Patents

Literature

400results about How to "Improve reading accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

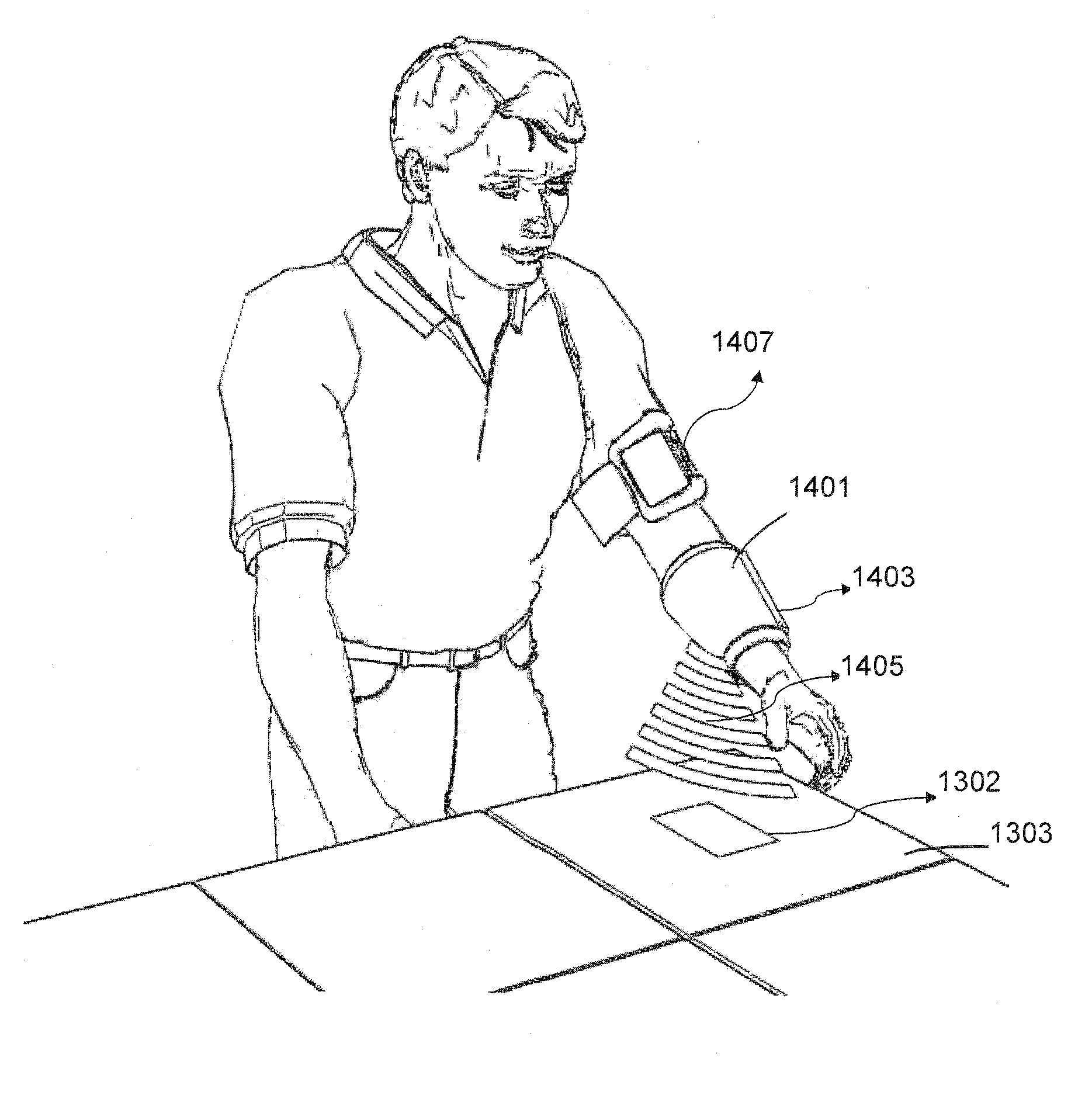

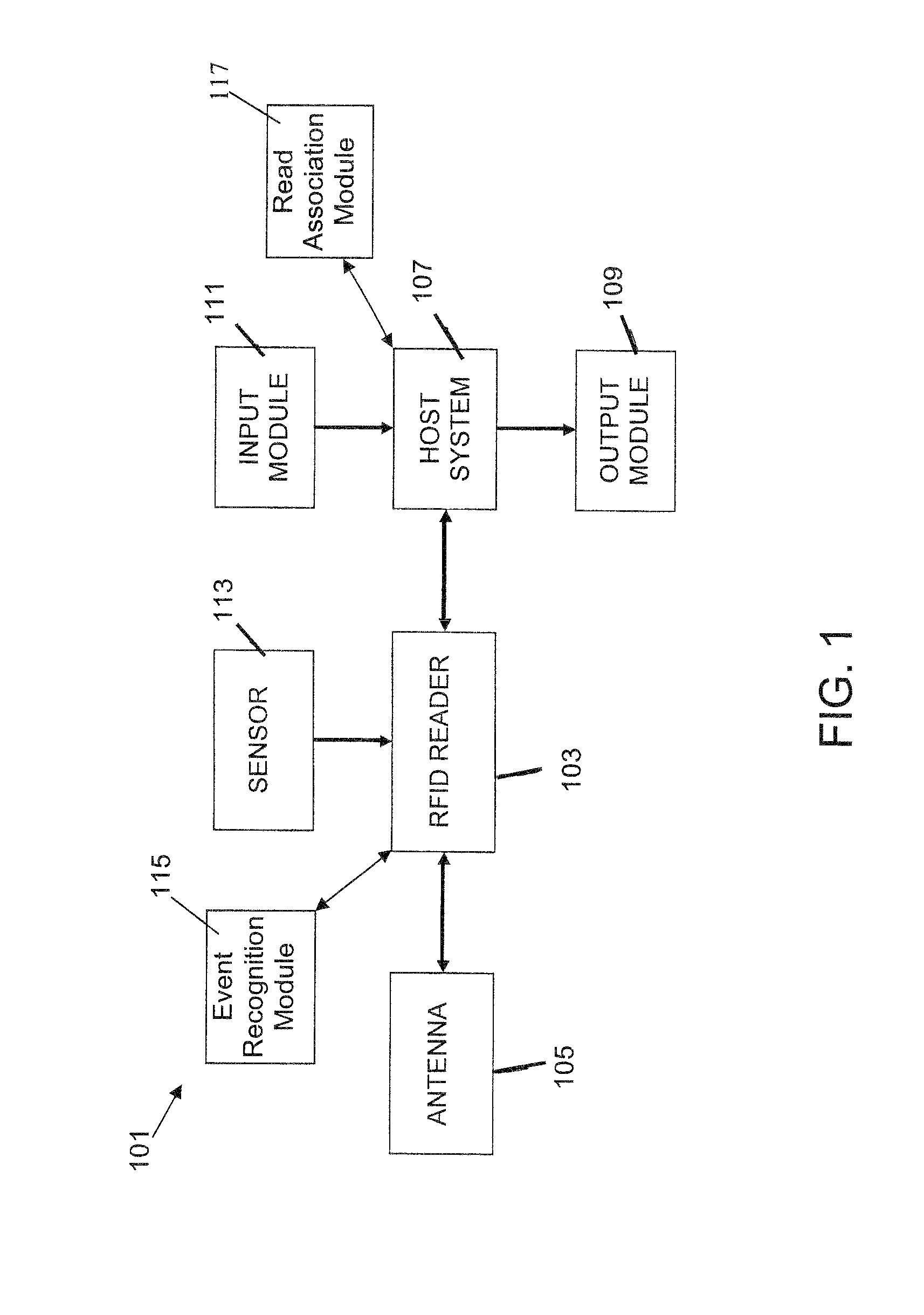

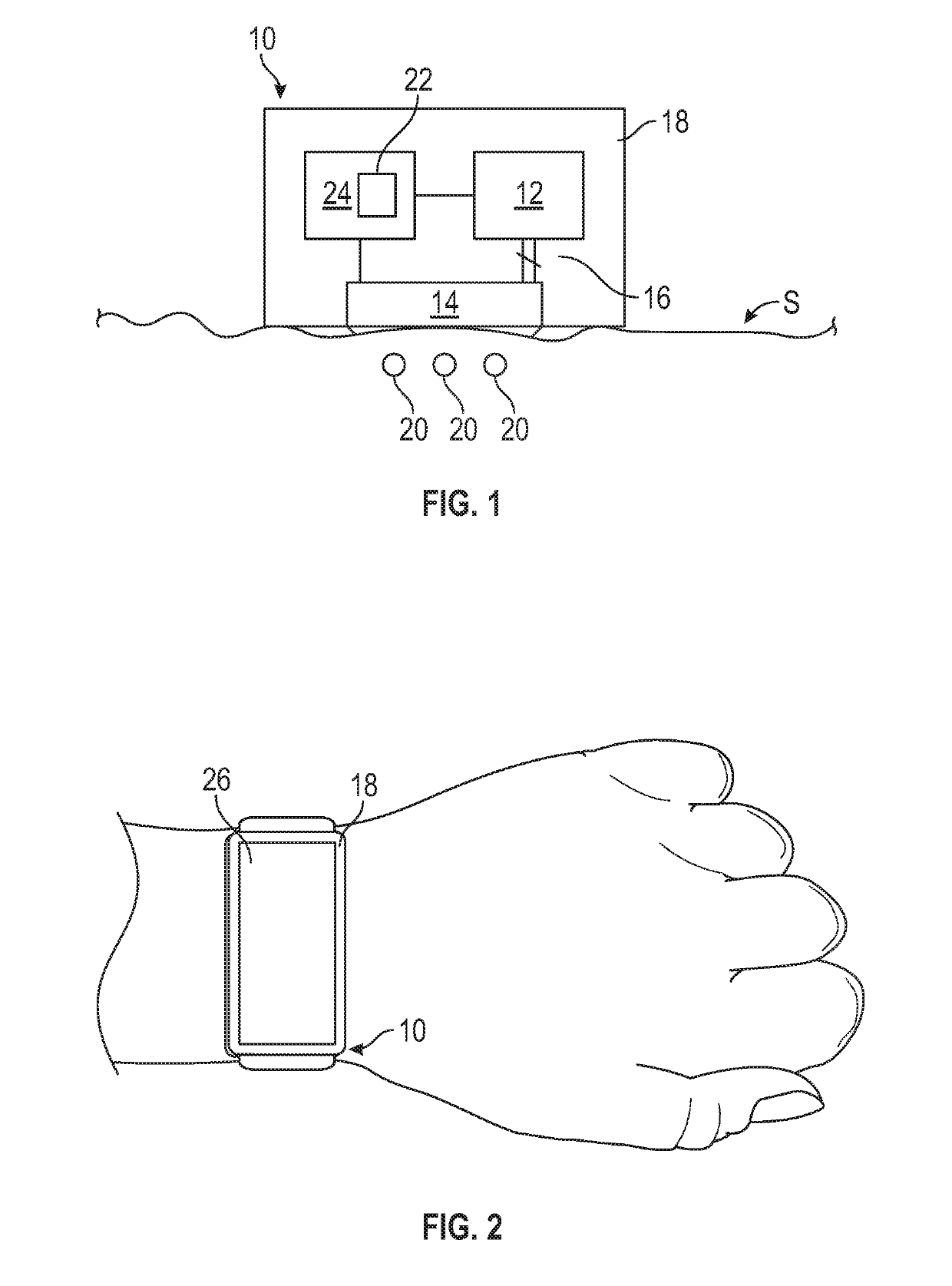

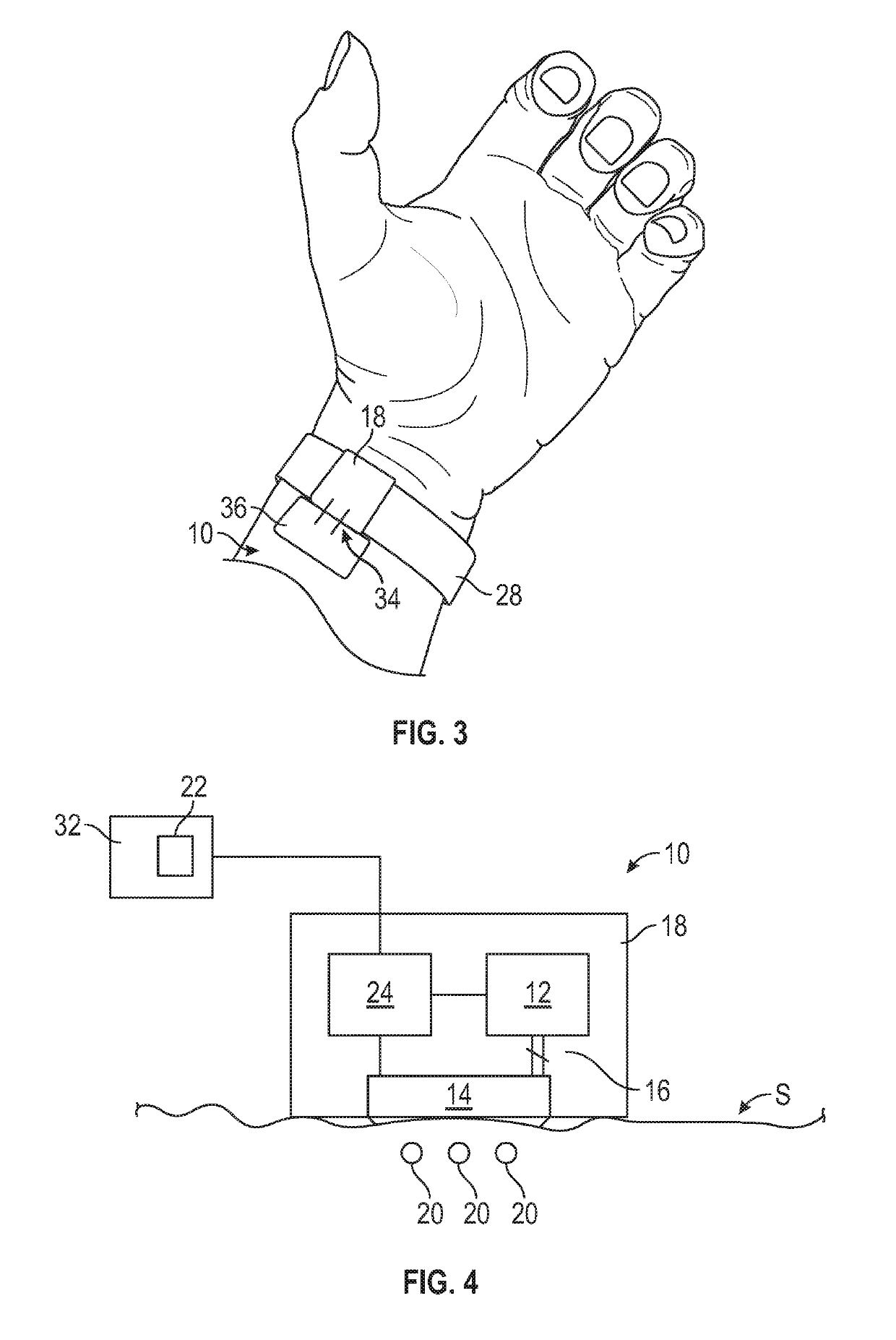

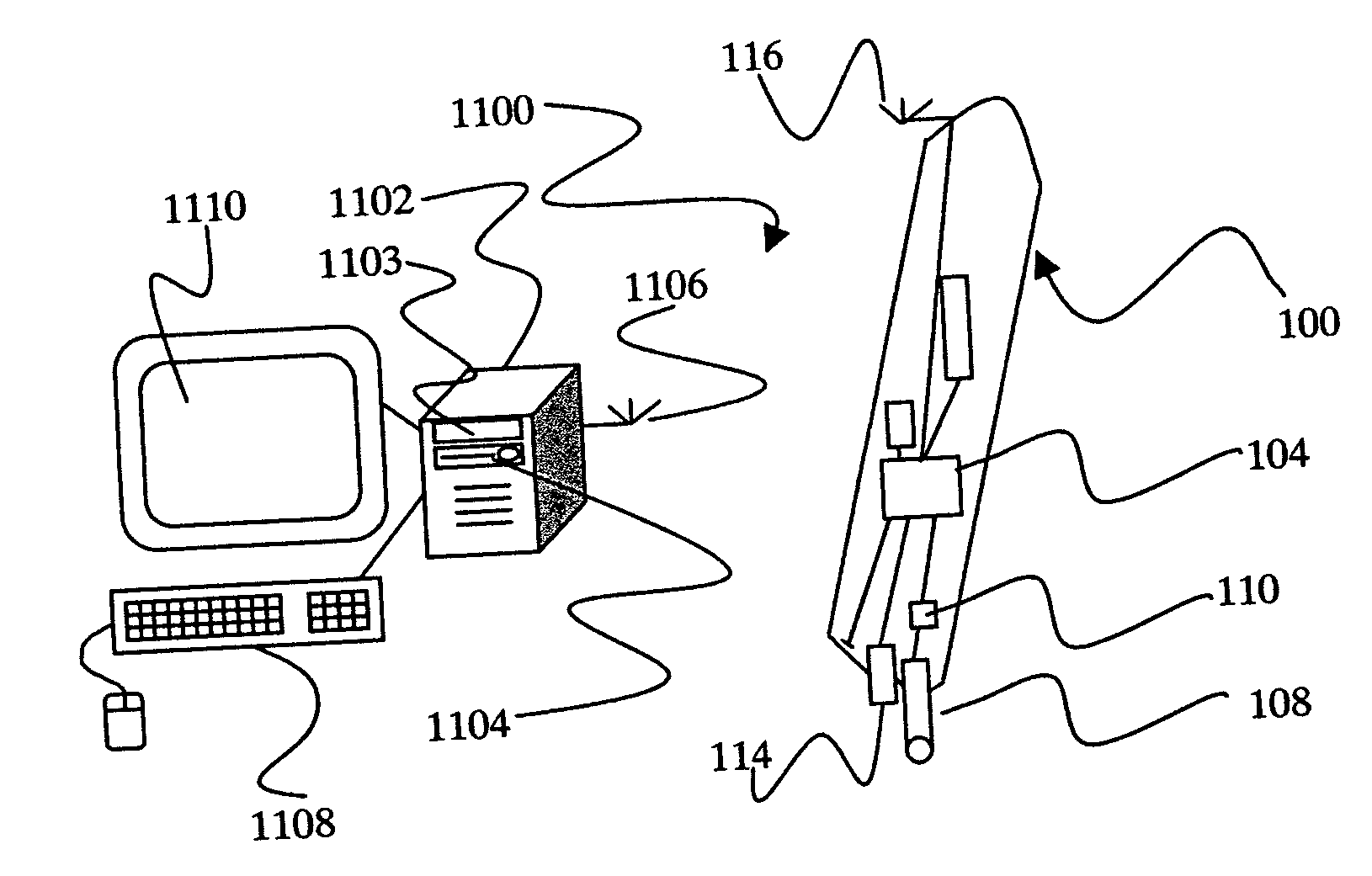

Wearable RFID system

ActiveUS20100271187A1Easy to readImprove reading accuracyMemory record carrier reading problemsSubscribers indirect connectionRadio frequencyRadio-frequency identification

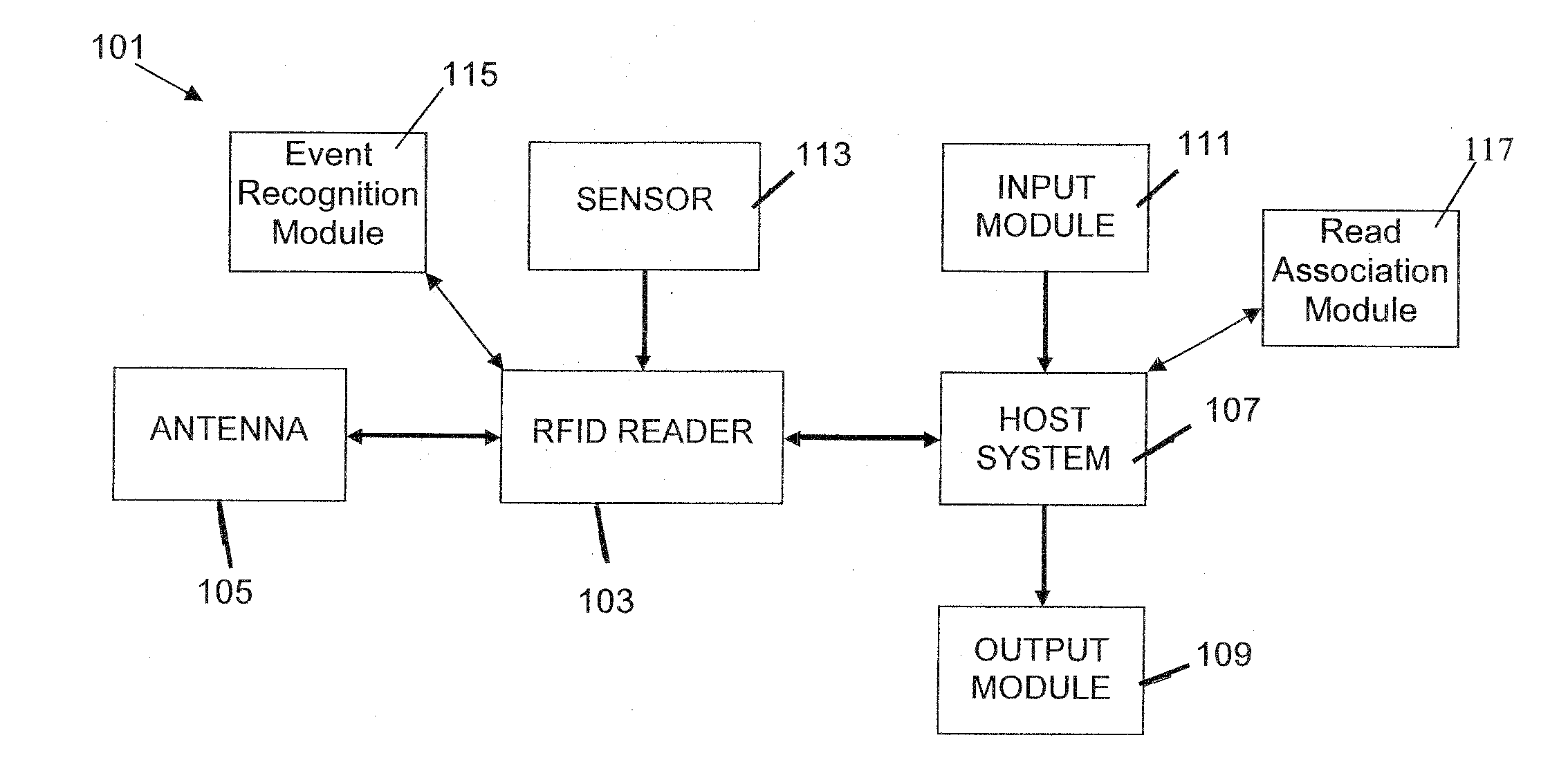

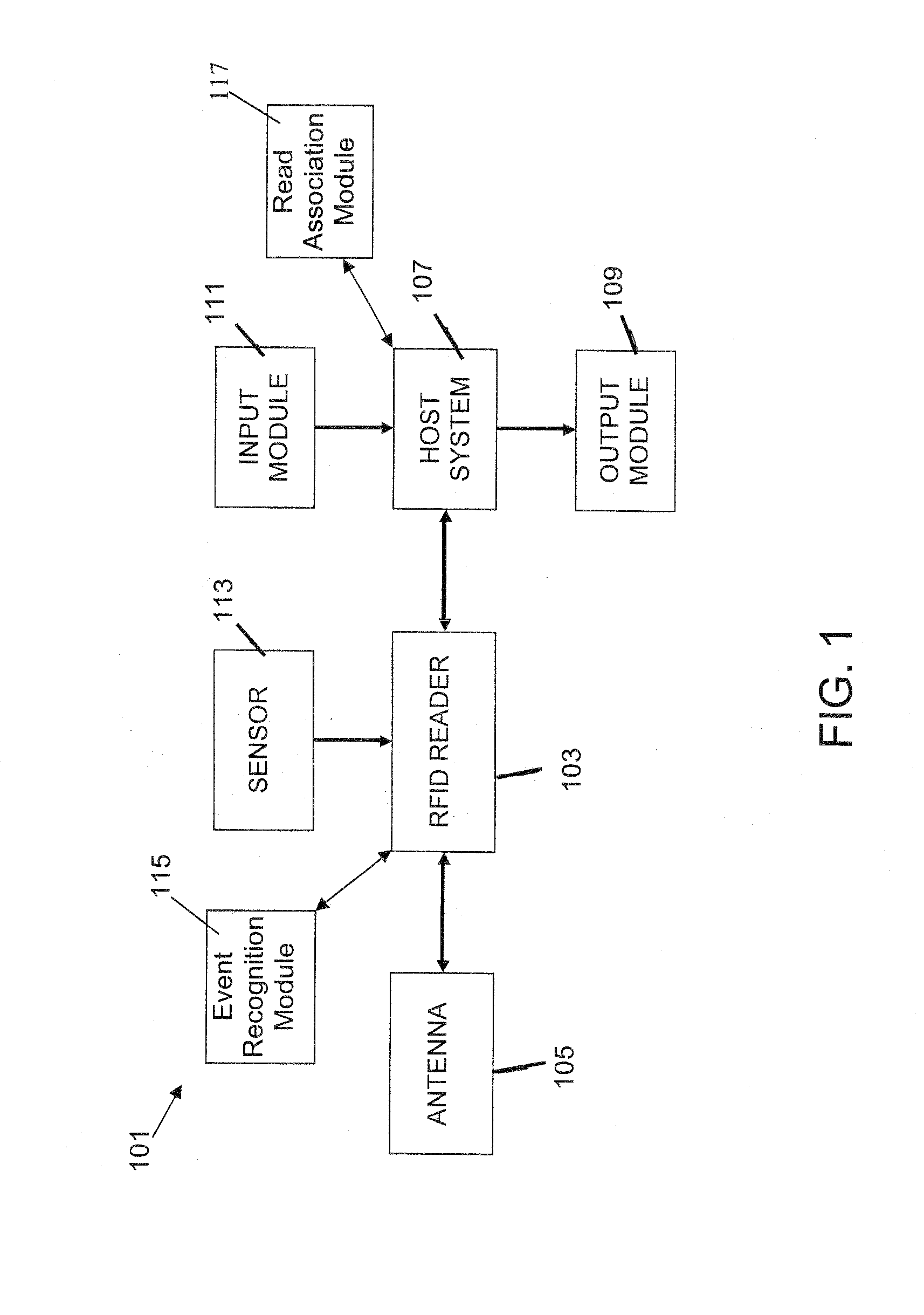

Apparatus and methods are provided for automatically interrogating a tagged object using radio frequency identification (RFID) when the object is moved. In one embodiment, a worker is outfitted with a wearable RFID system including an RF antenna, an RFID reader, and a holder to hold the antenna and reader during operation. The system is worn by the worker while the worker moves objects from one place to another. When the worker moves an object with an attached RFID tag, the antenna automatically begins scanning for signals from the object's RFID tag. When a RF signal is received by the antenna, the RFID reader collects the signal and transmits it to a host system which processes the signal to obtain information related to the object to which the RFID tag is attached.

