Self-compensating direct quick-connection pipeline

A self-compensating, direct technology, applied in the direction of mechanical equipment, couplings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention is described in further detail below in conjunction with accompanying drawing and embodiment thereof:

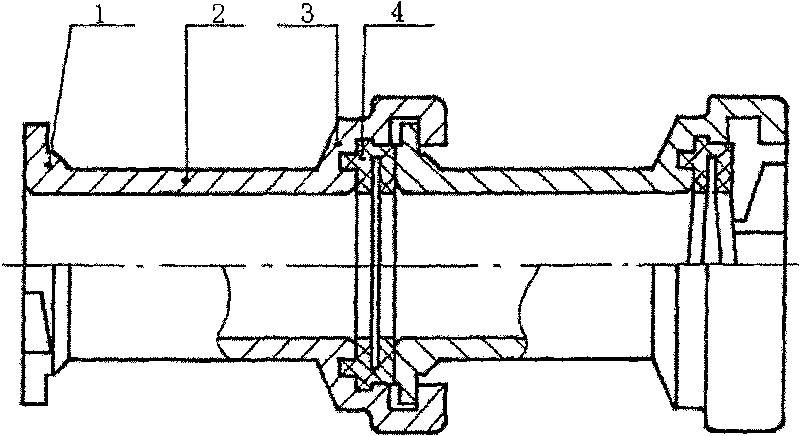

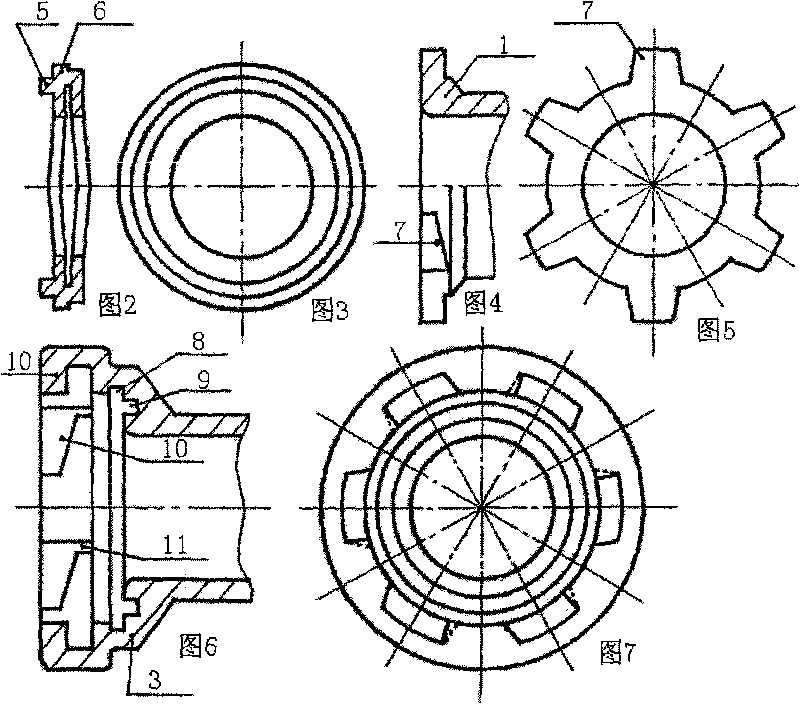

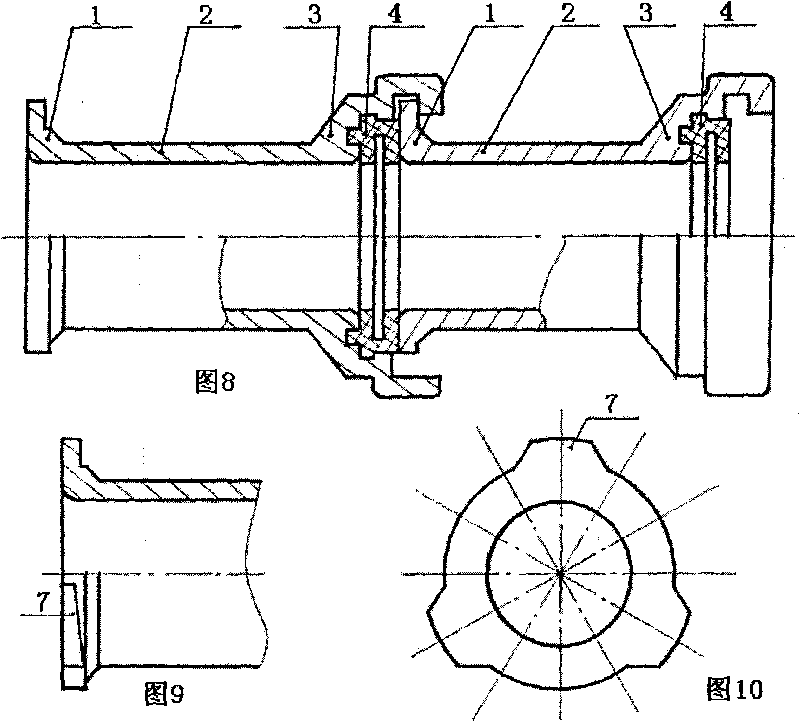

[0057] figure 1 The overall structure and assembly structure of the self-compensating direct quick-connect pipeline of the present invention are shown. It is characterized in that the rubber sealing ring 4 is provided with annular bosses 5 and 6 with openings respectively placed in the annular grooves 9 and 8 provided in the right head 3, and is connected with the nozzle in the inner cavity of the right head 3 The end faces are connected, and the outer edge of the left head 1 is provided with evenly distributed protrusions 7 with a spiral taper. In the process of fastening to the limit block 11 provided in the inner groove of the right head 3, the left head 1 is automatically pushed inward along the pipeline axial direction, and squeezes the rubber sealing ring 4 in the right head 3, just like inside the lid of a pressure cooker The structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com