Patents

Literature

35results about How to "Realize automatic slag removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible vortex power, automatic-deslagging and backlog-free hydraulic cylinder

InactiveCN105179366APlay the effect of automatic slag removalIncrease forceFluid-pressure actuatorsHydraulic cylinderEngineering

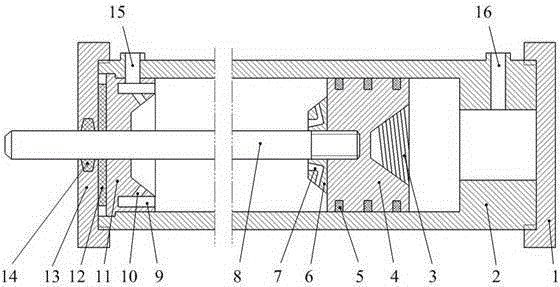

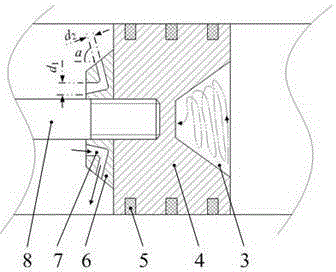

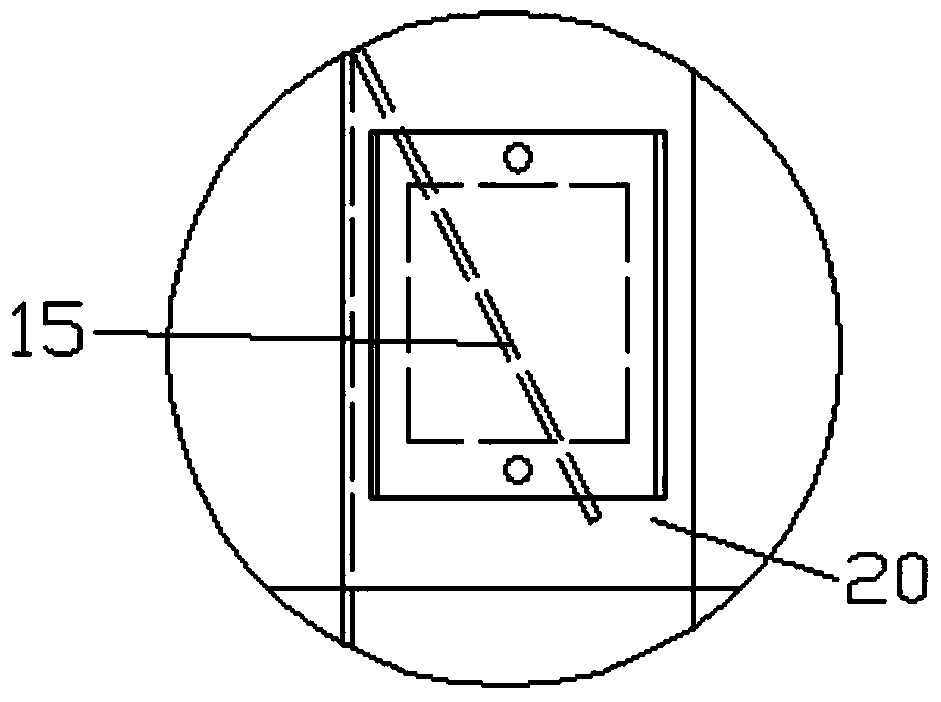

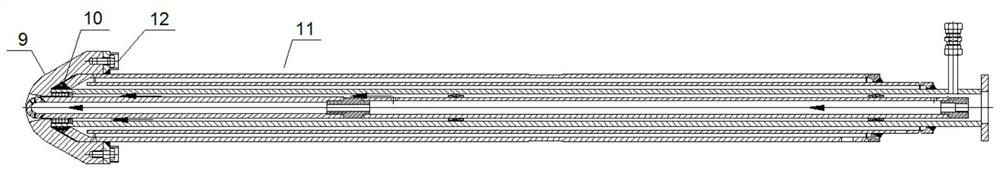

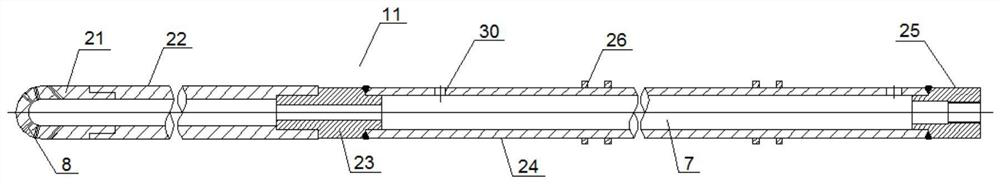

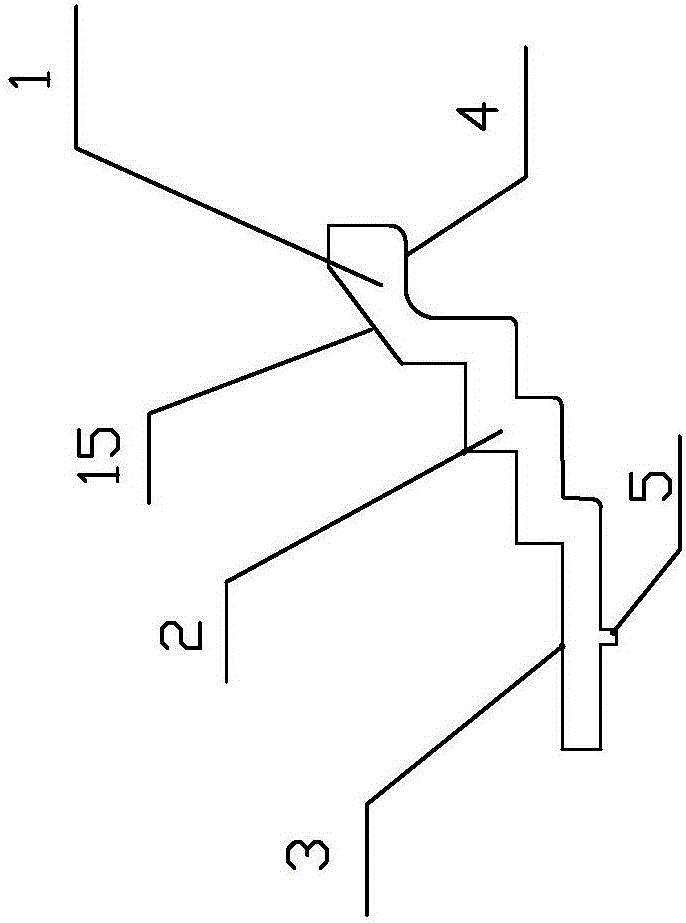

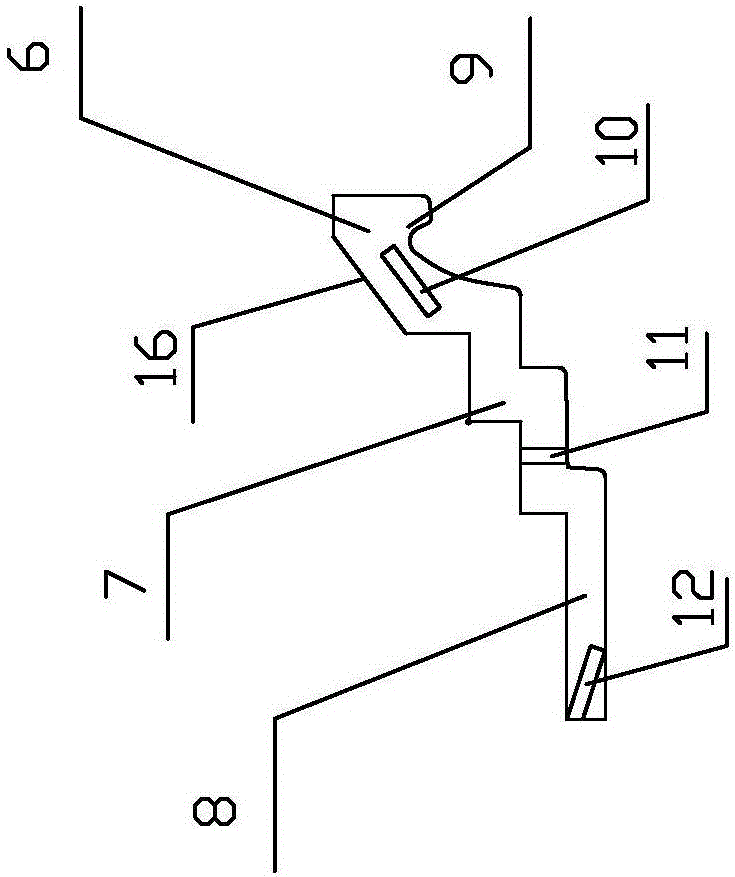

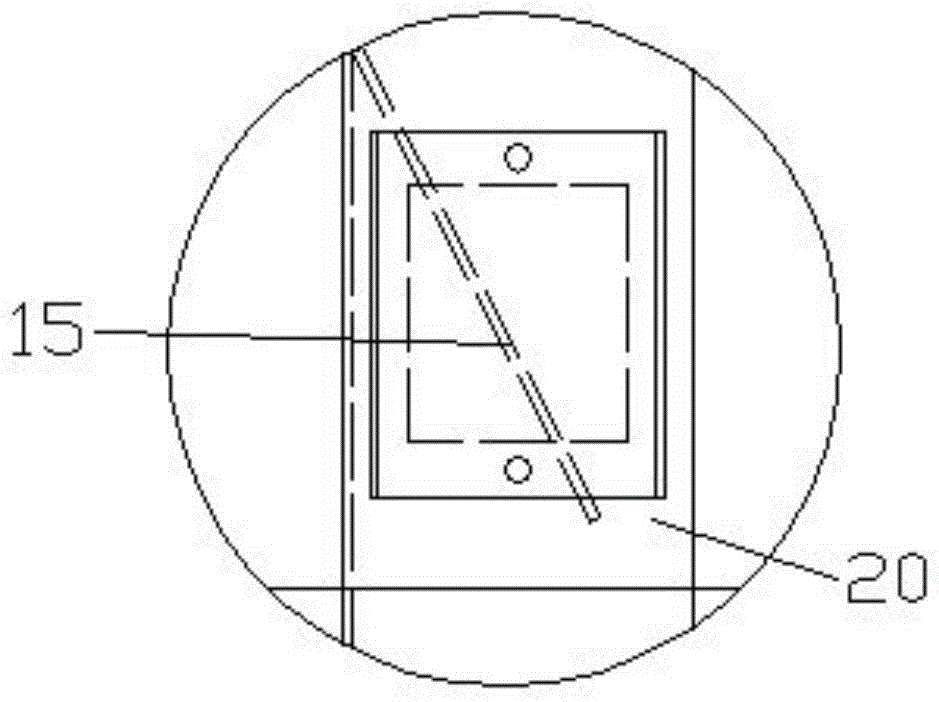

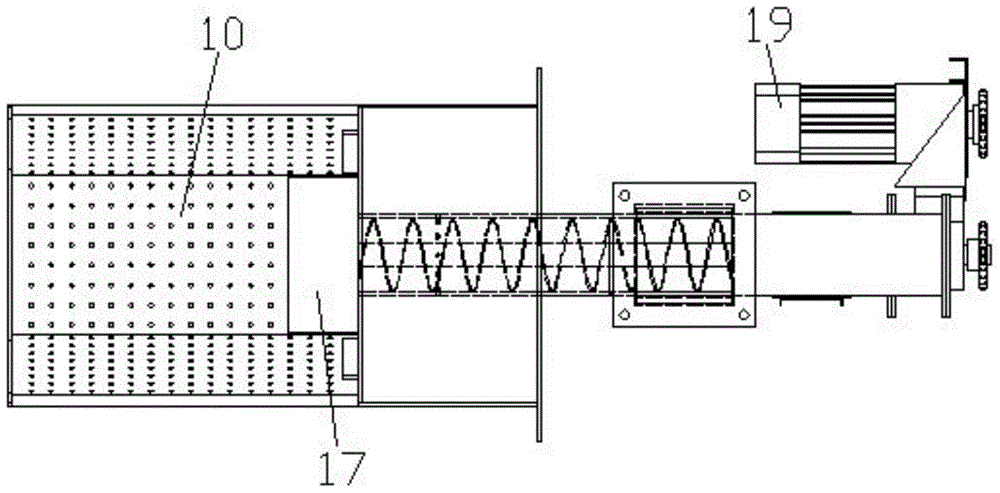

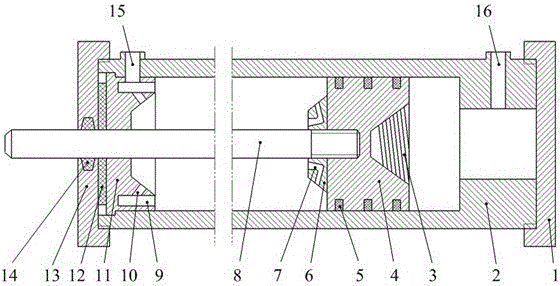

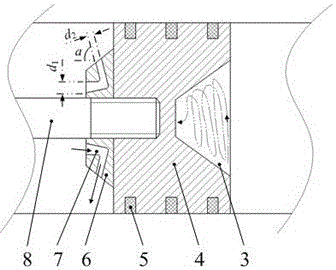

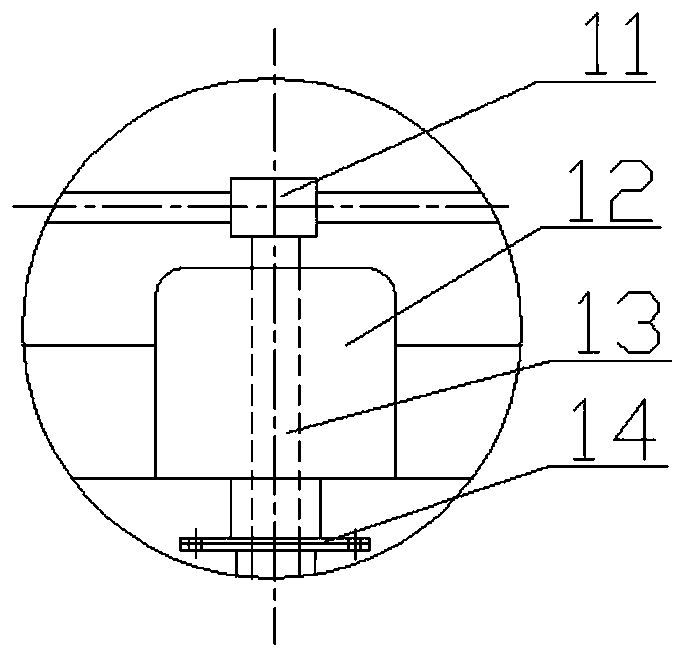

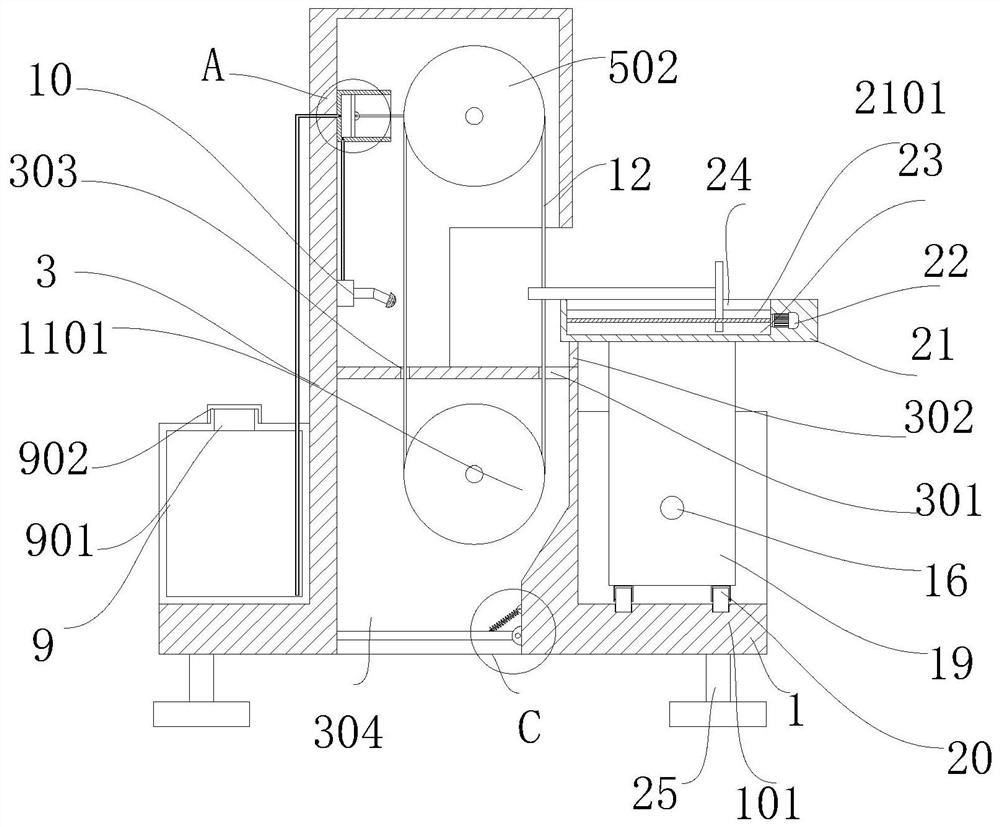

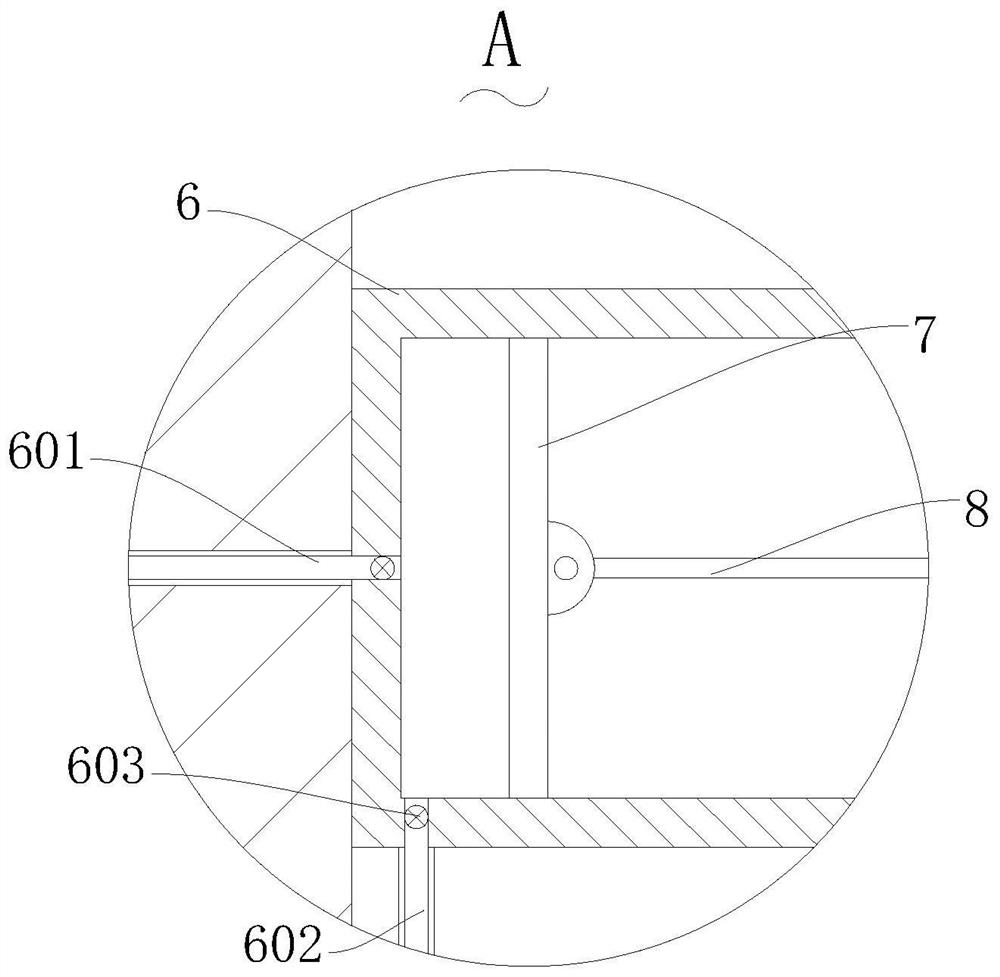

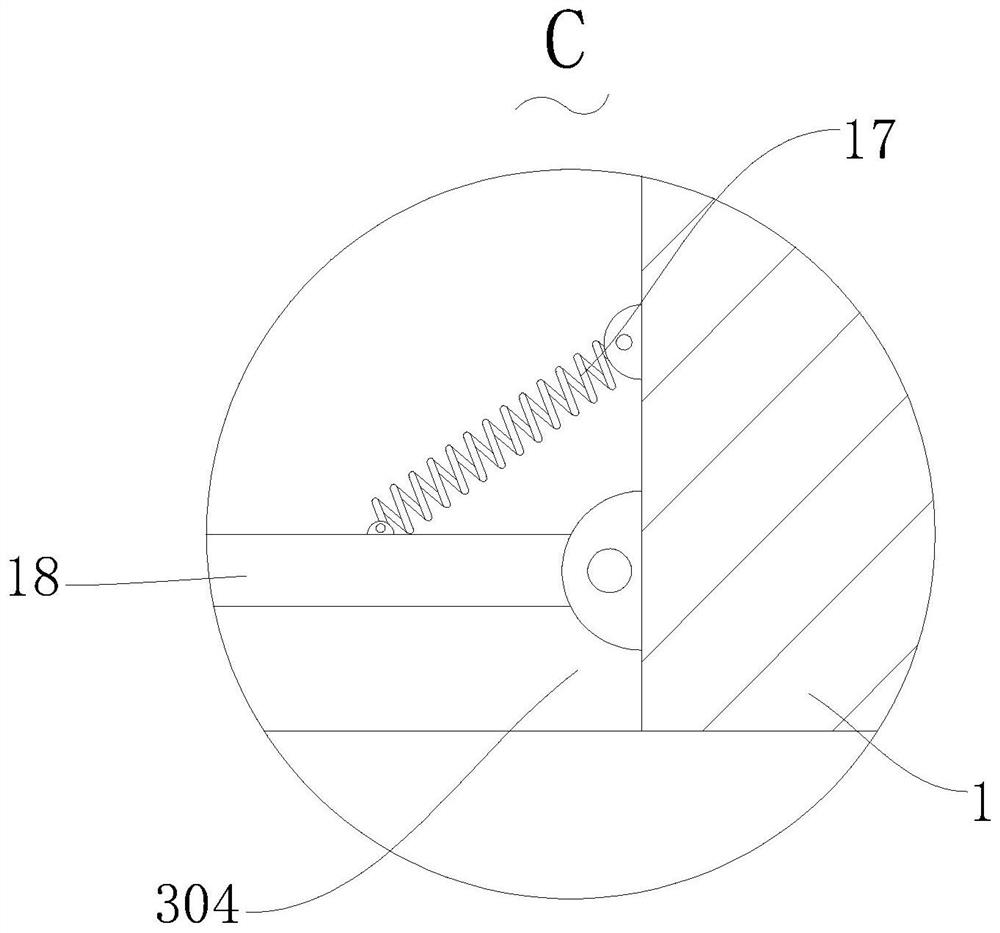

The invention provides a flexible vortex power, automatic-deslagging and backlog-free hydraulic cylinder. The flexible vortex power, automatic-deslagging and backlog-free hydraulic