Patents

Literature

117results about How to "Avoid thermal expansion and contraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

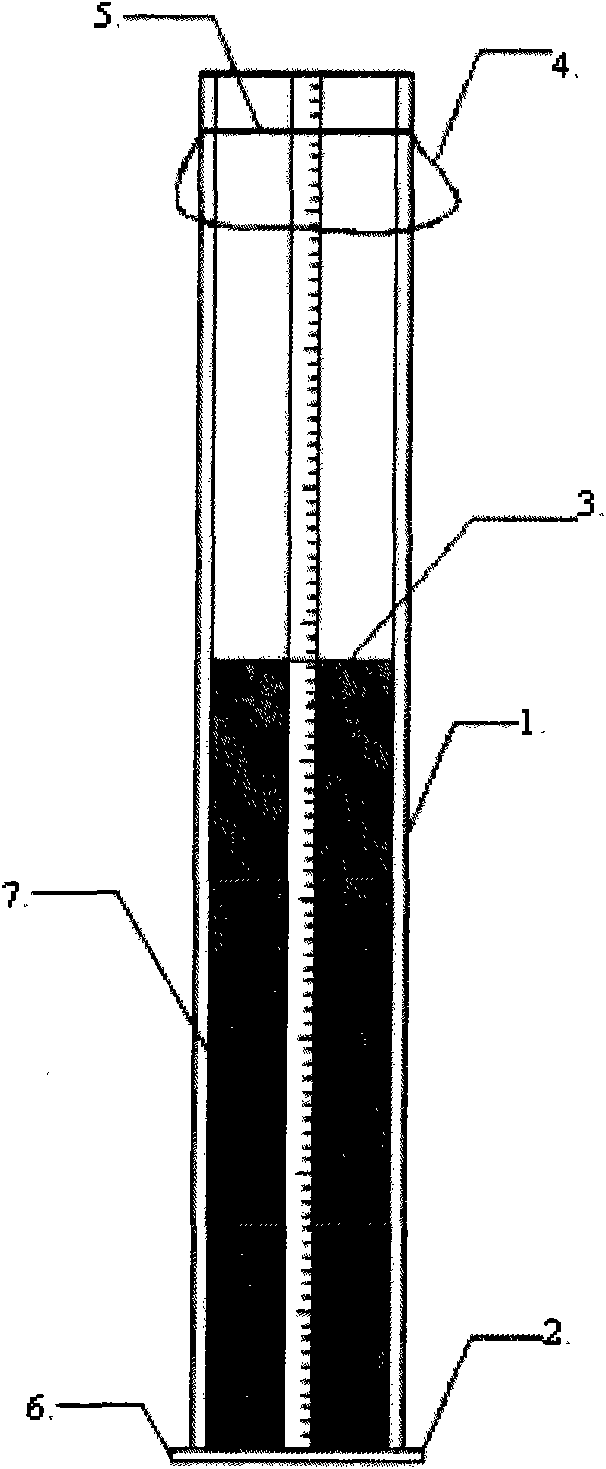

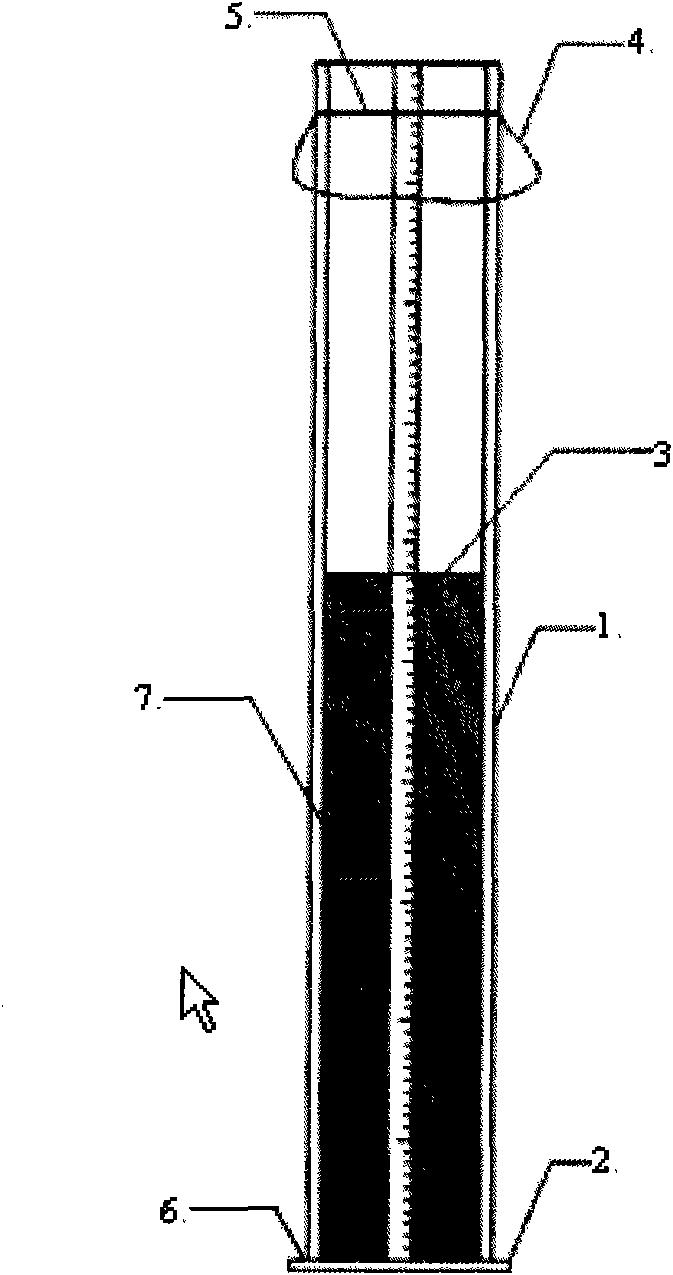

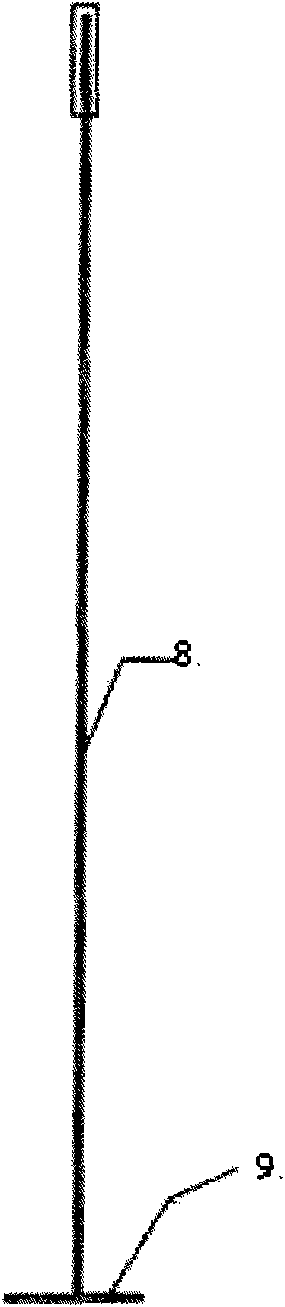

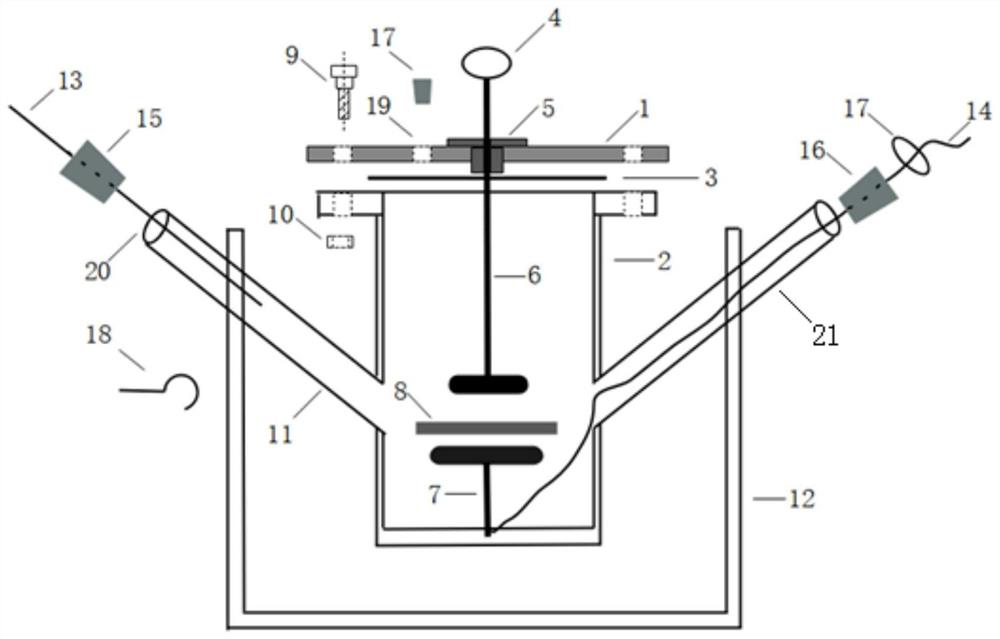

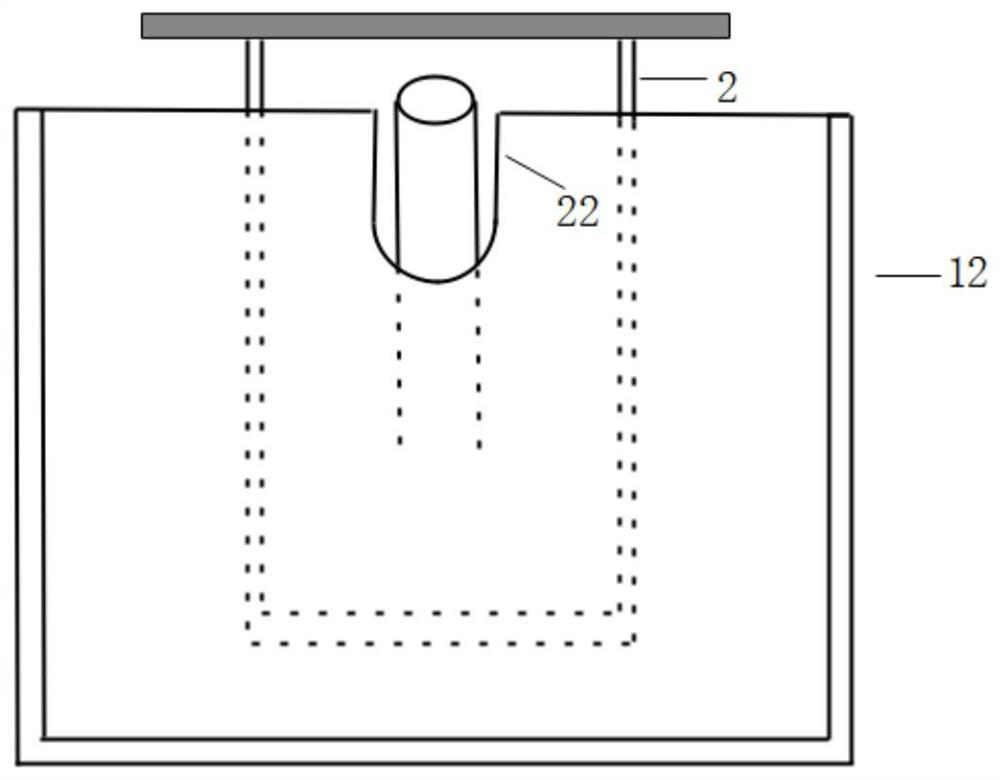

Testing device for simulating warp self-weight settlement consolidation process by settlement column indoors

InactiveCN101813690AStrong connectionIncreased durabilityEarth material testingStream regulationSlurrySmall footprint

The invention discloses a testing device for simulating a warp self-weight settlement consolidation process by a settlement column indoors, comprising an organic glass tube settlement column, a slurry stirrer, a soil sample geotome and the like. The body of the settlement column is connected with a base; a paper ruler is adhered outside the tube wall of the column body; slurry suspension is injected behind the body of the organic glass tube settlement column, the slurry suspension is stirred and mixed uniformly up and down by inserting the stirrer; the opening of the column body is sealed by a rubber band after the opening of the column body is sealed by a seal membrane; the settling height of the suspension level along with time is recorded by observing the paper ruler outside the tube wall so as to study the free settling law of the warp slurry under self-weight action; and after the warp self-weight settlement consolidation process is completed, soil is taken by the geotome layer by layer, the void ratio e of soil layers with different depths is detected, the warp self-weight consolidation law is studied, and the soil body consolidation coefficient cv is calculated. The testing device has the characteristics of small floor area, convenient operation, accurate and reliable data observation, less moisture loss, small soil sample disturbance and the like, and can be applied to early test study of river channel training, harbor desilting, backfill land reclamation and other engineering.

Owner:HOHAI UNIV

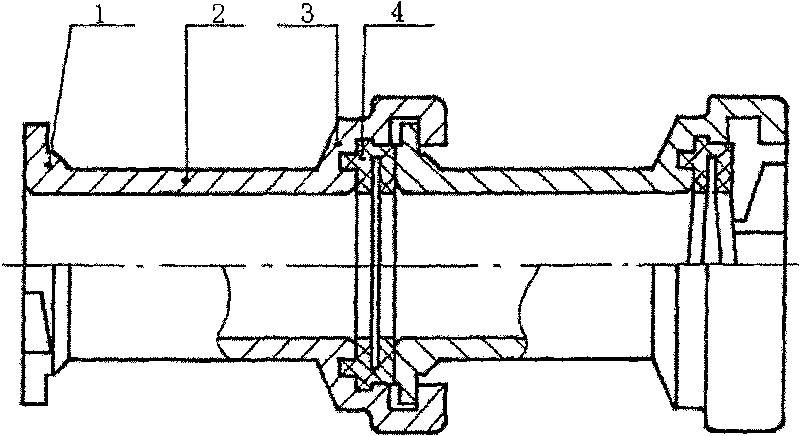

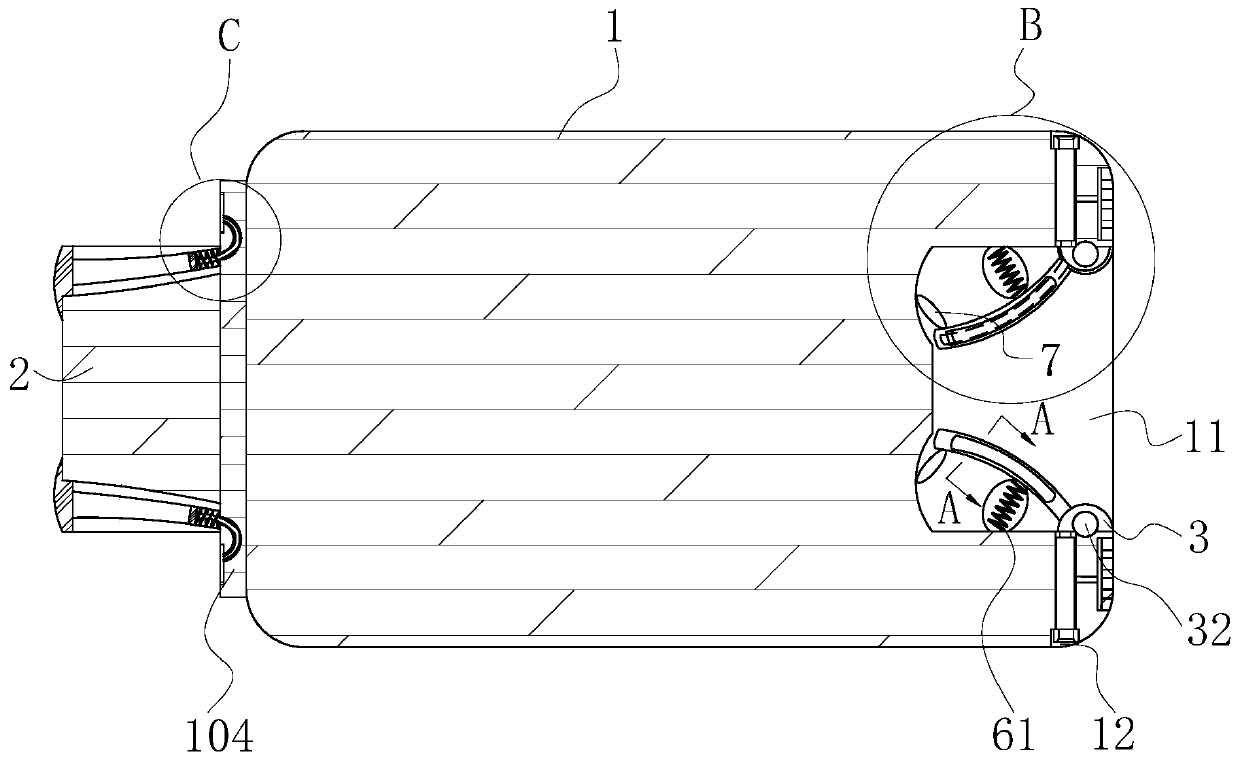

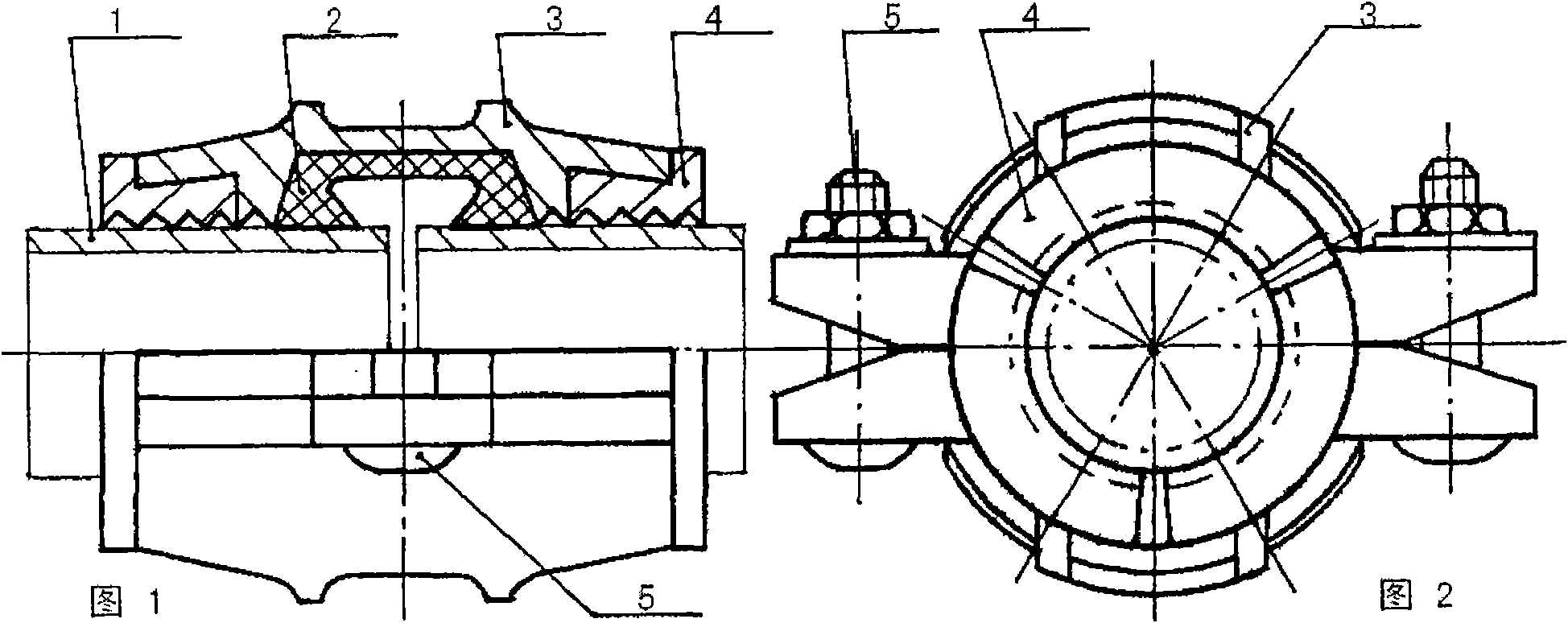

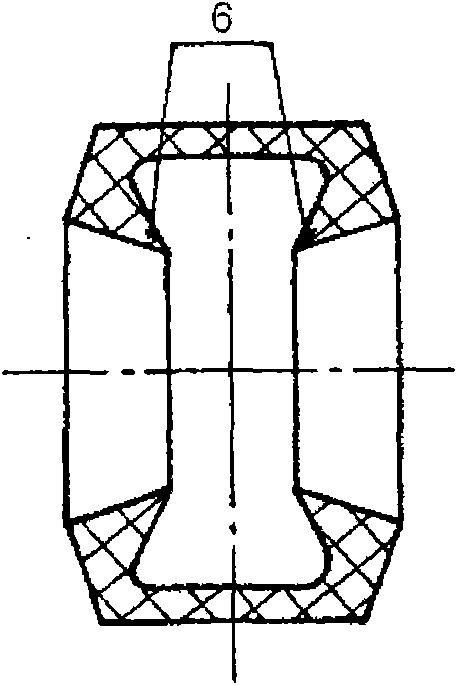

Self-compensating fastening type large-diameter fast joint

InactiveCN101344206AShorten the installation periodQuick connectionFluid pressure sealed jointsPipeline expansion-compensationPipe fittingOmni directional

The invention relates to a self-compensating fastening large-caliber fast adaptor which is used for butt jointing of two pipes and solves the defects of high cost and poor practicability in the prior art. The invention is characterized in that: the outer circumference of pipe fittings is encircled by a rubber sealing boot 2, a convex ring of which is arranged among the pipe fittings. Left and right sleeves 3 and 4 are respectively sheathed on the pipe fittings, and pressed on the outer surface of the rubber sealing boot 2. A trough 9 of the left sleeve 3 is meshed with a projection 12 of the right sleeve 4. A cotter pin 8 fixedly locks the left and right sleeves 3 and 4. A claw 5 is provided with a pointed teeth on the concave surface, arranged in dovetail inner cone troughs 11 and 14 in the left and right sleeves 3 and 4, pasted on the outer wall of the pipe fittings, can slide along the axial direction of the pipe fittings and concentrically contract to occlude and tighten the pipe fittings. The fast adaptor is high, middle and low pressure resistant. The self-compensating fastening omni-directional secure seal with firm soft syncretic is provided without welding or flange type, not being opened with trench type, and not being provided with a compensator additionally, thereby saving labor and time, especially under the condition of severe environment, the fast adaptor of the invention has the advantages of being convenient and fast, low cost, energy saving and environmental protection. The fast adaptor of the invention is used for connecting two pipes through which the fluid is to be conveyed.

Owner:王甲南

Low-voltage cable intermediate joint cold contraction technology

ActiveCN103337813AIncrease elasticityAvoid thermal expansion and contractionApparatus for joining/termination cablesSocial benefitsLow voltage

The invention belongs to the technical field of electric power, and especially relates to a low-voltage cable intermediate joint cold contraction technology, which can remedy defects such as coarse original material, poor insulation performance and sealing performance, weak tolerance mechanical strength, and easily getting heated and burnt of a 0.4kV low-voltage cable intermediate joint and significantly improve equipment safety running coefficients. The low-voltage cable intermediate joint cold contraction technology fundamentally helps to reduce fault probability of the 0.4kV low-voltage cable intermediate joint. The use of the new technology and the material provide effective technical support for personal safety and equipment safety, and at the same time helps electric power enterprises to save a large amount of maintenance funds, not only promotes increase of profits of the electric power enterprises but also achieves huge social benefit due to stable and continuous power supply.

Owner:STATE GRID CORP OF CHINA +1

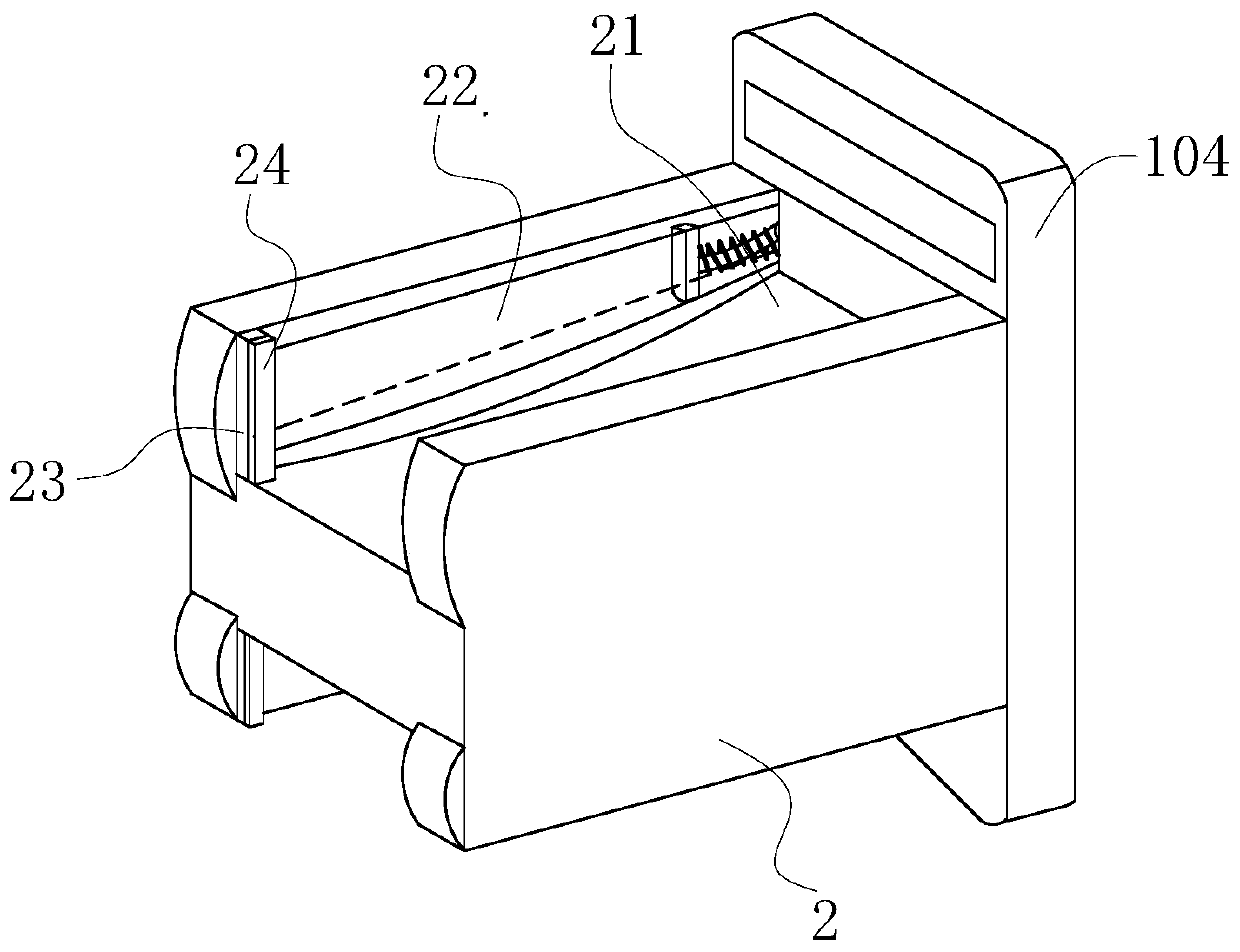

Self-compensating direct quick-connection pipeline

A self-compensating direct quick-connection pipeline comprises a left head 1, a pipeline 2, a right head 3 and a rubber sealing ring 4, is used for the contra-aperture quick connection of pipelines, and solves the defects that the prior pipe connection technique has high cost and poor practicability, wherein the left head 1 is inserted into and spirally buckled with the inner cavity of the right head 3, the rubber sealing ring 4 is compressed and sealed therein. The pipe fittings and valves of the self-compensating direct quick-connection pipeline are resistant to high pressure, medium pressure and low pressure, do not pull screw thread, are not welded, are not in flange mode, channeling mode and electric heating melting mode, are not additionally added with a compensator, are capable of realizing direct contra-aperture quick connection of the pipelines in severe environment conditions, such as lofty mountains and steep hills, deserts, water of rivers, lakes and seas, narrow space, windy, rainy, high-temperature and chill weather, combustible and explosive places, provide self-compensating lockable rigid-flexible omnibearing safety sealing, save labor and time, and have low cost, high efficiency, energy conservation and environment protection. The invention provides the self-compensating direct quick-connection pipeline for conveying fluids.

