Light steel mesh wall body and building house body built by light steel mesh wall body

A light-weight steel and wall technology, applied in construction, building components, building types, etc., can solve problems such as increased construction costs, low strength of light steel, and poor structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

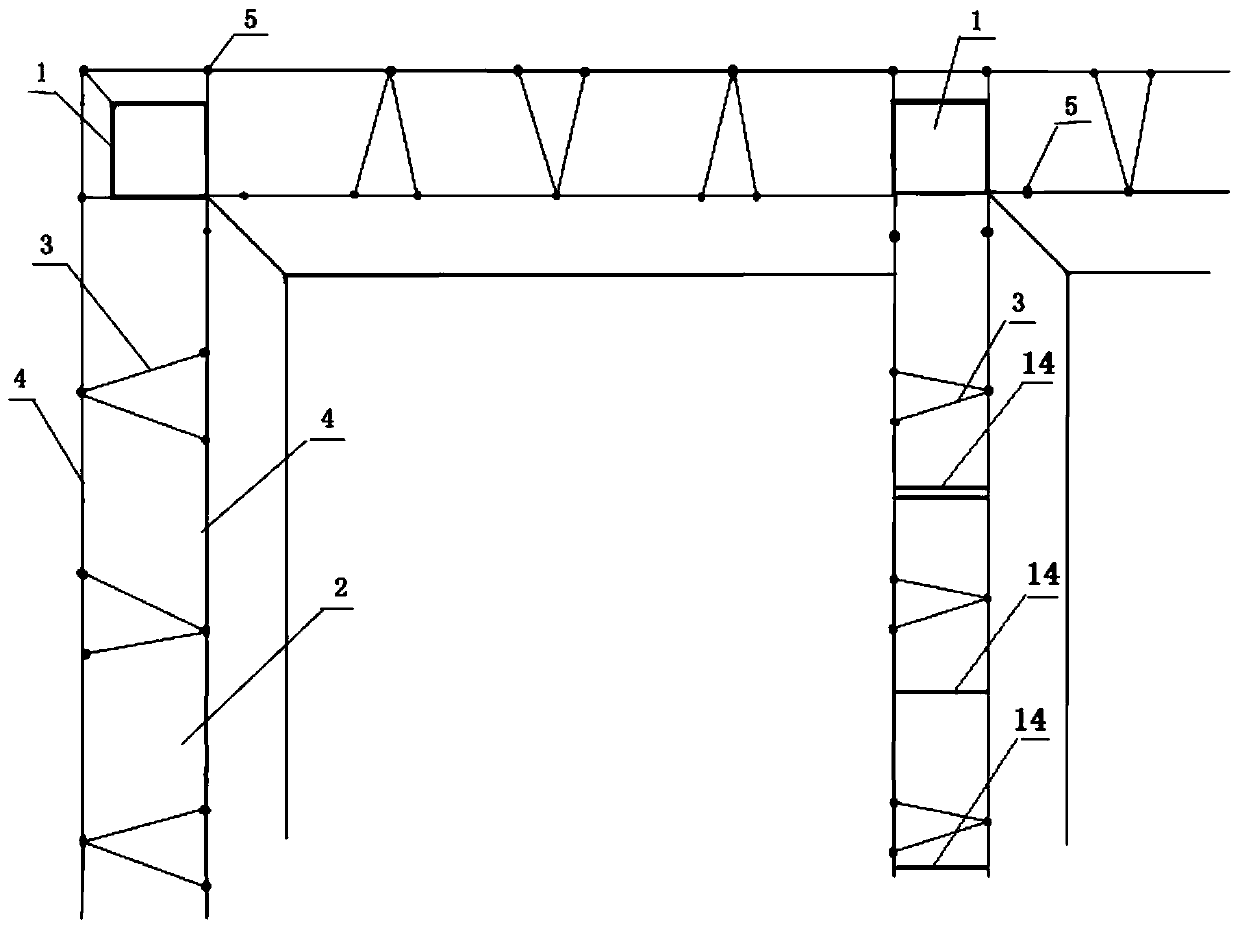

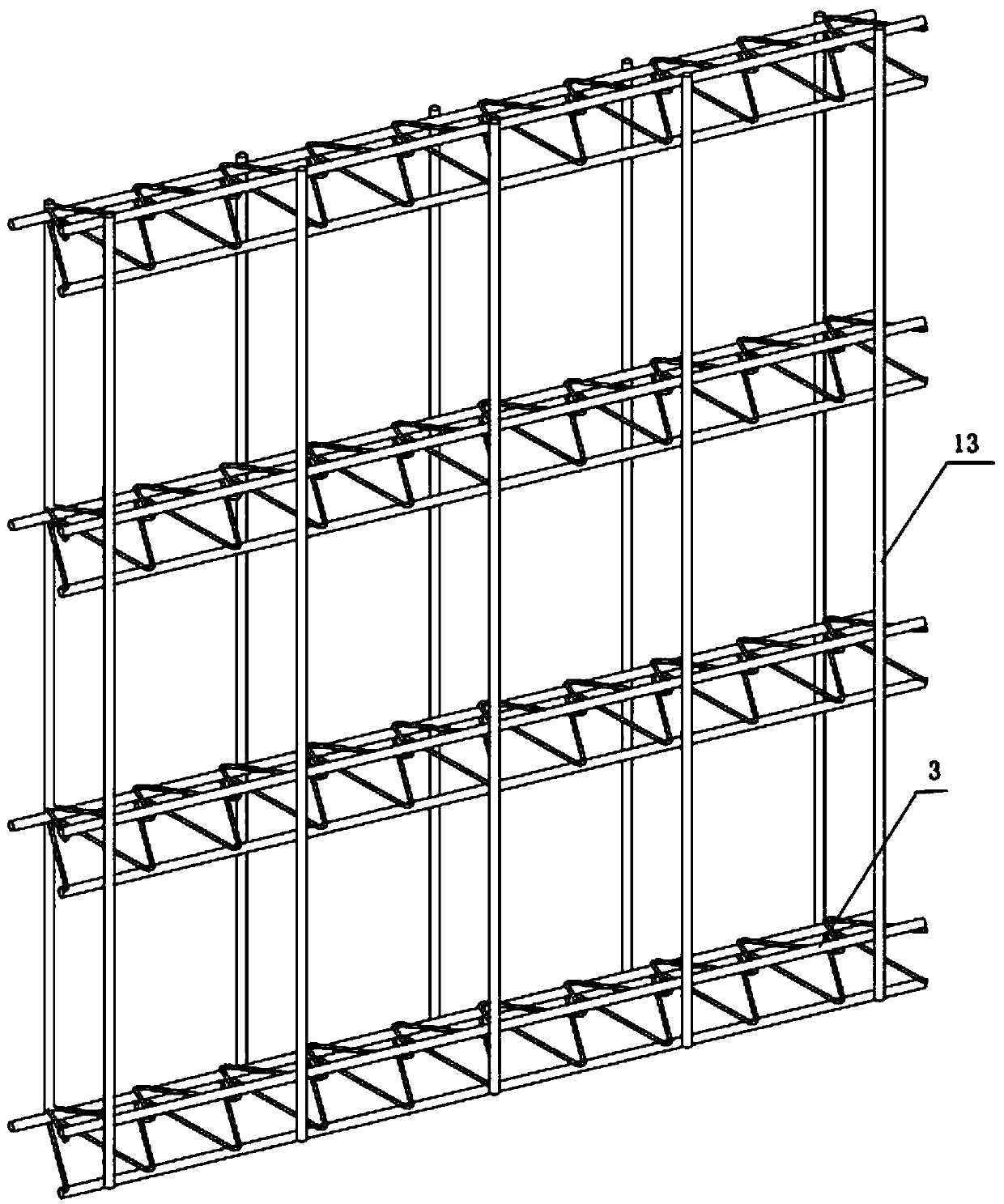

[0039] Such as figure 1 and figure 2 As shown, the light steel mesh wall includes a wall skeleton, the wall skeleton is arranged in the area surrounded by the steel column 1 and the steel beam 2, and concrete is poured in the wall skeleton; the outer periphery of the steel column 1 is provided with a tie rod 5 , the position of the tie rod is about 5-10cm away from the steel column. You can choose where to install the tie rod on the steel column according to the actual situation. Tie rods are set on the periphery. The tie rod 5 is welded to the steel column 1 and the steel beam 2 through a plurality of threaded steel bars 6. The tie rod 5 and the wall skeleton are located on the same straight line, and are connected with the wall skeleton through the expansion net 4 to form an integrated structure. Concrete wraps the steel column, which is not easy to crack and fall off; the tie rod 5 is angle steel, channel steel, square pipe or steel bar.