cylinder mainly comprises a cylinder barrel, an end cover A, an end cover B, a piston rod, a piston, a buffering block, a guide sleeve and a buffering pad. The flexible vortex power, automatic-deslagging and backlog-free hydraulic cylinder is characterized in that the piston with a spiral runner plays a role in flexible vortex power, and the buffering block with a deslagging runner plays a role in automatic deslagging. Through a circular truncated cone blind hole with a spiral runner, the flexible vortex boosting power is started when the piston rod extends out and is in a buffering static state when the piston rod draws back. Automatic deslagging is realized through the deslagging runner on the buffering block. A backlog-free buffering static state when the piston rod extends out and accelerating starting when the piston rod draws back are realized through a 45-degree inclining annular oil path in a guide sleeve.

Owner:UNIV OF JINAN

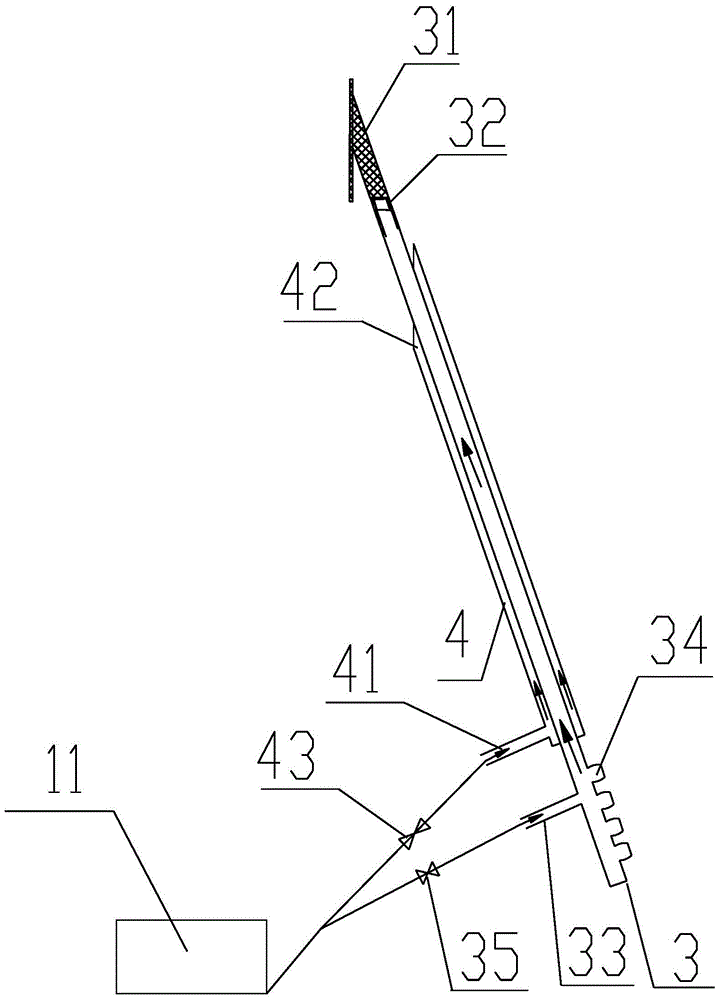

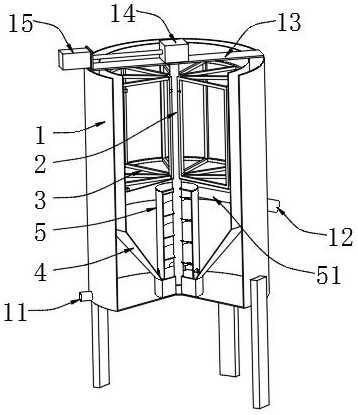

Automatic residue poking method and device for wind distribution plate of biomass circulating fluidized bed boiler

