Level meter

A technology of liquid level gauge and liquid level height, which is applied in the field of liquid level gauge, can solve the problems such as the inability to output the electric signal of liquid level height, and achieve the effect of simple structure, improved reading accuracy, and convenient automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

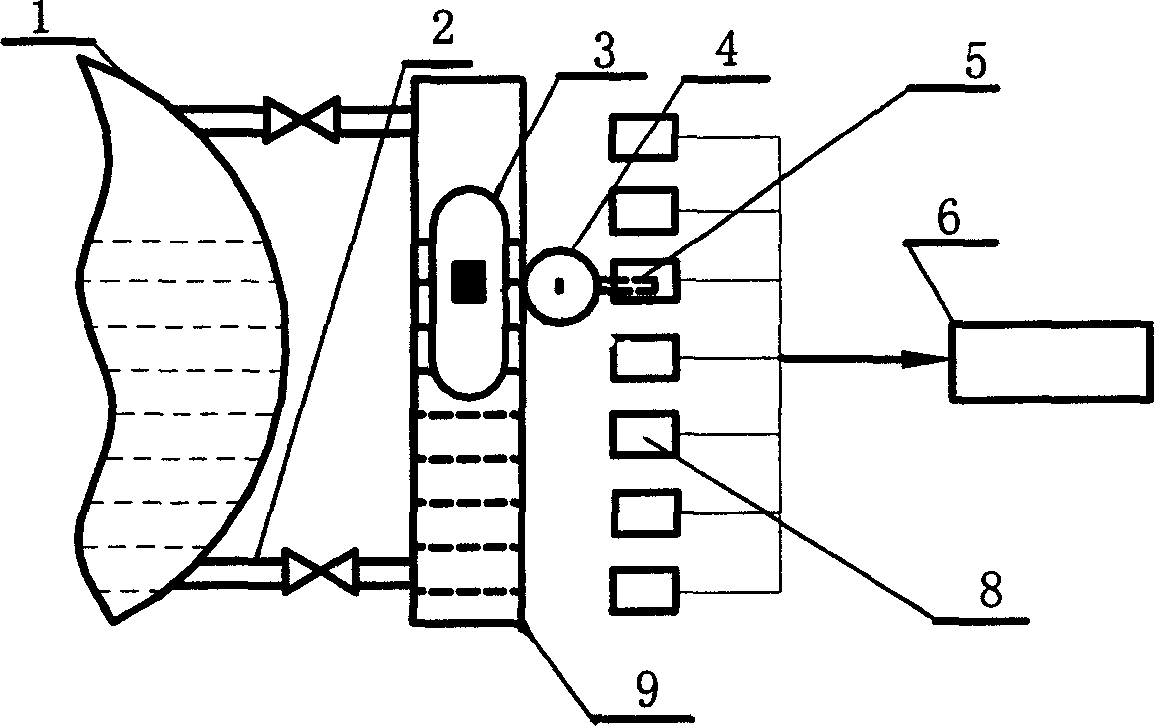

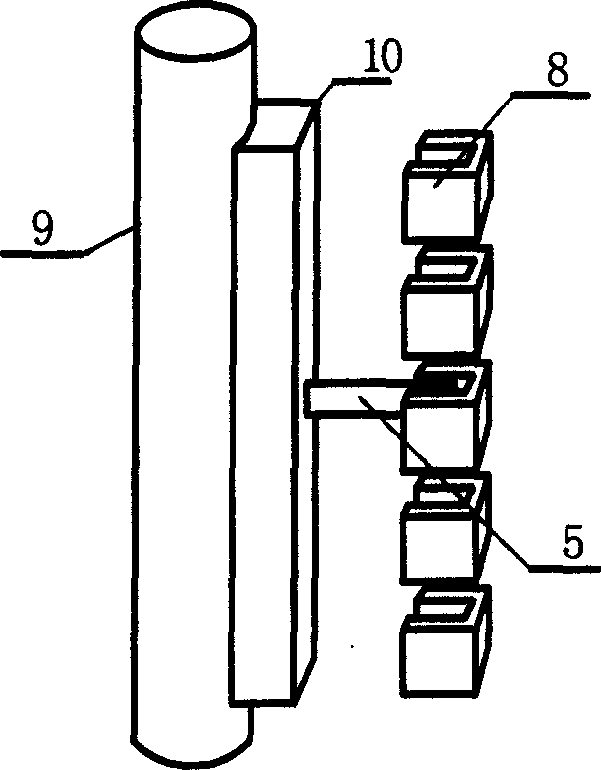

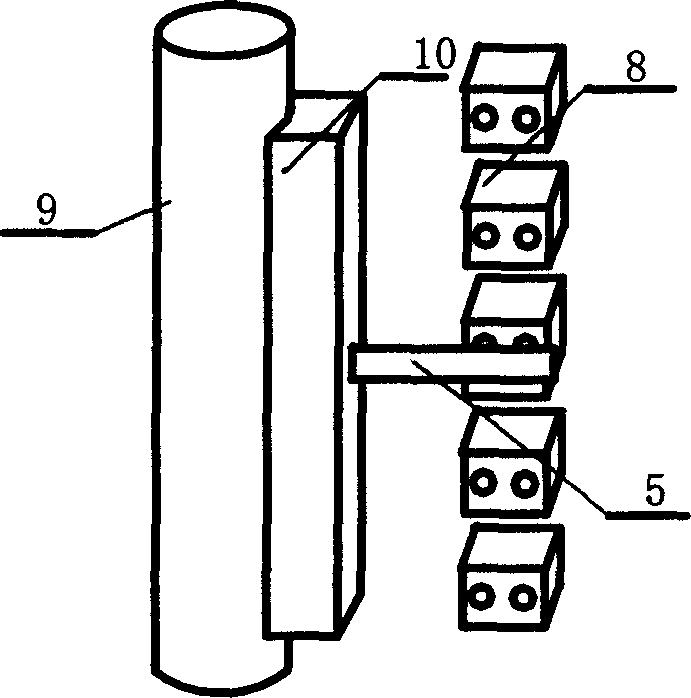

[0023] Such as figure 1 , figure 2 , Figure 4 As shown, the communicator 9 is fixed on the outside of the measured container 1 through the communicating water pipe 2 with a valve. A magnetic float 3 that rises and falls with the liquid level is arranged in the communicating device 9 . The outer wall of the connector 9 is fixed with two vertical guide rails 11. The rollers on both sides of the magnetic trolley 4 are mounted on the two guide rails 11 and can roll along the guide rails. Because the movement resistance is very small, the magnetic float 3 can drive the magnetic trolley through magnetic coupling. 4 Move flexibly along the guide rail. A vernier 5 protruding outwards is fixed on the magnetic tackle 4 . A group of transmissive photoelectric switches 8 are fixed vertically outside the connector 9, and each photoelectric switch is distributed at equal intervals; each photoelectric switch includes a pair of light-emitting diodes 13 and photoelectric receiving device...

Embodiment 2

[0027] Such as figure 2 As shown, in this implementation, the photoelectric switch is a reflective photoelectric switch, and the rest are the same as in Embodiment 1. When the photoelectric switch is not affected by the cursor 5, the photoelectric receiving device 14 does not receive the light signal; The light reflected by the vernier 5 is received by the photoelectric receiving device 14, so that the height of the liquid level in the container at that time can be known.

Embodiment 3

[0029] The signal processing module diagram of the photoelectric receiving device in the control unit in this embodiment is as follows Figure 7 As shown, no light-emitting diode scanning drive module is provided, and the rest are the same as in Embodiment 1. The control unit 6 includes a CPU, a photoelectric receiving device scanning drive module 64 and a received signal processing module 63 controlled by the CPU, and a corresponding address is given to each photoelectric switch in the CPU. The light-emitting diodes 13 of the photoelectric switch group are all lit by its drive circuit. When the photoelectric receiving element 14 receives light, it is processed by the received signal processing module 63 . Driven by the photoelectric receiving device scanning driving module 64 , the groups of photoelectric receiving elements 14 send signals to the CPU one by one from bottom to top. When there is no signal at the address, the outputs are all high level; when there is a signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com