Owner:METRC LLC

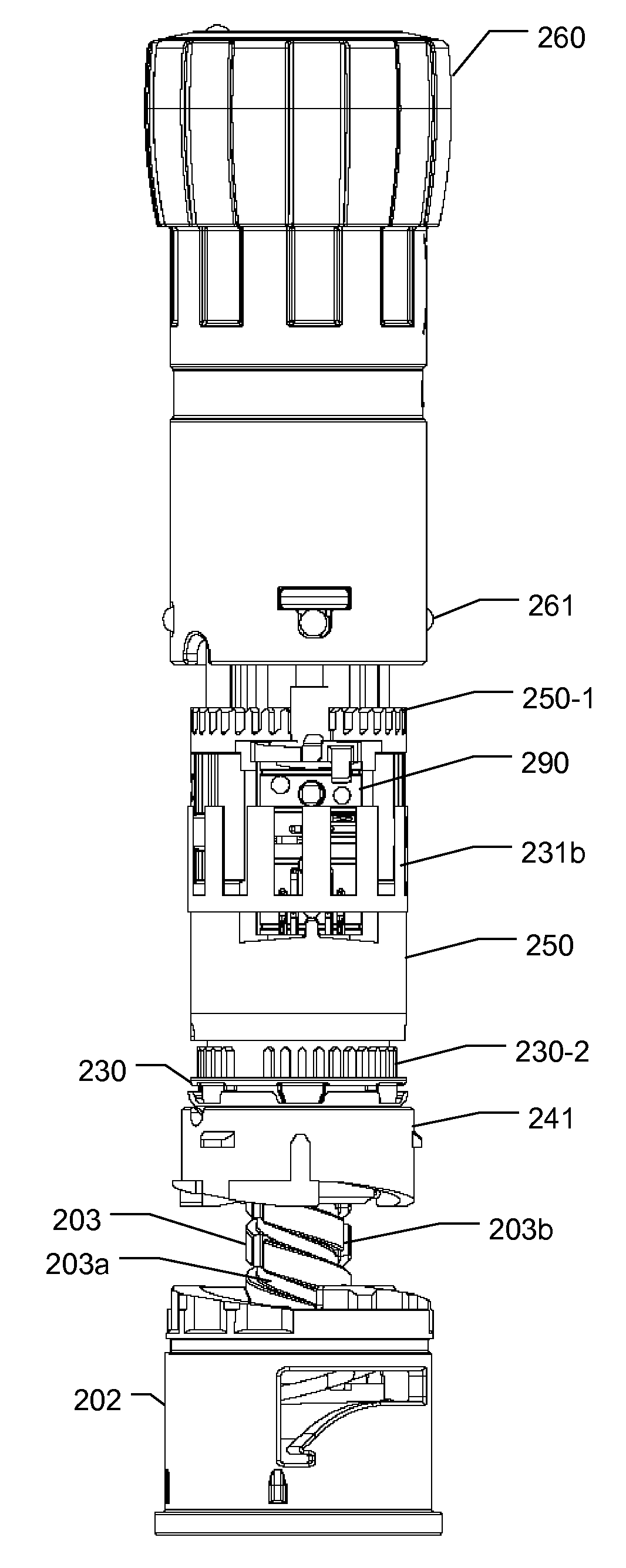

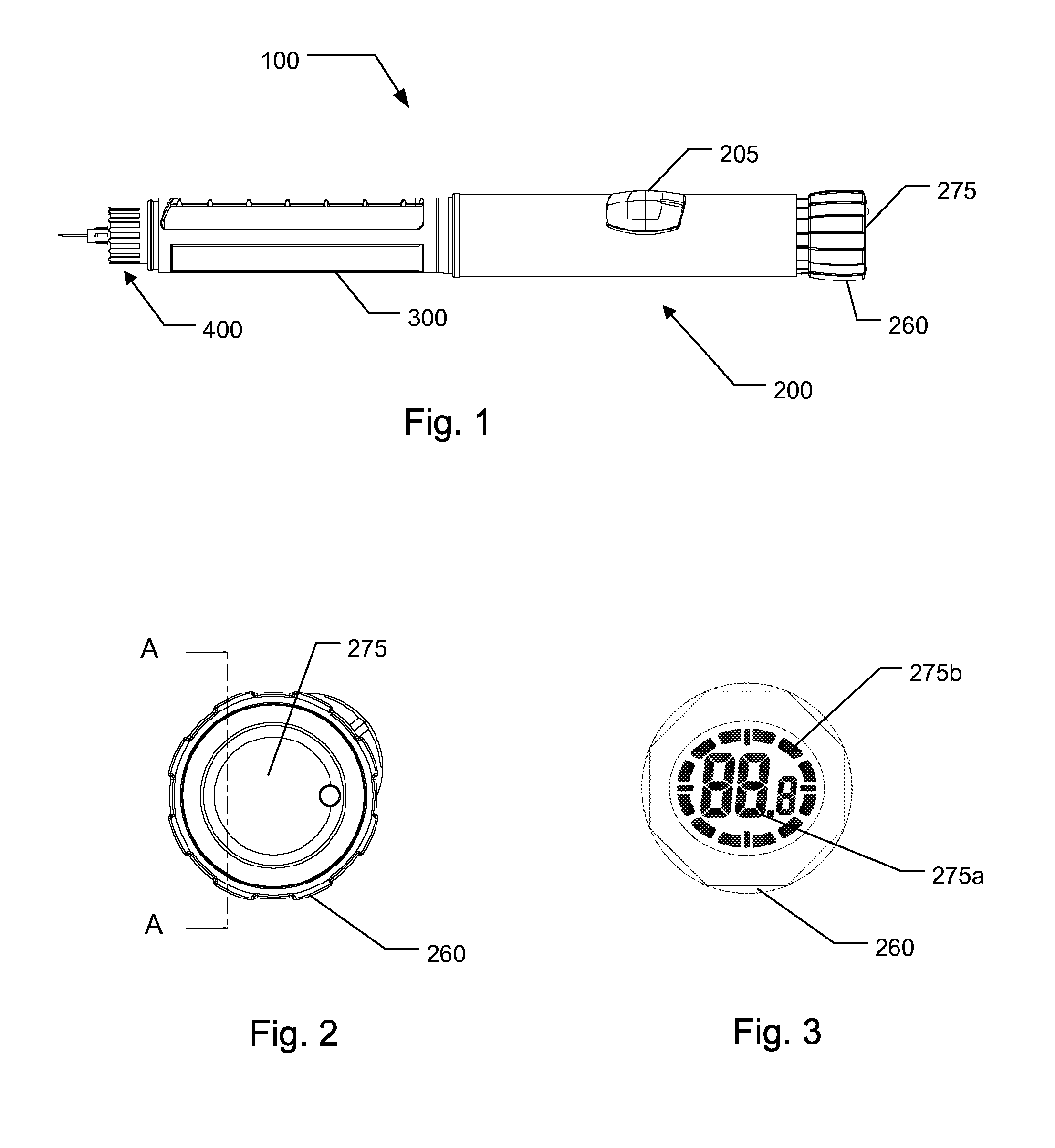

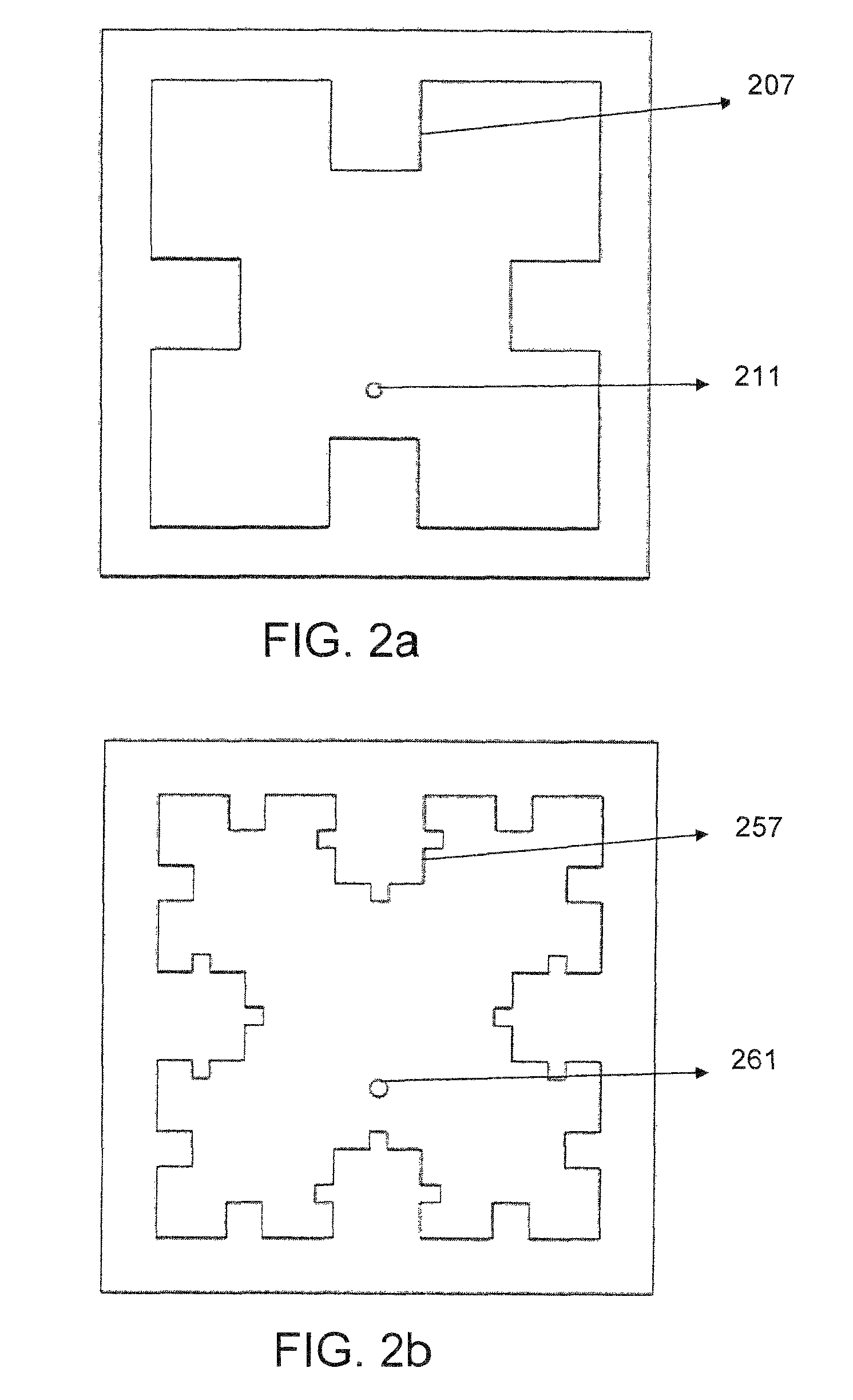

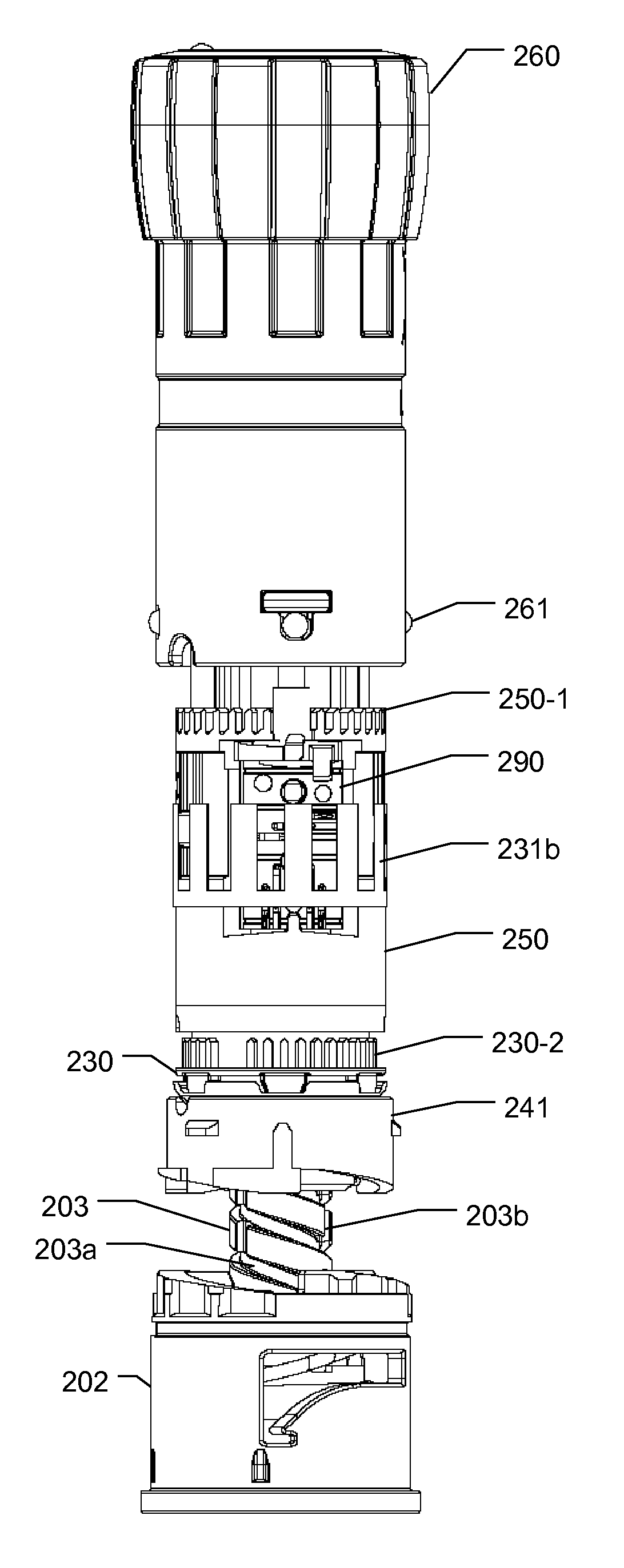

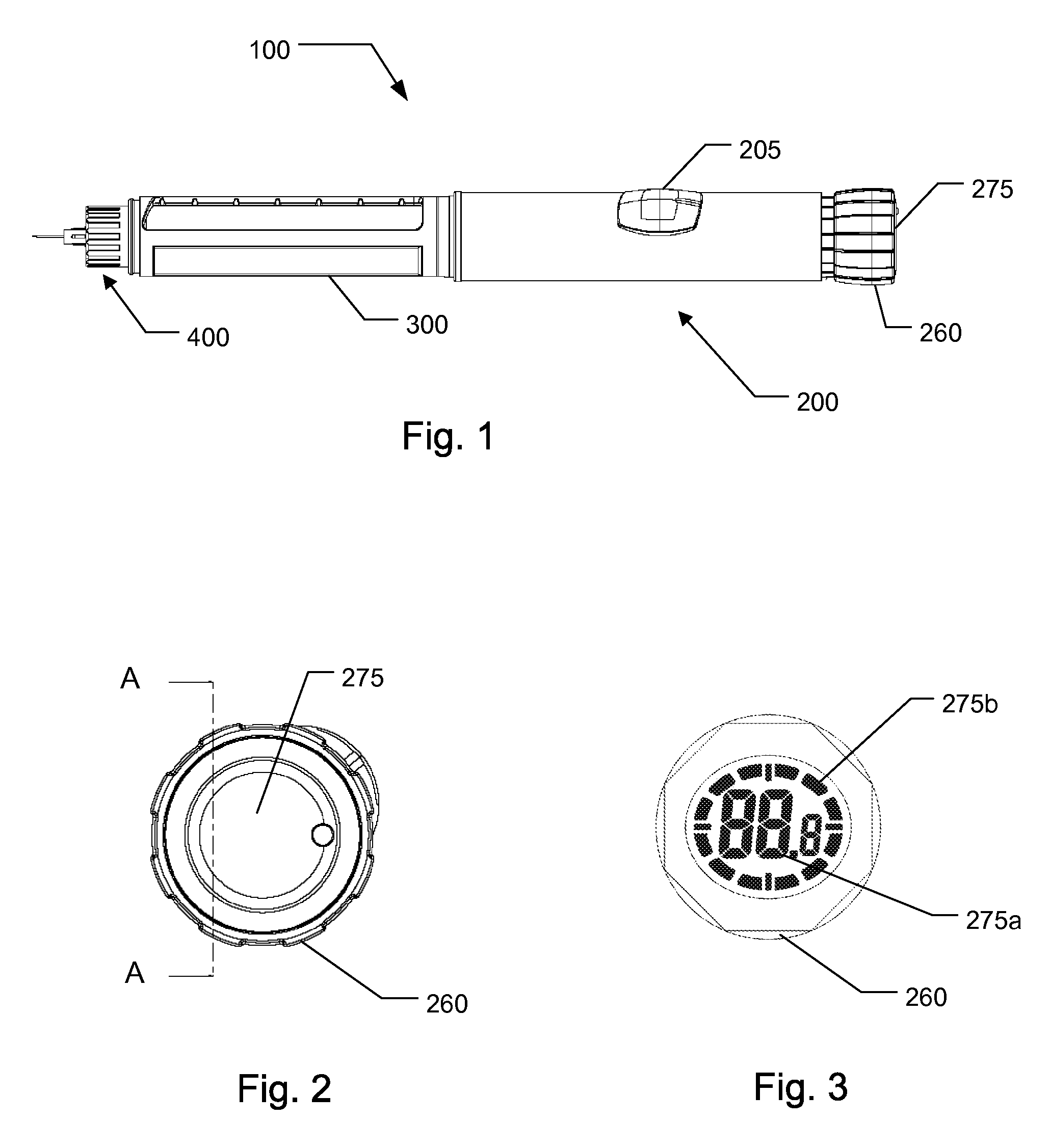

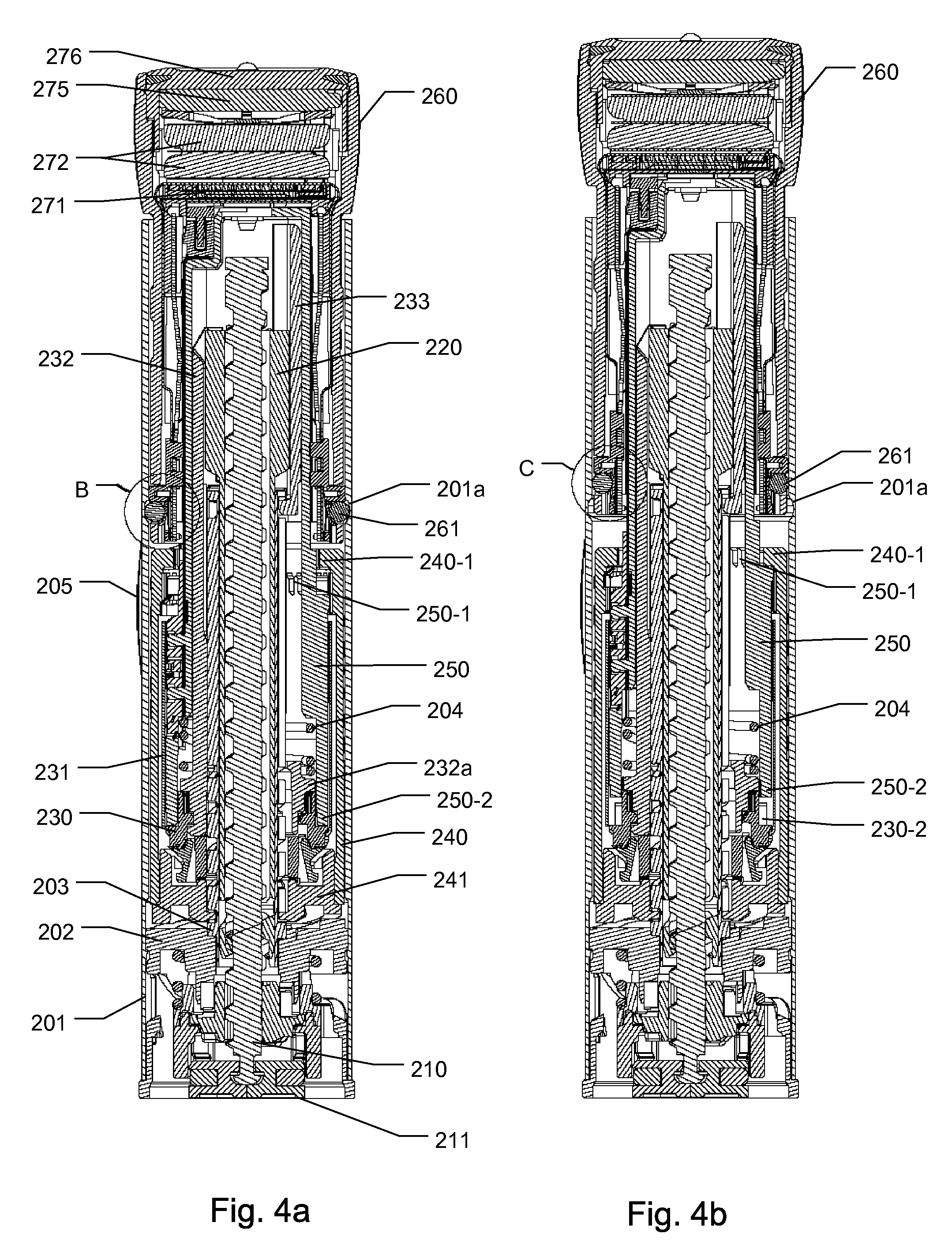

Electronically assisted drug delivery device

The present invention relates to electronically assisted drug delivery devices (100). The drug delivery device may include a Gray code type detector for sensing dosage data, wherein the detector comprises a code track consisting of a sequence of alternating markings and a plurality of detectors that are mutually spaced in a direction extending along the code track. The drug delivery device may also include a dosage selector (260) which is moved in a proximal direction upon dose setting and in a distal direction upon dose injection, where the dosage selector is latched in the end of dose position by a latching element, the latching element actuating an end of dose switch for signalling the end of dose state. The drug delivery device may also incorporate power-management arrangements which effectively minimizes power consumption for the incorporated electronic circuitry.

Owner:NOVO NORDISK AS

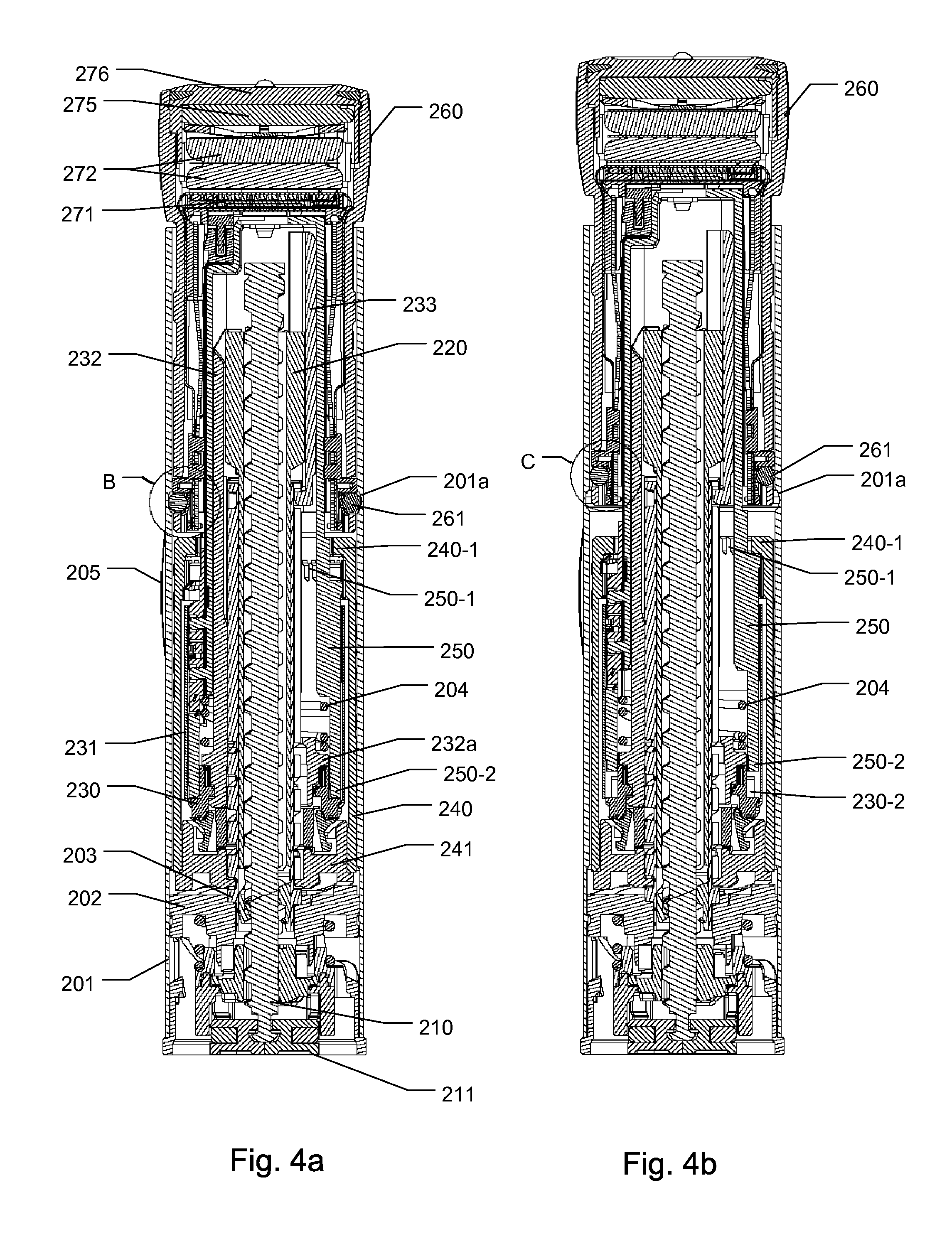

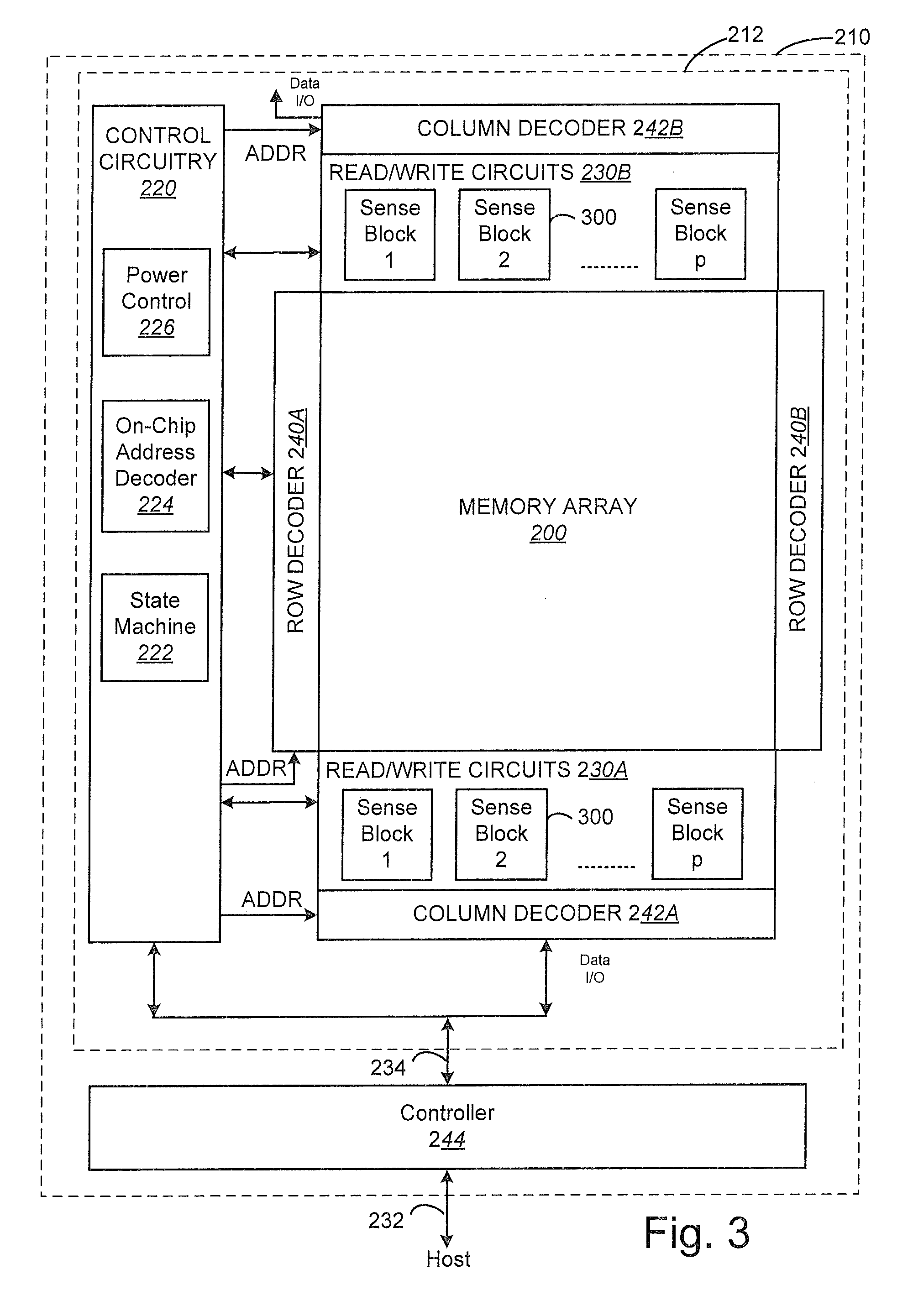

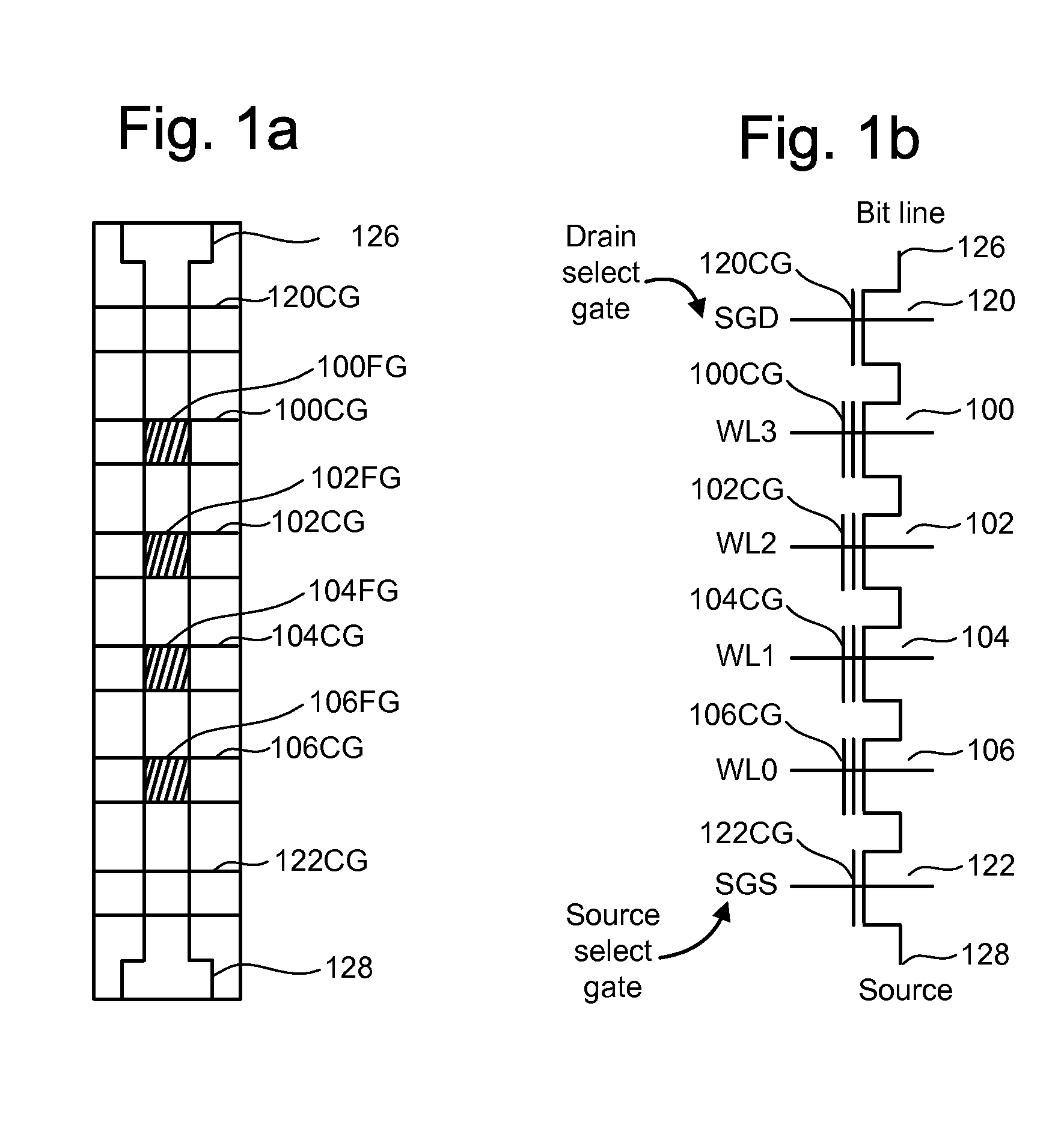

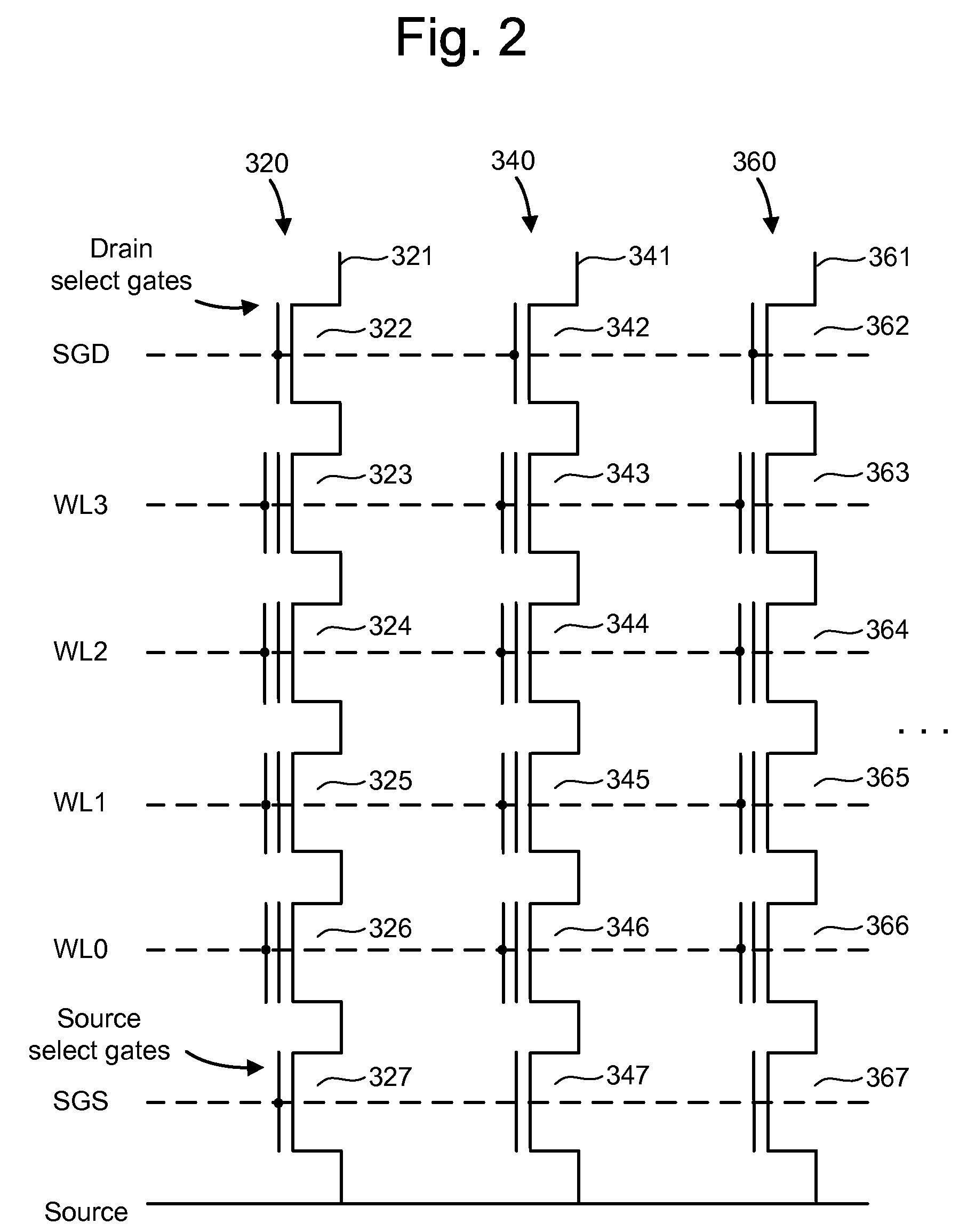

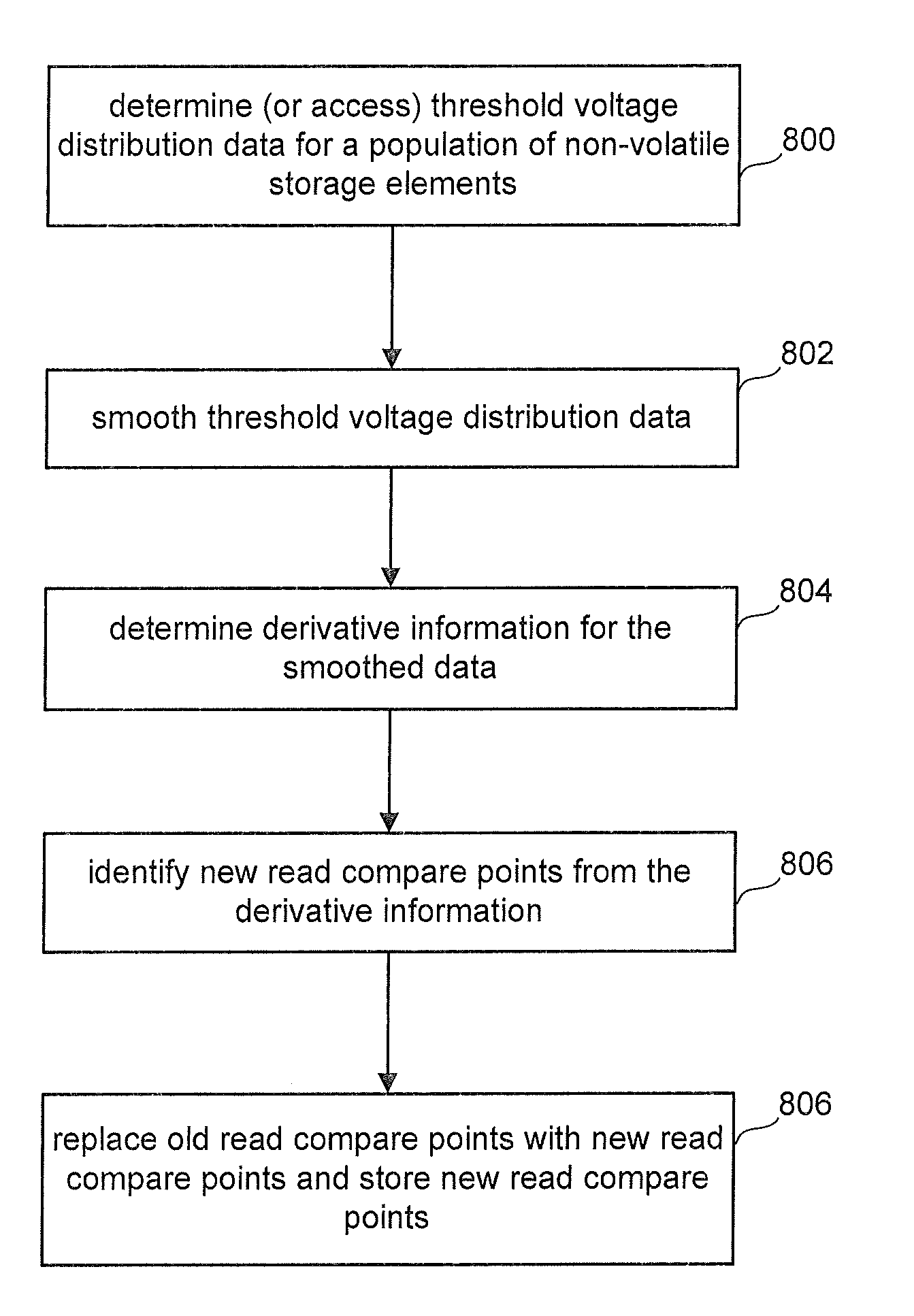

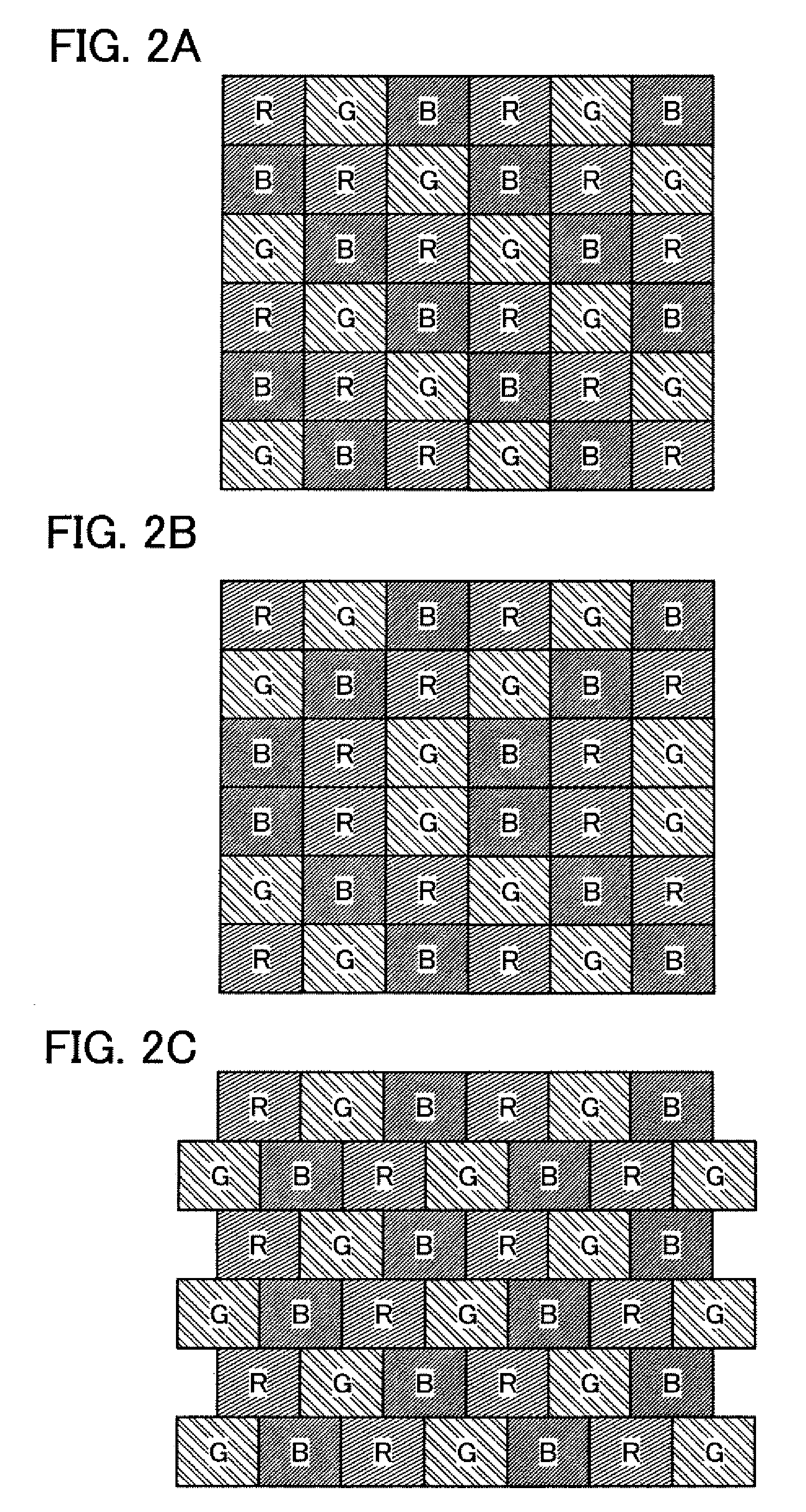

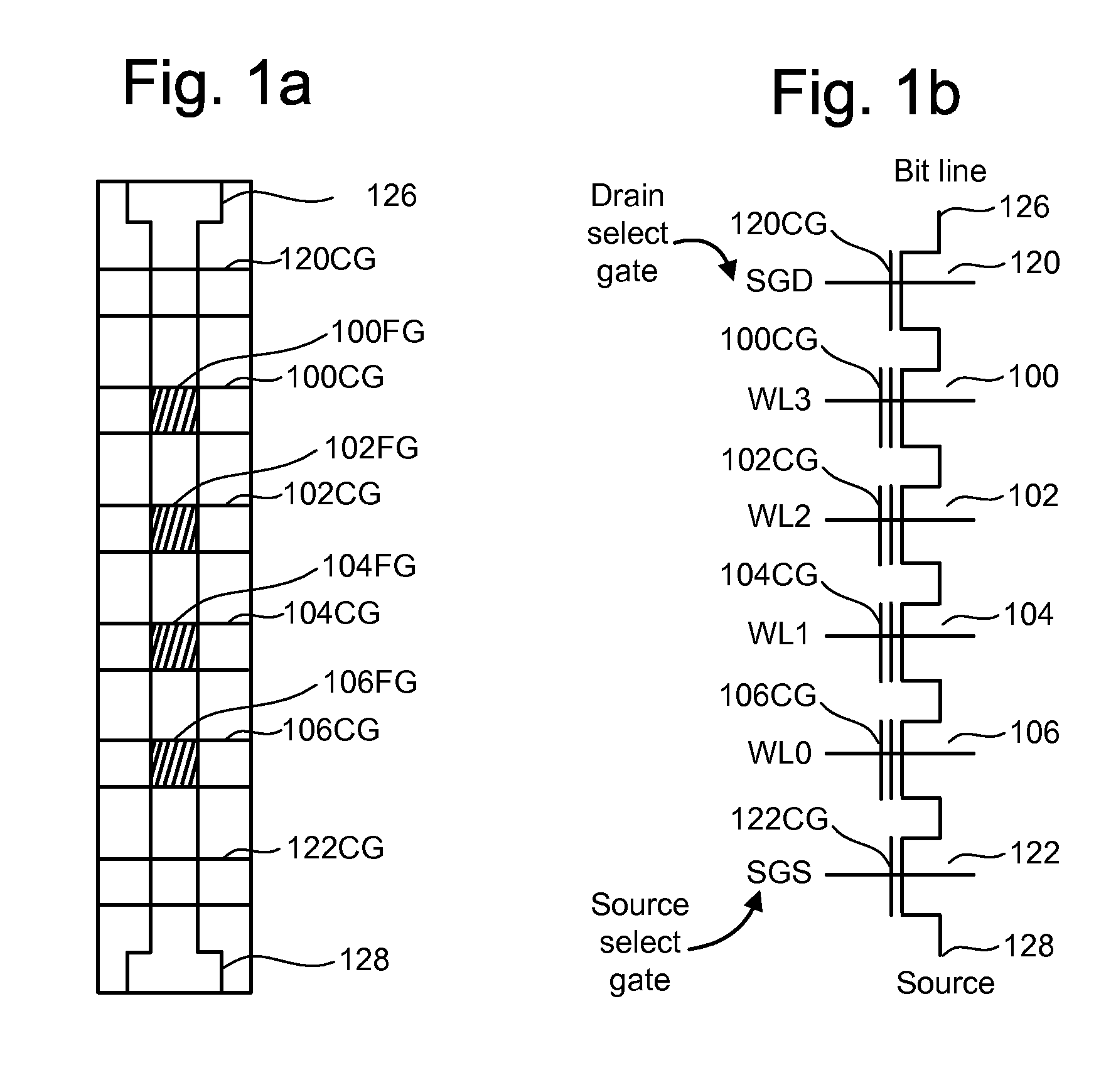

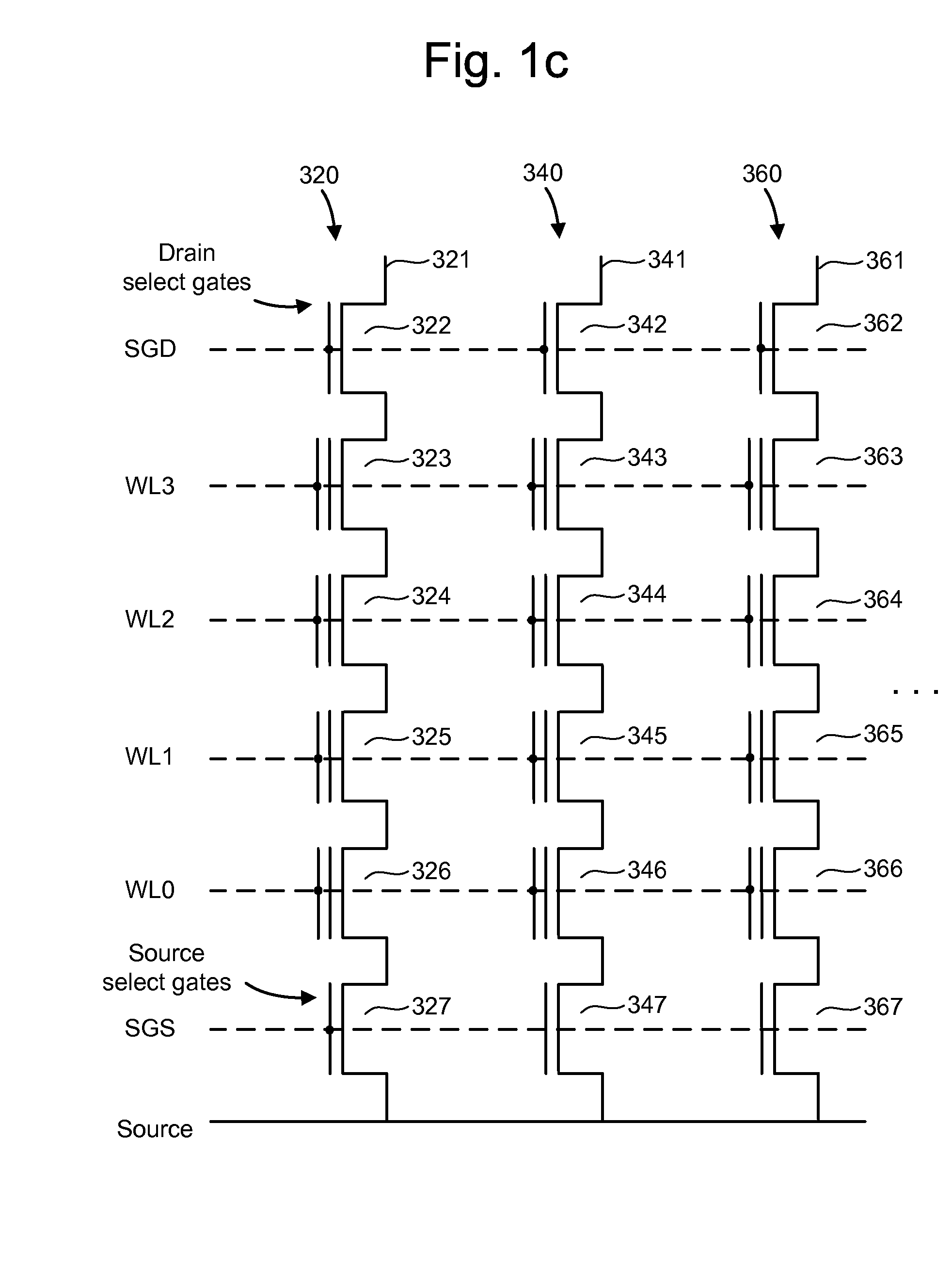

Dynamic and adaptive optimization of read compare levels based on memory cell threshold voltage distribution

ActiveUS20090282186A1Improve reading accuracyLevel of optimizationRead-only memoriesDigital storageData setAdaptive optimization

A process is performed periodically or in response to an error in order to dynamically and adaptively optimize read compare levels based on memory cell threshold voltage distribution. One embodiment of the process includes determining threshold voltage distribution data for a population of non-volatile storage elements, smoothing the threshold voltage distribution data using a weighting function to create an interim set of data, determining a derivative of the interim set of data, and identifying and storing negative to positive zero crossings of the derivative as read compare points.