Owner:王甲南

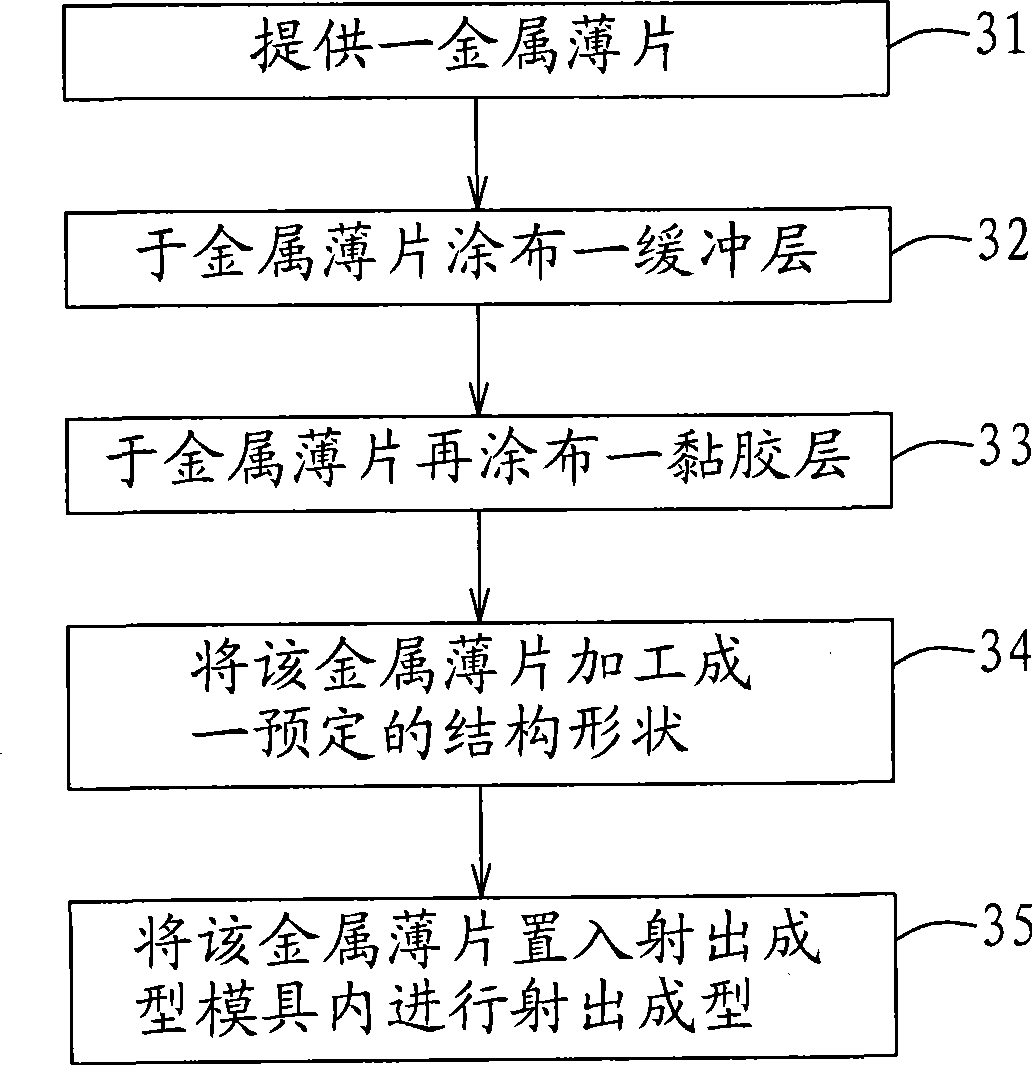

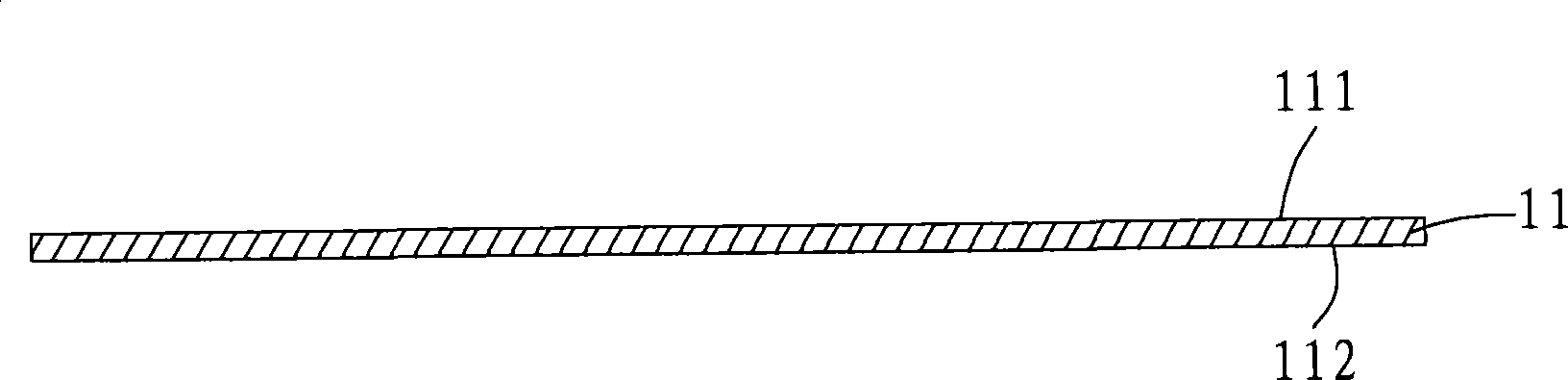

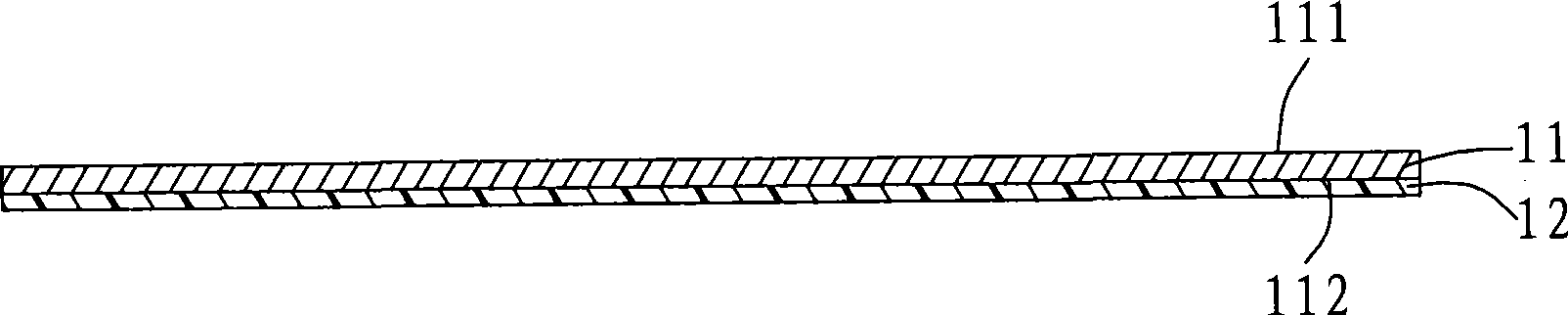

In-mold injection molding method producing finished product with metal surface and finished product thereof

InactiveCN101434120AAvoid thermal expansion and contractionBest Gluing MediumSynthetic resin layered productsMetal layered productsThermal expansionMetal sheet

The invention relates to an intra-mould injection molding method for a finished product with metal surface and the finished product. The intra-mould injection molding method comprises the following steps: a metal sheet with the outer surface and the inner surface is provided; the inner surface of the metal sheet is coated with a buffer layer for heat insulation; a viscose glue layer is coated on the metal sheet in order that the buffer layer is between the metal sheet and the viscose glue layer; the metal sheet coated with the buffer layer and the viscose glue layer is positioned inside an injection molding mould; the outer surface of the metal sheet faces to the inner wall of the mould; and the metal sheet is subjected to injection molding to obtain a combination body combined by the metal sheet and injection plastic. The finished product comprises a metal layer, the buffer layer, the viscose glue layer and a plastic layer. Before carrying out intra-mould injection molding on the metal sheet, the buffer layer is coated on the metal sheet; and the buffer layer can obstruct high temperature from the mould and liquid plastic in hot press molding and intra-mould injection, avoids producing thermal expansion and cold contraction of the metal sheet and provides a good agglutination medium between the metal sheet and the viscose glue layer, thereby improving the stability of agglutination between the metal sheet and the plastic.

Owner:KAOTAI TECH

Fixator for automobile carbon dioxide extinguisher

The invention discloses a fixator for an automobile carbon dioxide extinguisher. The fixator comprises a fixed frame, and the fixed frame is provided with a circular cavity and a first rectangular cavity; the circular cavity communicates with the first rectangular cavity; four clamping blocks are circularly arranged in the circular cavity; the four clamping blocks clamp a fire extinguishing tank together; rubber cushions are arranged between the clamping blocks and the fire extinguishing tank; two first springs are arranged between each clamping block and the inner wall of the circular cavity; two fixed blocks are symmetrically arranged in the first rectangular cavity; the fixed blocks are provided with limiting grooves; moving blocks are arranged in the limiting grooves; connecting plates are arranged at the ends, away from the limiting grooves, of the moving blocks; and a second spring is arranged between the two connecting plates. According to the fixator, the structure is stable, operation is convenient, the fire extinguishing tank is firmly and stably fixed, the fire extinguishing tank can be conveniently taken out and placed, and the fixator has a good aseismic function.

Owner:JIANGSU HENGAI MEDICAL EQUIP

Pipeline hanging bracket with adjusting function

Owner:CHONGQING HAOLONG MACHINERY CO LTD

Fabricated wood plastic plate

ActiveCN110107050APrevent thermal expansion and contractionAvoid thermal expansion and contractionFlooringMating connectionThermal expansion

The invention belongs to the technical field of wood plastic plates, and particularly relates to a fabricated wood plastic plate. The fabricated wood plastic plate comprises a plate body; an insertinggroove is formed in one end of the plate body, and an inserting block is arranged at the other end of the plate body; hinging seats are arranged at the upper end and the lower end of the inserting groove, and arc-shaped inserting plates are hinged to the hinging seats through hinging rods; arc-shaped sliding grooves are formed in the upper side face and the lower side face of the inserting block,and arc-shaped fixed grooves are formed in the two side faces of the arc-shaped sliding grooves; air guiding cavities are formed in the arc-shaped inserting plates, elastic expansion films are arranged on the two side faces of the arc-shaped inserting plates, and the air guiding cavities are connected with the elastic expansion films through air guiding grooves; the elastic expansion films and the arc-shaped fixed grooves are connected in a matched mode; and an elastic airbag is arranged in the inserting groove, thus the expanded elastic expansion films can be clamped into the arc-shaped fixed grooves, then the inserting block and the inserting groove can be quickly and fixedly connected, and the situation that the wood plastic plate is prone to expansion and contraction, then when wood plastic plates need to be mutually connected, reserved gaps are excessively large, and consequently stable connection between the wood plastic plates is affected is prevented.