ActiveCN105485672AImprove fluidizationReduce accumulationFluidized bed combustionApparatus for fluidised bed combustionBiomassCirculating fluidized bed boiler

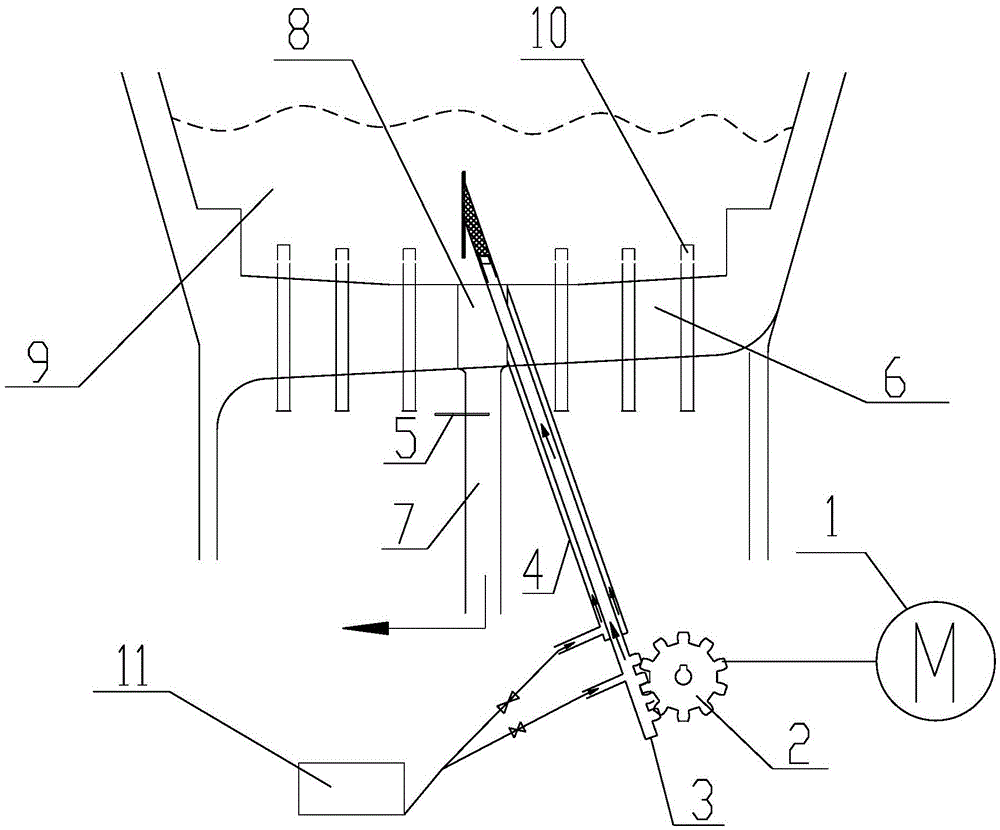

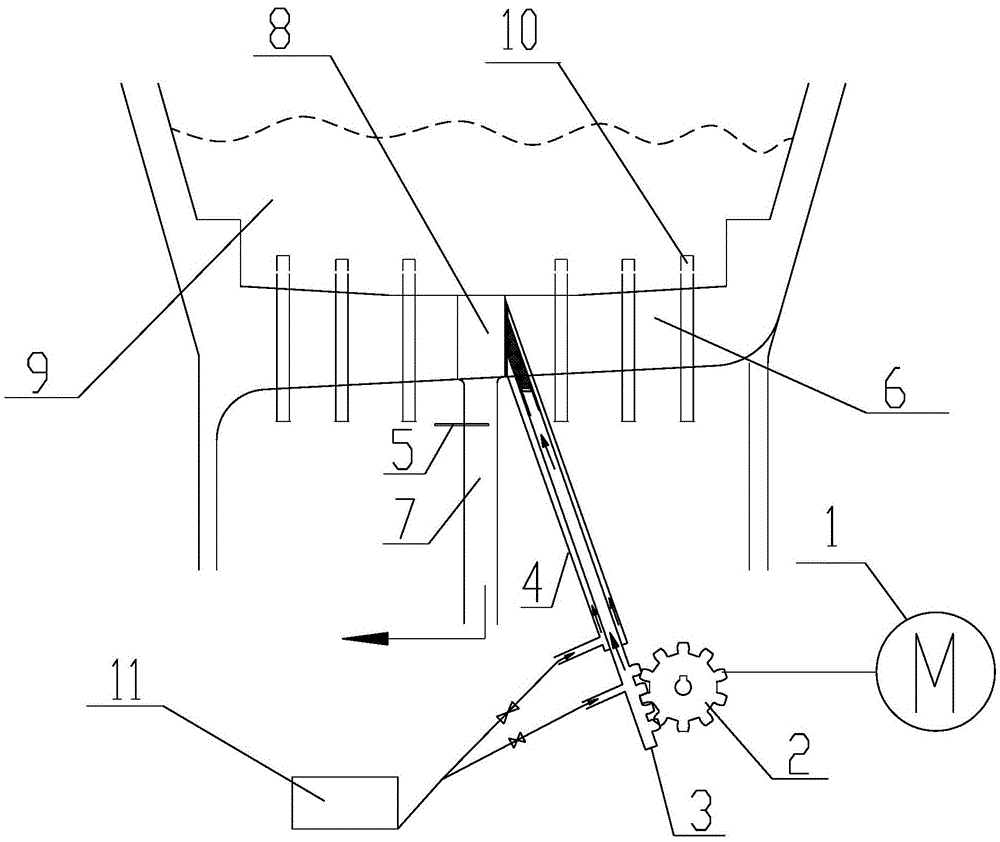

The invention discloses an automatic residue poking method and device for a wind distribution plate of a biomass circulating fluidized bed boiler. According to the technical scheme of the automatic residue poking method and device, an outer sleeve connected with a side wall opening of a residue discharging hole is arranged at the side wall opening of the residue discharging hole of the wind distribution plate and inclines relative to a residue discharging pipe, and a telescopic fluidization wind pipe with a residue poking head and fluidization wind outlets is arranged in an inner cavity of the outer sleeve. When the boiler operates normally, the residue poking head extends into a bed material above the residue discharging hole, and fluidization wind is injected to the periphery of the residue discharging hole through the fluidization wind outlets. When the residues need to be discharged from the boiler, the residue poking head draws back into the inner cavity of the outer sleeve so that the top of the residue poking head can be matched with the side wall opening of the residue discharging hole in a sealed manner. When the residues are blocked in the boiler in the discharging process, the residue poking head stretches out and draws back in the bed material above the residue discharging hole to finish physical stirring, large blocks of residues are broken, and meanwhile ash near the residue discharging hole can be continuously blown by injecting the fluidization wind, so that automatic residue poking is achieved. By the adoption of the automatic residue poking method and device, the defects brought by traditional manual residue poking are effectively overcome.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