Owner:SANDISK TECH LLC

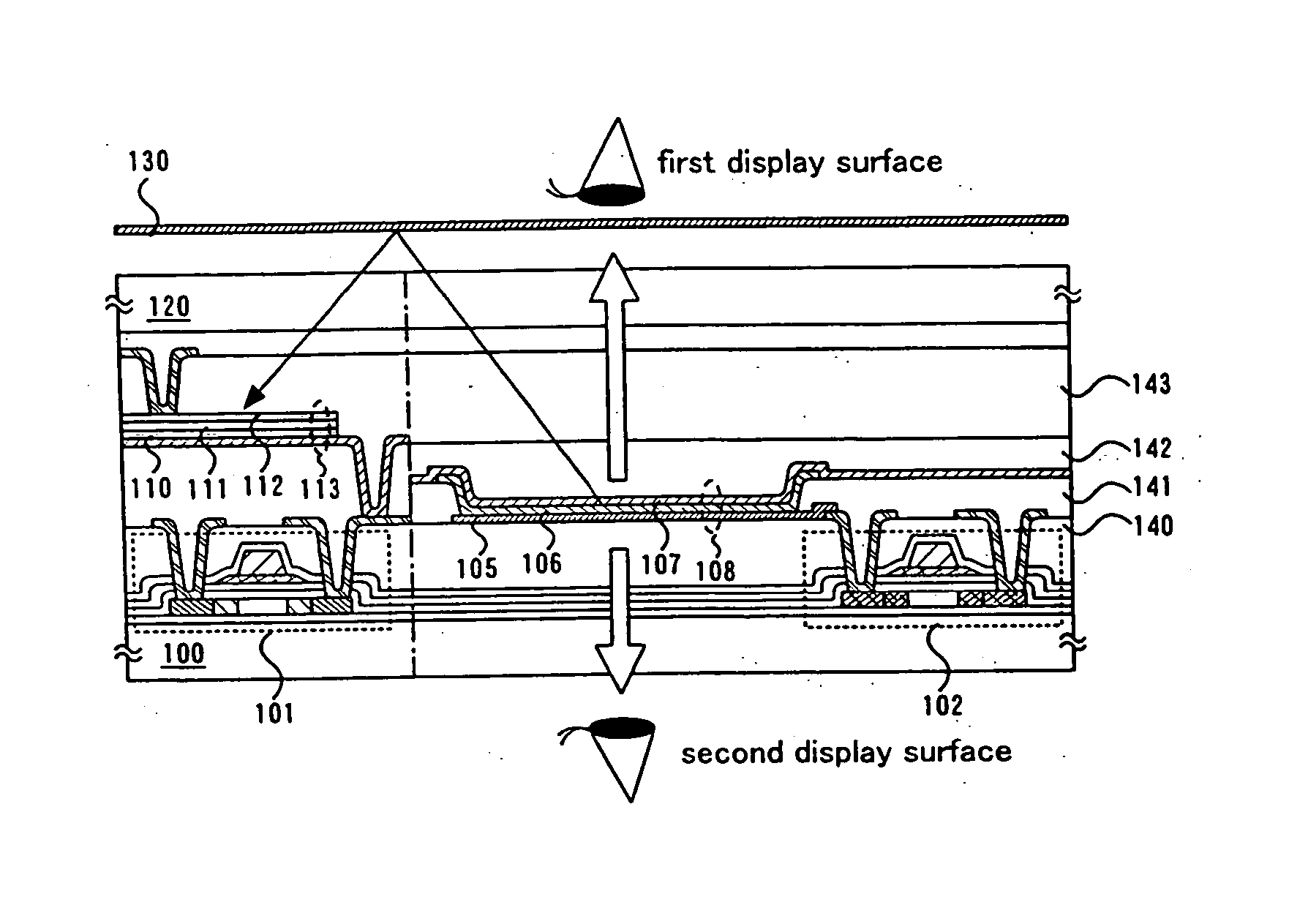

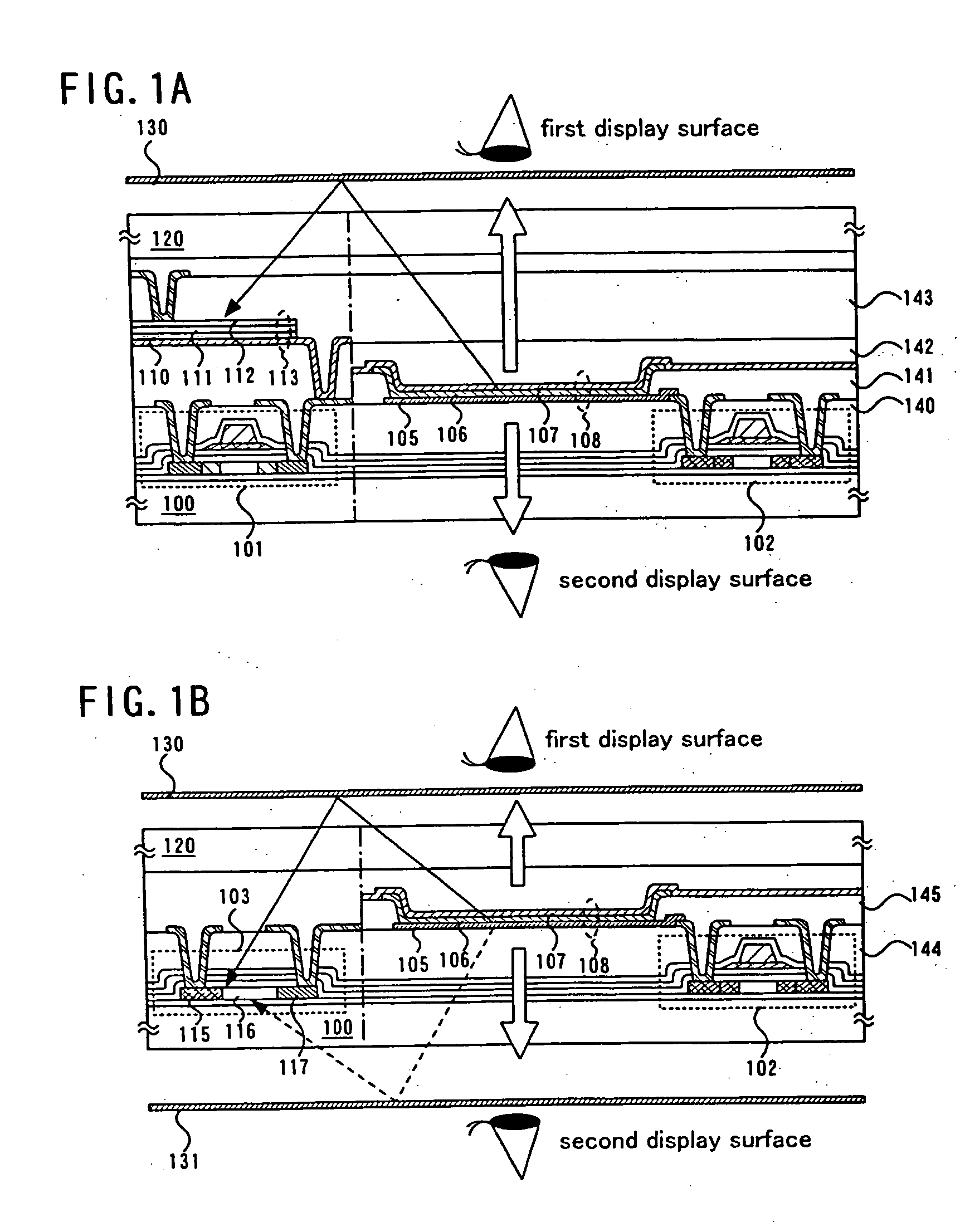

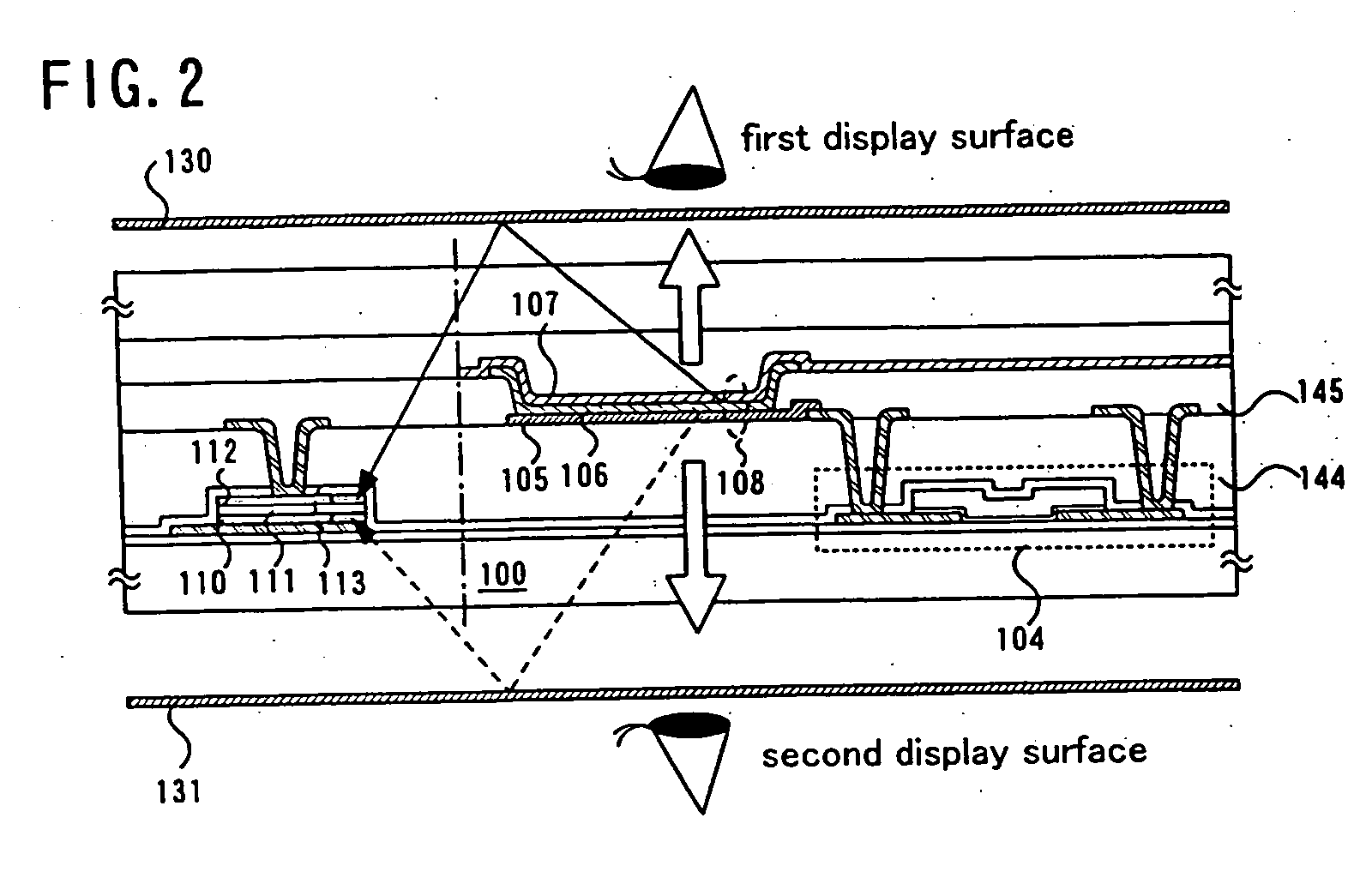

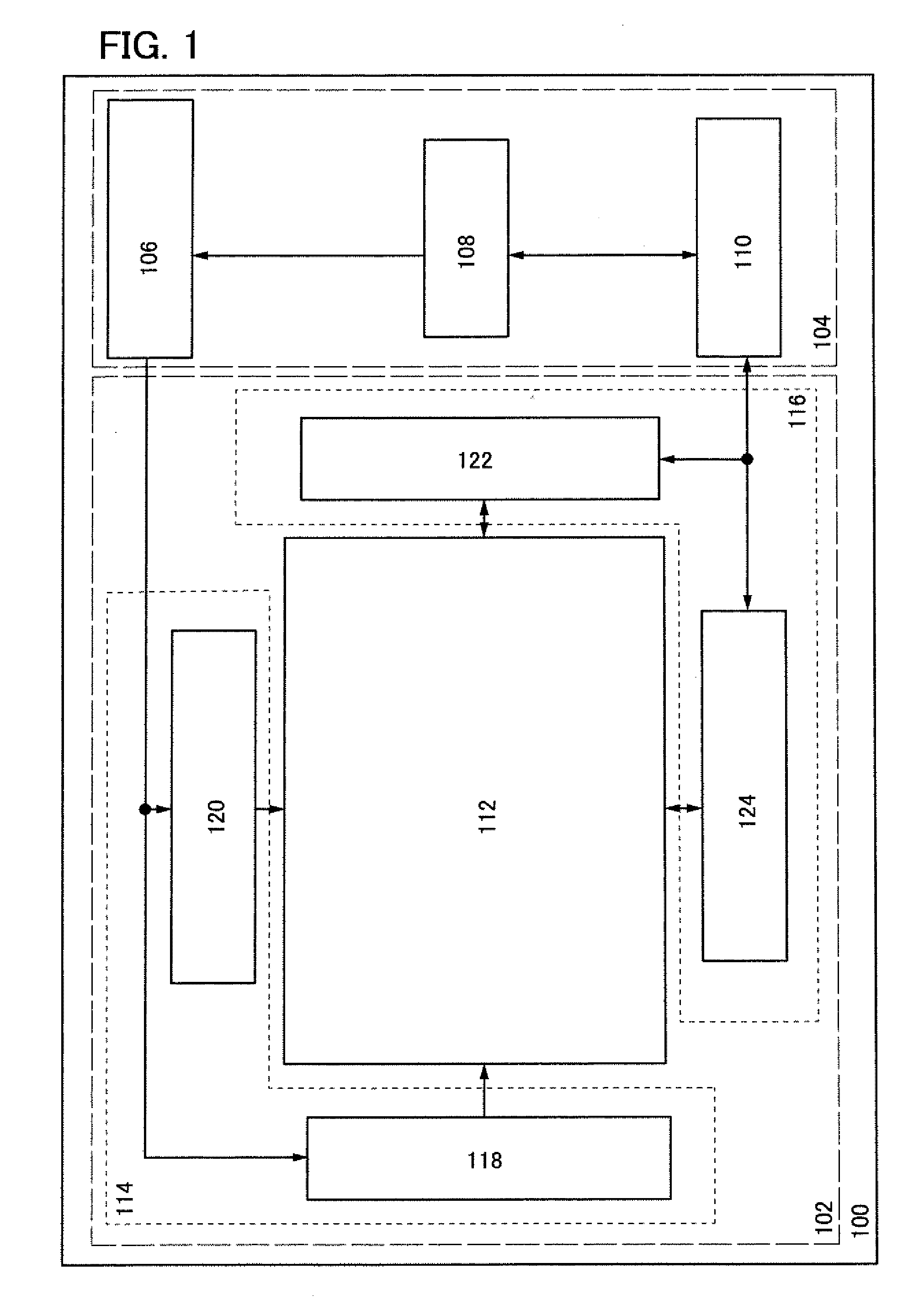

Display device and electronic device

InactiveUS20040263069A1Display device be small and thinSmall and thin and lightTelevision system detailsDischarge tube luminescnet screensDisplay deviceAdditional values

A display device and an electronic device in which more sophistication and a high added value are realized by obtaining a read function by incorporating an imaging device, and by using a panel with small volume can be provided. A display device and an electronic device according to the invention has a first display surface and a plurality of pixels arranged in matrix over one surface of a light transmitting substrate and a second display surface over the other surface of the substrate. The plurality of pixels are each provided with a transistor, an imaging device, and a light-emitting element which emits light to the first display surface and the second display surface. The light-emitting element has two functions of serving as a light source when information of a subject is read and displaying an image. Thus, a display device according to the invention has two functions of an image sensor function to read information of a subject by using an imaging device and a display function to display an image by using the imaging device and the light-emitting element.

Owner:SEMICON ENERGY LAB CO LTD

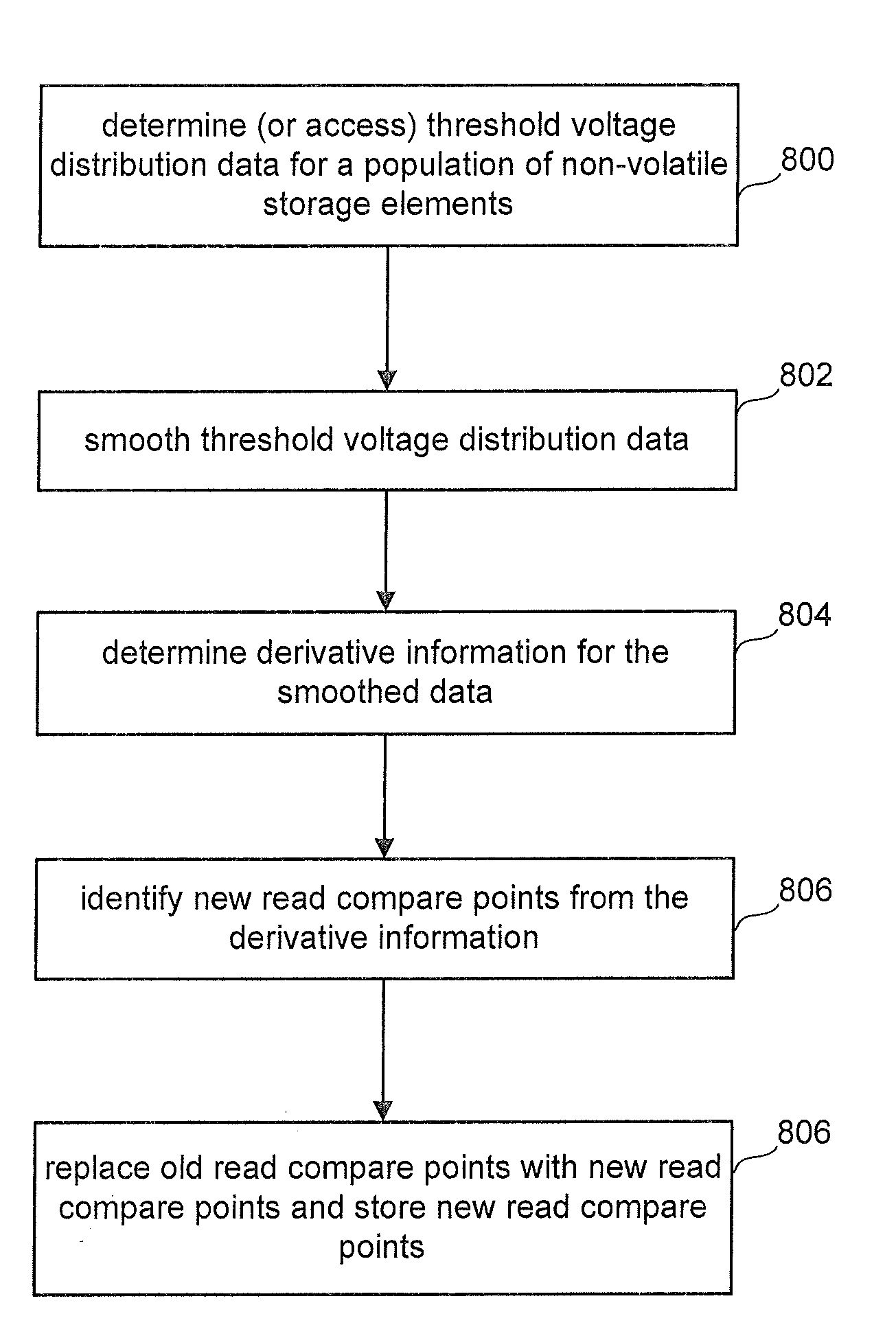

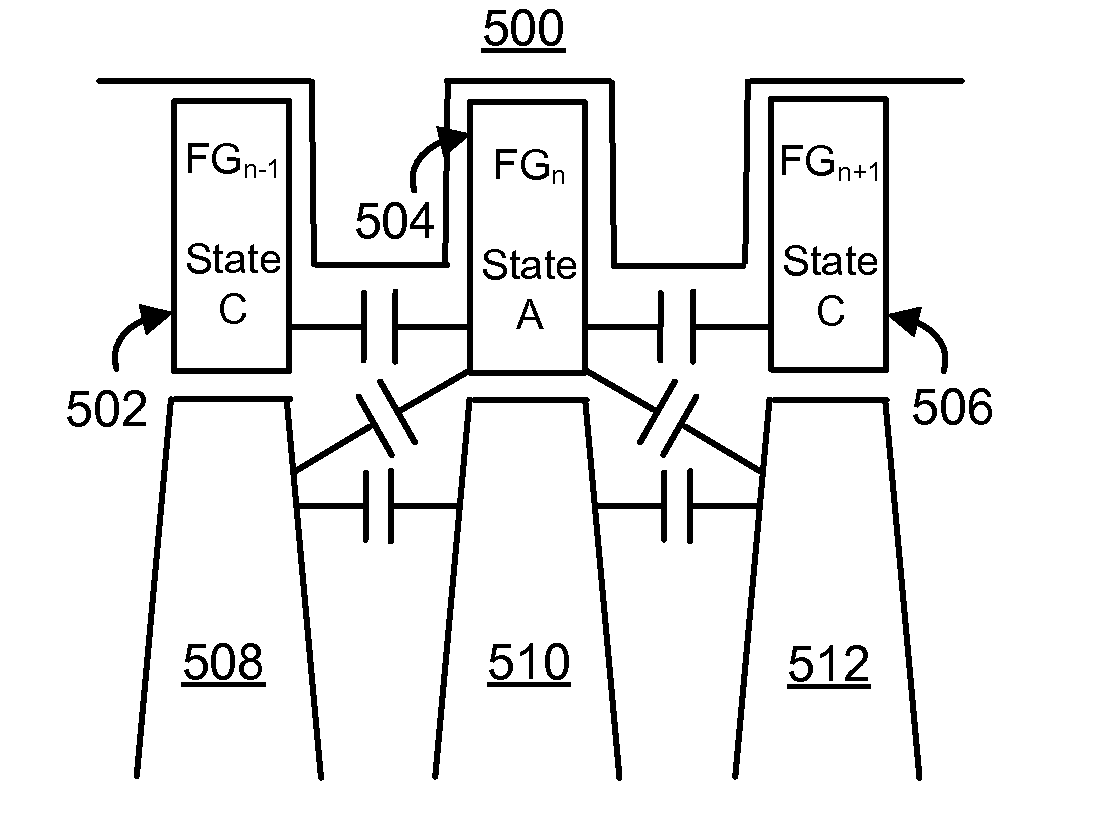

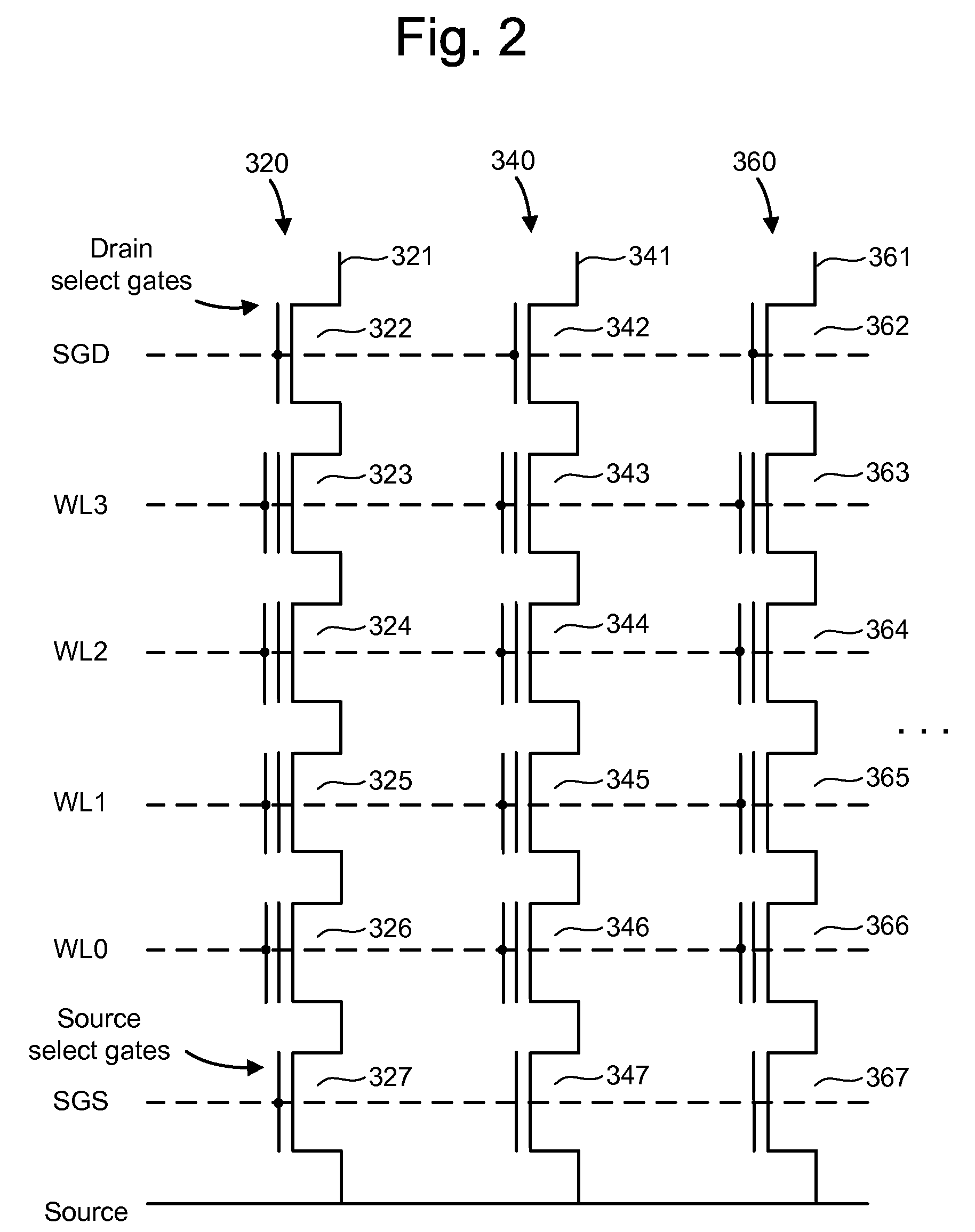

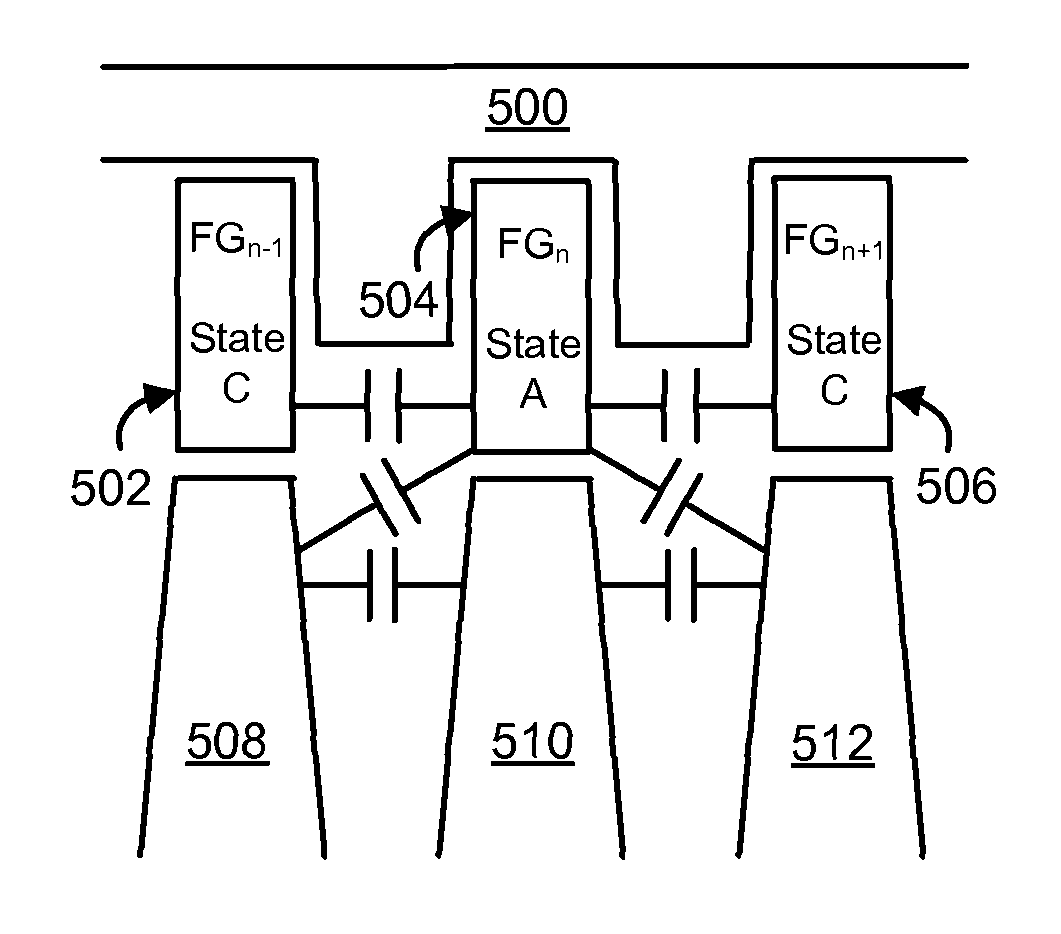

Compensating for coupling during read operations in non-volatile storage

Capacitive coupling from storage elements on adjacent bit lines is compensated by adjusting voltages applied to the adjacent bit lines. An initial rough read is performed to ascertain the data states of the bit line-adjacent storage elements, and during a subsequent fine read, bit line voltages are set based on the ascertained states and the current control gate read voltage which is applied to a selected word line. When the current control gate read voltage corresponds to a lower data state than the ascertained state of an adjacent storage element, a compensating bit line voltage is used. Compensation of coupling from a storage element on an adjacent word line can also be provided by applying different read pass voltages to the adjacent word line, and obtaining read data using a particular read pass voltage which is identified based on a data state of the word line-adjacent storage element.

Owner:SANDISK TECH LLC

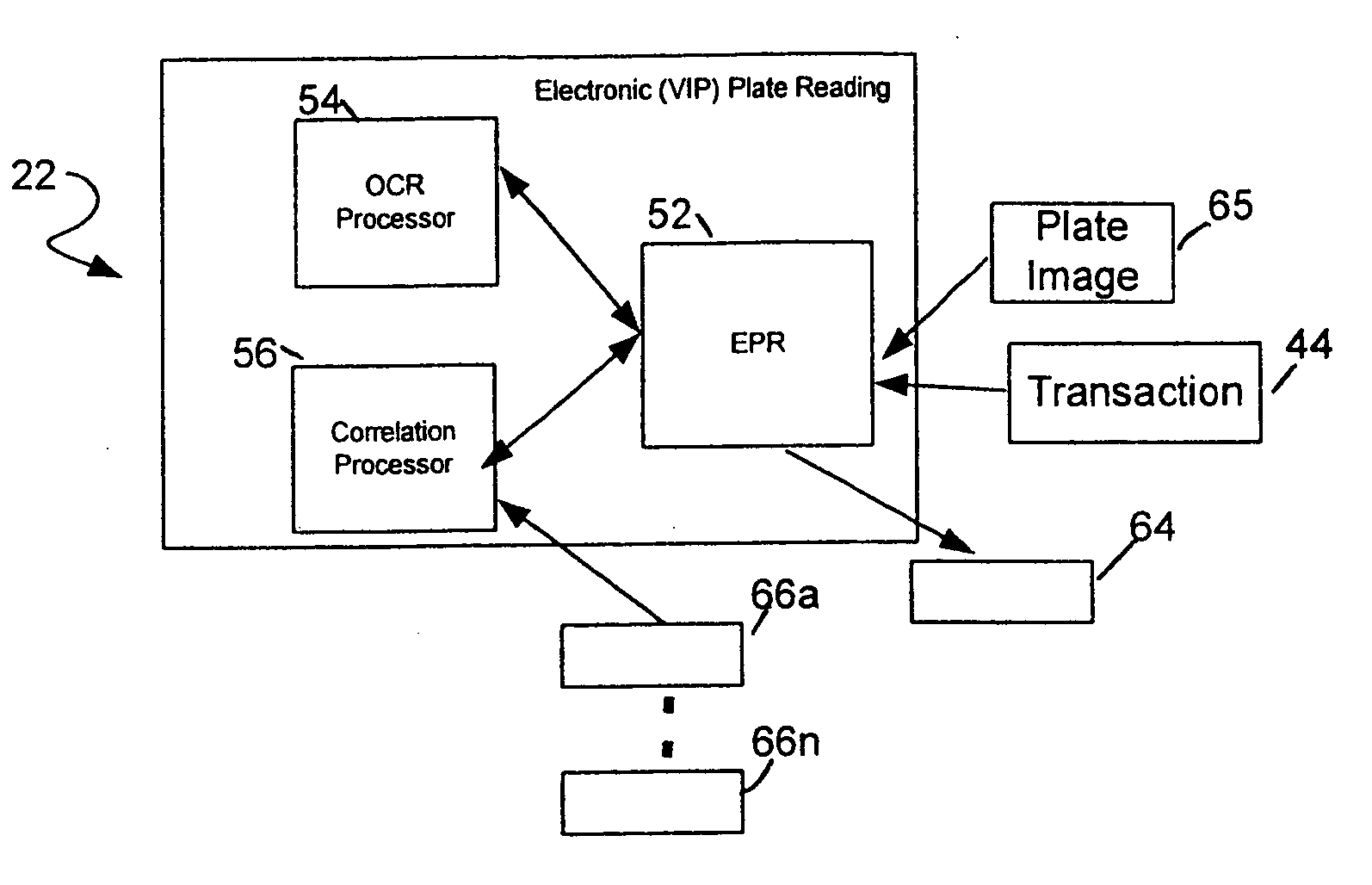

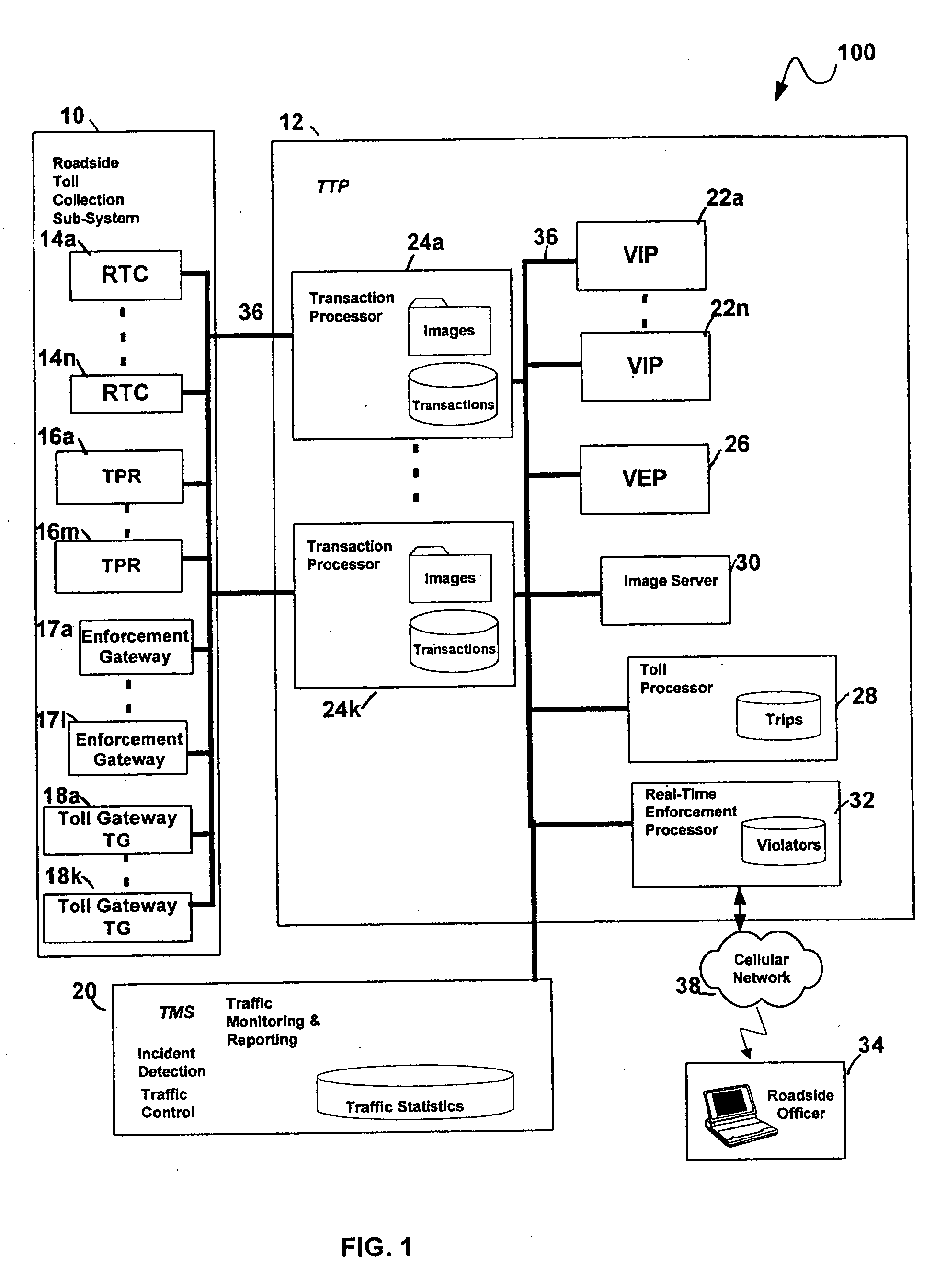

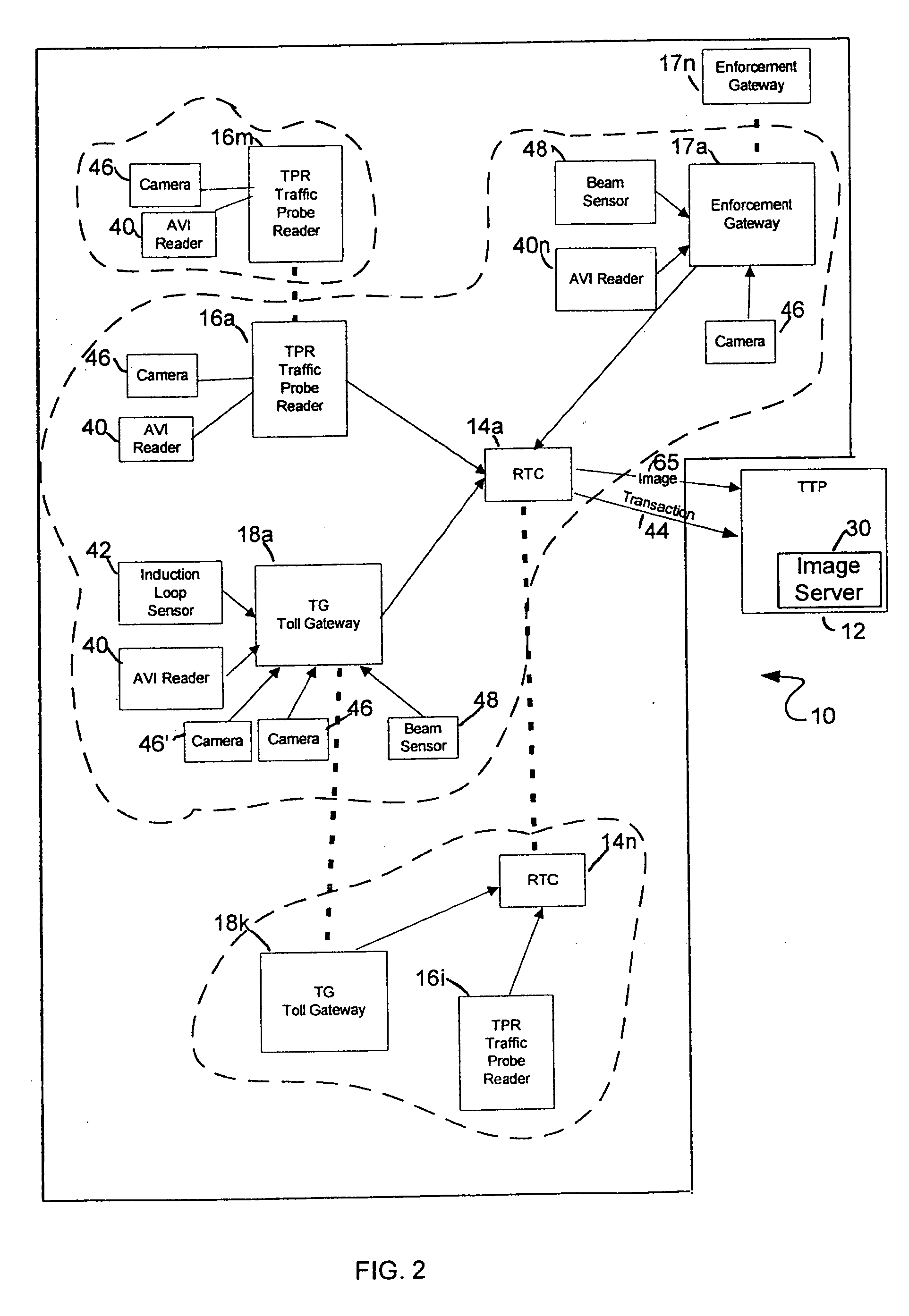

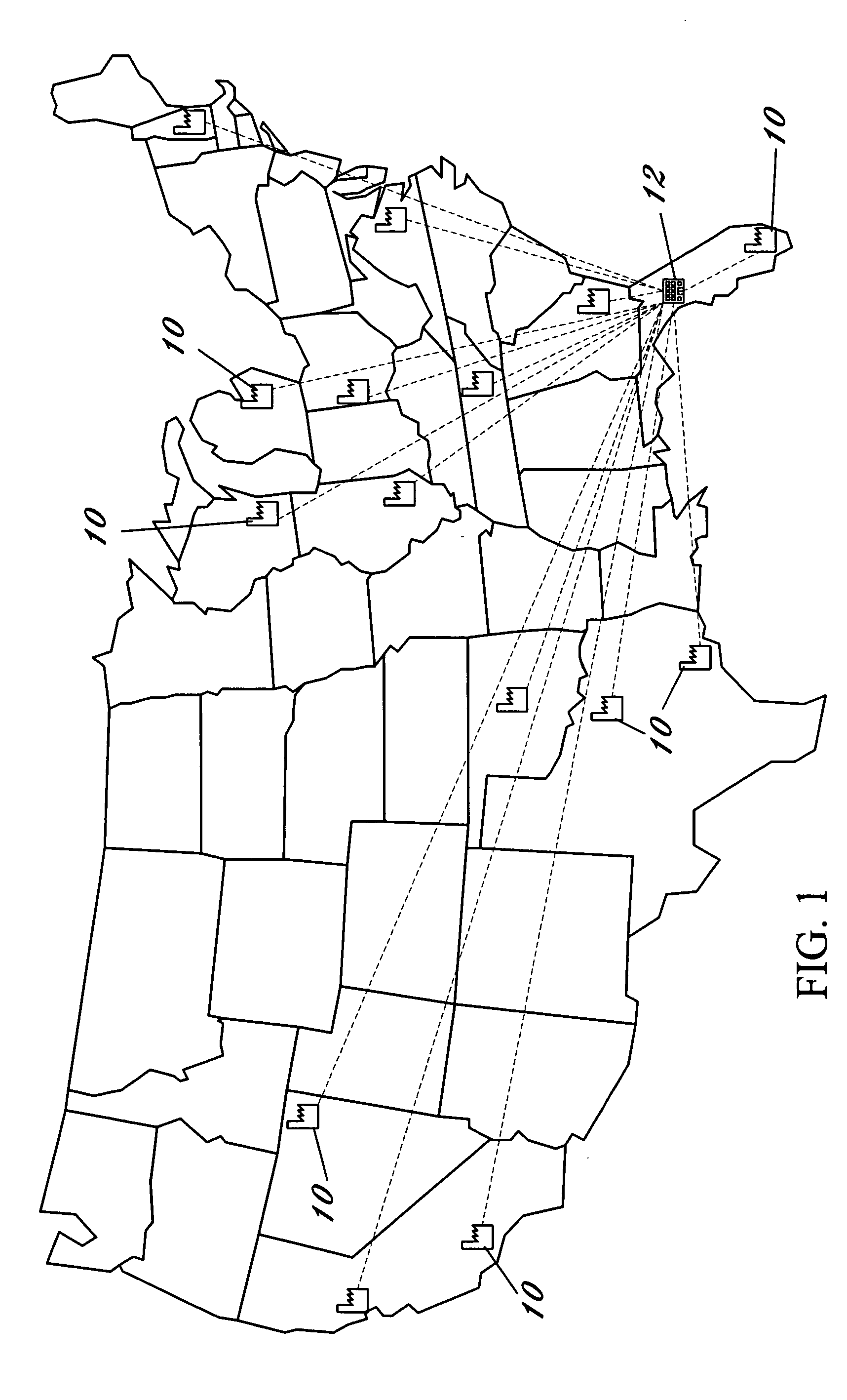

System and method for reading license plates

InactiveUS20060056658A1Reduce in quantityImprove reading accuracyTicket-issuing apparatusDetection of traffic movementPattern recognitionLicense