Owner:江苏昊星新材料有限公司

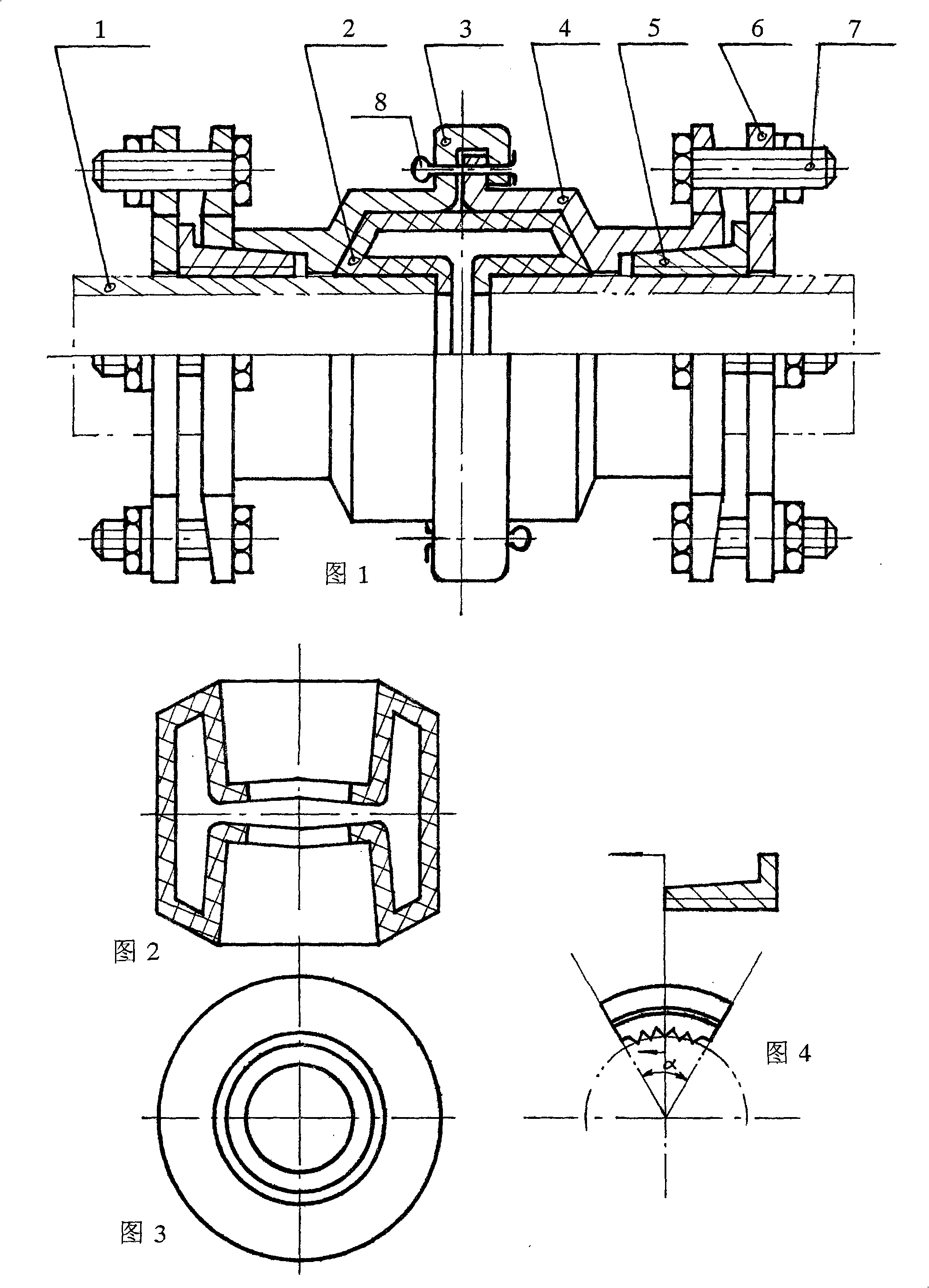

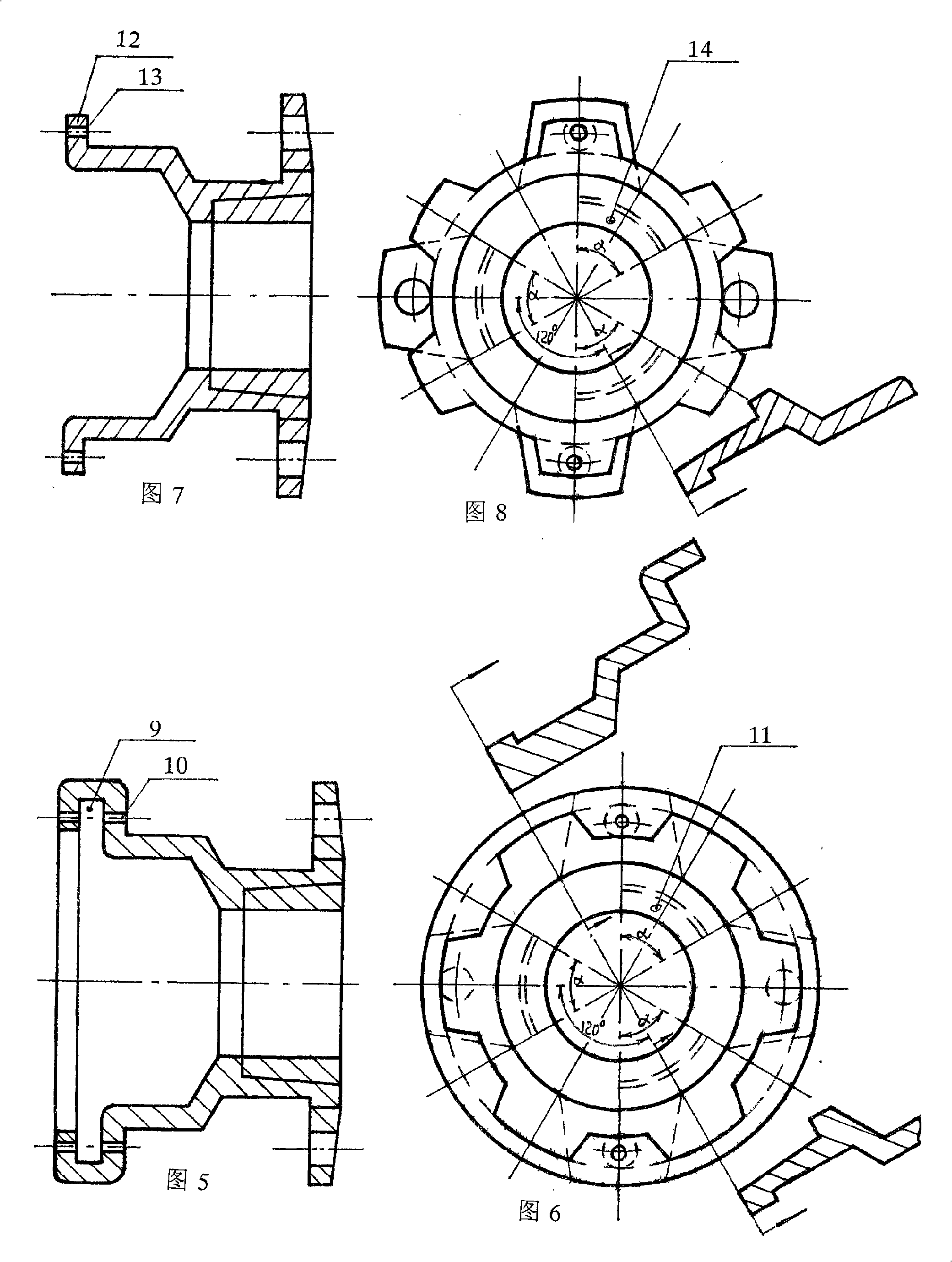

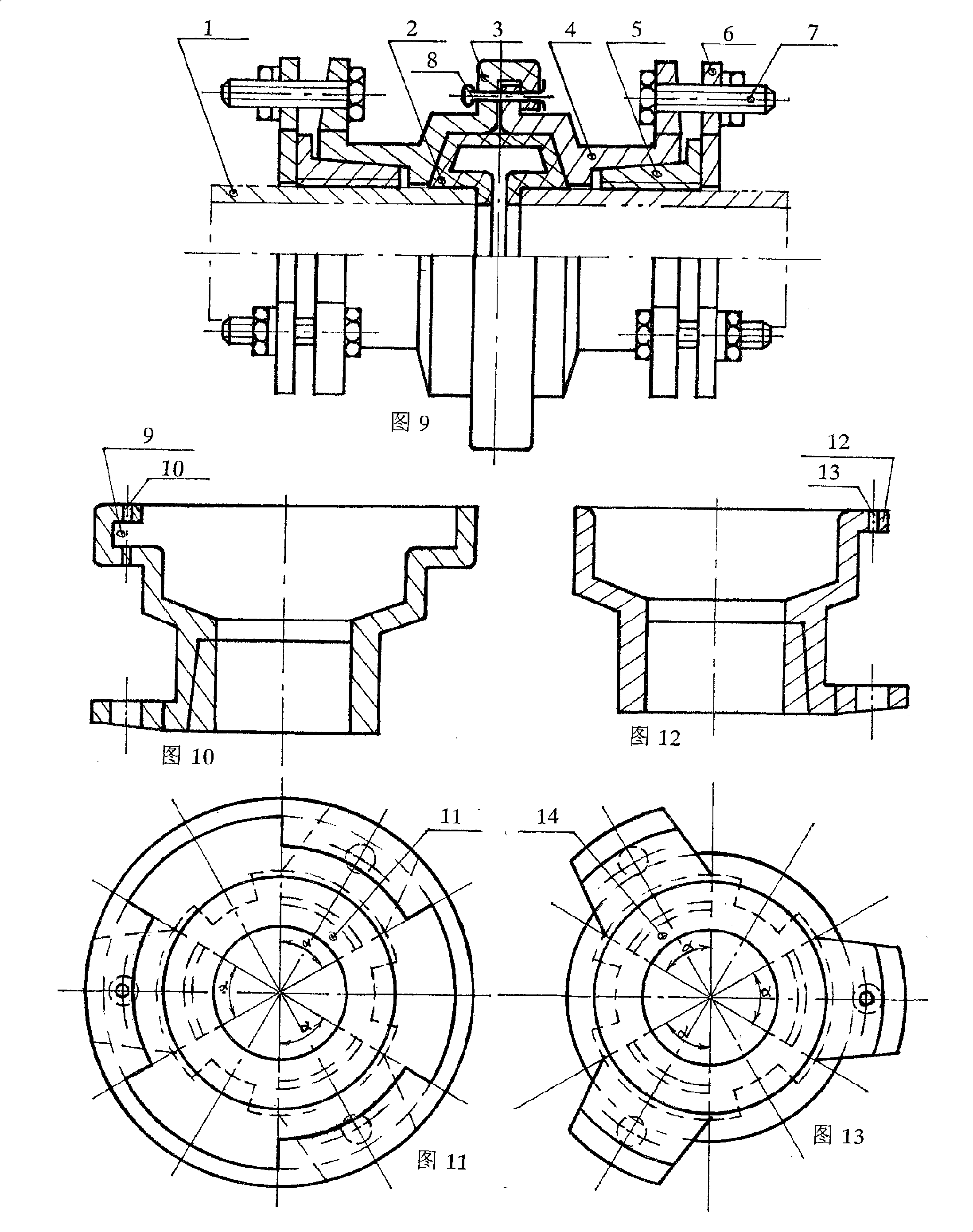

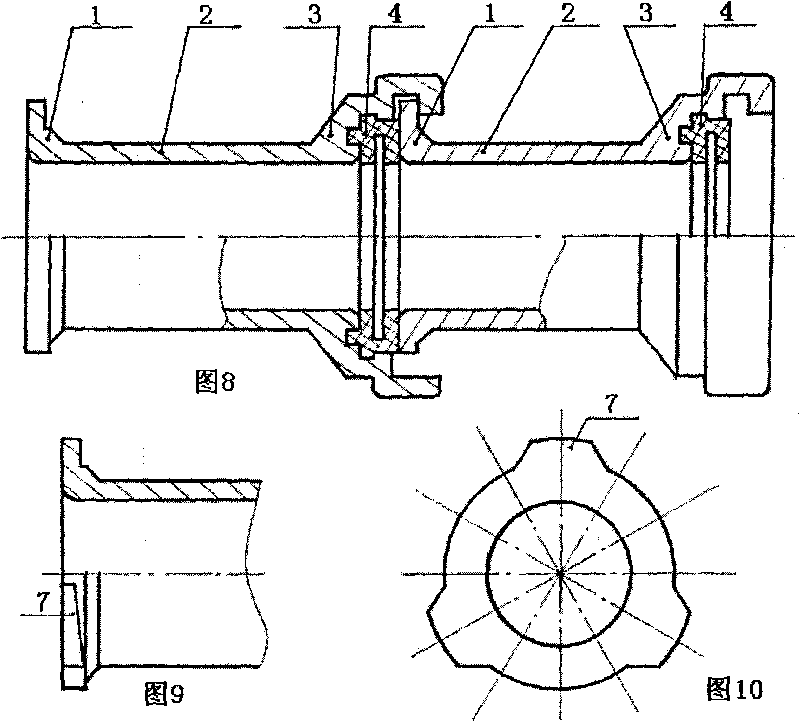

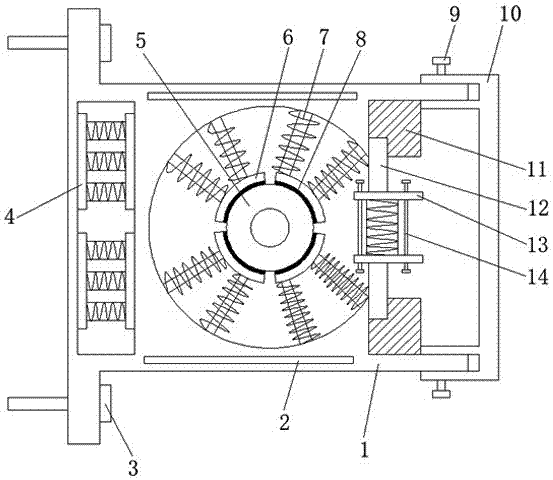

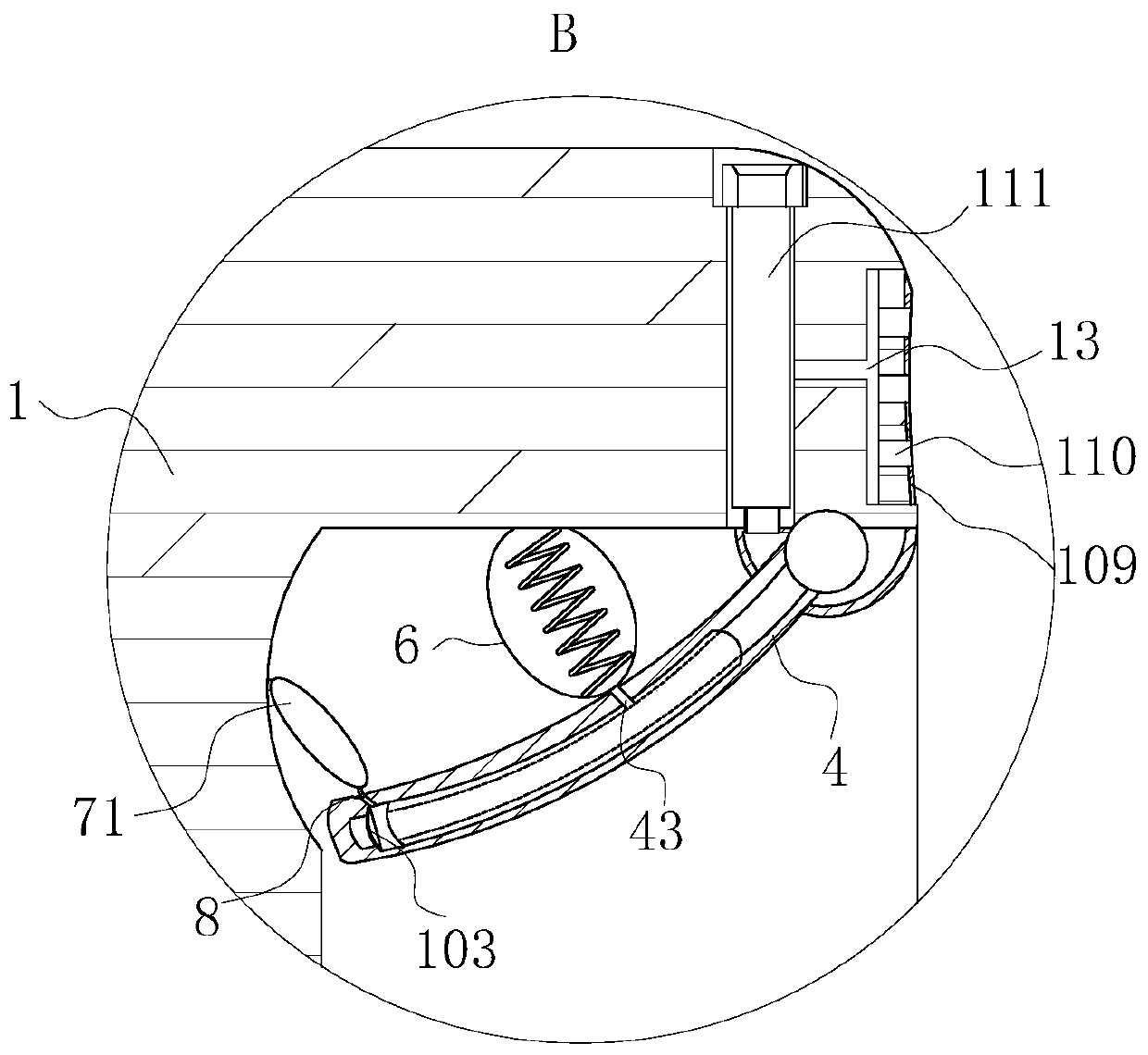

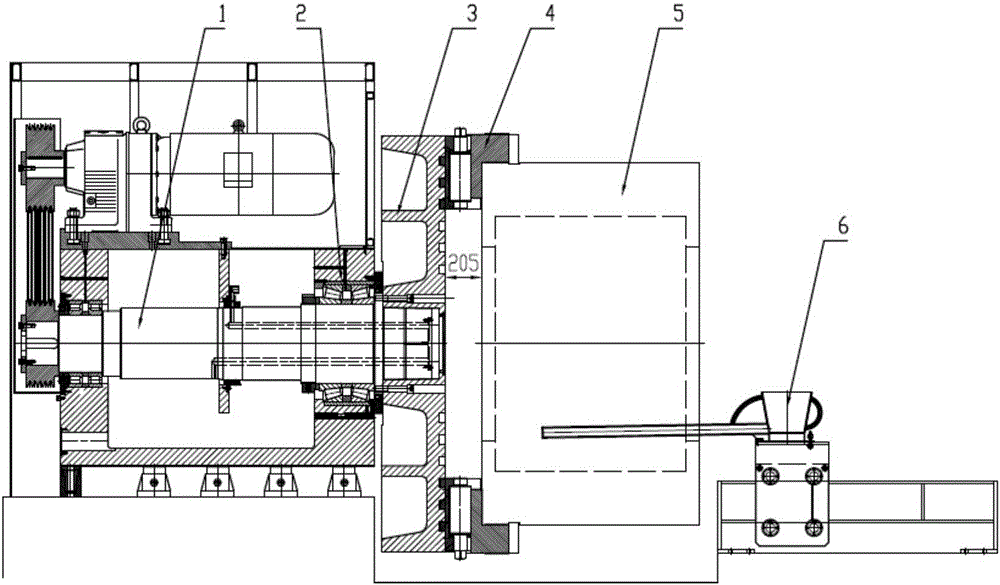

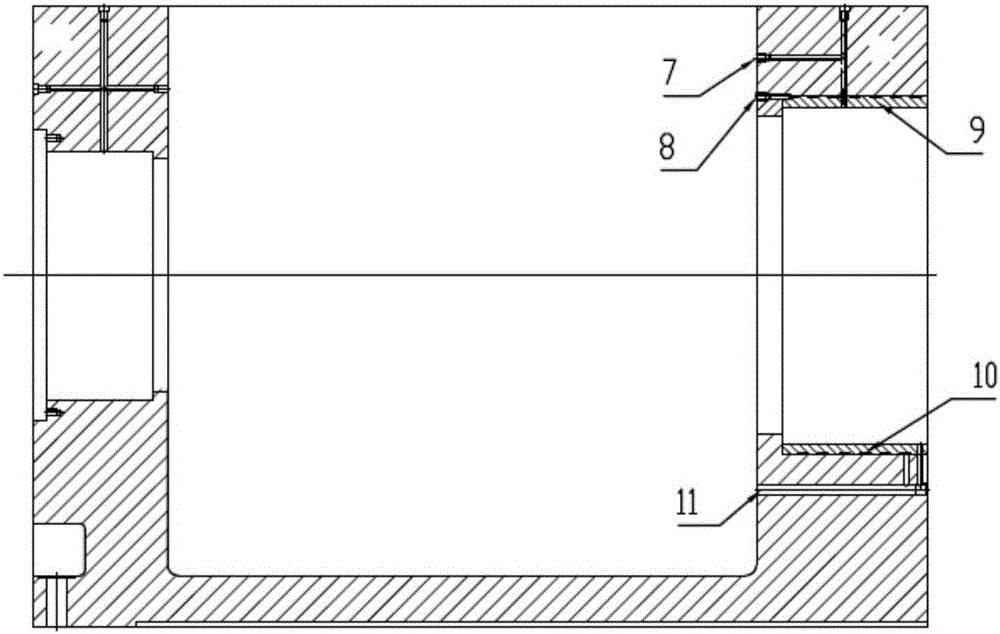

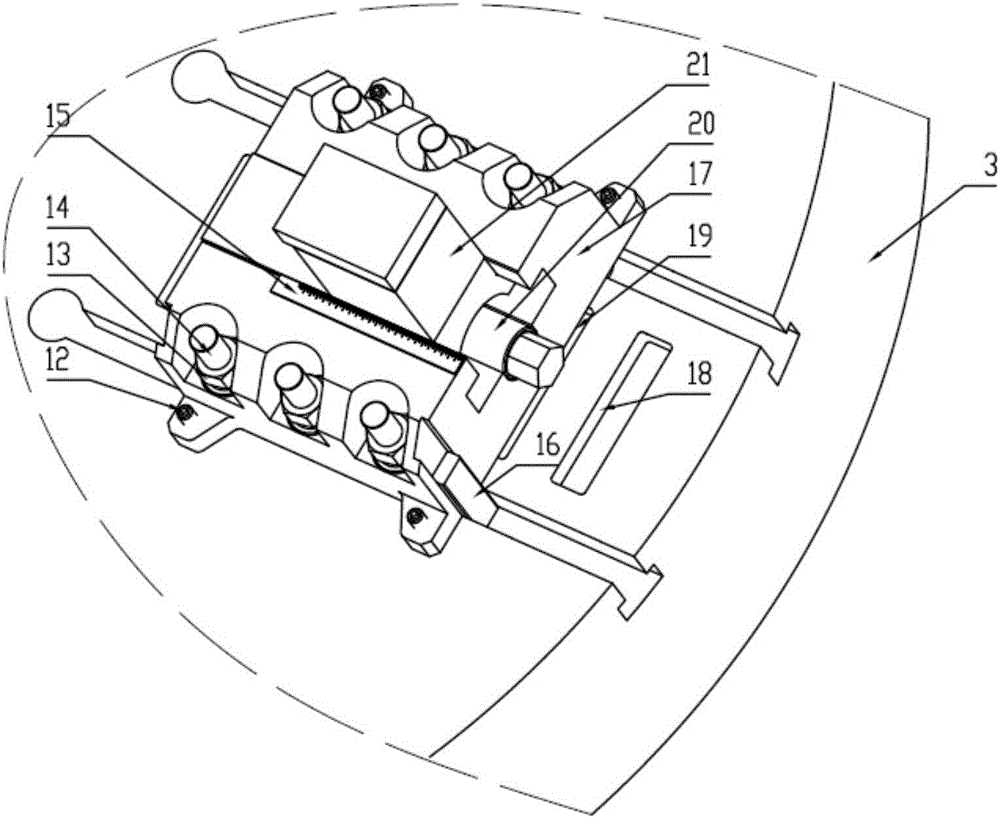

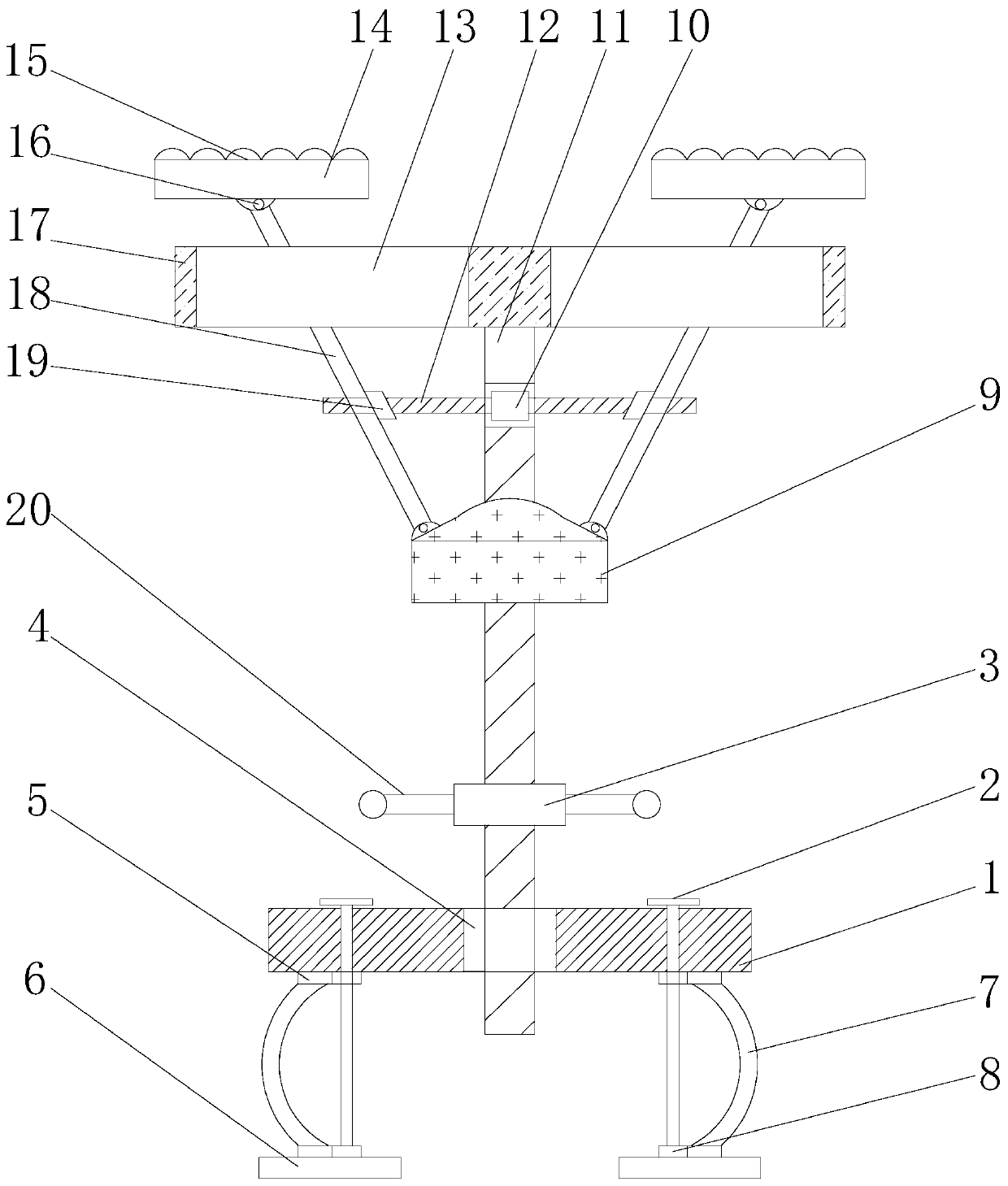

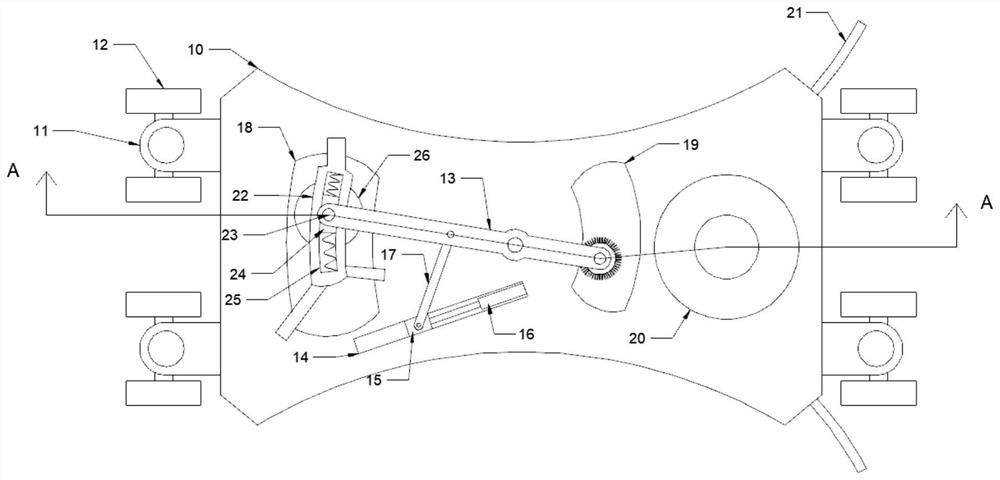

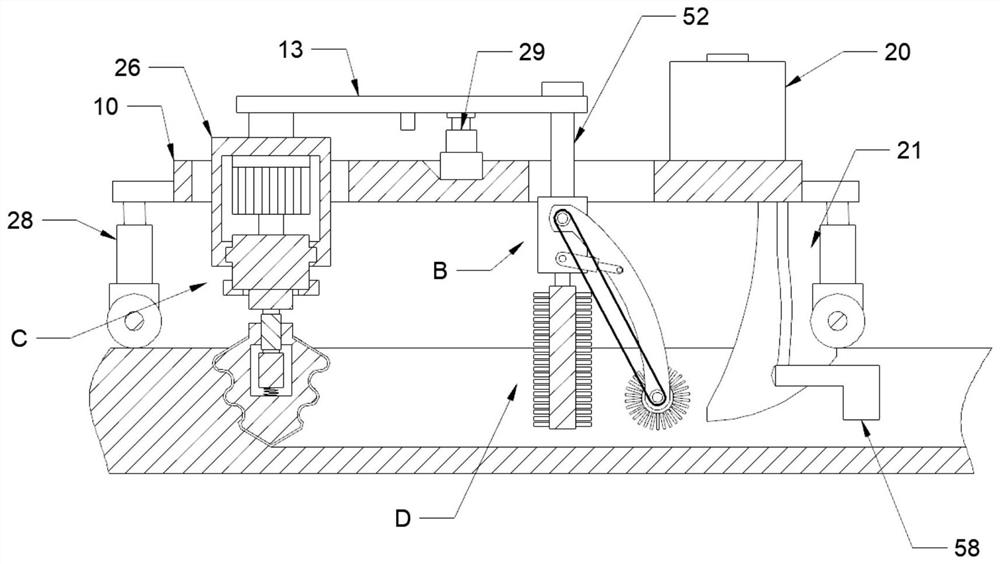

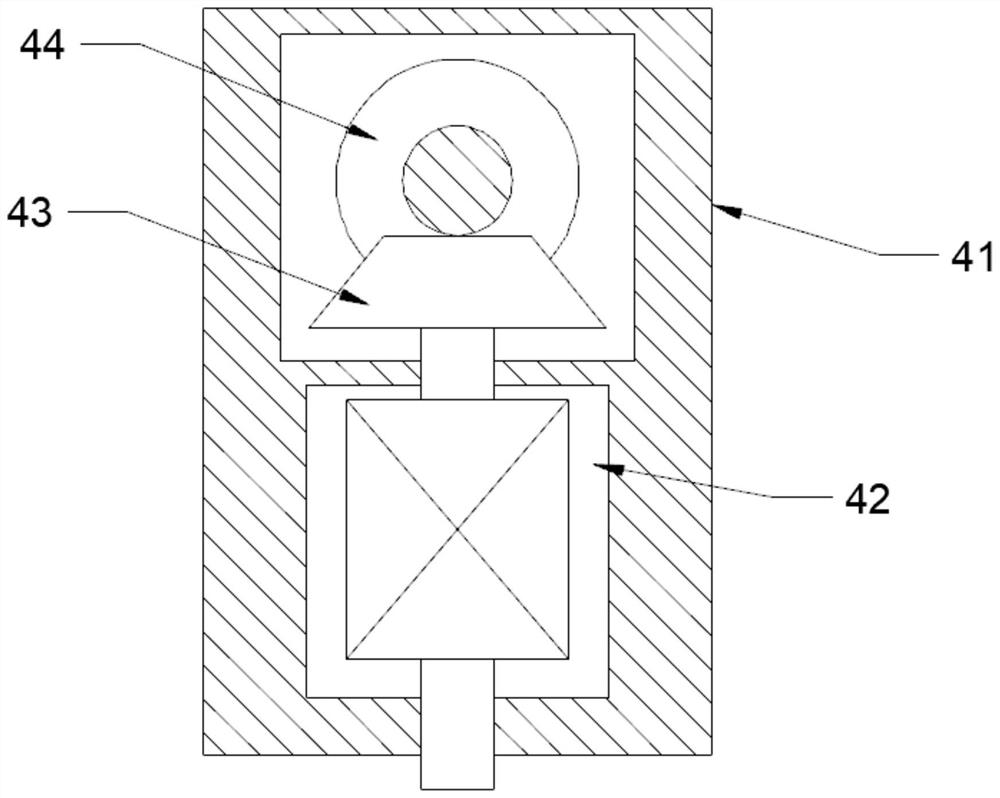

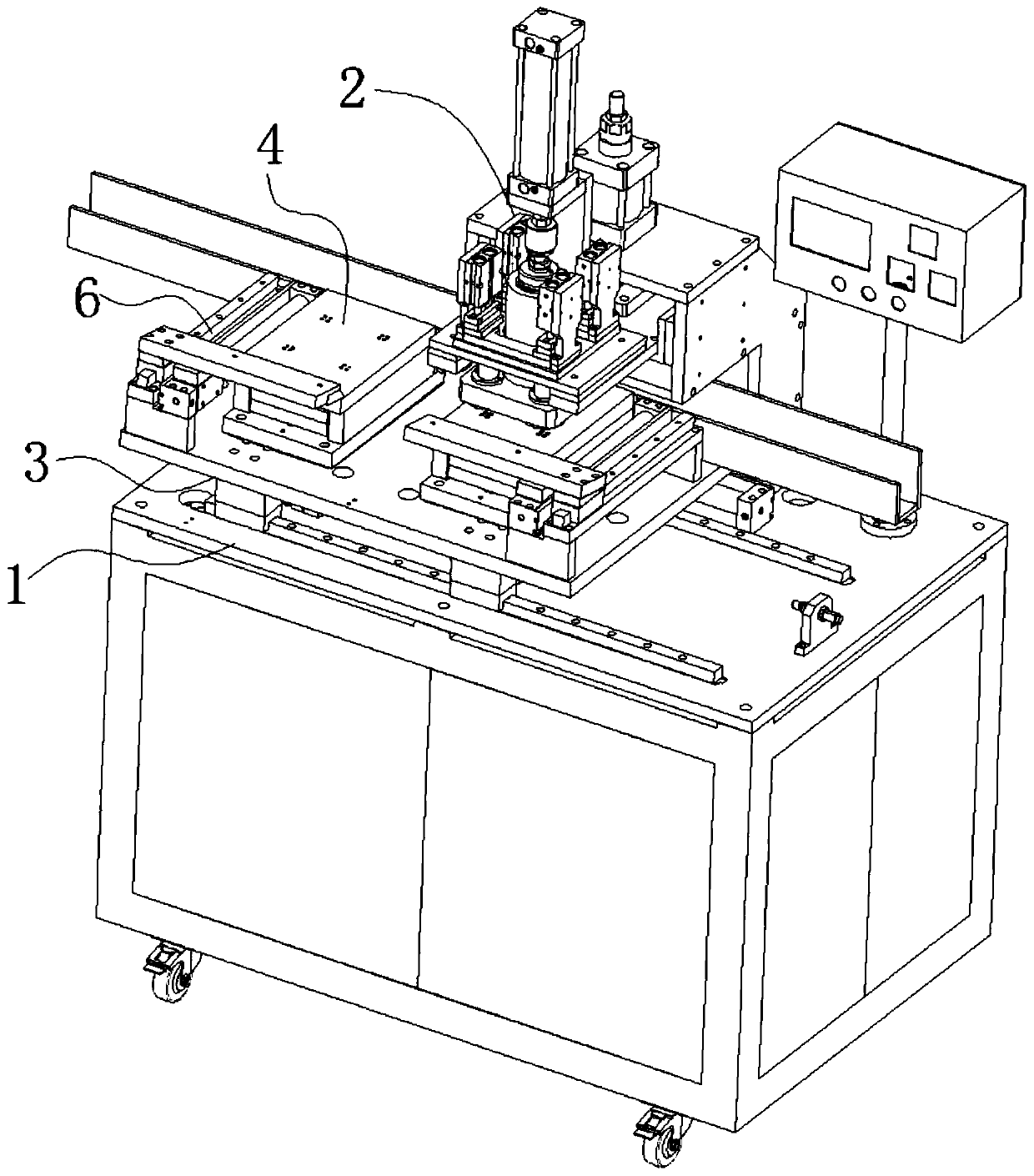

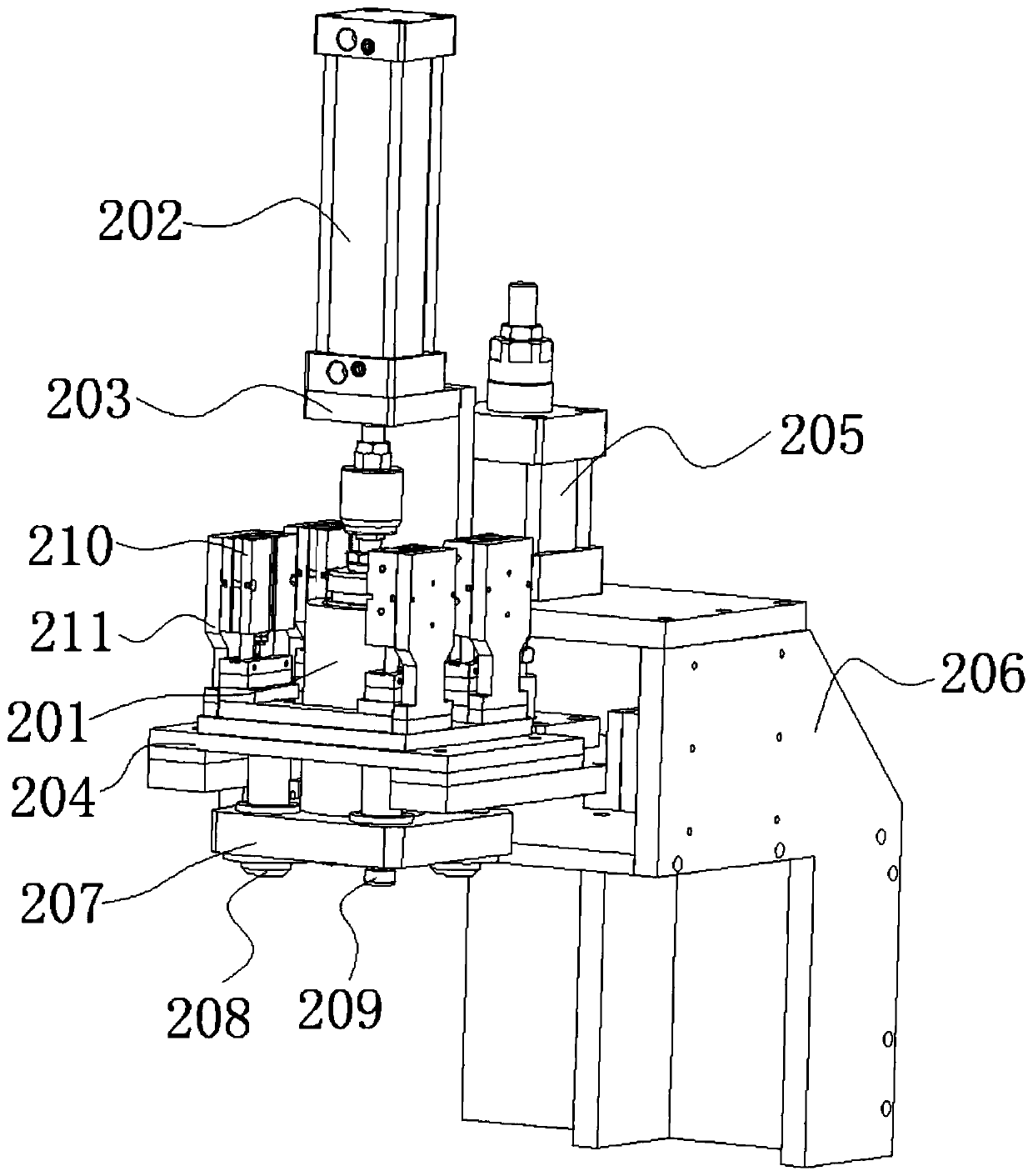

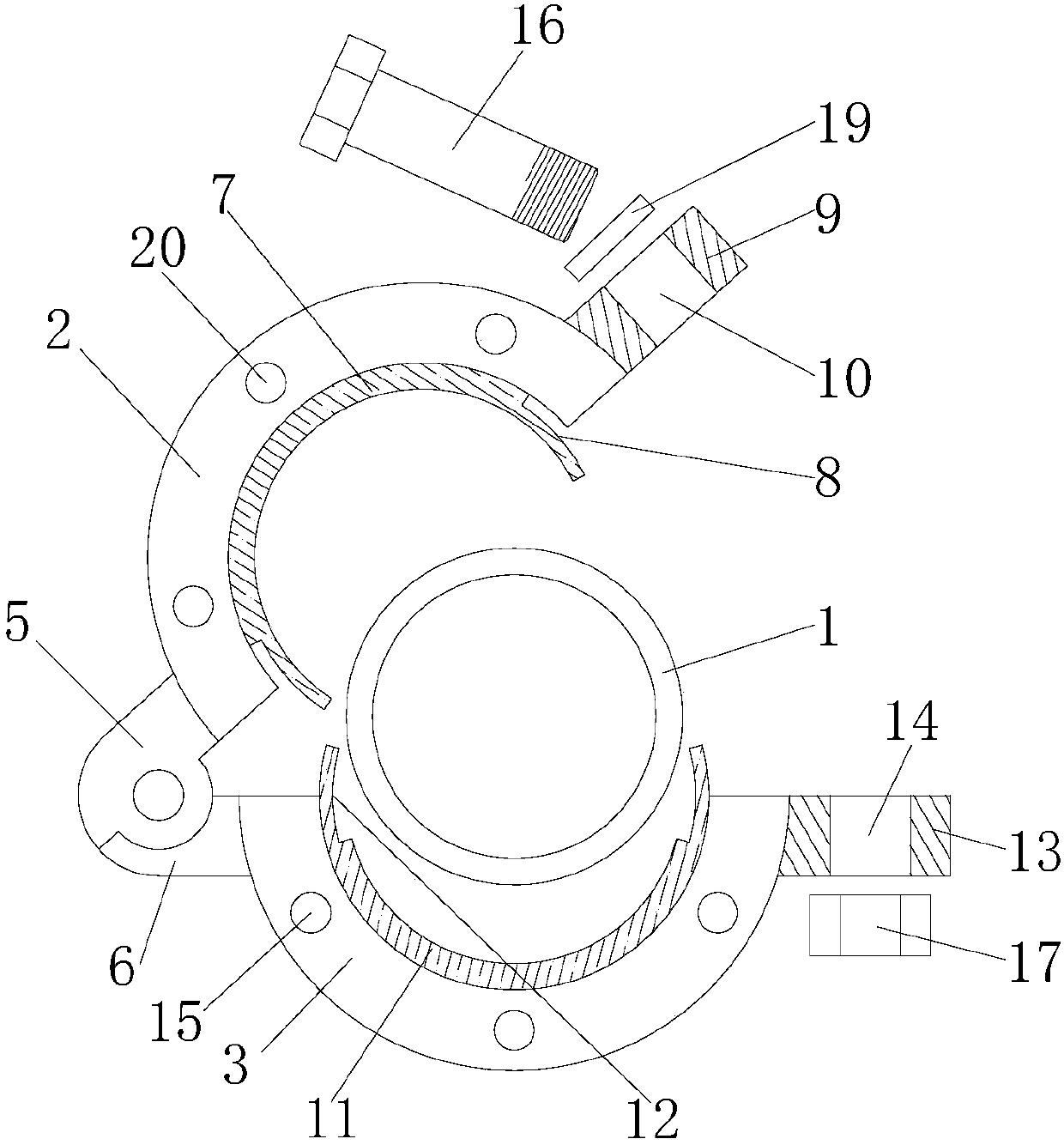

Special centrifugal casting machine for large-scale bearing bush babbitting

The invention discloses a special centrifugal casting machine for large-scale bearing bush babbitting. The special centrifugal casting machine comprises a speed reducer, a main shaft, a box body, a clamping disc and a casting system, wherein the speed reducer is connected with the main shaft through a belt pulley; the main shaft is mounted in the box body through a bearing, penetrates through the box body, and is connected with the clamping disc; a clamping claw assembly is arranged on the clamping disc and used for clamping a workpiece; a casting groove in the casting system extends into the inner cavity of the workpiece. The special centrifugal casting machine has the positive effects that the temperature rise in a moving part is greatly reduced, and thus the bearing is not easy to damage; in high-temperature workpiece babbitting process, a floating clamping claw mechanism is kept being in the clamping state, so as to avoid a heat expansion / cold contraction impact on the workpiece; through equidistant key grooves in a clamping claw seat, the equipment bearing capability is improved; a steel ruler is arranged on the obverse of the clamping claw seat for reference, so that the high-temperature workpiece can be quickly clamped and correctly positioned; and hydraulic thrust clamping is replaced by mechanical claw clamping, so as to increase the workpiece fixing reliability, reduce the maintenance frequency of a hydraulic system, and improve the product quality and the production efficiency.