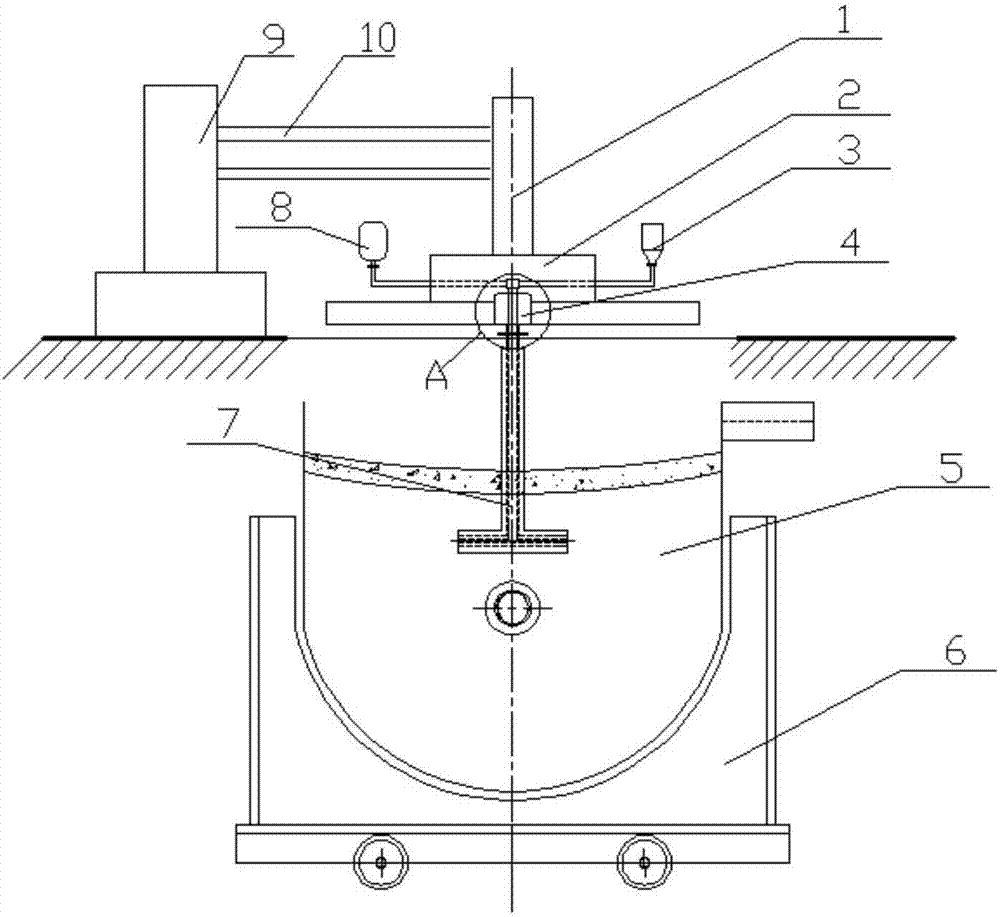

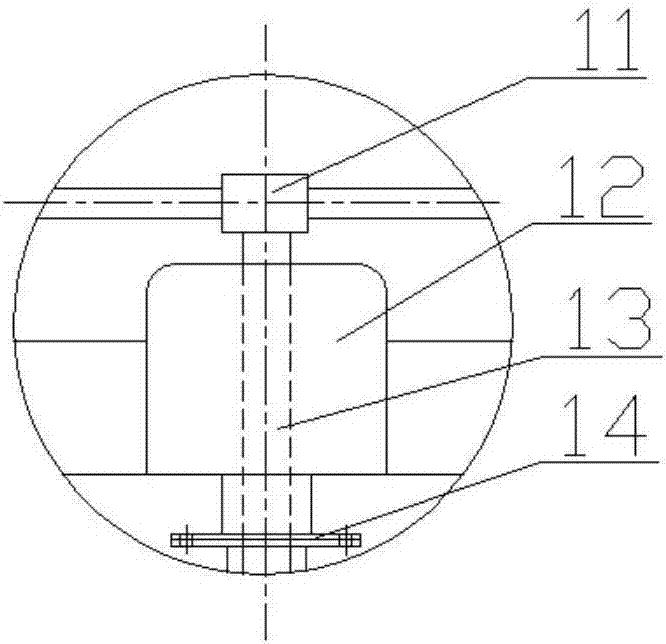

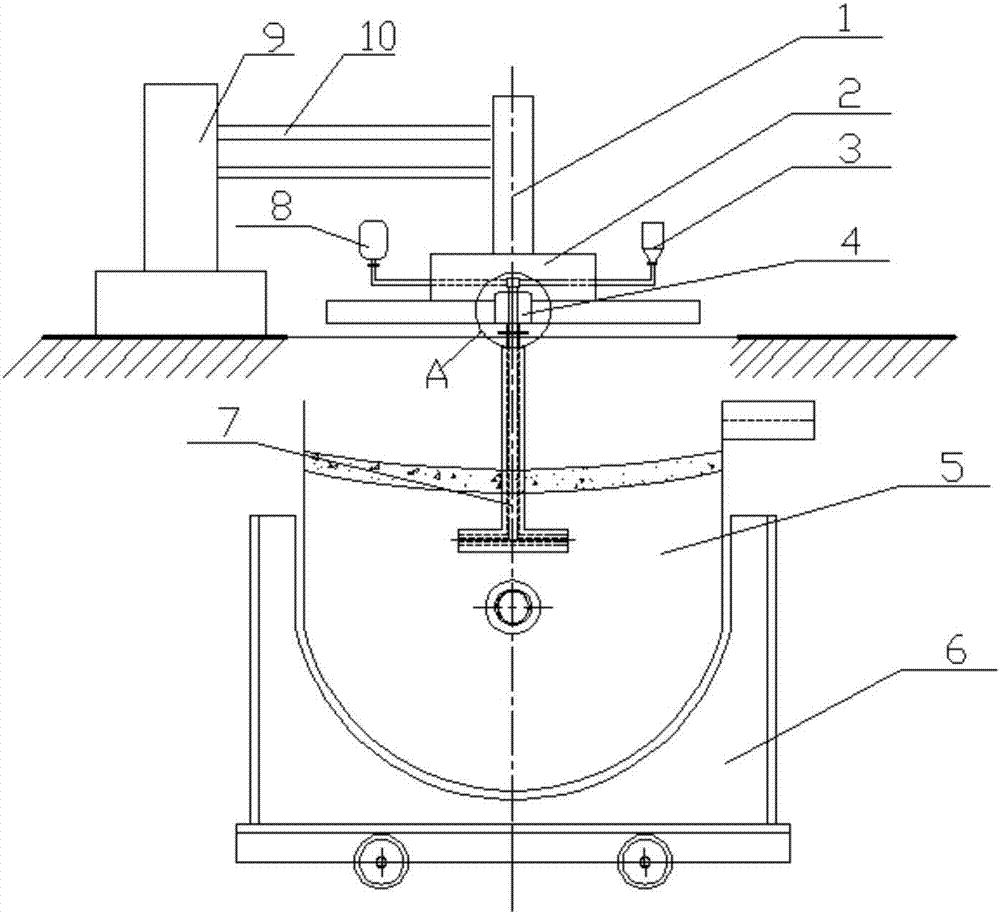

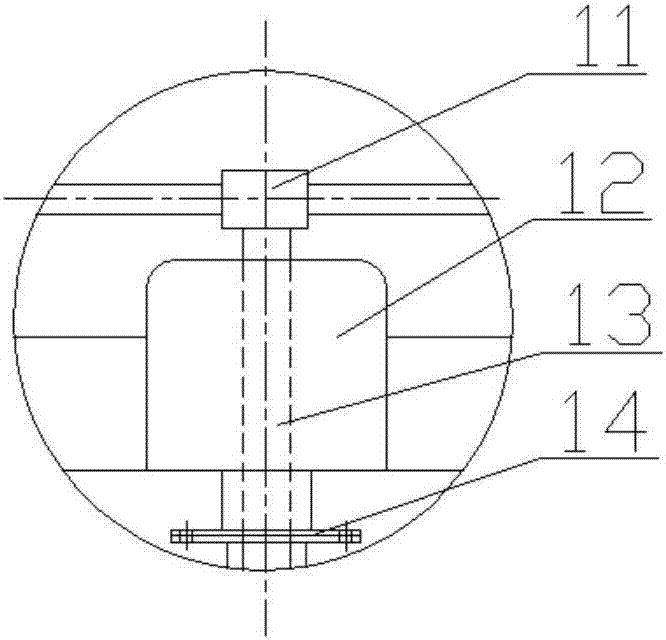

Molten iron dephosphorizing device adopting rotary injection of powder, and dephosphorizing method

The invention discloses a molten iron dephosphorizing device adopting rotary injection of powder, and a dephosphorizing method. Through the molten iron dephosphorizing device adopting rotary injection of powder, a multipoint simultaneous dephosphorizing process can be achieved by using an inverted T-shaped powder gun, and the dynamic conditions of dephosphorization reaction are improved; the dephosphorization rate is improved effectively, and the dephosphorization reaction speed increases; the dephosphorization processing time is shortened, and the investment is low; a feeding system and an injection system can be controlled automatically and adjusted on line; and the powder gun is prevented from being blocked effectively, and automatic deslagging of the powder gun can be achieved.

