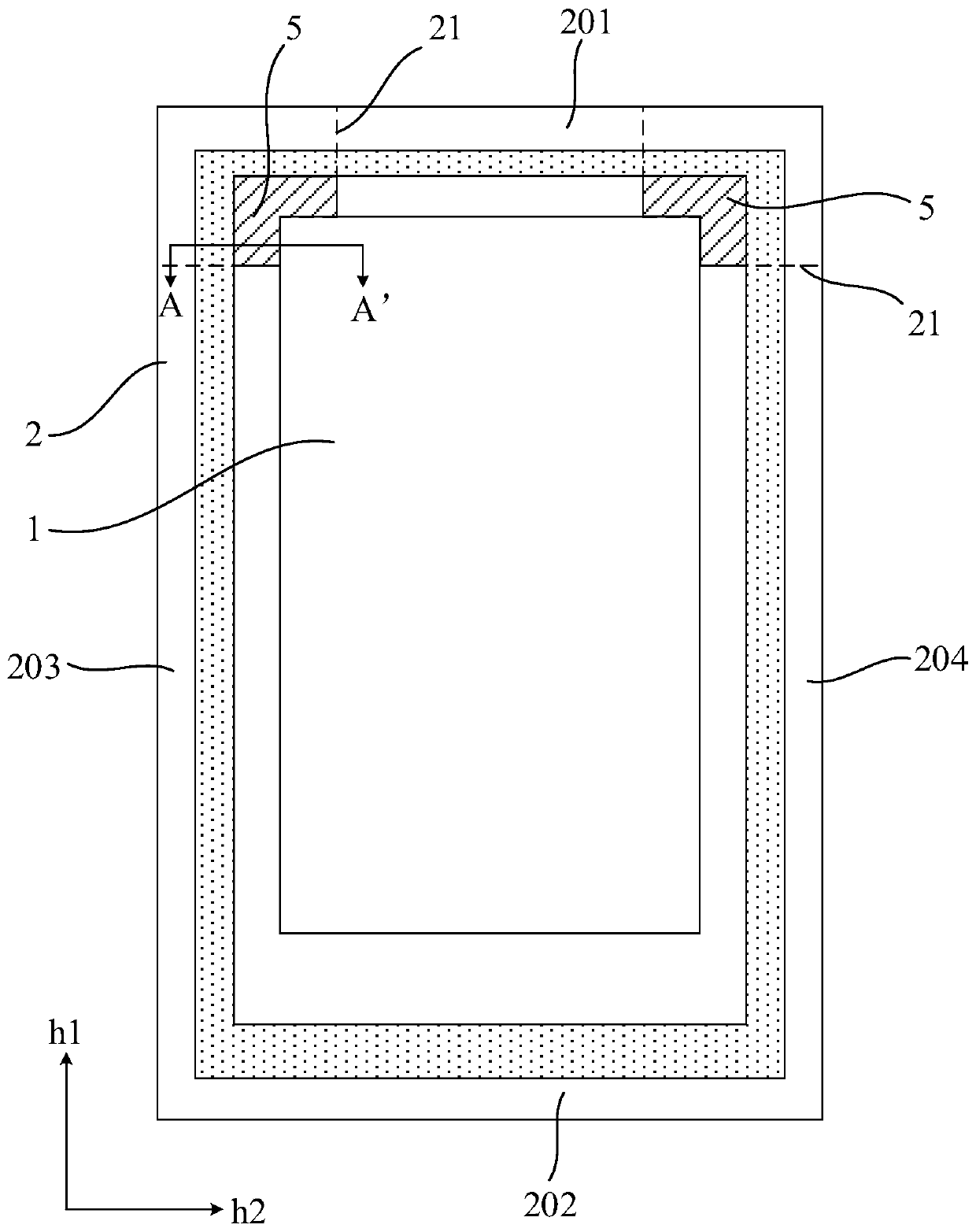

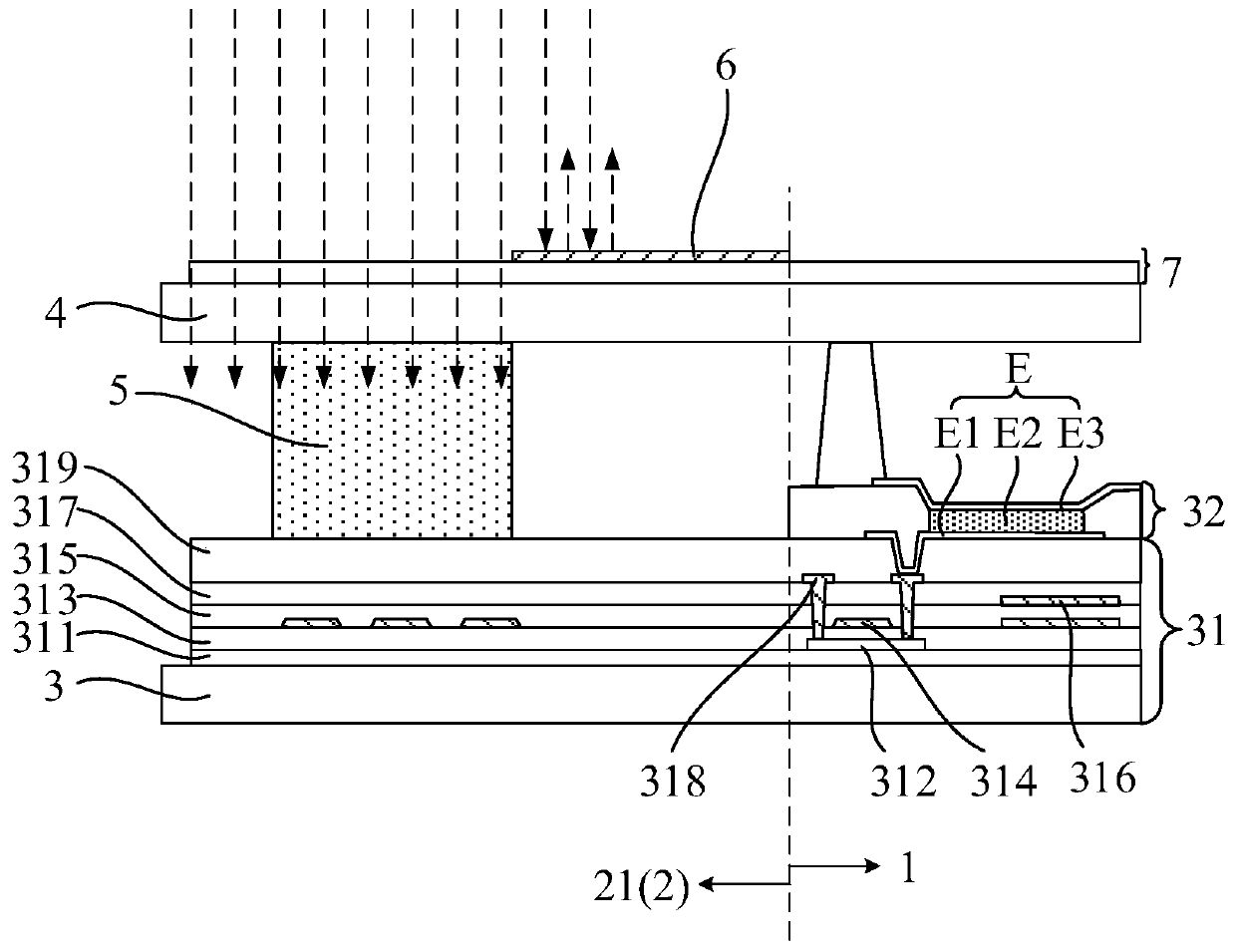

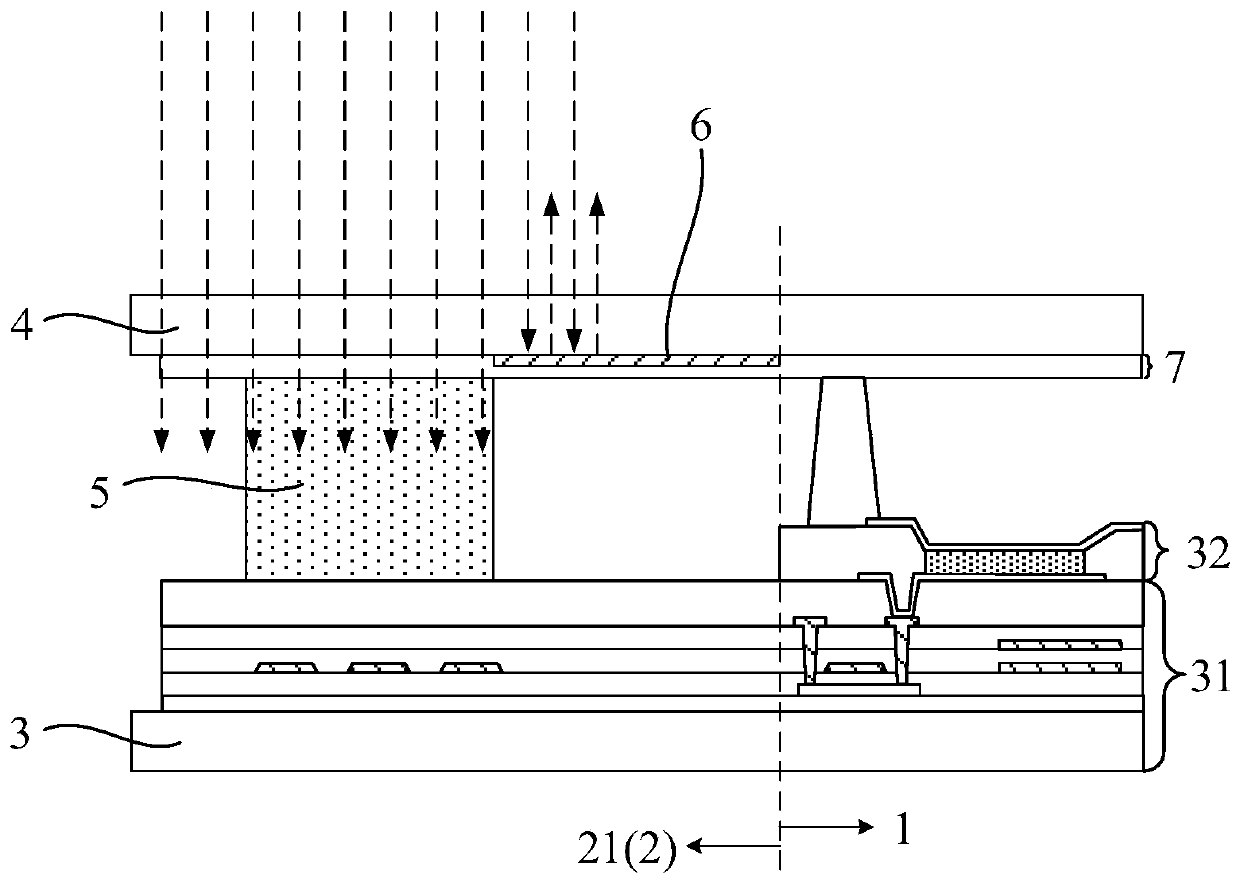

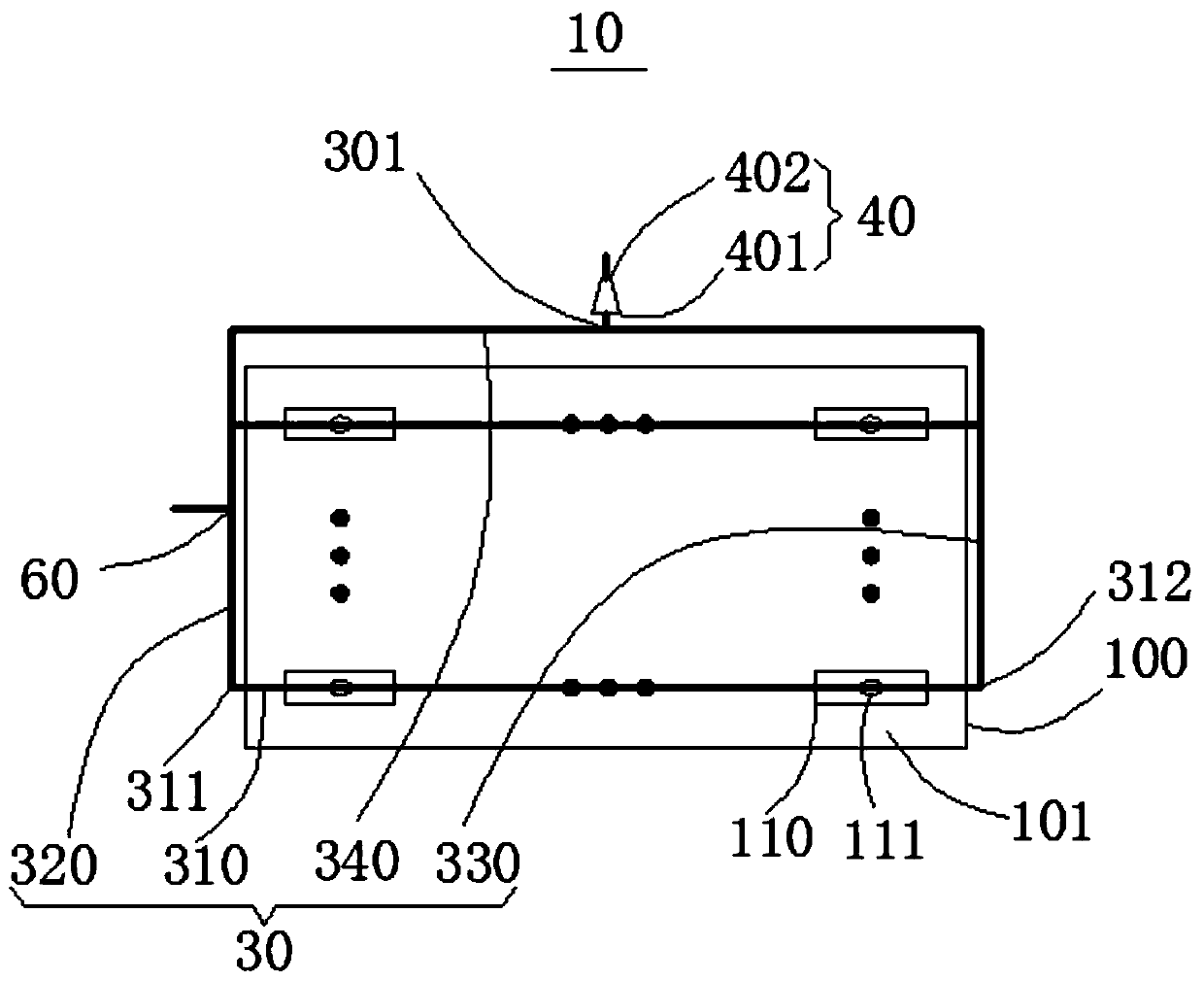

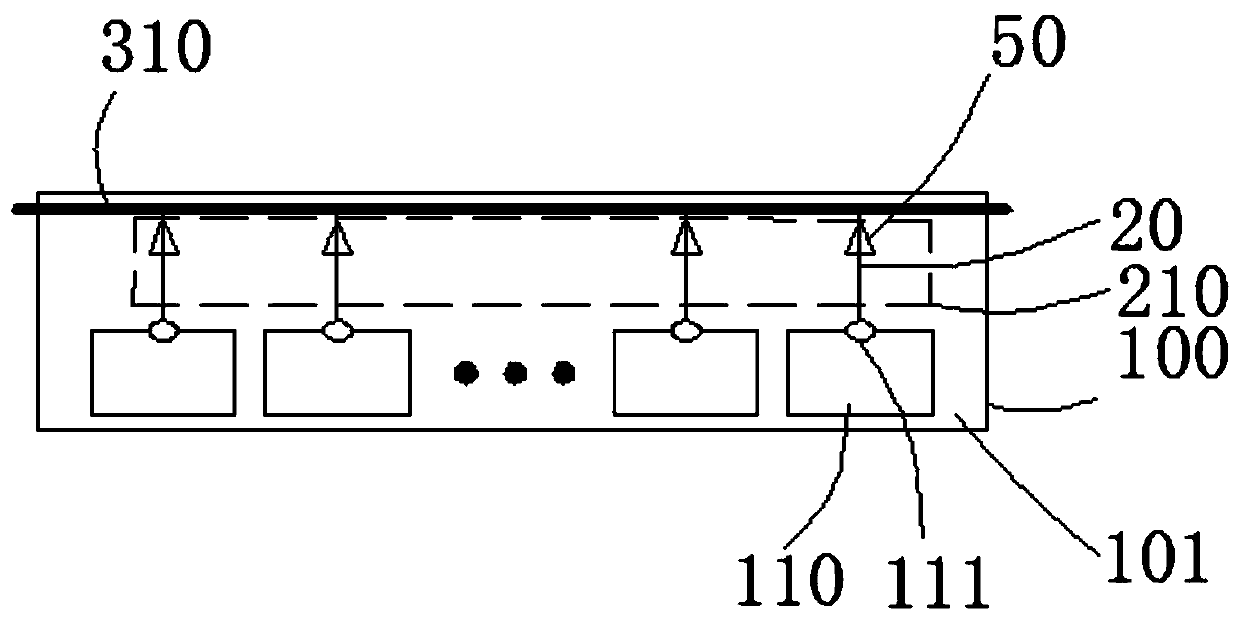

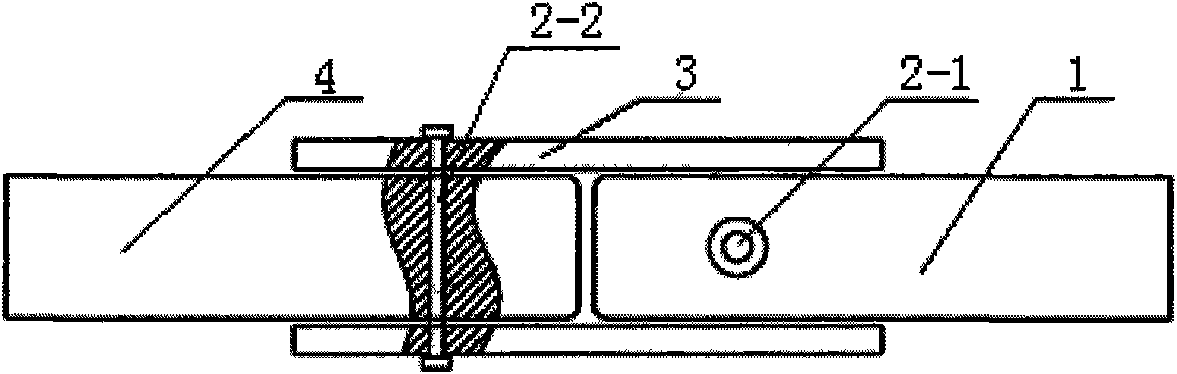

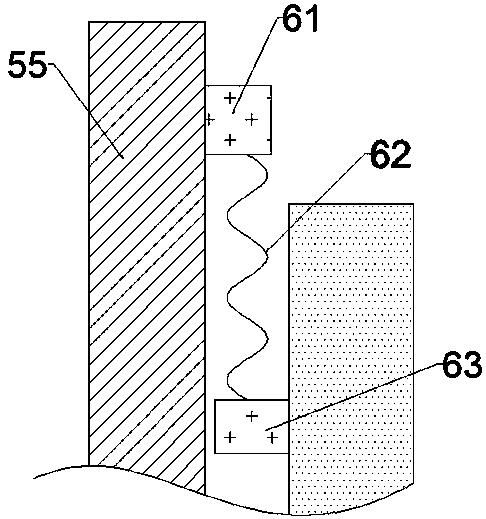

Display panel, display device and packaging method

ActiveCN110289370AReduce accumulationReduce the chance of burnsSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveDisplay device

The embodiment of the invention provides a display panel, a display device and a packaging method, relates to the technical field of display, and can reduce the probability that a device in a display area near a corner of the display panel is burnt in a packaging process. The display panel comprises a display area and a frame area surrounding the display area, and the frame area comprises a laser reflection corner area; a first substrate and a second substrate which are opposite to each other; in the frame area, packaging glue is arranged between the first substrate and the second substrate; and the laser reflection corner area is provided with a reflection structure. The film layer where the reflection structure is located is located at the side, away from the film layer where the first substrate is located, of the film layer where the packaging adhesive is located. And in the direction perpendicular to the plane where the display panel is located in the laser reflection corner area, the orthographic projection of the reflection structure is located between the orthographic projection of the packaging adhesive and the display area.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Low-voltage cable intermediate joint cold contraction technology

ActiveCN103337813AIncrease elasticityAvoid thermal expansion and contractionApparatus for joining/termination cablesSocial benefitsLow voltage

The invention belongs to the technical field of electric power, and especially relates to a low-voltage cable intermediate joint cold contraction technology, which can remedy defects such as coarse original material, poor insulation performance and sealing performance, weak tolerance mechanical strength, and easily getting heated and burnt of a 0.4kV low-voltage cable intermediate joint and significantly improve equipment safety running coefficients. The low-voltage cable intermediate joint cold contraction technology fundamentally helps to reduce fault probability of the 0.4kV low-voltage cable intermediate joint. The use of the new technology and the material provide effective technical support for personal safety and equipment safety, and at the same time helps electric power enterprises to save a large amount of maintenance funds, not only promotes increase of profits of the electric power enterprises but also achieves huge social benefit due to stable and continuous power supply.