Owner:DONGFANG TURBINE CO LTD

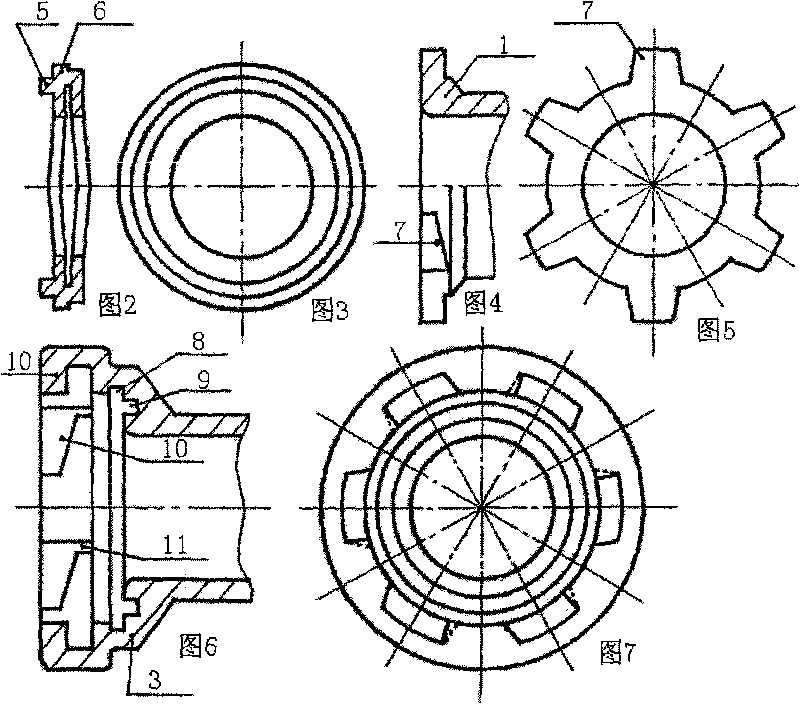

Self-compensating, locking and quick-connecting high-pressure pipe connector

InactiveCN101776192AShorten the installation periodImprove economic efficiencyPipeline expansion-compensationFastenerFusion welding

The invention relates to a self-compensating, locking and quick-connecting high-pressure pipe connector, which consists of a rubber sealing sleeve 2, a clamp hoop 3, a clamp claw 4 and a fastening component 5 and overcomes the defects of the existing pipe connection technology such as high cost and poor practicality. The self-compensating, locking and quick-connecting high-pressure pipe connector is characterized in that the rubber sealing sleeve 2 surrounds the excircle of a pipe, the angular ring of the open cavity of the rubber sealing sleeve 2 is arranged on two pipes. The clamp hoop 3 is symmetrically buckled with the pipe and is pressed on the outer surface of the rubber sealing sleeve 2, the upper annular pointed teeth of the clamp hoop 3 are adhered to the pipe, the inner arc-shaped surface of the clamp claw 4 is provided with a plurality of annular pointed teeth and is arranged in the inner conical groove of the clamp hoop 3, and the clamp claw 4 is adhered to the outer wall of the pipe and can slide along the axial direction of the pipe to concentrically contract, buckle and lock the pipe. The high-pressure pipe connector can resist high, medium and low pressure, and adopts no welding, no flange, no groove, no electric thermal fusion welding or no external compensator, and has the functions of self compensation, locking, all-round safe sealing due to integration of rigid and flexible features, and labor and time conservation. Particularly under harsh environmental conditions, the high-pressure pipe connector has the advantages of convenient and rapid connection, low cost, high efficiency, energy conservation, emission reduction and environmental protection. The invention can be used for connecting two pipes for fluid transmission.

Owner:王甲南

Supporting device of building structure

The invention discloses a supporting device of a building structure. The supporting device includes a bottom plate, fixing bolts, a fixing sleeve, a threaded hole, a connecting plate, a supporting plate, an arc-shaped steel plate, connecting nuts, a fixing block, a biaxial motor, a threaded rod, lead screws, a sliding groove, a movable plate, an anti-skid pad, a rotating shaft, a top plate, connecting rods, lead screw nuts, and a push rod. The supporting device is reasonable in structure, novel in design, easy to operate, and convenient to install, by pushing the push rod, the push rod drives the fixing sleeve and the threaded rod to rotate in the threaded hole in the center of the bottom plate, thus the length of threaded rod at both ends of the bottom plate is adjusted, the two lead screws rotate through the biaxial motor, the lead screw nuts on the two lead screws drive the connecting rods to rotate through the rotating shaft, the two connecting rods drive the movable plate and the anti-skid pad to slide in the sliding groove, the movable plate and the anti-skid pad are tightly attached to the surface of the building structure under the action of the connecting rods, supporting of building structures with different heights and shapes is convenient, and convenience and rapidity are realized.

Owner:NANJING UNIV OF SCI & TECH

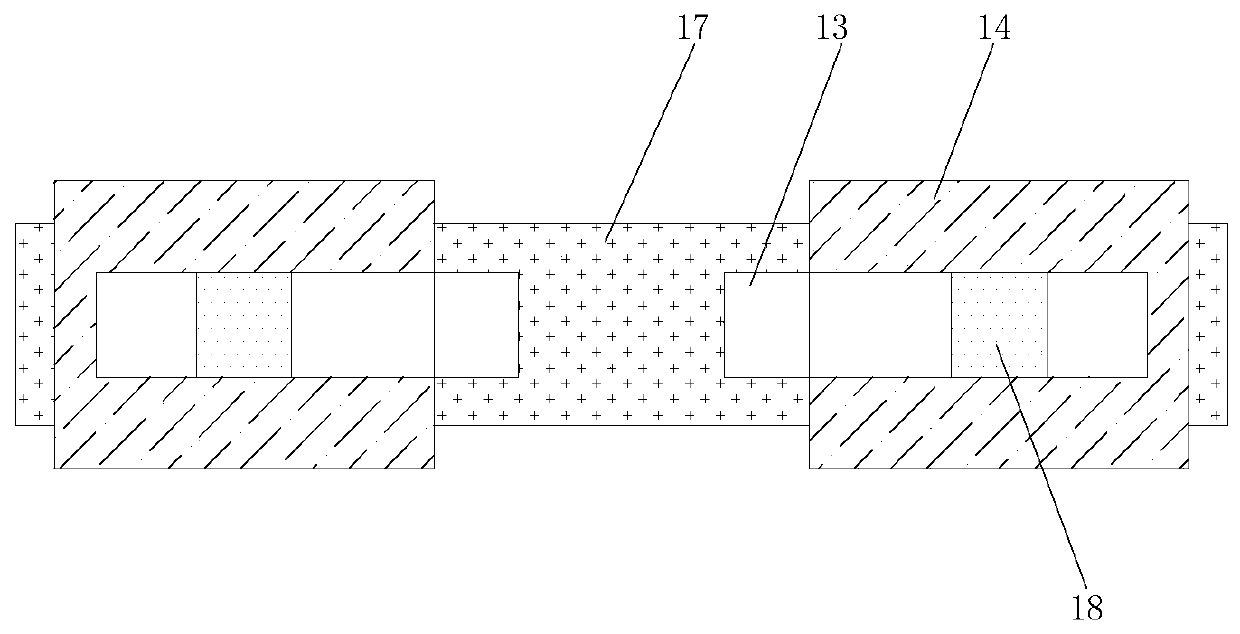

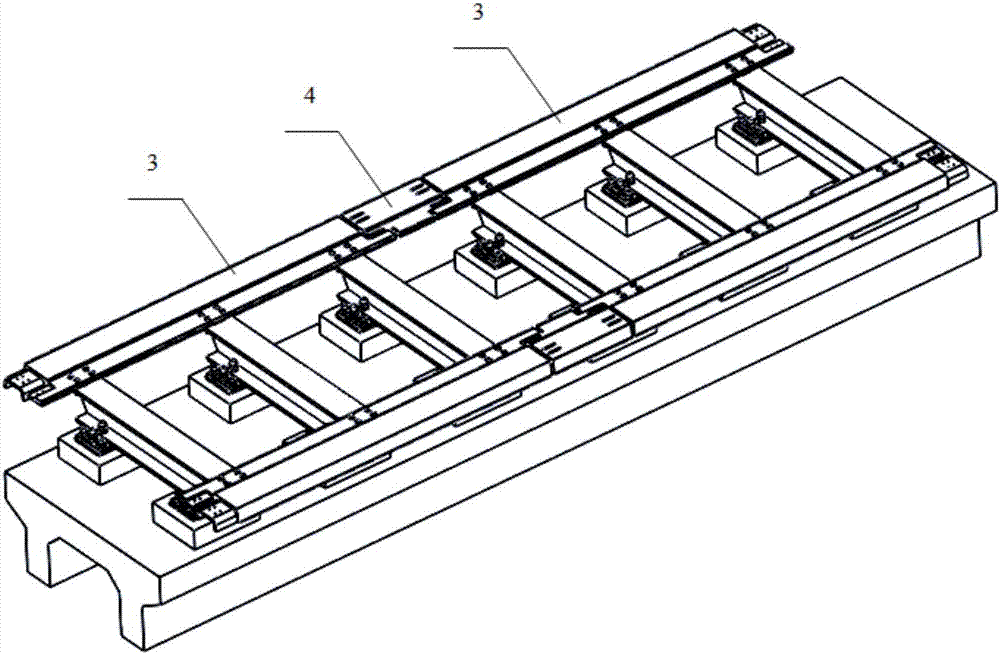

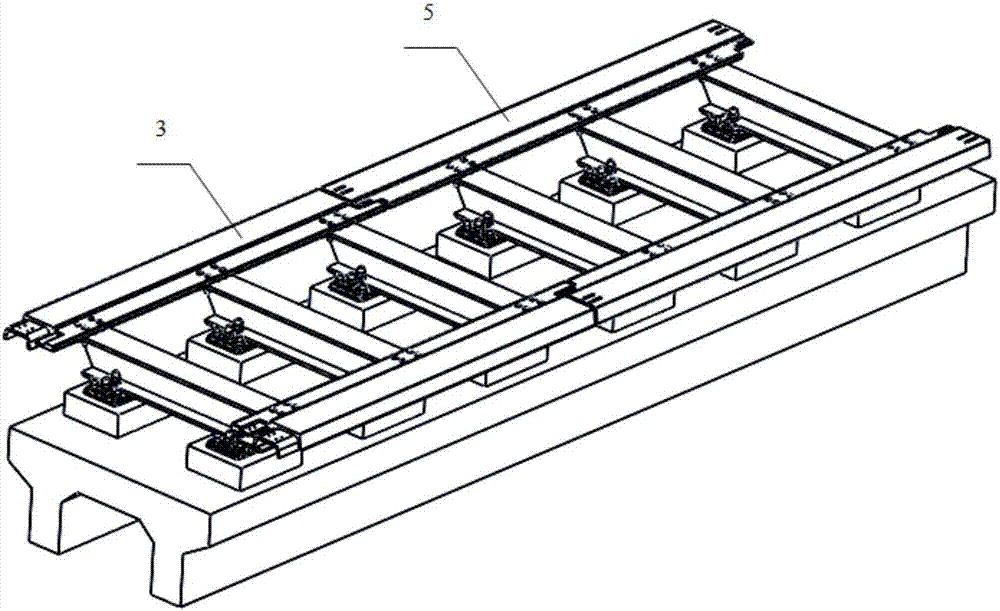

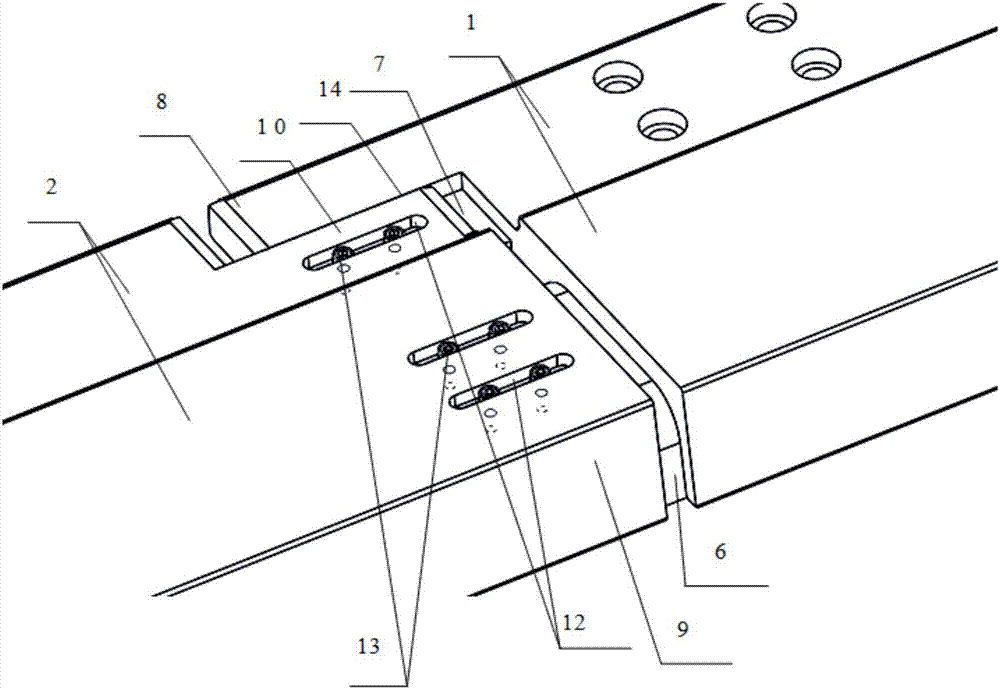

Magnetically-levitated track sleeper joint and magnetically-levitated track

PendingCN106868957AAvoid thermal expansion and contractionAvoid positionRailway tracksTrackwayMagnetic poles

A magnetic levitation rail row connector and a magnetic levitation track provided by the present invention, the magnetic levitation rail row connector includes a main connector and a secondary connector respectively arranged on two adjacent rail rows. The concave-convex fit of the main joint and the auxiliary joint can realize the vertical and horizontal limit adjustment of the rail row. The maglev track is composed of main joint rail row and auxiliary joint rail row connected in sequence. This solution forms a magnetic pole surface without excessive gaps through the concave-convex cooperation of the main joint and the auxiliary joint, avoiding the existence of the gap end face in the past. When the external temperature changes, the rail row can freely expand with heat and contract with cold and fluctuate in position, ensuring magnetic levitation The stable operation of the train reduces energy consumption.

Owner:SHANDONG LAIGANG CONSTR CO LTD +1

Transformer oil paper insulation long-time electric heating combined aging experiment device and method

ActiveCN111880054AAvoid corrosionAvoid thermal expansion and contractionTesting dielectric strengthHeating oilLow voltage

The invention discloses a transformer oil paper insulation long-time electric heating combined aging experiment device and method. An electrode plate of a high-voltage electrode is located in a sealing tank, an electrode stem of the high-voltage electrode extends out of an upper cover plate of the sealing tank, the electrode stem of the high-voltage electrode can move relative to the upper cover plate, and a low-voltage electrode is arranged at the bottom of the sealing tank. An insulation sample is arranged between the high-voltage electrode plate and the low-voltage electrode plate, the sidewall of the sealing tank is provided with a temperature measuring conduit and a ground wire wiring conduit which are communicated with the sealing tank, the temperature measuring conduit is blocked by a first rubber plug, the ground wire wiring conduit is blocked by a second rubber plug, and the temperature sensor shell is embedded into the first rubber plug. An inductive probe of the temperaturesensor is arranged at the bottom of the sealing tank, the grounding wire is embedded into and penetrates through the second rubber plug to be connected with the low-voltage electrode, the oil bath groove heats the sealing tank through heating oil in the oil bath groove, and the high-frequency current sensor is installed on the grounding wire. Accurate data reference can be provided for operationand maintenance decisions of the transformer.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +4

High-strength plane repairing equipment

InactiveCN113279313AImprove waterproof performanceDeep penetrationRoads maintainenceAdhesiveConstruction engineering

The invention relates to the related field of building maintenance equipment, and discloses high-strength plane repairing equipment which comprises a base plate, a vertically-through first swing groove is formed in the front side of the base plate, a vertically-through second swing groove is formed in the rear side of the base plate, and fixing rods are installed on the front portion and the rear portion of the base plate correspondingly. Adjusting telescopic rods are set on the lower sides of the fixing rods, and rollers are installed on the lower sides of the adjusting telescopic rods. According to the equipment, a cutter body is arranged, protrusions, grooves and cutting edges are arranged on the outer side of the cutter body, the cutter body can be rotated to cut plane cracks, the grooves with a certain width are formed, under the action of the protrusions and the grooves, the sections of the grooves are wavy grooves, the areas of the two sides of the two grooves are increased, and the repair adhesive can fully bond the wall bodies on the two sides conveniently.