Owner:ANGANG STEEL CO LTD

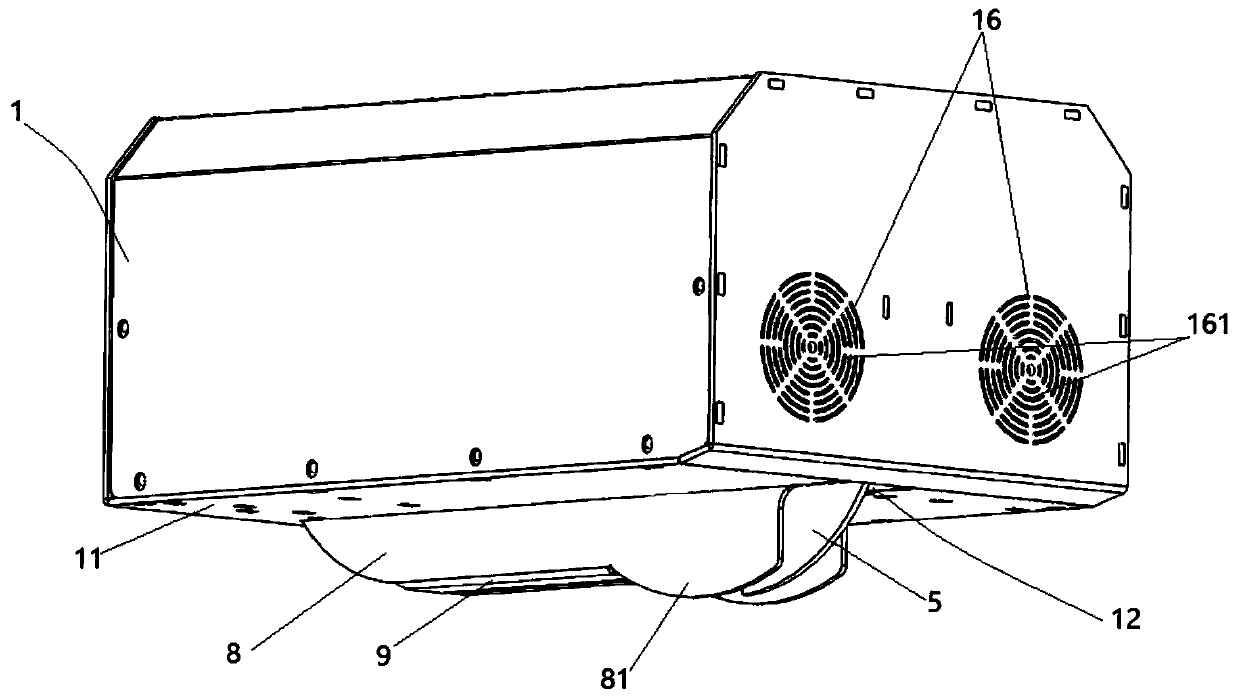

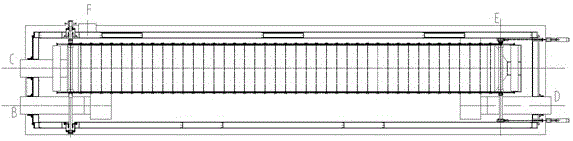

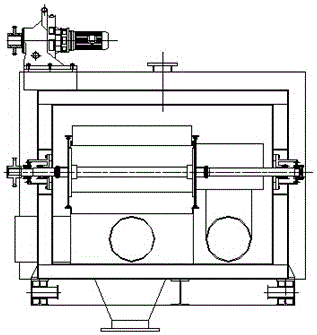

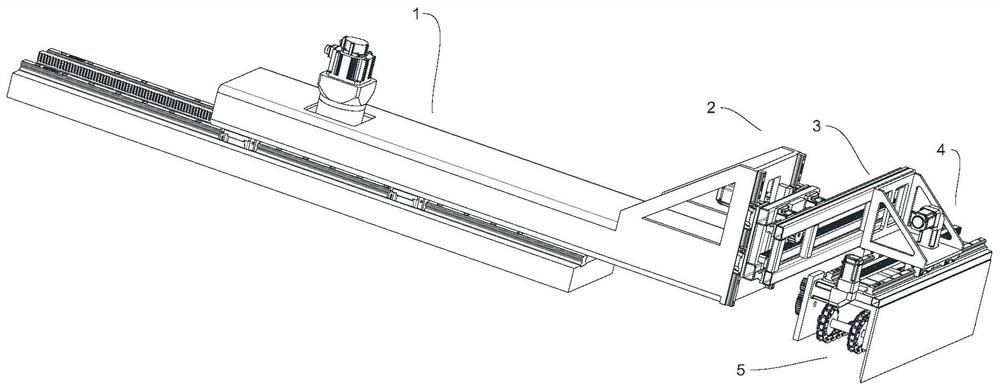

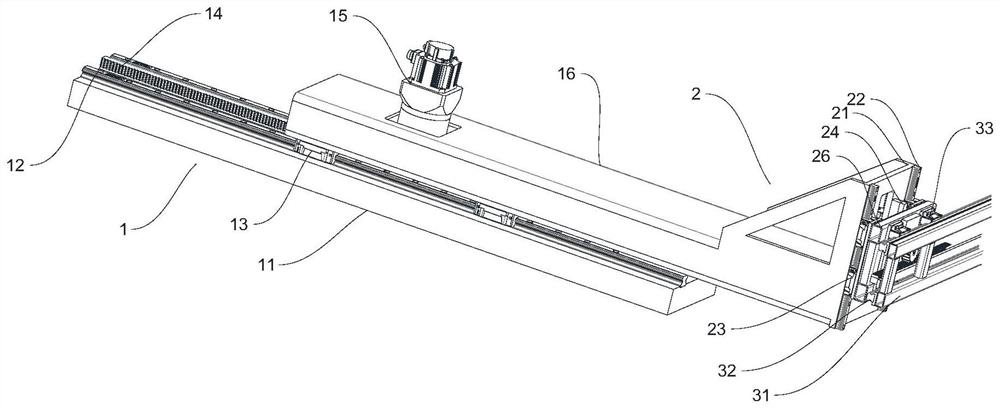

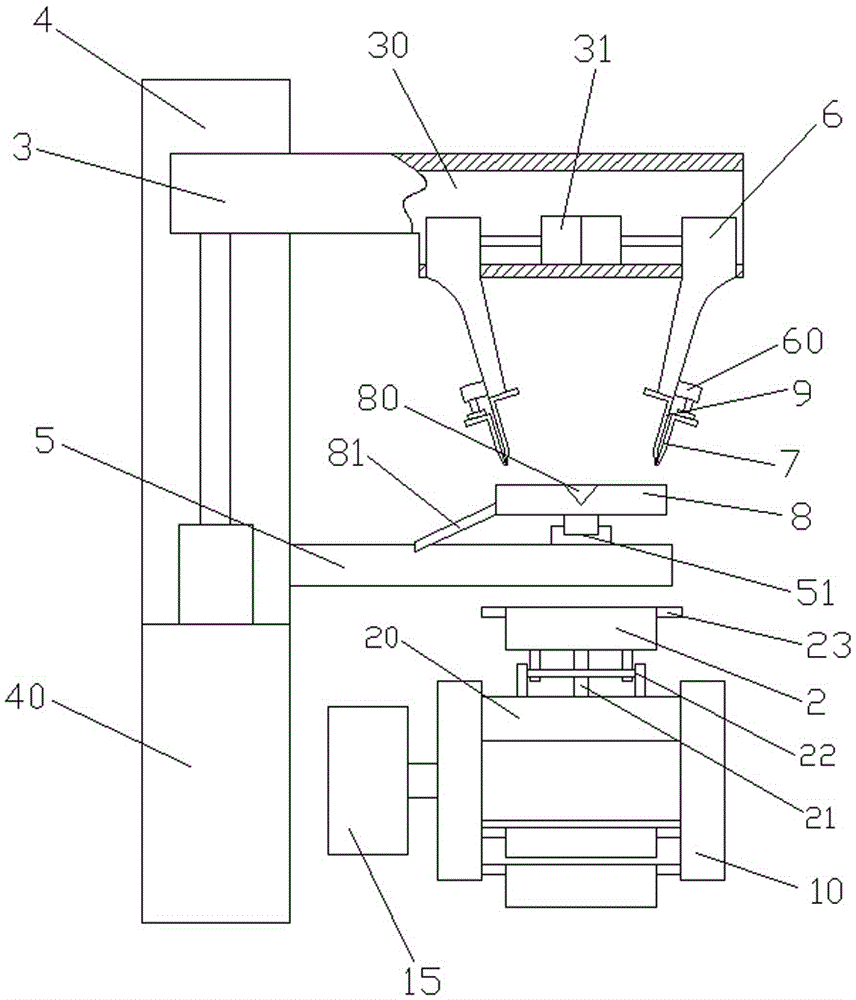

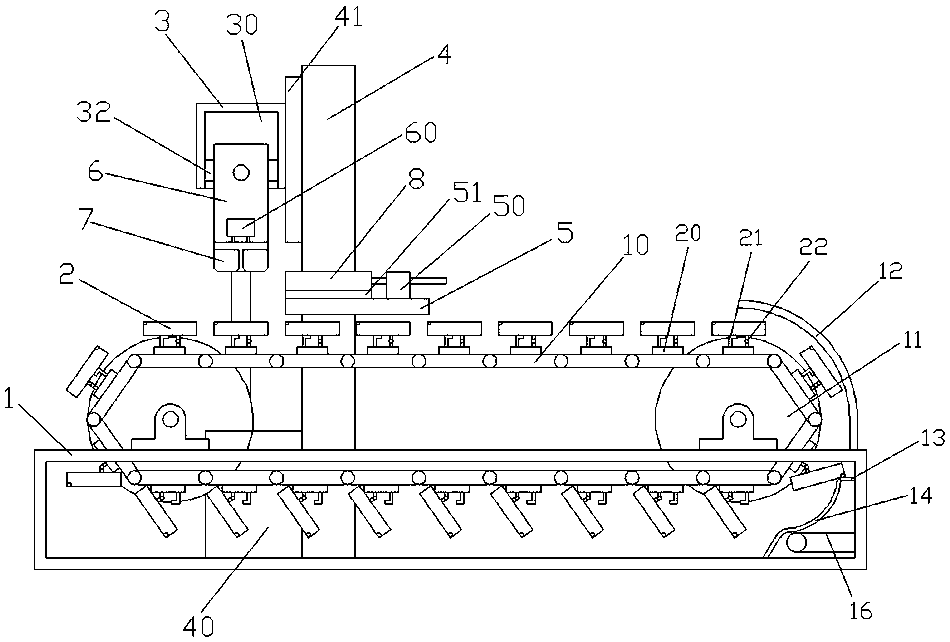

Slag removing machine for sword grid

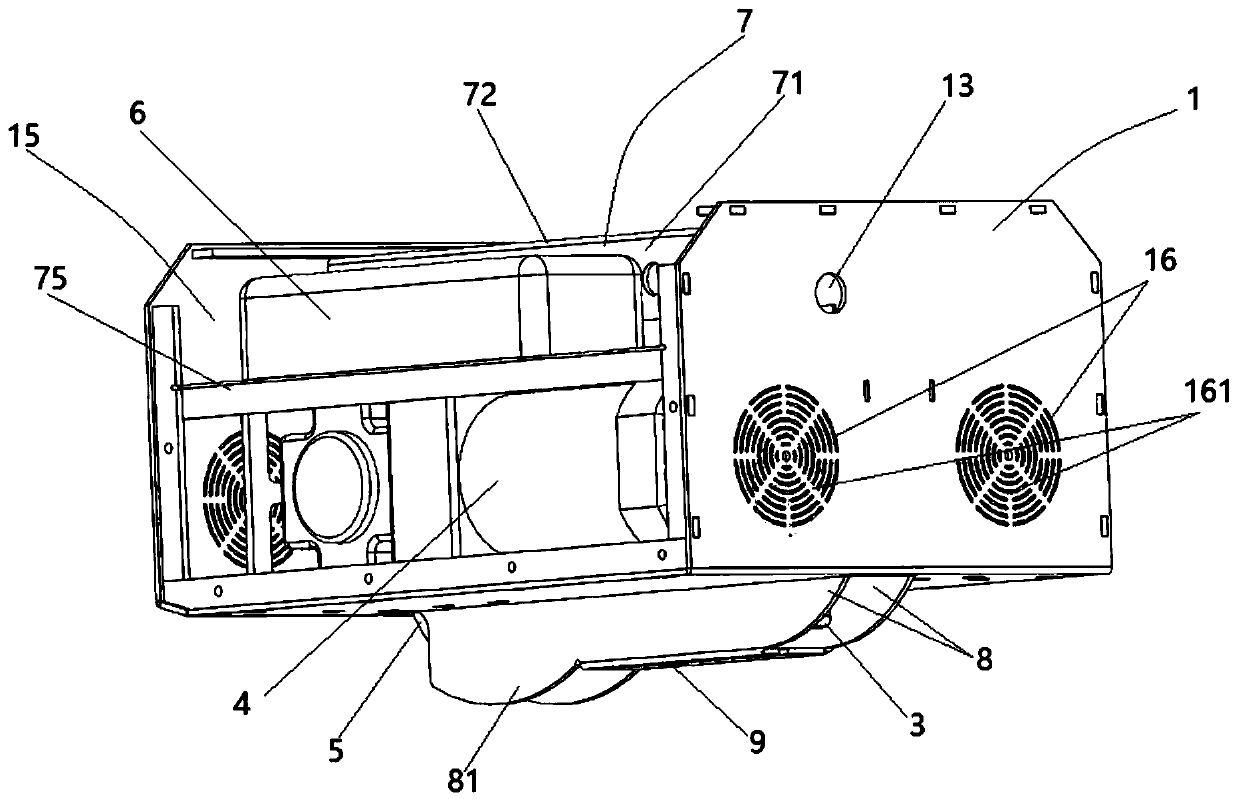

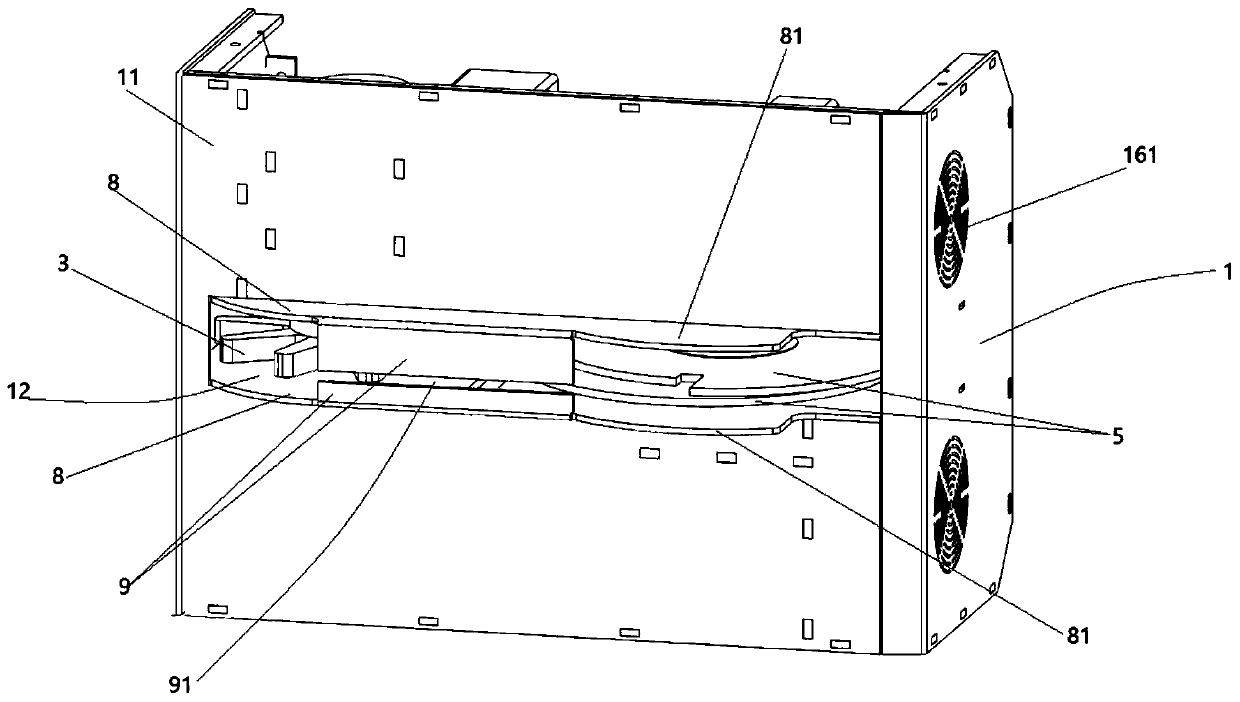

PendingCN110014228AReduce operating labor intensityReduce labor intensityLaser beam welding apparatusSlagDrive motor

The embodiment of the invention discloses a slag removing machine for a sword grid. The slag removing machine comprises a machine enclosure, a driving motor, a driving gear, a slag removing motor, twoslag removing blades, a control box, and a control panel, wherein a strip-type opening is formed in a baseplate of the machine enclosure; a control opening is formed in the upper surface of the machine enclosure; a power supply opening is formed in the side wall of the machine enclosure; the driving motor is arranged on the inner surface of the baseplate; the driving gear is arranged on a drivingshaft in a sleeving manner and is engaged with the tooth surface of a sword grid rack; the slag removing motor is arranged on the inner surface of the baseplate; axle holes are respectively formed inthe two slag removing blades; the two slag removing blades are arranged on an output shaft in a sleeving manner and respectively correspond to the two side walls of the sword grid rack; the control box is arranged at the upper part of the inner side of the machine enclosure and is electrically connected to an external power source through the power supply opening; and the control panel is arranged at the control opening and is in communication connection with the control box. The slag removing machine has low cost, high work efficiency and a relatively reasonable slag removal mode and is easyand simple to handle.

Owner:成都大地机械设备制造有限公司

Molten steel alloying device adopting rotary injection of powder, and alloying method

The invention discloses a molten steel alloying device adopting rotary injection of powder, and an alloying method. According to the molten steel alloying device adopting rotary injection of powder, multipoint simultaneous alloying can be achieved by using an inverted T-shaped powder gun; the rotary injection alloy powder method is used for alloying, the alloying temperature can be reduced, and the alloying time is shortened; the alloy yield is improved effectively, and the alloy elements after alloying are high in uniformity; a feeding system and an injection system can be controlled automatically and adjusted on line; and the powder gun is prevented from being blocked effectively, and automatic deslagging of the powder gun can be achieved.