Owner:VERTEX AEROSPACE LLC

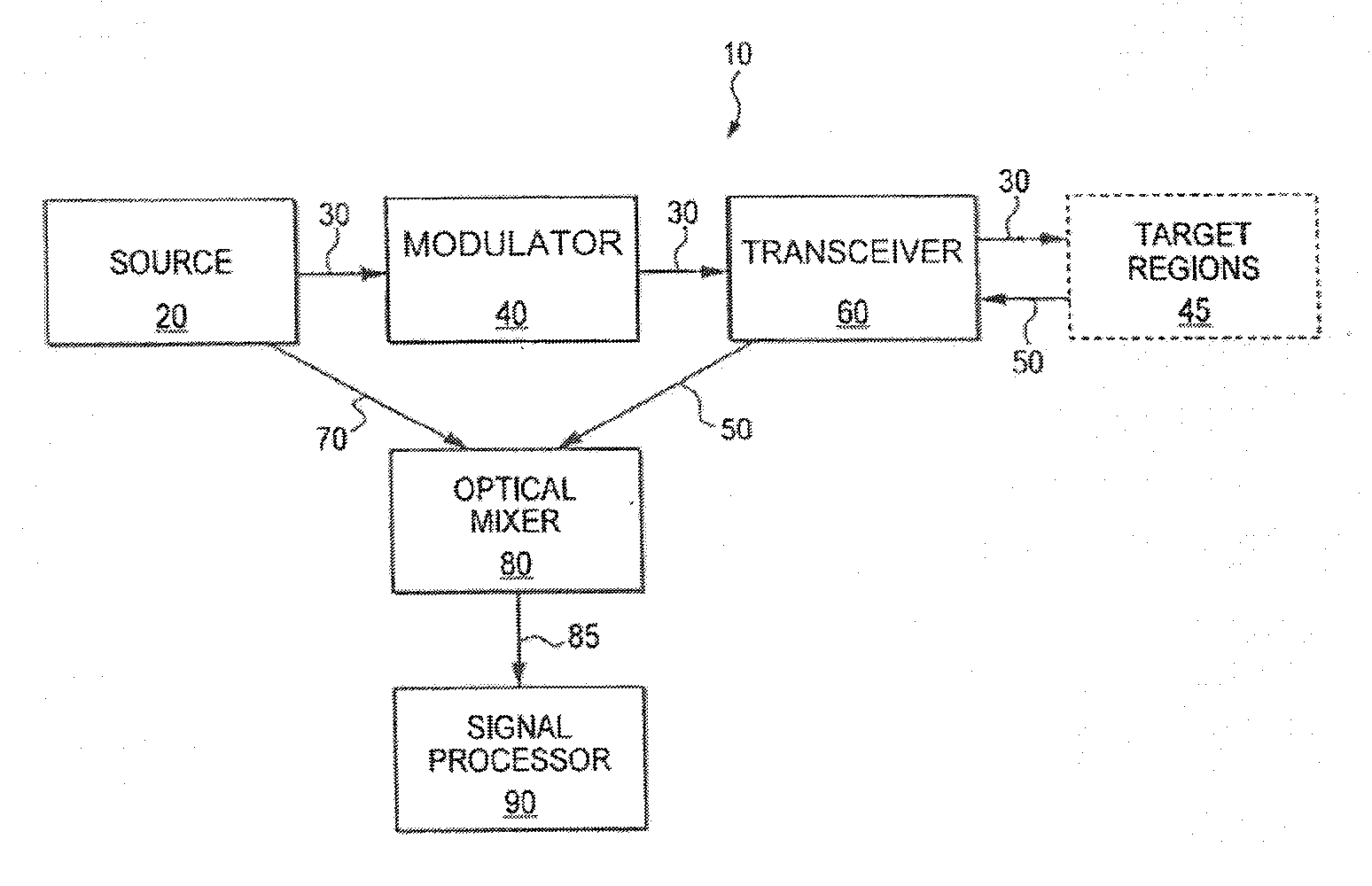

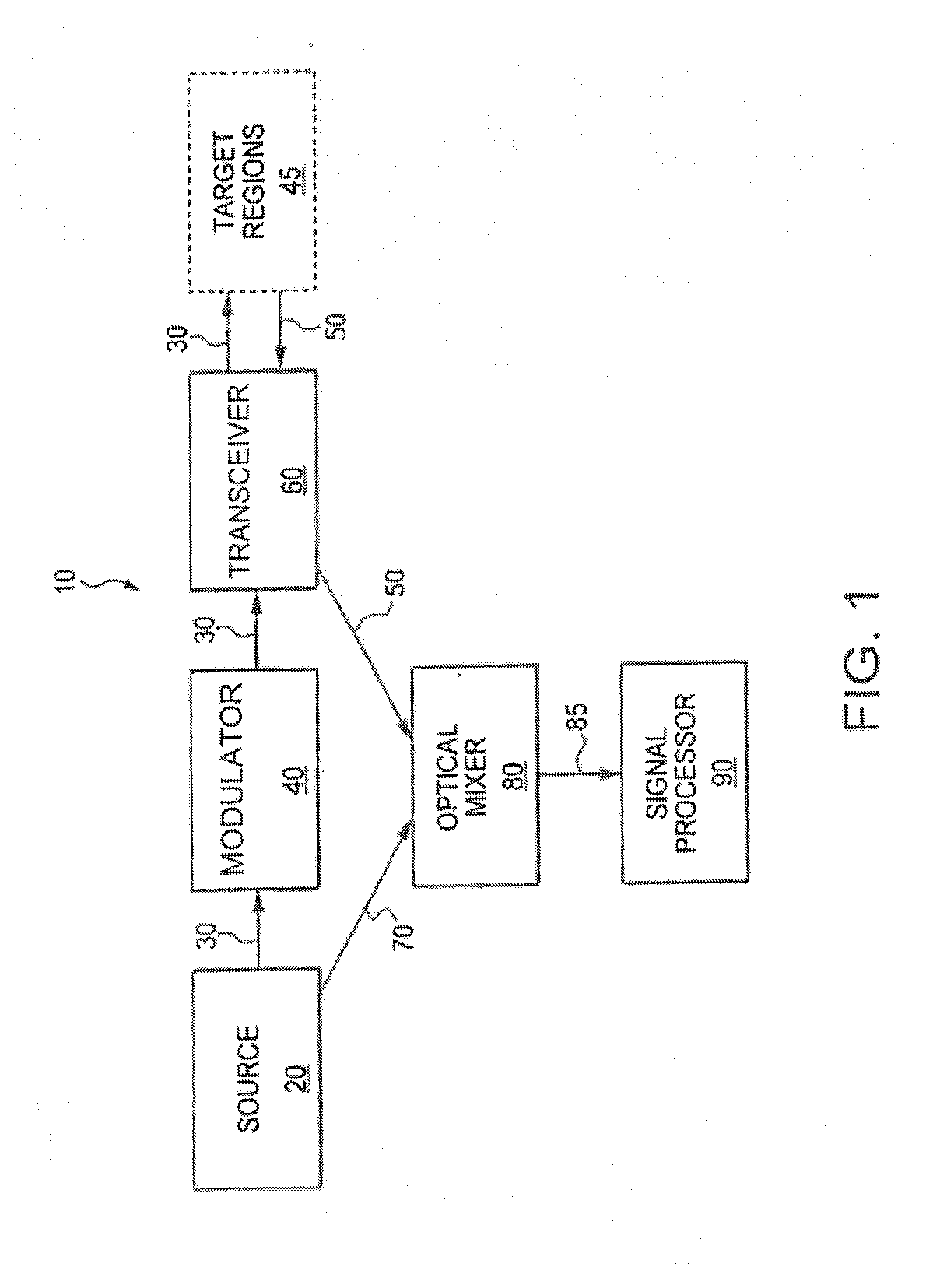

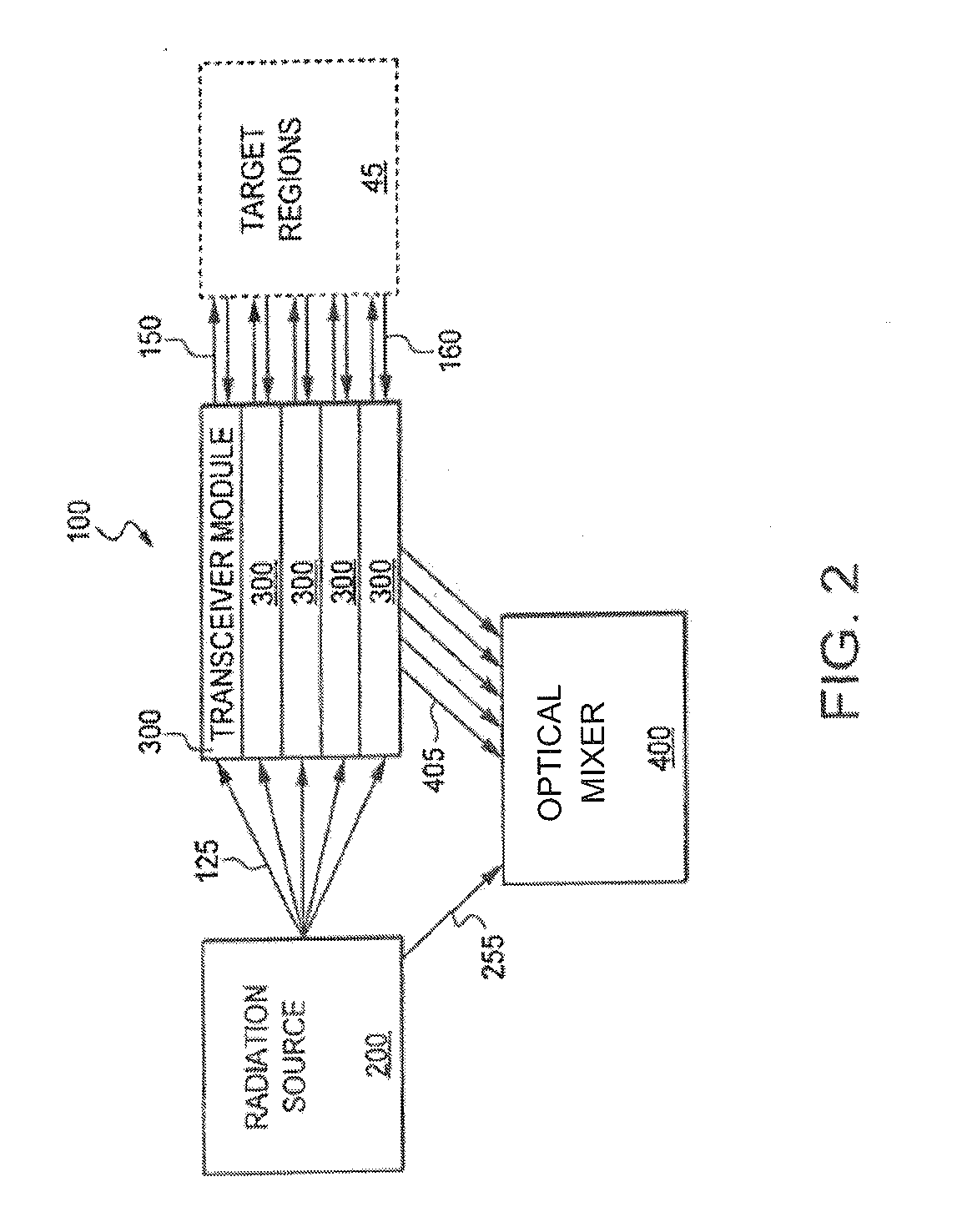

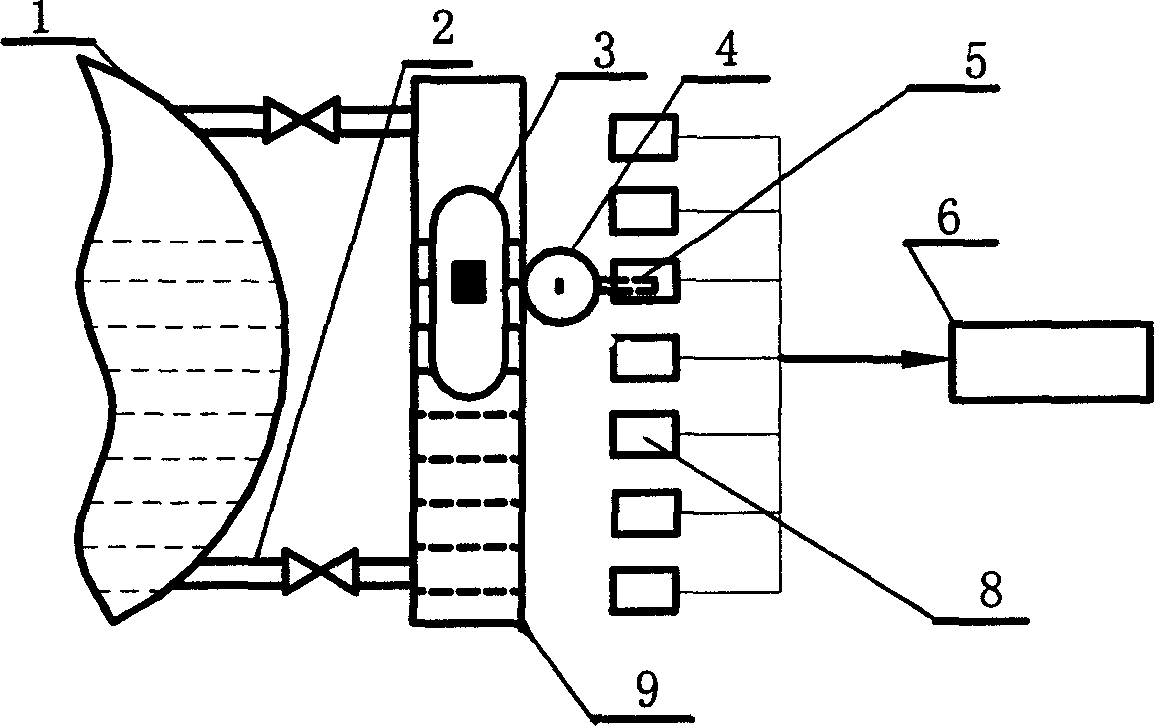

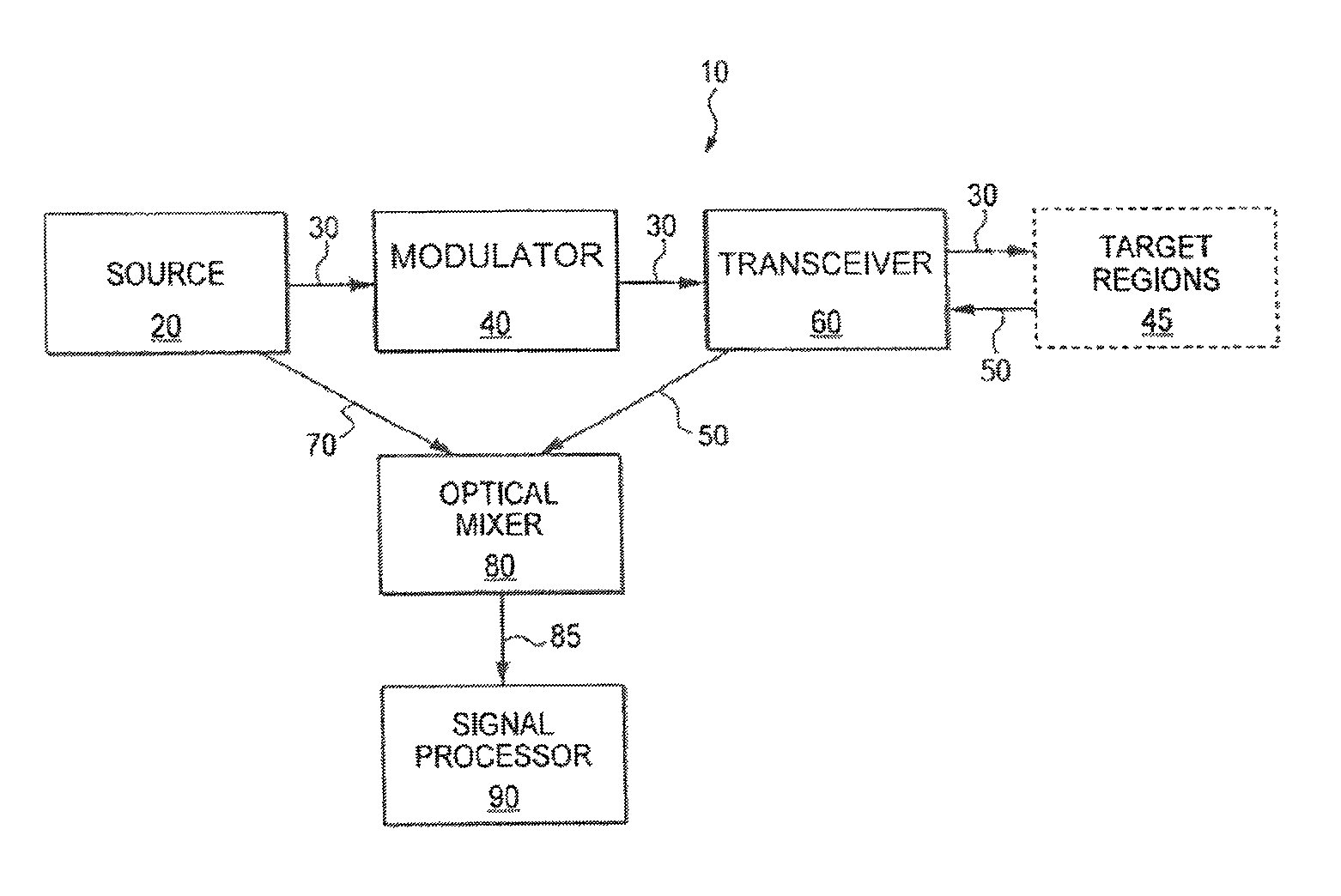

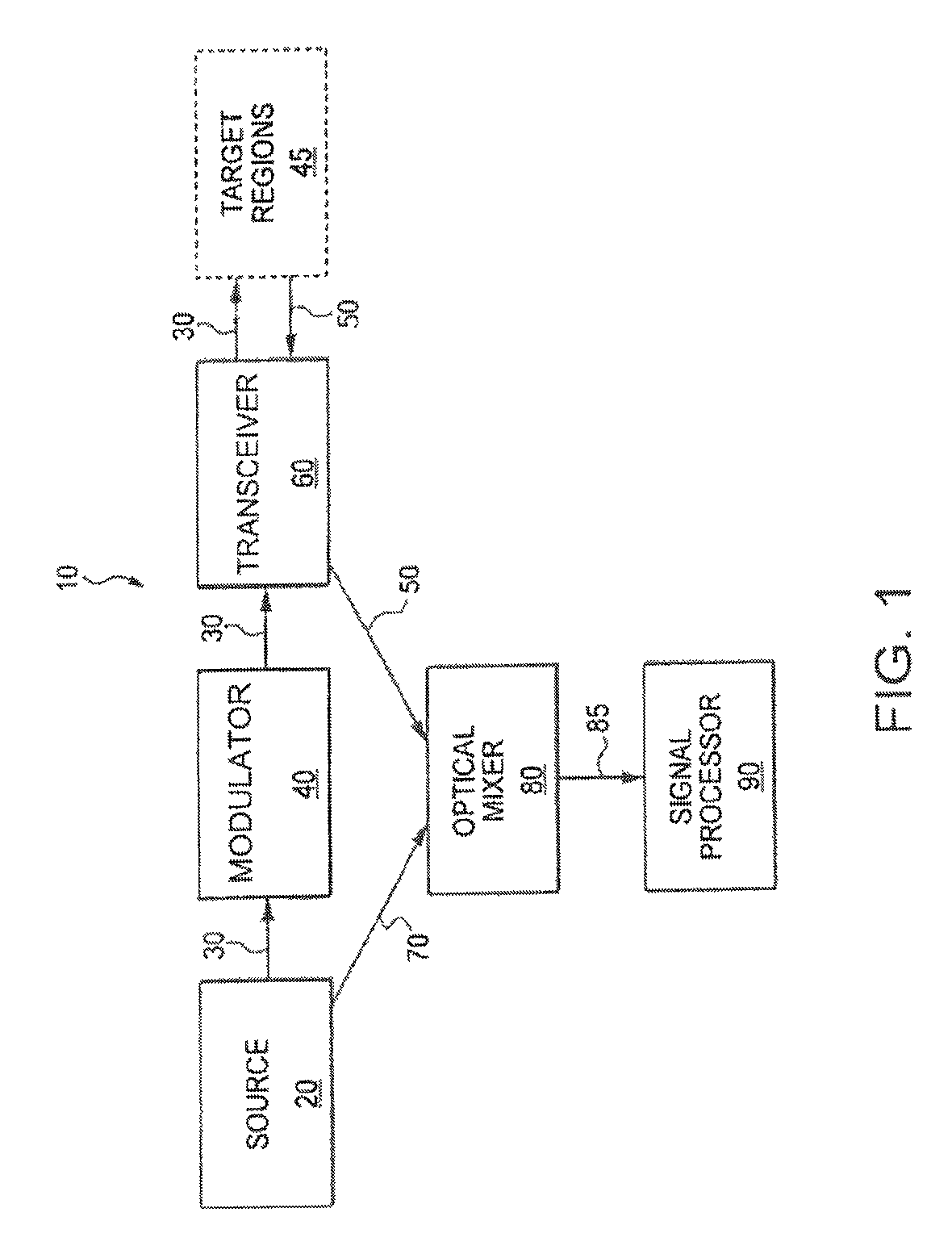

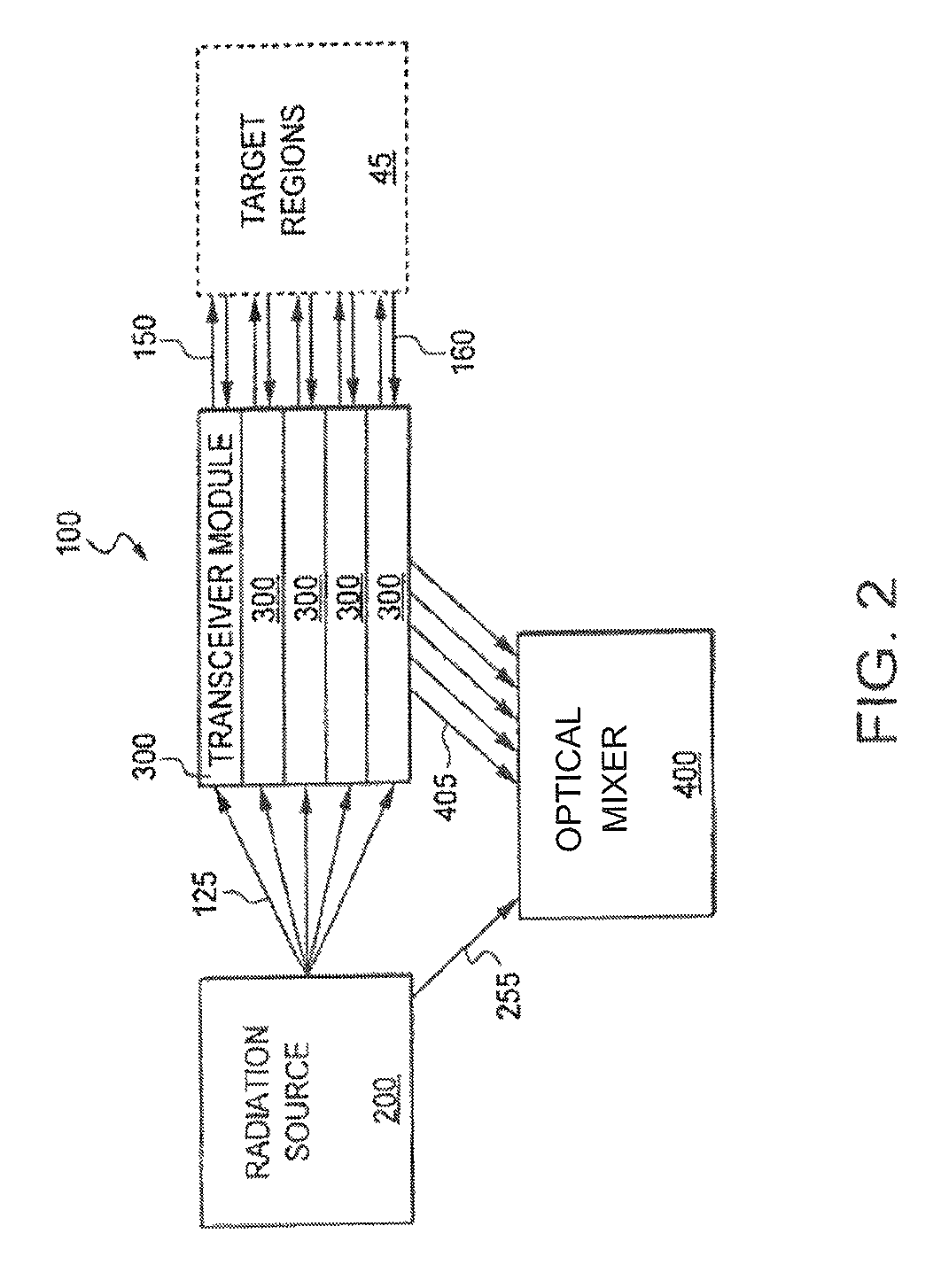

Laser Wind Velocimeter With Multiple Radiation Sources

ActiveUS20120206712A1Improve reading accuracyImprove timelinessWind motor combinationsMachines/enginesTransceiverAtmospheric sciences

A system and method for measuring wind velocities are provided. A laser wind velocimeter with a radiation source includes a fiber laser. All optical signals, transmitted and received, are conveyed by optical fibers. An amplifier amplifies a source laser, which is then transmitted to one or more transceivers. The one or more transceivers, each projecting along a different axis, and each with a single optical fiber input / output interface act as both the transmission device to focus the radiation at a target region, and as the receiving system for collecting reflected radiation. The one or more transceivers transmit radiation to the target region. A portion of the reflected radiation collected by the receiving system is analyzed to determine the Doppler shift, which can me used to measure wind velocity

Owner:RD2 LLC

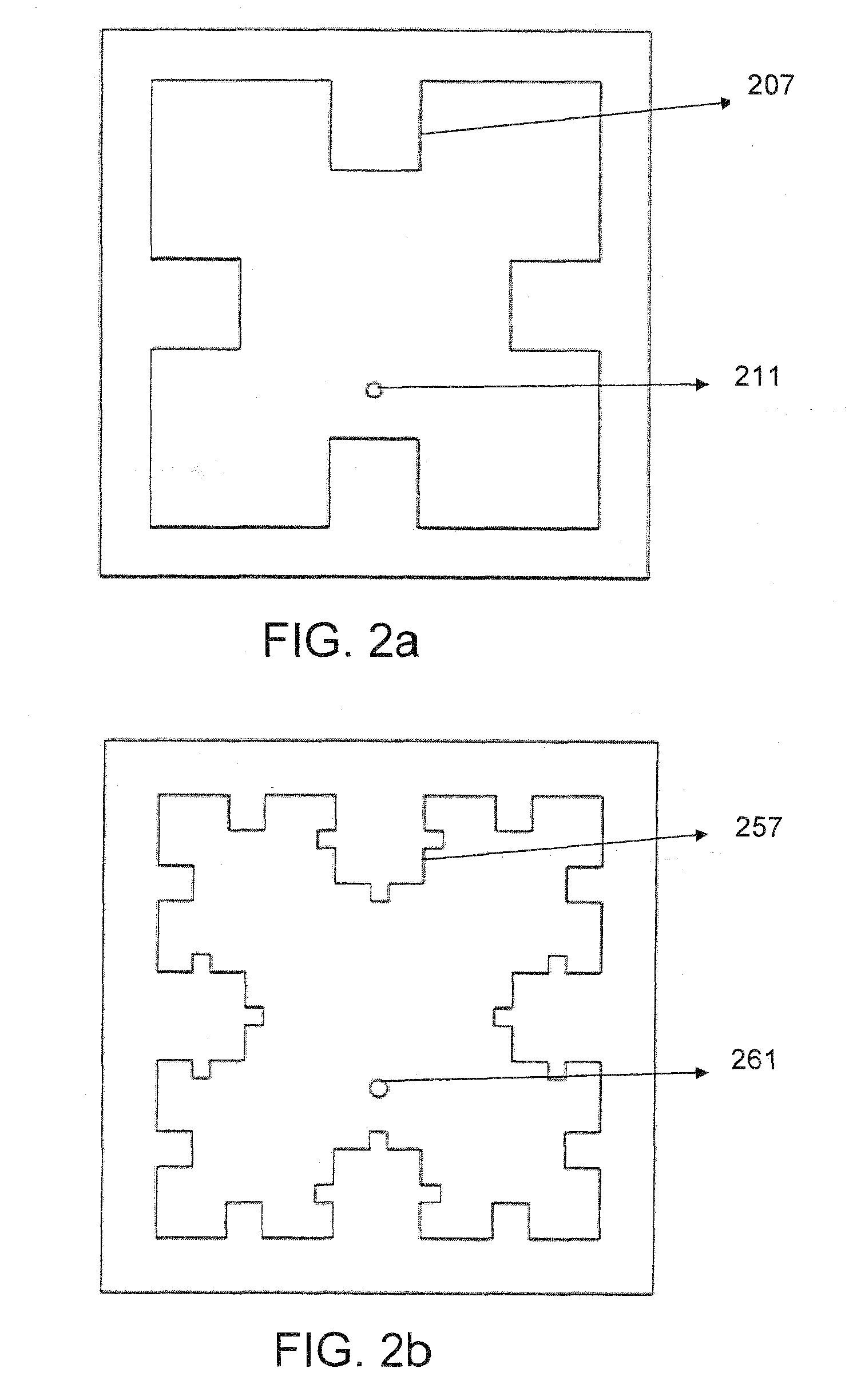

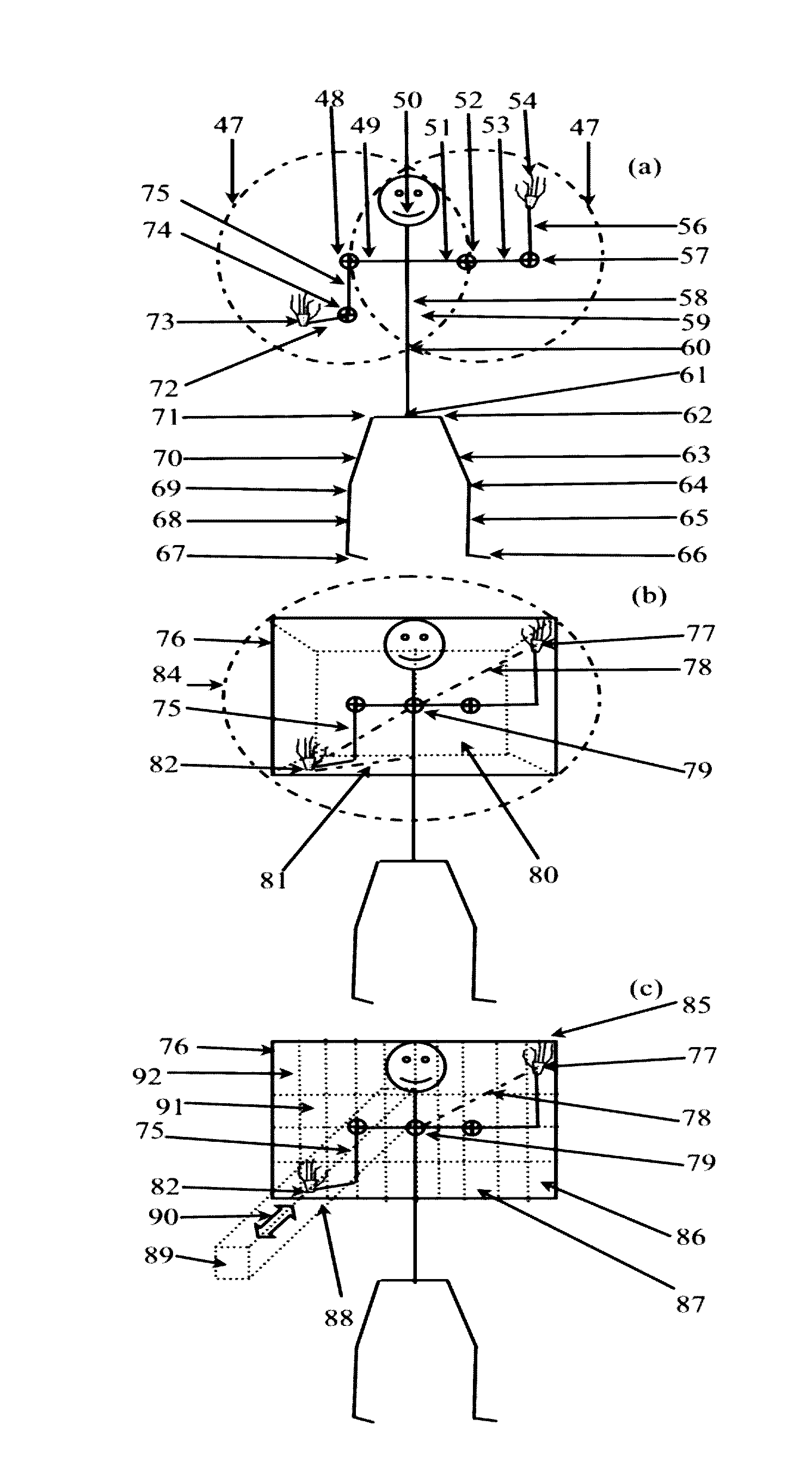

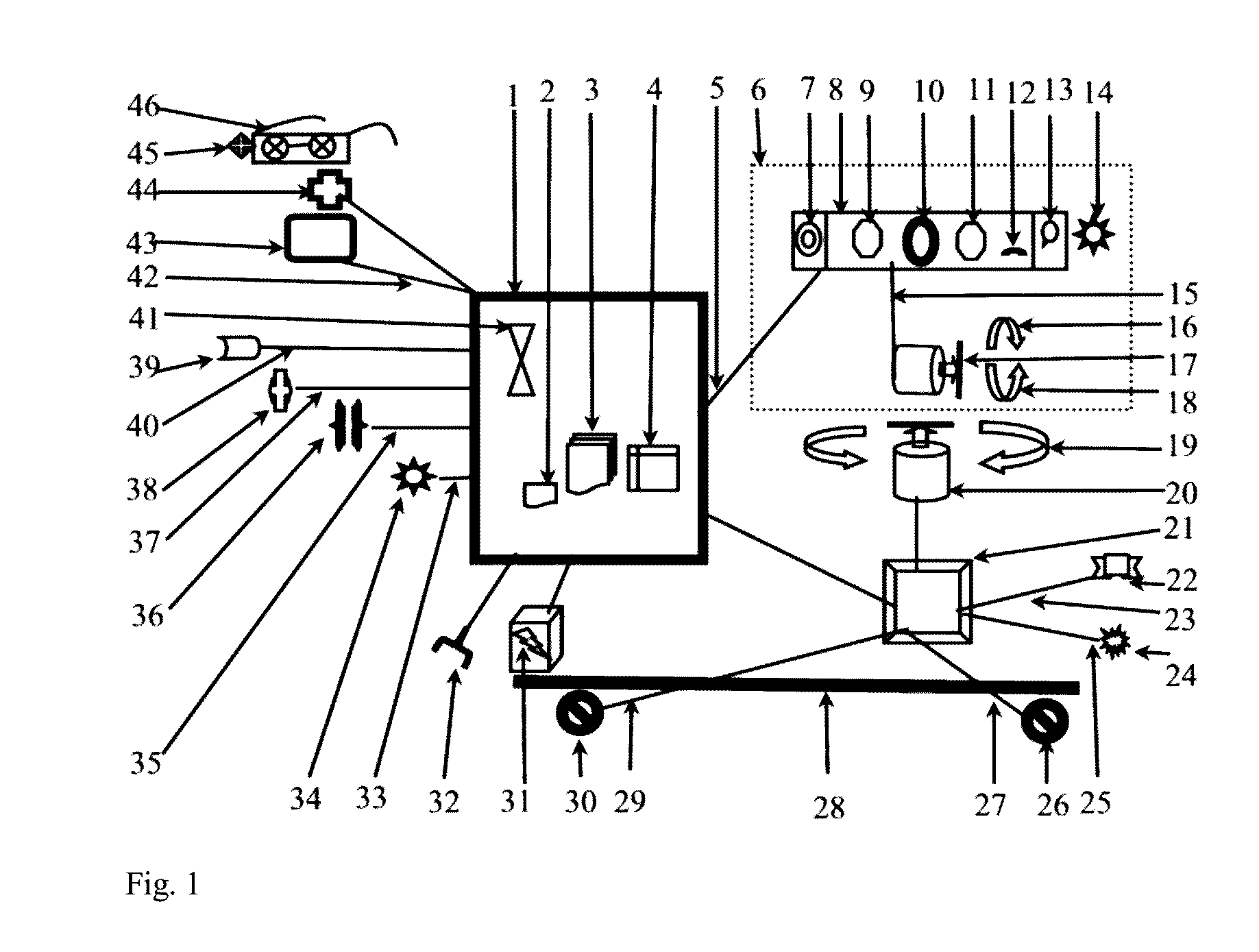

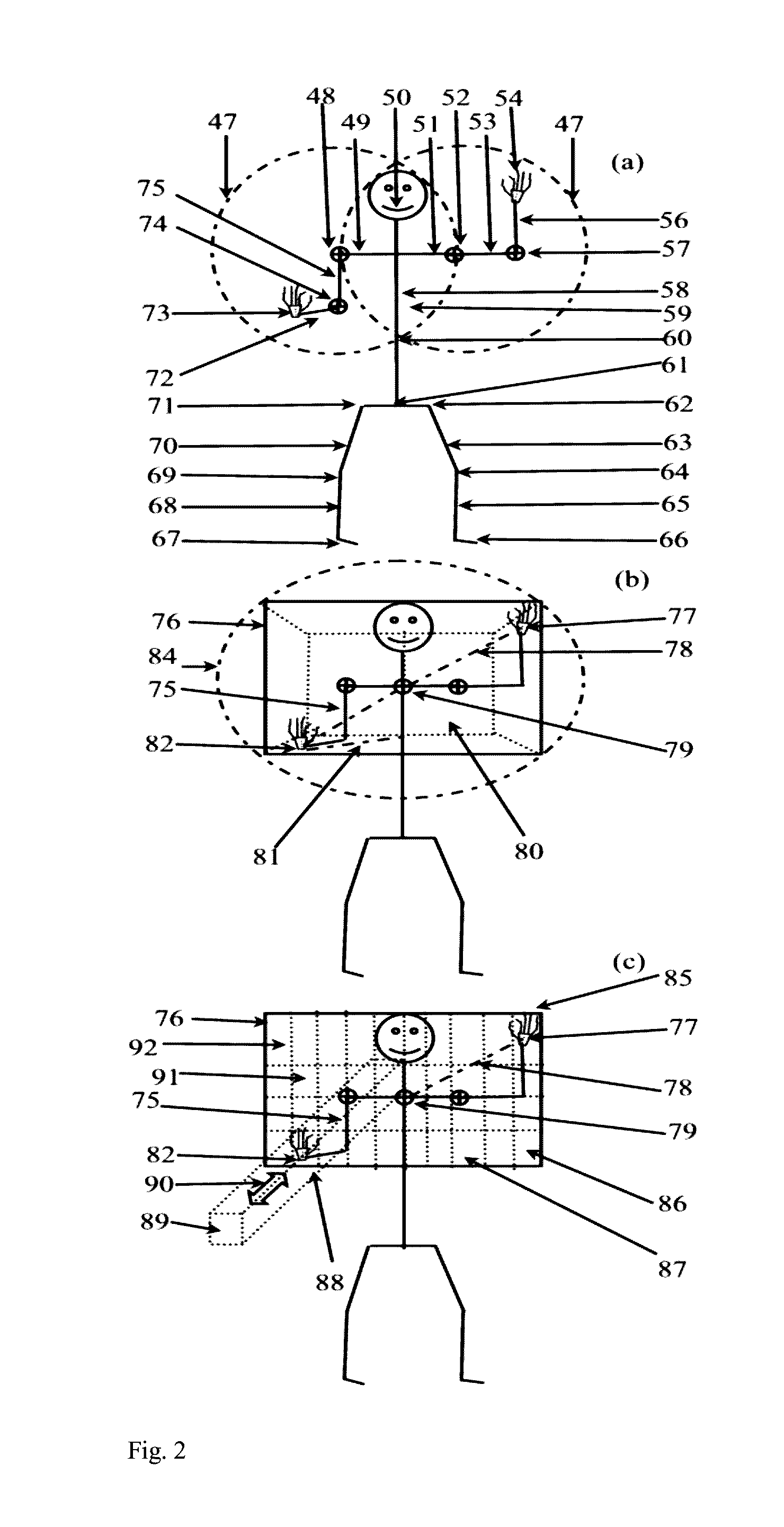

Gesture Interface Robot

ActiveUS20160350589A1Avoid injuryIncrease choiceInput/output for user-computer interactionTelevision system detailsGraphicsRemote control

Gesture Interface Robot auto measure work zone to establish virtual puzzle cell locate in user gesture comfortable area where easy moving hands gesture to push out select virtual keys, prevent injury. Robot drawing virtual keyboard images graphic that display each puzzle cell command, and video vision sensing detect user's hand location that on its virtual keyboard in the workspace zone. Special unique gesture hand sings design for enhances hand control virtual key selections. Push hand z dimension distant divide into 3 select zones. Real-time display highlight selected key graphic image to visual indicate for user to see. Using UIRT cable sending IR signal remote control computer, machine. Instantly generate virtual puzzle cell keyboard or controller that user selected. Introduce new gesture interface method, a Touch Screen Mouse combine with Puzzle Cell virtual keys in sandwich layers gesture zones method for operate computer keys and mouse operations, robot.