Owner:李艳丰

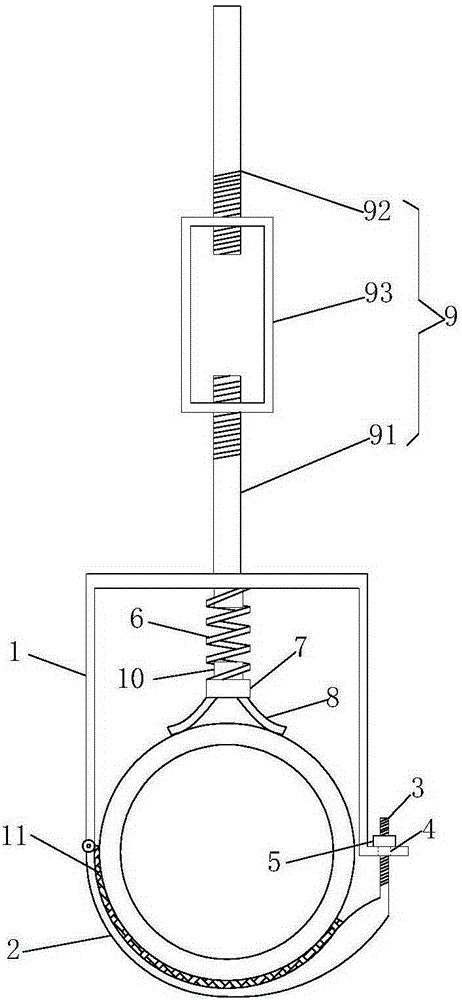

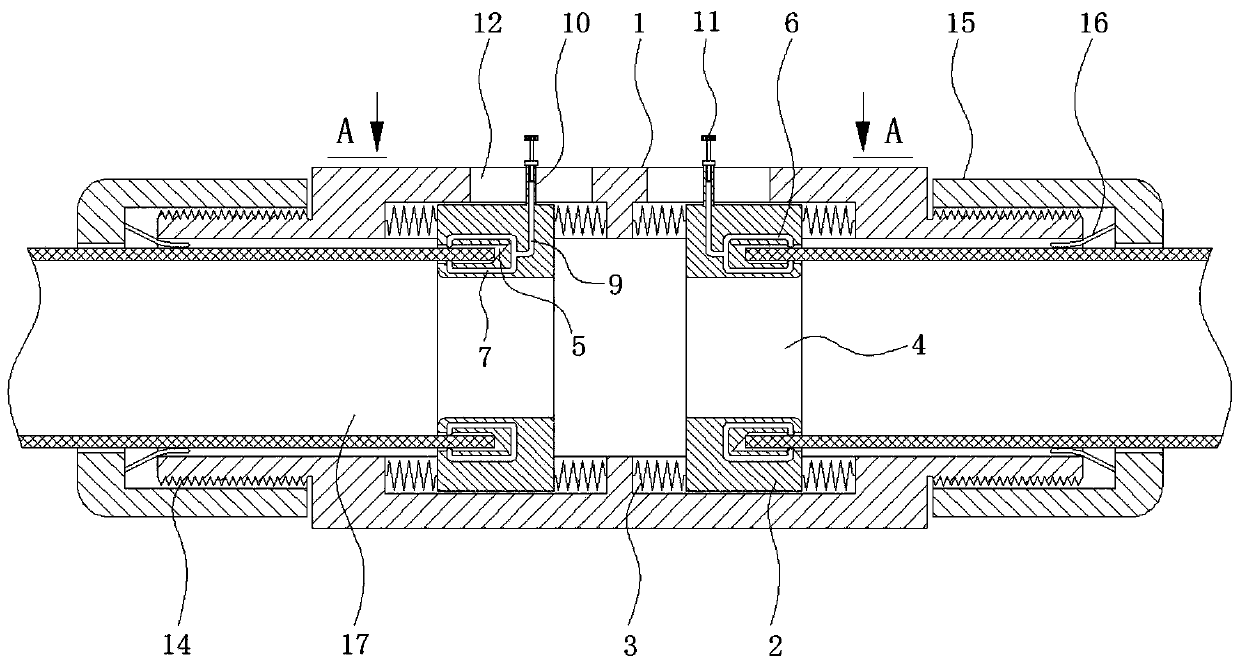

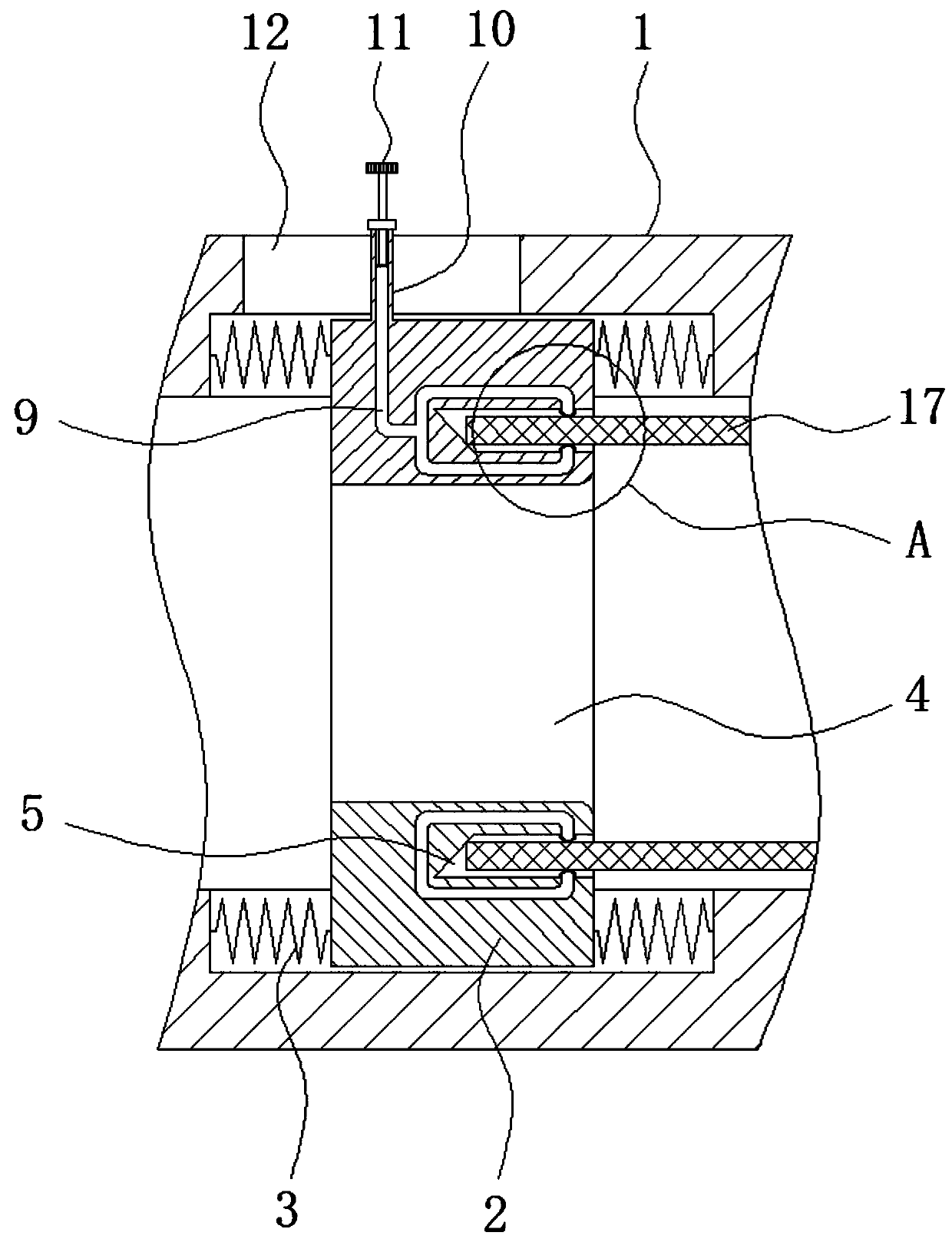

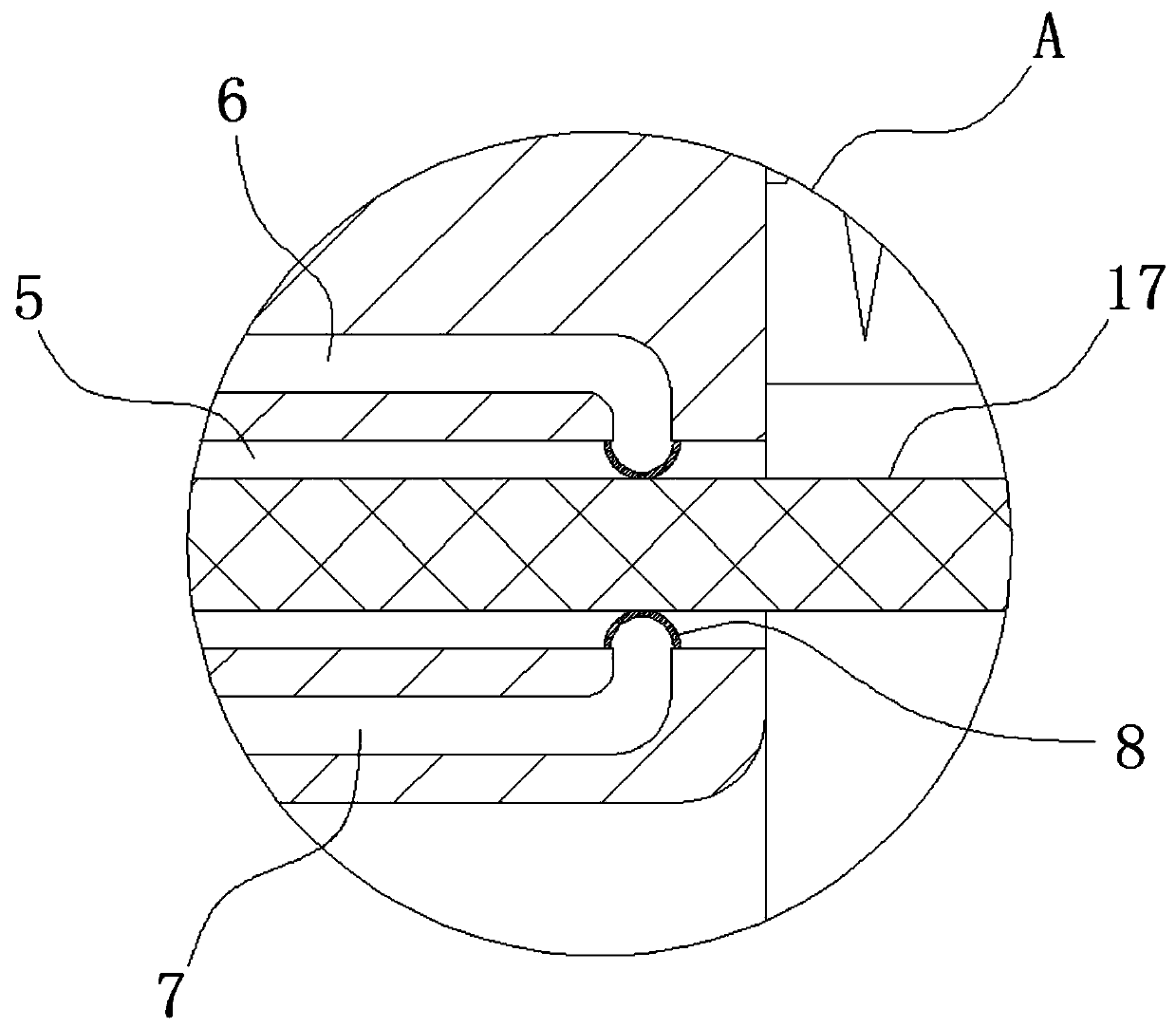

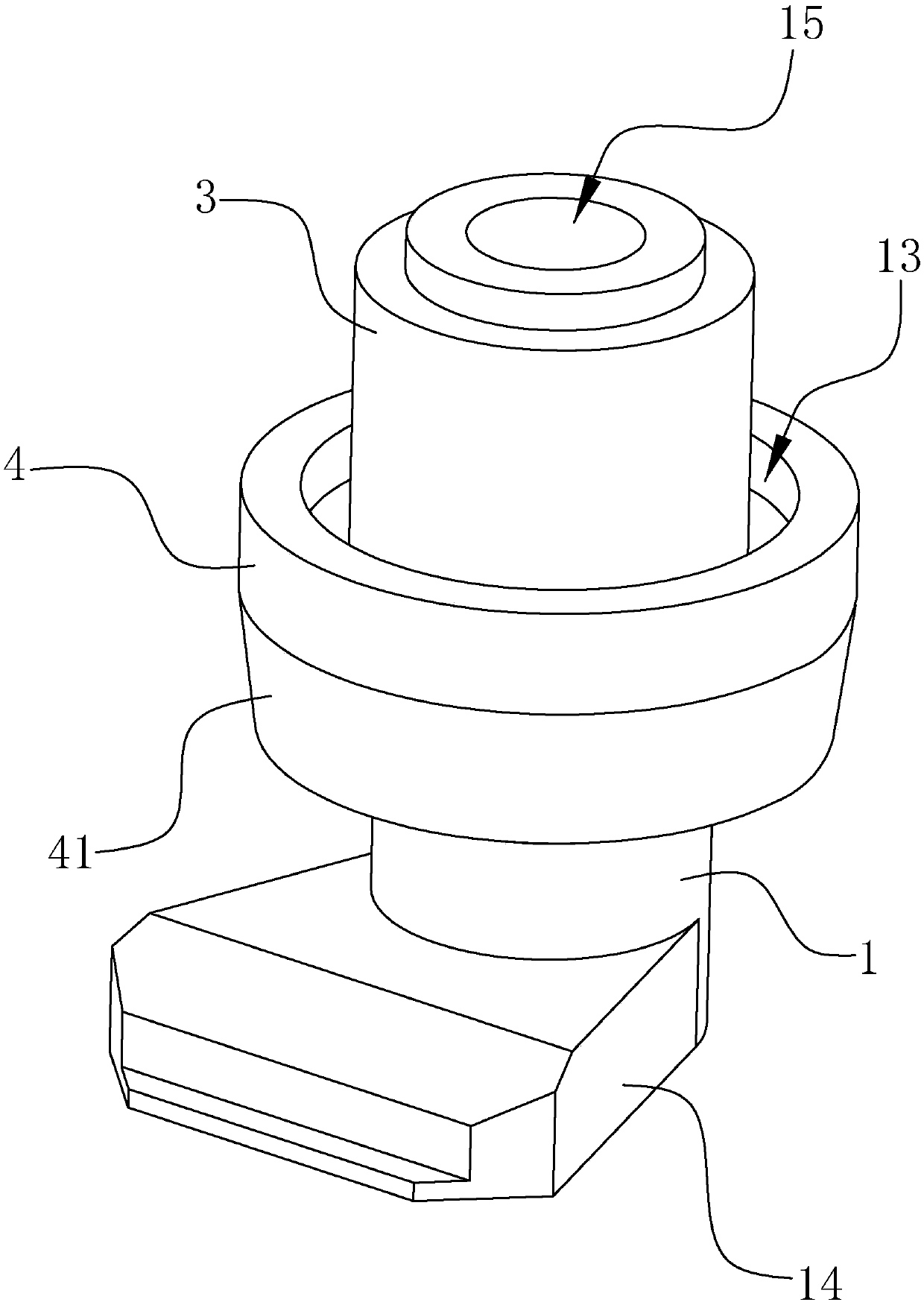

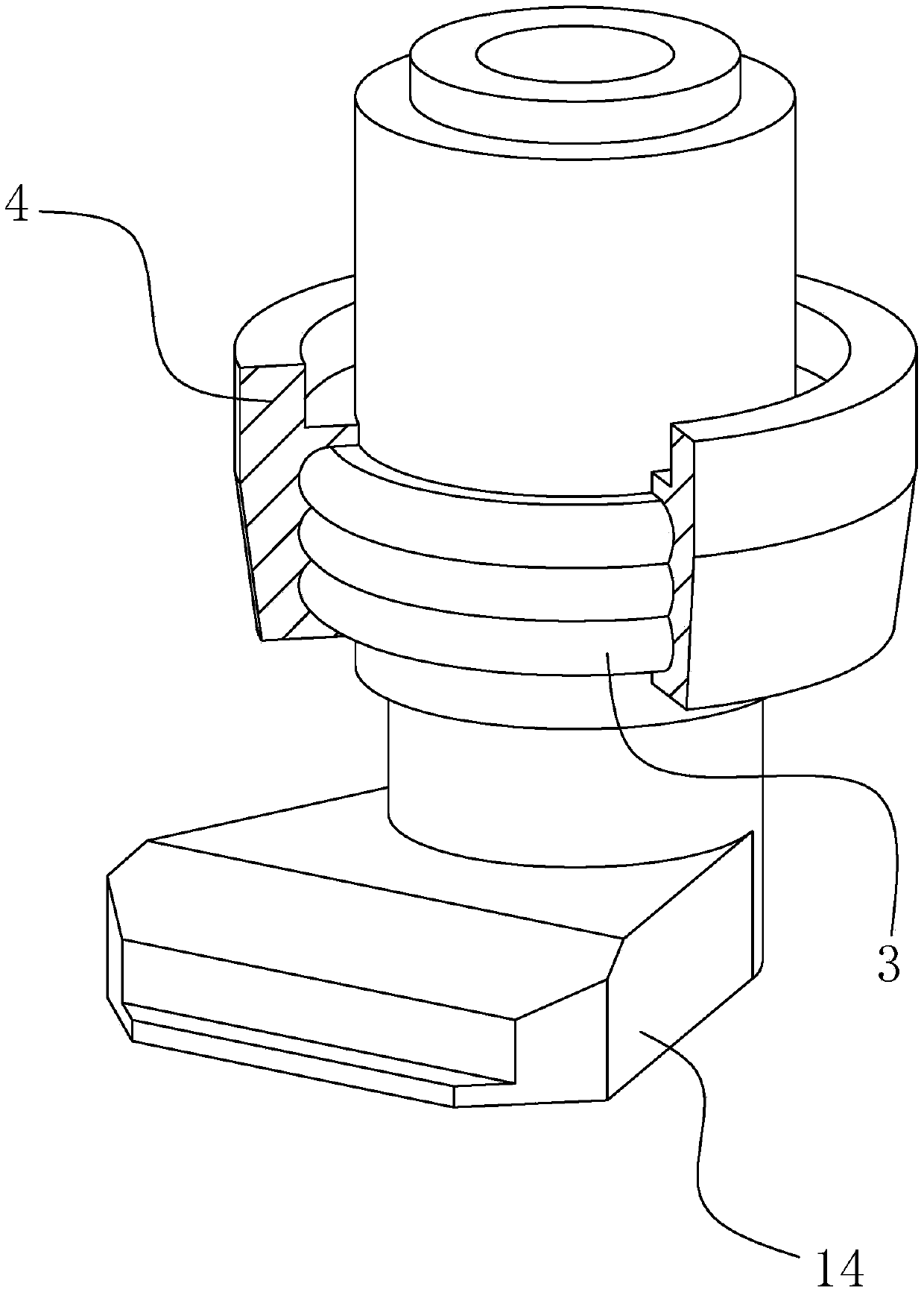

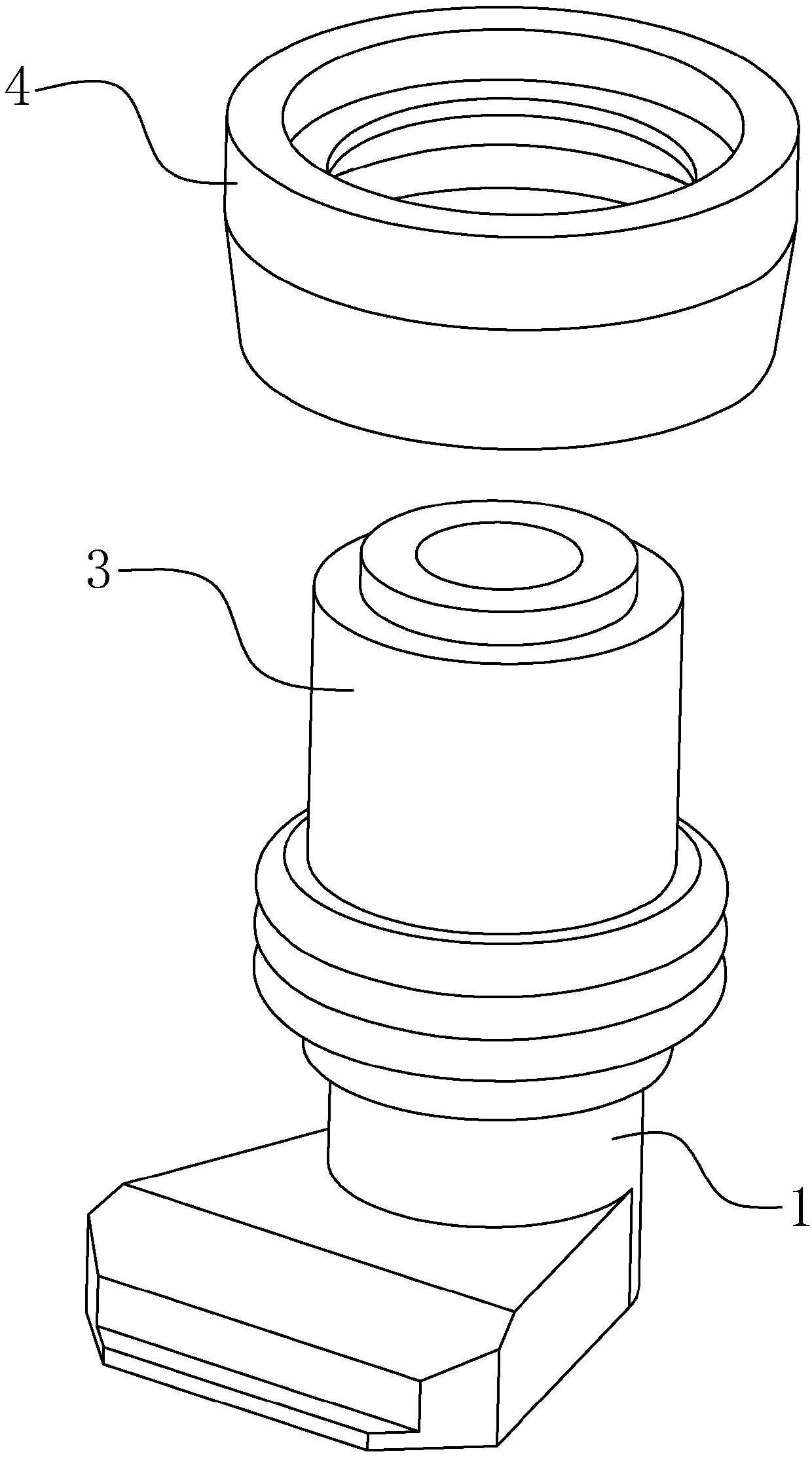

Pipe joint fastener for preventing thermal expansion and cold contraction

ActiveCN110242806AAvoid thermal expansion and contractionAvoid squeezingEngine sealsJoints with sealing surfacesThermal expansionPetroleum engineering

The invention provides a pipe joint fastener for preventing thermal expansion and cold contraction, and relates to the technical field of pipe joints. The pipe joint fastener for preventing thermal expansion and cold contraction comprises a joint, the inner portion of the joint is slidably connected with a positioning ring, the two sides of the positioning ring are fixedly connected with springs, the center of the positioning ring is provided with a circular hole, grooves are formed in the sides, facing the left and right ends of the joint, of the positioning ring, and an upper oil pipe and a lower oil pipe are arranged on the upper and lower sides of the grooves in the positioning ring. According to the pipe joint fastener for preventing thermal expansion and cold contraction, the sealing effect on the inner and outer sides of a pipe can be maintained when the pipe is deformed due to thermal expansion and cold contraction, no deviation occurs between the pipe and the joint, the problems of looseness of the joint and decreasing of the sealing performance are solved, meanwhile, the deformation of the pipe can be visually observed, analysis of deformation of the pipe on the joint is facilitated, and a basis is provided for future maintenance.

Owner:浙江环台精密机械股份有限公司

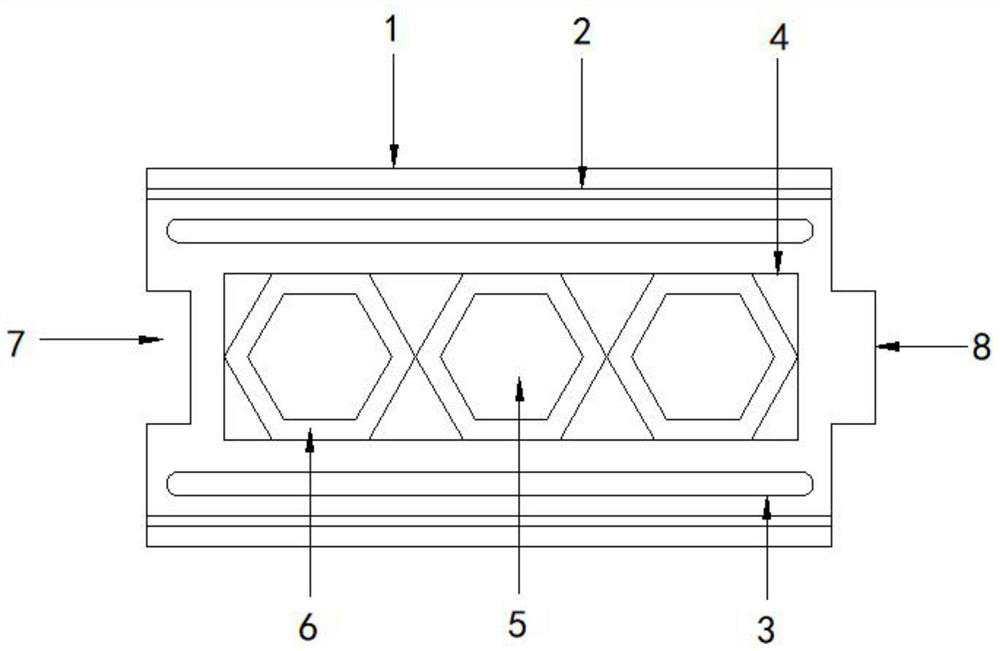

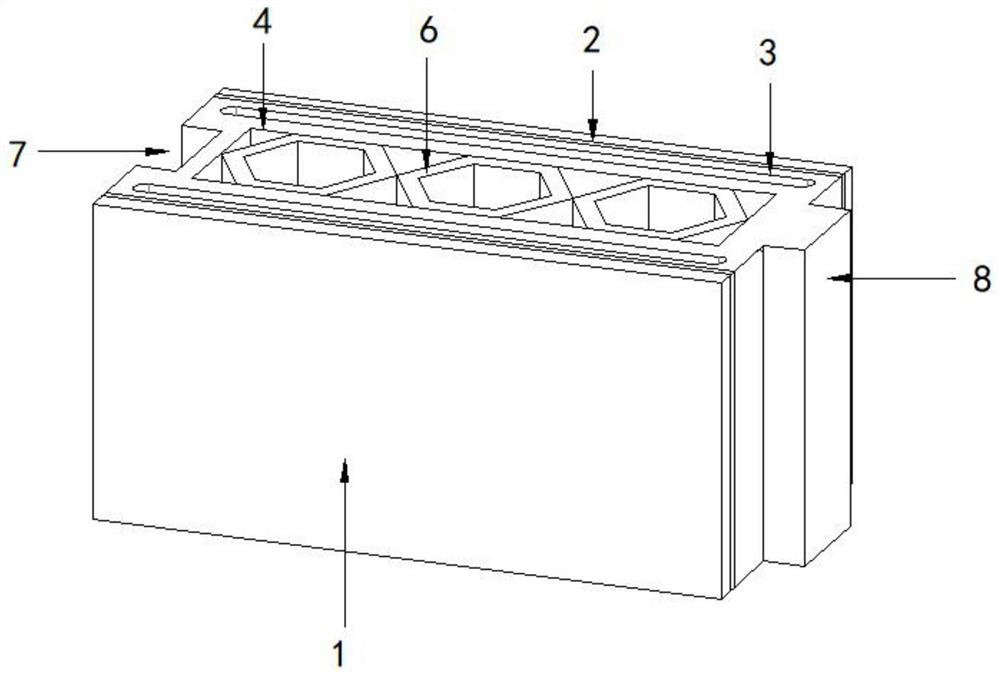

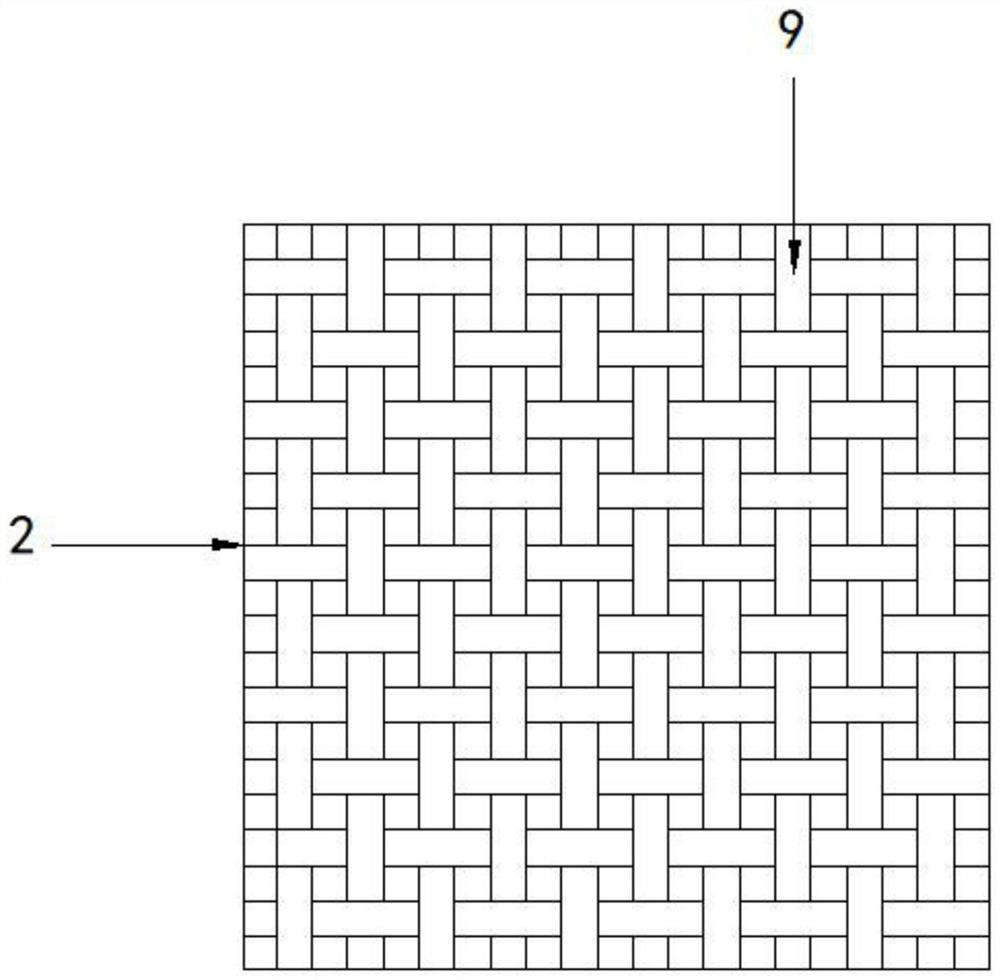

TRC recycled aggregate concrete block and processing method thereof

InactiveCN111809790ARealize energy savingRealize environmental protectionConstruction materialSolid waste managementBrickConstruction engineering

The invention discloses a TRC recycled aggregate concrete block and a processing method thereof. The TRC recycled aggregate concrete block comprises a block body. A pocket of a rectangular structure is formed in the block body. Two reinforcing plates are disposed in the pocket symmetrically about the central line. An orthohexagonal supporting structure is formed between the two reinforcing plates,and an orthohexagonal vent hole is formed in the middle of the supporting structure. Silencing grooves each of a long-strip-shaped structure are formed in the two sides of the pocket. Woven nets aredisposed on the two sides of the silencing grooves, and the woven nets and the block body are integrally formed by pouring. Waste concrete, waste blocks and waste lime-sand mortar in a construction site are used as raw materials, so that waste resources are sufficiently used, and the aims of energy conservation, emission reduction and environmental protection are realized; and the pocket is formedin the block body, and the reinforcing plates are disposed in the pocket, so that the weight of the block body is reduced, meanwhile, the structural strength of the block body is ensured, and light-weight assembling is facilitated.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

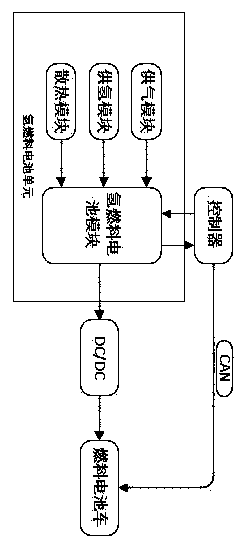

Hydrogen fuel cell system

InactiveCN110450678AAvoid thermal expansion and contractionFuel cell controlPropulsion by batteries/cellsHydrogen fuel cellEngineering

The invention provides a hydrogen fuel cell system, and belongs to the field of fuel cells. The hydrogen fuel cell system comprises a hydrogen fuel cell unit and a hydrogen fuel cell vehicle, and further comprises a controller connected to the hydrogen fuel cell unit for providing energy for the vehicle, the hydrogen fuel cell unit is connected to the hydrogen fuel cell vehicle through a converter, and the controller is connected to the hydrogen fuel cell vehicle through a CAN bus. The cell system is simple in structure, small in space occupation area and free of pollution.

Owner:ZHEJIANG BELORD DRIVE TECH

Manufacturing method of double-injection-molded battery terminal for battery

InactiveCN109638216AEliminate cracksAvoid corrosionLead-acid accumulatorsSmall-sized cells cases/jacketsEngineeringDouble injection

A manufacturing method of a double-injection-molded battery terminal for a battery comprises the following steps: processing a conductive pole into a metal pole with an annular convex ring in the middle, a base at the bottom and an electric connection part at the top; coating a resin coupling agent on the outer peripheral surfaces of the metal pole and the annular convex ring, and placing the metal pole in a mold with the temperature of 190-250 DEG C and the pressure of 15-80 kg for injection molding of a soft inner injection molding layer; placing a metal column body in a mold with the temperature of 190-250 DEG C and the pressure of 50-120kg, arranging a hard outer plastic layer on the outer peripheral surface of the inner injection molding layer at the position of the annular convex ring in an injection molding manner, and when the hard plastic layer is arranged on the inner injection molding layer in an injection molding manner, the inner peripheral wall of the outer plastic layercompressing the outer diameter of the inner injection molding layer by 0.1-1mm and being tightly pressed and fastened together; and taking out the pole of the injection-molded hard outer plastic layerfrom the mold. The manufacturing method has the advantages of convenience in processing, low manufacturing cost, simple pole structure, convenience in mounting, capability of being used for high-speed rails and good shockproof and leakage-proof effects.

Owner:ZHEJIANG HONGDA SPECIAL RUBBER PRODS

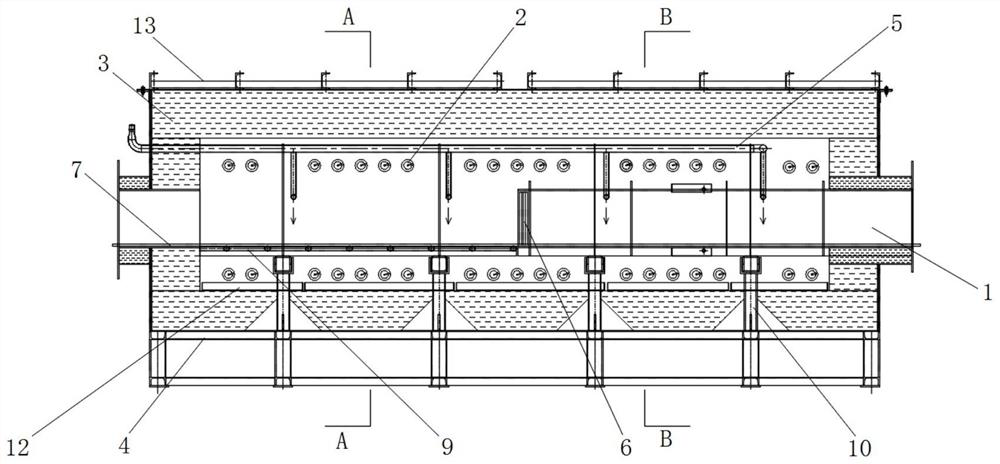

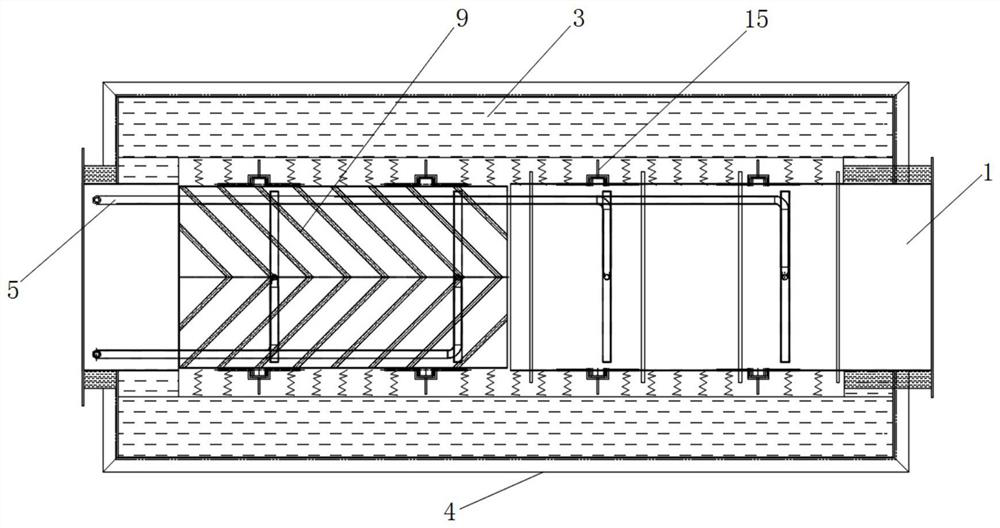

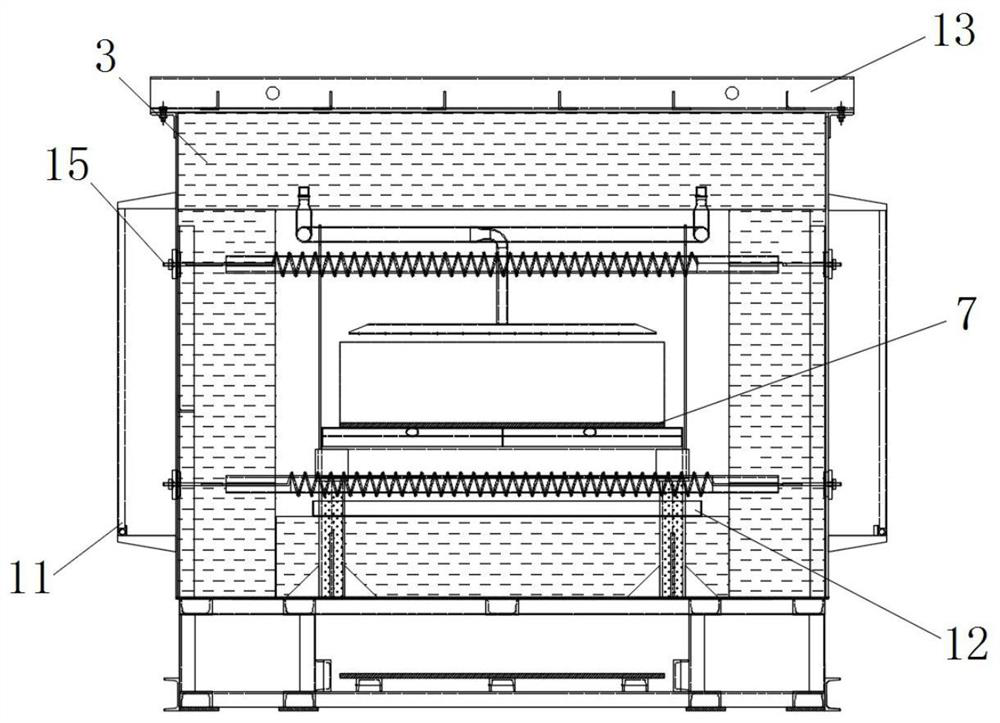

Brazing section of novel efficient energy-saving brazing furnace

InactiveCN111604557AImprove welding efficiencyFast heating rateHeating appliancesSoldering auxillary devicesMetallurgyMaterials science

The invention discloses a brazing section of a novel efficient energy-saving brazing furnace, and relates to the field of brazing section equipment. The following scheme is provided for solving the problem that when an aluminum product in an existing brazing furnace is heated in the brazing section and welded to a part, the welding efficiency is low due to the fact that the temperature of the brazing section is increased slowly. The brazing section comprises a furnace shell, wherein furnace tops are fixedly installed on the two sides of the top end of the furnace shell through bolts, a mufflesupporting frame is fixedly installed at the bottom end of the furnace shell, a muffle is fixedly installed at the end, close to the furnace tops, of the muffle supporting frame, a mesh belt supporting frame is fixedly installed at one end of the muffle, a mesh belt is arranged at the top end of the mesh belt supporting frame, heat preservation layers are arranged between the muffle and the furnace tops and between the muffle and the furnace shell, and heaters are arranged at the upper ends and the lower ends of the two sides of the furnace shell. According to the brazing section, the production welding efficiency can be improved, the service life of equipment can be prolonged, the problem that the heating efficiency of an existing brazing section is low is solved, the use cost of the equipment is reduced, and the occupied area is small.