Owner:ANGANG STEEL CO LTD

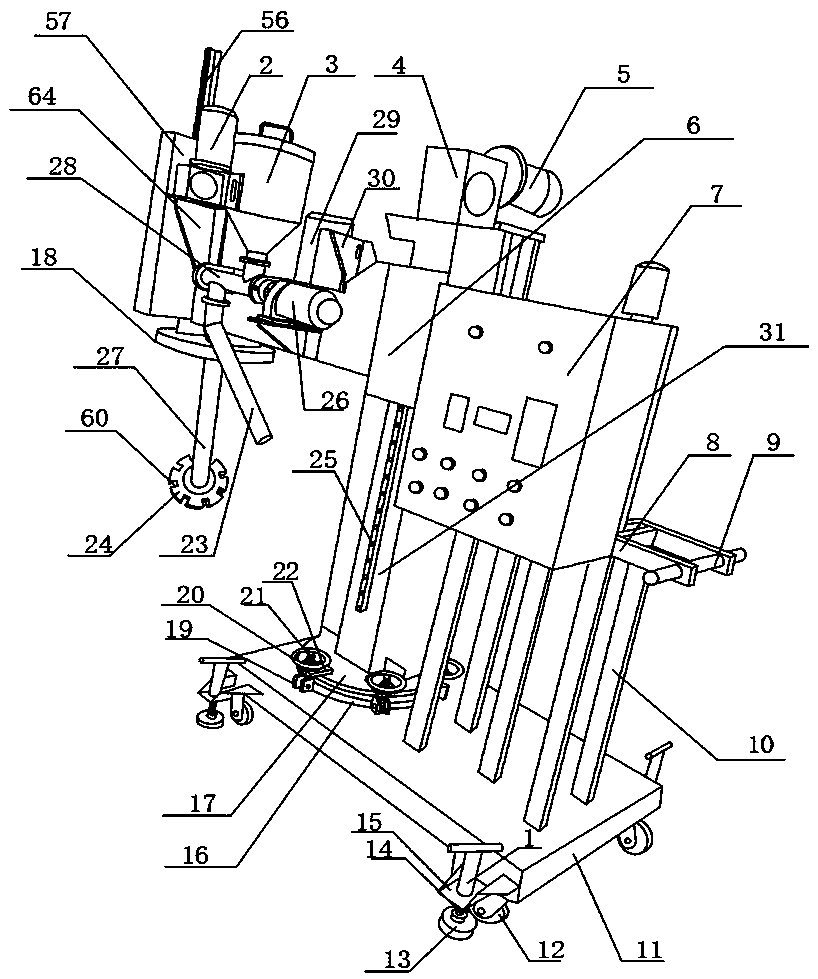

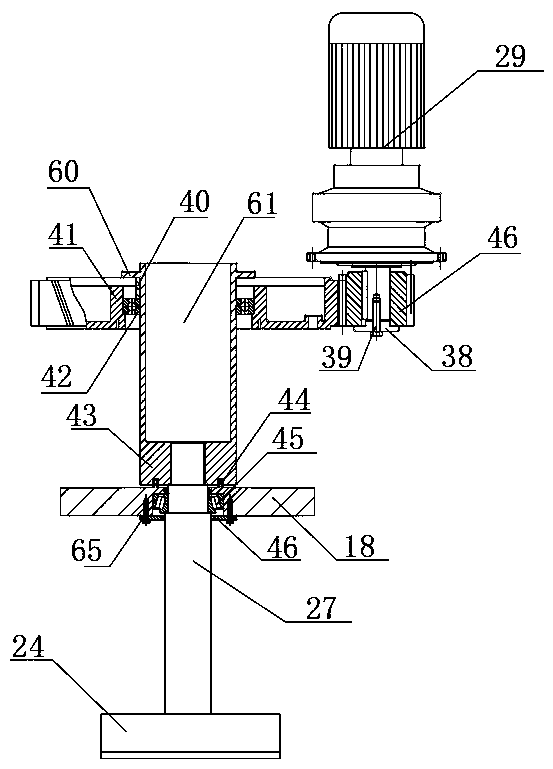

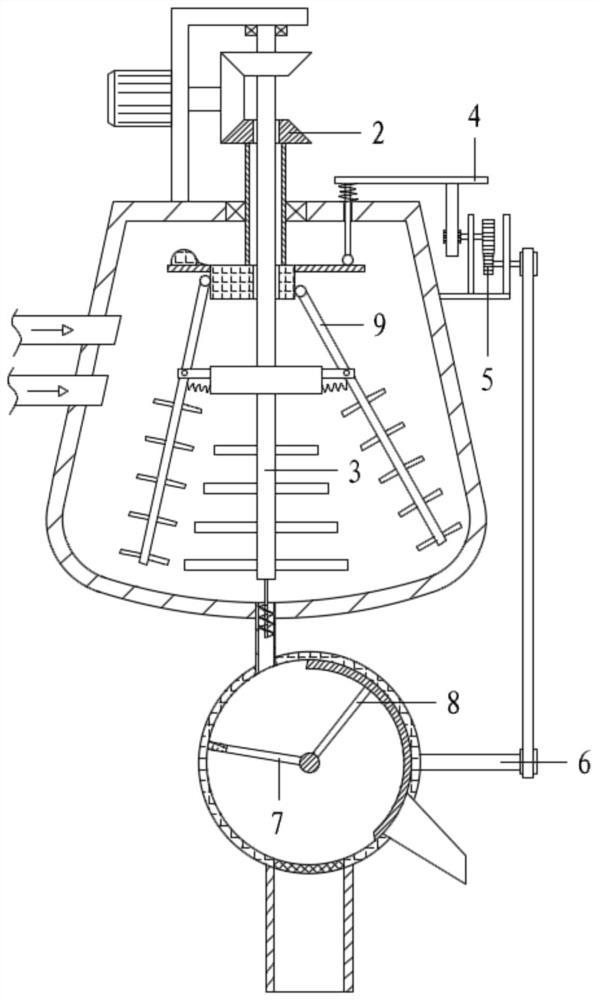

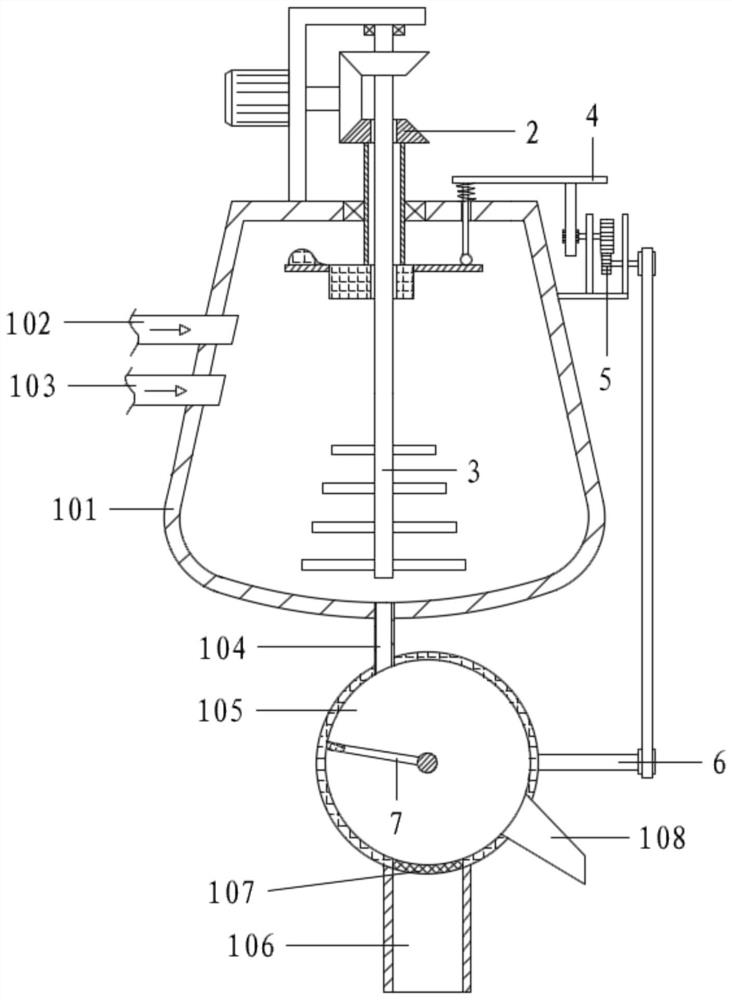

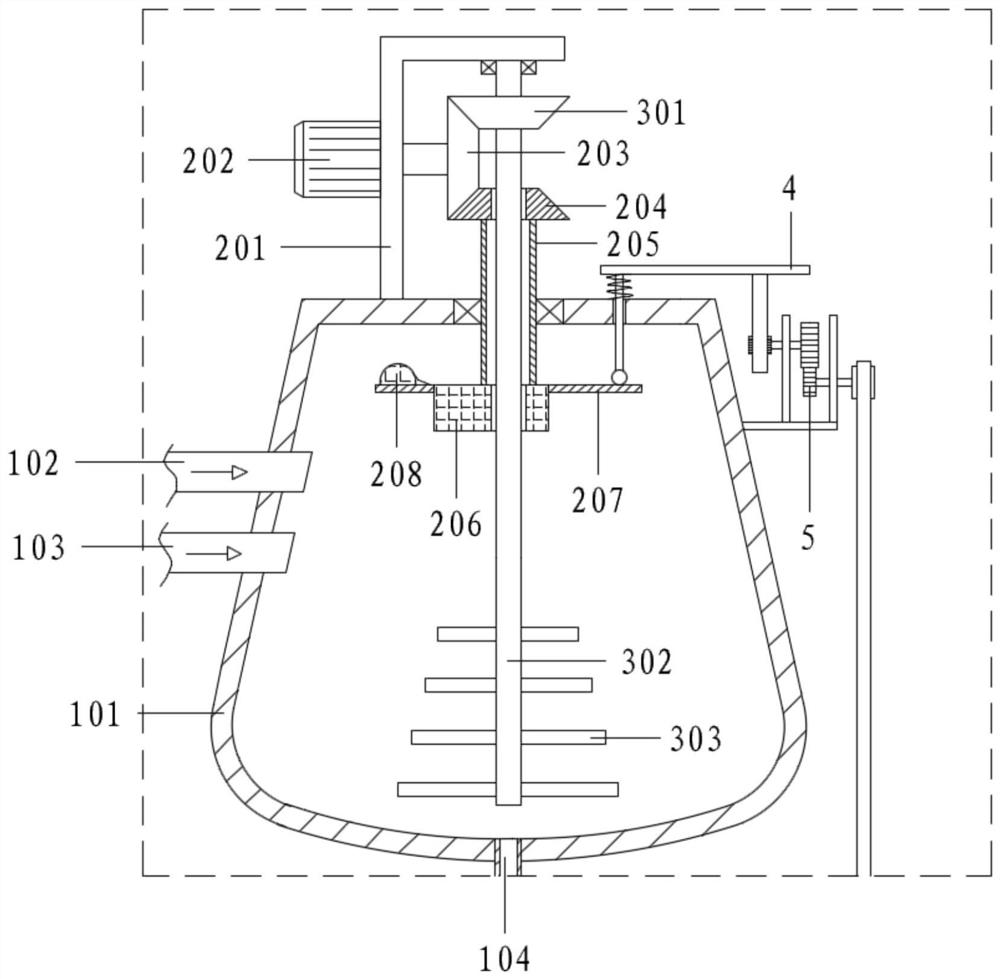

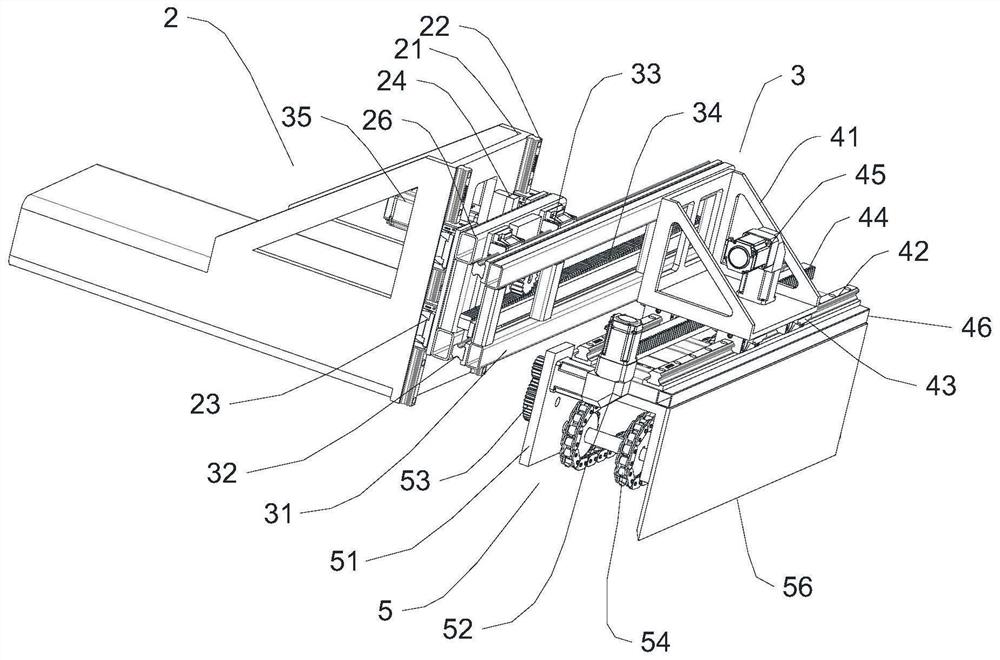

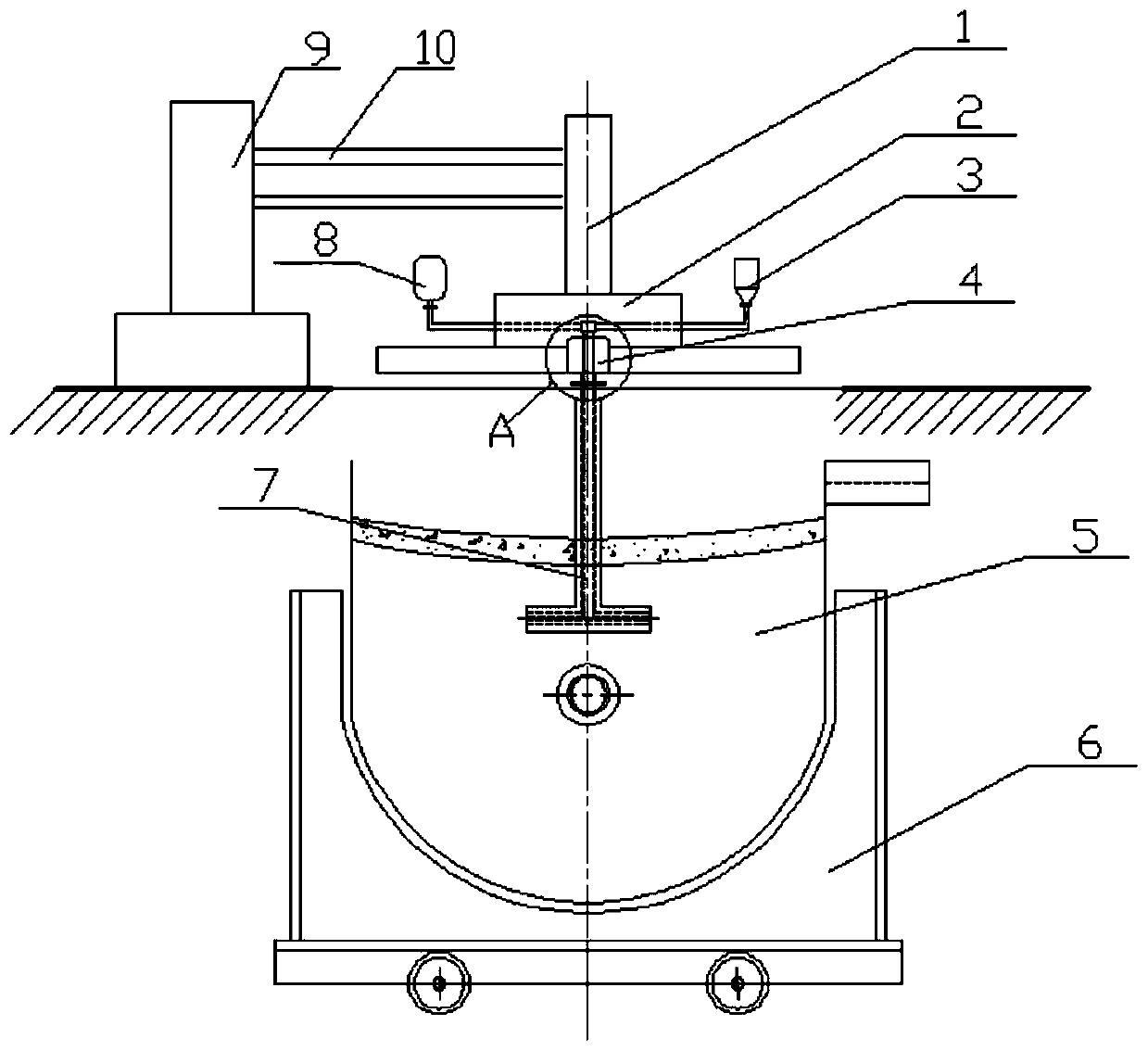

Movable type molten copper refining, deslagging and stirring device

The invention discloses a movable type molten copper refining, deslagging and stirring device. The device comprises a moving platform, and the moving platform is provided with a molten copper refiningagent adding device and a molten copper deslagging and stirring device through a mounting bracket. The overall lifting, dropping and rotation of the mounting bracket are realized by a bracket liftingdevice and a rotating device, the molten copper refining agent adding device is automatically adjusted relative to the molten copper position, position adjusting capacity of a stirring plate in molten copper is realized by a secondary rotating device and a secondary lifting device, and technical functions of uniformly stirring molten copper, automatically removing slag and adding a refining agentin real time are realized. The stirring plate can uniformly stir the molten copper outwards when rotating forwards and can suck waste slag floating on the surface of the molten copper by a notch anda spiral chute to enter a stirring pipe to be moved out in a reverse rotating process, and automatic cleaning performance of the waste slag is realized.