Owner:STATE GRID CORP OF CHINA +1

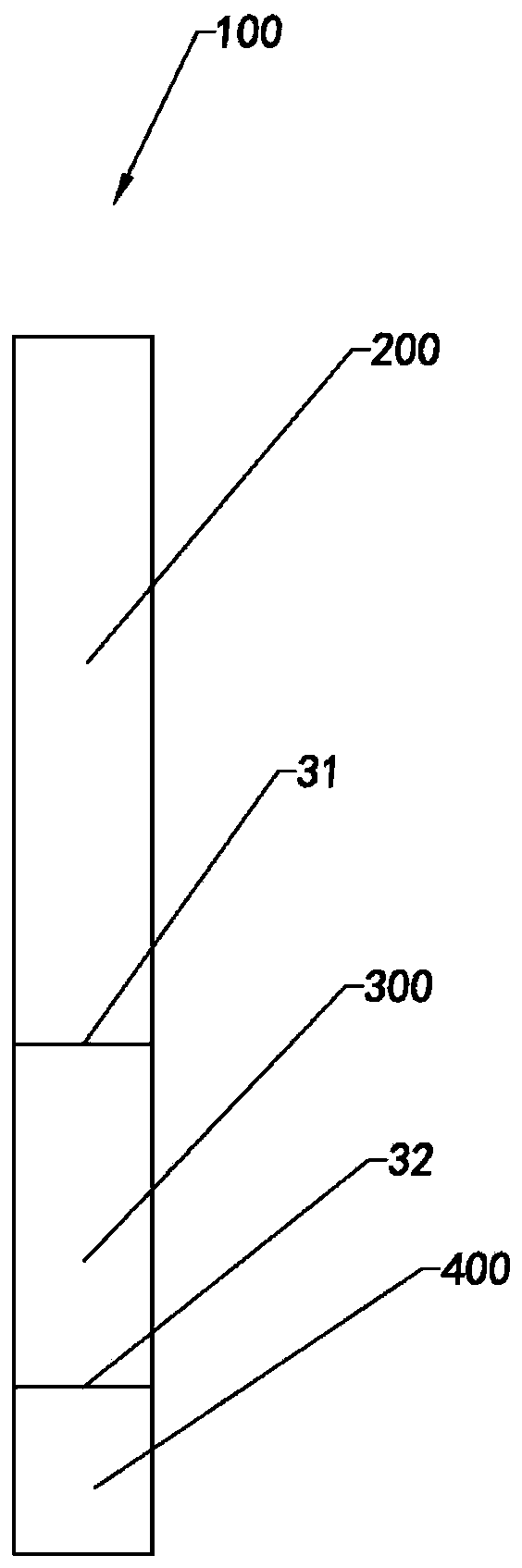

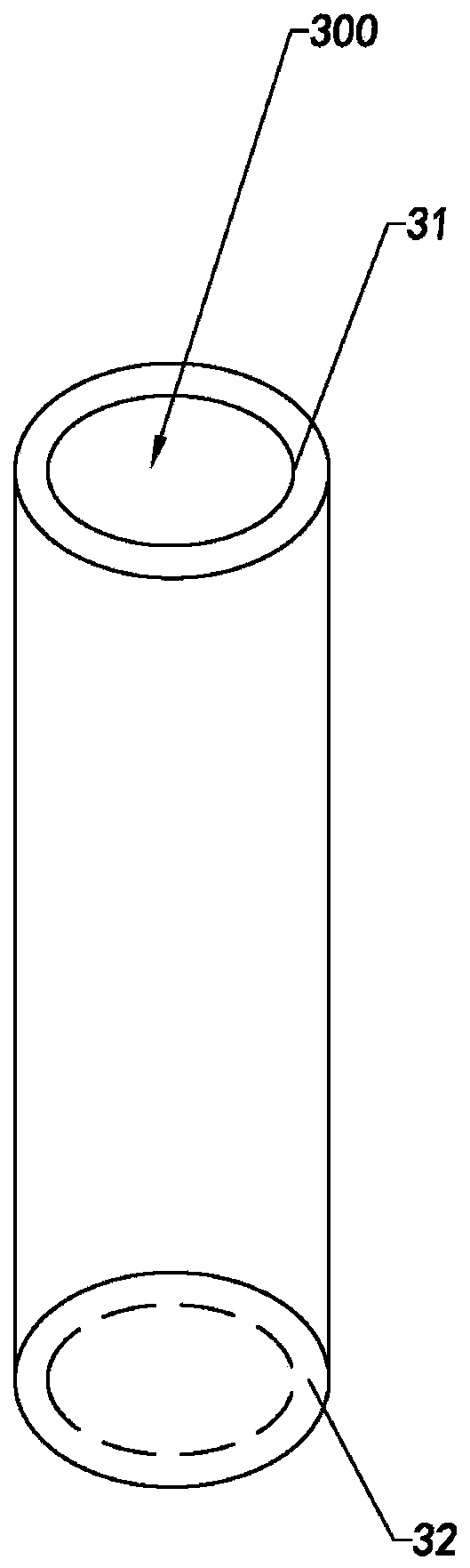

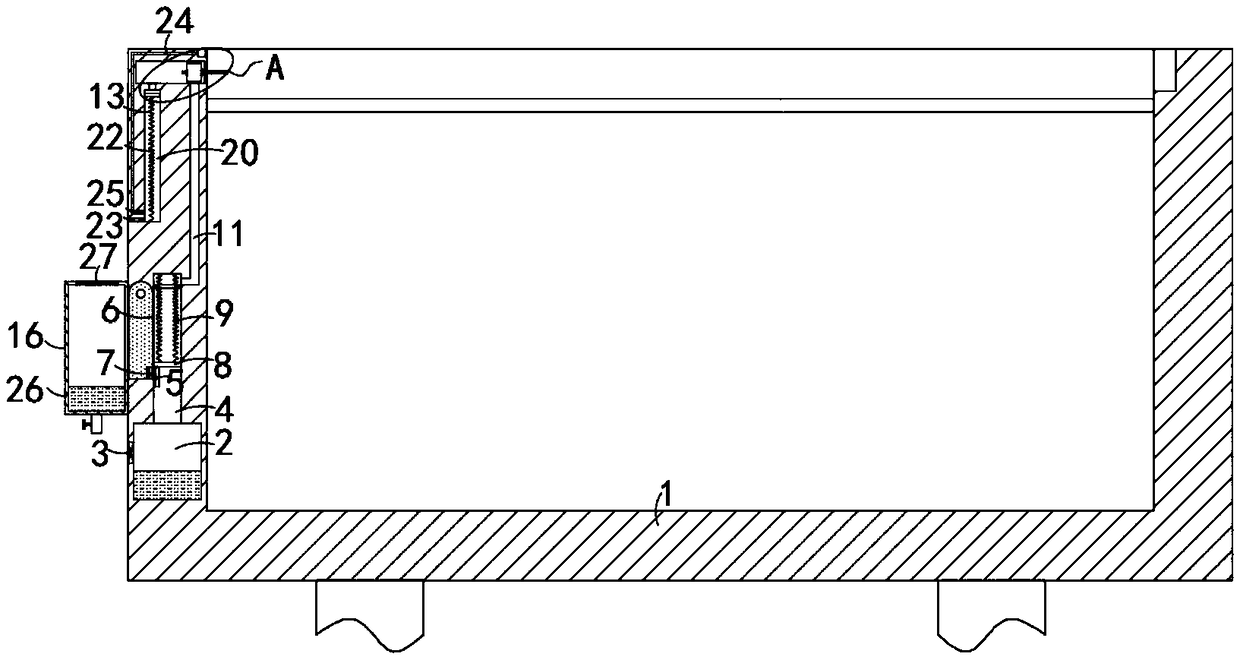

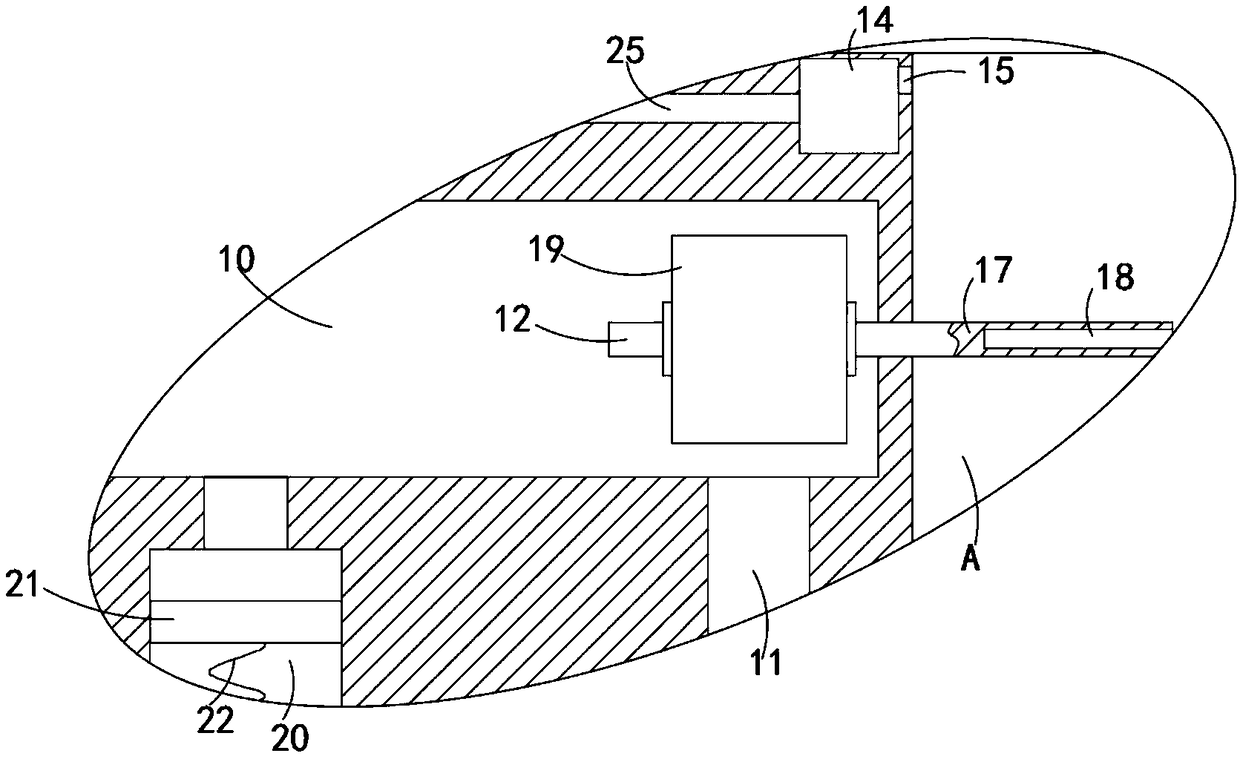

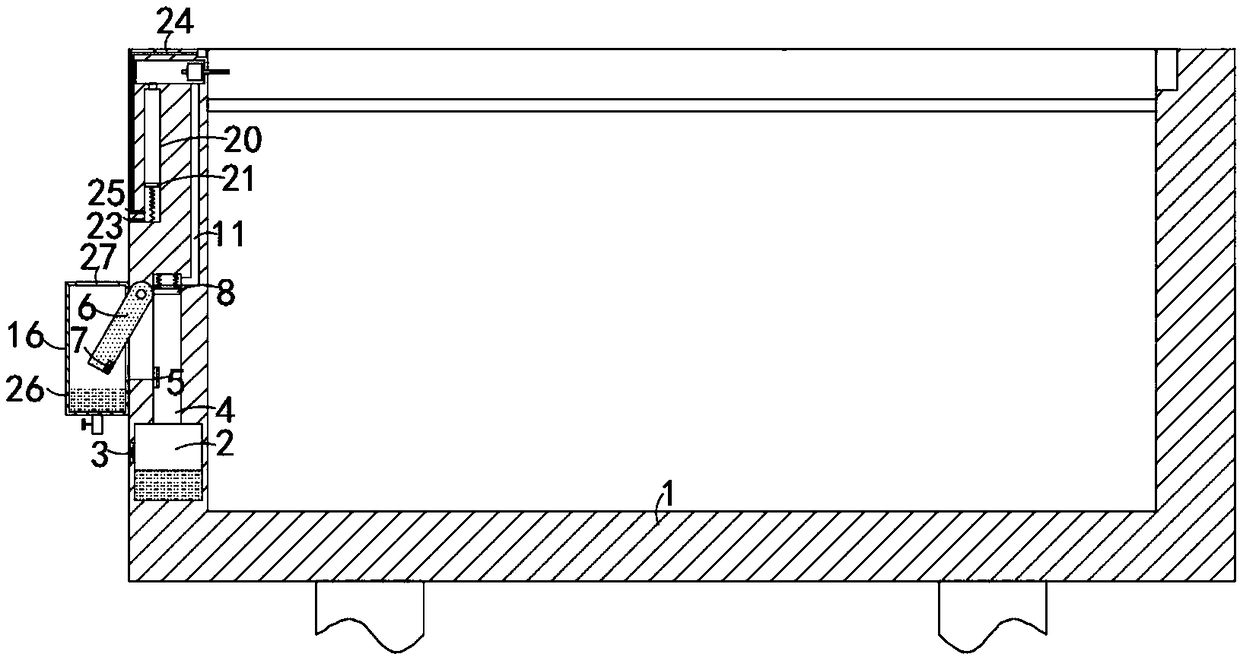

Battery pack flue gas flow channel system and battery pack

PendingCN110459719AReduce explosionReduce the chance of burnsSeveral cell simultaneous arrangementsCells cooling/heatingCombustionFlue gas

The invention relates to a battery pack flue gas flow channel system and a battery pack. The battery pack flue gas flow channel system comprises a plurality of branch pipelines, a main pipeline and acooling device, wherein the plurality of branch pipelines are respectively communicated with the main pipeline to form a combustible mixed gas dredging channel. The combustible mixed gas dredging channel dredges a combustible mixed gas generated by the single batteries during thermal runaway to the outside of the battery pack, so that the accumulation of the combustible mixed gas in the battery pack is reduced, and thus the explosion and combustion probability of the battery pack is reduced. Furthermore, the cooling device is arranged at an exhaust port of the main pipeline, thereby reducing the temperature of the combustible mixed gas at the exhaust port of the main pipeline, and effectively avoiding the gas explosion at the exhaust port of the main pipeline. Therefore, the battery pack flue gas flow channel system reduces the explosion and combustion probability of the battery pack and improves the safety of the battery pack.

Owner:TSINGHUA UNIV

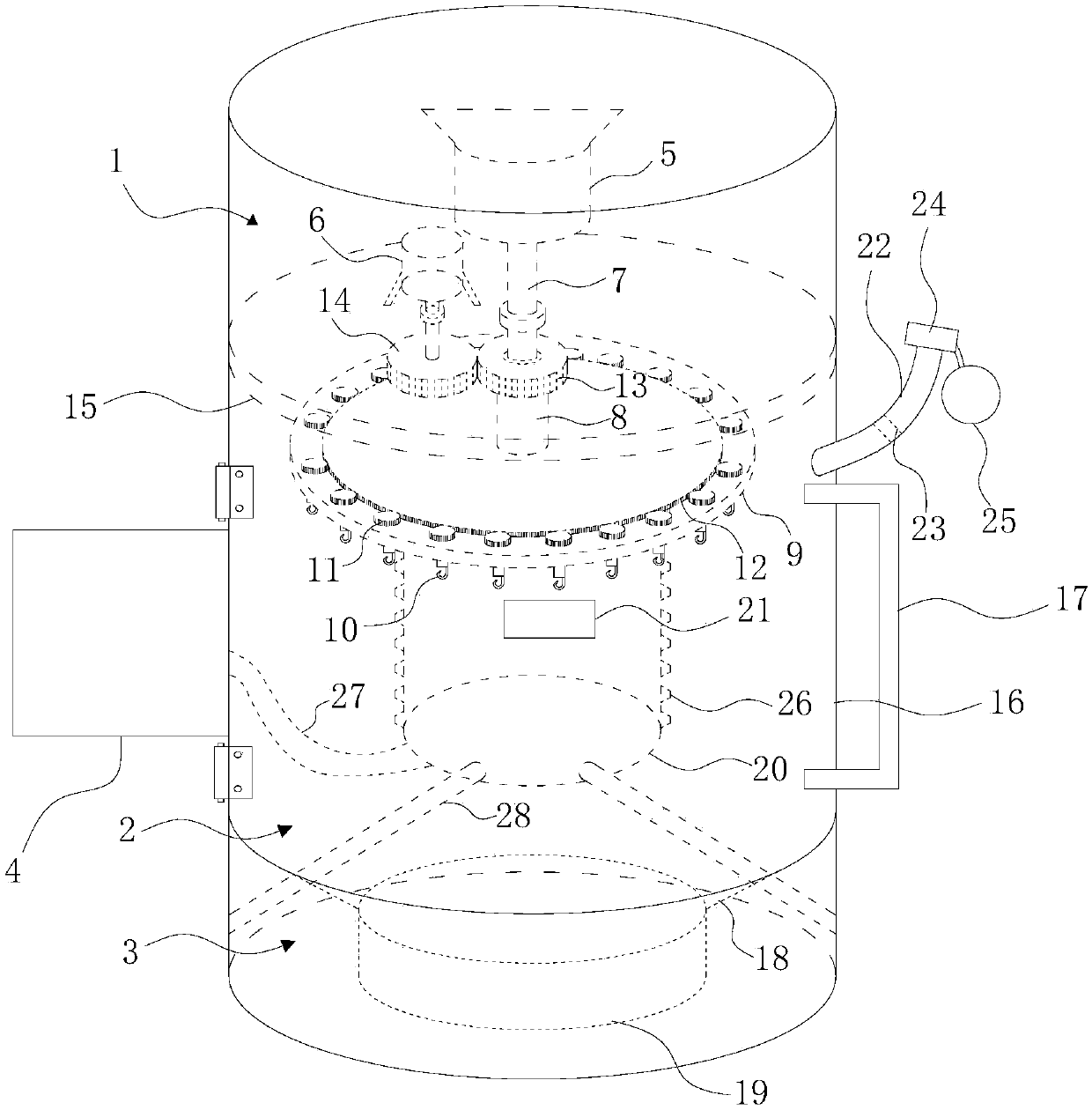

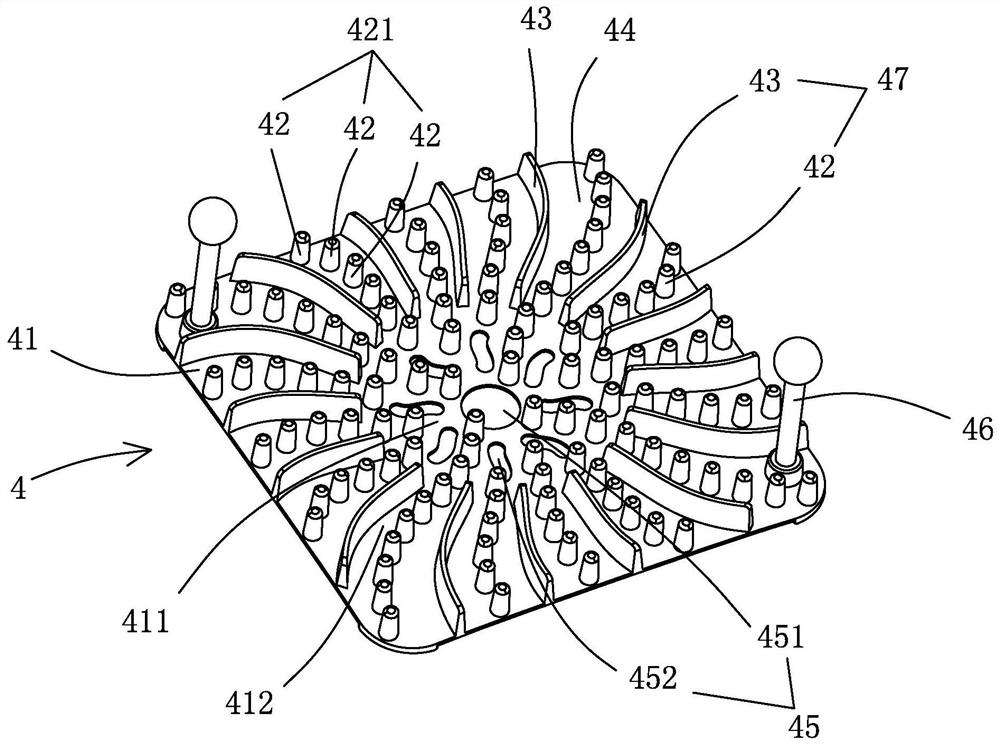

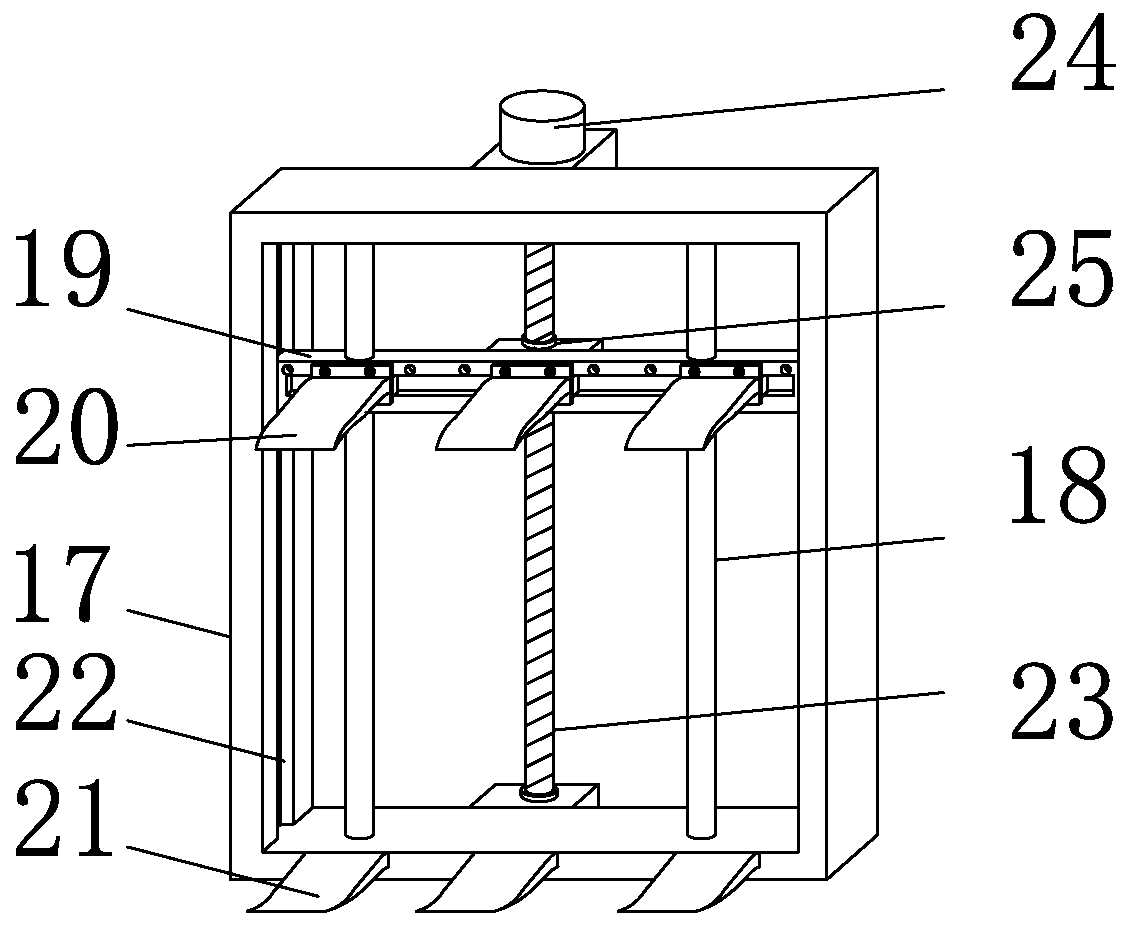

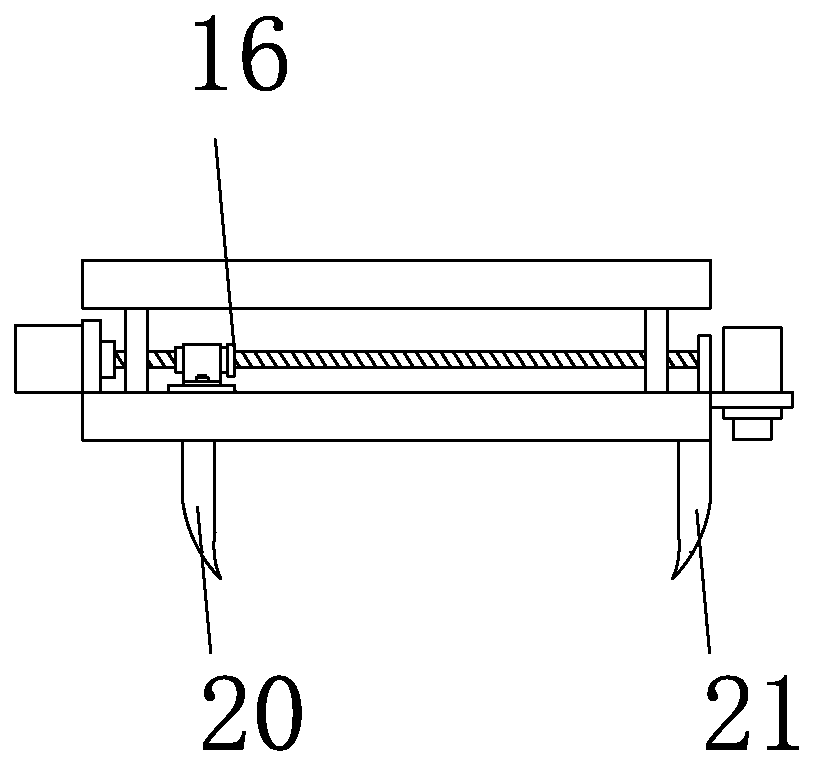

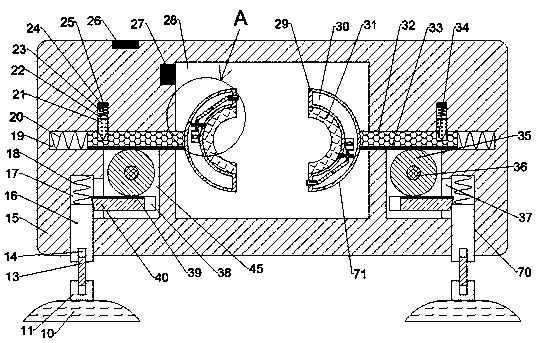

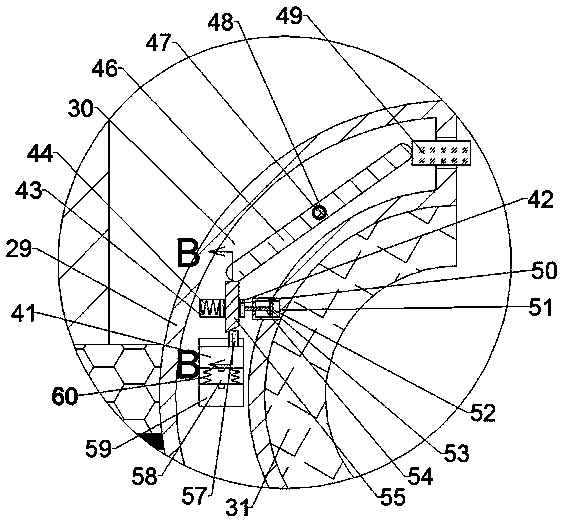

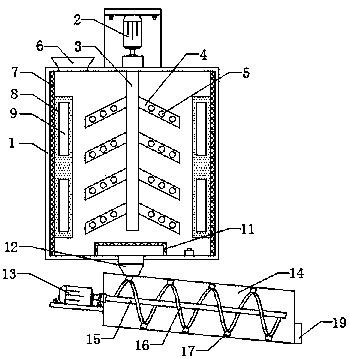

Duck roasting machine

InactiveCN107927015AQuality improvementEvenly heatedDispersed particle filtrationOven doors/gatesMotor driveEngineering

The invention relates to the technical field of food processing equipment, in particular to a duck roasting machine. The duck roasting machine comprises a machine body, a heating device, a rack, driving device and a control device, wherein the machine body is provided with a power chamber, a duck roasting chamber and an oil collecting chamber, the rack and the driving device are arranged in the machine body, the rack comprises a tray, a main rotary shaft and an auxiliary rotary shaft, a plurality of hooks are connected on the periphery of the tray through bearings, a main rotary motor is connected with the main rotary shaft, an auxiliary rotary motor is connected with the auxiliary rotary shaft, the main rotary motor drives the tray to rotate around the main rotary shaft, the auxiliary rotary motor drives the hooks to rotate, the heating device roasts ducks, and the control device controls the working states of the main rotary motor, the auxiliary rotary motor and the heating device. The duck roasting machine can rotate ducks automatically, manual turning is not required, ducks are uniformly heated, the quality of roasted ducks is improved, and the labor intensity of workers is reduced.