Owner:天津华耐机械设备制造有限公司

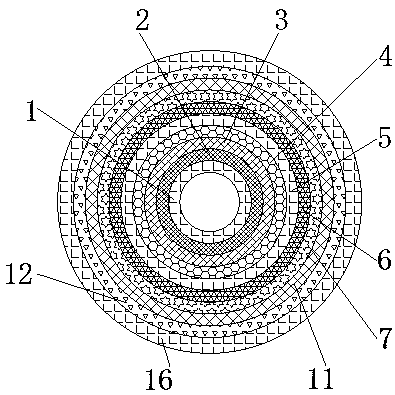

HDPE reinforcing rib-enhanced corrugated pipe long in service life

PendingCN107559420AImprove practicalityShorten the timeSynthetic resin layered productsBellowsUser needsSurface layer

The invention discloses a HDPE reinforced corrugated pipe with long service life, which includes an acid-proof layer, the surface of the acid-proof layer is fixedly connected with a waterproof layer, and the surface of the waterproof layer is fixedly connected with a PE layer. The surface of the PE layer is fixedly connected with an anti-alkali layer, the surface of the anti-alkali layer is fixedly connected with stainless steel, and the surface of the stainless steel is fixedly connected with a fireproof layer. The present invention solves the problem by setting an anti-alkali layer, stainless steel, fire-proof layer, high-temperature resistant layer, copper oxide layer, polytetrafluoroethylene layer, carbon fiber layer, cold-proof layer, wear-resistant layer, PU layer, polyurethane layer and nylon layer. The existing HDPE reinforced corrugated pipe has a short service life, which leads users to frequently purchase new HDPE reinforced corrugated pipes, which wastes a lot of time and financial resources of users and reduces the cost of HDPE reinforced corrugated pipes. To solve the practical problem of the pipe, the HDPE reinforced corrugated pipe with long service life has the advantage of long service life.

Owner:江苏佳润管业有限公司

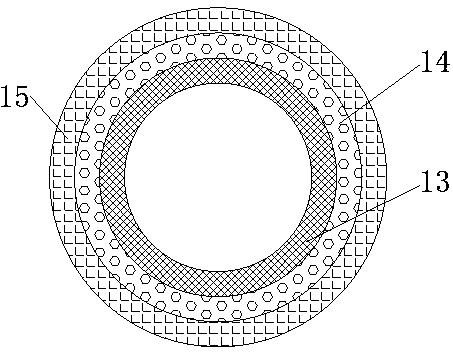

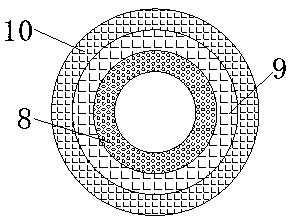

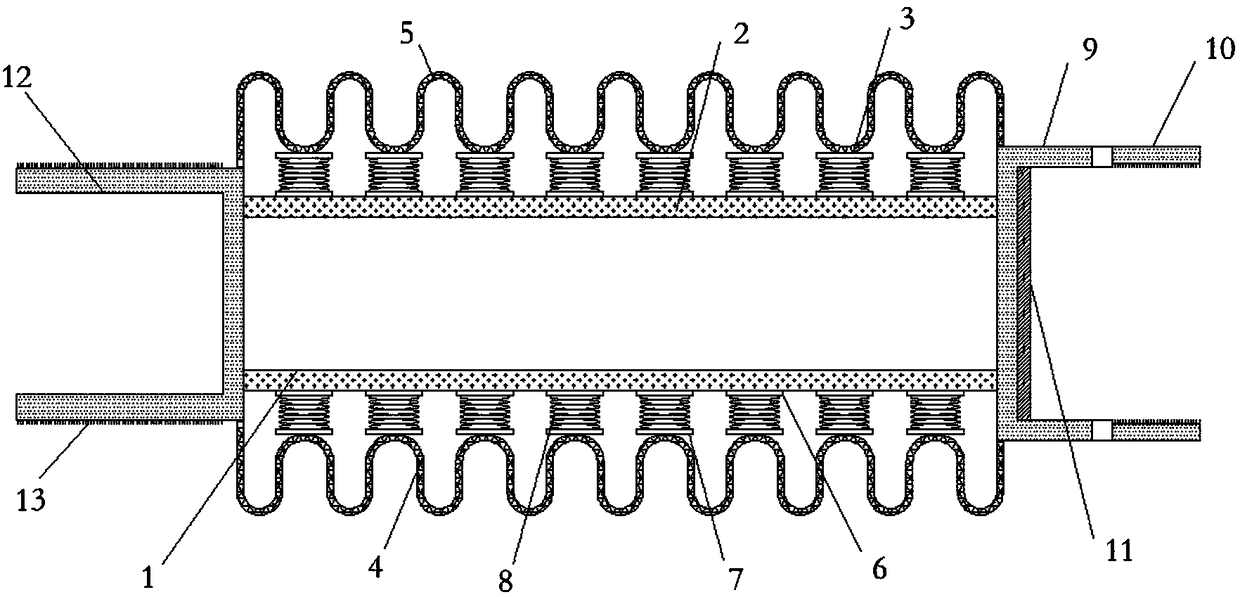

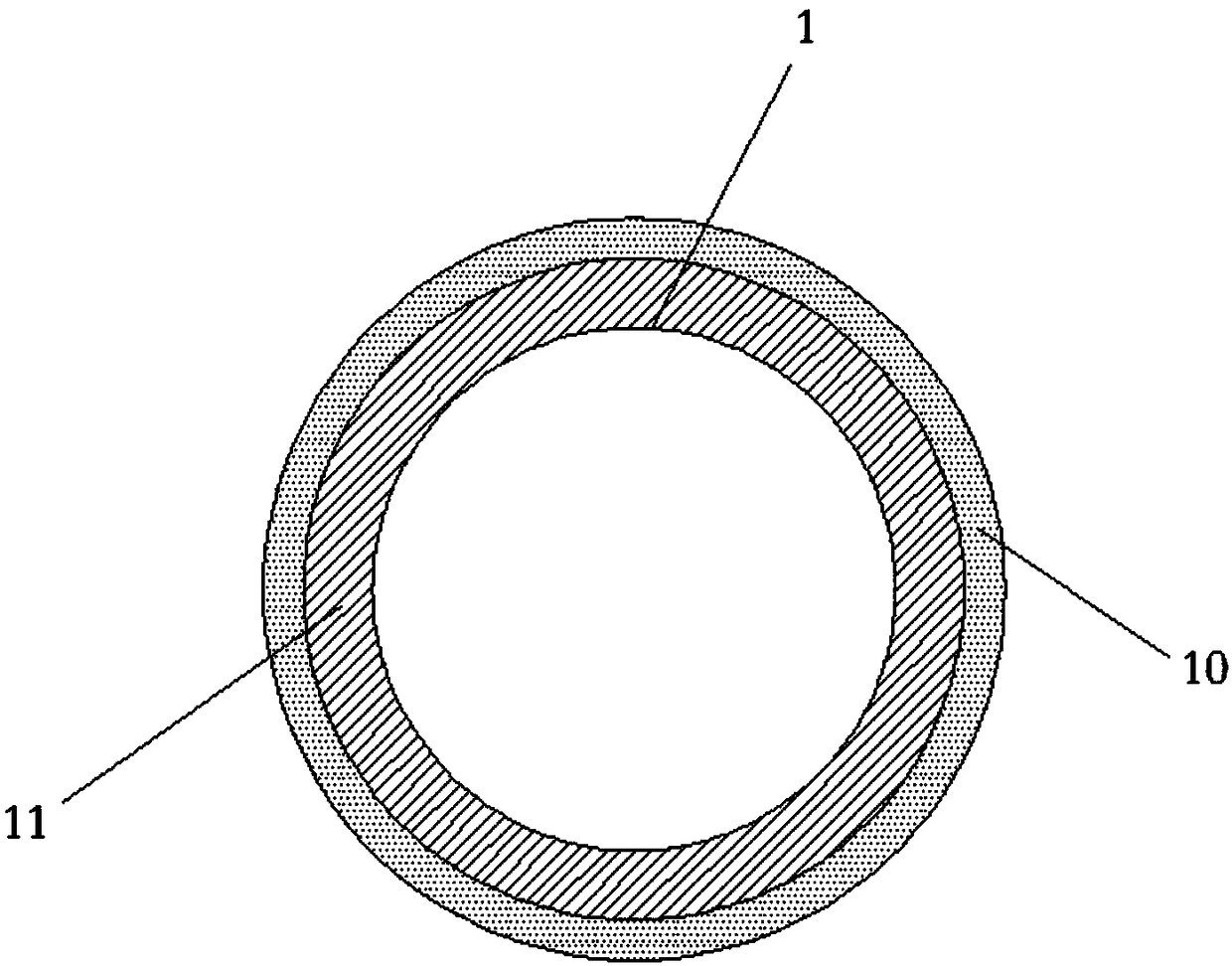

High-strength thermal-insulation double-wall corrugated tube

InactiveCN108468879AAvoid thermal expansion and contractionAvoid damageThermal insulationPipe protection by thermal insulationThermal insulationDouble wall

The invention discloses a high-strength thermal-insulation double-wall corrugated tube. The high-strength thermal-insulation double-wall corrugated tube comprises an inner wall, a thermal-insulation layer, a buffer device, a corrugated outer wall, a fiber reinforcing layer, a male joint and a female joint, wherein the thermal-insulation layer is fixedly arranged on the outer surface of the inner wall; the buffer device is arranged at the outer side of the thermal-insulation layer; the buffer device comprises an upper gasket, a lower gasket and a spring; one side of the upper gasket is fixed with the outer surface of the thermal-insulation layer; the other side of the upper gasket is fixedly connected with one end of the spring; the other end of the spring is fixedly connected with one sideof the lower gasket; and one side, away from the spring, of the lower gasket is fixedly connected with the bottom of the corrugated outer wall. According to the high-strength thermal-insulation double-wall corrugated tube disclosed by the invention, the thermal-insulation layer can be used for performing thermal insulation on liquid transported inside the inner wall, and further can be used for preventing the inner wall from a thermal-expansion cold-contraction phenomenon when the outside temperature fiercely changes, so that the inner wall is protected, the inner wall is prevented from beingdamaged, and the service life of the inner wall is prolonged; and moreover, pressure on the corrugated outer wall is eliminated through the buffer device, so that the corrugated outer wall is prevented from being damaged.

Owner:ANHUI LAN BO WATER SUPPLY EQUIP CO LTD

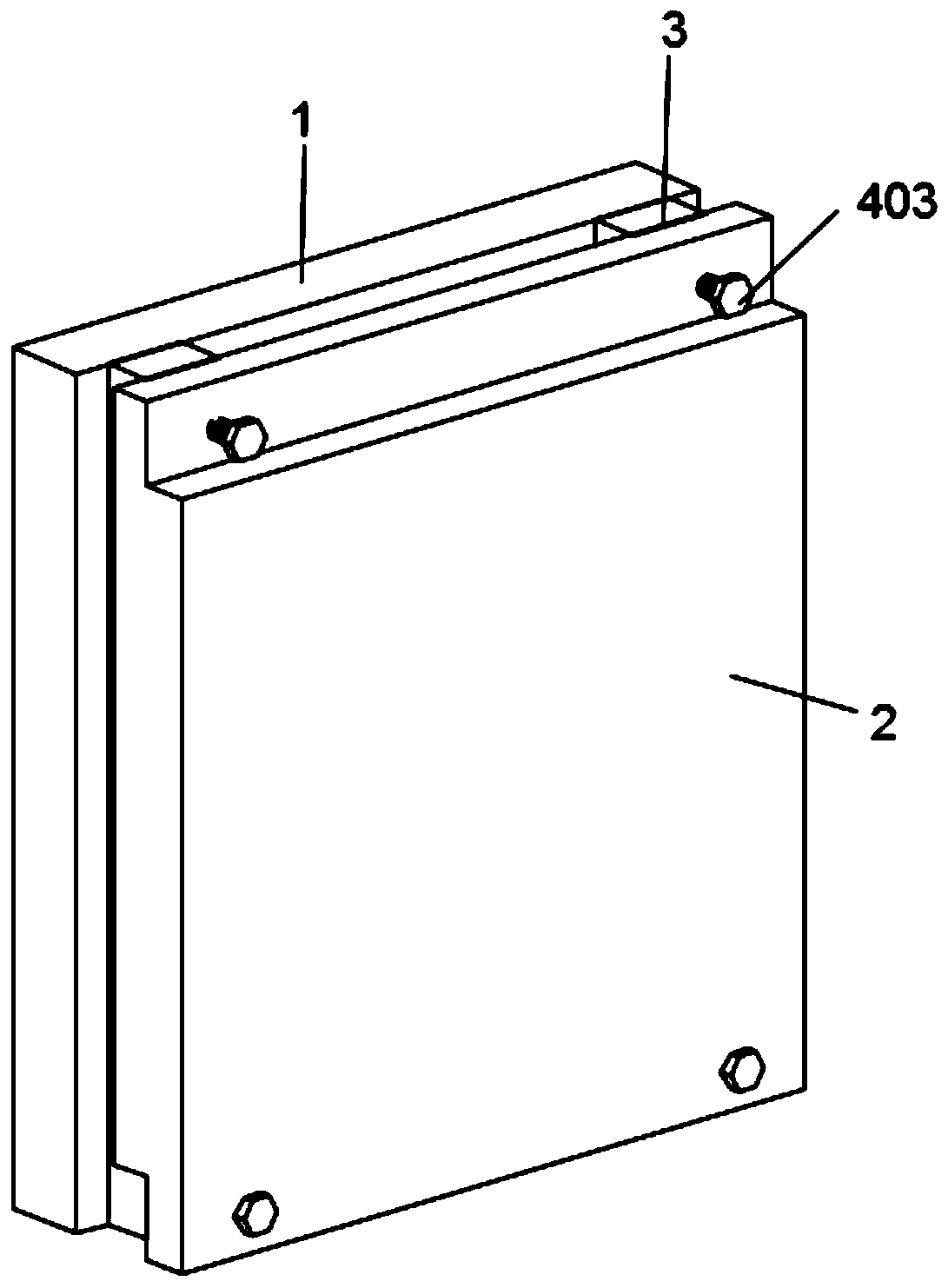

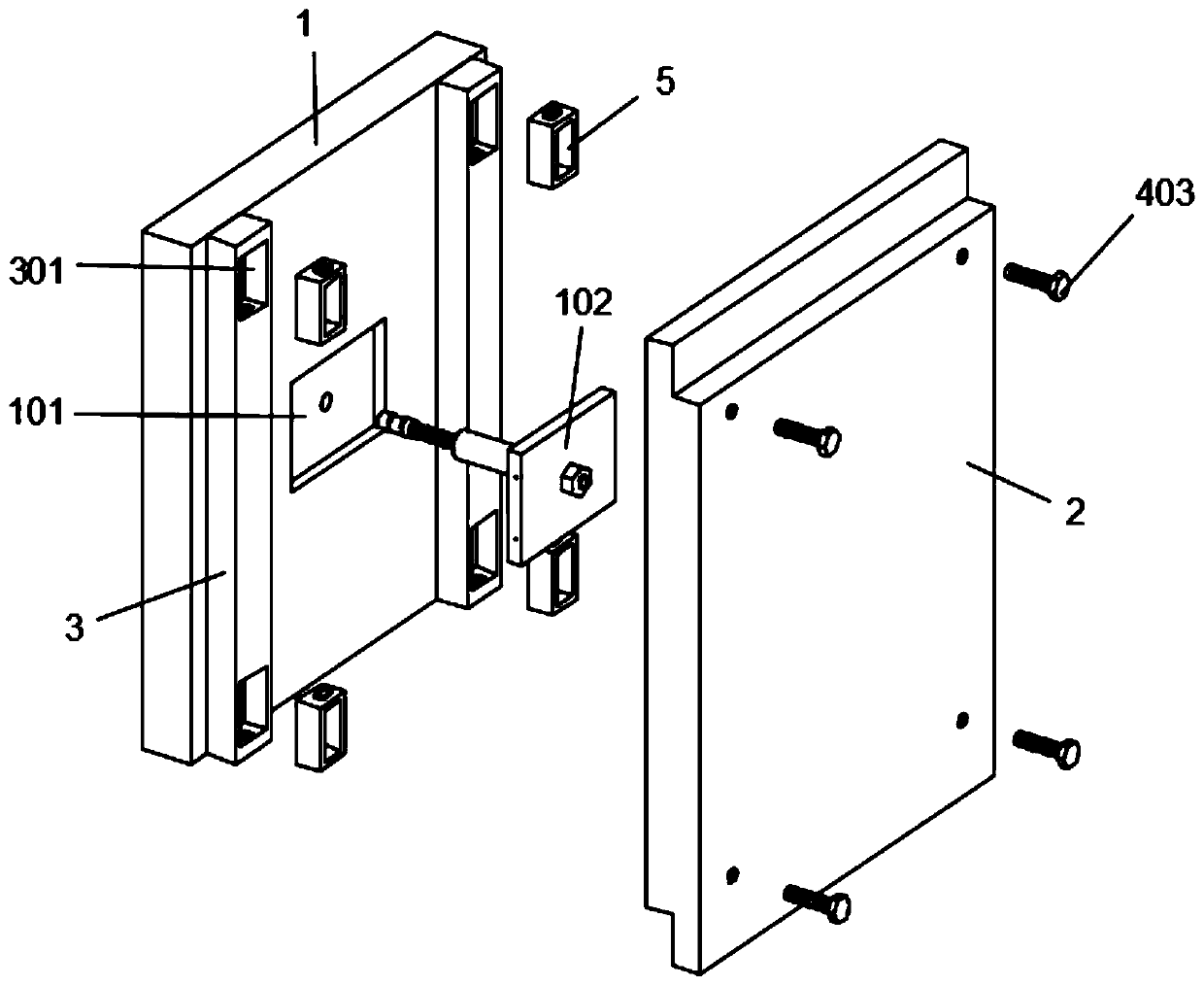

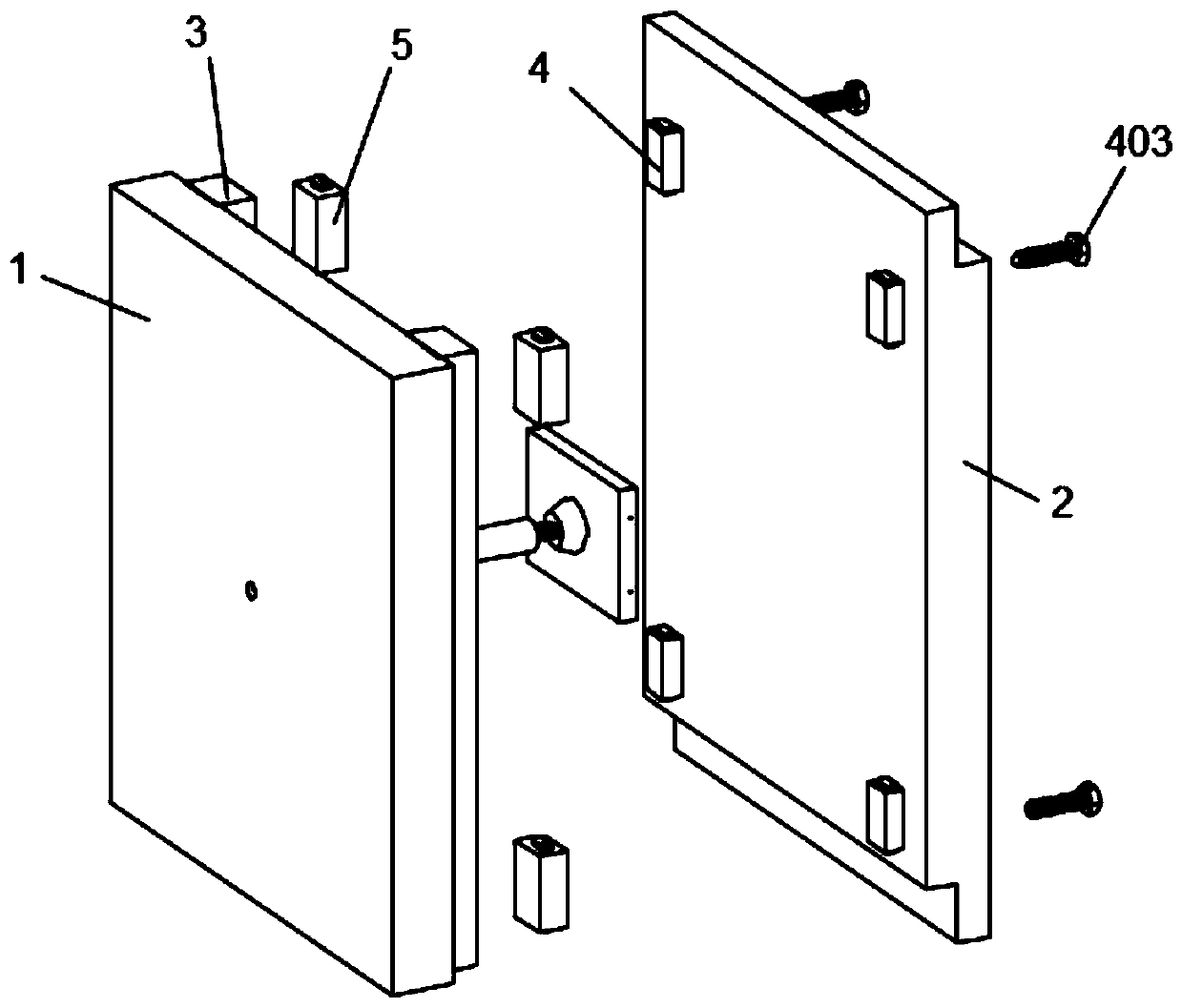

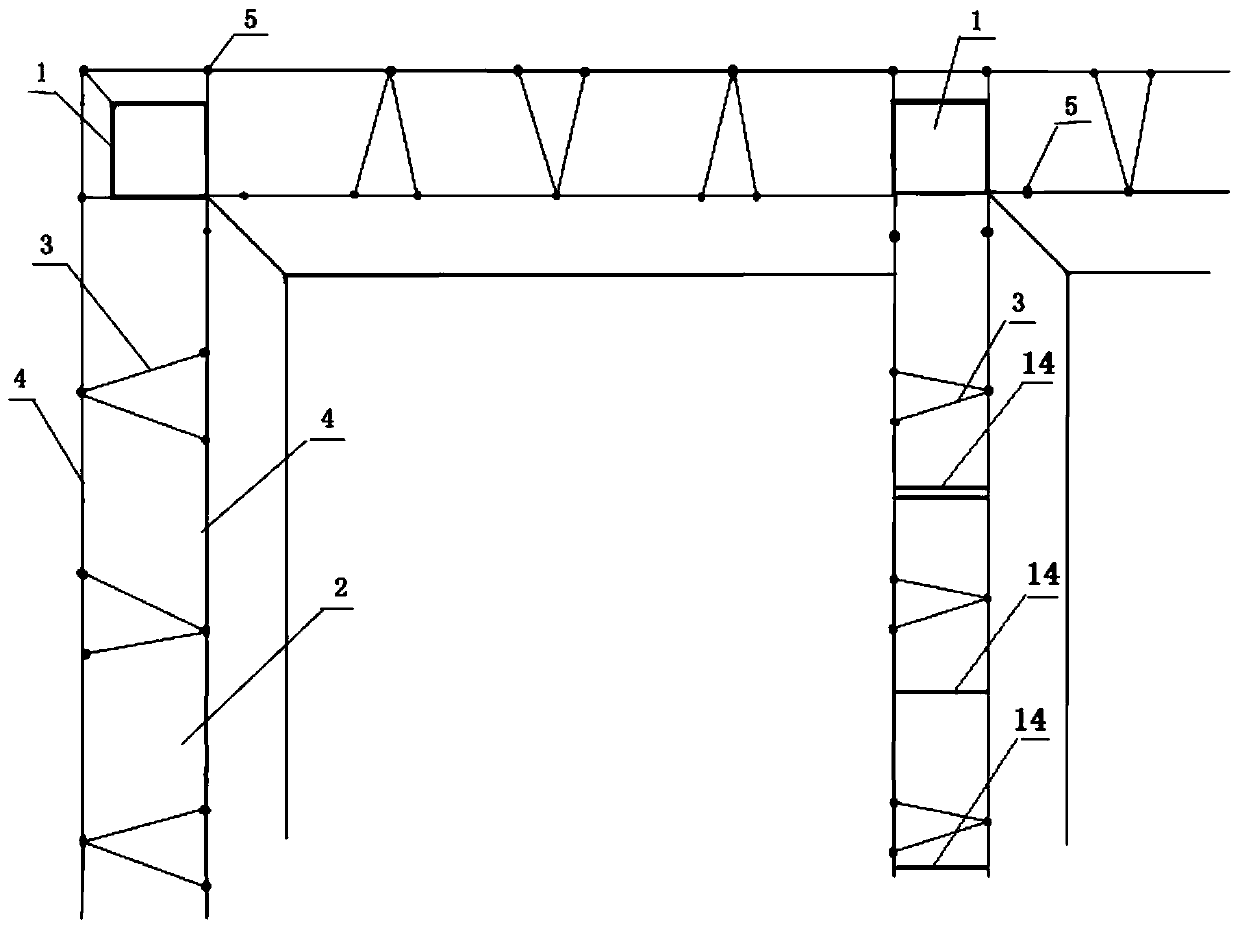

Aluminum-plastic panel mounting and connecting structure for outer wall mounting

ActiveCN110821071AAvoid thermal expansion and contractionQuick installationCovering/liningsFlooringEngineeringExternal cladding

The invention discloses an aluminum-plastic panel mounting and connecting structure for outer wall mounting, and belongs to the technical field of building structures. The aluminum-plastic panel mounting and connecting structure for outer wall mounting comprises a heat preservation plate and an aluminum-plastic panel body arranged on the front side of the heat preservation plate, wherein an anchoring groove is formed in the middle of the heat preservation plate; an anchoring component is arranged in the anchoring groove; the heat preservation plate is fixedly connected with a wall through theanchoring component; two connecting square timbers are symmetrically arranged between the aluminum-plastic panel body and the heat preservation plate; the connecting square timbers are fixedly connected with the heat preservation plate through woodworking nails, connecting protrusions are arranged at the four corners of the rear wall of the aluminum-plastic panel body; the outer sides of the connecting protrusions are sleeved with connecting sleeves; and the connecting sleeves are in clamping fit with locking grooves formed in the ends of the connecting square timbers. The aluminum-plastic panel mounting and connecting structure is reasonable in structural design, the situation that the mounting structure of an aluminum-plastic panel is damaged when the wall expands with heat and contractswith cold is avoided, rapid mounting by workers is facilitated, the mounting difficulty is reduced, and the mounting time is shortened.

