High-strength plane repairing equipment

A high-strength, flat technology, applied in road repair, roads, roads, etc., can solve the problems of poor flat sealing and easy cracks, etc., and achieve the effects of strong flat waterproof, fast repair, and avoid thermal expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

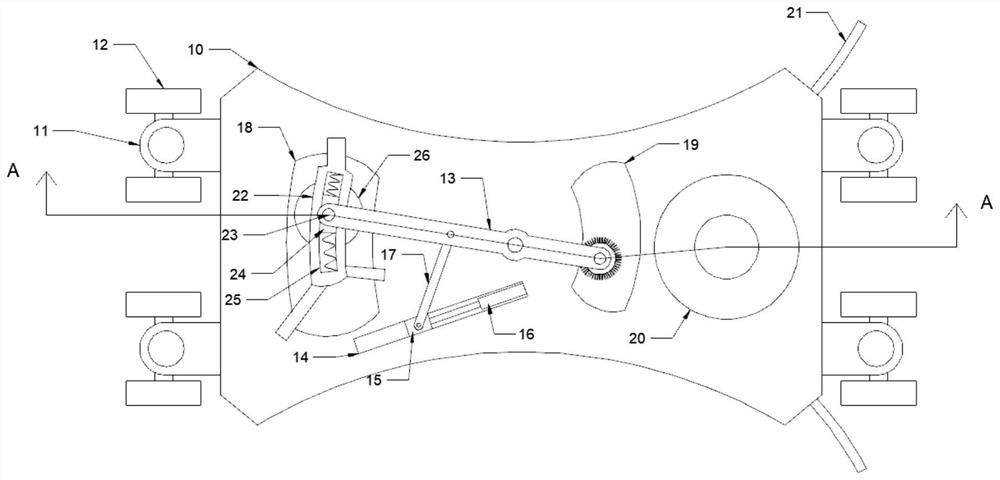

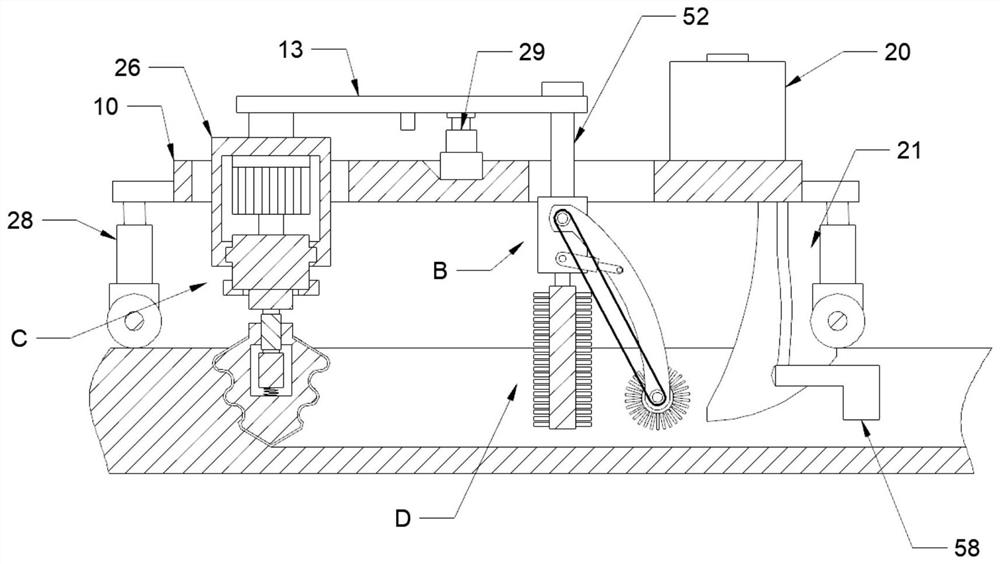

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

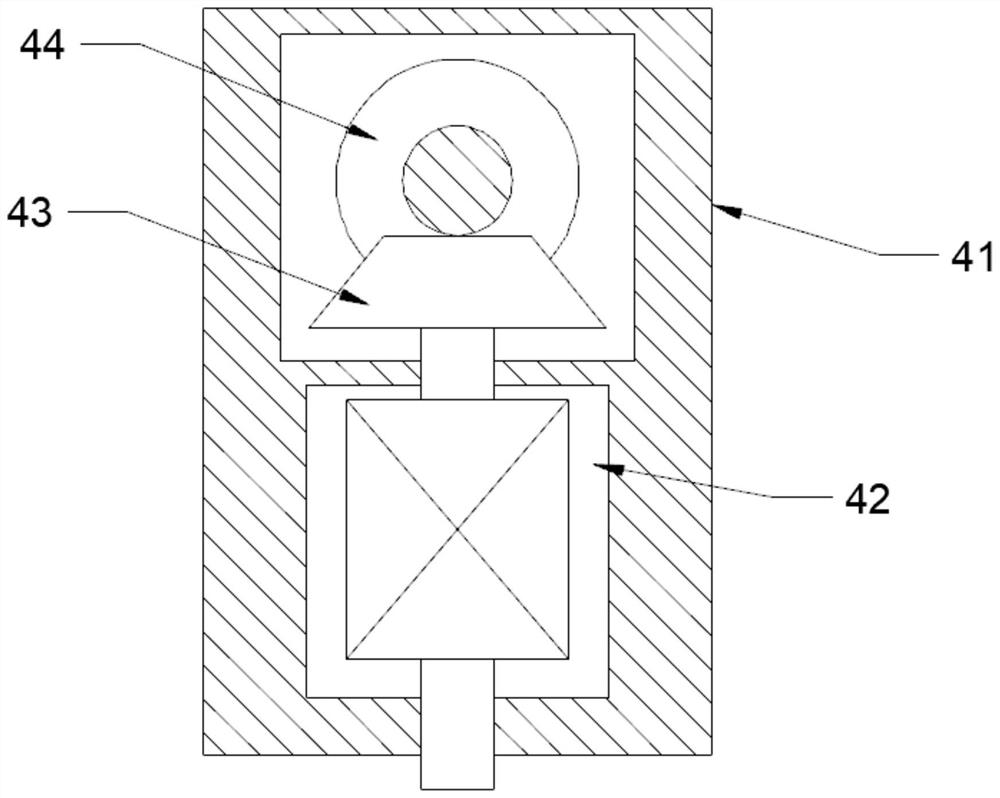

[0024] A high-strength plane repairing device described in conjunction with accompanying drawings 1-5 includes a base plate 10, the front side of the base plate 10 is provided with a first swinging groove 18 that is transparent up and down, and the rear side of the base plate 10 is provided with The upper and lower transparent second swing grooves 19, the front and rear of the base plate 10 are respectively equipped with fixed rods 11, the lower side of the fixed rod 11 is provided with an adjustable telescopic rod 28, and the lower side of the adjustable telescopic rod 28 is equipped with a roller 12, A central telescopic rod 29 is installed in the middle of the upper side of the base plate 10. A swing rod 13 is provided for the axis rotation of the central telescopic rod 29. A power housing 26 is provided on the lower side of the front side of the swing rod 13. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com