Owner:柳州市鼎福通用机械厂

Corrosion-prevention and compression-resistant lithium battery shell and production method therefor

InactiveCN105552254AExtended service lifeGuaranteed service lifeJackets/cases materialsLi-accumulatorsParyleneOxygen

The invention provides a corrosion-prevention and compression-resistant lithium battery shell. The lithium battery shell is characterized by comprising an aluminum layer, a parylene layer and a hard anti-scratch layer, wherein the aluminum layer is manufactured into the main body part of the battery shell; the parylene layer is plated on the outer side of the aluminum layer, and then the aluminum layer is coated with the hard anti-scratch layer; and the parylene layer is plated on the inner side of the aluminum layer. The corrosion-prevention and compression-resistant lithium battery shell has the beneficial effects that the service life of the lithium battery is greatly prolonged, the probability of bulging, capacity fading and other abnormal accidents in the use process of the lithium battery is lowered, the cracked area of the battery shell after the battery is extruded is decreased, the contact area between a cell and external oxygen is decreased, and the safety of the lithium battery in use is improved.

Owner:郭菲

Open mill

The invention relates to an open mill, and relates to the technical field of artificial leather production equipment. The open mill comprises a rack; two extrusion rolls driven by a hydraulic motor are rotatably arranged on the rack at intervals; multiple installing frames distributed in the axis direction of the extrusion rolls are arranged on the portions, located over the extrusion rolls, of the rack; a hydraulic cylinder is arranged on the lower surface of each installing frame, a piston rod of each hydraulic cylinder is provided with a fixing frame, and the vertical projections of axes of the fixing frames and the vertical projections of axes of the extrusion rolls incline in a staggered manner; and a cutter and multiple guiding wheels are arranged on the lower surface of each fixing frame in the length direction, and the cutters are inclined. According to the open mill, sheet rubber materials are cut through the cutters and turned over through the guiding wheels, manual operation is replaced, on the one hand, the labor intensity of workers is greatly reduced, on the other hand, potential safety hazards are reduced, and the probability that the hands are scalded after the workers work for a long time is decreased.

Owner:ZHEJIANG BAIDELI TANNERY CO LTD

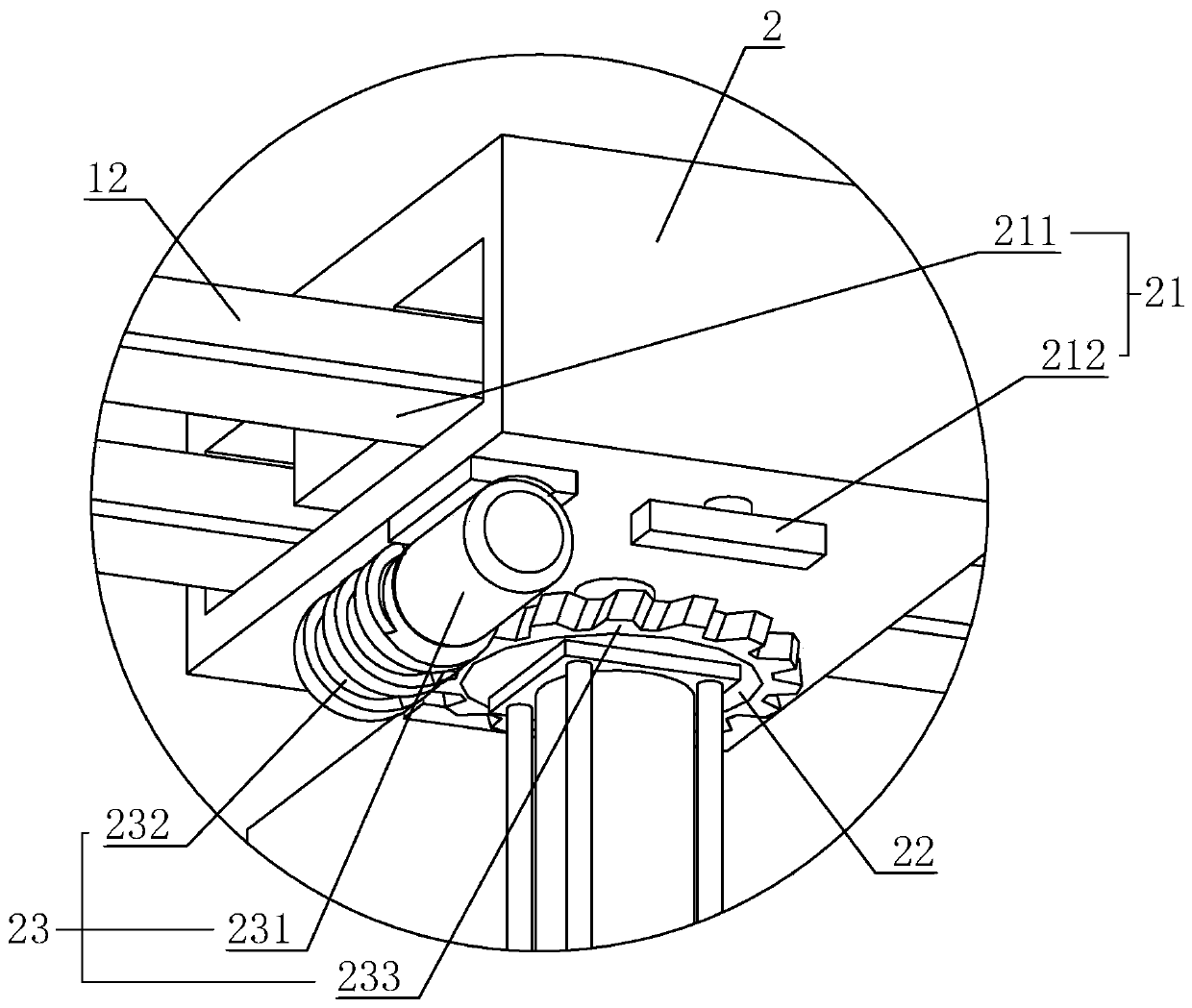

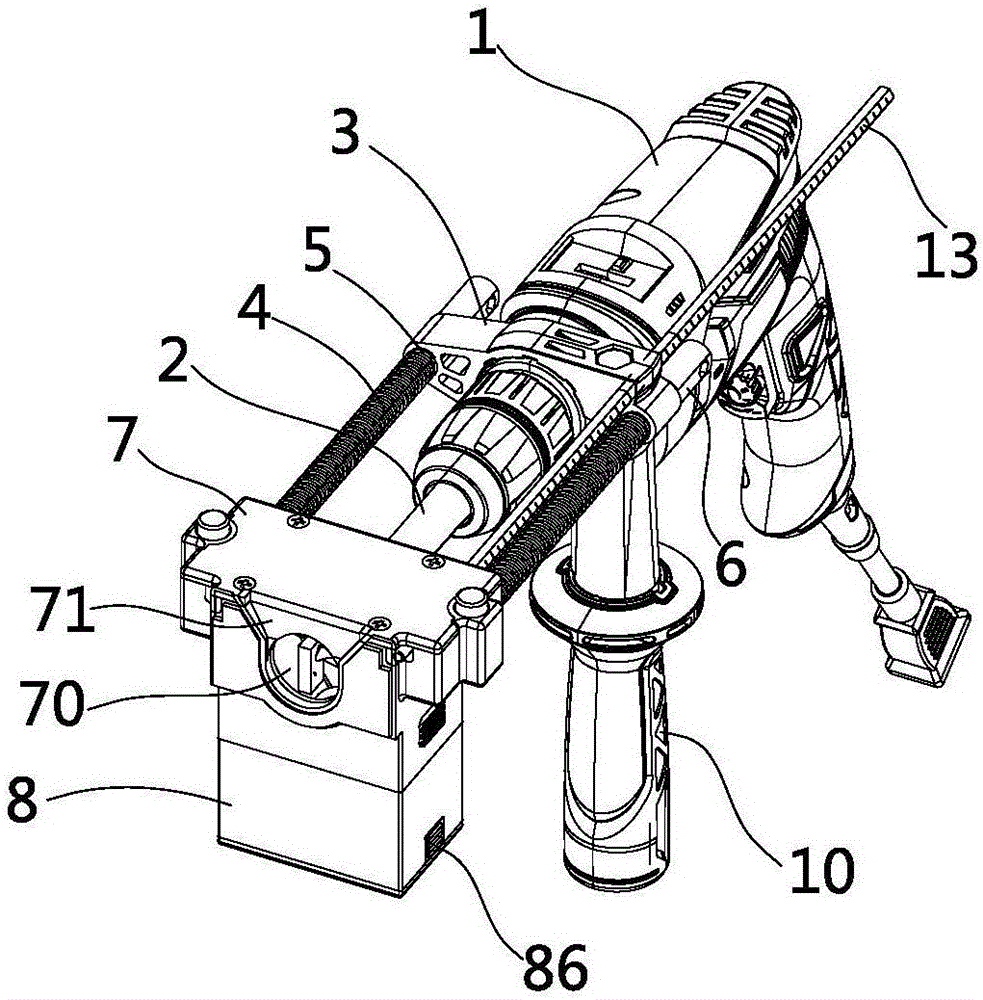

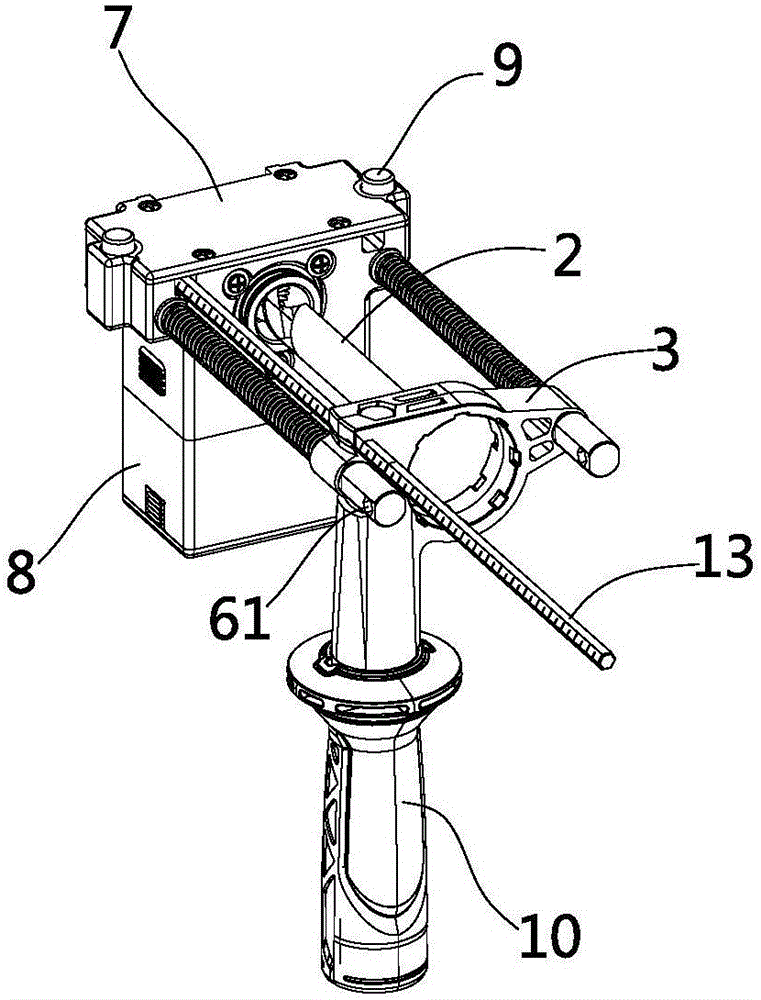

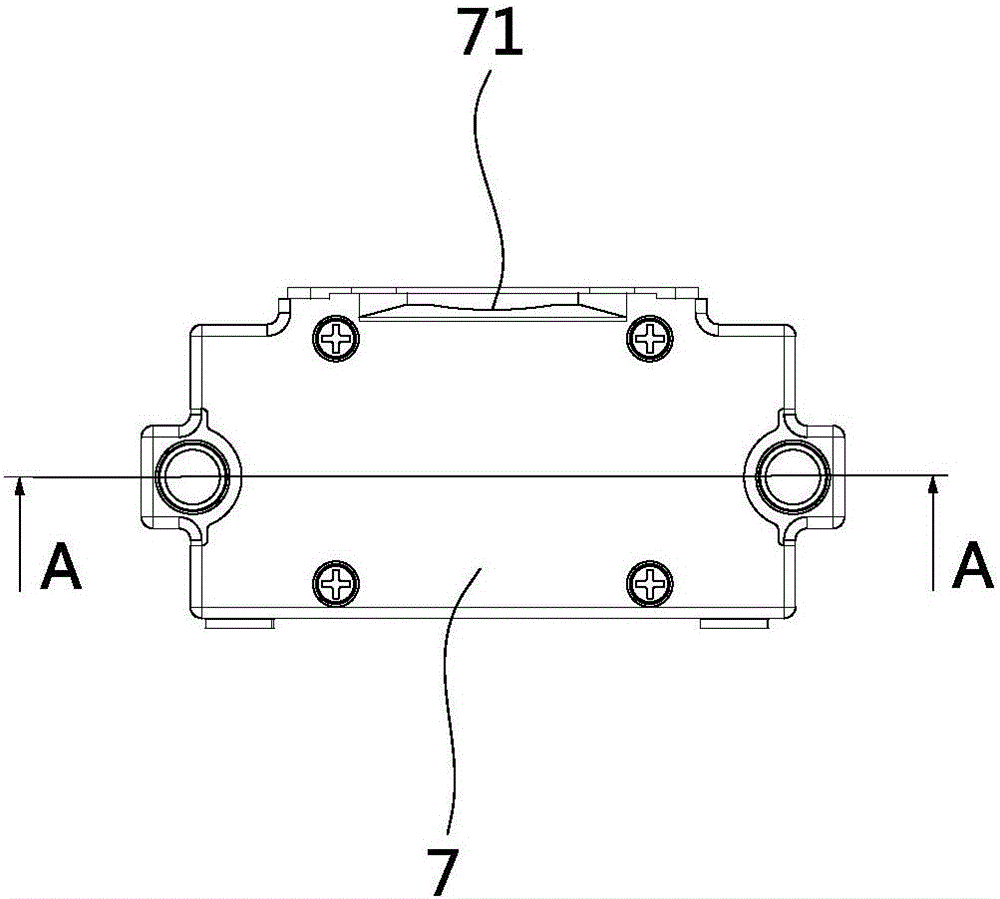

Dust collecting device for electric tool

PendingCN106584371AAvoid accumulationPrevent dispersionPortable power-driven toolsDrill bitElectrical and Electronics engineering

The invention discloses a dust collecting device for an electric tool, belongs to the technical field of electric tools, and aims at solving the technical problems of poor dust collecting effect and complex structure of an existing dust collecting device. The dust collecting device of the electric tool is characterized in that the electric tool comprises an electric tool body, and a drill bit mounted on the electric tool body. The dust collecting device comprises a box body, a supporting rod assembly, and a bracket mounted on the electric tool body; the box body is mounted on the bracket through the supporting rod assembly; the bracket is in slide fitting with the supporting rod assembly; the box body comprises an upper box body and a lower box body which are detachably connected; an air inlet and a through hole through which the drill bit can pass are formed in the upper box body; a ventilating dust collecting part, an air outlet, and a fan assembly mounted between the dust collecting part and the air outlet are arranged in the lower box body; when the fan assembly works, air flows from the air inlet into the dust collecting part and then is exhausted through the air outlet, so as to collect dust into the dust collecting part.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

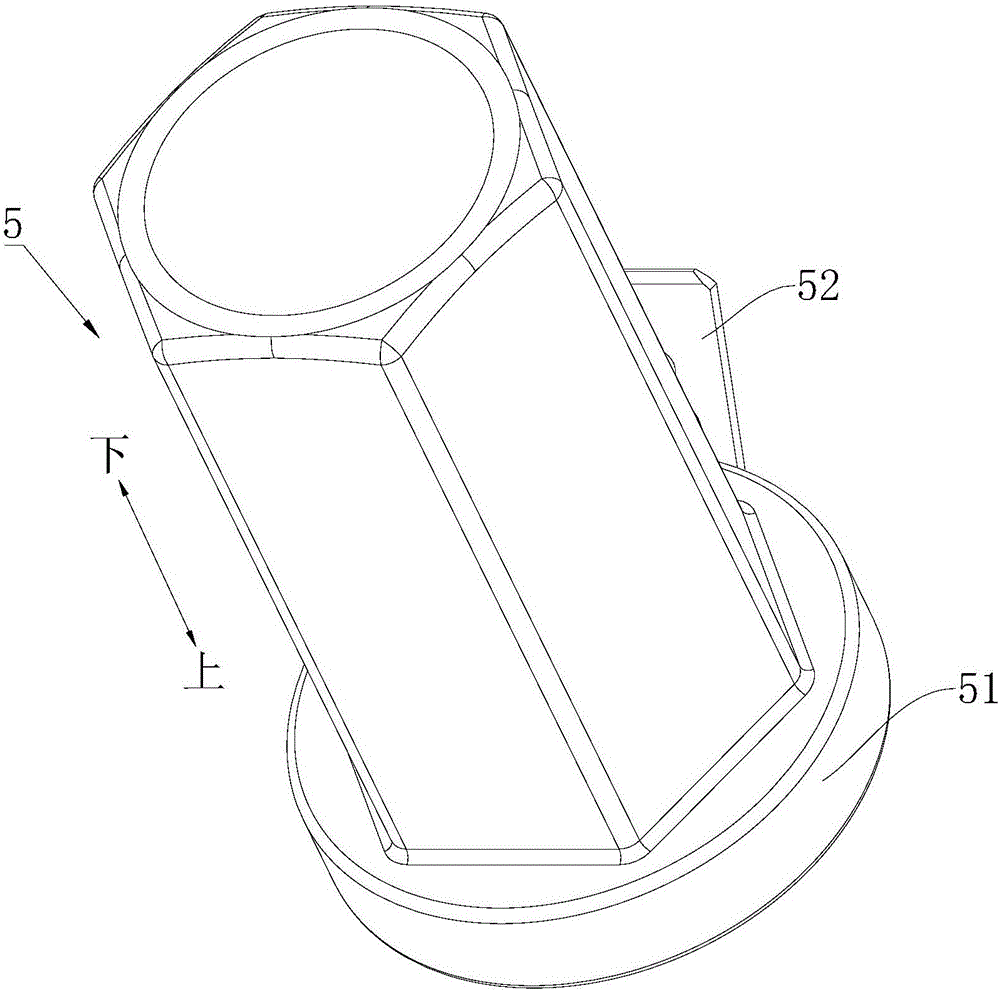

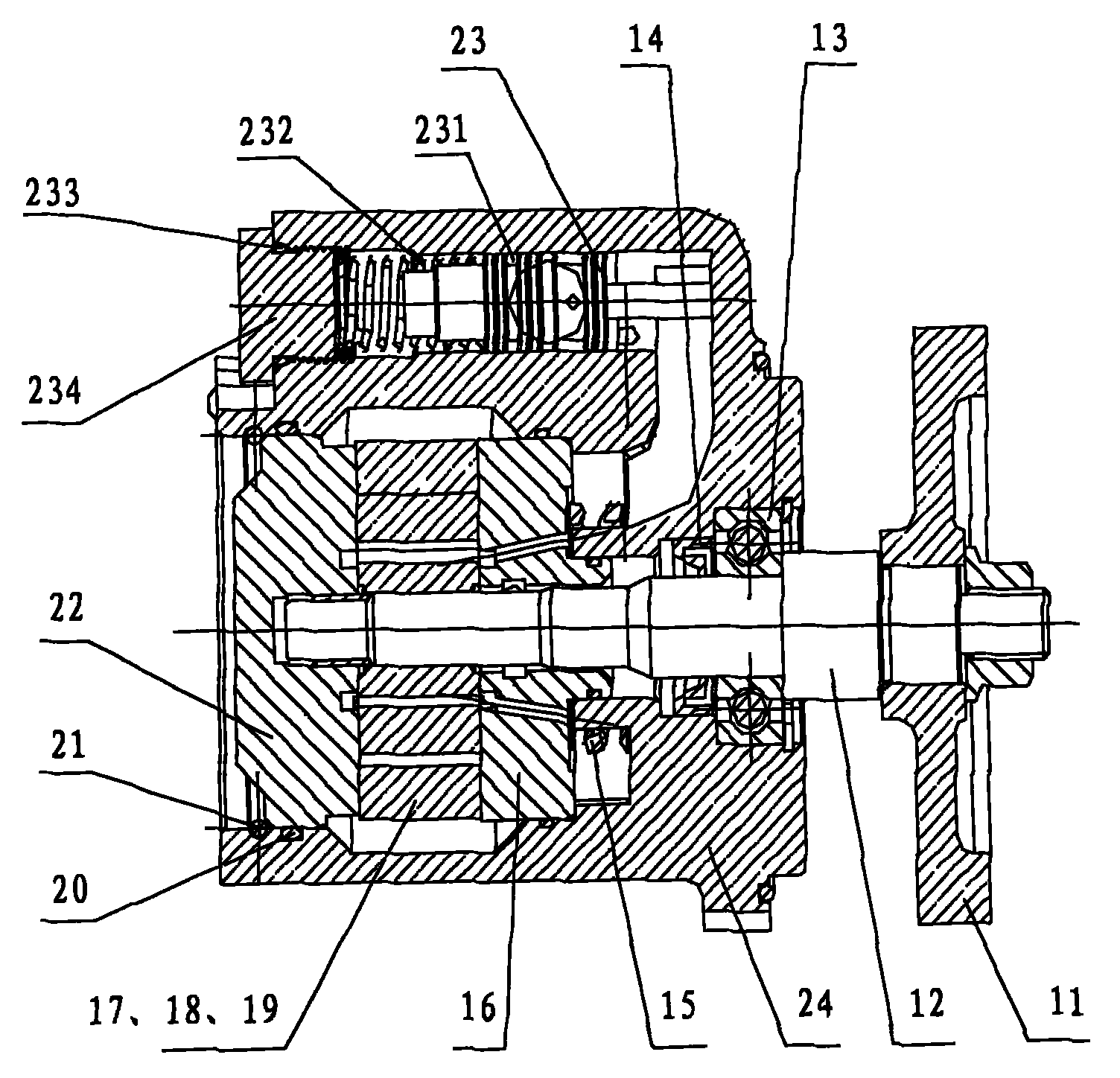

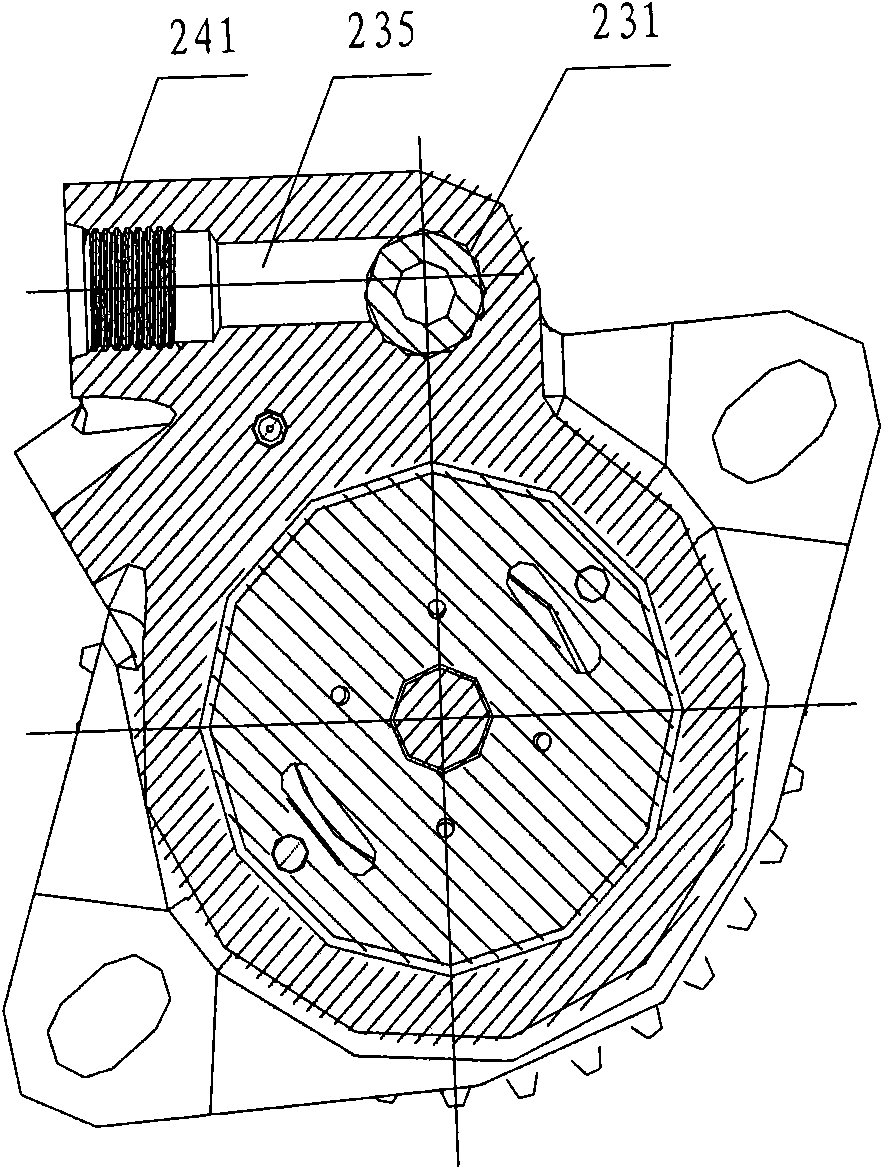

Overload protecting structure of mud pump

InactiveCN101586570AAvoid burnsReduce the chance of burnsSpecific fluid pumpsPump controlDrive motorShear force

The invention provides an overload protecting structure of a mud pump, the rotating shaft of the drive motor thereof is connected with the rotating shaft of the mud pump by a torque transmitting sleeve, the end part of the rotating shaft of the drive motor and the end part of the rotating shaft of the mud pump in the toque transmitting sleeve have a clearance, the rotating shaft of the drive motor and the rotating shaft of the mud pump are respectively fixed to the wall of the torque transmitting sleeve by overload protecting pins, the overload protecting pin for fixing the rotating shaft of the drive motor and that for fixing the rotating shaft of the mud pump are in orthometric distribution; the maximal shearing force of the overload protecting pins is preset according to the rated shearing force of the drive motor determined by the overload test. The invention can effectively prevent the blocking of the mud pump due to the pump cavity flow path and the burning of the drive motor caused by the overlarge shearing force for rotating the bearing.