Owner:江苏国兴建设项目管理有限公司

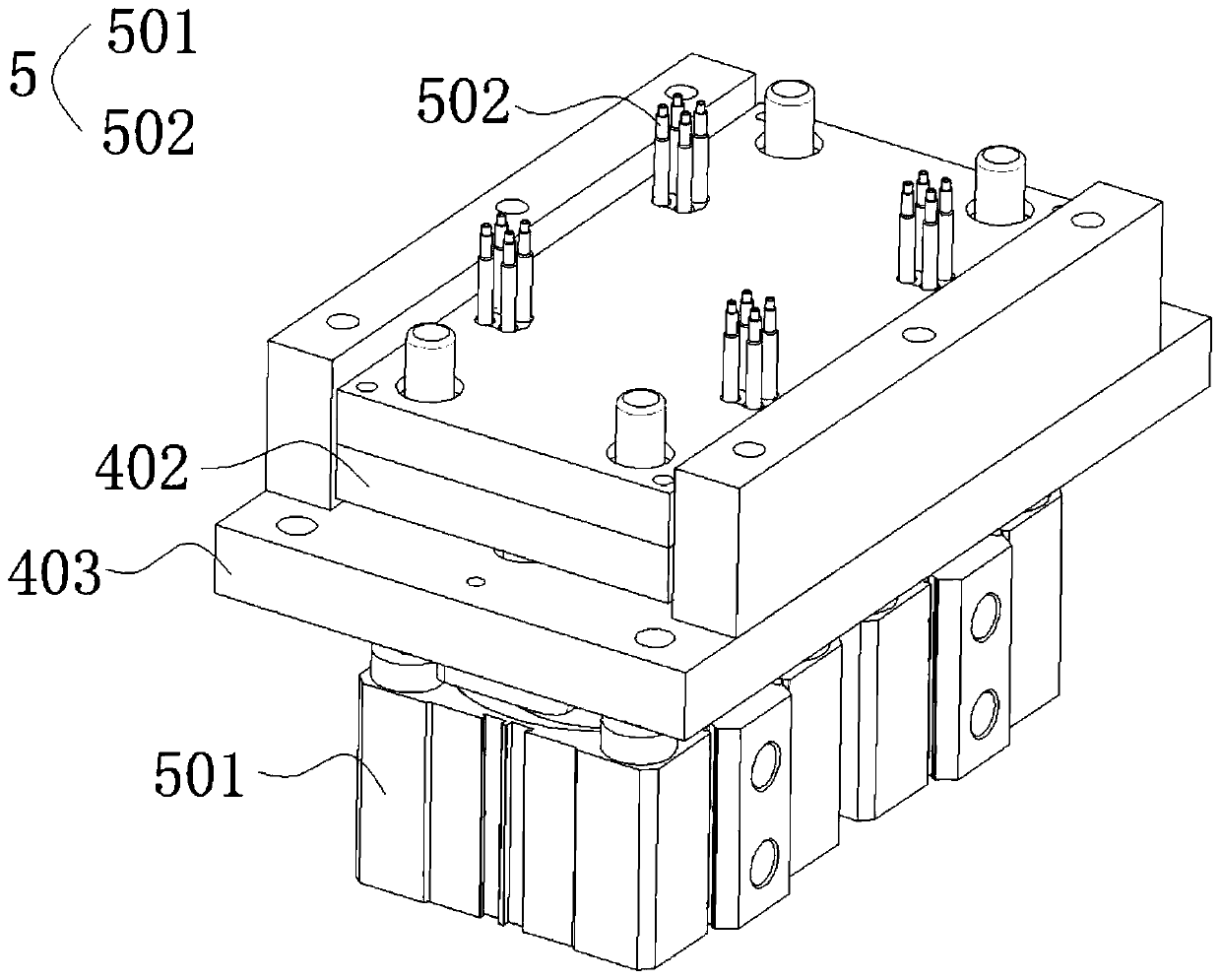

Tin ring casting method and device

ActiveCN111482578APrevent flying outStable flowWelding/cutting media/materialsSoldering mediaButt jointTin

The invention provides a tin ring casting method and device. The tin ring casting method includes the following steps of S1, putting a tin material into a feeding cylinder, and heating the feeding cylinder so that the tin material can be hot-molten into molten tin and the molten tin can flow into a closed discharge port to stand for use; S2, ejecting an ejector pin in a die to exhaust the air in aproduct molding groove, and making a notch of the product molding groove seamlessly attached to and in butt joint with the discharge port; S3, pressurizing the feeding cylinder, opening the dischargeport, making the ejector pin retreat to empty the product molding groove, and injecting the molten tin into the product molding groove, wherein the molten tin injection time is controlled to be 0-1 s; S4, disengaging the discharge port out of the die so that the molten tin can be cooled and molded; and S5, automatically ejecting out the cooled and molded tin ring, and pushing away the die for collection treatment. The tin ring casting device comprises a feeding mechanism, a molding and moving module, a molding structure, an ejecting-out mechanism and a pushing mechanism. The tin ring castingmethod and device have the advantages that the product specification and quality are unified, material waste is reduced, and time and labor are saved.

Owner:惠州市天维五金制品有限公司

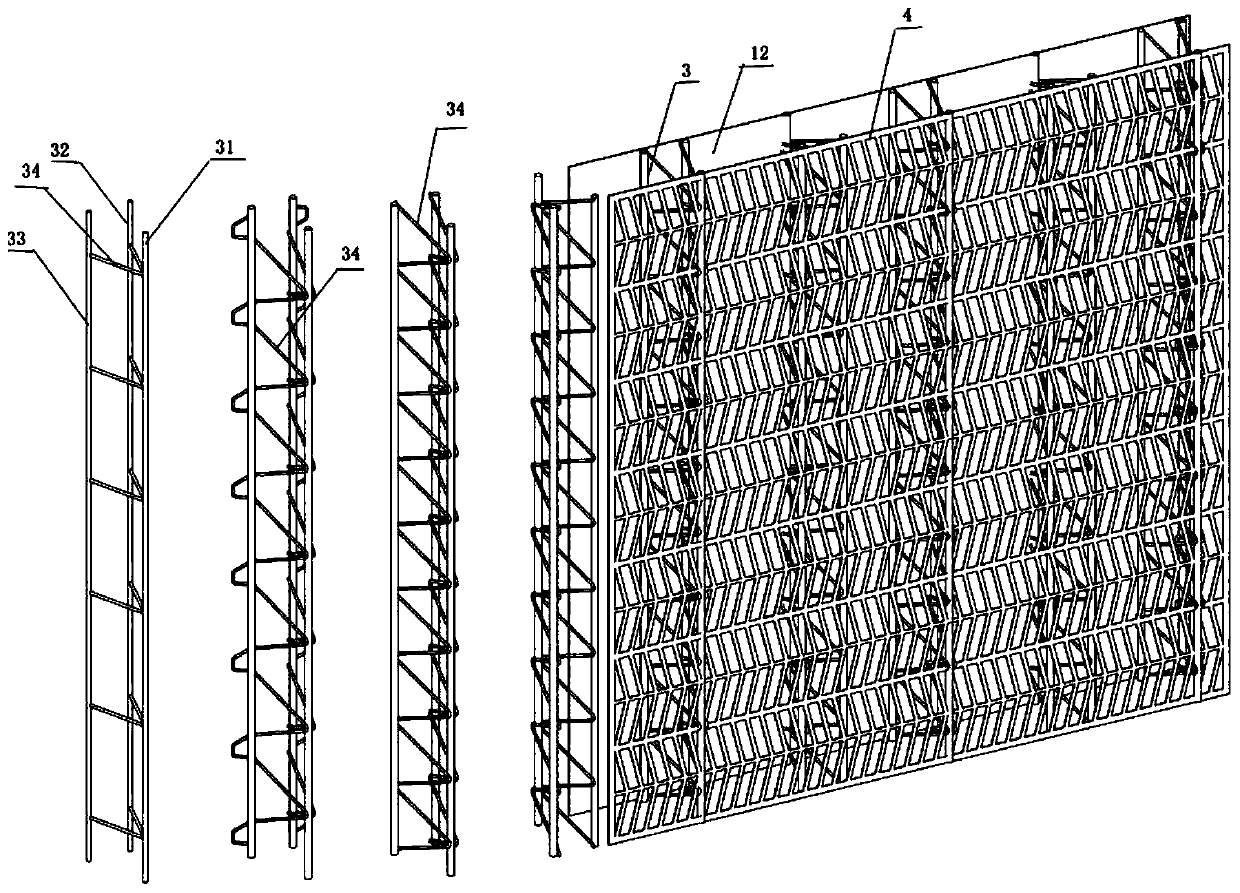

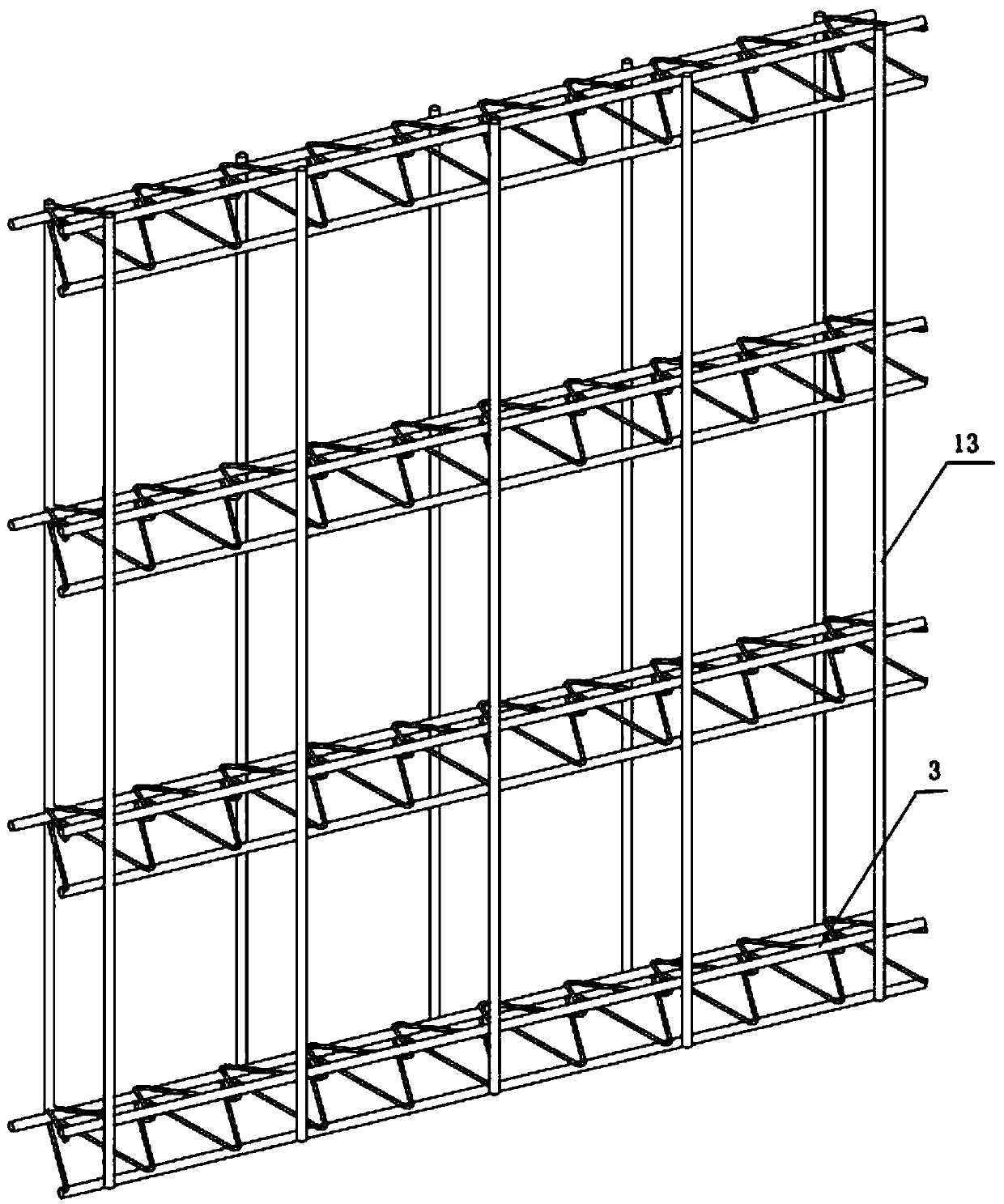

Light steel mesh wall body and building house body built by light steel mesh wall body

PendingCN111379354APlay a fighting roleImprove seismic performancePhotovoltaic supportsBuilding roofsCalcium silicateEarthquake resistance

The invention discloses a light steel mesh wall body and a building house body built by the light steel mesh wall body. The light steel mesh wall body comprises a wall framework arranged in an area defined by steel columns and steel beams, the wall body framework comprises a plurality of triangular steel structure units, the inner sides and the outer sides of the triangular steel structure units are covered with expanded metal mesh or calcium silicate boards, and concrete is poured in the wall body framework; each triangular steel structure unit comprises a first steel bar, a second steel barand a third steel bar which form angle with one another, and the first steel bars and the second steel bars and the first steel bars and the third steel bars are connected through a plurality of web member steel bars. According to the light steel mesh wall body and the building house body built by the light steel mesh wall body, the problem of thermal expansion and cold contraction of a steel structure is solved, joints of the wall columns and the wall body and joints of the beams and floor slabs are protected against cracking and falling off, an outer wall is beautiful and does not need to berepaired permanently, and troubles are saved; the earthquake resistance, the fire resistance and the heat insulation property are improved, and the house body cost is reduced.

Owner:金国洪

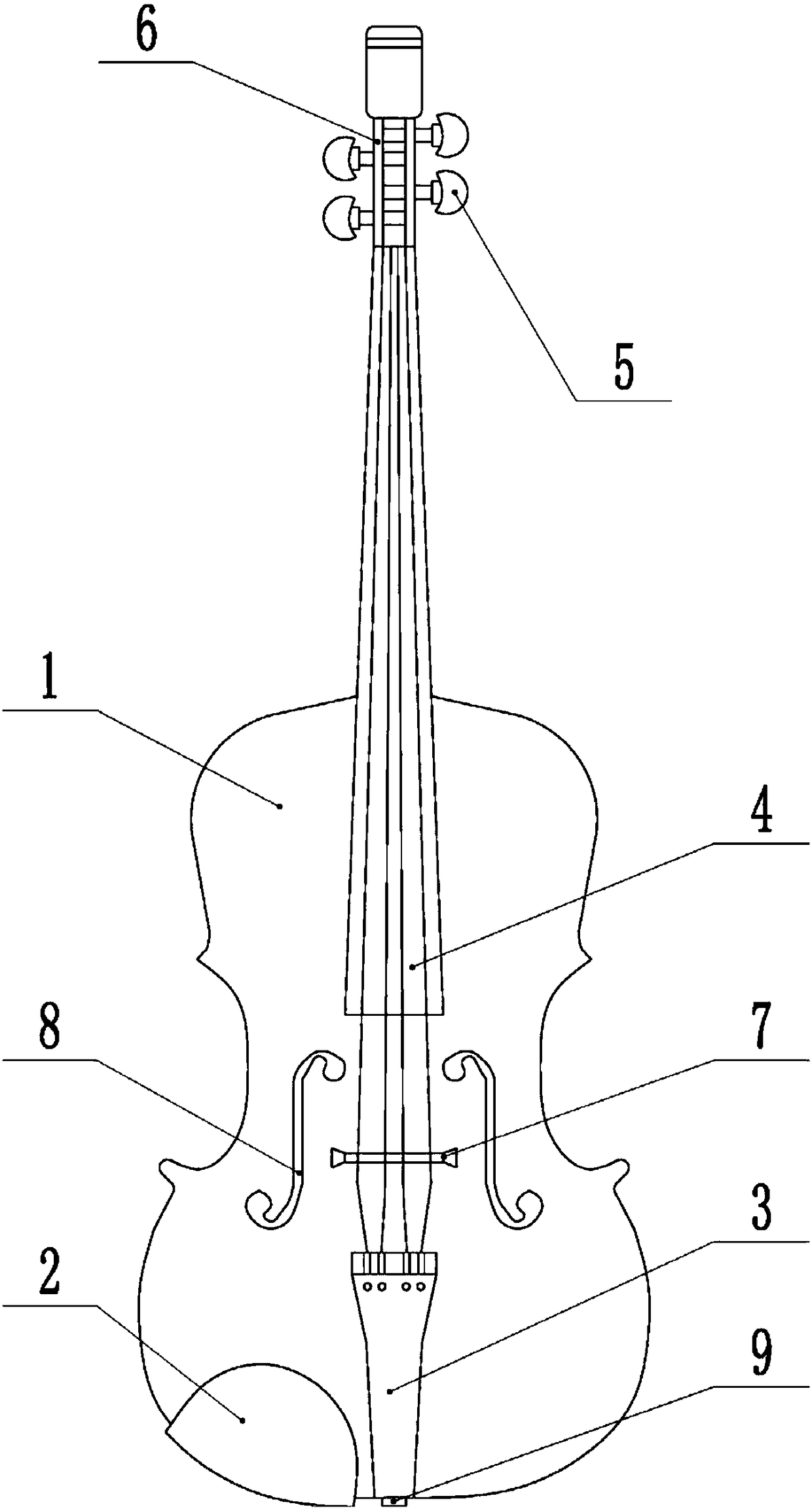

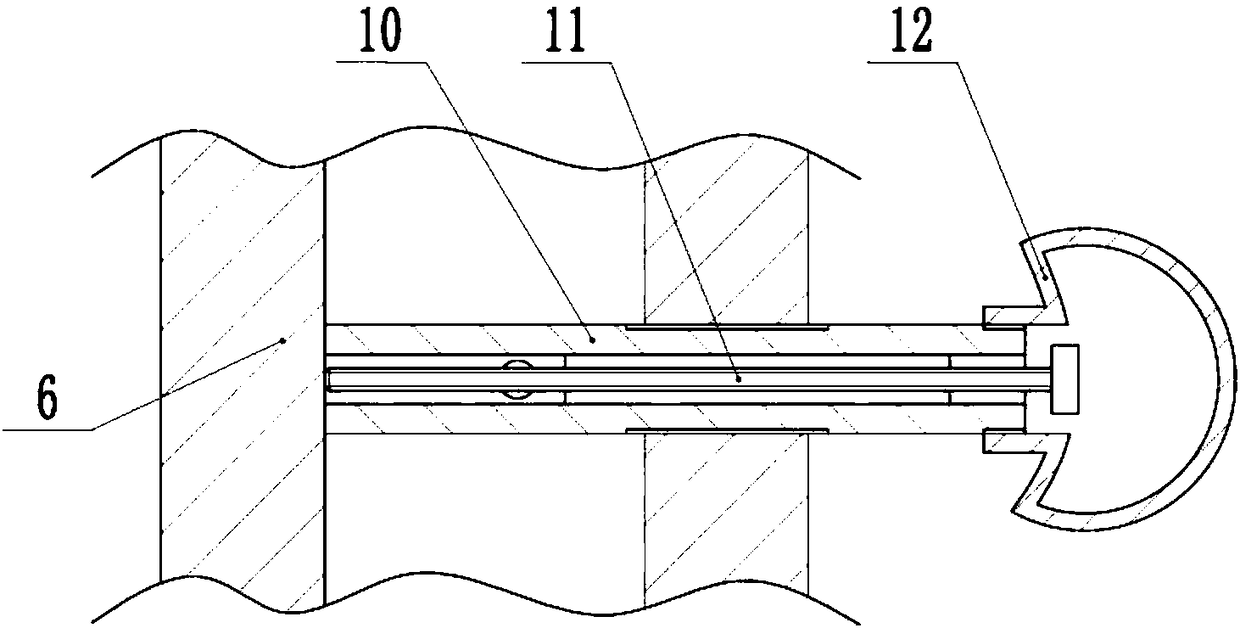

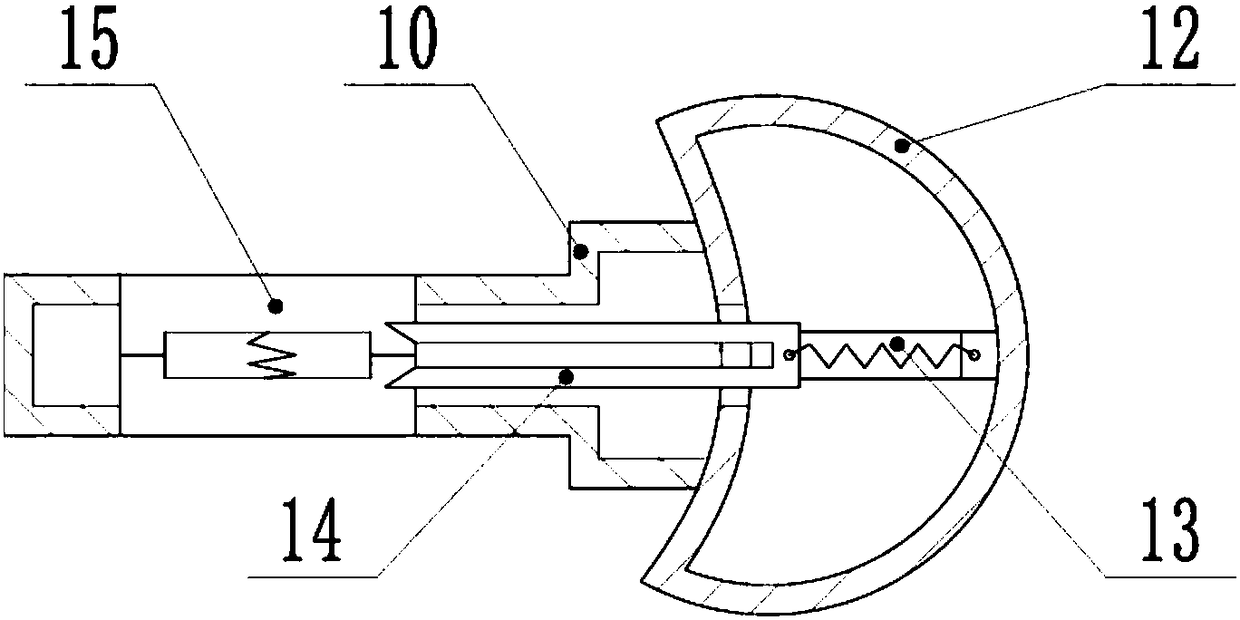

Standard appliance for collective teaching of Huang bell

The invention relates to a standard appliance for collective teaching of the Huang bell. The standard appliance comprises a violin, the violin comprises a violin body, a saitenhalter and a fingerboardare fixed to the upper surface of the violin body, a tail button is mounted on the bottom of the violin body, a tailgut is connected between the saitenhalter and the tail button, a chin rest is fixedat the position, on the left side of the saitenhalter, of the violin body, a pegbox is fixed to the top of the fingerboard, a peg is rotatably connected to the pegbox, a rotation-preventing mechanismis arranged on the peg, and the fingerboard and the tailgut are made of high molecular synthetic materials. Compared with the prior art, the technical scheme has the advantages that through the innovative design of the peg, the fingerboard and the tail rope, while the tone of the violin is fixed to the standard tone, the demands of the collective teaching are satisfied.