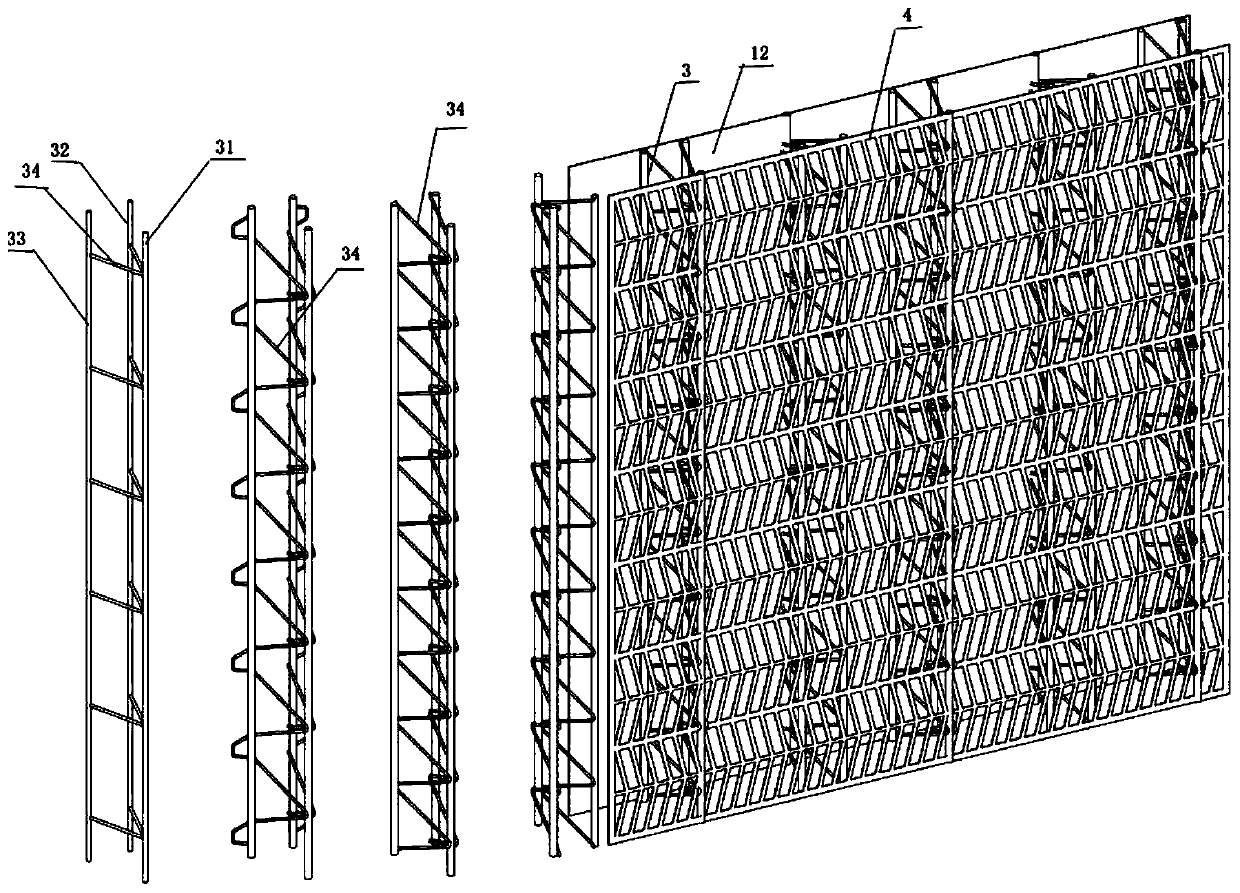

[0040]The wall skeleton includ...

Embodiment 2

[0046] Such as Figure 7 ~ Figure 11 As shown, several square columns 10 are fixed between adjacent steel columns in the building body constructed by using the light-weight steel mesh wall, and a support is installed under the steel columns to support the whole body off the ground to form an empty bottom. The base 16; the steel column 1 and the steel beam 2 are galvanized steel columns and galvanized steel beams, and the connection between the steel column and the steel beam, the steel beam and the steel beam, and the column and the steel beam are all welded with triangular braces 17 , The welding position and size of the triangular brace can be determined according to the actual situation, and the triangular brace is a triangular plate, threaded steel bar, square tube or channel steel. Because the columns, beams and walls of the concrete frame structure of the external wall and the steel structure frame absorb water unevenly, expand and contract with heat and shrink to crack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com