Owner:李新桥

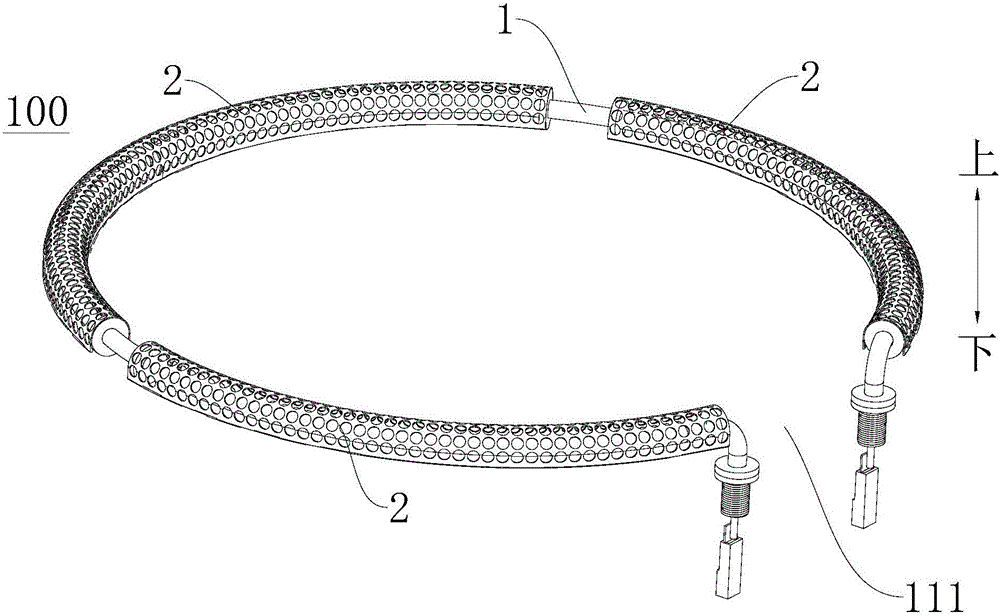

Heating pipe assembly for dish washing machine and dish washing machine provided with same

InactiveCN105942953AReduce the chance of burnsImprove the safety of useTableware washing/rinsing machine detailsOhmic-resistance heating detailsIgnition pointScalding

The invention discloses a heating pipe assembly for a dish washing machine and the dish washing machine provided with the heating pipe assembly. The heating pipe assembly for the dish washing machine comprises a heating pipe and a heating pipe cover, wherein the heating pipe comprises a heating pipe body and wiring terminals connected with the two ends of the heating pipe body; the heating pipe cover covers the outer surface of the heating pipe; and at least one part of the heating pipe cover is located above the heating pipe body and covers the upper surface of at least one part of the heating pipe. According to the heating pipe assembly for the dish washing machine, disclosed by the invention, the heating pipe cover covers the upper surface of at least one part of the heating pipe and a user cannot easily directly touch the heating pipe, so that the probability of scalding can be reduced. Furthermore, when tableware (such as plastic or other tableware with relatively low ignition points and melting points) falls off, the tableware cannot be in direct contact with the heating pipe easily, so that the tableware can be protected and the use safety of the heating pipe assembly is improved.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG +1

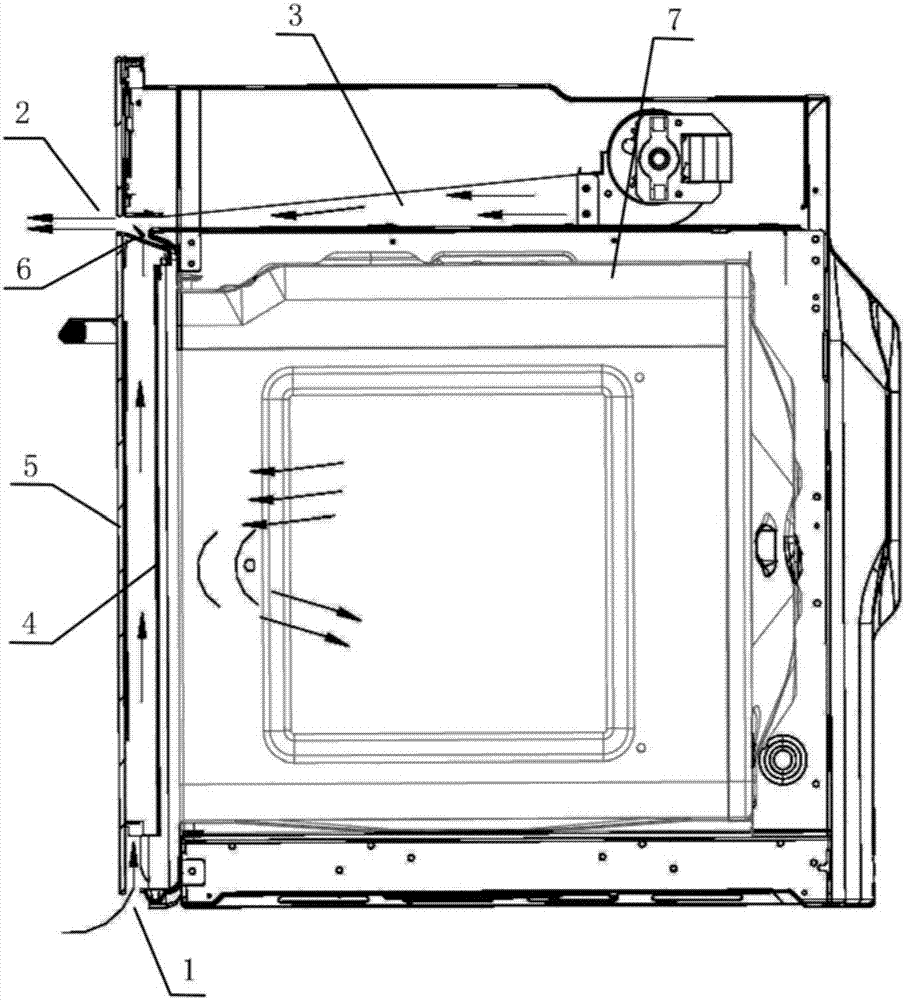

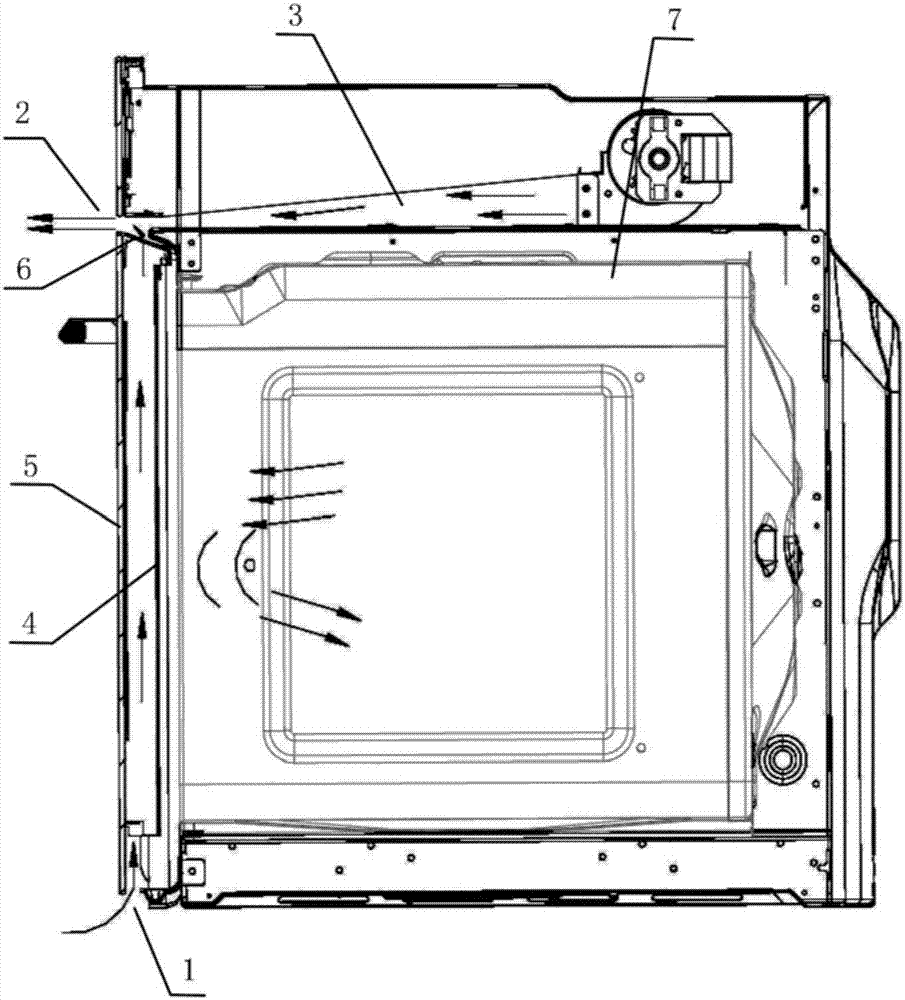

Door structure and baking oven applying same

PendingCN107997620AReduce the temperatureAchieve double coolingRoasters/grillsCold airProcess engineering

The invention relates to a door structure and a baking oven applying the same. The door structure comprises a door body with a cavity inside, and an air inlet and an air outlet are formed in the doorbody. By the design of the door structure, heat radiation inside an inner container of the baking oven can be taken away, cold air on the periphery of the baking oven can be sucked into a door, doublecooling of the door of the baking oven is realized, the temperature of the door of the baking oven is effectively reduced, and the probability of scalding caused by too high temperature of the door is maximally reduced. Great change of the structure is omitted, and cost and development time are maximally saved.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD

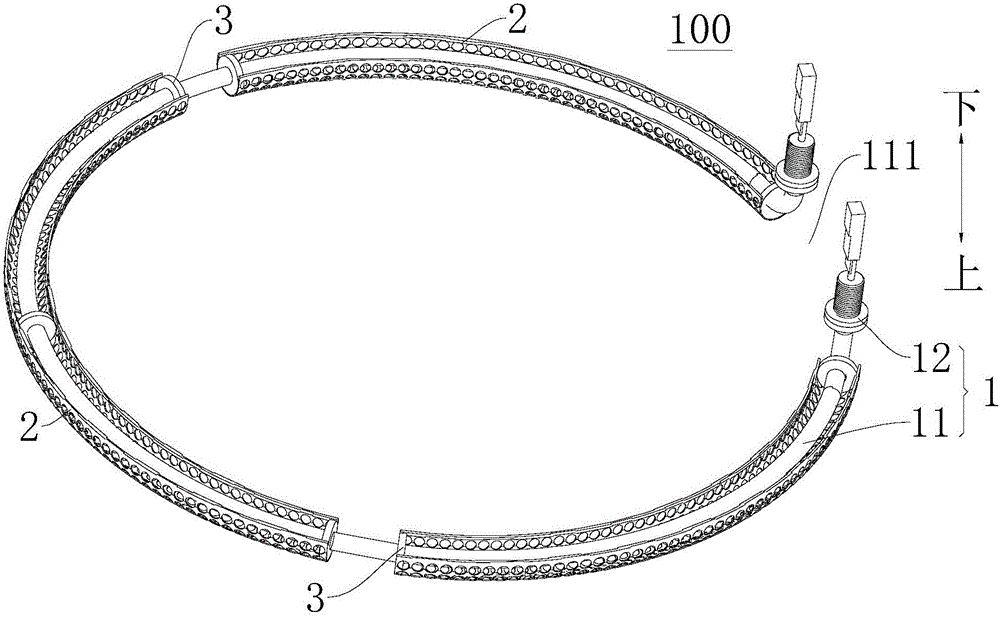

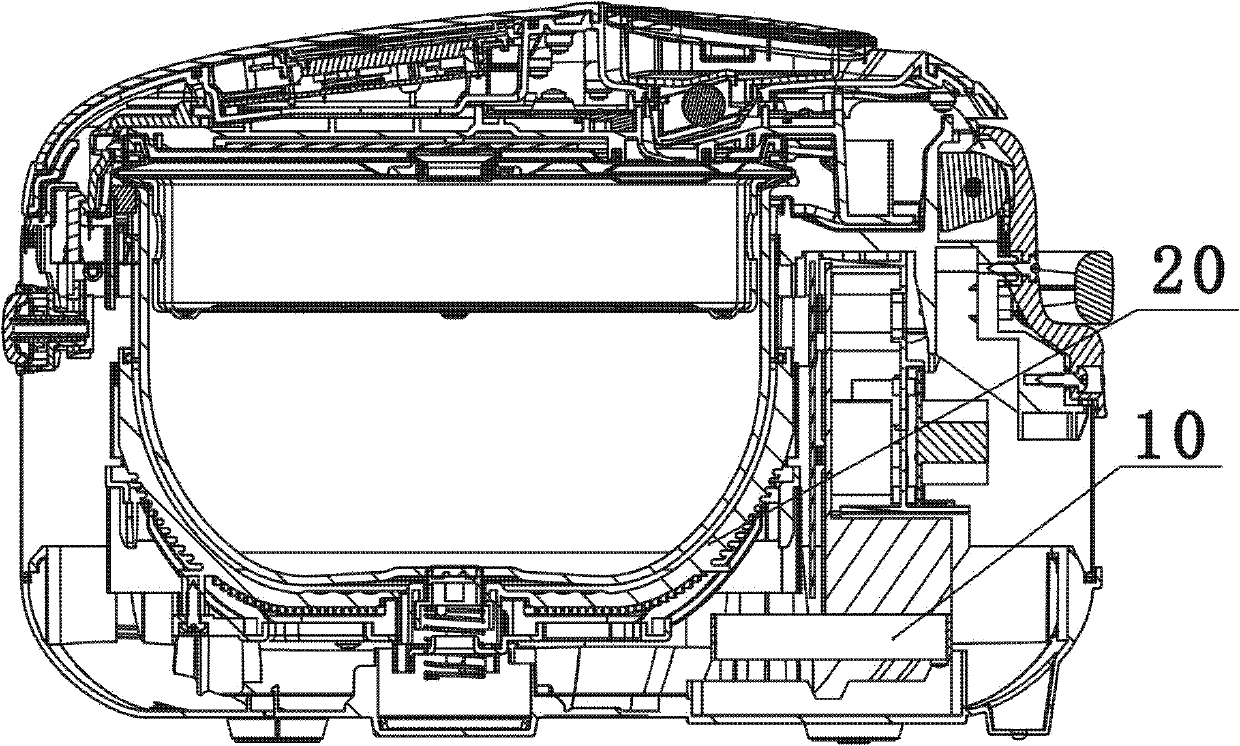

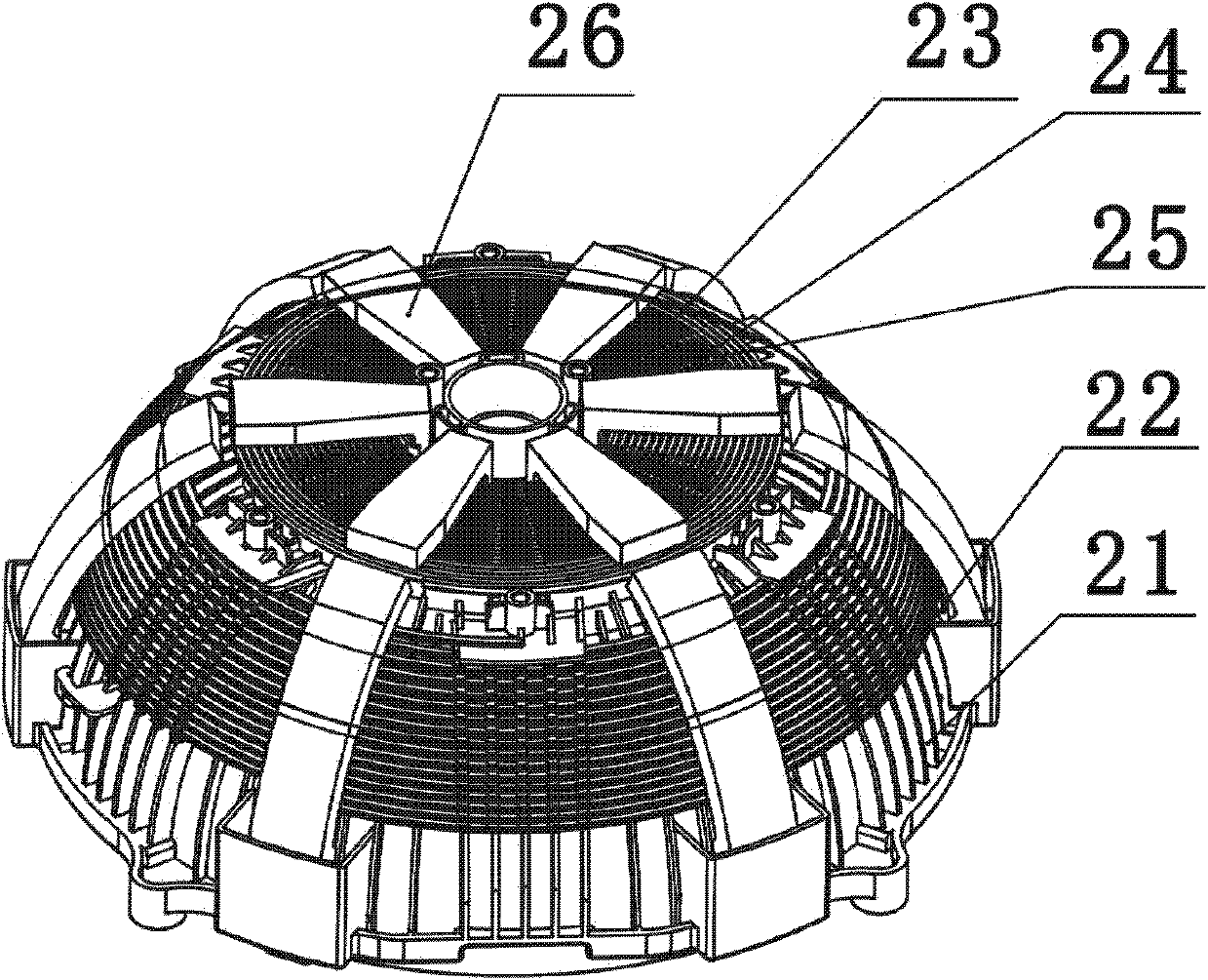

Electro-magnetic induction heating rice cooker

ActiveCN102697375AHigh strengthImprove heating efficiencyCoil arrangementsWarming devicesMagnetic heatingEngineering

The invention discloses an electro-magnetic induction heating rice cooker, relating to the technical field of kitchen appliances, and solving the problem about the low heating efficiency of the heating wire coil of the existing electro-magnetic induction heating cookware. The electro-magnetic induction heating rice cooker disclosed by the embodiment of the invention comprises a cooling fan, a protective cover and a heating coil, wherein the heating coil comprises a bottom heating coil and a side heating coil; the bottom heating coil is installed on the bottom part of the protective cover; the side heating coil is installed on the bottom side wall of the protective cover in an intertwining way; a plurality of support ribs arranged along the radial direction are arranged on the side wall of the protective cover; the side heating coil is erected on the support ribs; the clearances between the side heating coil and the side wall of the protective cover form a heat dissipation passage; the side heating coil is formed by the harnesses of flat wires in the intertwining way; a slot is formed on each support rib; and the flat wires are plugged into the slots. The electro-magnetic induction heating rice cooker is mainly used as the cookware, including electro-magnetic heating rice cookers, electro-magnetic heating electric pressure cookers and the like.

Owner:JOYOUNG CO LTD

Styrene butadiene rubber (SBR) sponge composite material and preparation method thereof

The invention discloses a styrene butadiene rubber (SBR) sponge composite material and a preparation method thereof and relates to the preparation method of the SBR sponge composite material. SBR rubber 1502 is prepared by the following steps of: sequentially adding 30 to 50 mass parts of ethylene propylene terpolymer, 170 to 180 mass parts of light calcium carbonate serving as a filler, 28 to 30 mass parts of argil, 23 to 25 mass parts of black smoke serving as a reinforcing agent N330, 67 to 70 mass parts of naphthenic oil serving as a softener, 2.7 to 3 mass parts of dispersant AFLUX-42, 2 to 2.3 mass parts of antioxidant, 2.5 to 2.8 mass parts of protective wax, 2.7 to 2.8 mass parts of stearic acid, 9 to 9.5 mass parts of zinc oxide, 5 to 6 mass parts of vulcanizing agent and vulcanizing agent aid, 19 to 21 mass parts of activated charcoal (AC) foaming agent, 70 to 73.5 mass parts of flame retardant and 2.5 to 2.8 mass parts of processing aid into an internal mixer for mixing, performing thin passing, cooling and extruding; performing primary vulcanization and secondary vulcanization; and foaming. The composite material has the advantages that: an ethylene-propylene-diene monomer (EPDM) has high ageing resistance, saturation non-polarity and non-self-reinforcing property and can absorb a large amount of oil and a large number of fillers; simultaneously, the flame retardant is added, so that the product has high flame retardance and high antistatic property.