Owner:CHIU HSIEN HSIANG

Wearable RFID system

ActiveUS8674810B2Easy to readIncreased read rangeMemory record carrier reading problemsSubscribers indirect connectionRadio frequencyRadio-frequency identification

Owner:METRC LLC

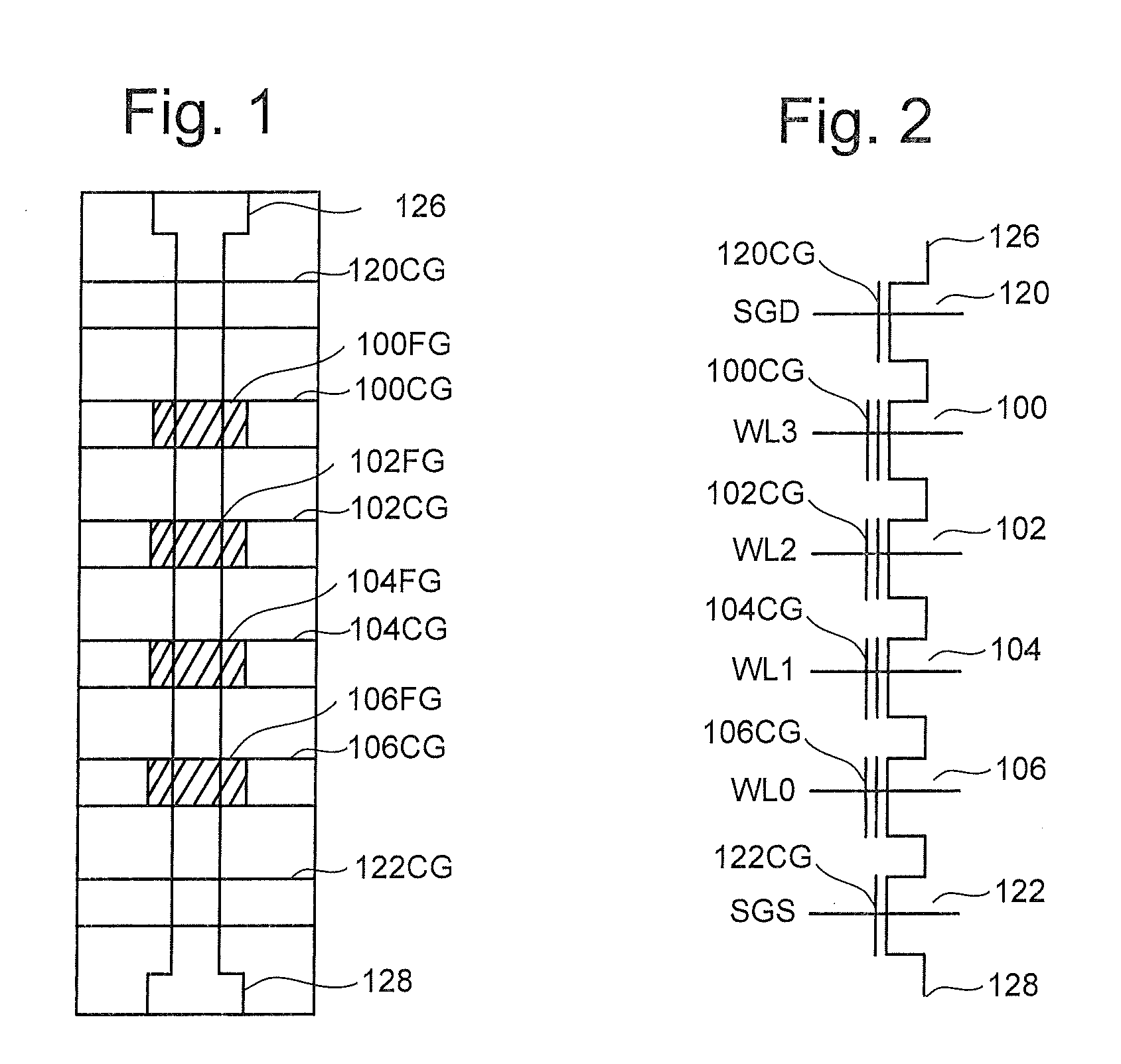

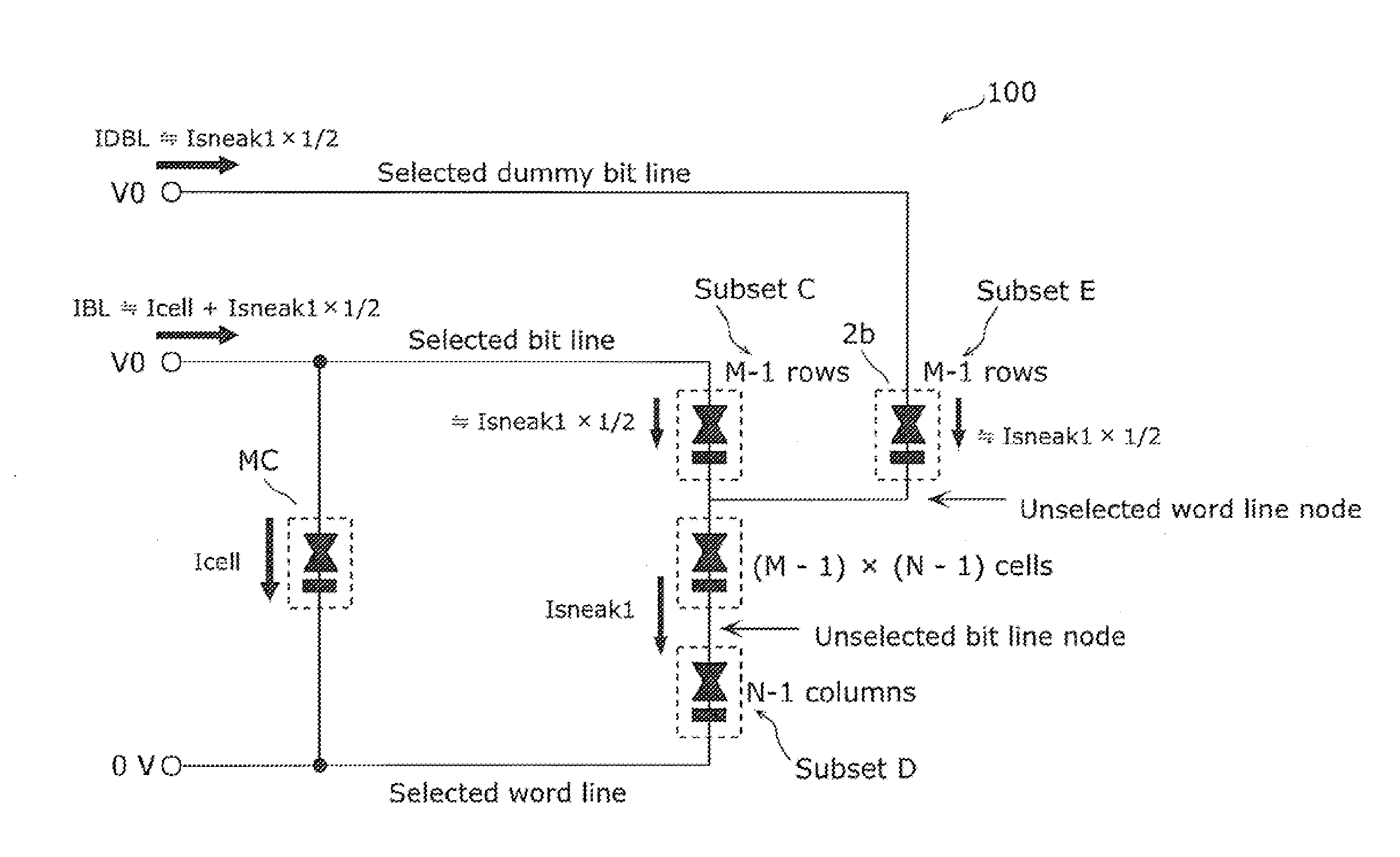

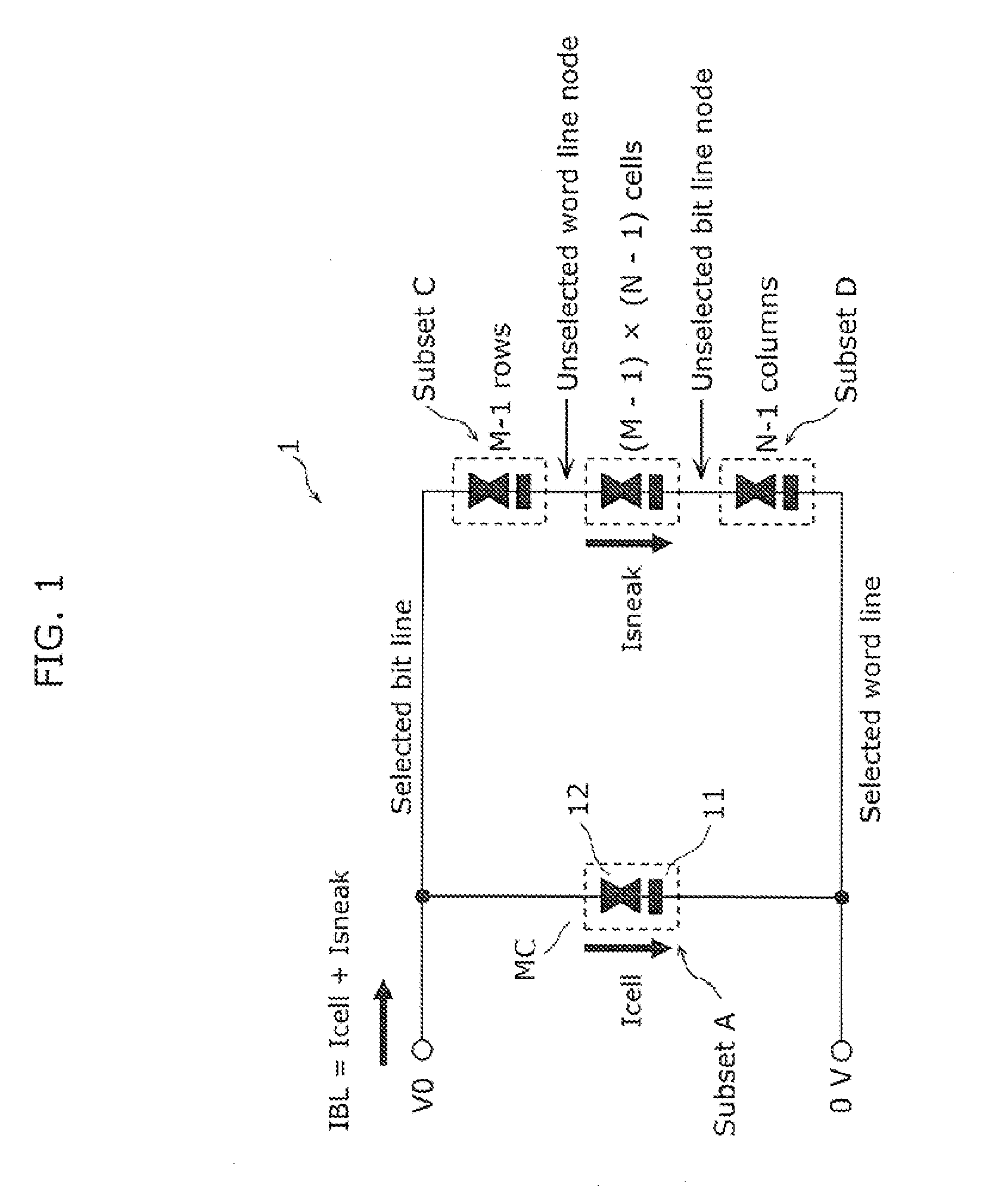

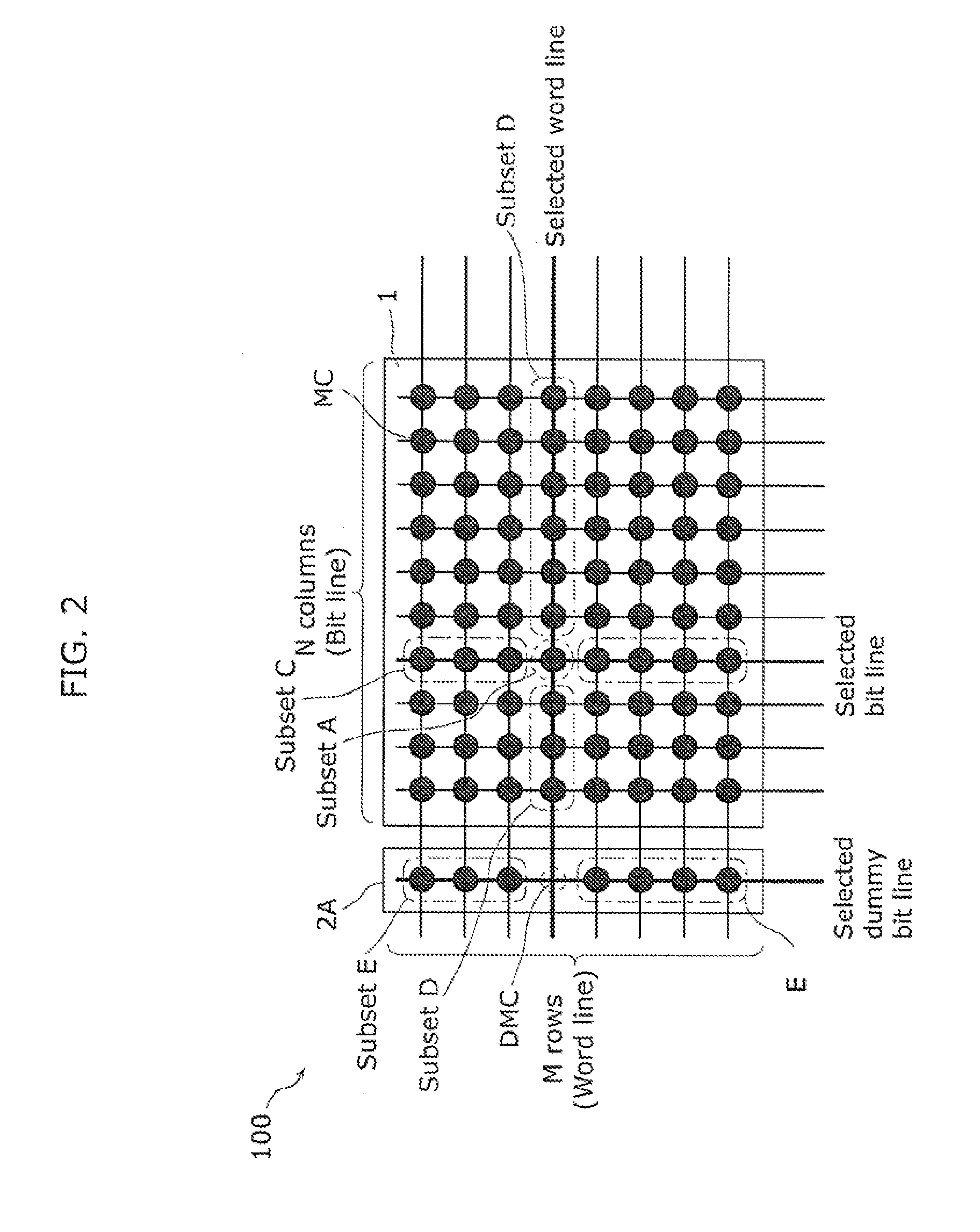

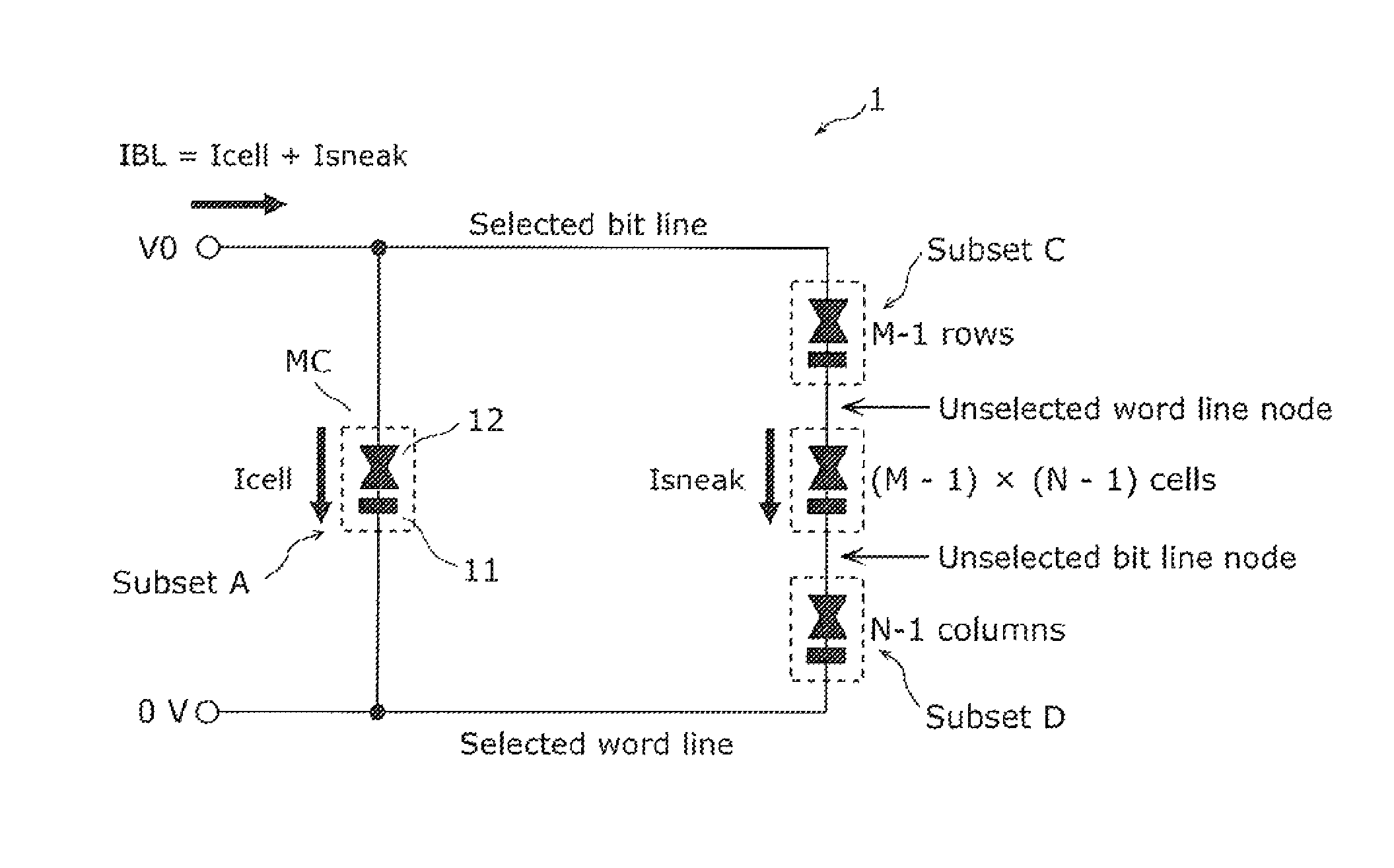

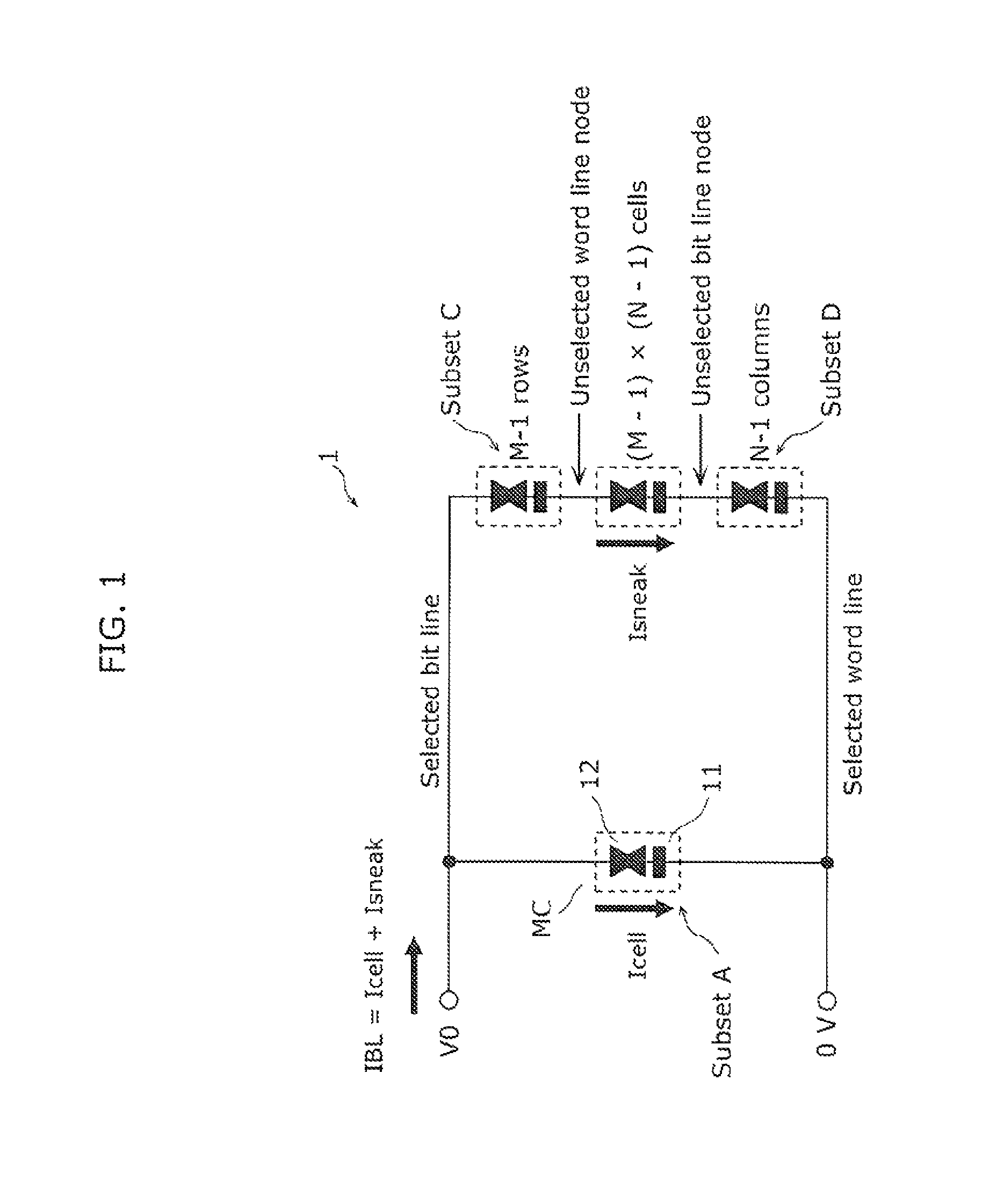

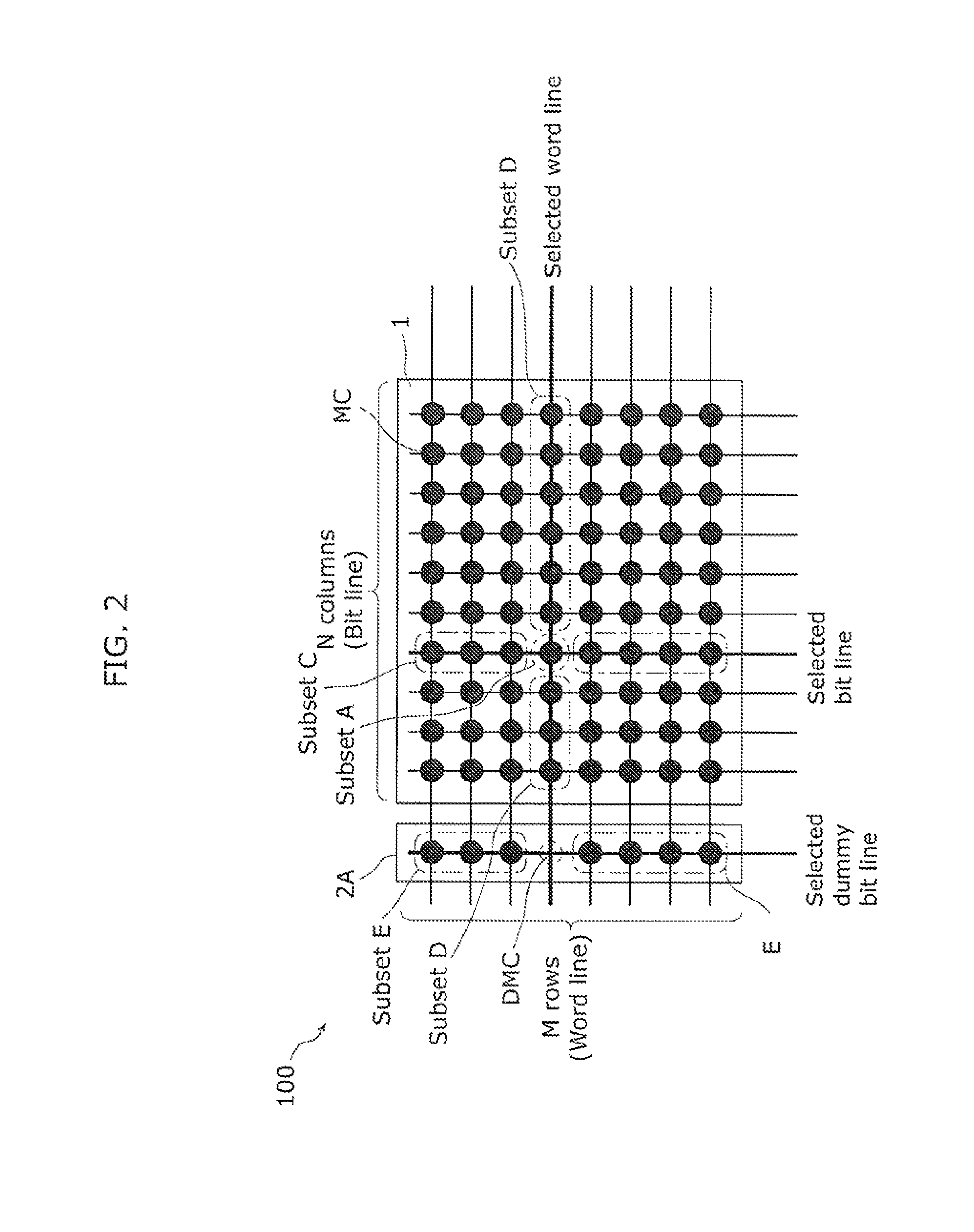

Nonvolatile semiconductor memory device and read method for the same

ActiveUS20130148406A1Low detection sensitivityImprove reading accuracyDigital storageBit lineMemory cell

A cross point nonvolatile memory device capable of suppressing sneak-current-caused reduction in sensitivity of detection of a resistance value of a memory element is provided. The device includes perpendicular bit and word lines; a cross-point cell array including memory cells each having a resistance value reversibly changing between at least two resistance states according to electrical signals, arranged on cross-points of the word and bit lines; an offset detection cell array including an offset detection cell having a resistance higher than that of the memory cell in a high resistance state, the word lines being shared by the offset detection cell array; a read circuit (a sense amplifier) that determines a resistance state of a selected memory cell based on a current through the selected bit line; and a current source which supplies current to the offset detection cell array in a read operation period.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

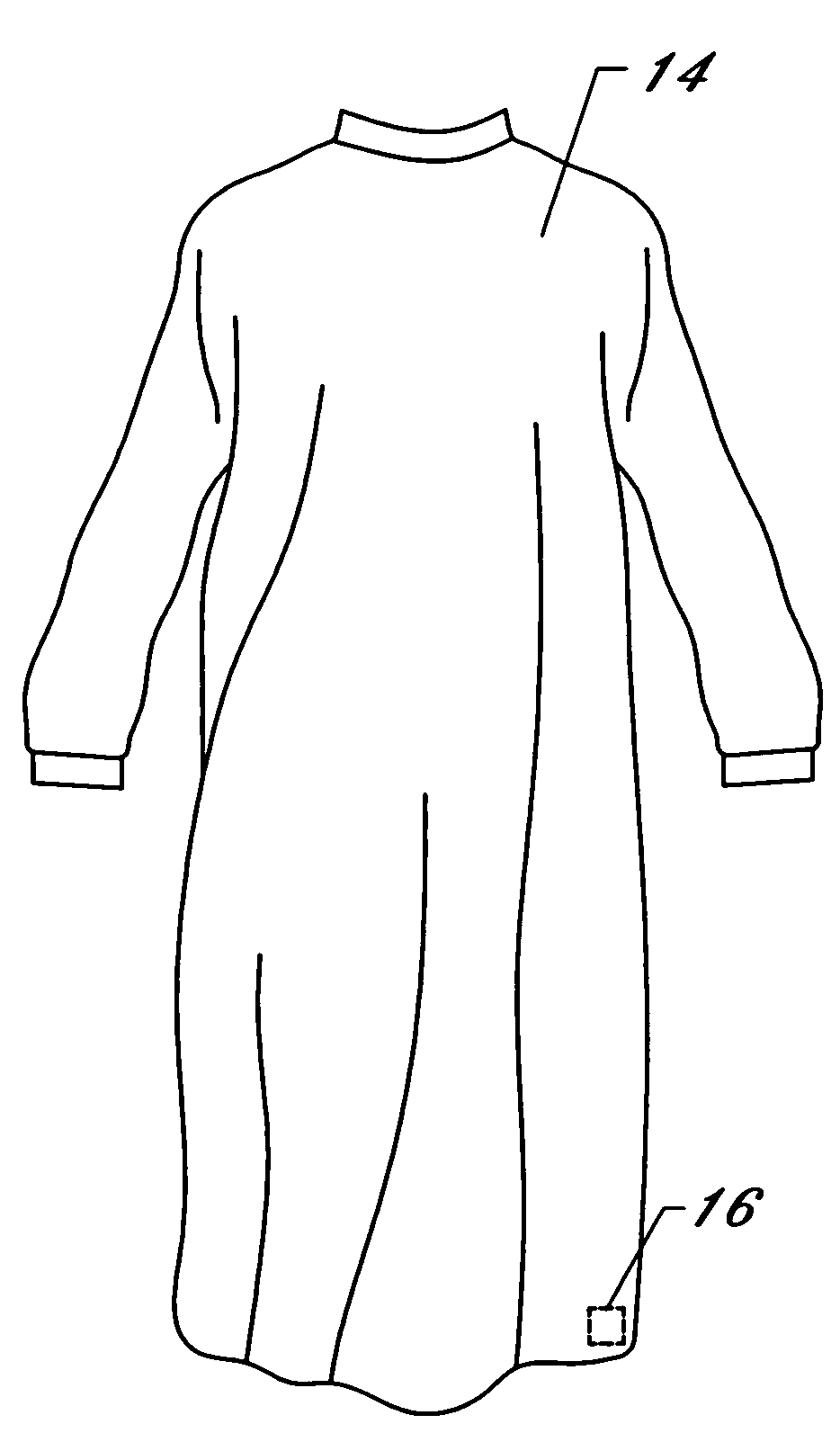

Management and distribution of surgical supplies within an RFID enabled network

InactiveUS20050280536A1Avoid radio frequency interferenceReduce laborData processing applicationsDigital data processing detailsDistribution systemQuality control

The present invention contributes to advancements in the art of inventory management and distribution by providing a system and method for processing, distributing, and tracking reusable inventory items. Reusable articles, such as surgical garments and accessories, are adapted with radio frequency identification (“RFID”) tags having unique identification numbers. A “reader” is used to retrieve stored information from the tags without requiring direct contact or clear line-of-sight. The reusable articles are processed and distributed using an inventory management system wherein lifecycle data is obtained for each reusable article. The reusable articles are distributed to the end users from central processing facilities, used, returned, cleaned, inspected, folded, sterilized, and returned to inventory for re-distribution. Periodic quality control inspections are conducted in response to predetermined usage parameters. The use of RFID tags and a corresponding computer network allows for the acquisition of data corresponding to each reusable article within a distribution system having multiple remote distribution and processing facilities. The acquired data is transmitted to a central computer processing system via a secured wide area computer network for use and analysis. Data processing computer servers at each remote distribution and processing facility electronically linked to a central data processing server provide a fail-safe network for acquired data.

Owner:SRISURGICAL EXPRESS

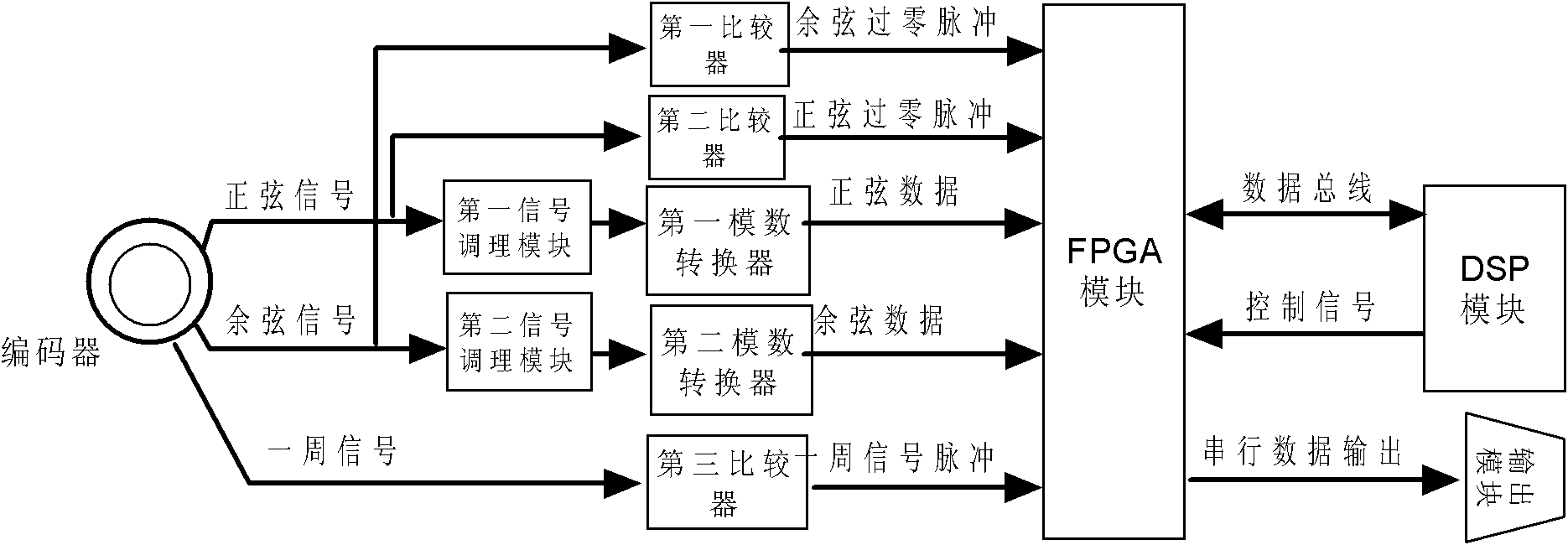

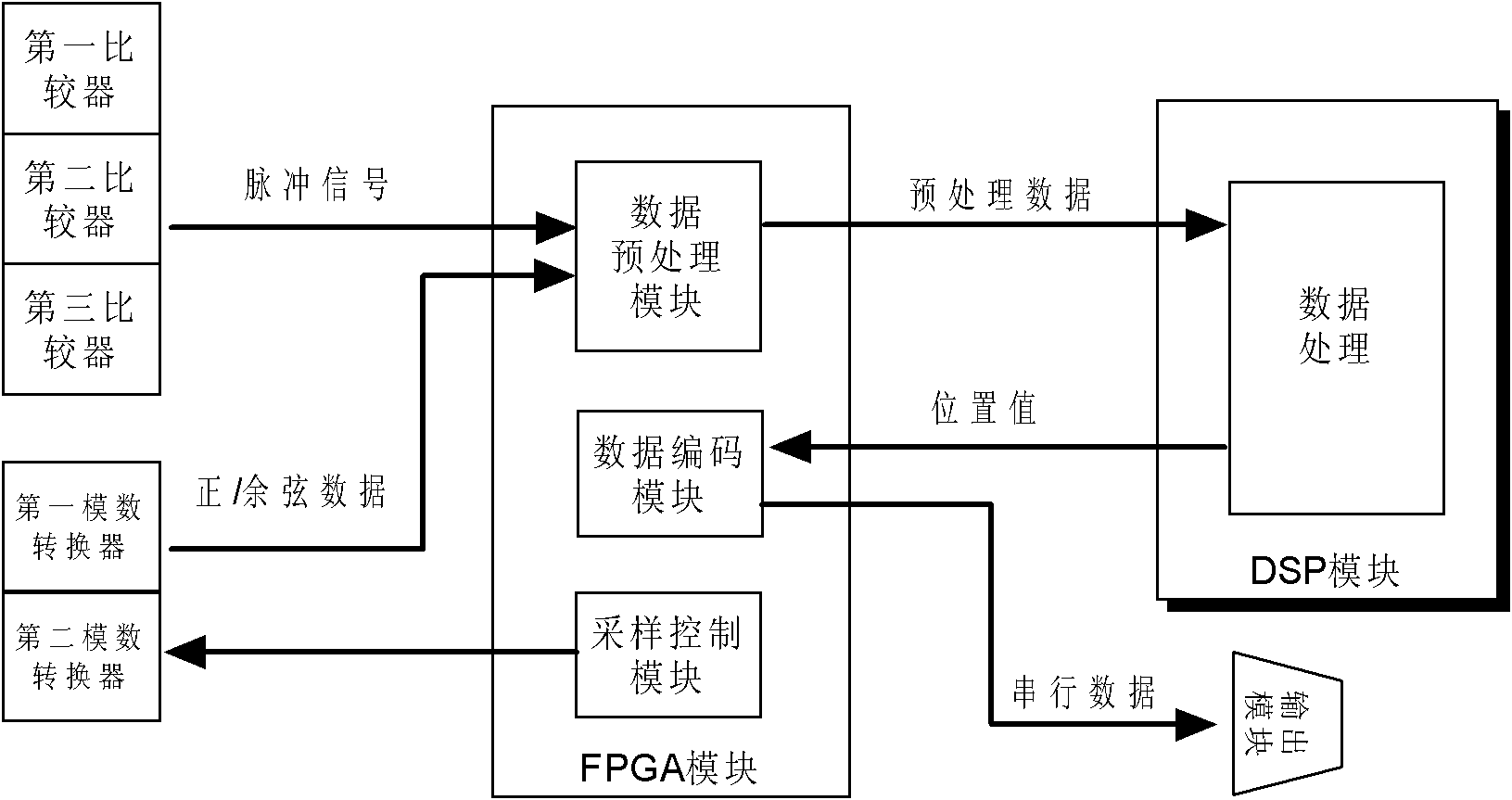

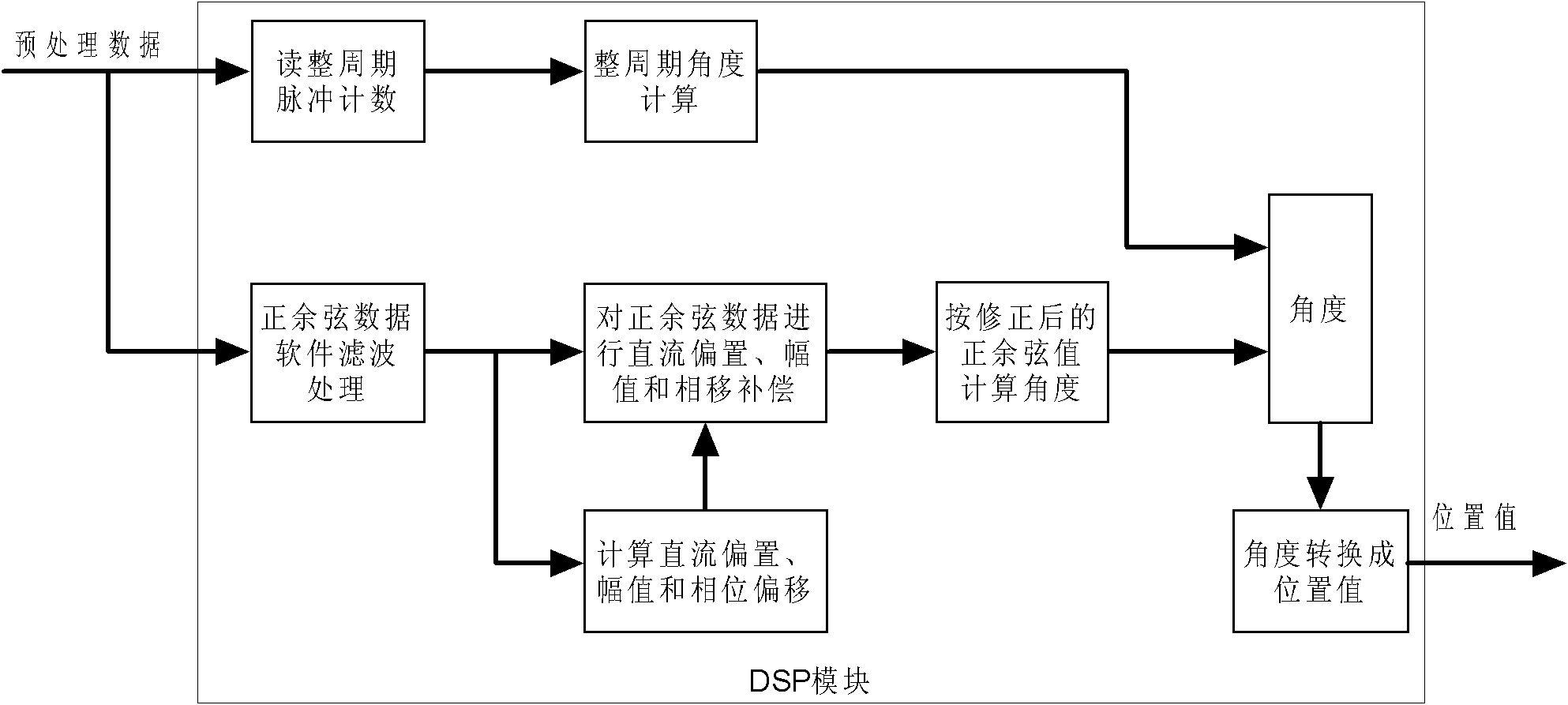

Device for subdividing sine signal and cosine signal of position sensor and coding data, and implementation method thereof

ActiveCN102111158ATrue reflection of actual location indicationAccurately capture immediate valuesAnalogue-digital convertersConverting sensor output electrically/magneticallySignal conditioningComputer module

The invention provides a device for subdividing sine signals and cosine signals of a position sensor and coding data, comprising a coder, a first signal conditioning module, a second signal conditioning module, a first analog-to-digital converter, a second analog-to-digital converter, a first comparator, a second comparator, a third comparator, a FPGA (Field Programmable Gate Array) module, a DSP(Digital Signal Processor) module and an output module. The invention further provides a method for subdividing sine signals and cosine signals of the position sensor and coding data. In the method, the multiple interpolation subdivision carried out on the sine signals and cosine signals output by the coder, and detection precision of the position signal is improved to achieve high resolution control and reduce the cost of the high-precision coder.

