Special centrifugal casting machine for large-scale bearing bush babbitting

A technology of centrifugal casting and bearing pads, which is applied in the field of centrifugal pouring machines dedicated to large bearing pad castings. It can solve the problems of reduced production efficiency, easy slippage, and poor centering ability, so as to improve product quality and production efficiency, and increase equipment carrying capacity. , to avoid the effect of thermal expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

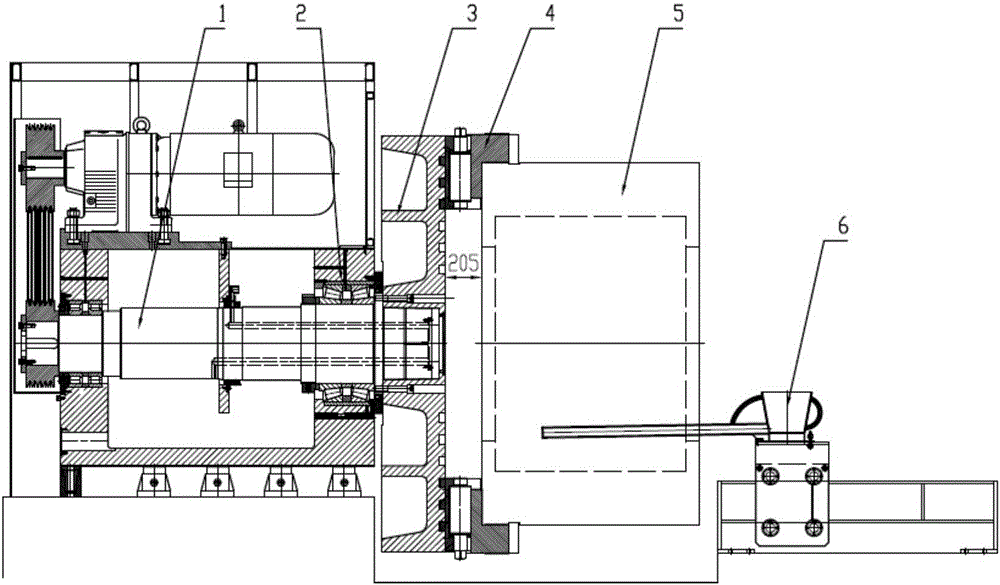

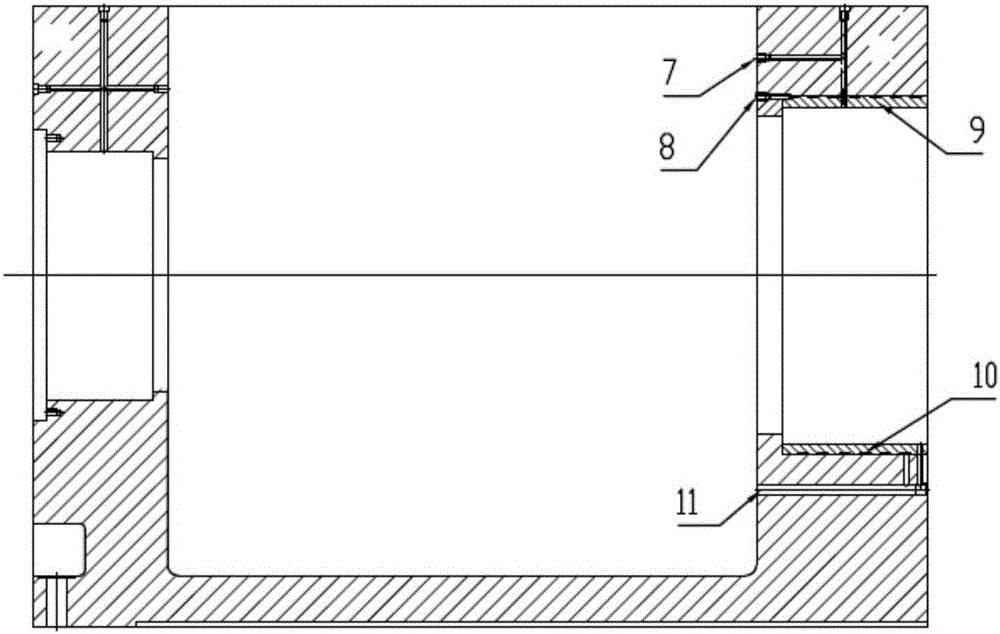

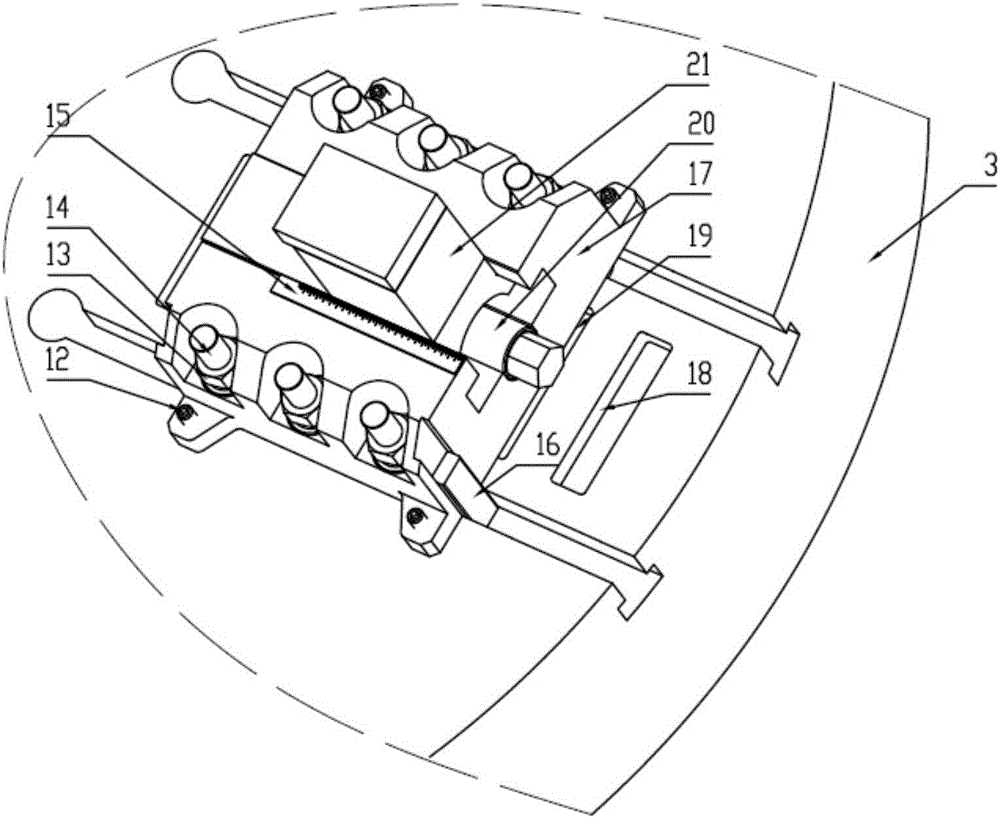

[0023] A special centrifugal casting machine for large-scale bearing bush pouring, such as figure 1 As shown, it includes: spindle 1, box body 2, chuck 3, jaw assembly 4, workpiece 5, casting system 6, etc., wherein:

[0024] The reducer is connected to the main shaft 1 through the pulley, the main shaft 1 is installed in the box body 2 through the bearing, the main shaft 1 passes through the box body 2 and connects with the chuck 3, and the chuck 3 is provided with a jaw assembly 4 for clamping the workpiece 5 ; The casting groove of the casting system 6 extends into the cavity of the workpiece 5 . Spindle 1 is equipped with a cooling circulation oil hole, coupled with circulating cooling oil on the surface of the spindle, the spindle is cooled inside and outside at the same time, achieving the purpose of cooling the spindle.

[0025] There is a certain distance (205mm) between the workpiece 5 and the chuck 3 after installation, and the temperature is transferred to the spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com