Owner:ZHIHE FUJIAN TECH

Myrica rubra branch pruning and maintenance method

ActiveCN106489647AEasy to reverseStretch direction is easy to controlCultivating equipmentsHorticulture methodsEngineeringMyrica rubra

Provided is a Myrica rubra branch pruning and maintenance method. The method is characterized by comprising the following steps: (1) determining a pruning object and a pruning period, the pruning object: the Myrica rubra tree with a tall tree body and an inner chamber illuminated by dim light, selecting the branches of which the inserted positions in the Myrica rubra tree are unreasonable, the stretching directions are not ideal and the thickness of the bases are 1.5-4 cm; the pruning period: after the end of Myrica rubra harvest, choosing to conduct pruning in a sunny day or a dry cloudy day before the weather 'into the volts'; (2) pruning operation, using a cutting knife to carve more than three lines on the selected branches in the longitudinal direction, with the carved lines deeply reaching the xylem, then holding the carved branches and forcing to twist, and homeopathic changing the stretching directions of the branches and rotating until the desired position; (3) maintenance after pruning. The method has the advantages of simple operation and good pruning effect.

Owner:慈溪市林特技术推广中心

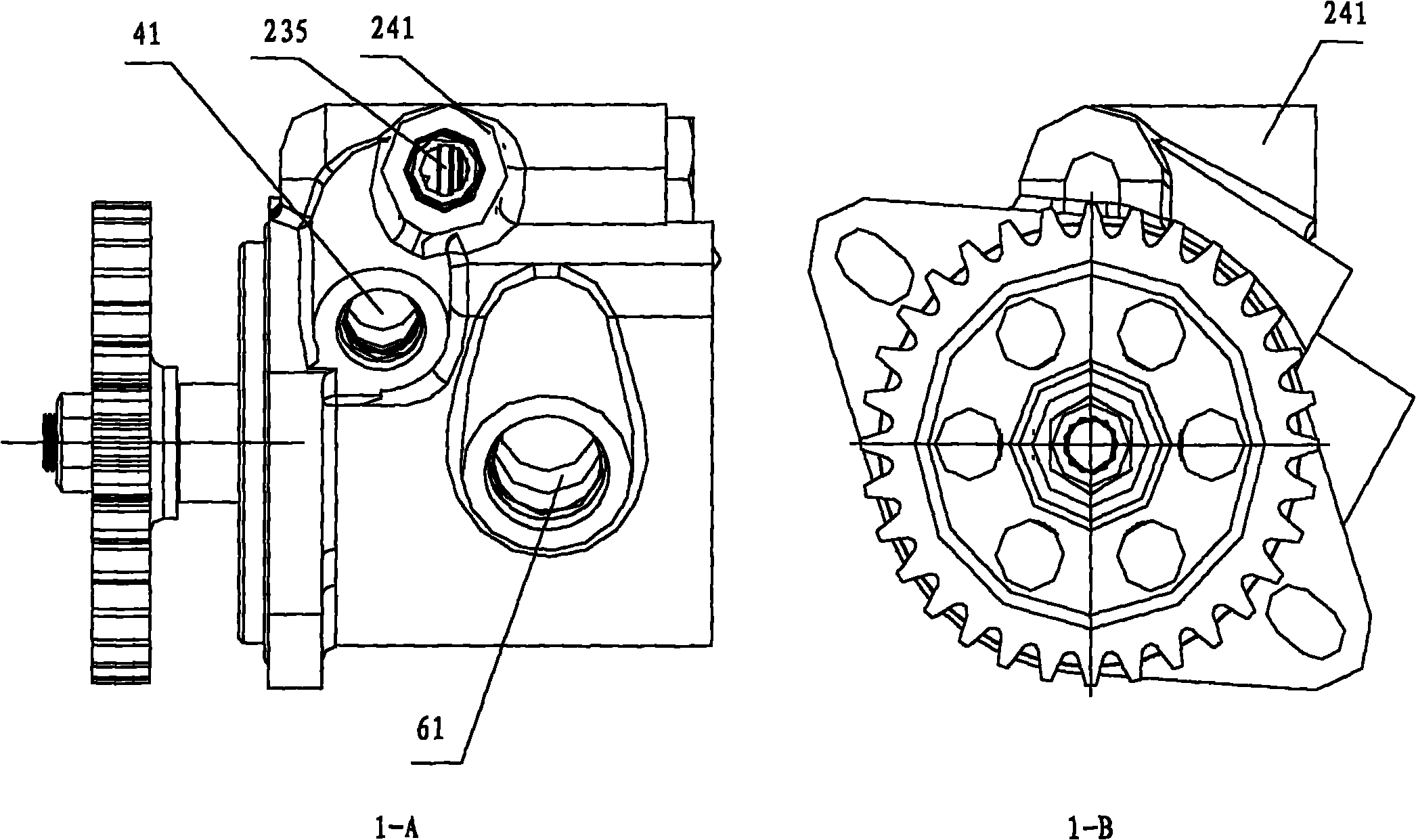

Steering pump of automobile power steering system

InactiveCN101988495AImprove the lubrication effectExtend your lifeRotary piston pumpsFluid steeringGear driveCentrifugal force

The invention discloses a steering pump of an automobile power steering system, which comprises a gear driven by an engine, a spindle and a rotor, wherein a vane in the rotor is attached to the inner surface of a stator tightly under the action of centrifugal force to complete the process of oil sucking and pressing, an oil inlet of the steering pump is communicated with a steering oil storage tank, an oil outlet is communicated with a steering gear assembly. In addition, the steering pump also comprises a current-stabilizing overflow valve which is communicated with a steering pump oil chamber and used for controlling the maximum rated pressure of oil liquid in the steering pump, an overflow hole is arranged at the valve hole of the current-stabilizing overflow valve on a steering pump shell, and the overflow hole is communicated with the steering oil storage tank. The steering pump has the advantages of simple structure and good reliability; and by the invention, the problem that the oil temperature of the steering pump is raised quickly in specific conditions can be solved efficiently.

Owner:GUANGXI YUCHAI MASCH CO LTD

Energy-saving high-efficiency coffee bean baking machine

ActiveCN108606344AReduce consumptionImprove baking efficiencyFood treatmentCombustorProcess engineering

The invention discloses an energy-saving high-efficiency coffee bean baking machine. The energy-saving high-efficiency coffee bean baking machine comprises a base, wherein a baking machine body, a cooling disk and a tail gas box are mounted at the top end of the base; the baking machine body is located between the cooling disk and the tail gas box; an inner cylinder and a gas filtering plate are mounted in the baking machine body; the gas filtering plate is located below the inner cylinder; a thermal mixing cavity and a combustion cavity are separately formed in two sides of the gas filteringplate; a combustor is mounted in the combustion cavity; and a fuel gas pipe is connected between the combustion cavity and the base. According to the energy-saving high-efficiency coffee bean baking machine disclosed by the invention, an exhaust pipe, the tail gas box, a gas return pipe, the thermal mixing cavity, a fan, the gas filtering plate and the combustion cavity are arranged, when the baking machine operates, and fuel gas enters the baking machine body, the fuel gas is combusted through ignition of the combustor, so that expansion combustion is realized in the combustion cavity, and the temperature is quickly raised; after combustion, generated high-temperature gas penetrates through the gas filtering plate to enter the thermal mixing cavity, and then the high-temperature gas is guided to the inner cylinder through the fan to heat and bake coffee beans.

Owner:扬州市生态科技新城杭集中小企业服务中心有限公司

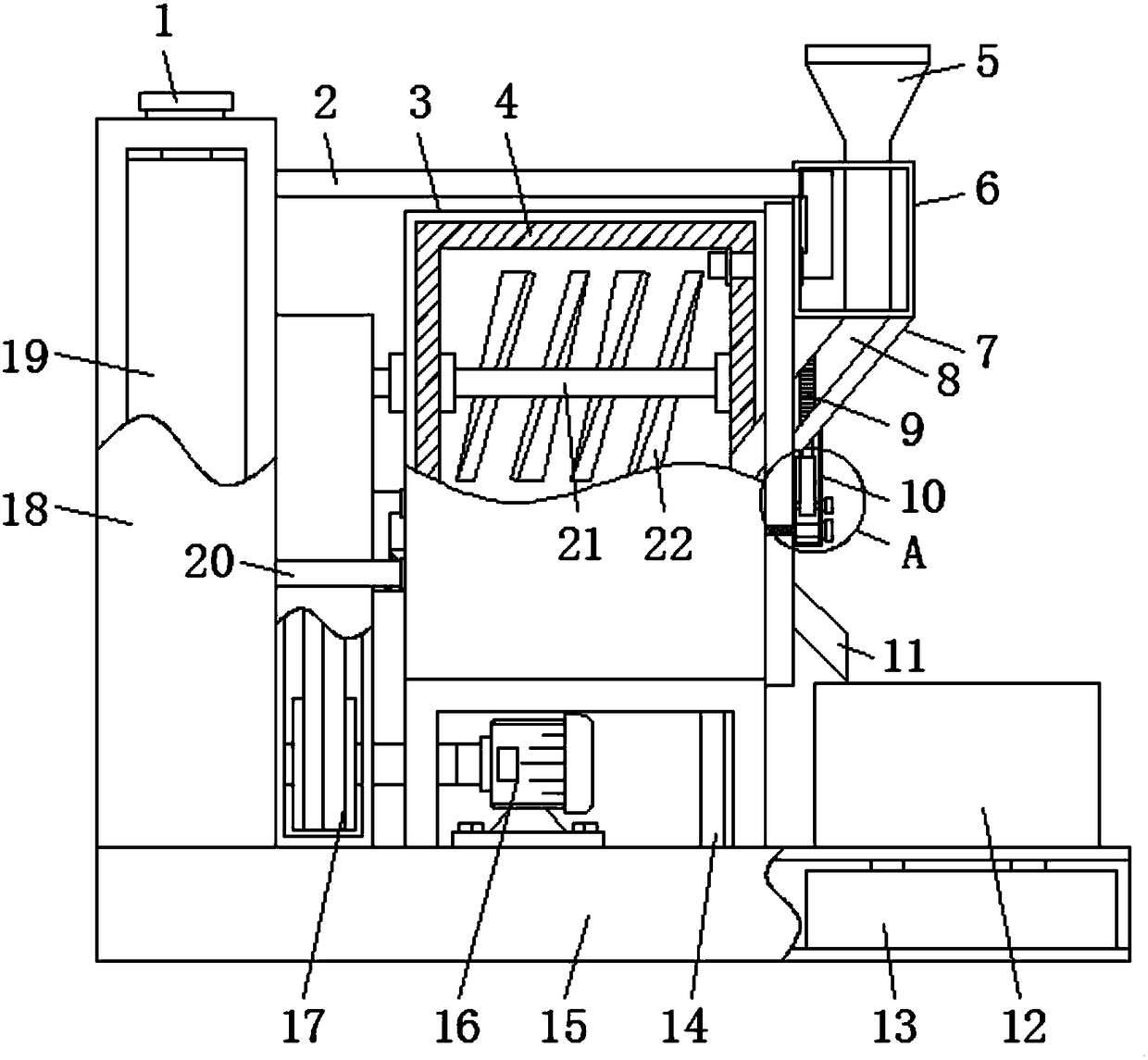

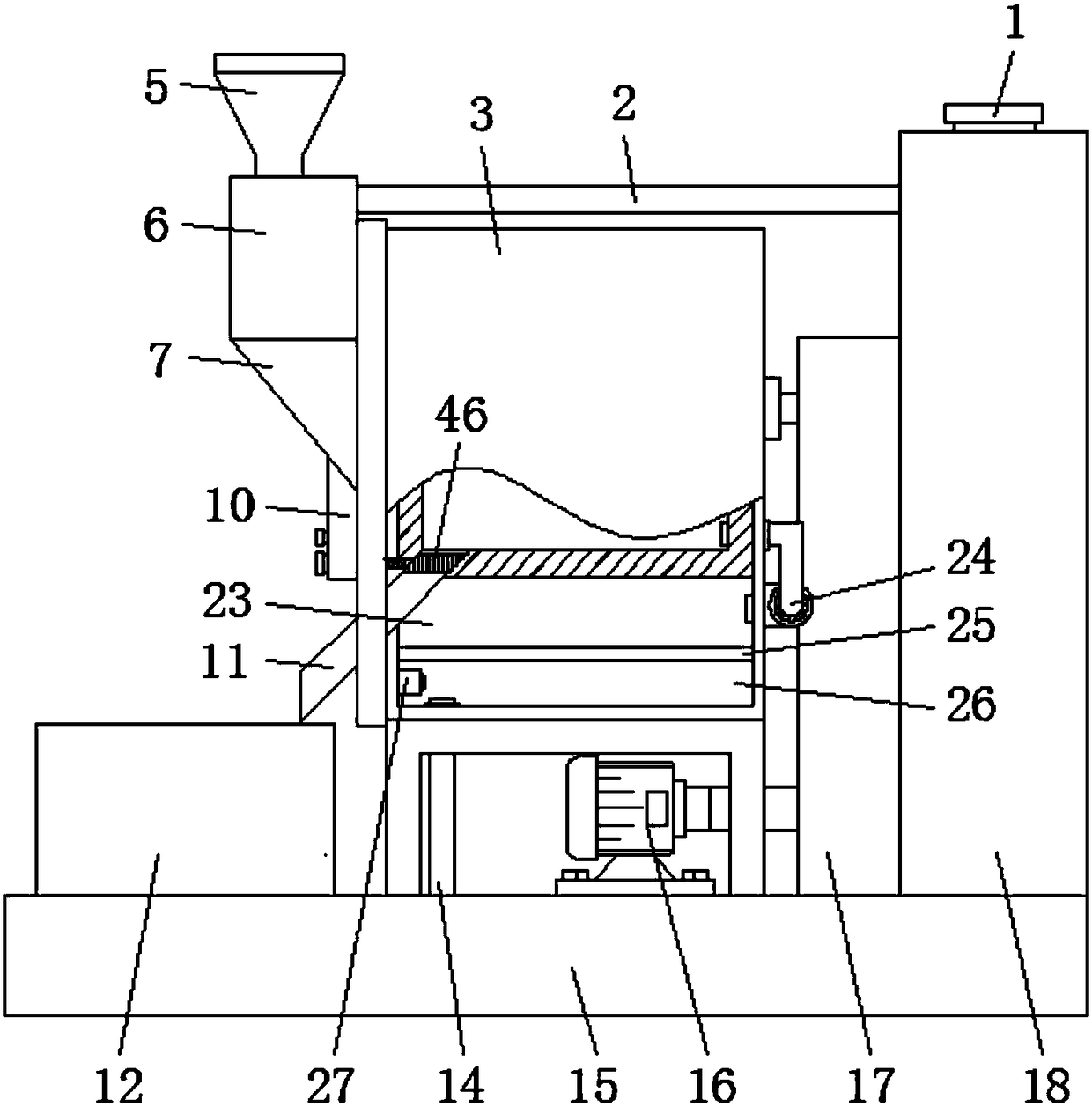

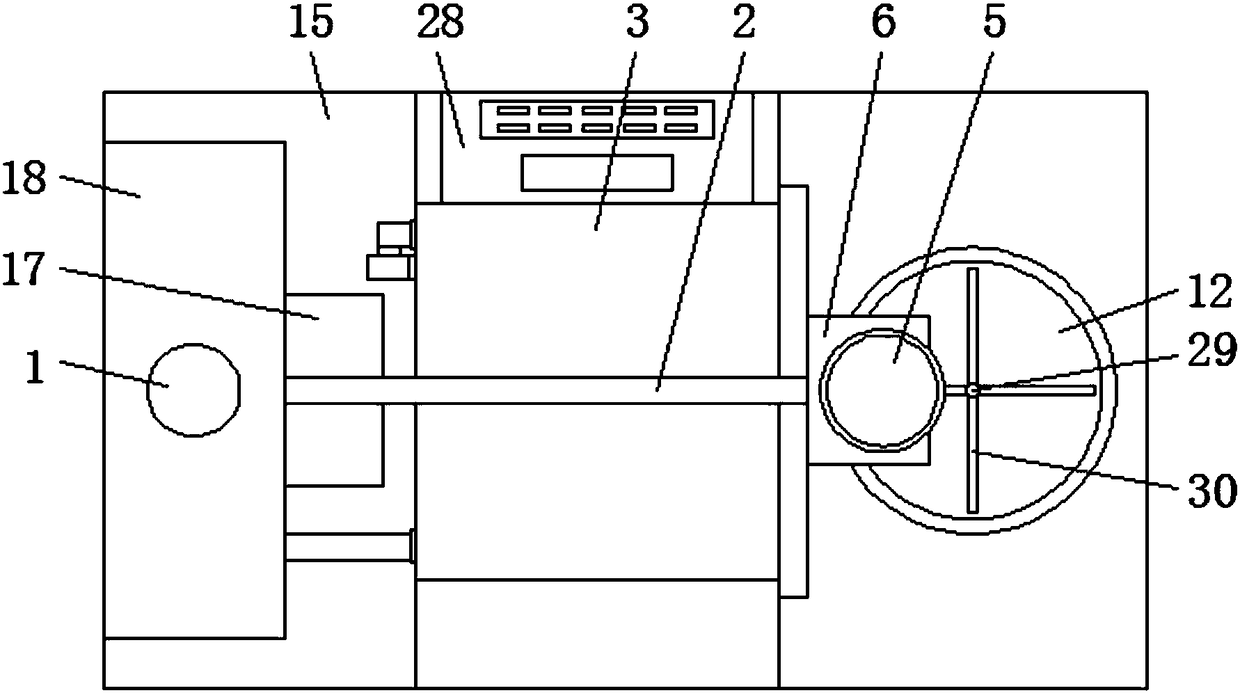

Environment-friendly easily-decomposed corrugated paper and processing technology thereof

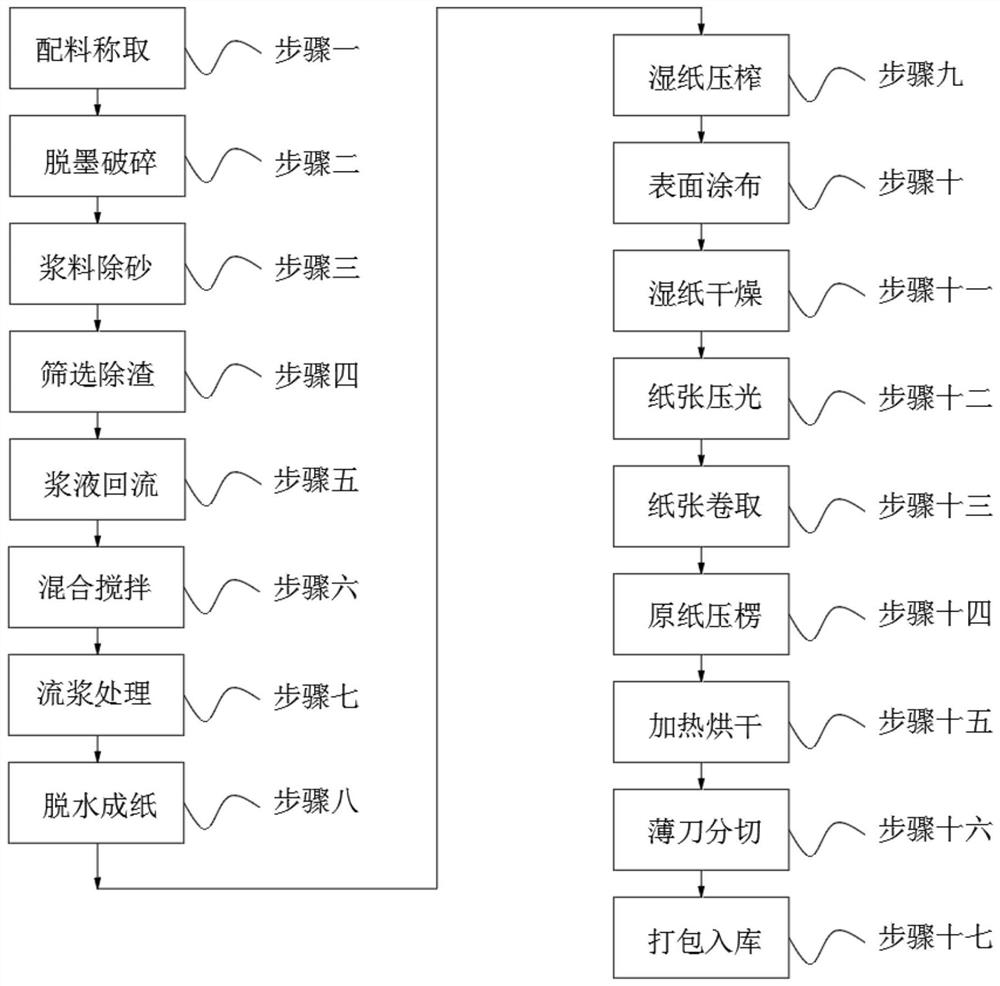

InactiveCN111910456ALow costImprove economic efficiencyMechanical working/deformationPaper recyclingCorn starchFlame resistance

The invention discloses environment-friendly easily-decomposed corrugated paper and a processing technology thereof.The environment-friendly easily-decomposed corrugated paper is prepared from 30-40 parts of straw pulp board, 100-120 parts of waste paper, 0.5-0.7 part of deinking agent, 0.12-0.2 part of retention aid, 1-3 parts of polyurethane, 4-7 parts of flame retardant and 5-10 parts of corn starch glue.The processing technology of the environment-friendly easily-decomposed corrugated paper comprises the following steps: 1, ingredient weighing; 2, deinking and crushing; 3, slurry desanding; 4, screening and deslagging; 5, residual slurry refluxing; 6, mixing and stirring; 7, slurry flowing treatment; 8, dehydrating to form paper; and 9, wet paper squeezing. According to the method, pulp residues are recycled into a high-concentration hydraulic crusher to be crushed and filtered to form accepted pulp, so that recycling of waste pulp residues is achieved; corrugated paper is bonded through corn starch glue, so that decomposition of the corrugated paper is facilitated; the corrugated paper is rapidly dried through a carton drying machine, so that the solidification time of the corn starch glue is shortened; and by adding a flame retardant agent, the flame retardant property of the corrugated paper is improved.

Owner:广大纸品(中山)有限公司

Plant firmware, production method of plant firmware and heat-not-burning cigarette with plant firmware

PendingCN110464042AReduce the temperatureThere will be no burning mouthTobacco treatmentTobacco devicesAdhesiveHeat not burn

The invention discloses plant firmware, a production method of the plant firmware and a heat-not-burning cigarette with the plant firmware. The plant firmware has a first end and a second end; at least one diffusion channel is formed from the first end to the second end of the plant firmware; and the plant firmware is prepared by molding tobacco paste formed by mixing 4-6 parts by weight of tobacco raw material powder, 5-9 parts by weight of a smoking agent, 4-7 parts by weight of a forming agent and 2-4 parts by weight of an adhesive.