Owner:GSK CNC EQUIP

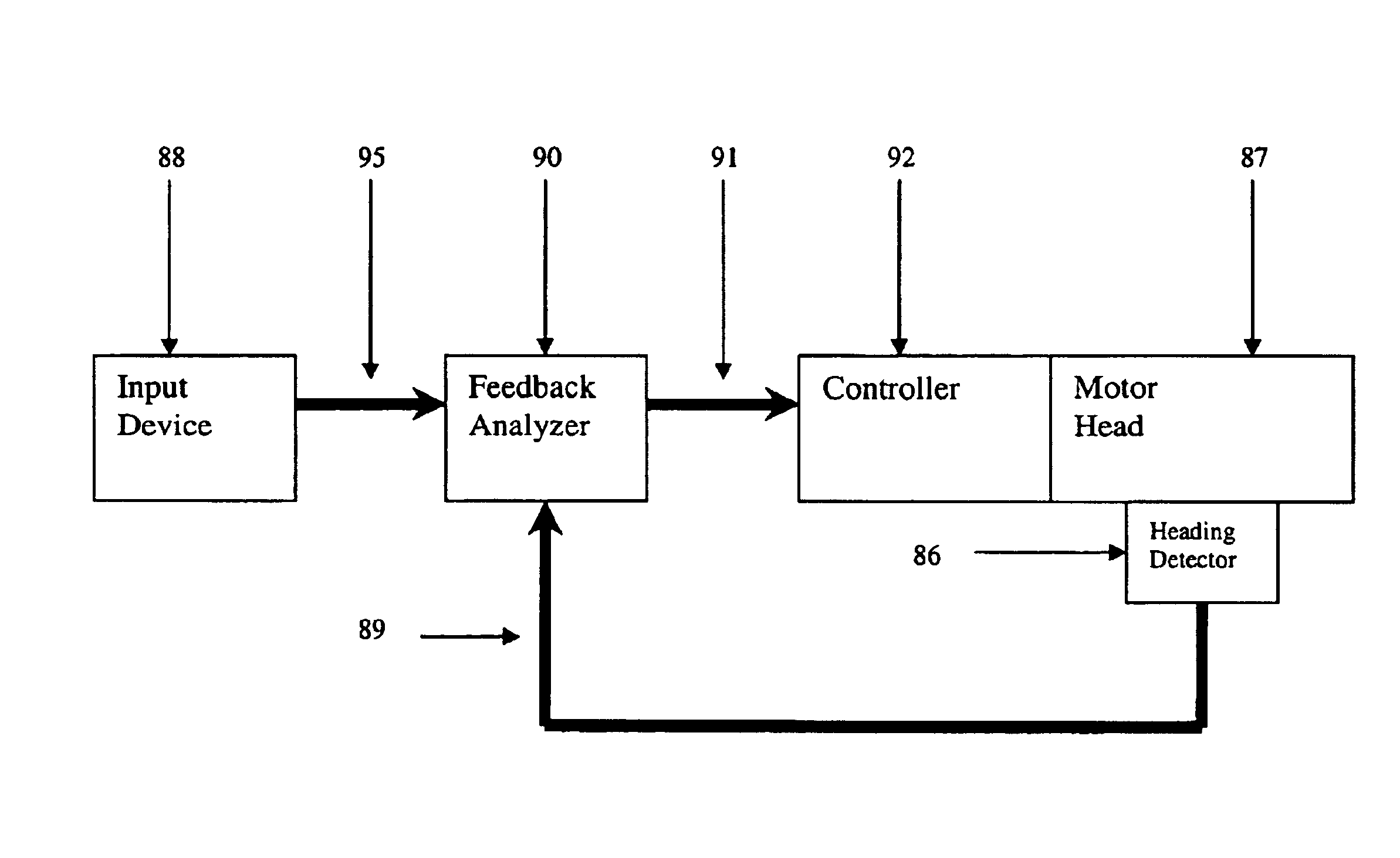

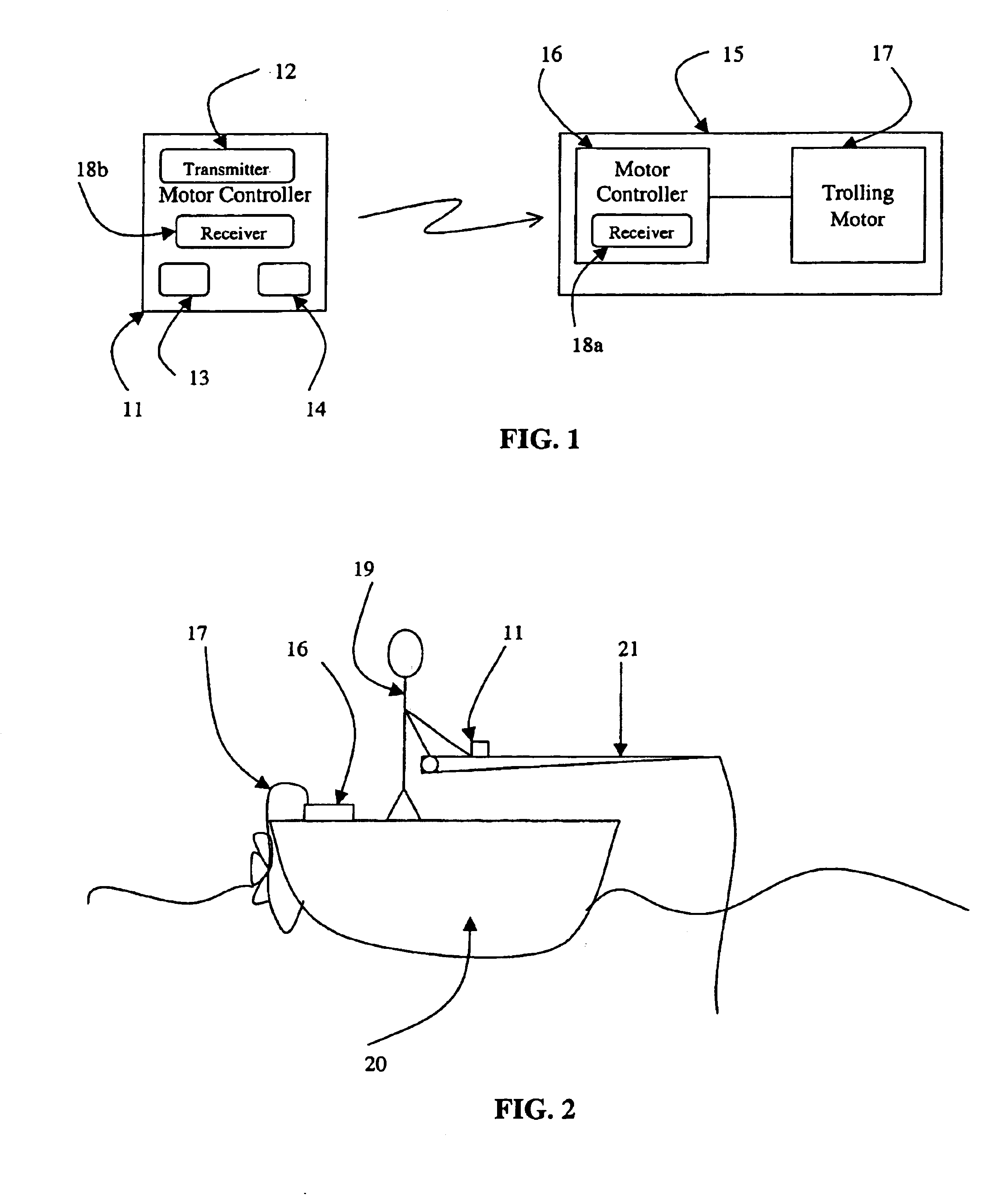

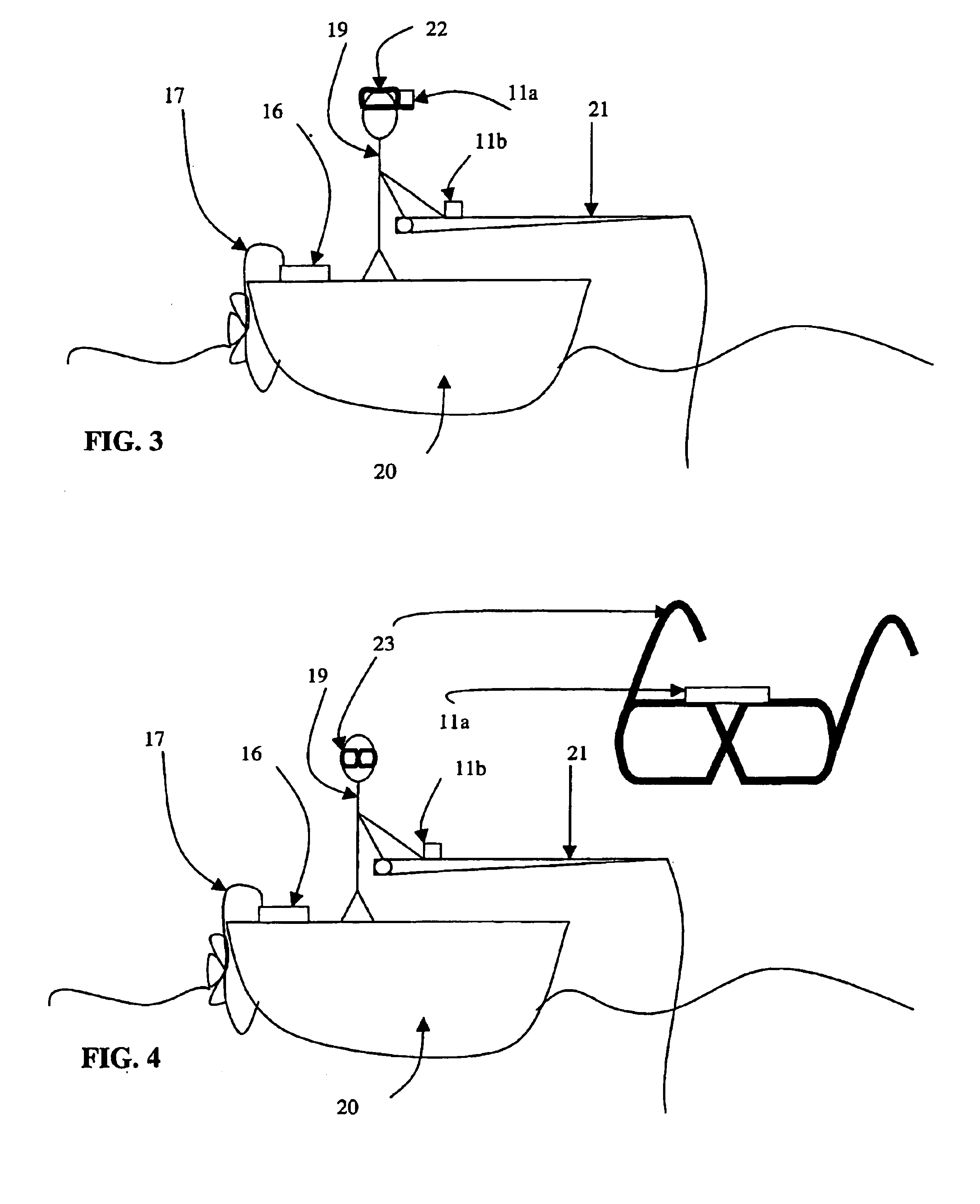

Point-n-click steering

InactiveUS6995527B2Improve reading accuracyTelemetry/telecontrol selection arrangementsPropulsion power plantsTrolling motorDirection information

The present system is a system for controlling a trolling motor in a fishing boat. The system comprises a transmitting unit and a receiving unit. The transmitting unit includes a direction sensor, a selection switch, and a transmitter. The direction sensor automatically senses the direction to which the user desires to steer the fishing boat when the user points the direction sensor in that direction. The user then uses the selection switch, and by “clicking” the switch once the transmitter sends a signal with the direction information to the receiving unit. The receiving unit then receives the signal containing the direction information, and affects the trolling motor in such a way that it steers the fishing boat in the desired direction.

Owner:INNOVATIVE TECH CORP

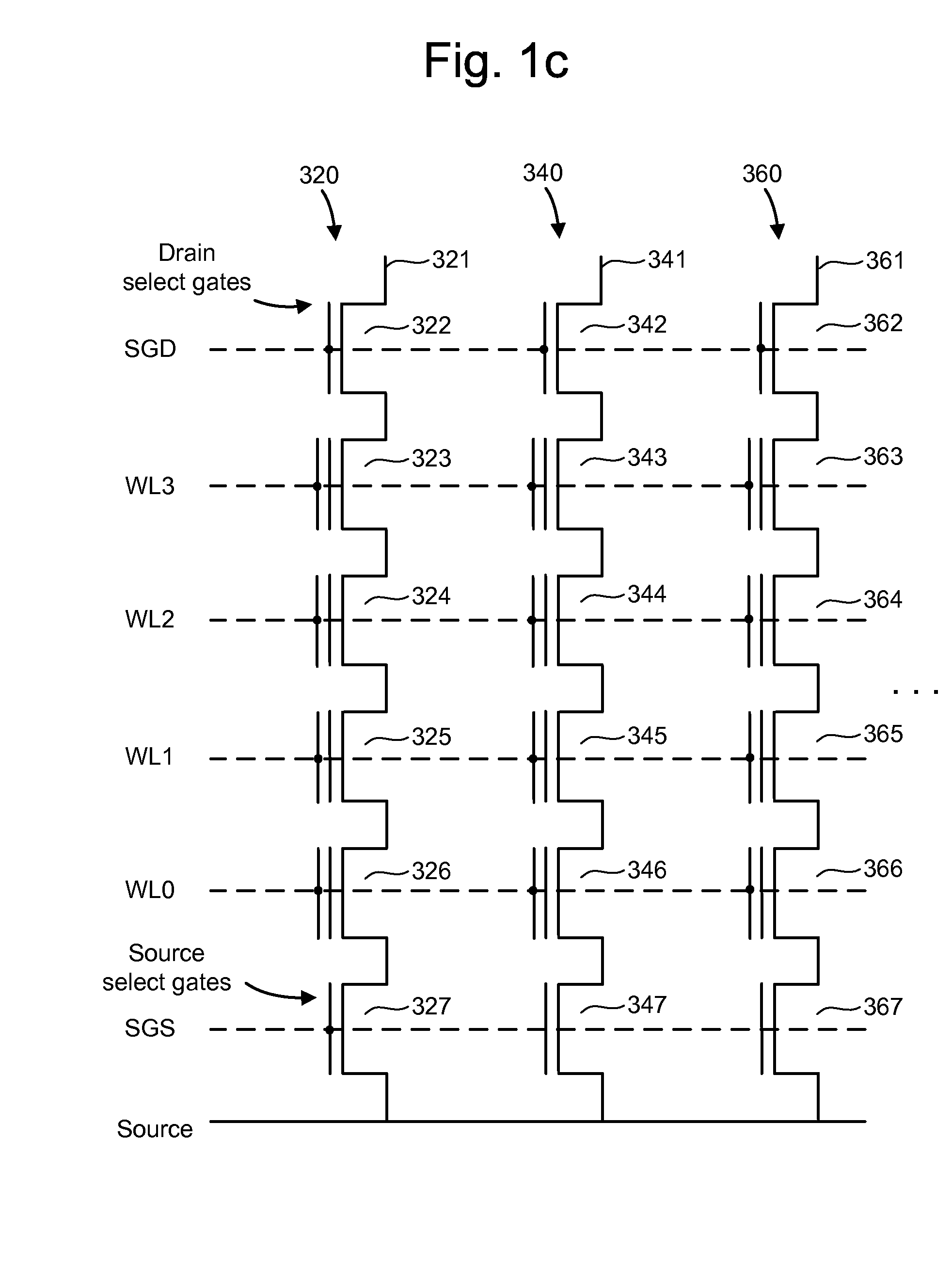

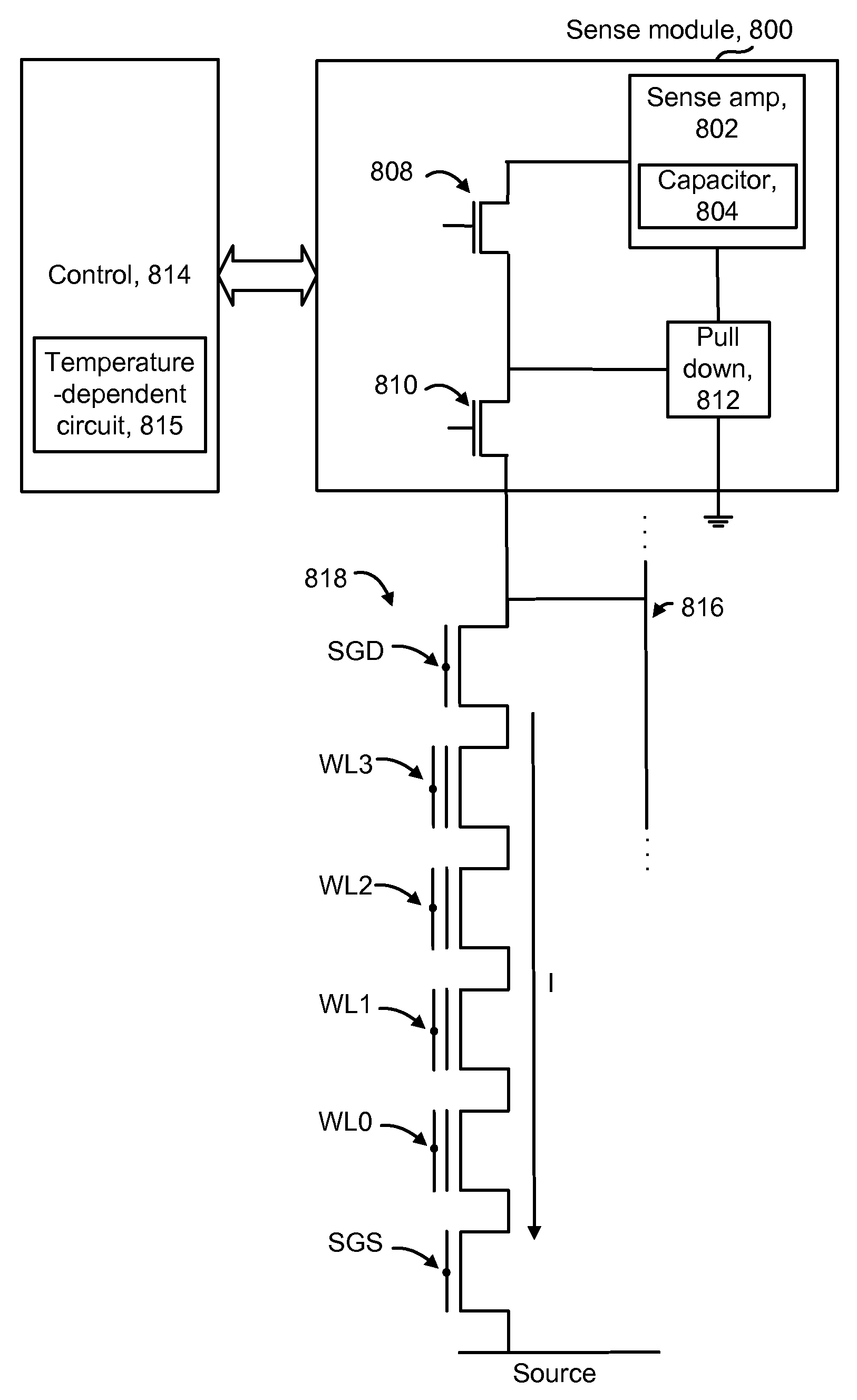

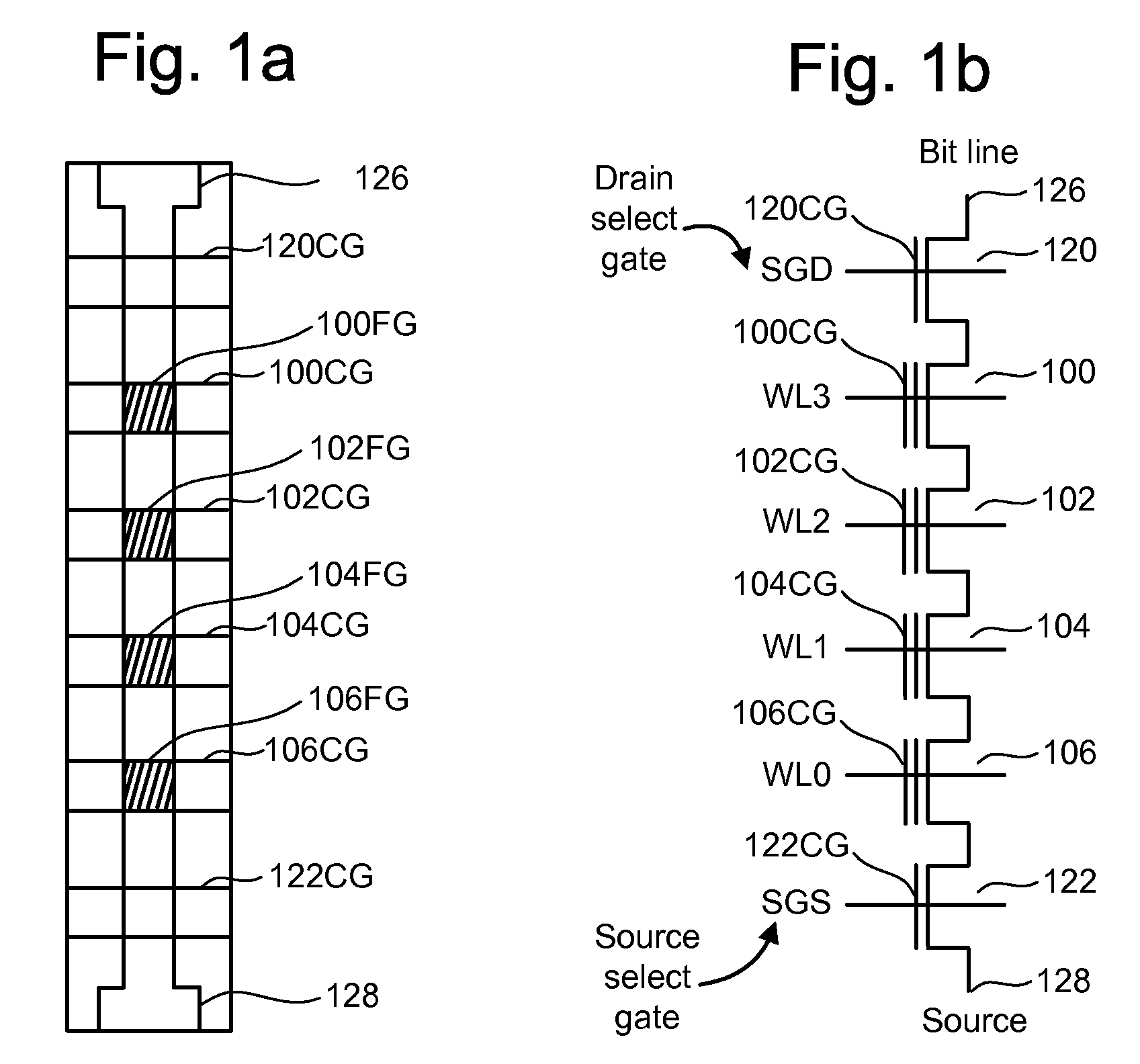

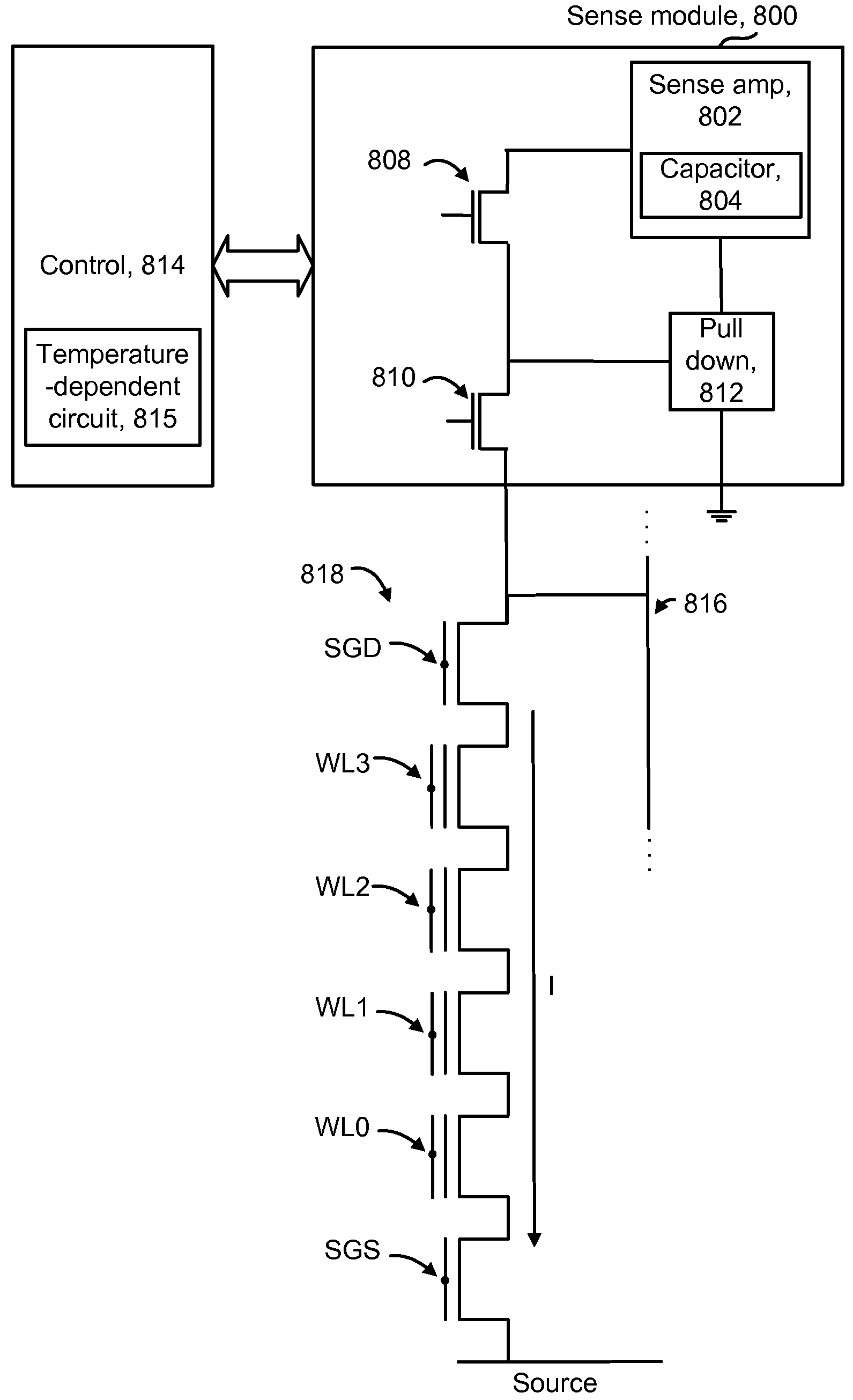

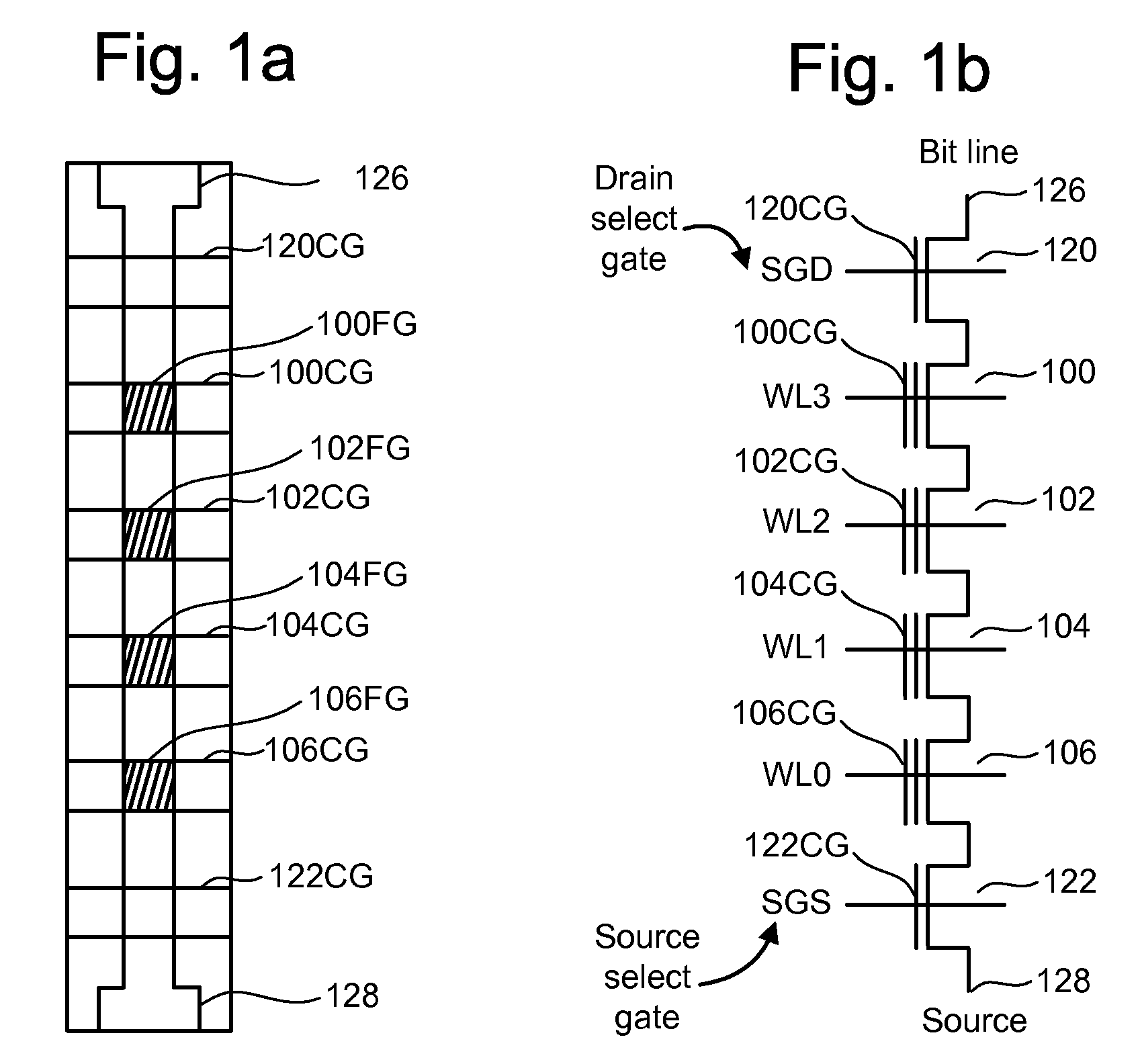

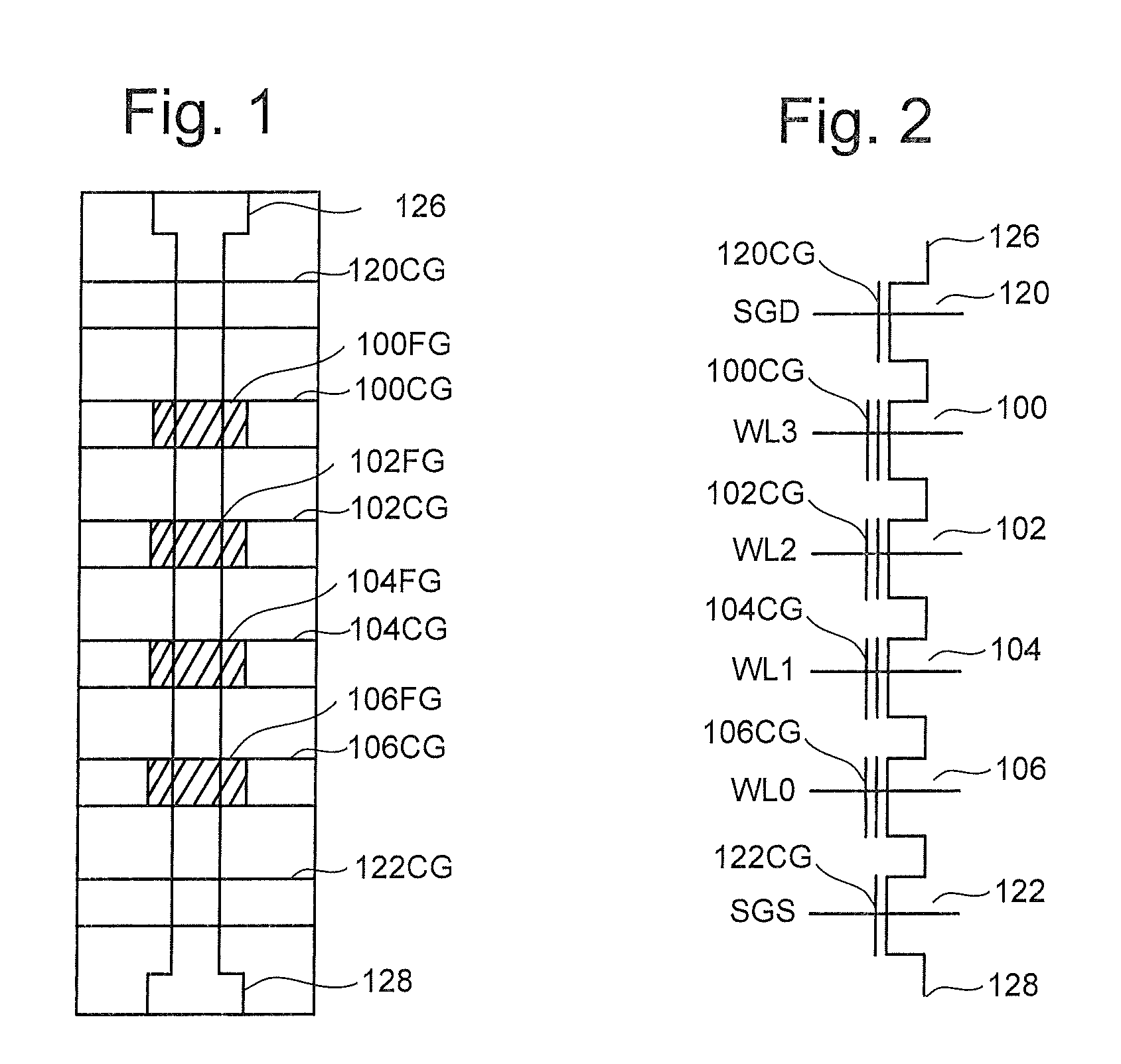

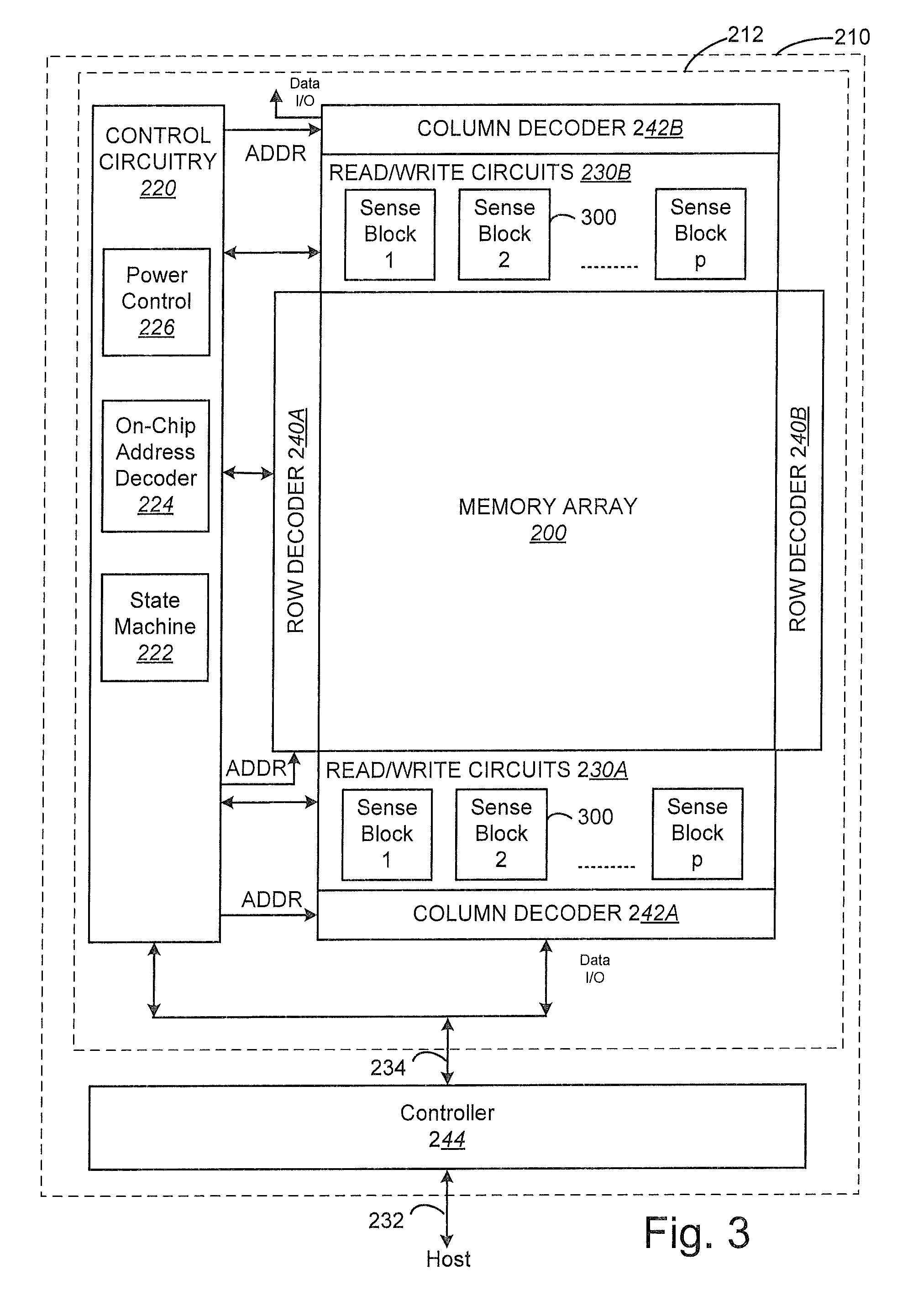

Data state-based temperature compensation during sensing in non-volatile memory

Temperature effects in a non-volatile storage device are addressed by providing a data state-dependent, and optionally temperature dependent, sense current during verify and read operations. A different sense current is provided for each data state, so that a common temperature coefficient is realized for storage elements with different data states. The temperature coefficient for higher states can be reduced to that of lower states. During sensing, a sense time can be adjusted to achieve a desired sense current when a selected storage element is in a conductive state. A fixed voltage trip point may be maintained. During the sense time, a pre-charged capacitor discharges into a selected storage element such as via a bit line and NAND string, when the selected storage element is in a conductive state. The discharge level is translated to a current which is compared to a state-dependent, and optionally temperature dependent, reference current.

Owner:SANDISK TECH LLC

Data state-based temperature compensation during sensing in non-volatile memory

ActiveUS20100074014A1Improve reading accuracyRead-only memoriesDigital storageBit lineState dependent

Temperature effects in a non-volatile storage device are addressed by providing a data state-dependent, and optionally temperature dependent, sense current during verify and read operations. A different sense current is provided for each data state, so that a common temperature coefficient is realized for storage elements with different data states. The temperature coefficient for higher states can be reduced to that of lower states. During sensing, a sense time can be adjusted to achieve a desired sense current when a selected storage element is in a conductive state. A fixed voltage trip point may be maintained. During the sense time, a pre-charged capacitor discharges into a selected storage element such as via a bit line and NAND string, when the selected storage element is in a conductive state. The discharge level is translated to a current which is compared to a state-dependent, and optionally temperature dependent, reference current.

Owner:SANDISK TECH LLC

Dynamic and adaptive optimization of read compare levels based on memory cell threshold voltage distribution

ActiveUS7957187B2Improve reading accuracyImprove accuracyRead-only memoriesDigital storageData setAdaptive optimization

A process is performed periodically or in response to an error in order to dynamically and adaptively optimize read compare levels based on memory cell threshold voltage distribution. One embodiment of the process includes determining threshold voltage distribution data for a population of non-volatile storage elements, smoothing the threshold voltage distribution data using a weighting function to create an interim set of data, determining a derivative of the interim set of data, and identifying and storing negative to positive zero crossings of the derivative as read compare points.

Owner:SANDISK TECH LLC

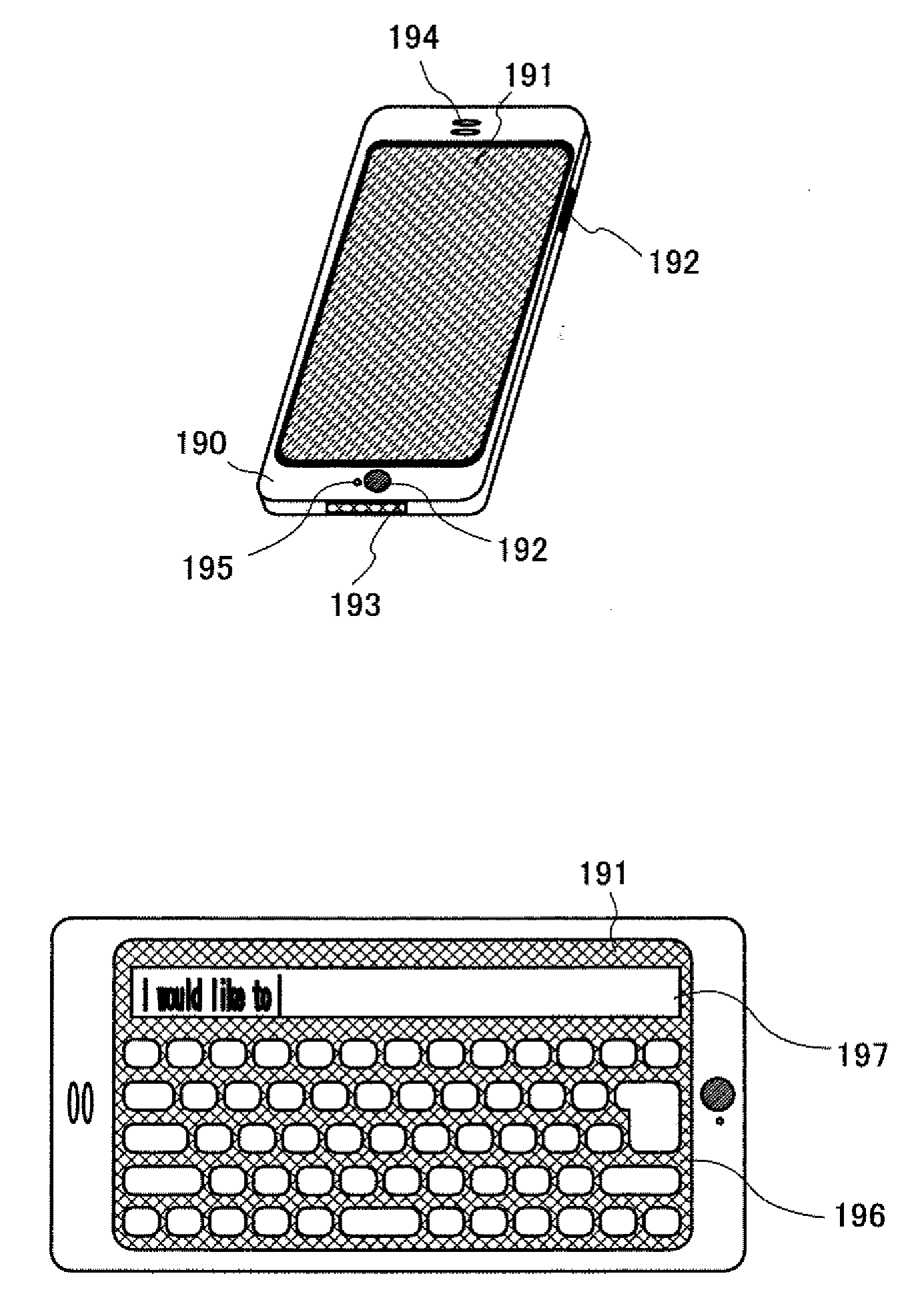

Touch panel and method for driving the same

ActiveUS20100085331A1High sensitivity detectionImprove reading accuracyCathode-ray tube indicatorsDetails for portable computersHigh ReadingsTouchpad

A touch panel having high reading accuracy of an object to be detected is provided. In a method for driving a touch panel which is provided with a photo sensor in a pixel, an image is displayed in a display portion of a touch panel, a detection region is determined by detecting approach or contact of an object to be detected in a state in which the image is displayed, and the object to be detected is read while substantially equalizing the intensity of light of pixels in the detection region per unit time and unit area. The intensity of light of the pixels per unit time and unit area, which is to be substantially equal, is preferably the maximum intensity of light in the detection region before adjustment, more preferably, the intensity of light for white display.