Owner:重庆琴小宝教育科技有限公司

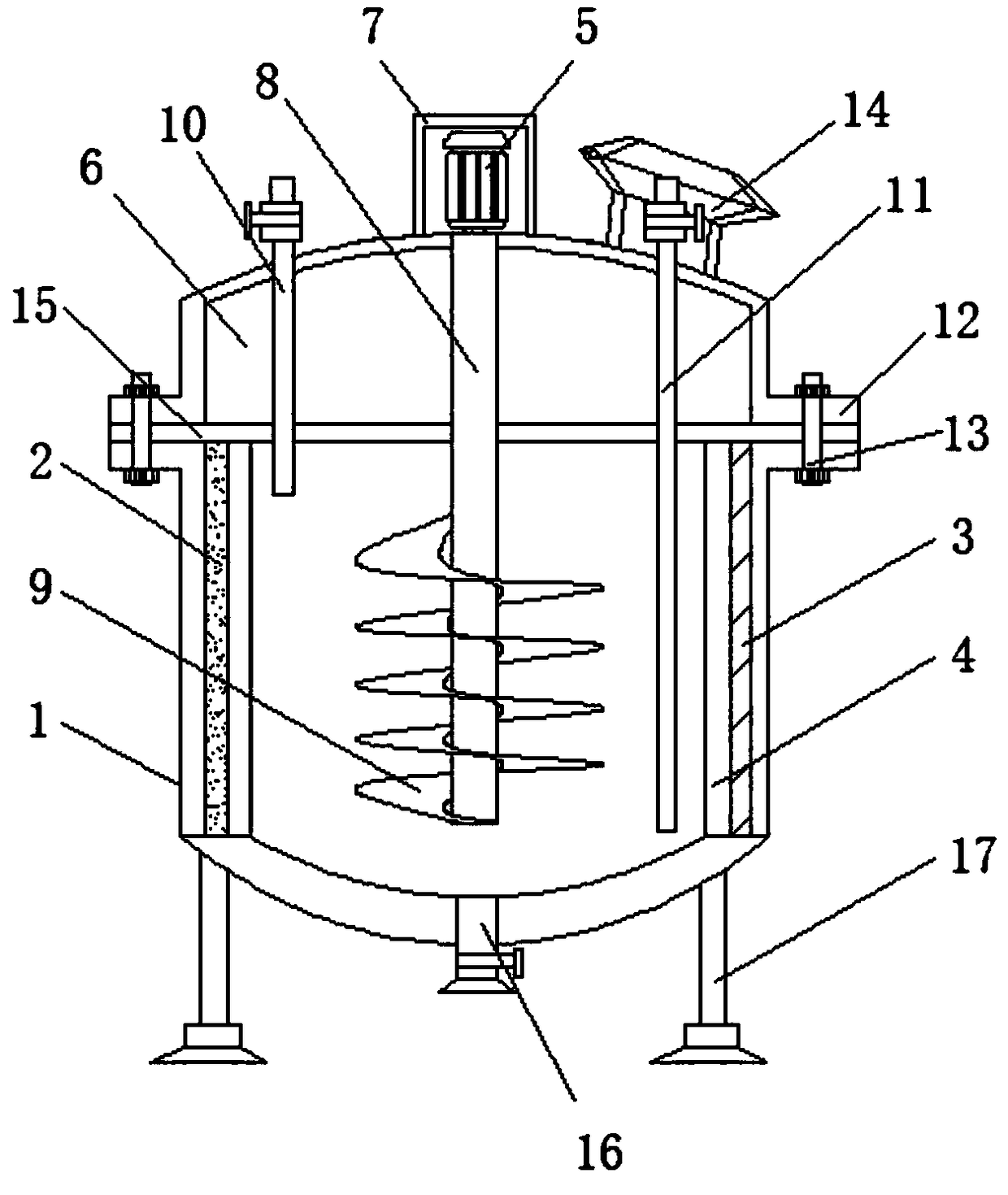

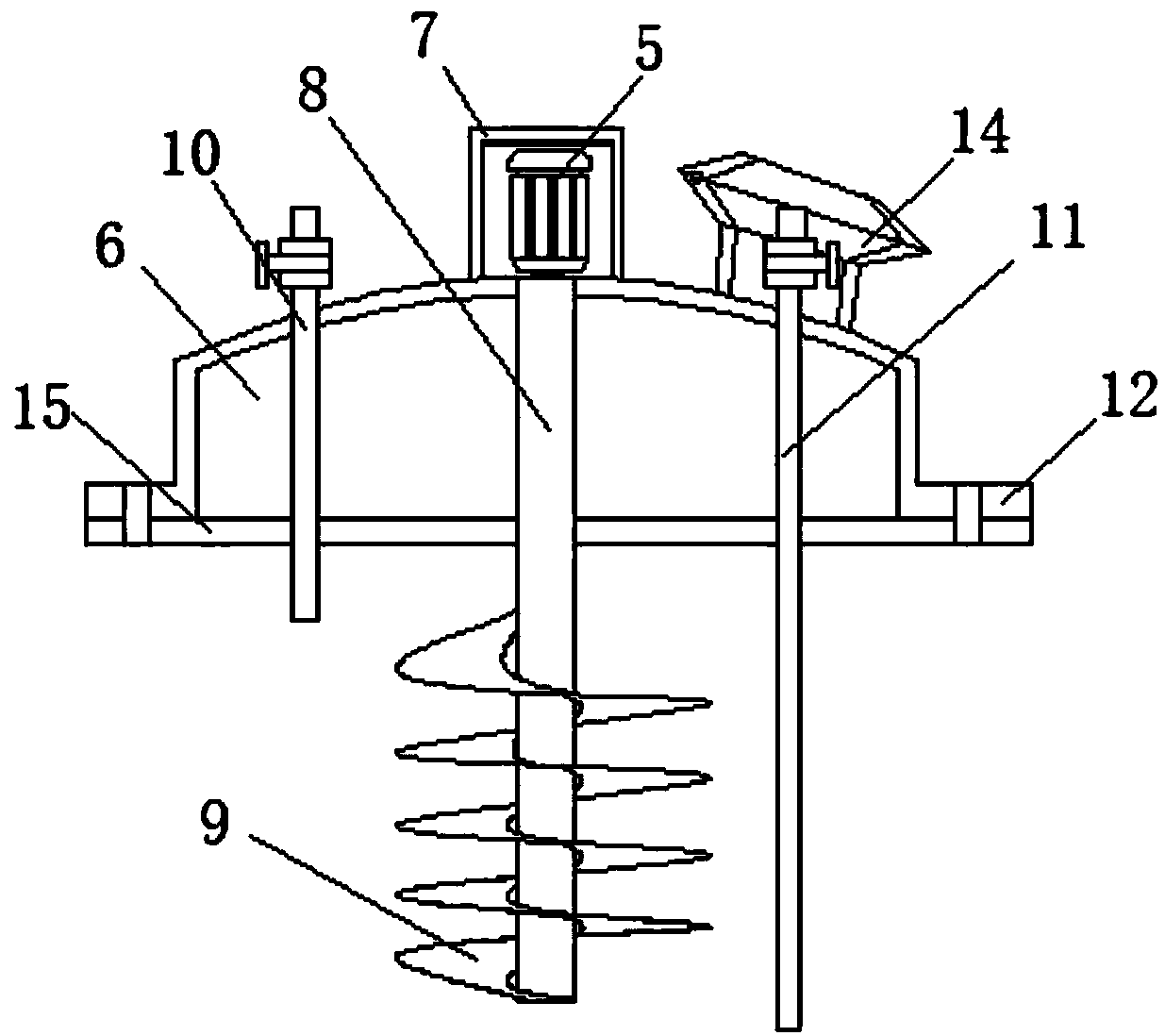

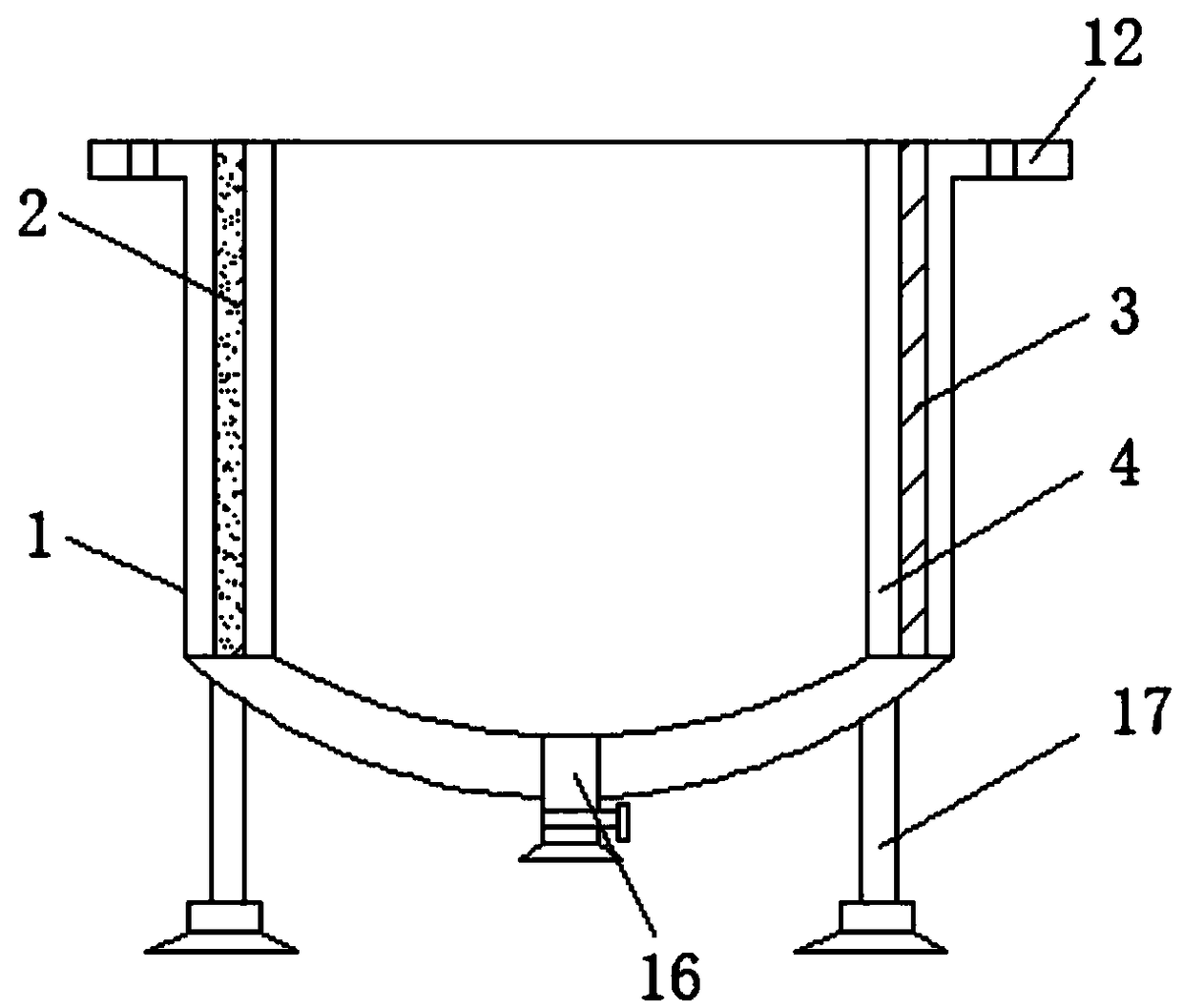

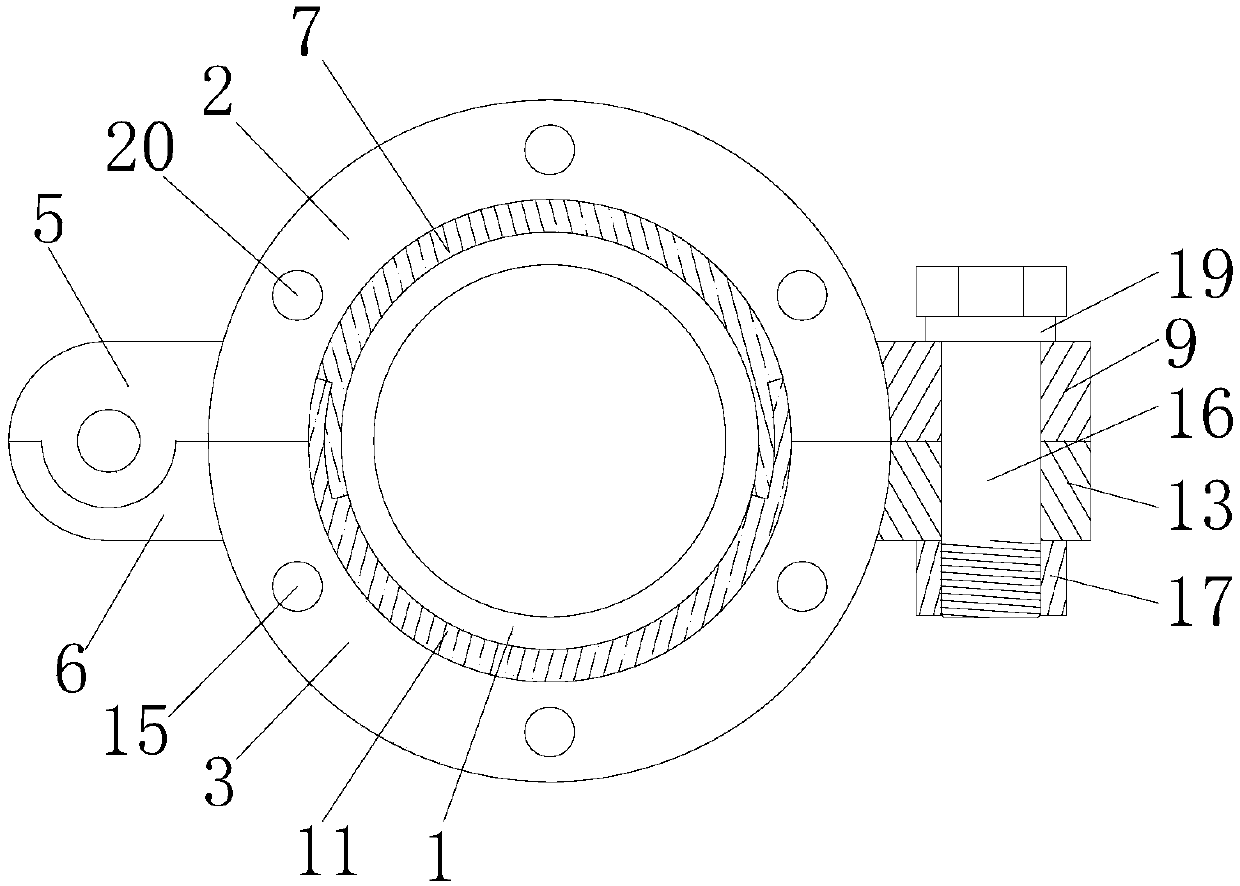

High pressure reactor

InactiveCN108554315AAvoid thermal expansion and contractionReduce the risk of explosionPressure vessels for chemical processMotor driveInsulation layer

The invention discloses a high pressure reactor, which comprises a reactor body. An electromagnetic heater is arranged at one side inside the reactor body. a refrigerator is arranged at the other sideinside the reactor body. A heat-insulation layer is arranged on the inner wall of the reactor body. The top of the outer side of the reactor body is provided with a raised ring. The top of the reactor body is provided with a reactor cover. A protective cover is arranged at the middle position of the top of the reactor cover. Through a first air-duct and a second air-duct, a buffer effect is achieved when switching between heating and cooling of the high pressure reactor. Thus, expansion and contraction of the high pressure reactor are avoided, explosion risk of the high pressure reactor is reduced, health and safety of workers are better guaranteed, and work efficiency is improved. Through a motor driving a first rotating shaft to rotate, stirring vanes are driven to stir reactants in thehigh pressure reactor and then the reaction effect of the reactants is better.

Owner:朱三宝

Inner lining stainless steel pipe fitting joint

The invention discloses an inner lining stainless steel pipe fitting joint. The inner lining stainless steel pipe fitting joint comprises pipe bodies, a first clamping plate, a second clamping plate and a sealing ring, wherein a first connecting hole is formed in the front face of the first clamping plate; a first connecting block is transversely and fixedly connected to the left side of the outersurface of the first clamping plate; and a first fixing block is transversely and fixedly connected to the right side of the outer surface of the first clamping plate. Through the cooperation of thefirst clamping plate, the second clamping plate, the sealing ring, the first connecting block, a first sealing gasket, a first placing groove, the first fixing block, a second sealing gasket, a secondplacing groove, a second fixing block, a second connecting hole, a semi-threaded bolt, a nut and a third through hole, the joint of the two pipe bodies can be effectively connected and sealed, and the maintenance of a pipeline by a maintainer is facilitated; and meanwhile, the problems that a joint of a traditional flange connection mode cannot be reused and resources are wasted are solved, and the inner lining stainless steel pipe fitting joint has the advantage of secondary utilization and is worth popularizing.

Owner:JIANGSU SHUNLONG PIPE TECH CO LTD

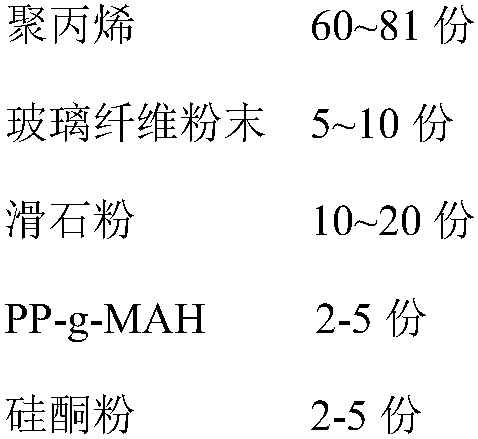

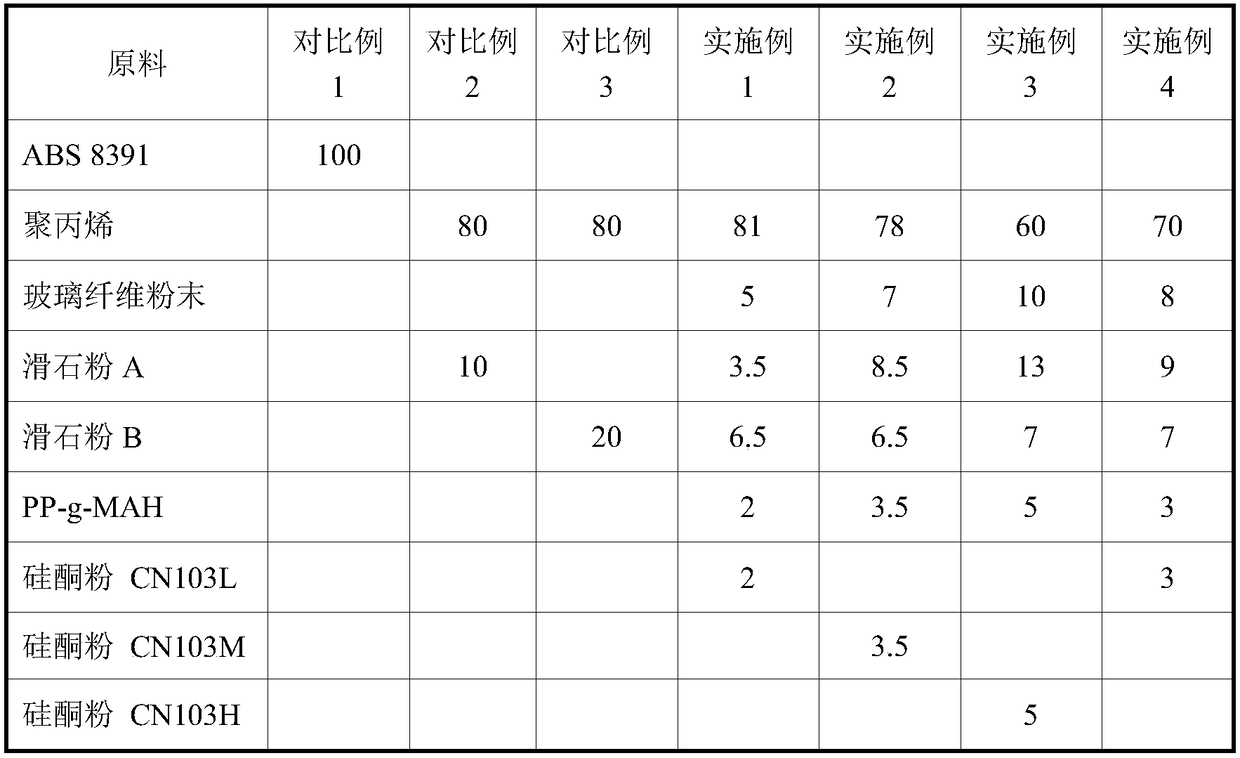

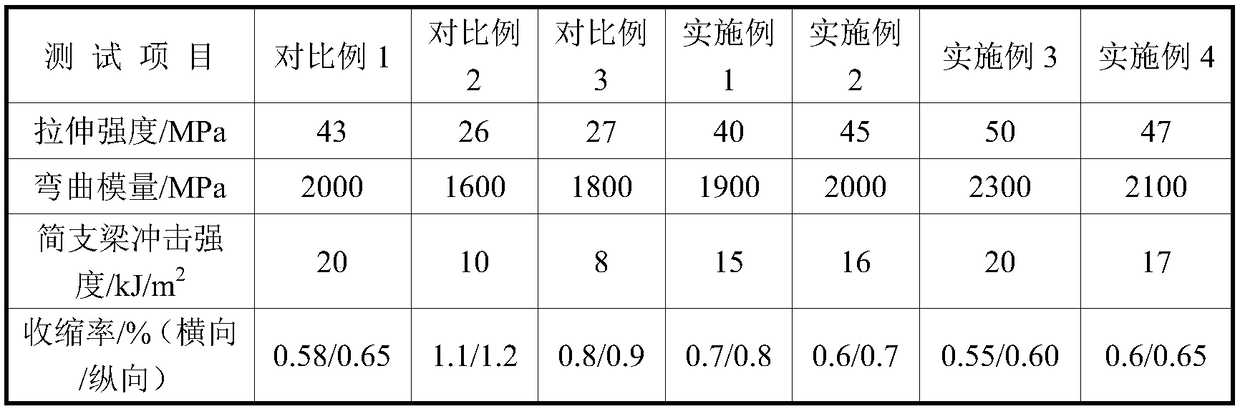

Reinforced polypropylene composite material capable of replacing ABS as well as preparation method and application of reinforced polypropylene composite material

The invention provides a reinforced polypropylene composite material capable of replacing ABS as well as a preparation method and application of the reinforced polypropylene composite material. The material is prepared from the following raw materials in parts by weight: 60 to 81 parts of polypropylene, 5 to 10 parts of glass fibers, 2 to 5 parts of PP-g-MAH and 2 to 5 parts of silicone powder; talcum powder is a mixture formed by mixing talcum powder A with talcum powder B according to the mass ratio ranging from 1:2 to 2:1; D50 of the talcum powder A is 1 to 2 microns and D50 of the talcum powder B is 10 to 15 microns. According to the preparation method disclosed by the invention, by adding glass fiber powder and the talcum powder with different particle sizes into the polypropylene, the strength and the toughness of a final material are close to those of an ABS material; in addition, by adding a special silicone powder additive, the surface of a product subjected to injection molding has no floating fibers and the reinforced polypropylene composite material can replace the ABS material.

Owner:合肥卡洛塑业科技有限公司

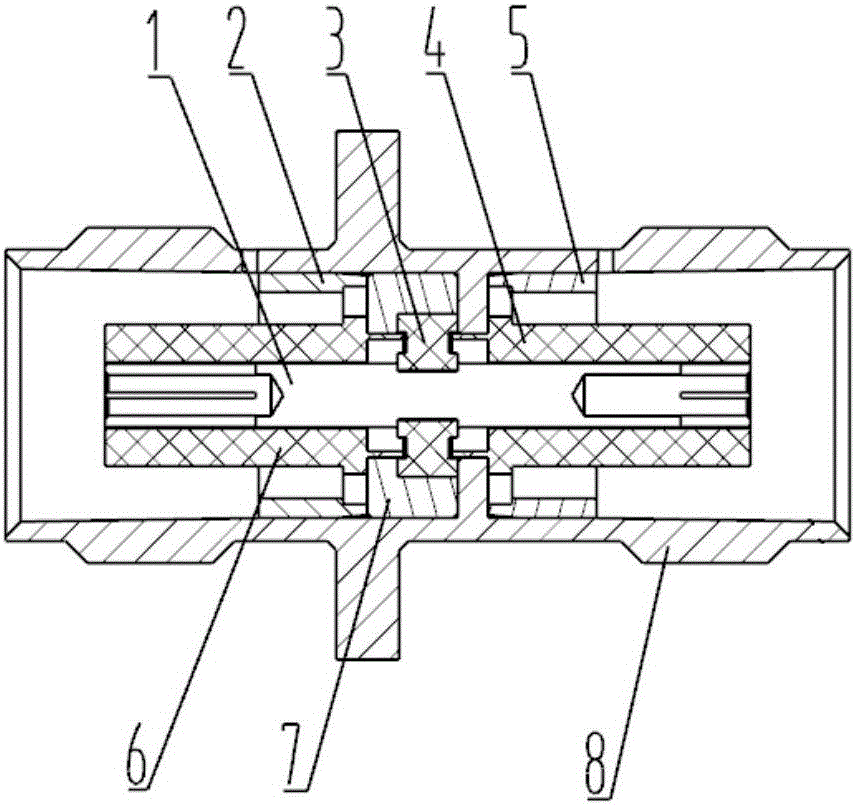

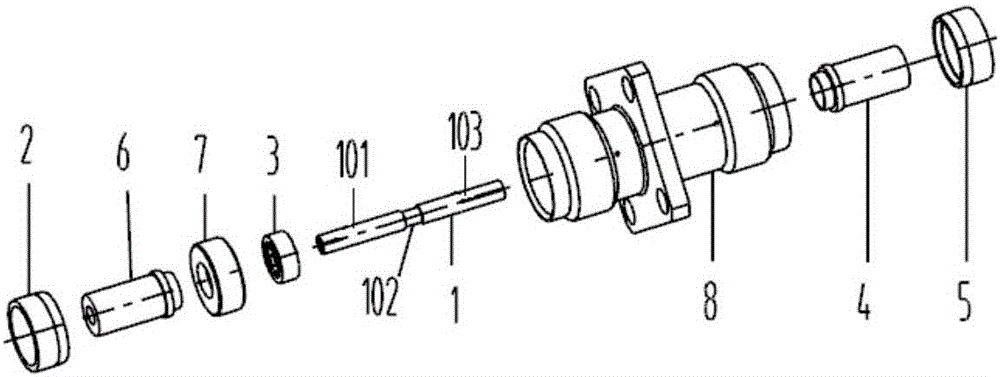

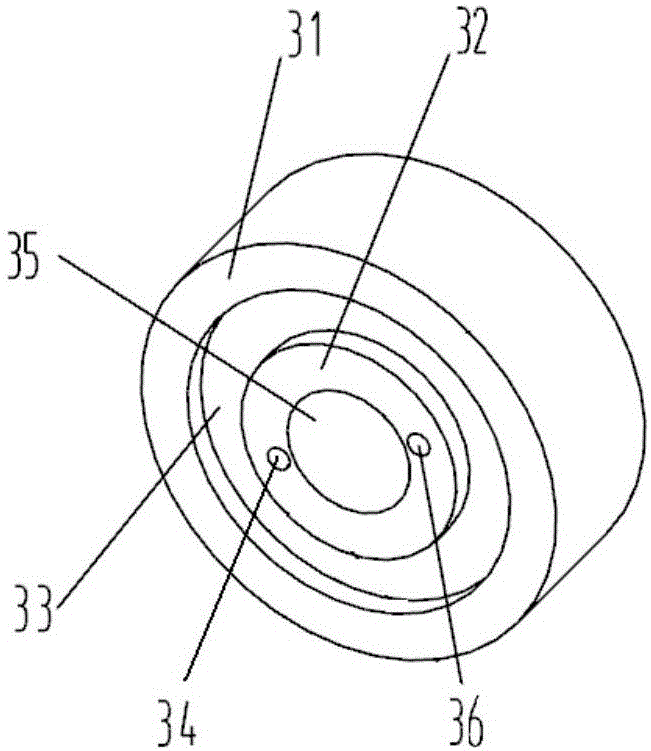

Large power TNC connector for aerospace and assembling method thereof

ActiveCN106803619AImprove mechanical propertiesImprove reliabilityContact member assembly/disassemblySecuring/insulating coupling contact membersSpace environmentMicrowave transmission

The present invention discloses a large power TNC (Threaded Neill-Concelman) connector for aerospace and an assembling method thereof. The connector comprises a jack, a first pressing sleeve, a second pressing sleeve, an inner insulator, a first outer insulator, a second outer insulator, a casing pipe and a housing which have center lines located at the same axis. The jack comprises a center groove, and a first central hole and a second hole which are arranged at two sides of the center groove. The inner insulator is embedded in the center groove is pressed into the casing pipe through the first pressing sleeve. The first central hole is embedded in the first outer insulator, and the second central hole is embedded in the second outer insulator. The first pressing sleeve is arranged at the outer side of the first outer insulator and between the first outer insulator and the housing. The second pressing sleeve is arranged at the outer side of the second outer insulator and between the second outer insulator and the housing. The large power TNC connector for aerospace and the assembling method thereof realize the high reliability space environment resistance performance of the TNC connector on the basis of ensuring the microwave transmission parameters.

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP

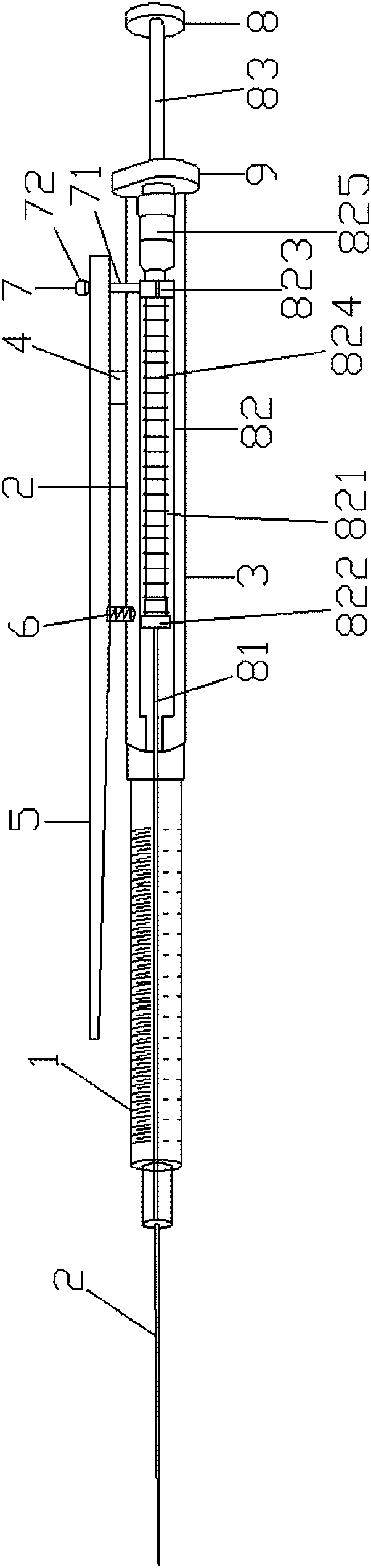

Semi-automatic sample feeding needle

ActiveCN109452985AAvoid thermal expansion and contractionAutomatic syringesMedical devicesAnimals experimentsMedicine

The invention discloses a semi-automatic sample feeding needle, which comprises a needle tube, a needle head and a cylinder-shaped body, wherein one end of the needle tube is connected with the needlehead, the other end of the needle tube is connected with the cylinder-shaped body, the outside of the cylinder-shaped body is connected with an upper quick pressing rod through a balance bracket, thequick pressing rod is arranged above the needle tube and the cylinder-shaped body and is parallel to the needle tube and the cylinder-shaped body, the front end of the quick pressing rod is providedwith a braking spring which acts downwards on the outer wall of the cylinder-shaped body, the rear end of the quick pressing rod is provided with a speed regulating guide rod, the lower end of the speed regulating guide rod acts on the inner side of the cylinder-shaped body, and the cylinder-shaped body is internally provided with a liquid quantity pull rod used for drawing liquid medicine. The needle is a semi-automatic sample feeding needle and can trigger a device to quickly feed samples after the needle is inserted, hands do not directly contact the tube wall, and the reagent can be prevented from expanding with heat and contracting with cold. The semi-automatic sample feeding needle can be used, by one researcher, to independently complete the fixed-point, positioning, fixed-speed andquantitative medicine feeding operation for an animal experiment body.

Owner:江苏阀邦半导体材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com