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

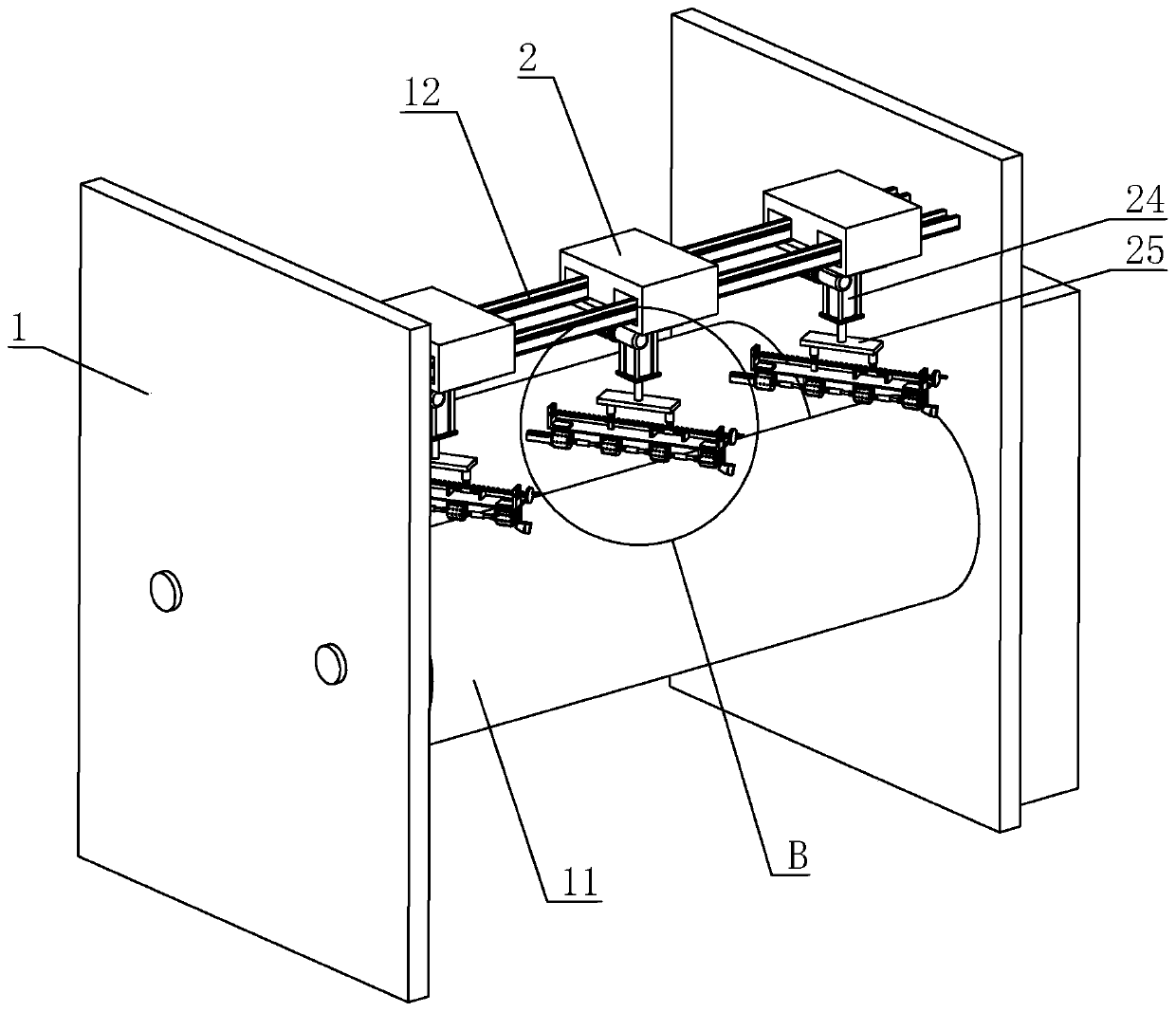

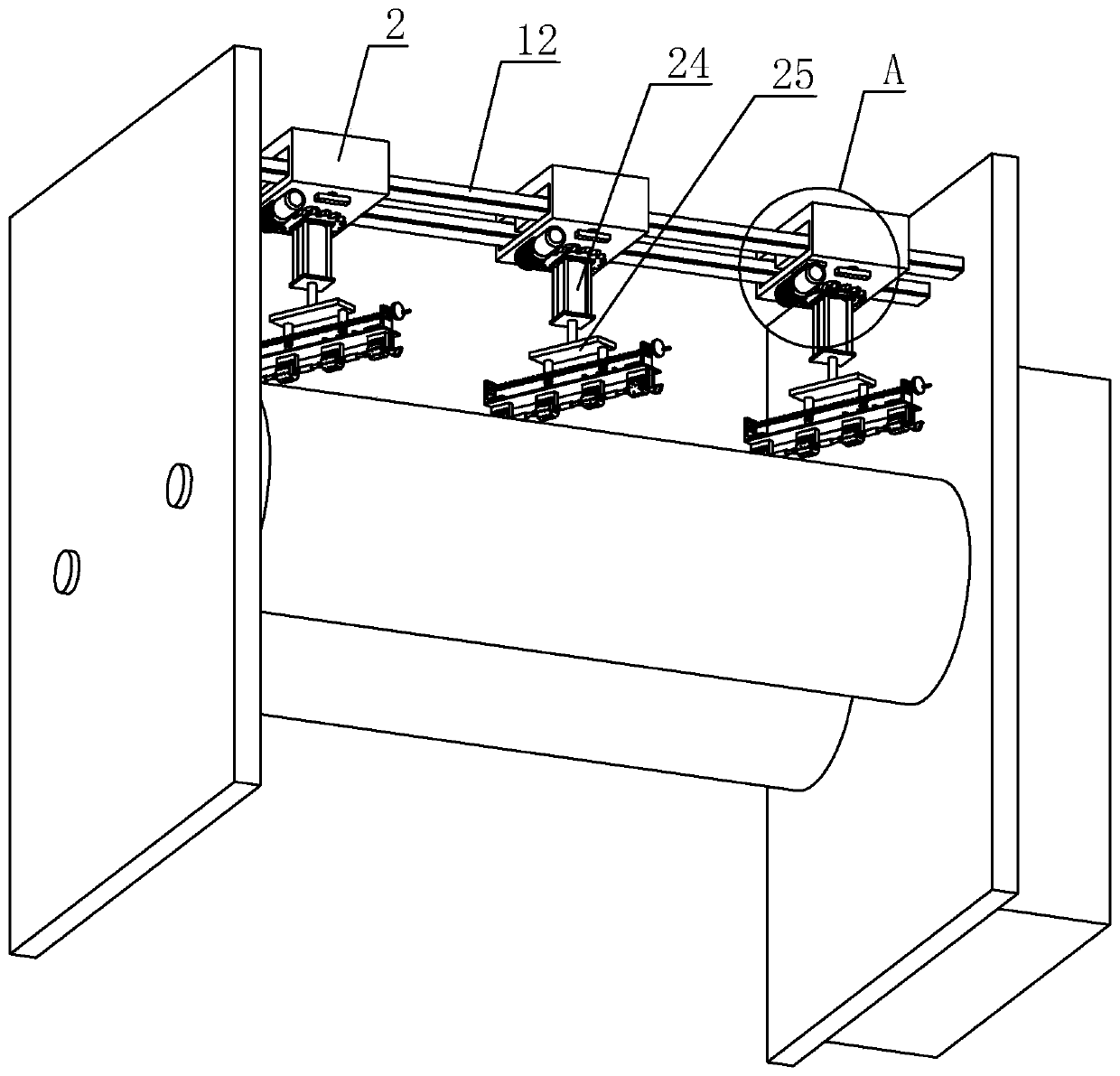

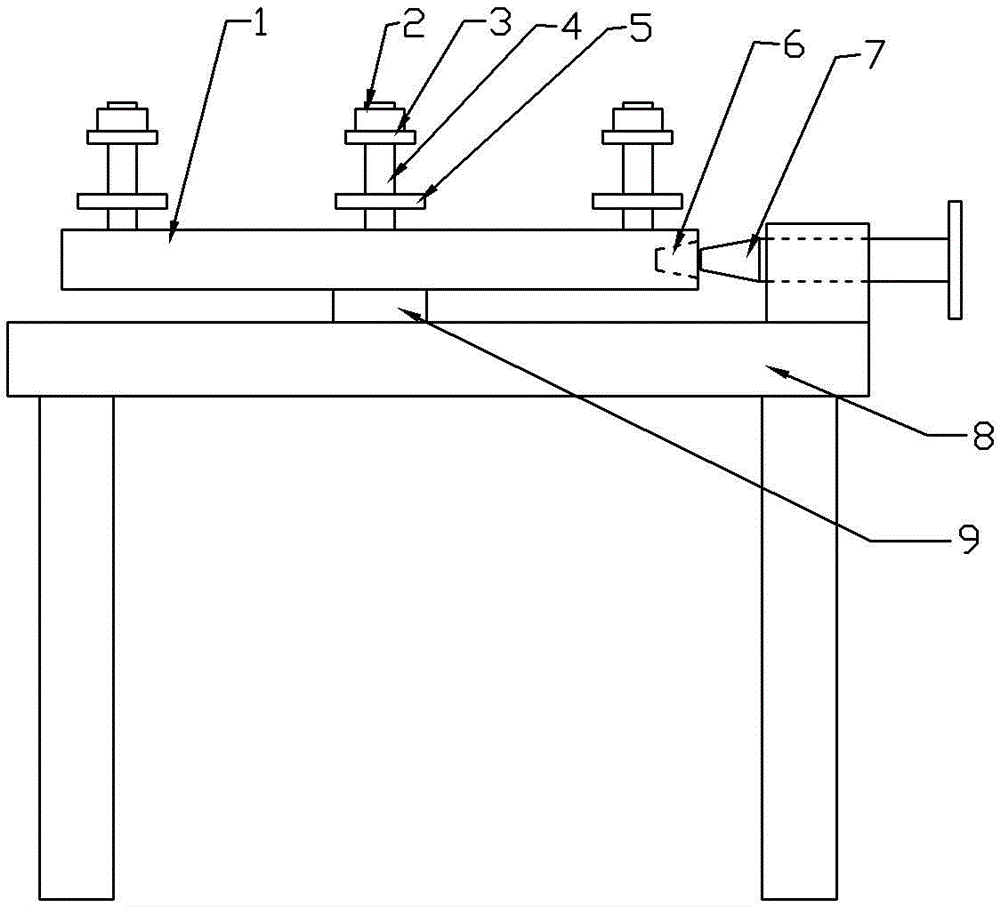

Gear clamping device of gear shaping machine

InactiveCN105290525AImprove processing efficiencyShorten the intervalGear-cutting machinesGear teethGear wheelEngineering

The invention discloses a gear clamping device of a gear shaping machine. The gear clamping device comprises a rack, a bearing table is arranged above the rack, and a rotating shaft is arranged between the bearing table and the rack. The axis of the rotating shaft is perpendicular to the top face of the bearing table, the upper portion of the rotating shaft is fixedly connected with the bearing table, and the lower portion of the rotating shaft is rotatably connected with the rack. The bearing table is provided with a plurality of limiting holes, the rack is provided with limiting rods matched with the limiting holes, and the limiting rods and the rack are in threaded connection. At least two locating columns are arranged on the top of the bearing table, the axis of each locating column is parallel to the axis of the rotating shaft, and the locating columns are distributed in an annular array with the axis of the rotating shaft as the central line. The locating columns are rotatably connected with the bearing table, and fastening mechanisms used for pressing gears are arranged on the upper portions of the locating columns. The gear clamping device has the beneficial effect of improving the gear machining efficiency.

Owner:CHONGQING YUQING MACHINERY MFR

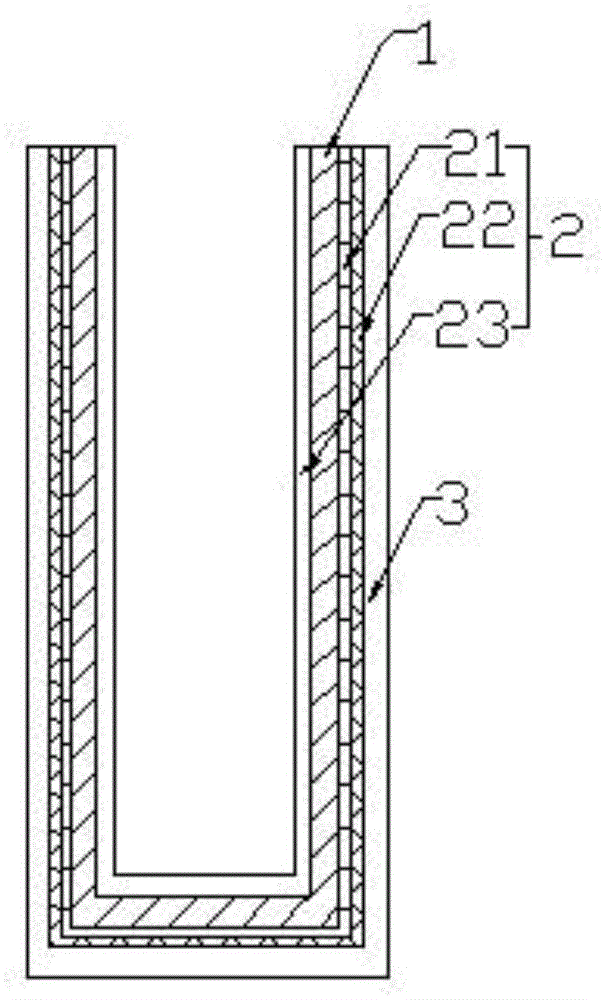

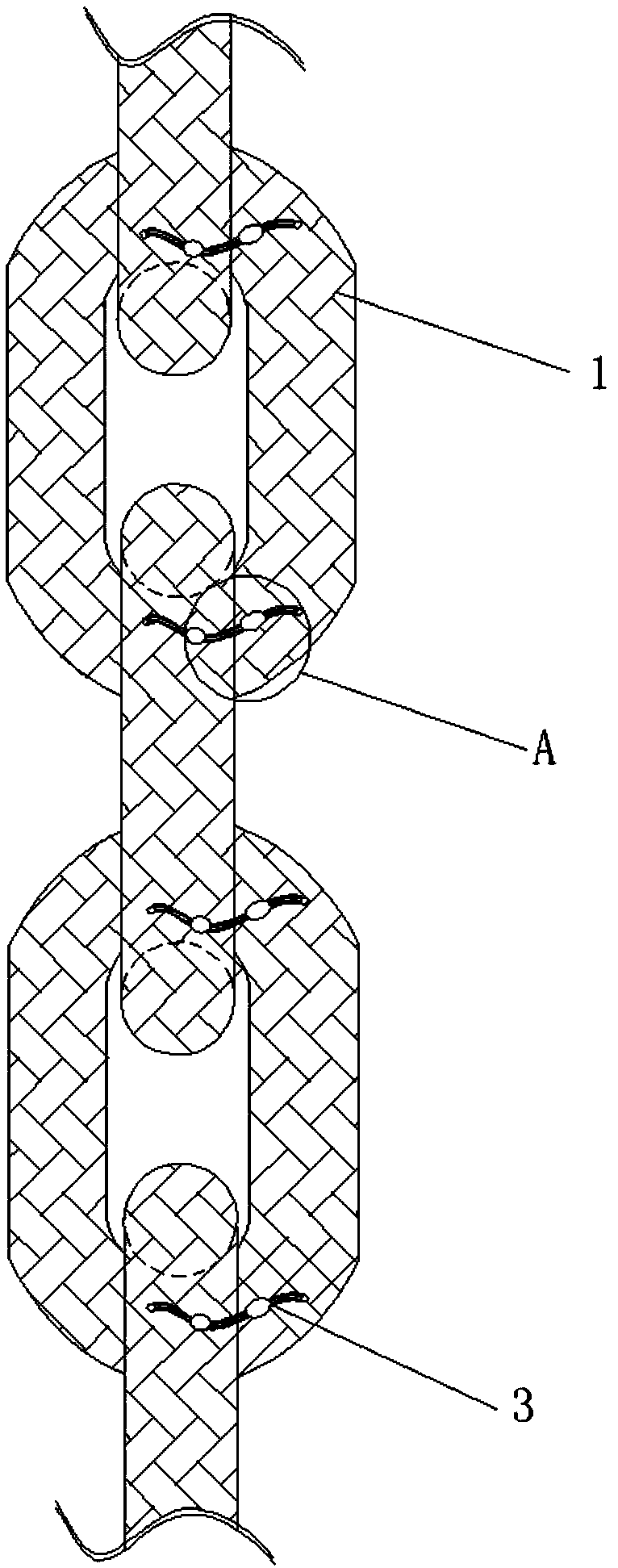

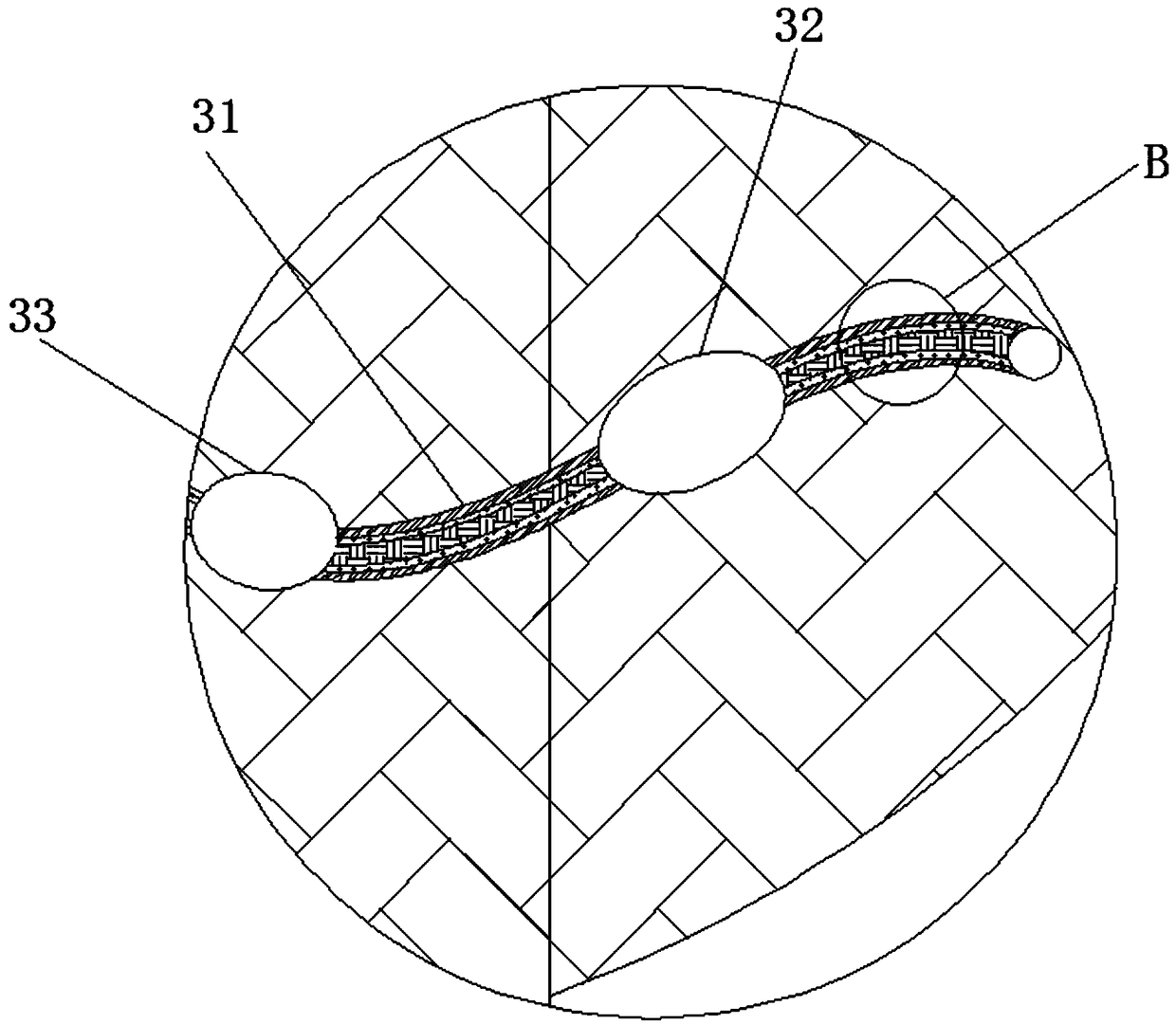

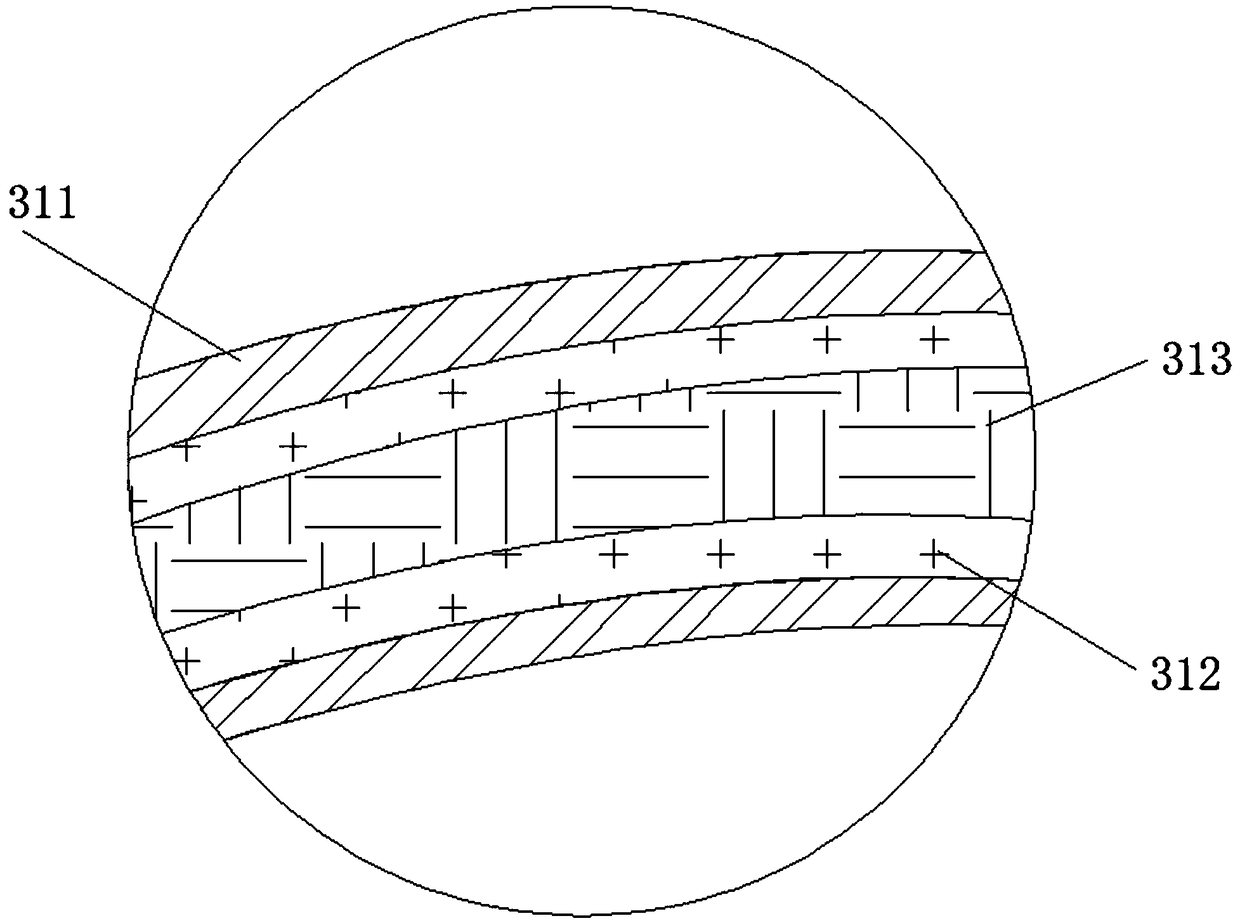

Manned high-speed elevator carbon fiber reinforced cold-resistant and flame-retardant balance compensation chain

The invention discloses a manned high-speed elevator carbon fiber reinforced cold-resistant and flame-retardant balance compensation chain, and belongs to the field of elevator balance compensation chains. The manned high-speed elevator carbon fiber reinforced cold-resistant and flame-retardant balance compensation chain comprises multiple lock rings and lock ring sleeves; the lock ring sleeves are wrapped on the outer sides of the lock rings; micro alarm pieces are connected between two lock rings; the lock ring sleeves are provided with insulation layers, flame-retardant layers and outer protecting layers in sequence from inside to outside; carbon fibers are applied to production of the lock ring and the lock ring sleeves of the elevator balance compensation chain; through the characteristics of high-temperature resistance, friction resistance, corrosion resistance, cold resistance, weight and high strength of carbon fiber composite materials, the safety use performances of the elevator balance compensation chain can be improved; and even if the lock ring sleeves are accidentally damaged and split, two lock rings serve as leads for contact and communication to connect with the micro alarm pieces, so that an alarm can be timely given to remind passengers and related workers, safety maintenance measures are conveniently adopted timely, and potential safety hazards are removed.