Owner:SEMICON ENERGY LAB CO LTD

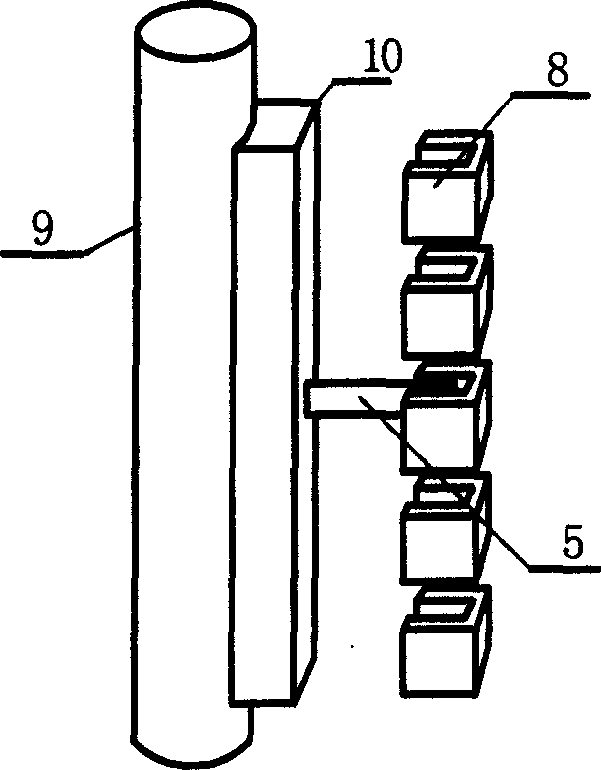

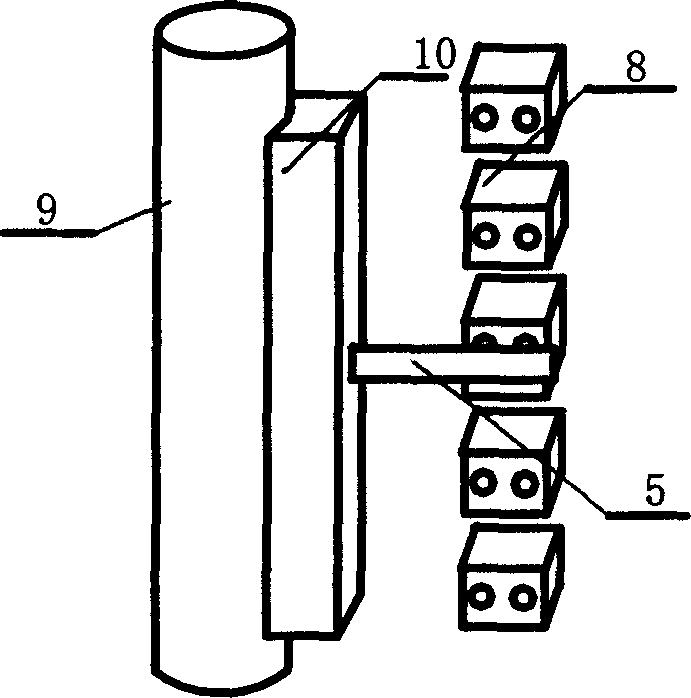

Level meter

InactiveCN1560574ASimple structureReal-time quick responseLevel indicators by floatsLevel sensorEngineering

The invention discloses a fluid level gage applied to high pressure boiler. The fluid level gage includes a connector connected to the measured container, the connector has a magnetic float elevating with the fluid level, the external side of the connector has a vernier coupled with the magnetic float, several photoelectric switches are arranged on the measured container with the fluid height, the vernier corresponds to different photoelectric switch when it is in different height, thus it is shaded and reflected; each photoelectric switch is connected to the control unit, it outputs voltage different to other photoelectric switch according to the voltage of the photoelectric switch, acquires the fluid height of the measured container. The device in the invention can provide fluid level electric signal output.

Owner:JINAN UNIVERSITY

Electronically assisted drug delivery device

The present invention relates to electronically assisted drug delivery devices (100). The drug delivery device may include a Gray code type detector for sensing dosage data, wherein the detector comprises a code track consisting of a sequence of alternating markings and a plurality of detectors that are mutually spaced in a direction extending along the code track. The drug delivery device may also include a dosage selector (260) which is moved in a proximal direction upon dose setting and in a distal direction upon dose injection, where the dosage selector is latched in the end of dose position by a latching element, the latching element actuating an end of dose switch for signalling the end of dose state. The drug delivery device may also incorporate power-management arrangements which effectively minimizes power consumption for the incorporated electronic circuitry.

Owner:NOVO NORDISK AS

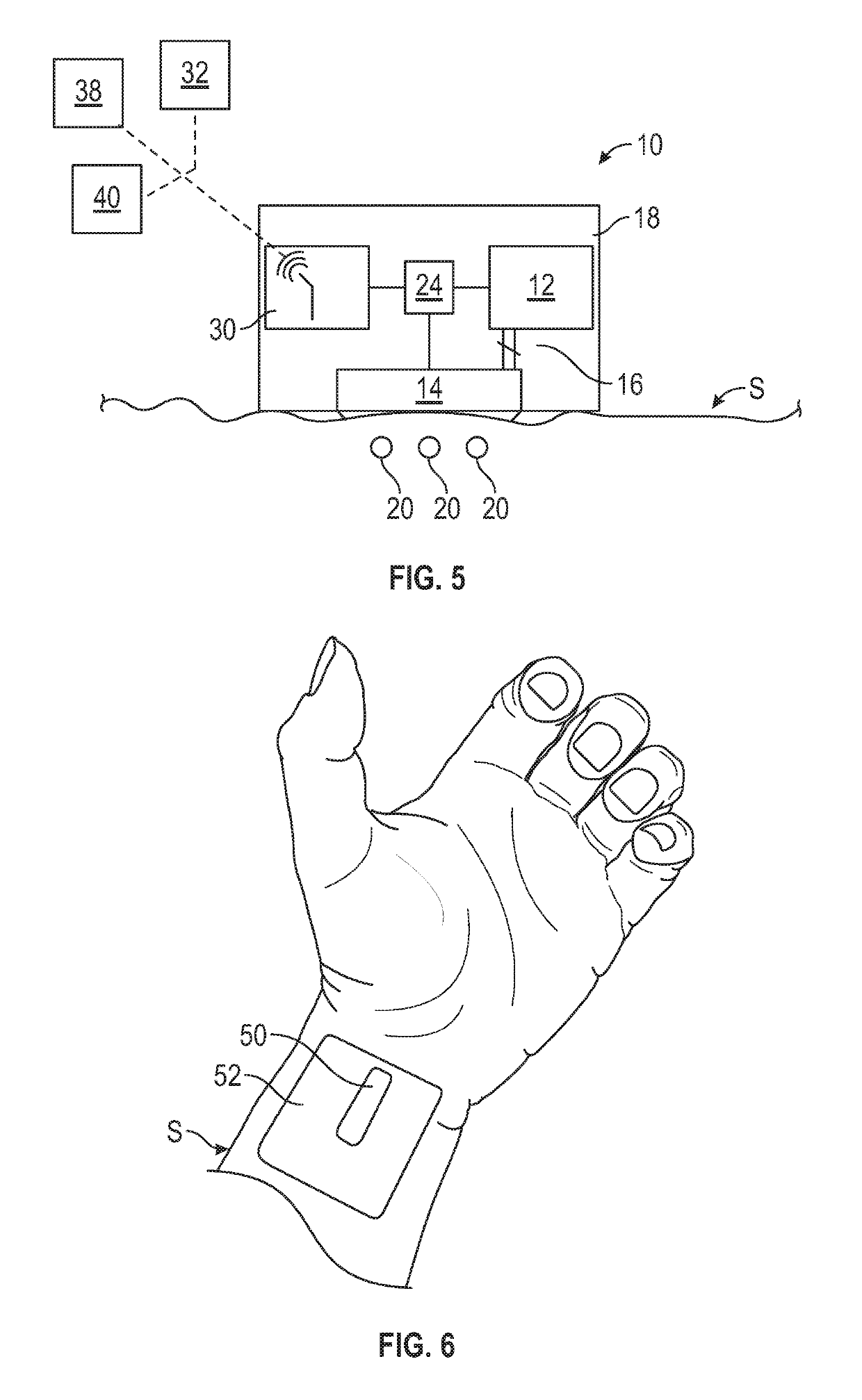

Blood glucose tracking system

ActiveUS20190290161A1Improve reading accuracyMeasuring/recording heart/pulse rateBlood characterising devicesMicrowaveEmergency medicine

A blood glucose tracking system and method measures emitted microwave energy transmitted to and accepted by blood vessels in a desired target area of a patient in order to determine, in real time and in vivo, appropriate blood glucose levels. A measurement unit comprises a transmitter operatively connected to an antenna to deliver energy towards appropriate subcutaneous blood vessels. The measurement unit determines an accepted energy power value in the blood vessels associated with the desired target area. This measurement energy power value is compared with a calibration value, and the difference is used to determine a resultant blood glucose value. The determined blood glucose value may further be acclimatized using additional sensed values compensating for biological and ambient factors relevant to the patient. The final determined blood glucose value can be displayed for reading and / or transmitted and stored for recording for further reference.

Owner:CHASE ARNOLD

Compensating for coupling during read operations in non-volatile storage

Capacitive coupling from storage elements on adjacent bit lines is compensated by adjusting voltages applied to the adjacent bit lines. An initial rough read is performed to ascertain the data states of the bit line-adjacent storage elements, and during a subsequent fine read, bit line voltages are set based on the ascertained states and the current control gate read voltage which is applied to a selected word line. When the current control gate read voltage corresponds to a lower data state than the ascertained state of an adjacent storage element, a compensating bit line voltage is used. Compensation of coupling from a storage element on an adjacent word line can also be provided by applying different read pass voltages to the adjacent word line, and obtaining read data using a particular read pass voltage which is identified based on a data state of the word line-adjacent storage element.

Owner:SANDISK TECH LLC

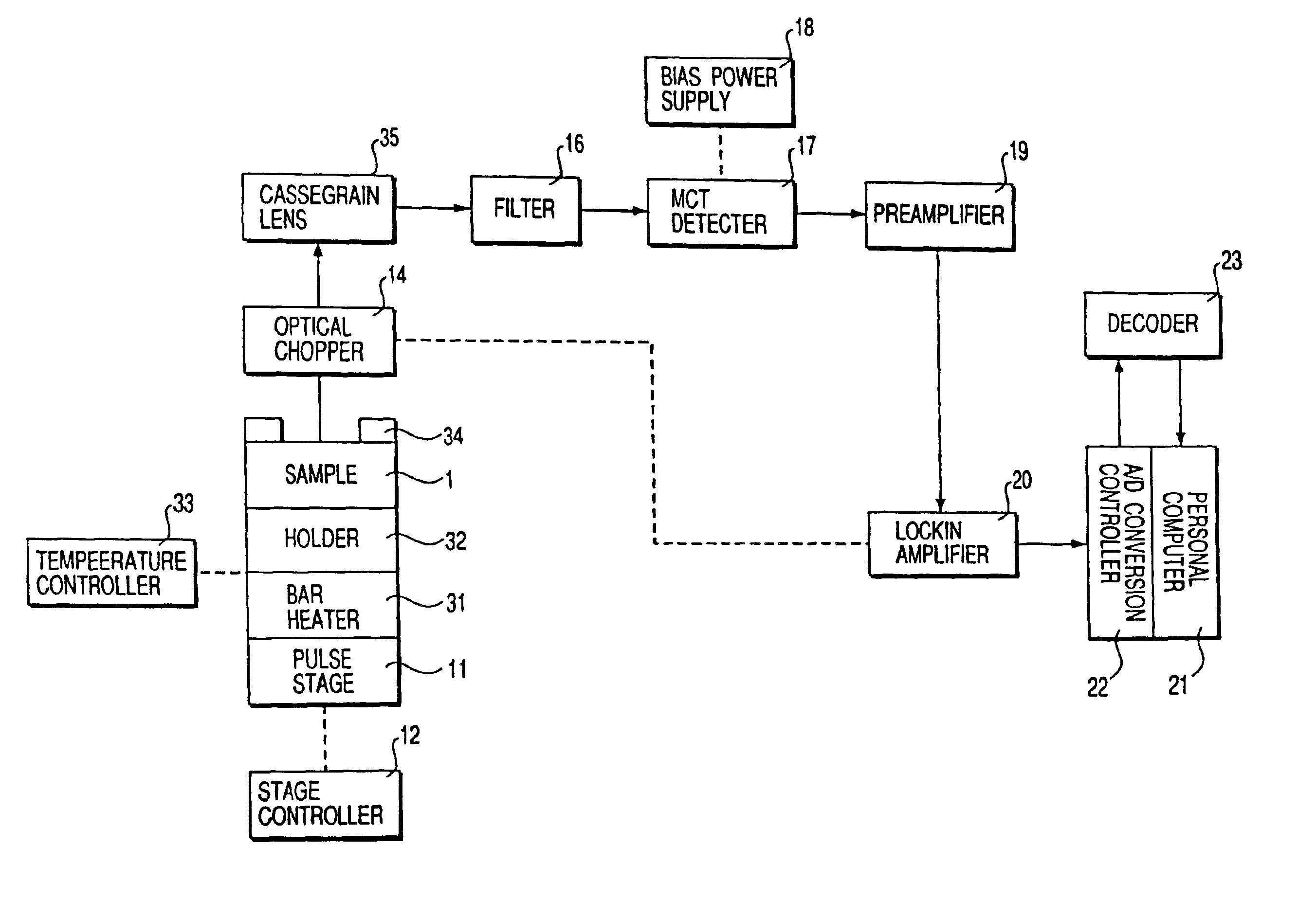

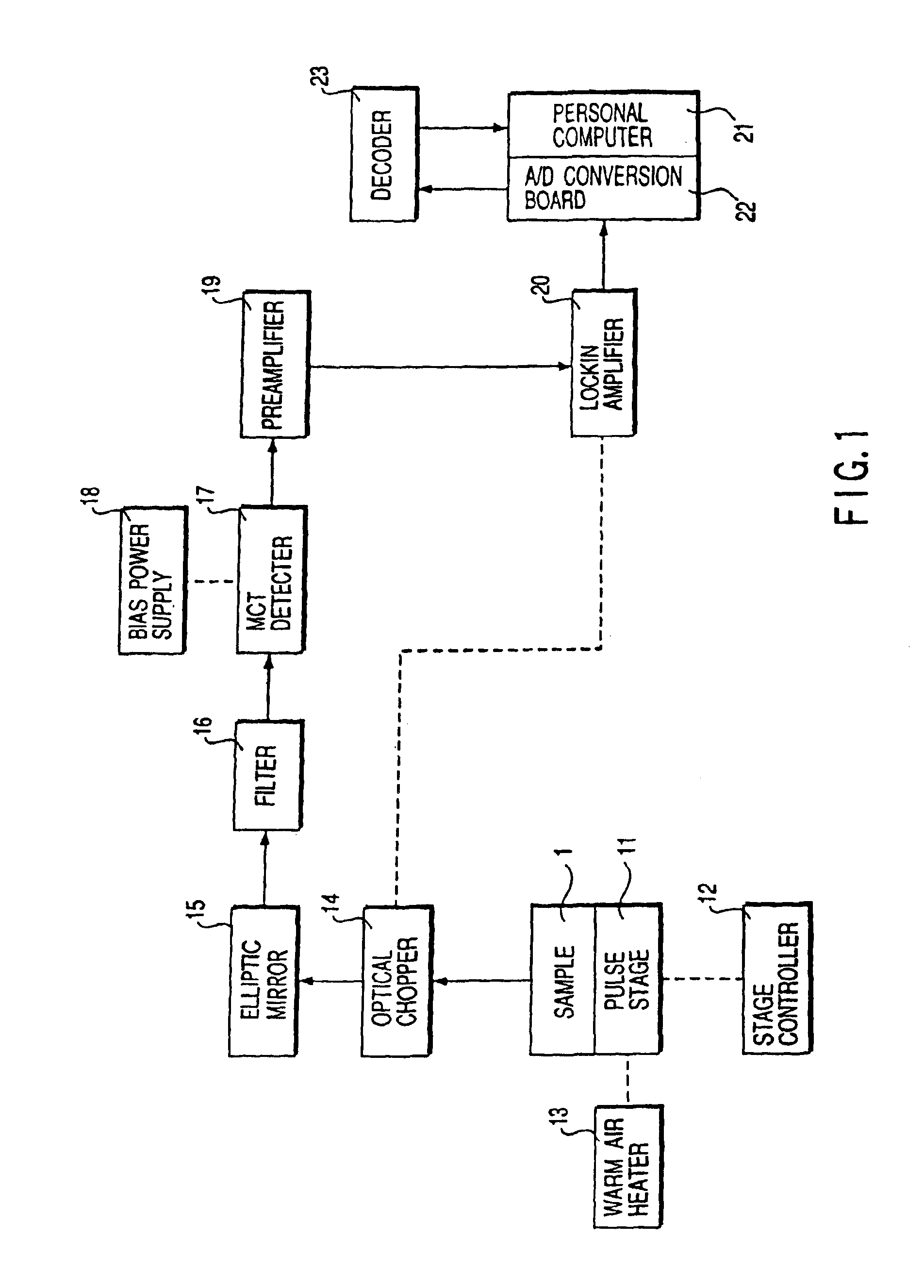

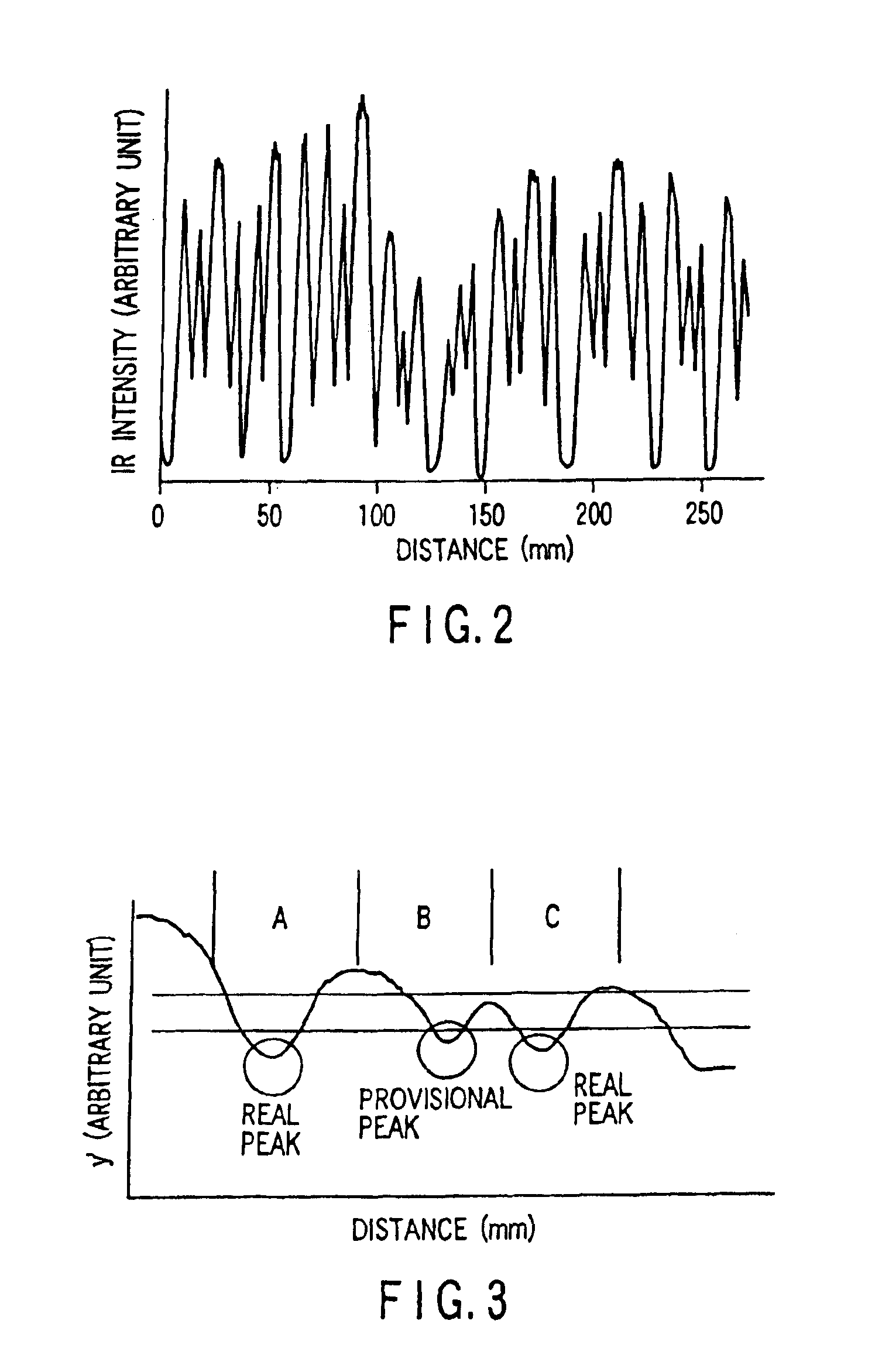

Method and apparatus for reading invisible symbol

InactiveUS6857573B2Improve reading accuracySensing by electromagnetic radiationLength waveComputer science

An article including a substrate and an invisible symbol on the substrate is disclosed. The invisible symbol is formed by a compound which includes a cyano group and has an infrared absorption wavelength apart from that of the substrate when heated.

Owner:KK TOSHIBA

Nonvolatile semiconductor memory device and read method for the same

ActiveUS8953363B2Low detection sensitivityImprove reading accuracyDigital storageBit lineMemory cell

A cross point nonvolatile memory device capable of suppressing sneak-current-caused reduction in sensitivity of detection of a resistance value of a memory element is provided. The device includes perpendicular bit and word lines; a cross-point cell array including memory cells each having a resistance value reversibly changing between at least two resistance states according to electrical signals, arranged on cross-points of the word and bit lines; an offset detection cell array including an offset detection cell having a resistance higher than that of the memory cell in a high resistance state, the word lines being shared by the offset detection cell array; a read circuit (a sense amplifier) that determines a resistance state of a selected memory cell based on a current through the selected bit line; and a current source which supplies current to the offset detection cell array in a read operation period.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

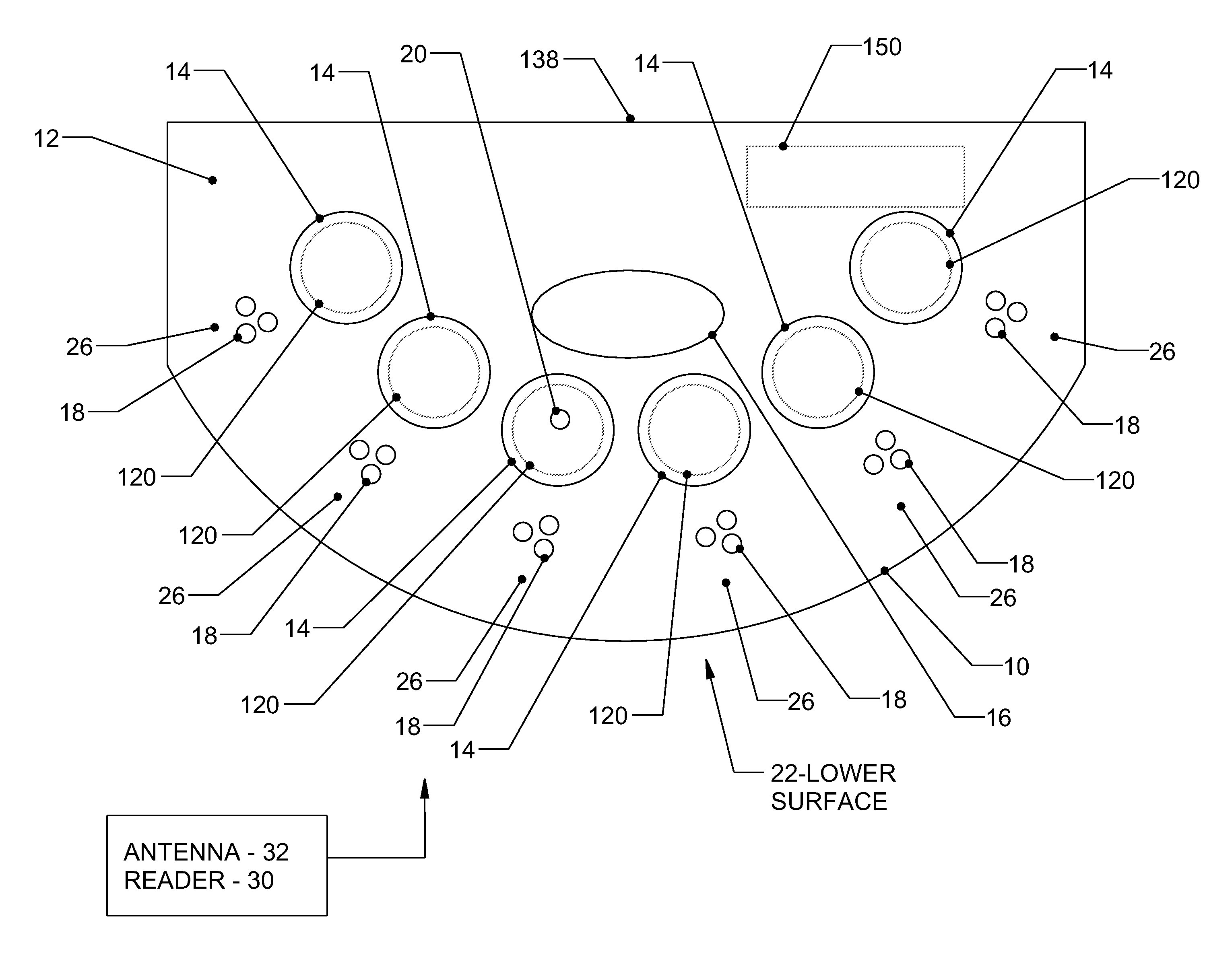

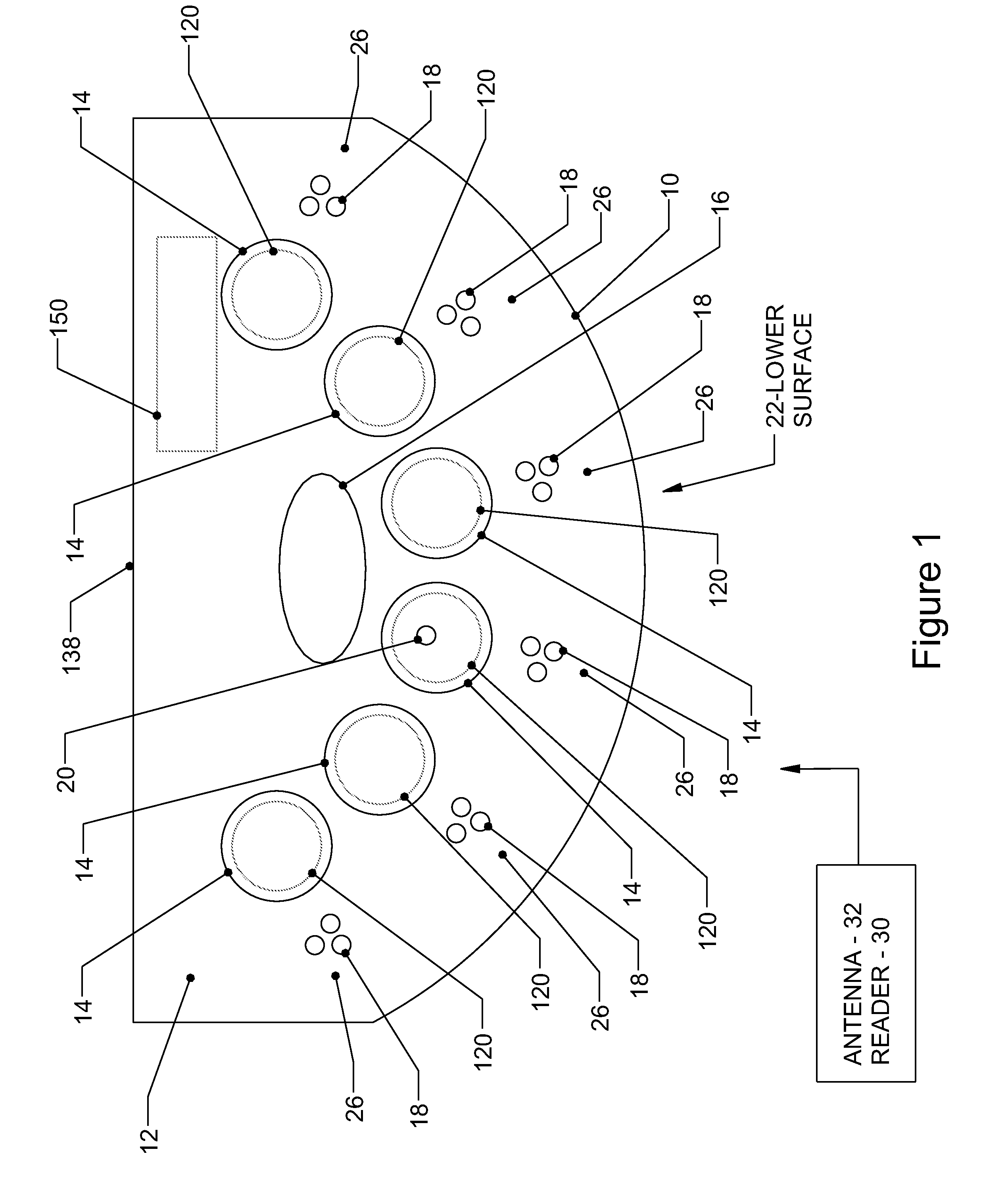

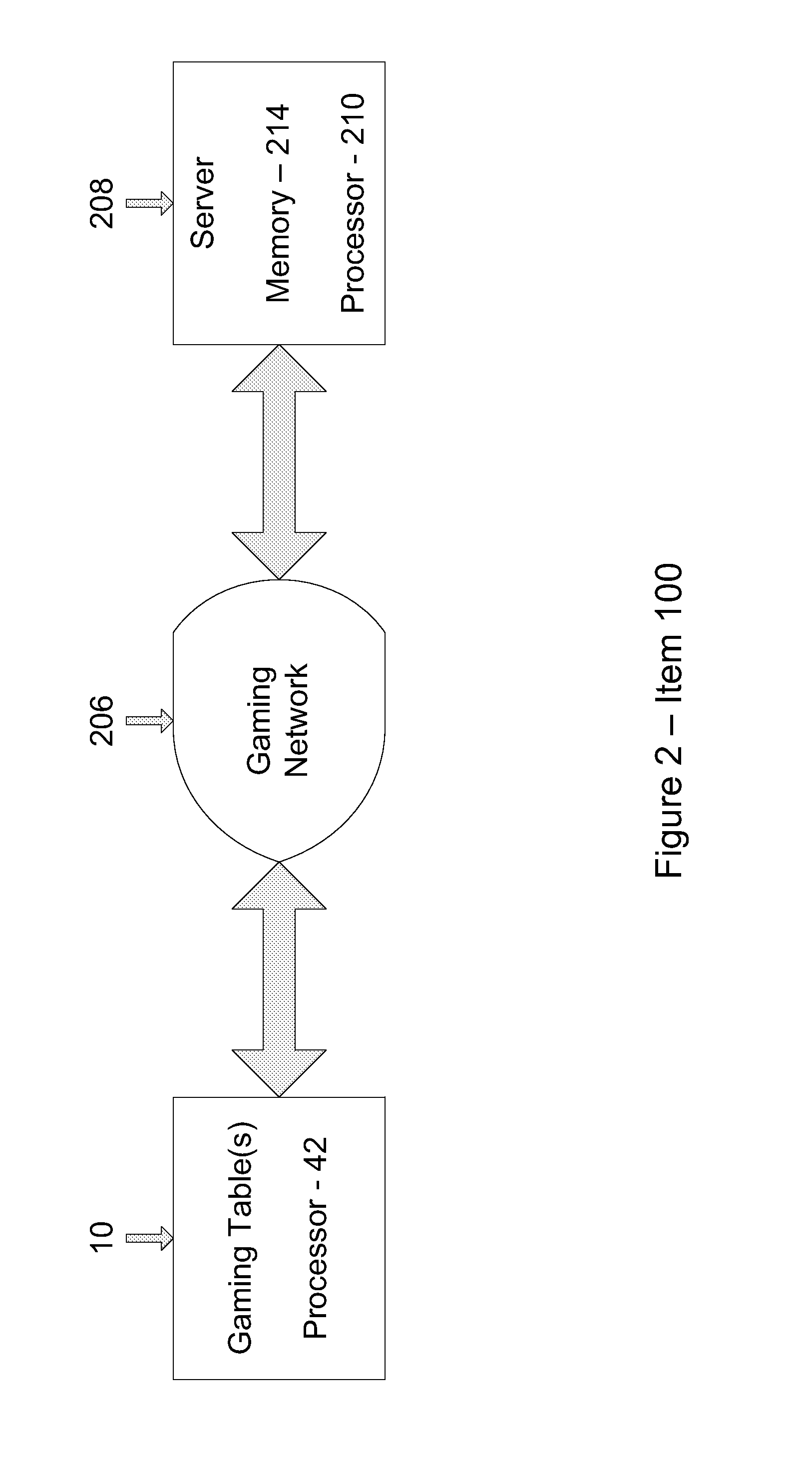

Shape control of magentic fields for table games

ActiveUS20110089634A1Improve reading accuracyAccurate trackingBoard gamesApparatus for meter-controlled dispensingShape controlElectromagnetic field

A gaming table with an upper surface that includes a gaming chip placement area and a lower surface opposite the upper surface is provided. The gaming table also includes a housing coupled to one of the upper surface and the lower surface of the gaming table, an antenna coupled to the housing, wherein the antenna is configured to form an electromagnetic field that defines a zone of communication in which a gaming chip including a radio frequency identification (RFID) tag can be read. The gaming table also includes a substantially-contiguous highly permeable magnetic material layer coupled to the antenna, the highly permeable magnetic material layer defining an outermost boundary of the zone of communication of the antenna, such that a strength of the electromagnetic field at any region beyond the defined boundary of the zone of communication is below a threshold level for communication with an RFID gaming chip, and a reading device coupled to the housing, wherein the RFID reading device is configured to read data transmitted by an RFID gaming chip when the RFID gaming chip is in the zone of communication.

Owner:IGT

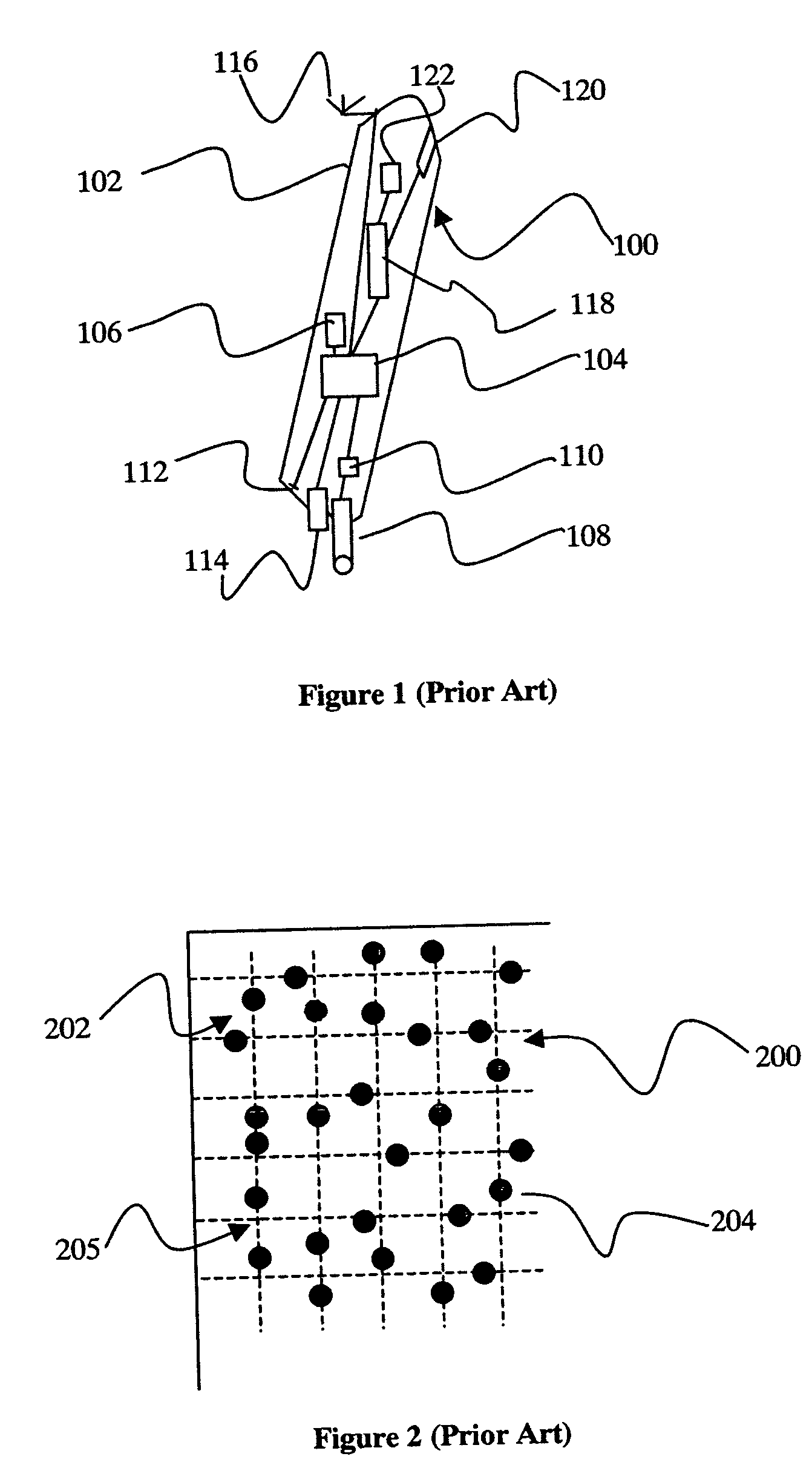

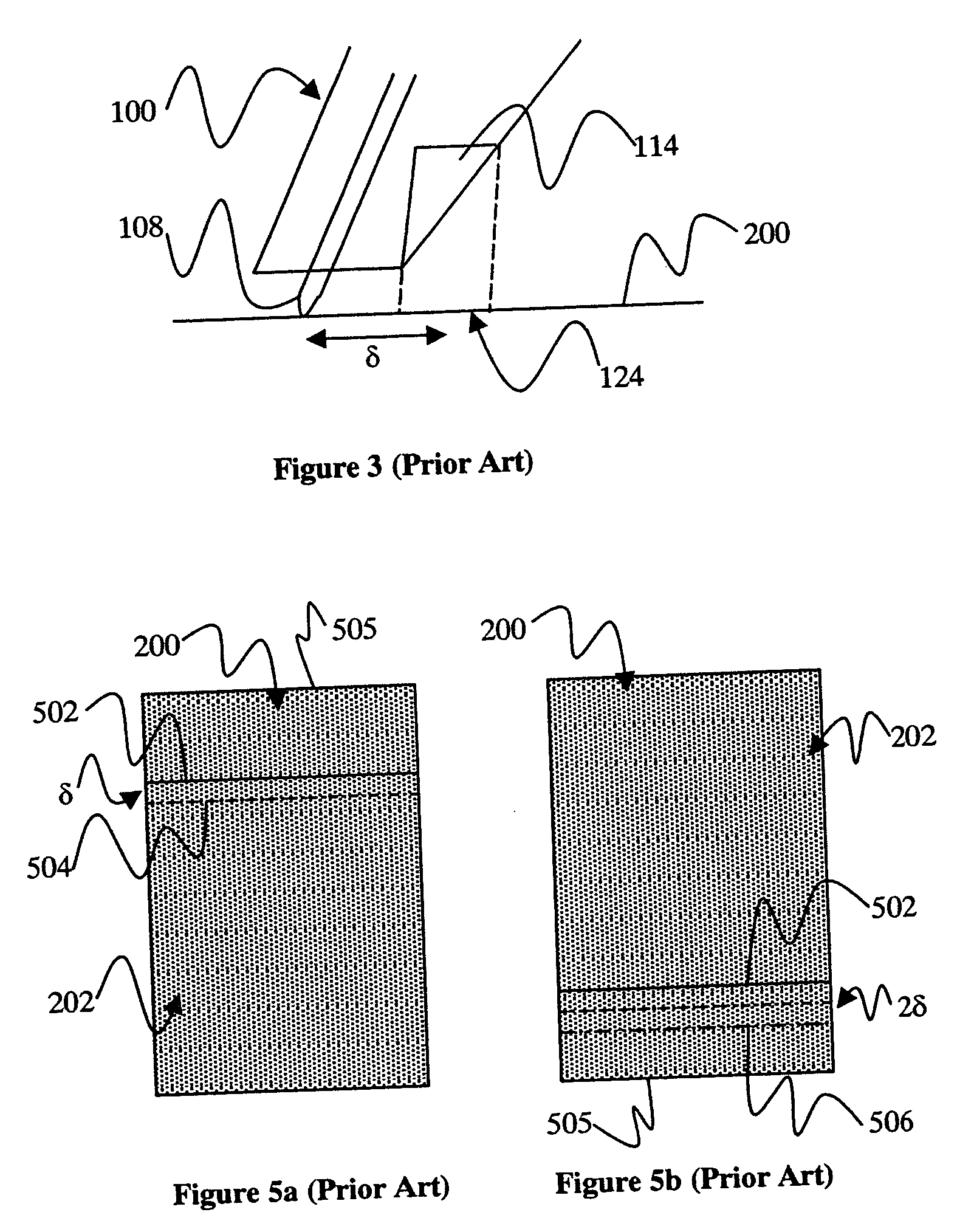

Calibrating digital pens

InactiveUS20060022963A1Improve reading accuracyImprove accuracyInput/output for user-computer interactionCathode-ray tube indicatorsSoftwareDigital paper

A method of calibrating a digital pen (100) comprises the steps of: i) acquiring calibration data indicative of parameters indicative of an offset between a nib (108) of the pen (100) and a field of view (124) of a camera (114) whilst the pen is in use; and ii) using the calibration data to compensate for the offset in subsequently acquired pen usage data. A digital pen, digital paper and software for calibrating a digital pen and a network comprising a digital pen are also disclosed.