Owner:ZHEJIANG WANZHONG MACHINERY MFG

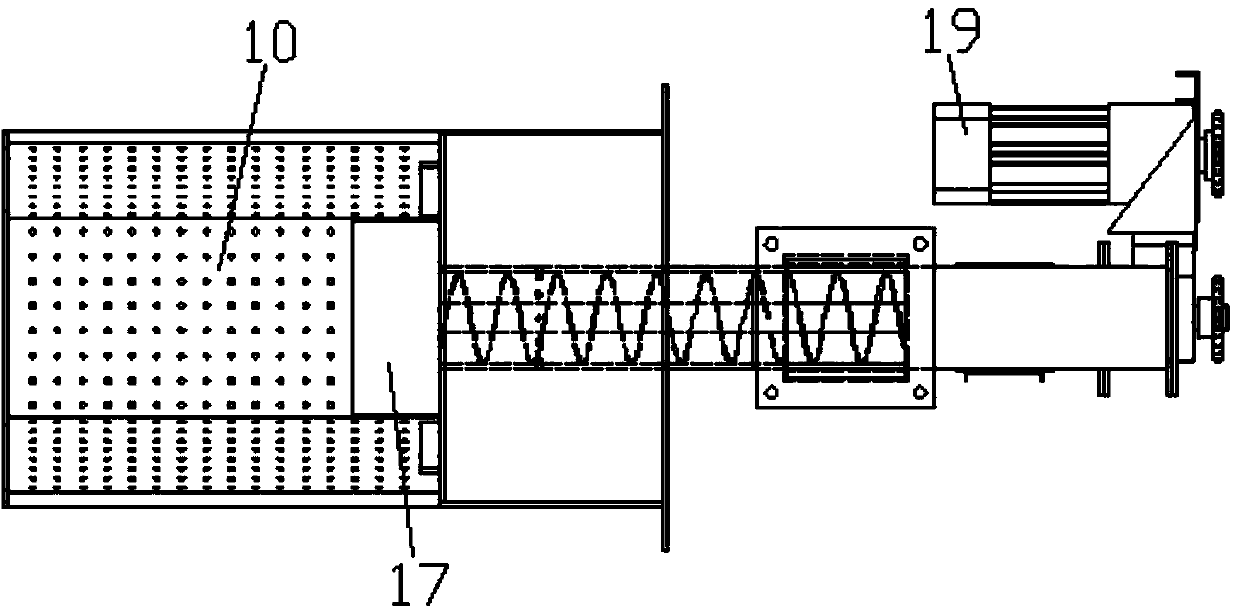

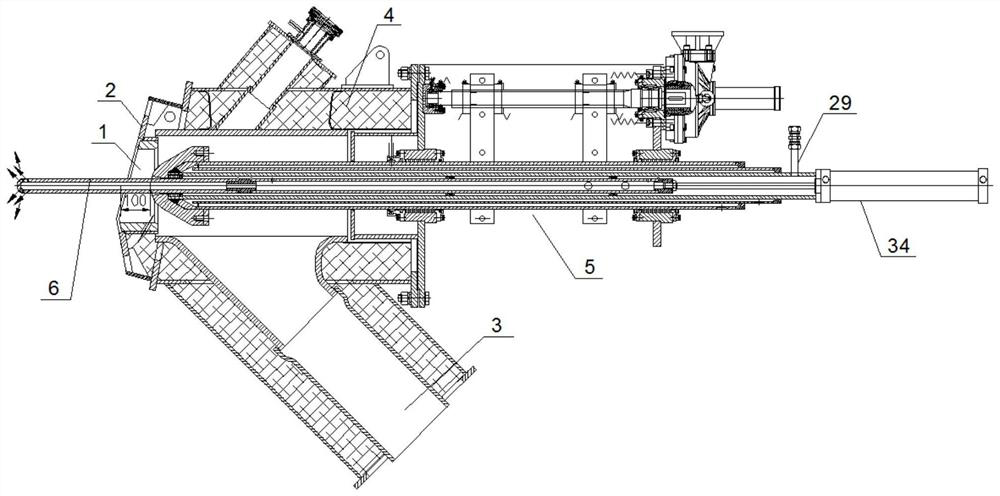

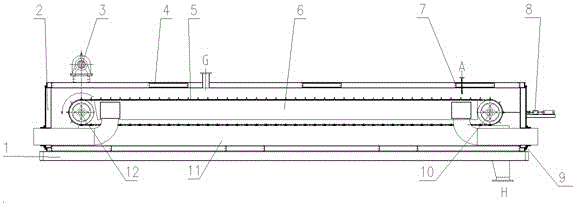

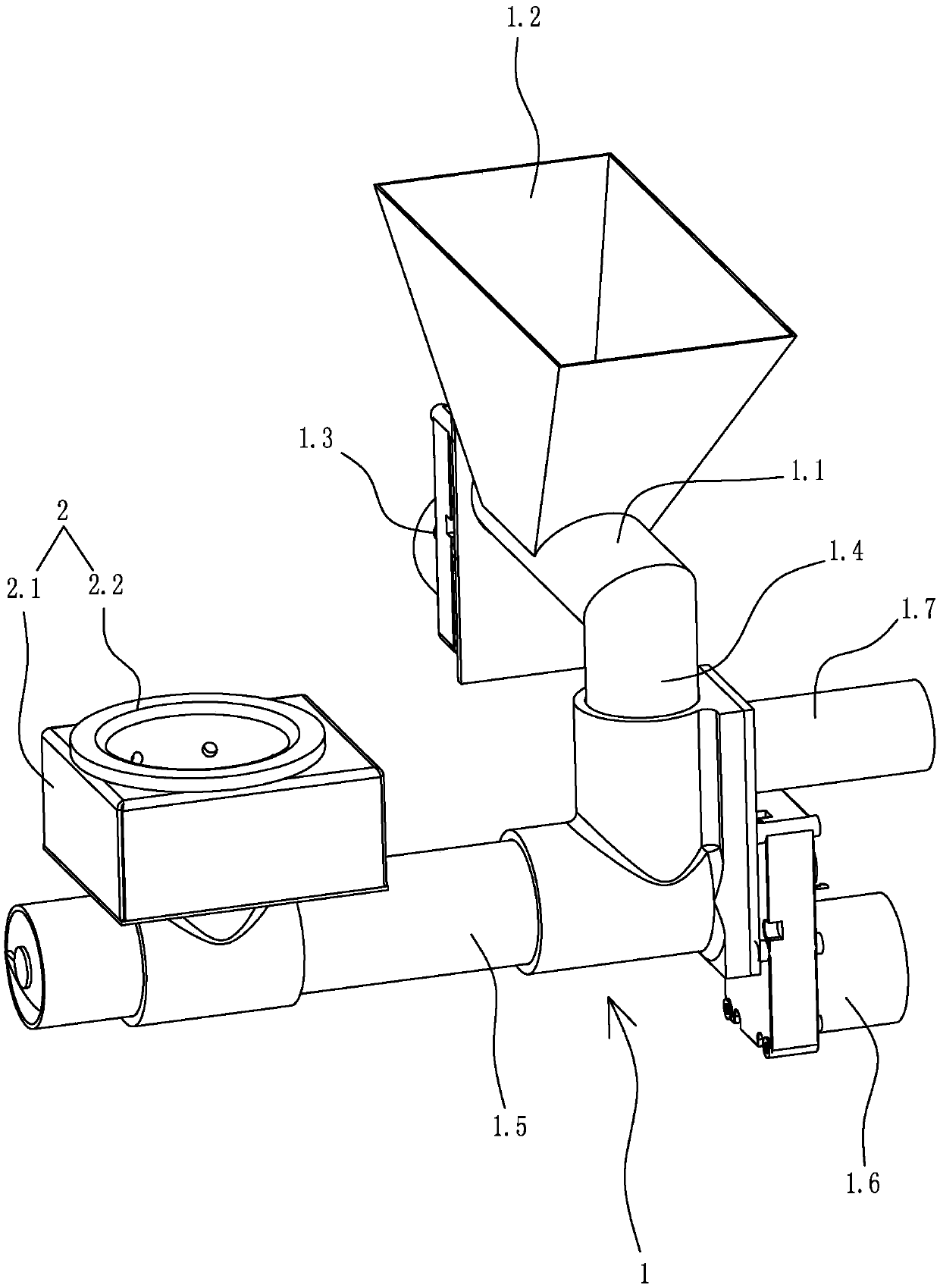

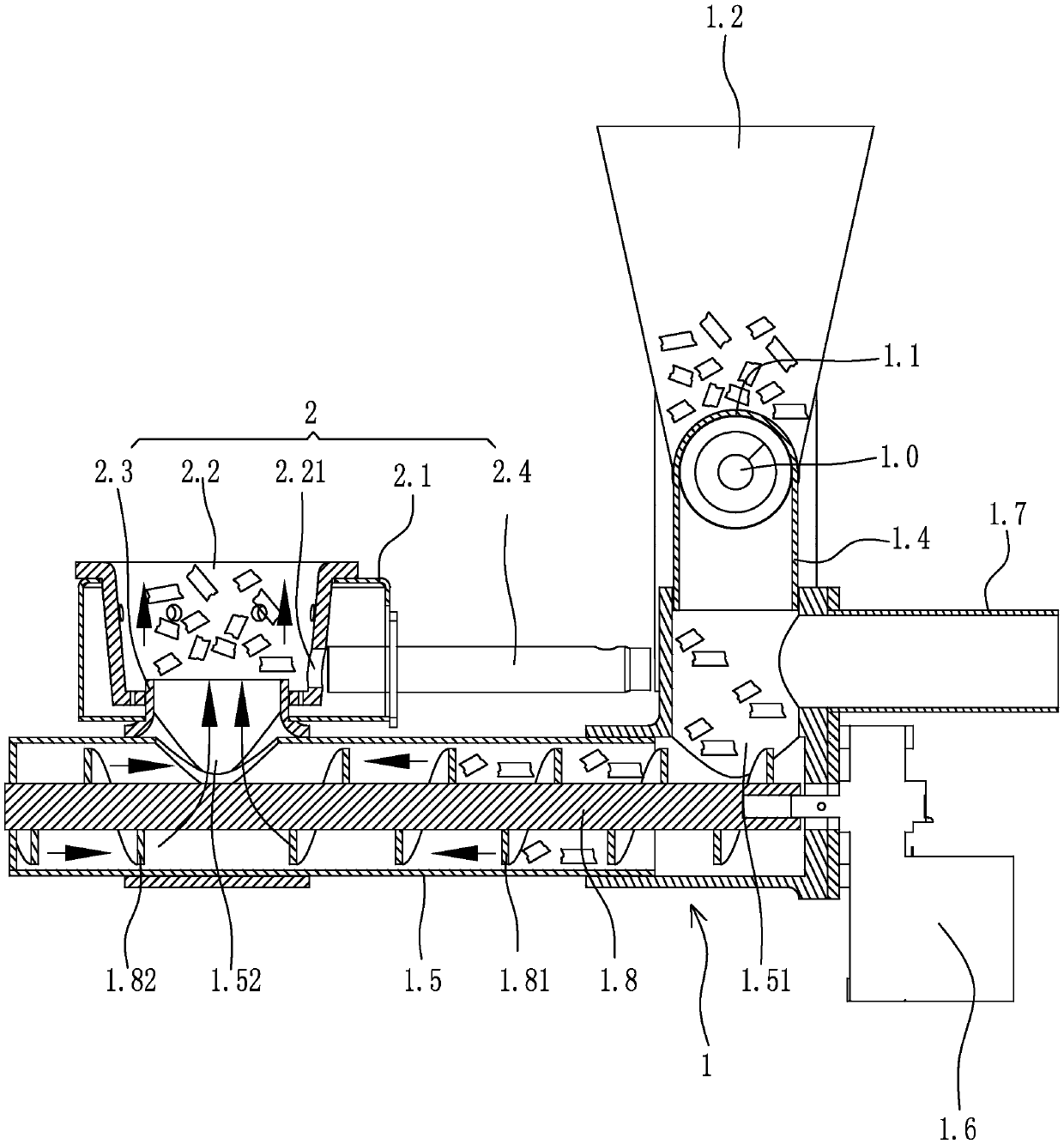

Conveyer with double augers

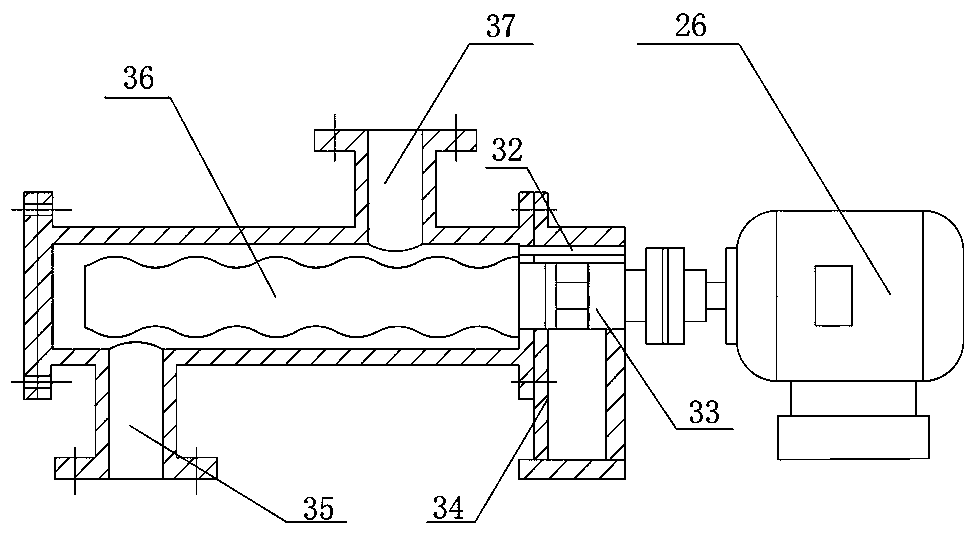

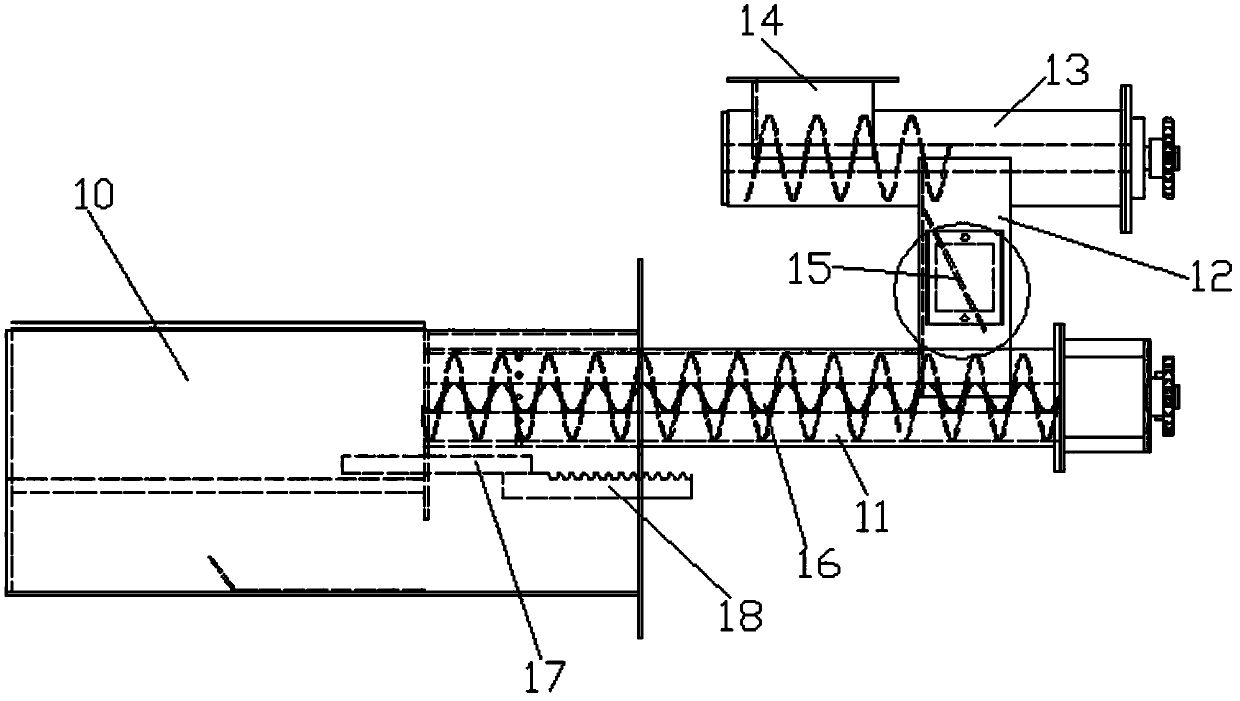

ActiveCN103697460AImprove ventilationPrevent flashbackSolid fuel combustionLump/pulverulent fuel feeder/distributionCombustion chamberSlag

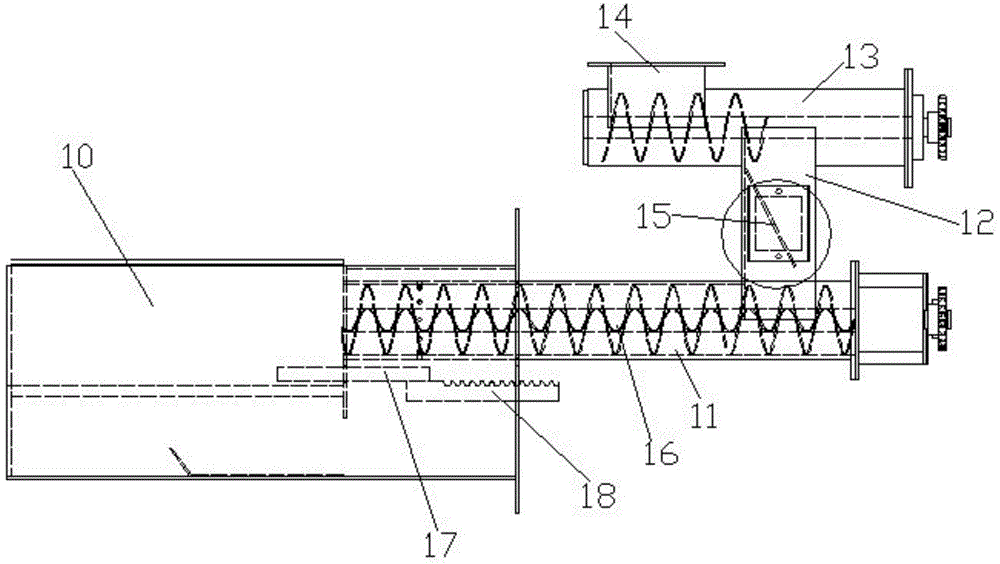

The invention provides a conveyer with double augers, and belongs to the technical field of heating equipment. The conveyer with the double augers comprises a combustion chamber and an ignition system, wherein a conveying mechanism is arranged on one side of the combustion chamber and specifically comprises a conveying pipe, a connecting pipe, a feeding pipe, a feeding opening and a spiral pushing rod; the conveying pipe is arranged on one side of the combustion chamber; the connecting pipe is arranged at the tail of the conveying pipe; the feeding pipe is arranged on the connecting pipe; the feeding opening is formed in an end of the feeding pipe; the spiral pushing rod is arranged in the conveying pipe and the feeding pipe; a tempering-proof plate is arranged in the connecting pipe; and a slag pushing mechanism is arranged on one side of the combustion chamber and is positioned below the conveying mechanism. Materials are conveyed by the conveying pipe and the feeding pipe which are arranged vertically; the tempering-proof plate is arranged between the conveying pipe and the feeding pipe, so that a tempering phenomenon is avoided, and the safety is improved; and slag in the combustion chamber can be removed by the slag pushing mechanism regularly, the slag can be automatically removed, the problem that cokes are generated easily during combustion and are adhered to the bottom of the combustion chamber is solved, the normal combustion space and smooth ventilation of the combustion chamber are guaranteed, and the combustion efficiency is improved.