Owner:JIANGSU XINGHUA RUBBER BELT

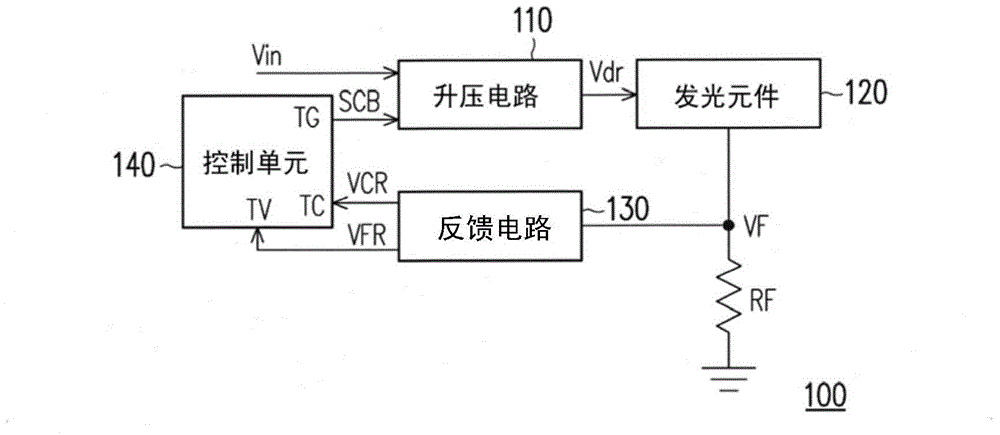

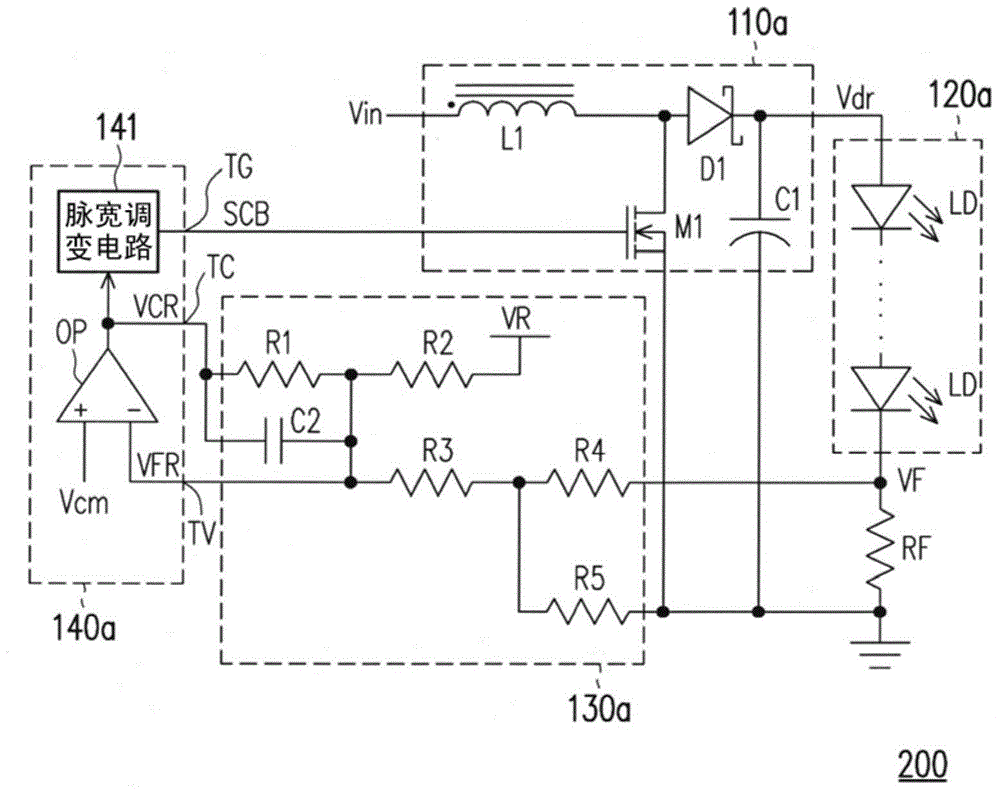

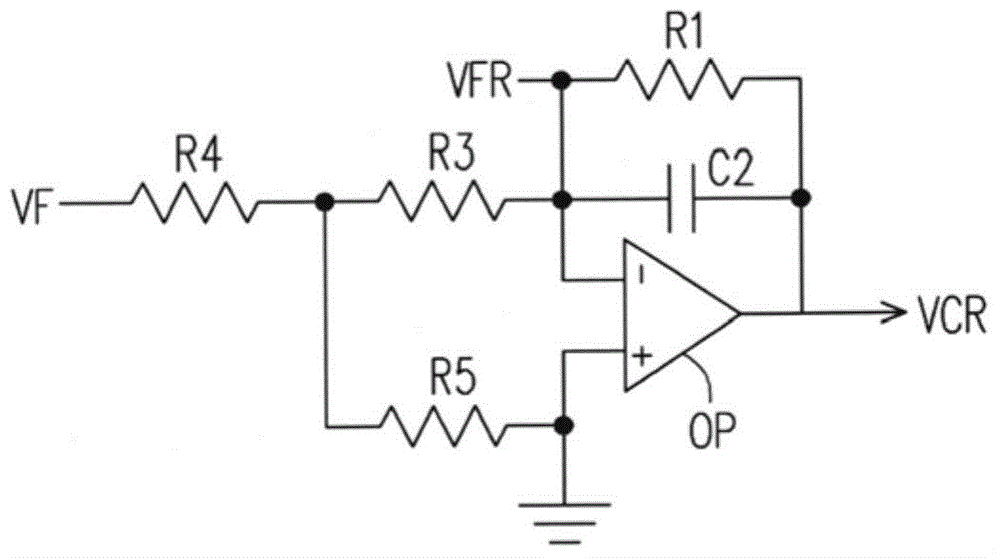

Light source device

InactiveCN104640269AReduce cross pressureReduce the chance of burnsElectric light circuit arrangementControl signalVoltage reference

A light source device comprises a boosting circuit, a light emitting component, a feedback resistor, a feedback circuit and a control unit. The boosting circuit decides boosting times of input voltage according to boosting controls signals of the control unit and provides driving voltage to the light emitting component. The feedback resistor is serially connected with the light emitting component. The feedback circuit receives feedback voltage provided by the feedback resistor and provides feedback reference voltage and control reference voltage to the control unit, and the feedback reference voltage is higher than the feedback voltage. The control unit adjusts duty cycle of the boosting control signals according to the received control reference voltage.

Owner:CORETRONIC (SUZHOU) CO LTD

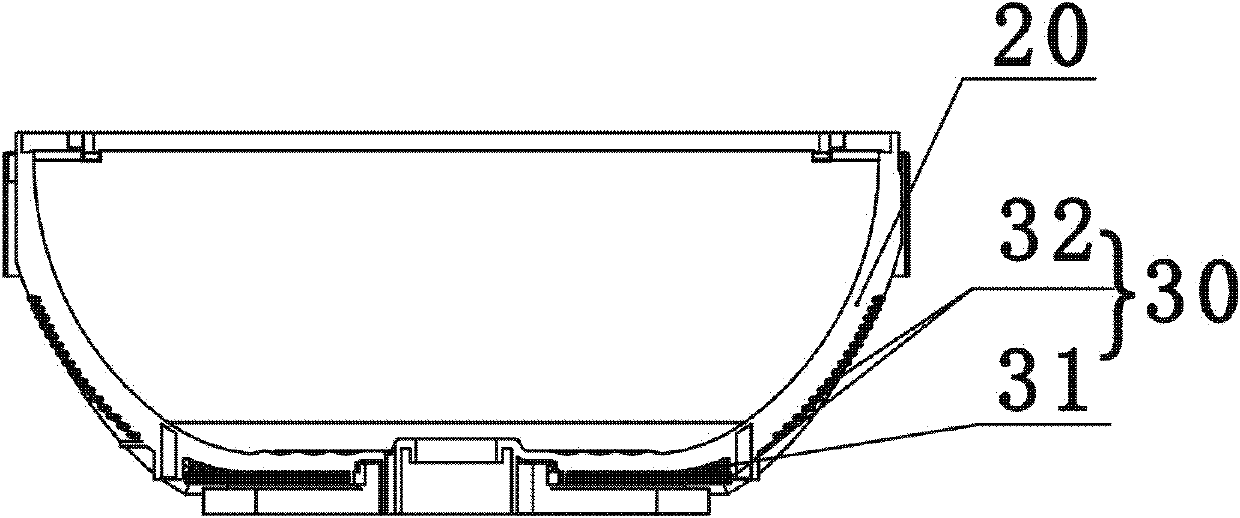

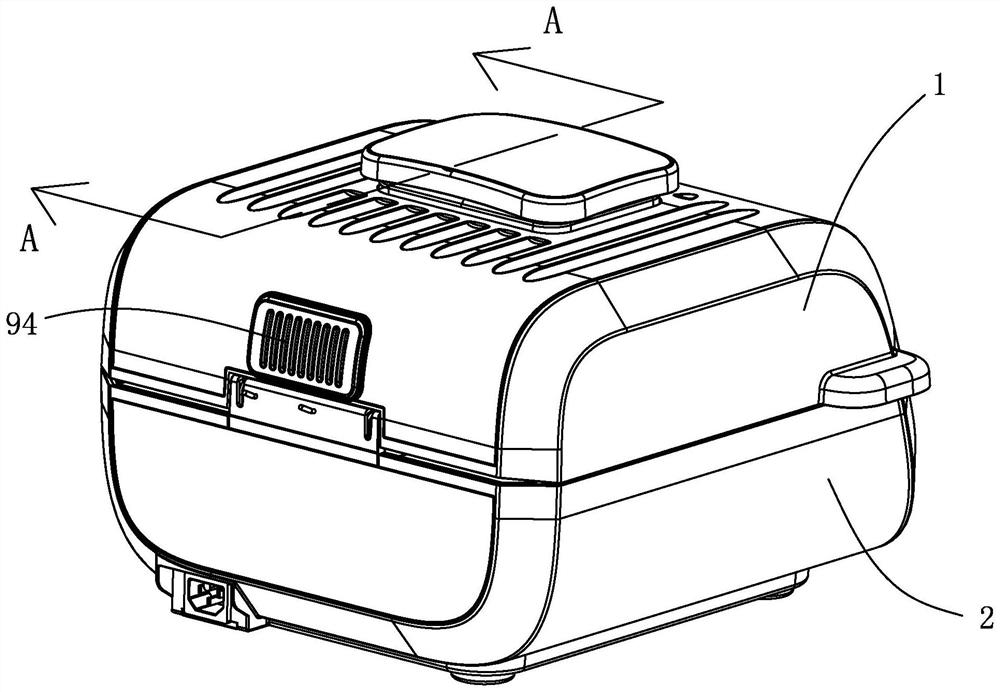

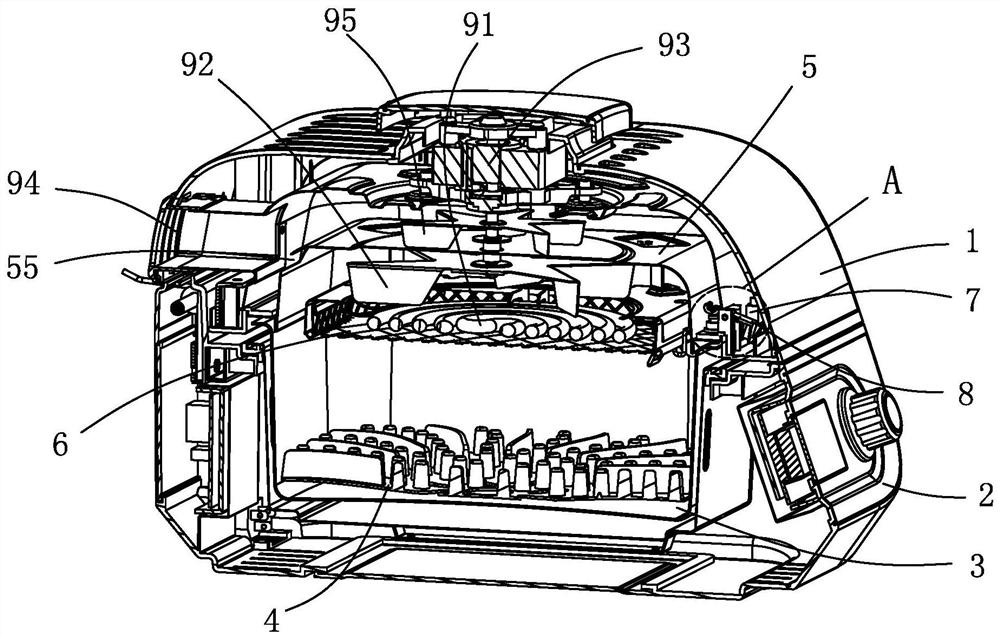

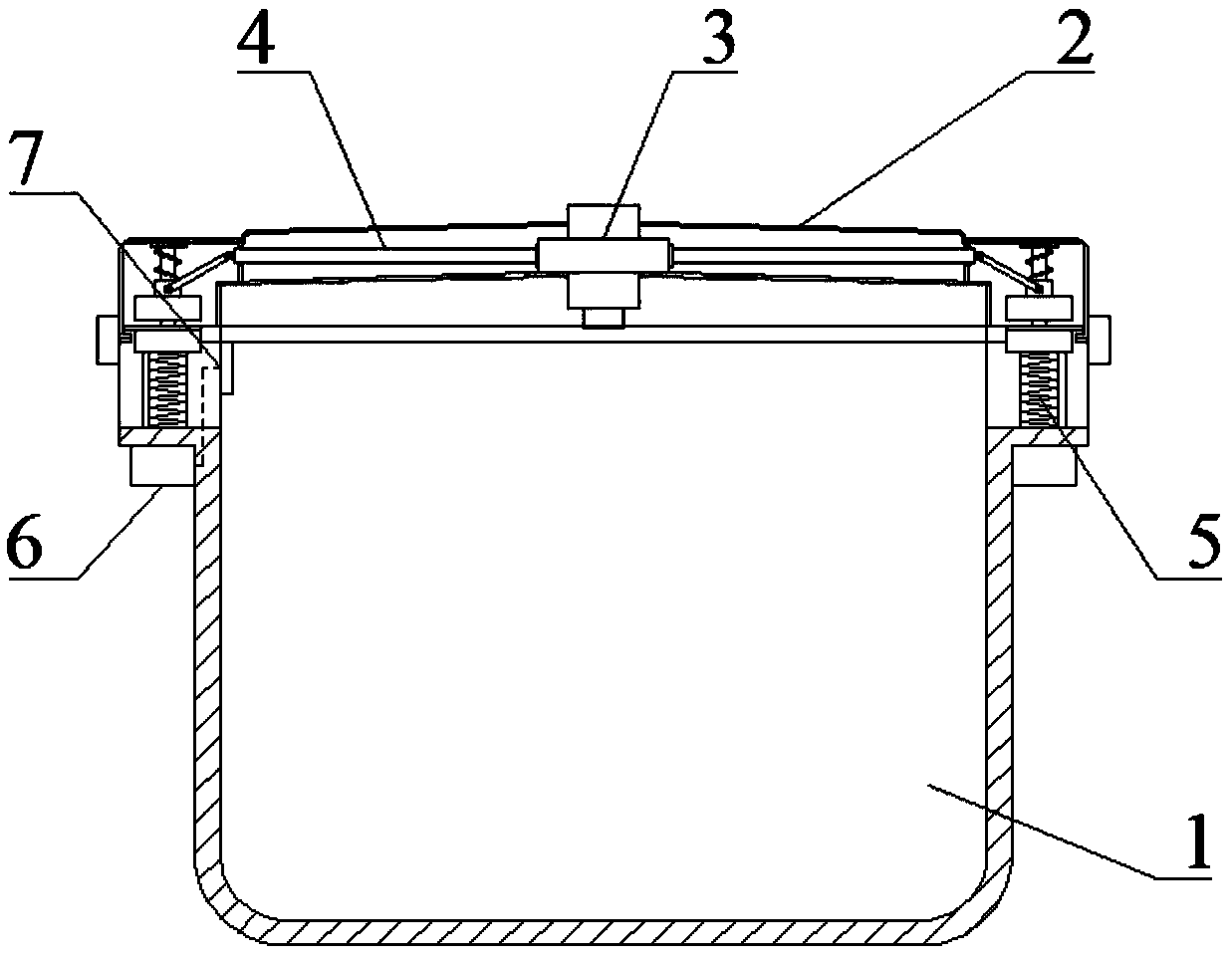

Multifunctional air fryer

PendingCN111973001AAvoid stickingGreat tasteDispersed particle filtrationRoasters/grillsEngineeringFood material

The invention provides a multifunctional air fryer which comprises a fryer cover, a fryer body and an inner fryer, a baking tray is arranged in the inner fryer and comprises a baking tray body, and aplurality of supporting parts arranged at intervals are arranged on the baking tray body. For the multifunctional air fryer, food materials are supported through the supporting parts arranged on the baking tray body at intervals and can not contact with the baking tray body. When the multifunctional air fryer is used for frying the food materials, the food materials are effectively prevented fromadhering to the baking tray, so that the food materials are effectively prevented from blocking the oil leakage holes in the baking tray, the food materials are conveniently separated from grease, andthe taste of the fried food materials is improved.

Owner:DEA GENERAL AVIATION HLDG CO LTD

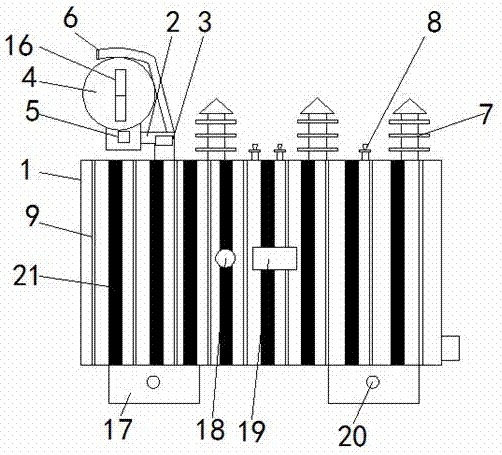

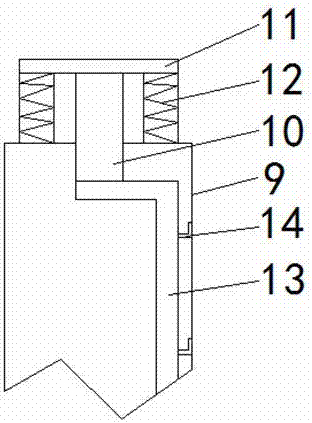

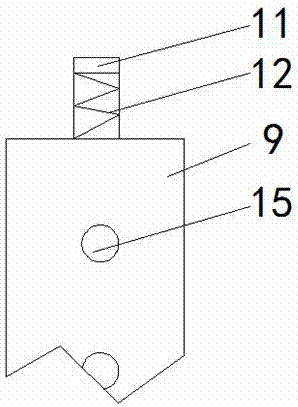

Flame-proof transformer

InactiveCN107170557AReduce the temperatureLower oxygen levelsTransformers/inductances coolingFire rescueTransformerFire control

The invention discloses a flame-proof transformer, which comprises a transformer body, an oil pipe is arranged at the upper end of the transformer body, a gas relay is connected to the oil pipe, an oil storage tank is arranged at the end of the oil pipe far away from the transformer body, and a gas passage is arranged at the upper end of the oil storage tank. One end is connected to the inside of the transformer body, and the surface of the transformer body is evenly provided with heat dissipation oil pipes, and a flame-proof pipe is provided between the heat-dissipating oil pipes, and a high-pressure carbon dioxide liquid is provided in the fire-proof pipe, and a sealing plug is provided at the upper end of the fire-proof pipe, and a connecting plug is provided at the upper end of the sealing plug. Compression springs are arranged symmetrically at the two ends of the connecting rod, the lower end of the sealing plug is provided with an L-shaped connecting rod, and several plugs are uniformly arranged on the L-shaped connecting rod. Beneficial effect: by setting the anti-flame tube, when a large amount of high temperature is generated in the transformer body, the carbon dioxide generated in the anti-flame tube is discharged through the opening of the transformer body by using the principle of thermal expansion and contraction, so as to achieve the effect of fire extinguishing.

Owner:HEFEI DONGJIU ELECTRICAL CO LTD

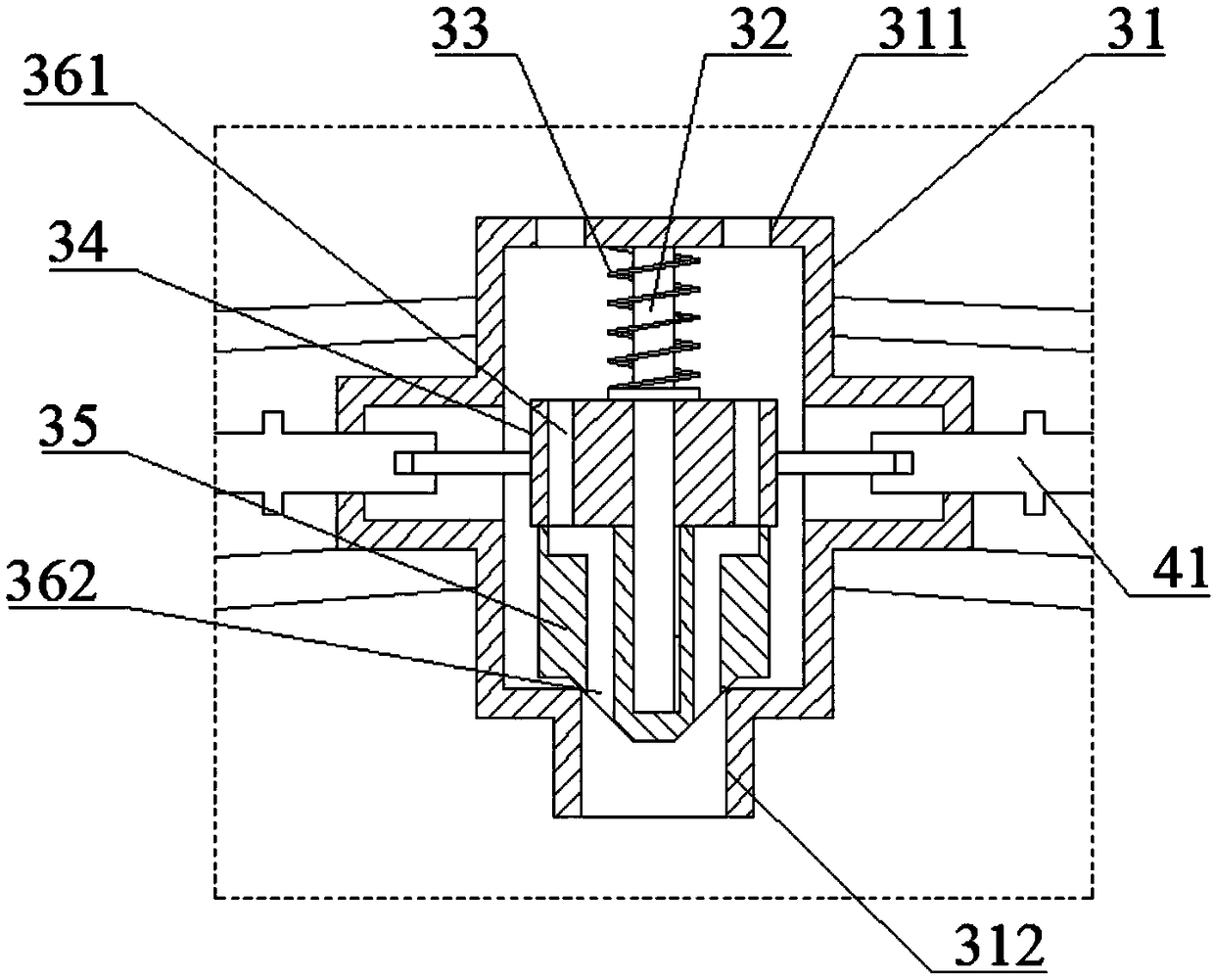

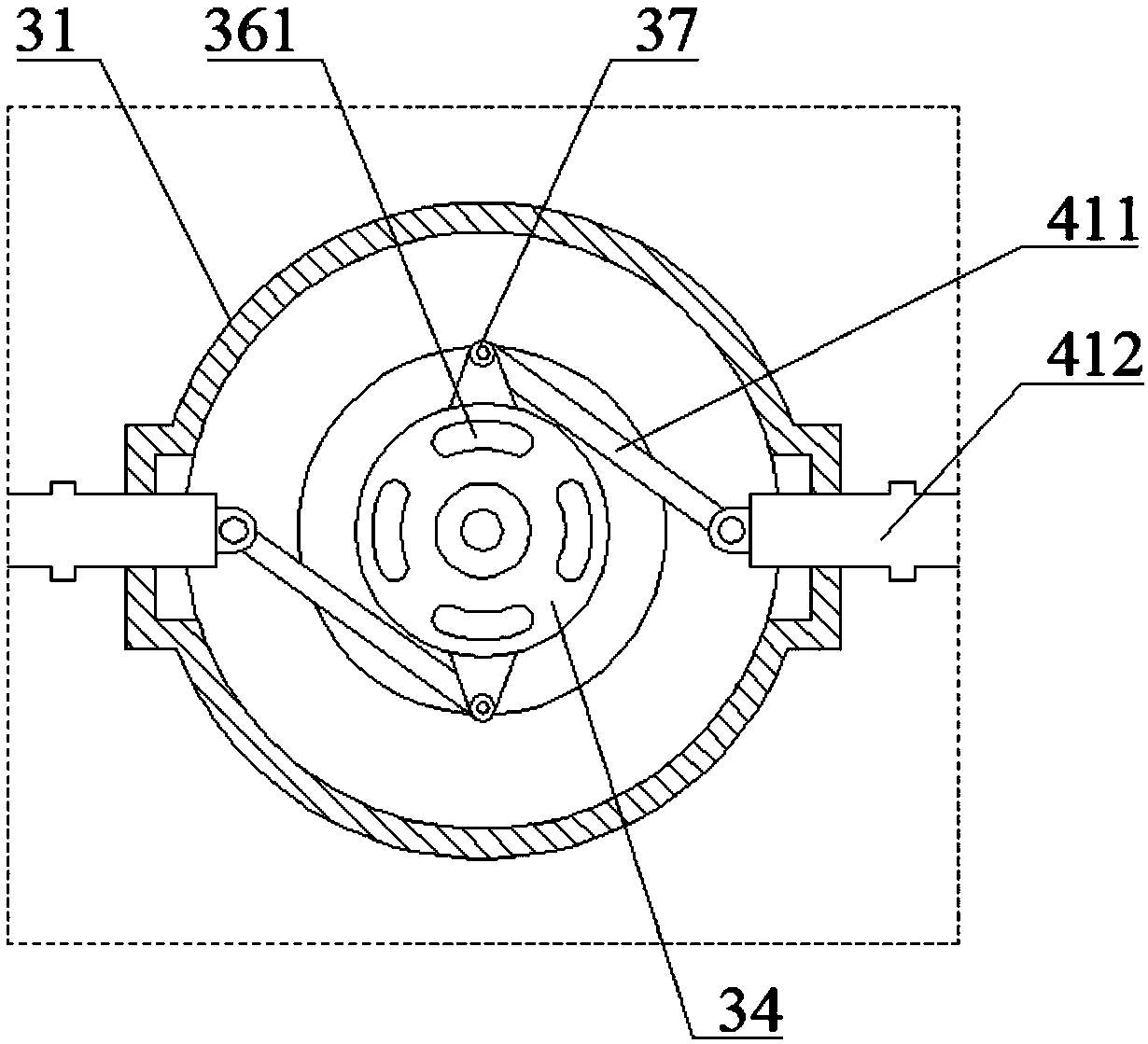

Intelligent pressure-controlled pressure cooker

PendingCN109222634AImprove reliabilityAvoid manually opening the purge valvePressure-cookersCookerBe star

The invention provides an intelligent pressure-controlled pressure cooker, comprising a pot body, a pot cover, a safety valve, a linkage mechanism and an electromagnetic attraction mechanism. In application, if the air pressure in the pot is higher than the preset value, the pressure relief body in the safety valve is jacked up to form a gap, and gas is discharged from the pot through the gap to realize pressure control. A magnetic attractive mechanism is star when gas needs to be discharge, and that magnetic float is magnetically attracted to form a moving action, and the formed moving actionis transmit to the gas discharge through the linkage mechanism, so that the gas discharge is rotated so that the first gas discharge hole and the second gas discharge hole are communicated to form anair discharge passage, and the gas in the pot is discharged. The pressure cooker can accomplish pressure control and deflation through one safety valve, avoids setting multiple valve bodies on the pot cover, improves the reliability of the autoclave, realizes gas release in the pot through electromagnetic adsorption, avoids manually opening the deflation valve, and reduces the scald probability.