Owner:HEWLETT PACKARD DEV CO LP

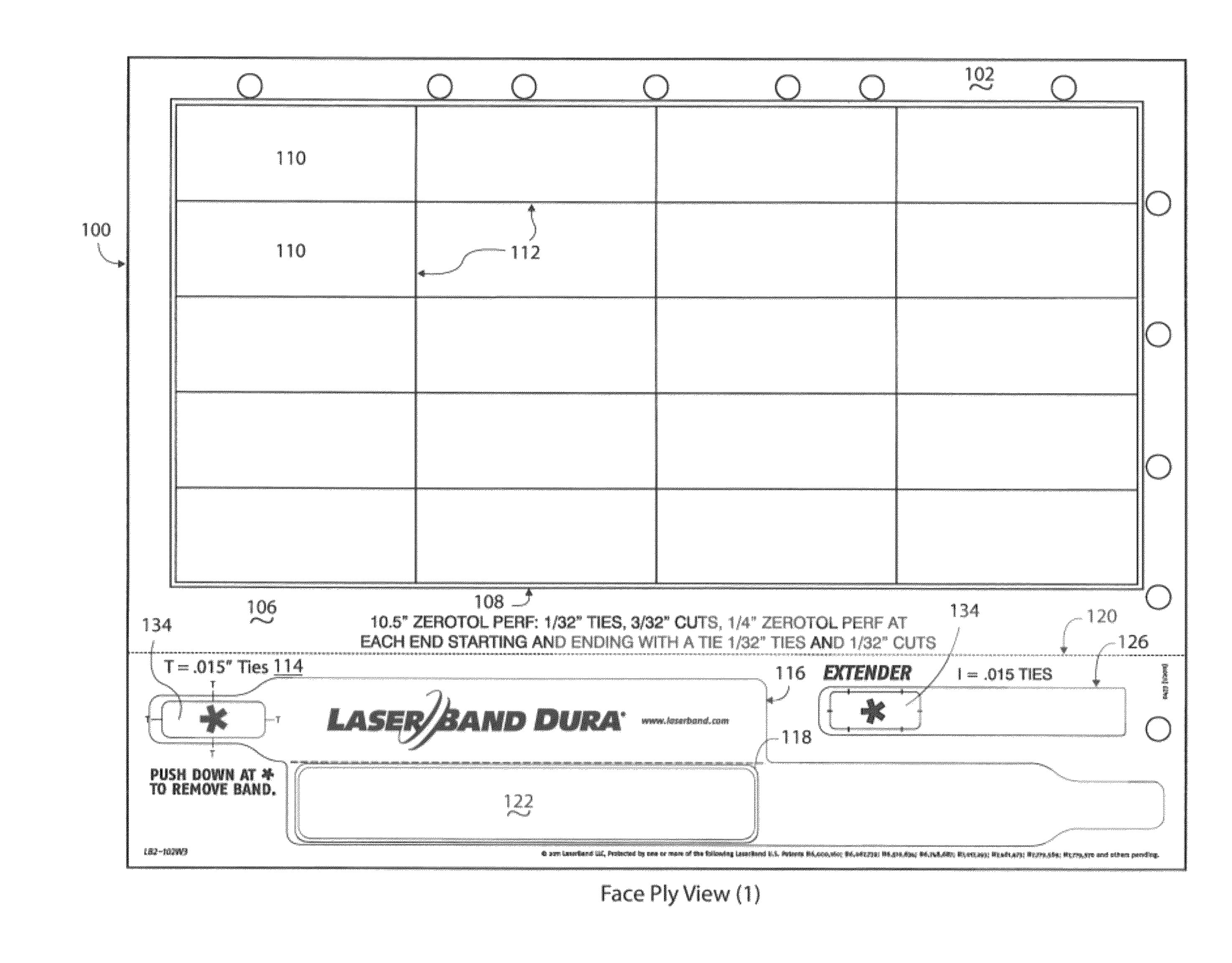

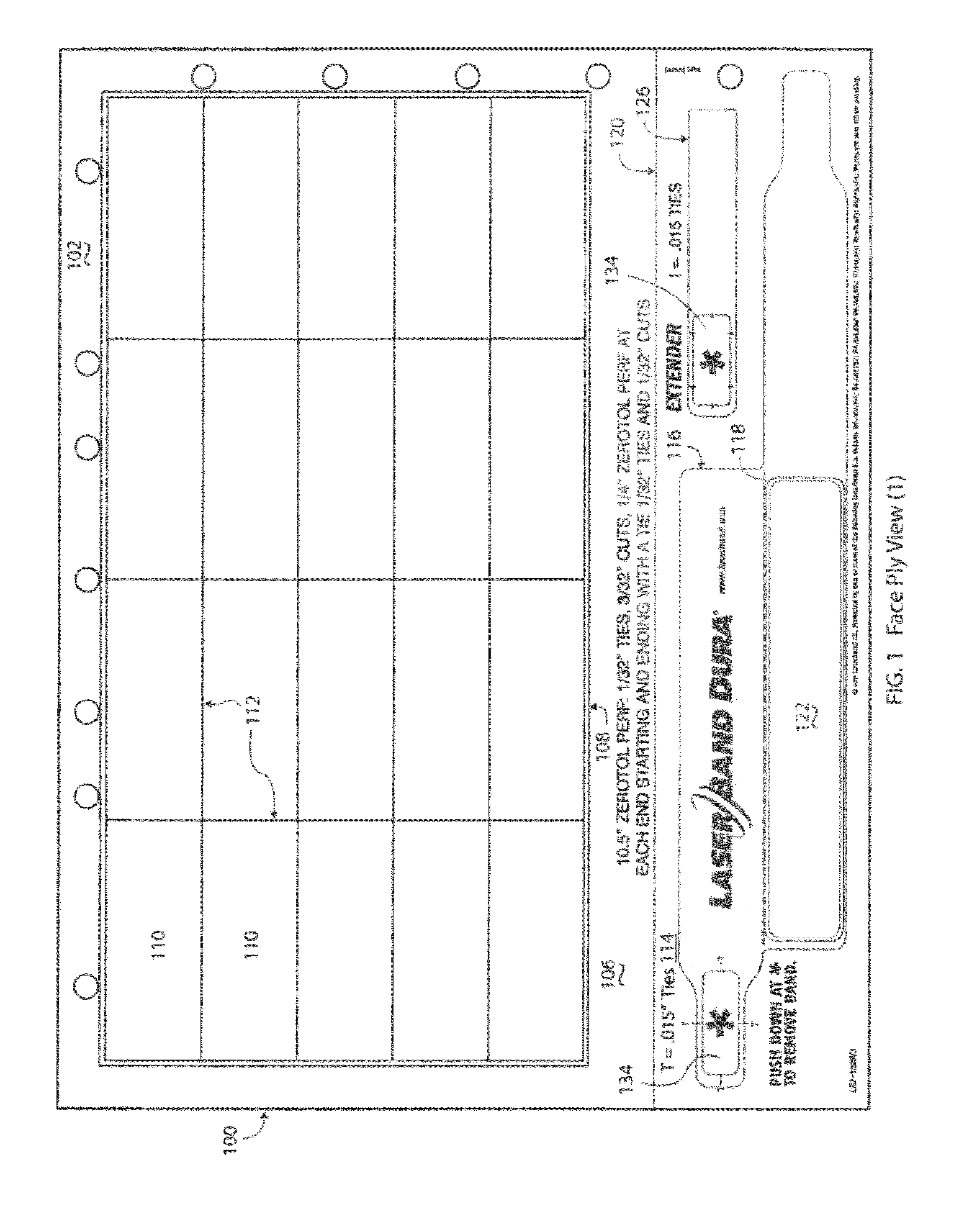

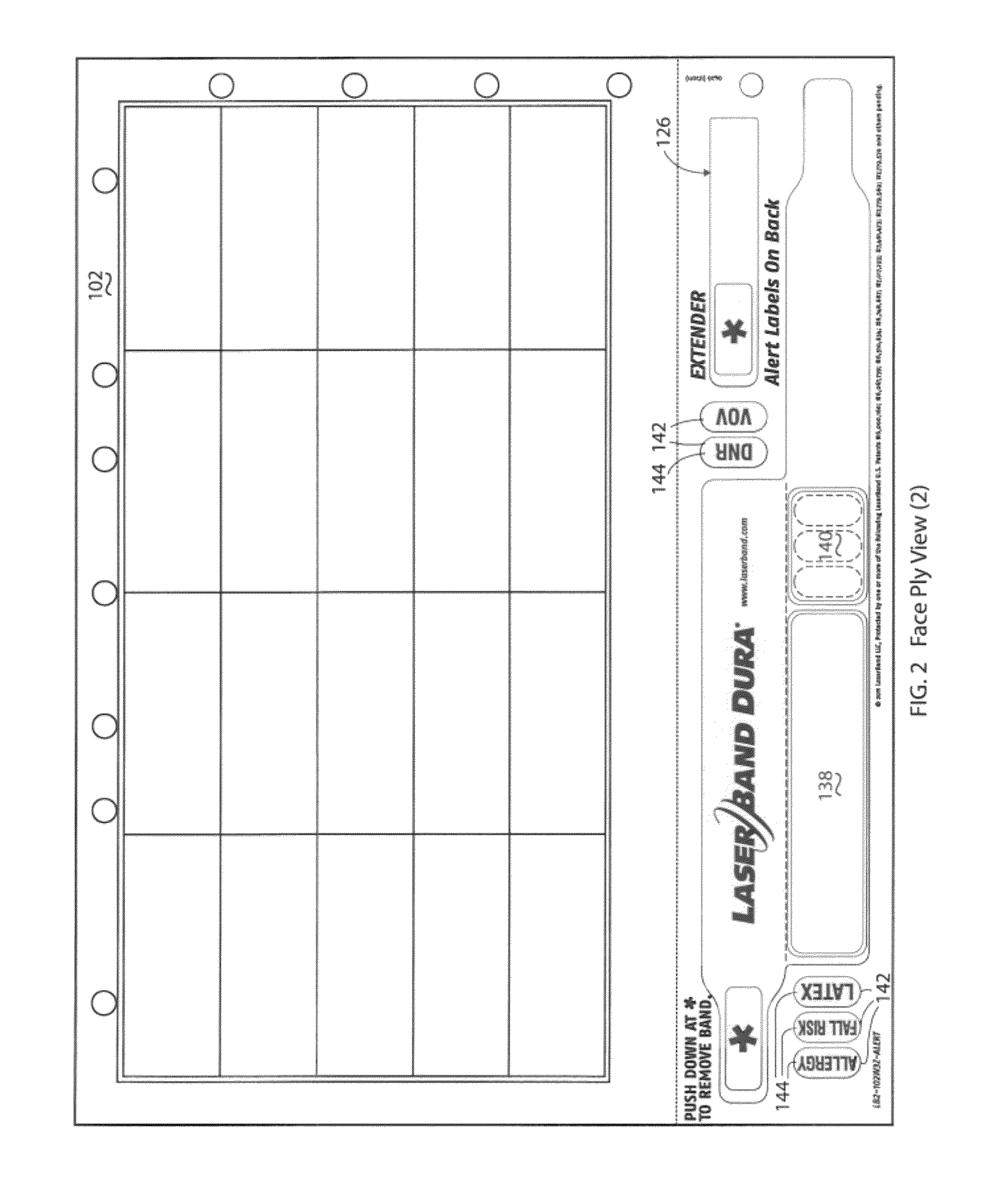

Business form with self laminating wristband with reduced image area

ActiveUS8776417B2Shorten the lengthAvailable spaceStampsOther printing matterEngineeringBusiness forms

A business form comprising a face ply and a lamination ply includes a matrix of self adhering labels positioned in a label area and a self laminating wristband positioned in a wristband area, all of which are defined by die cuts therein for removal upon use. The wristband is comprised of a left edge justified, reduced length imaging area releasably adhered to a laminating portion comprising a pair of laminating panels one of which is smaller sized to merely laminate the imaging area and with self adhering tabs at opposite ends of the panels. A wristband extender is die cut into the lamination ply within the profile of the wristband. A second embodiment includes a pair of separated imaging areas in the same space as the single imaging area along with special precautions labels die cut into the lamination ply for application to the second smaller imaging area. The wristband may be provided separately in an envelope sized sheetlet or in a page size form with multiple wristbands but no labels.

Owner:ZEBRA TECH CORP

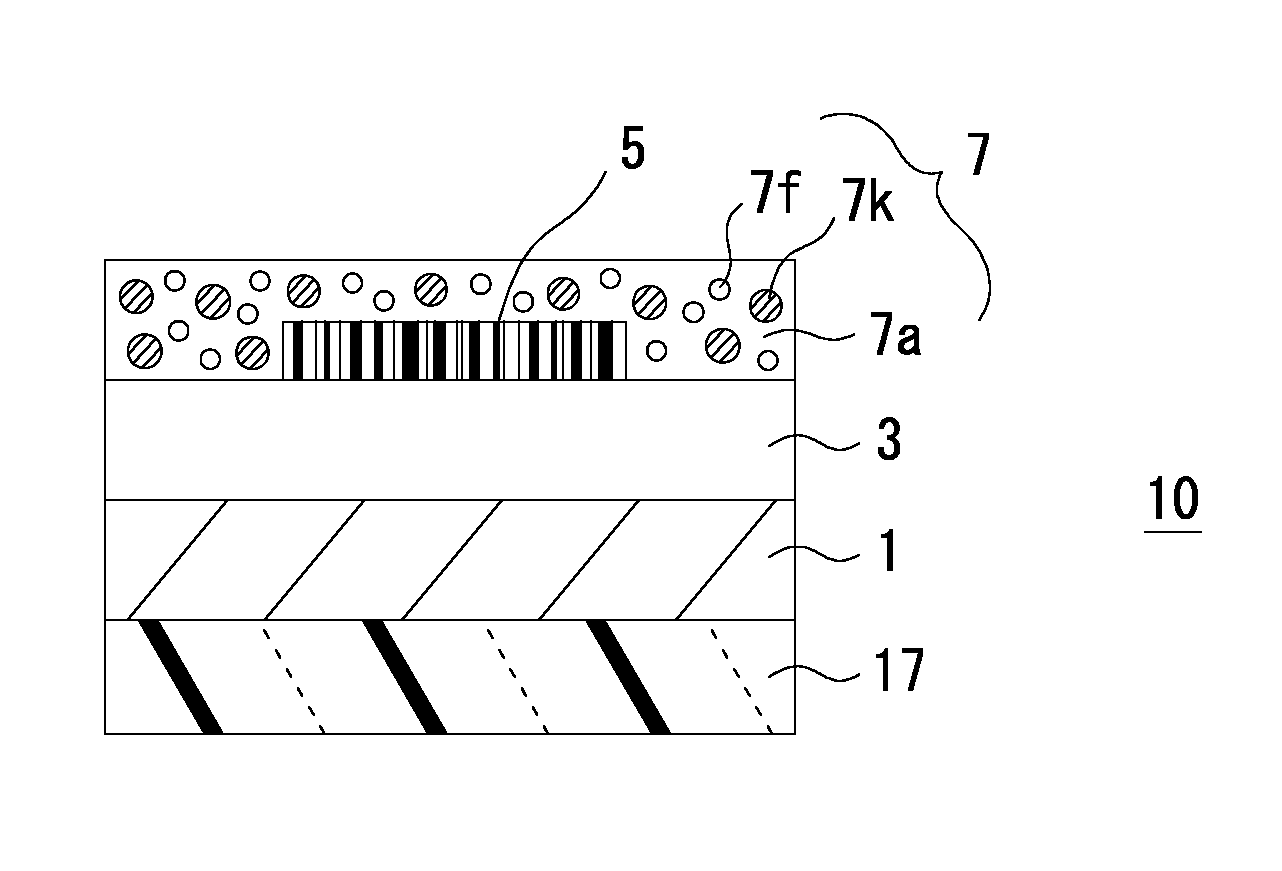

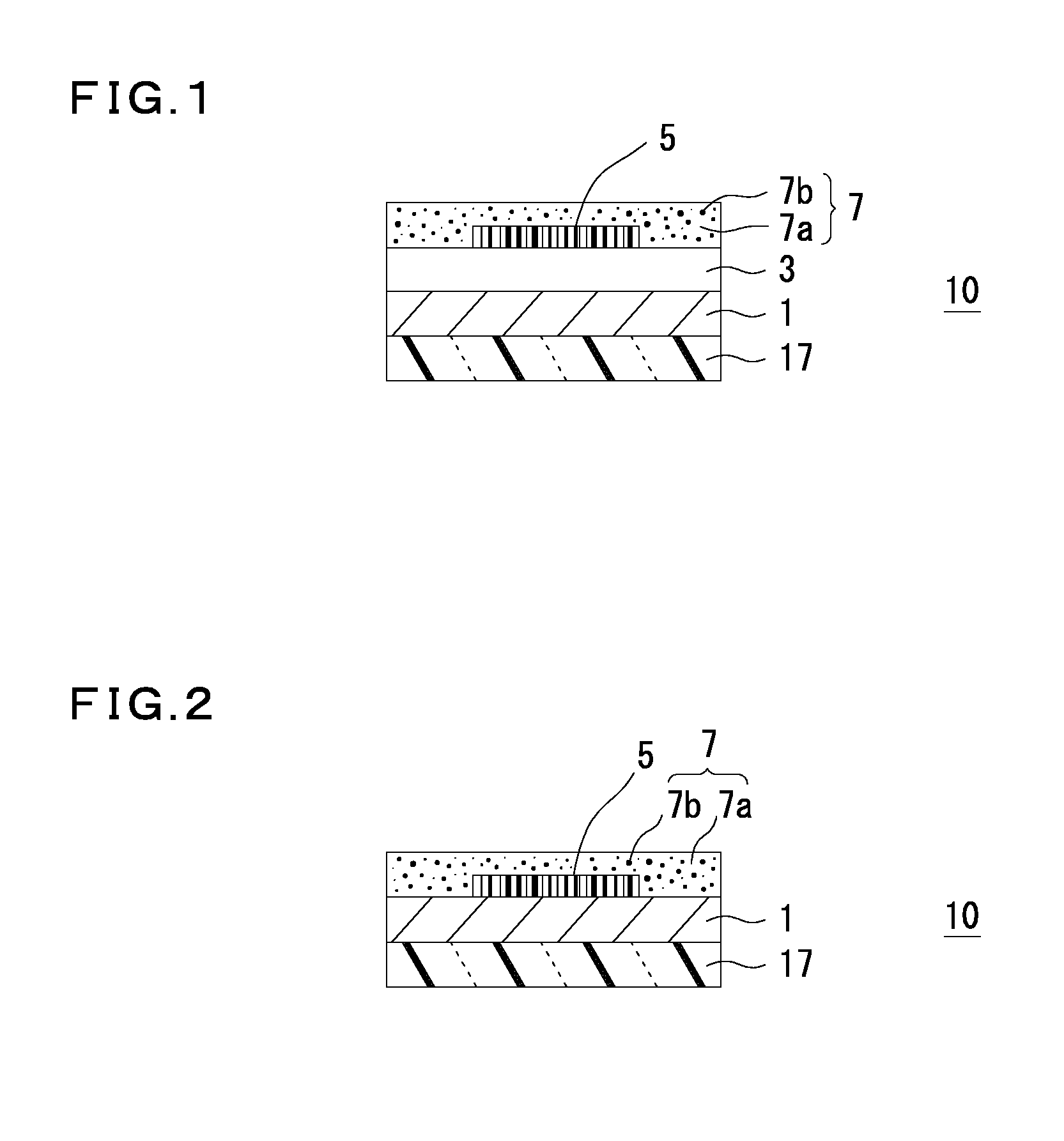

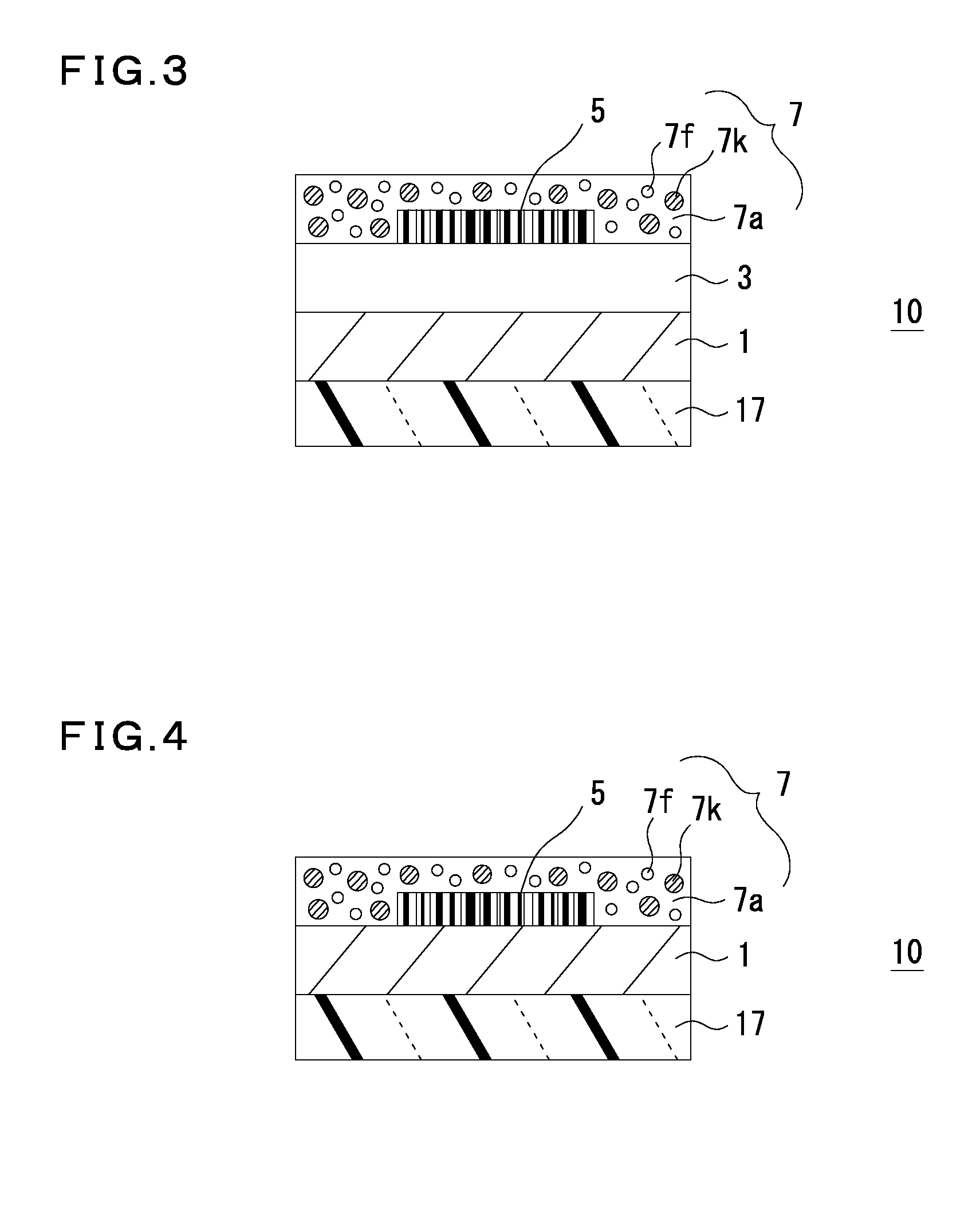

Laminate, package, packaging sheet, packaging material, label and container

ActiveUS8491976B2Small sizeImprove reading accuracyEnvelopes/bags making machineryStampsBarcodePack material

A laminate and the like capable of improving the barcode reading accuracy with a configuration having a smaller number of layers is provided. Further, a laminate and the like capable of further improving the barcode reading accuracy and further reducing the size of a barcode portion even when applied to a conventional layer configuration is provided. The laminate includes a colored barcode print layer 5, a base material layer 1, and a bead-containing coating layer 7 having beads 7b dispersed in a resin 7a.

Owner:TOYO ALUMINIUM KK

Laser wind velocimeter with multiple radiation sources

ActiveUS8508723B2Improve reading accuracyImprove timelinessMachines/enginesWind motor combinationsTransceiverAtmospheric sciences

A system and method for measuring wind velocities are provided. A laser wind velocimeter with a radiation source includes a fiber laser. All optical signals, transmitted and received, are conveyed by optical fibers. An amplifier amplifies a source laser, which is then transmitted to one or more transceivers. The one or more transceivers, each projecting along a different axis, and each with a single optical fiber input / output interface act as both the transmission device to focus the radiation at a target region, and as the receiving system for collecting reflected radiation. The one or more transceivers transmit radiation to the target region. A portion of the reflected radiation collected by the receiving system is analyzed to determine the Doppler shift, which can me used to measure wind velocity.

Owner:RD2 LLC

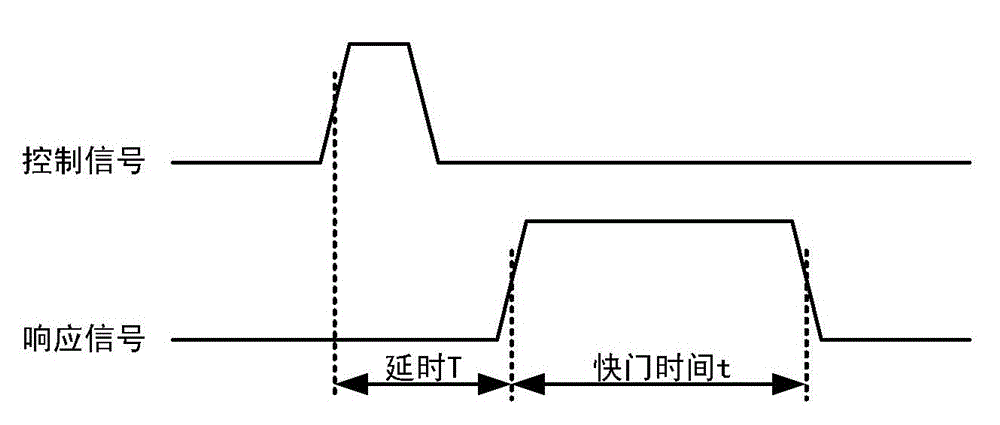

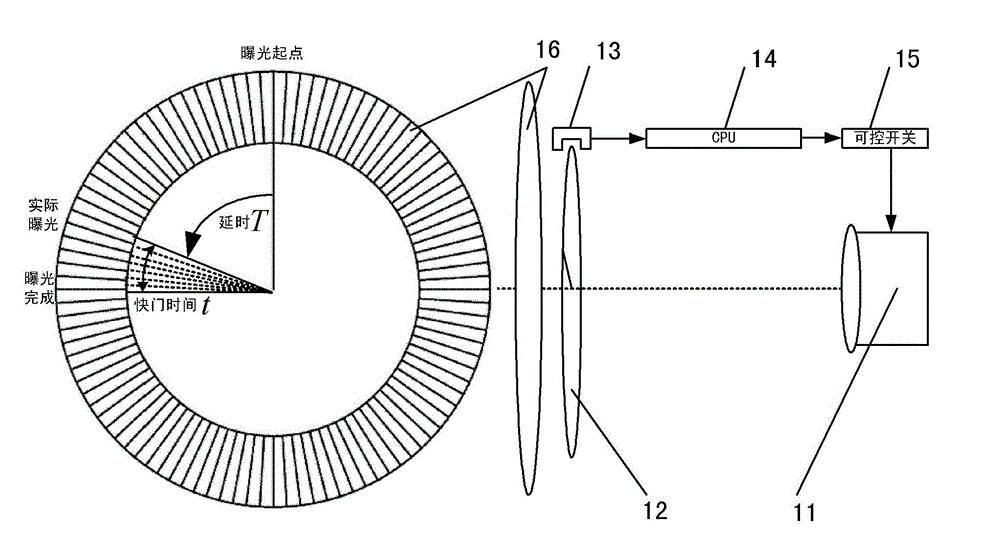

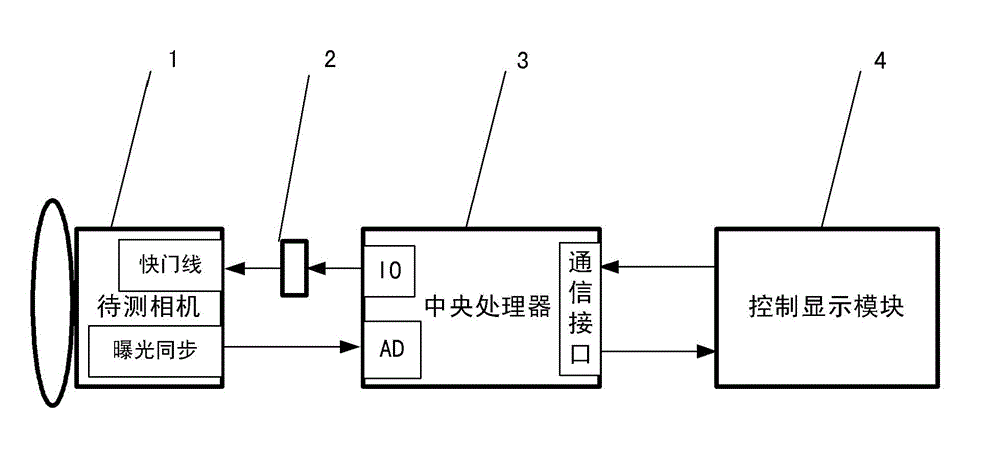

Improved shutter delay measurement system

InactiveCN103336405ANo manual reading requiredMeet the requirements of measurement accuracyPhotographyShootComputer module

The invention relates to an improved shutter delay measurement system which is characterized by comprising a to-be-measured camera, a controllable switch, a central processing unit and a control display module, wherein the central processing unit comprises an analog-to-digital converter and a counter; the controllable switch is positioned between a shutter release of the to-be-measured camera and a central processing unit; the central processing unit is connected with the control display module; the analog-to-digital converter is connected with an exposure synchronous signal end of the to-be-measured camera; the control display module gives a shooting instruction; after receiving the instruction of the control display module, the central processing unit controls the controllable switch to allow the to-be-measured camera to shoot; the counter is started at the moment; a synchronous signal is fed back to the central processing unit after the to-be-measured camera shoots; the counter stops counting at the moment, and transmits a count value to the control display module for processing and displaying; the delay and shutter time of each to-be-measured camera can be measured according to the count value; and the count frequency can be changed by changing a count cycle value of the central processing unit through software, that is the measurement precision of a camera shutter is changed.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

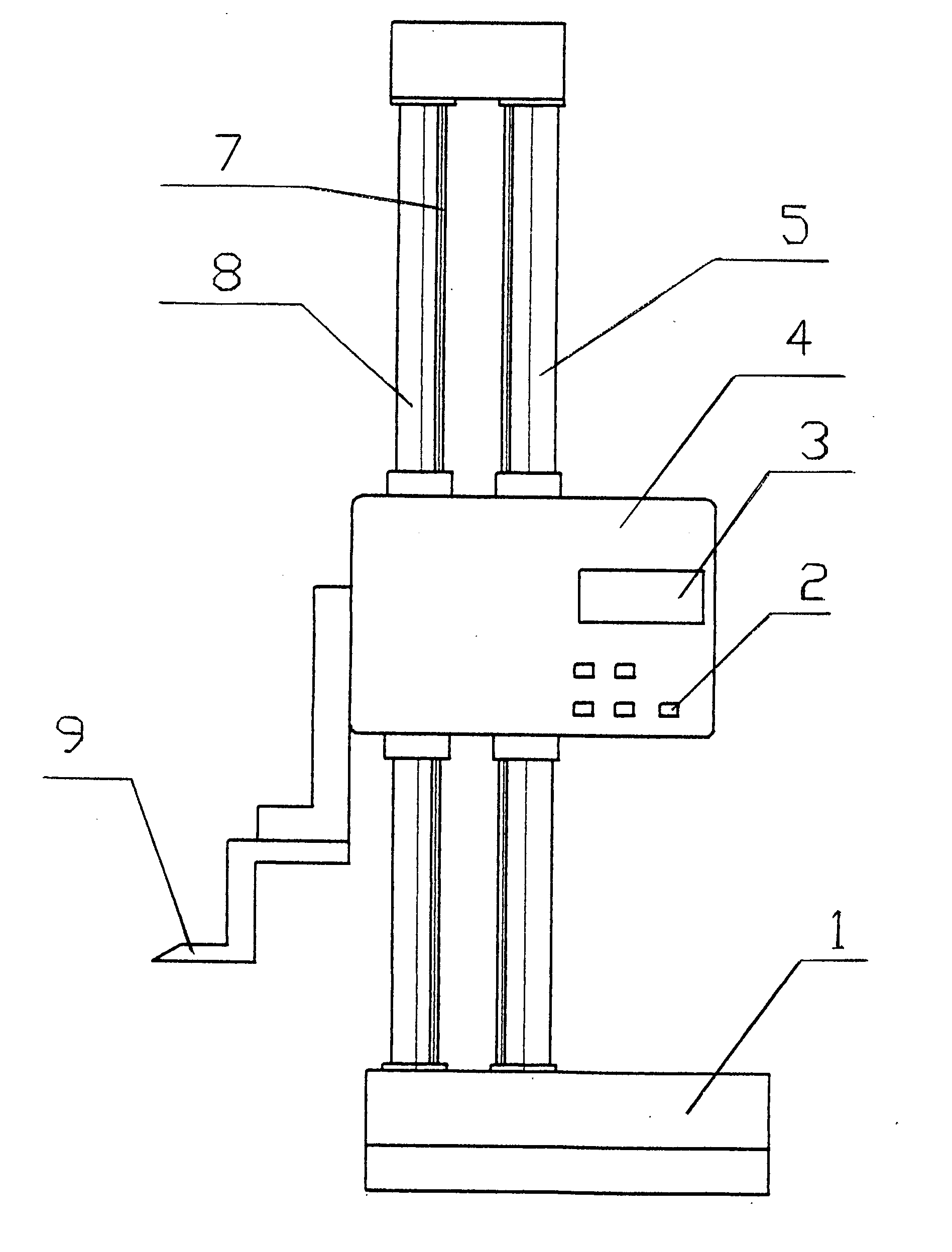

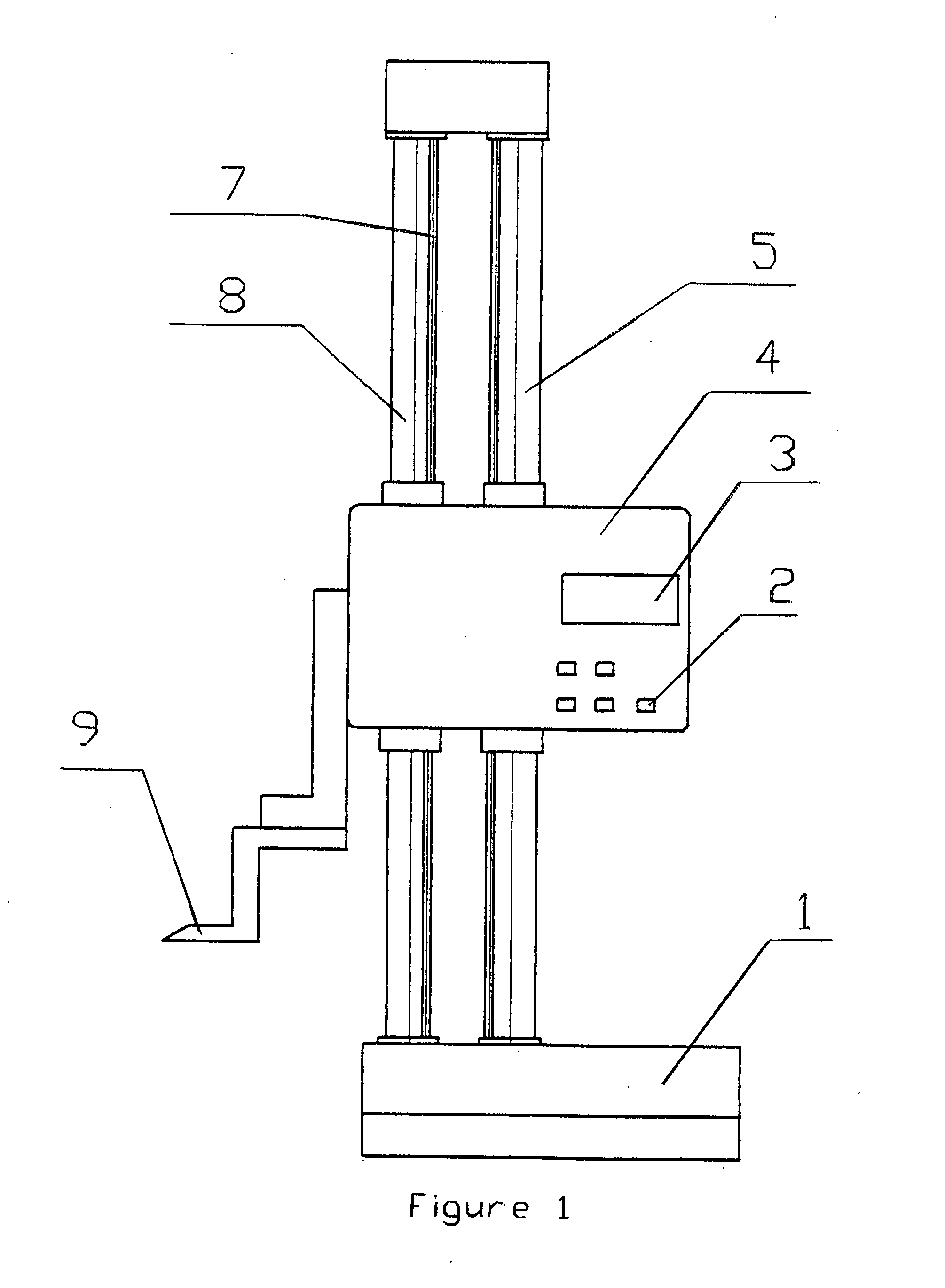

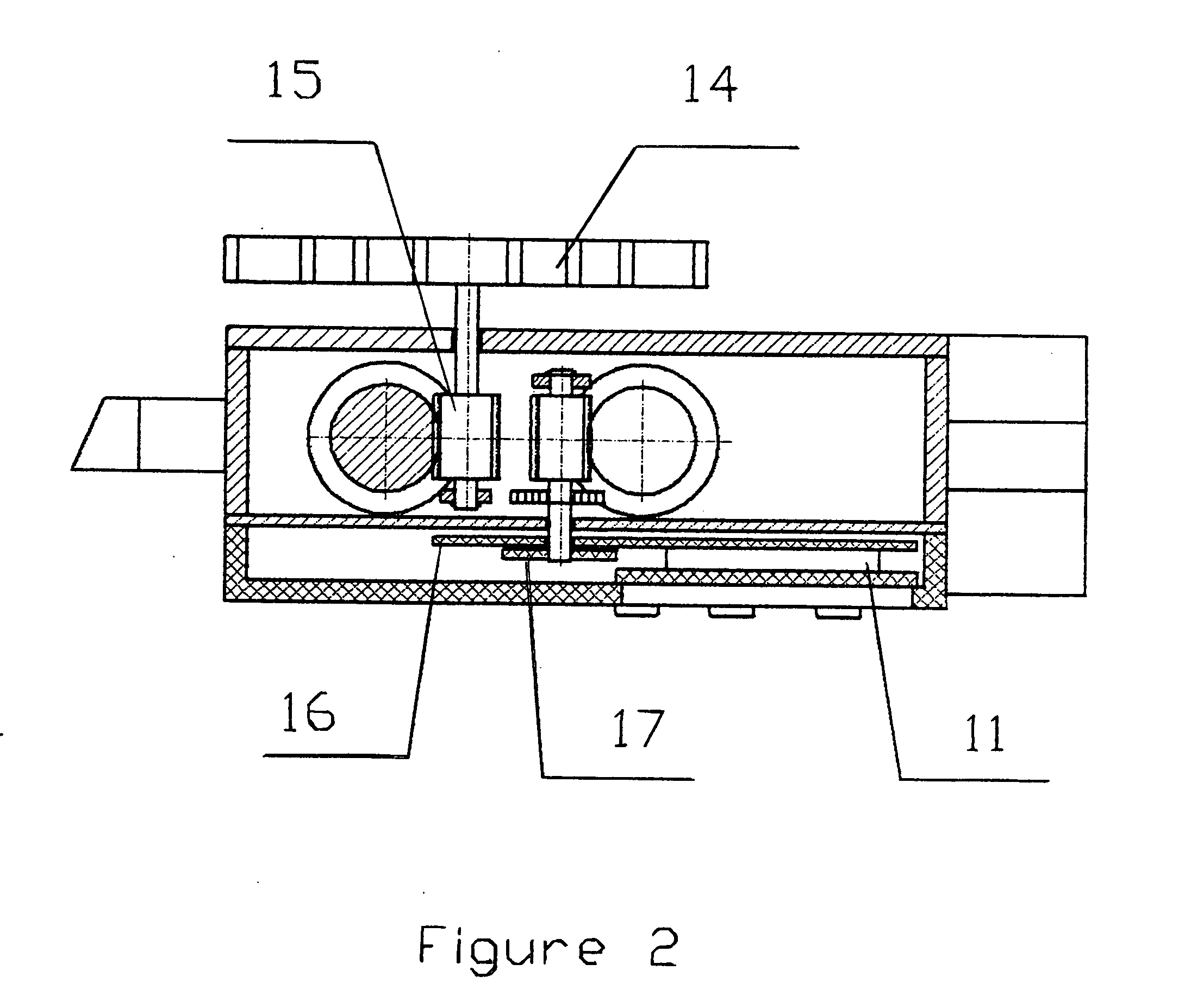

Linear moving capacitive sensor twin column electronic height gauge

InactiveUS20060137204A1Low costReduced measurement accuracyFeeler-pin gaugesUsing electrical meansOn columnEngineering

The present invention is an electronic height gauge utilizing new technology and includes a first column (Column 1) and a second column (Column 2), a display unit with a cover, a measuring scriber, a fixed capacitance sensor and a linear moving capacitance sensor. The fixed capacitance sensor is located on a flat surface on Column 1, flat surface having a length equivalent to the length of Column 1. The linear moving capacitance sensor is located inside the display unit cover positioned to face the fixed capacitance sensor. The fixed capacitive sensor and linear moving capacitive sensors are facing toward each other only, and do not make direct physical contact with the fixed capacitor sensor when the height gauge is operating in upward and downward movements. The fixed and moving capacitive sensors are instead making only electrical contact with each other when the height gauge is making upward and downward movements. This linear direct data non-contact sensor transfer system results in high accuracy of measurements, which also ensures the repeatability of accurate measurements. Also, since the fixed capacitance sensor and the linear moving capacitance sensor have no physical contact with each other, there is no wear and tear damage on either component part, thereby leading to a longer life of use with stability in accurate measurements and repeatability. Because the measuring system is comparatively simple, and easy to assemble and service and maintain compared to the existing rotary capacitive sensor electronic height gauges that exist on the market, the overall cost of production and maintenance is minimized. On the second column (Column 2), a simple rack and gear system is added. These gears of column 2 are connected to a hand wheel located on the rear of the display unit. The handwheel is used for making upward and downward vertical movements. This rack and gear system of column 2 of the present invention is only used to aid the same in making upward and downward movements, and does not affect the measuring accuracy of the height gauge, as it did in the height gauges that have existed on the market.

Owner:INT PRECISION INSTR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com