Large power TNC connector for aerospace and assembling method thereof

A connector and high-power technology, which is applied in the parts, connection, and contact assembly/disassembly of the connection device, which can solve the damage of the connector, cannot meet the high-low temperature mutation transmission high-power use requirements, and reduce product reliability. To prevent thermal expansion and contraction, improve anti-low pressure discharge capability, and increase creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the public implementation manners of the present invention in detail with reference to the accompanying drawings.

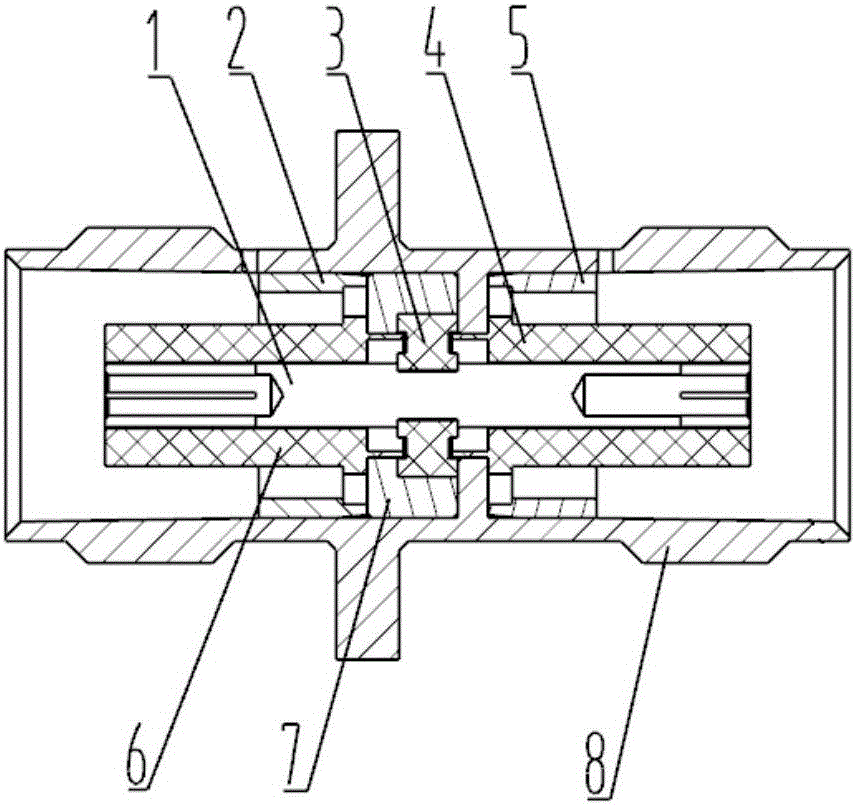

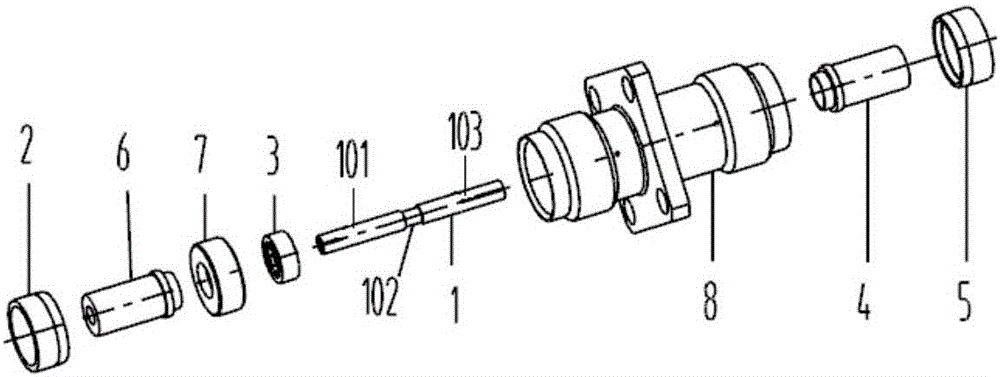

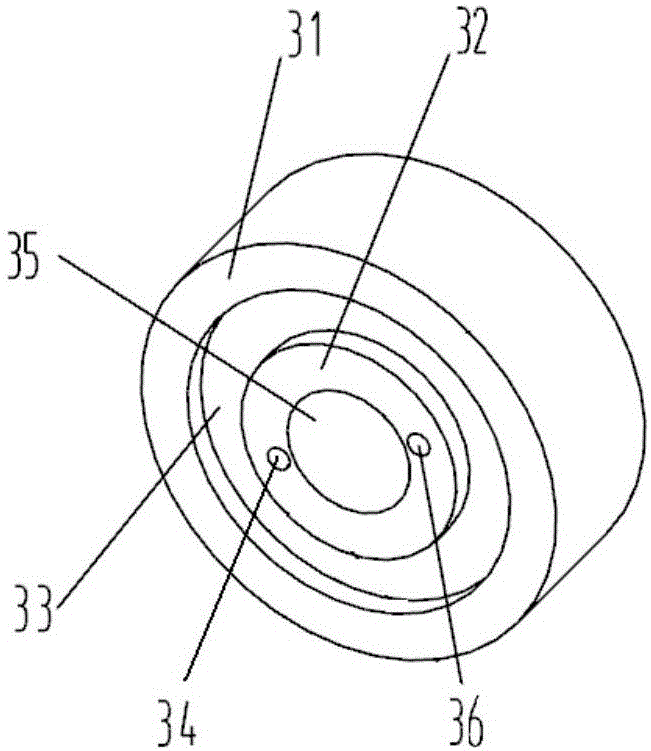

[0053] refer to figure 1 , shows a schematic cross-sectional structure diagram of an aerospace high-power TNC connector in an embodiment of the present invention. refer to figure 2 , shows an assembly diagram of a high-power TNC connector for aerospace in an embodiment of the present invention. combine figure 1 with figure 2 , in this embodiment, the high-power TNC connector for aerospace includes: a socket 1 whose center line is located on the same axis, a first ferrule 2, a second ferrule 5, an inner insulator 3, and a first outer insulator 6 , the second outer insulator 4 , the bushing 7 and the housing 8 . Wherein, the socket 1 , the first pressing sleeve 2 , the second pressing sleeve 5 , the inner insulator 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com