Owner:NANJING ENWELL TECH SERVICE CO LTD

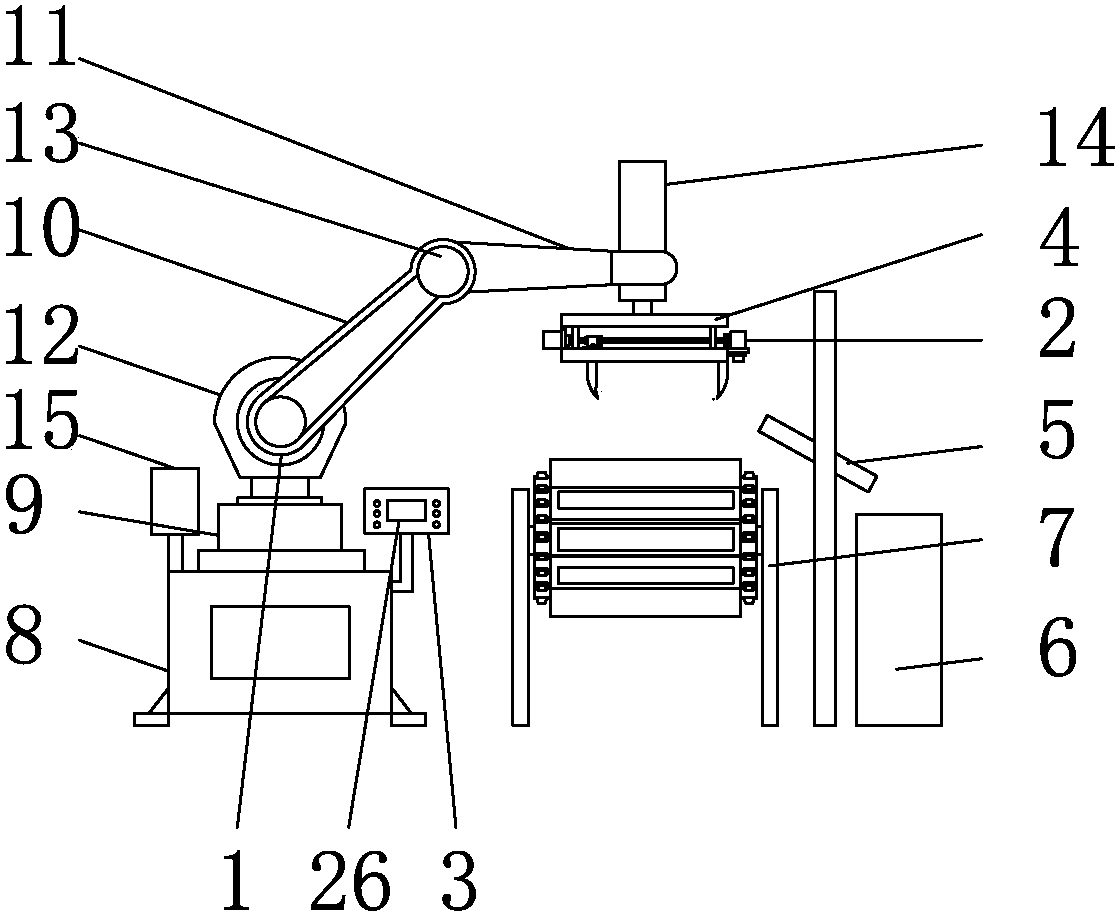

Automatic slagging-off method for aluminum ingot production

InactiveCN110899685ARealize automatic slag removalReduce the chance of burnsCasting cleaning apparatusIngot castingCasting mold

The invention discloses an automatic slagging-off method for aluminum ingot production. Firstly, each passing aluminum ingot casting mold is automatically recognized and three-dimensionally positionedthrough a visual positioning sensor; the three-dimensional coordinates of the aluminum ingot casting mold are fed back to a PLC master controller; the PLC master controller sends a command to a robotcontroller according to a programming program; the robot controller controls a mechanical arm to operate according to the programming program; a slagging-off tool is moved to the upper parts of one or more adjacent slagging-off casting molds needing slagging off; then, a slagging-off screw rod driving mechanism in the slagging-off tool drives a movable shovel to move from one end of the casting mold to the other end of the casting mold; scum at the upper part of the casting mold is pushed to move towards one end; and then the movable shovel and a fixed shovel accumulate the scum from the twosides, the scum is lifted up and unloaded into a slag receiving disc under the further operation of the robot and falls into a slag receiving box through the slag receiving disc; the problems that inan existing slagging off mode, workers are prone to being scalded, the working efficiency is low, and scraping missing and slag leaking are prone to occurring are solved.

Owner:云南云铝海鑫铝业有限公司

Ankle sprain fixing and hot compress equipment

InactiveCN110811977AAvoid secondary damageEffective heatTherapeutic coolingTherapeutic heatingPhysical medicine and rehabilitationEngineering

The invention discloses ankle sprain fixing and hot compress equipment which comprises a hot compress box, wherein a hot compress cavity is formed in the hot compress box; two transverse grooves are formed in the hot compress box; a hot compress mechanism is arranged in each transverse groove, and comprises a transverse rod capable of moving leftwards and rightwards in the transverse groove; two rotating cavities are formed in the hot compress box; and an ascending and descending mechanism is arranged in each rotating cavity, and comprises a transmission shaft arranged at the back end wall ofthe rotating cavity. The ankle sprain fixing and hot compress equipment has the advantages that hot compressed can be effectively performed on the sprained ankle; the heating and warm keeping effectscan be maintained for a long time; when the temperature is too high, the heating can be automatically stopped; and the scald possibility is reduced. The ankle sprain fixing and hot compress equipmentcan also be used for fixing the ankle position, so that the secondary injury on an injured person is avoided; and when the injured person sleeps, the injured part can be raised, so that the recovery effect is improved.

Owner:青岛山大齐鲁医院(山东大学齐鲁医院(青岛))

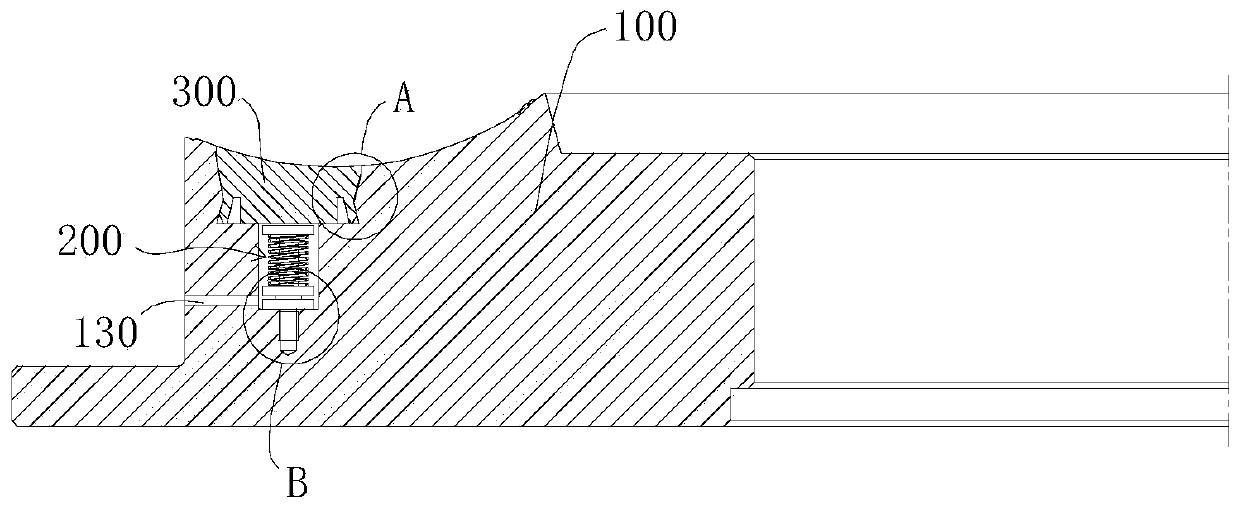

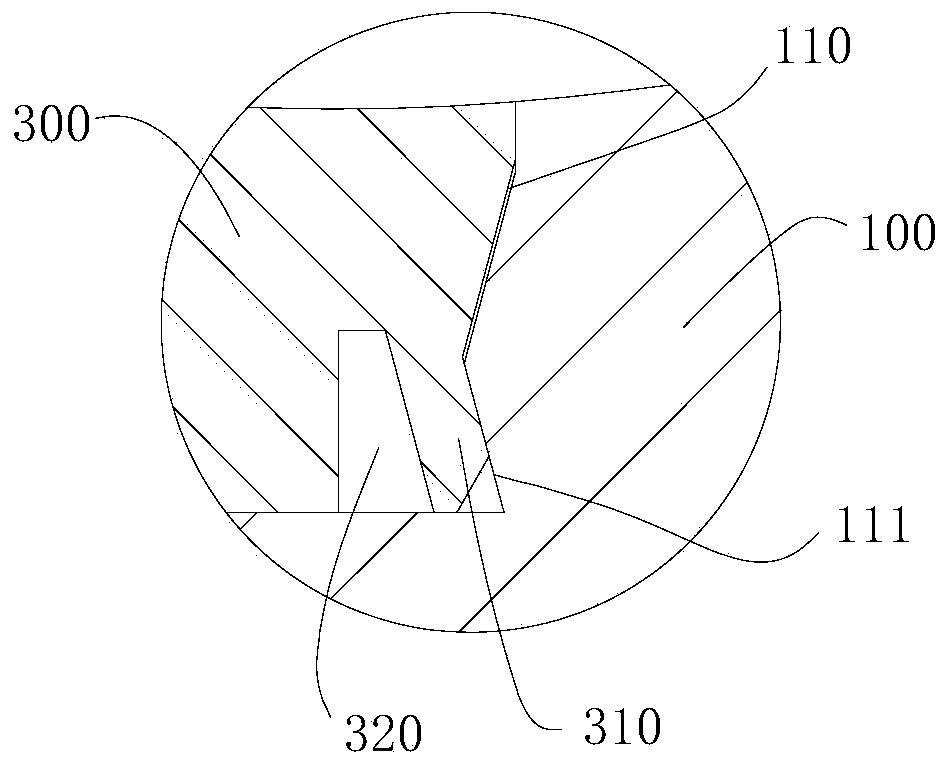

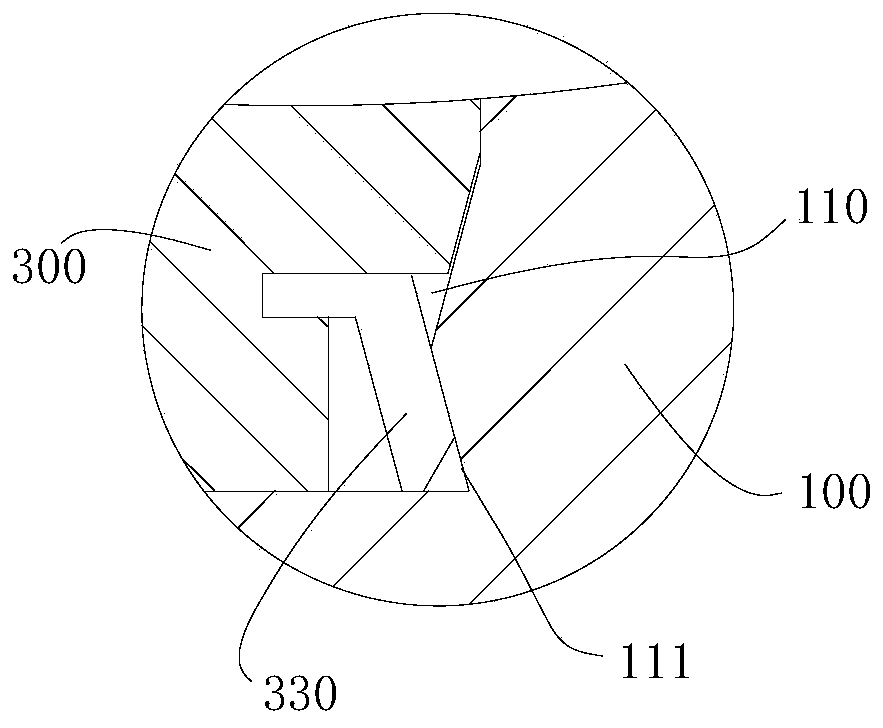

Tire mold side plate and tire mold

The invention provides a tire mold side plate and a tire mold, and relates to the technical field of tire processing. The tire mold side plate comprises a side plate body and an electromagnetic ejection mechanism, wherein the side plate body is provided with an embedding groove for embedding a movable type block, a mounting groove is formed in the bottom of the embedding groove, and the electromagnetic ejection mechanism is accommodated in the mounting groove; the electromagnetic ejection mechanism comprises a first magnet and a second magnet, the second magnet is positioned above the first magnet in the depth direction of the mounting groove, and the opposite sides of the first magnet and the second magnet have the same polarity; and at least one of the first magnet and the second magnetis an electromagnet. The tire mold comprises the movable type block and the tire mold side plate, and the movable type block is embedded in the embedding groove. The movable type block of the tire mold is convenient to disassemble and assemble, the damage to the side plate body in the disassembling and assembling process is small, and the normal use of the tire mold is ensured.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Automatic-rotating barbecue

ActiveCN109349936ARealize automatic flipReduce labor intensityRoasting apparatusRoasters/grillsEvaporationEngineering

The invention belongs to the technical field of barbecue devices, and particularly relates to an automatic-rotating barbecue. The automatic-rotating barbecue comprises a barbecue body, a first cavityis formed in the side wall of one end of the barbecue body, evaporation liquid is stored at the bottom of the first cavity, a feeding opening is formed in the side wall of the first cavity, and is filled with a first sealing plate, multiple first gas guide holes are vertically formed in the top face of the first cavity, first magnets are fixedly connected to the inner walls of the first gas guideholes, gas discharging holes are formed in the side walls of the first gas guide holes, a second sealing plate is rotationally connected to the top faces of the gas discharging holes, second magnets which are in magnetic connection with the first magnets are embedded into the side wall of the second sealing plate, first piston plates are slidingly arranged in the first gas guide holes in the upperportions of the first magnets through sealing, and multiple first springs are fixedly connected to the upper ends of the first piston plates. The automatic-rotating barbecue has the advantages that barbecued food can be automatically turned over, it can also be avoided that the eyes are smoked by barbecuing smoke, and barbecuing operation is further facilitated.

Owner:佛山市奥星五金制品有限公司

Material stirring device for industrial automation

InactiveCN109351278AComplete and compact structural designLow thermal conductivityRotary stirring mixersTransportation and packagingMotor shaftElectric heating

The invention discloses a material stirring device for industrial automation. The device comprises a stirring machine body, a stirring shaft, stirring rods, an electric heating wire, a controller, a conveying cylinder and a single chip MCU; a feeding port is formed in the top of the stirring machine body, a first servo motor is arranged at one side of the feeding port, a motor shaft of the first servo motor is connected with the stirring shaft through a coupler, and the stirring rods are uniformly fixed to the two sides of the stirring shaft; through holes are formed in the stirring rods, a heating layer is arranged on the wall of the stirring machine body, the electric heating wire is laid in the heating layer, diversion plates are welded to the inner wall of the stirring machine body, each diversion plate is provided with two square holes, and a cylindrical filtering net is arranged at the bottom of the stirring machine body and fixed to the portion, above a first discharging port, of the bottom of the stirring machine body. Through the arrangement of the electric heating wire, materials are heated, temperature can be provided for an endothermic reaction, the reaction speed is increased, the through holes are formed in the stirring rods, the resistance of the stirring rods can be reduced, and the stirring speed is increased.

Owner:XIAN YONGXIN TECH CO LTD

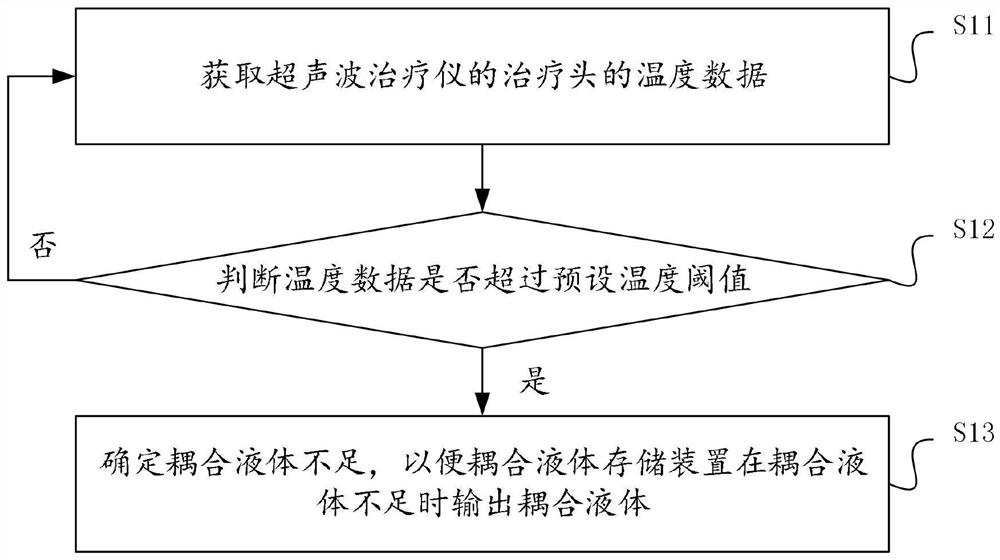

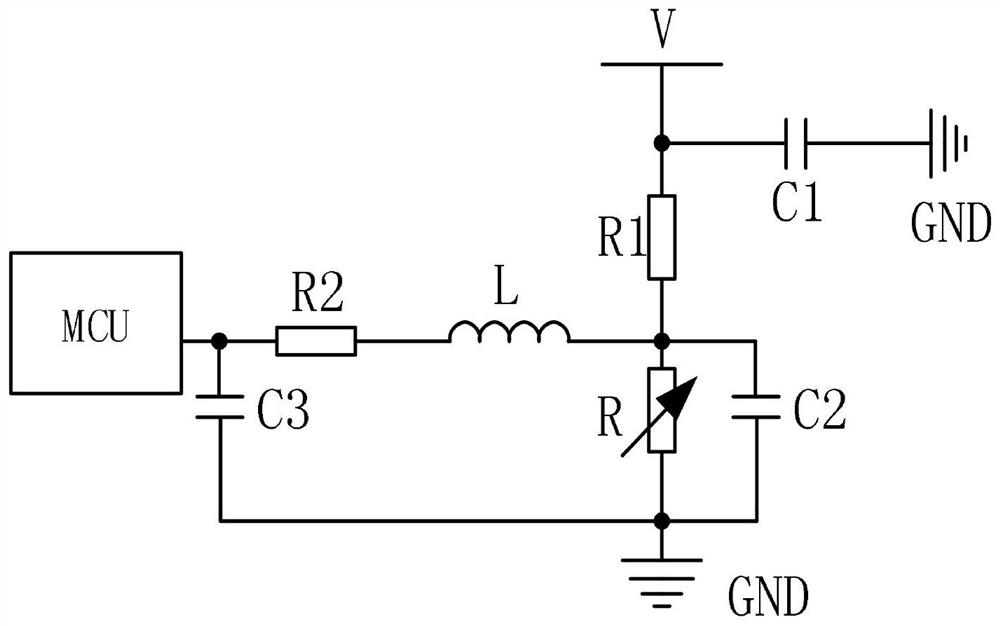

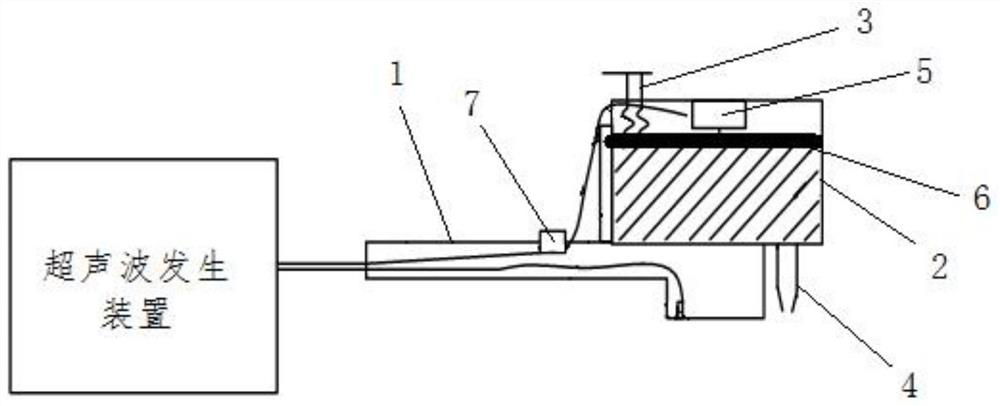

Ultrasonic coupling liquid output method, device and equipment and storage medium

The invention discloses a coupling liquid output method of an ultrasonic therapeutic apparatus. The method comprises the following steps: acquiring temperature data of a therapeutic head of the ultrasonic therapeutic apparatus; judging whether the temperature data exceed a preset temperature threshold value or not; and if yes, determining that the coupling liquid is insufficient, so that a coupling liquid storage device outputs the coupling liquid when the coupling liquid is insufficient. In the use process of the therapeutic head of the ultrasonic therapeutic apparatus, the temperature data of the therapeutic head is monitored, and when the temperature of the therapeutic head is too high, it is determined that the coupling liquid needs to be output on the basis that the temperature of the therapeutic head can rapidly rise when the coupling liquid is insufficient, so that the difficulty that an operator judges whether the coupling liquid needs to be added or not is lowered, the timeliness of adding the coupling liquid is ensured, so that the therapeutic effect of ultrasonic treatment is improved, and the possibility that the skin is scalded is reduced. The invention further provides a coupling liquid output device and equipment of the ultrasonic therapeutic apparatus and a computer readable storage medium, which have the above beneficial effects.

Owner:ANYANG XIANGYU MEDICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com