Owner:郑文虎

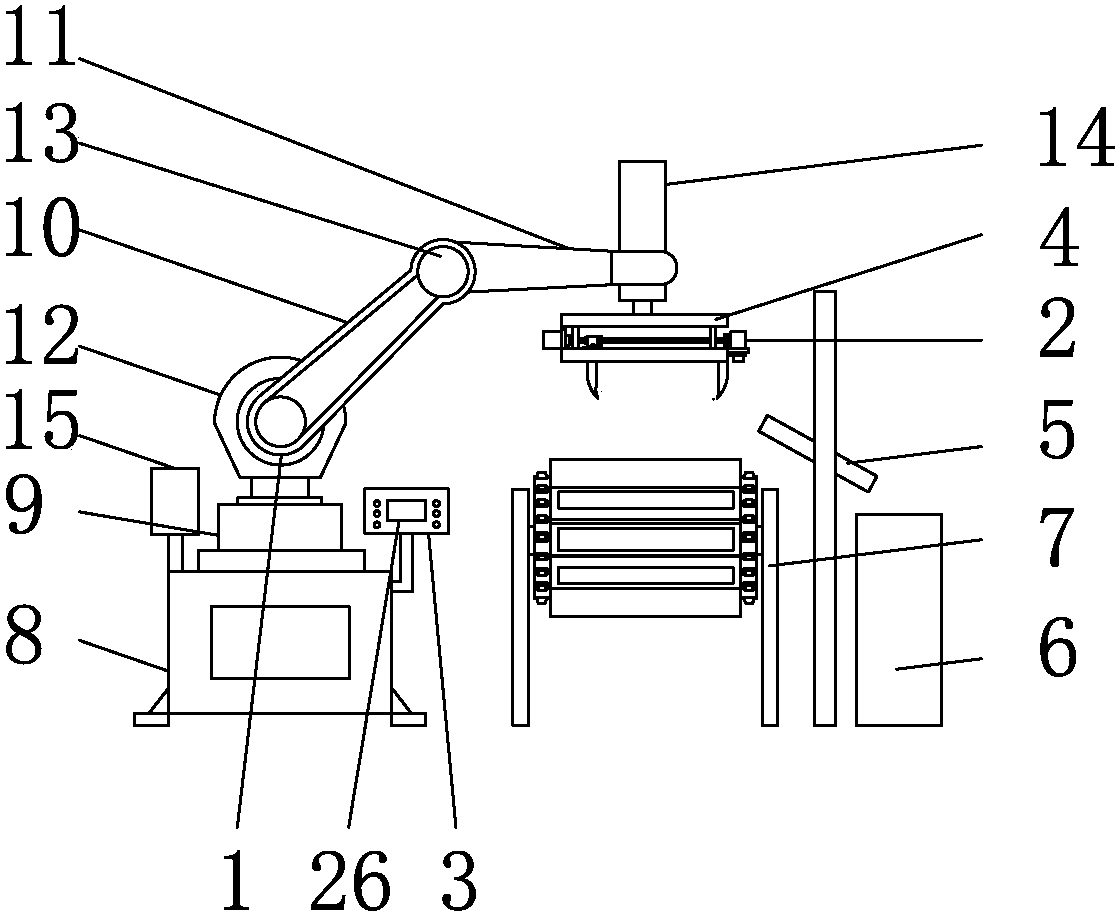

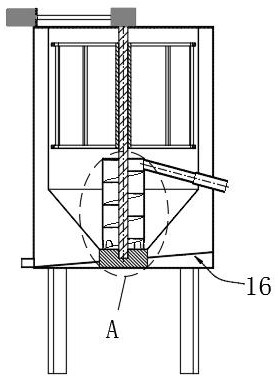

Automatic slagging-off method for aluminum ingot production

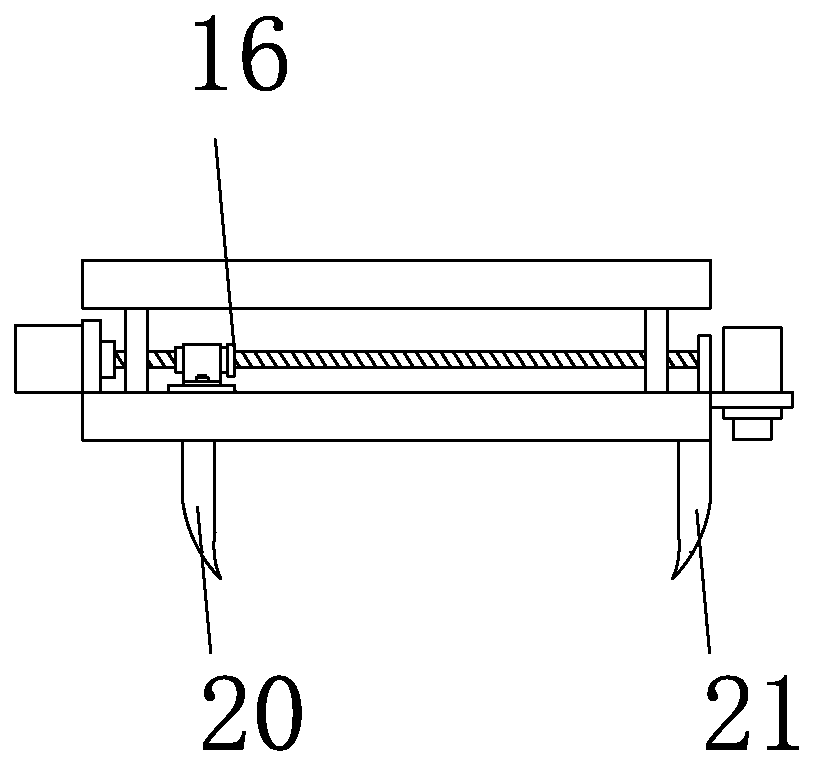

InactiveCN110899685ARealize automatic slag removalReduce the chance of burnsCasting cleaning apparatusIngot castingCasting mold

The invention discloses an automatic slagging-off method for aluminum ingot production. Firstly, each passing aluminum ingot casting mold is automatically recognized and three-dimensionally positionedthrough a visual positioning sensor; the three-dimensional coordinates of the aluminum ingot casting mold are fed back to a PLC master controller; the PLC master controller sends a command to a robotcontroller according to a programming program; the robot controller controls a mechanical arm to operate according to the programming program; a slagging-off tool is moved to the upper parts of one or more adjacent slagging-off casting molds needing slagging off; then, a slagging-off screw rod driving mechanism in the slagging-off tool drives a movable shovel to move from one end of the casting mold to the other end of the casting mold; scum at the upper part of the casting mold is pushed to move towards one end; and then the movable shovel and a fixed shovel accumulate the scum from the twosides, the scum is lifted up and unloaded into a slag receiving disc under the further operation of the robot and falls into a slag receiving box through the slag receiving disc; the problems that inan existing slagging off mode, workers are prone to being scalded, the working efficiency is low, and scraping missing and slag leaking are prone to occurring are solved.

Owner:云南云铝海鑫铝业有限公司

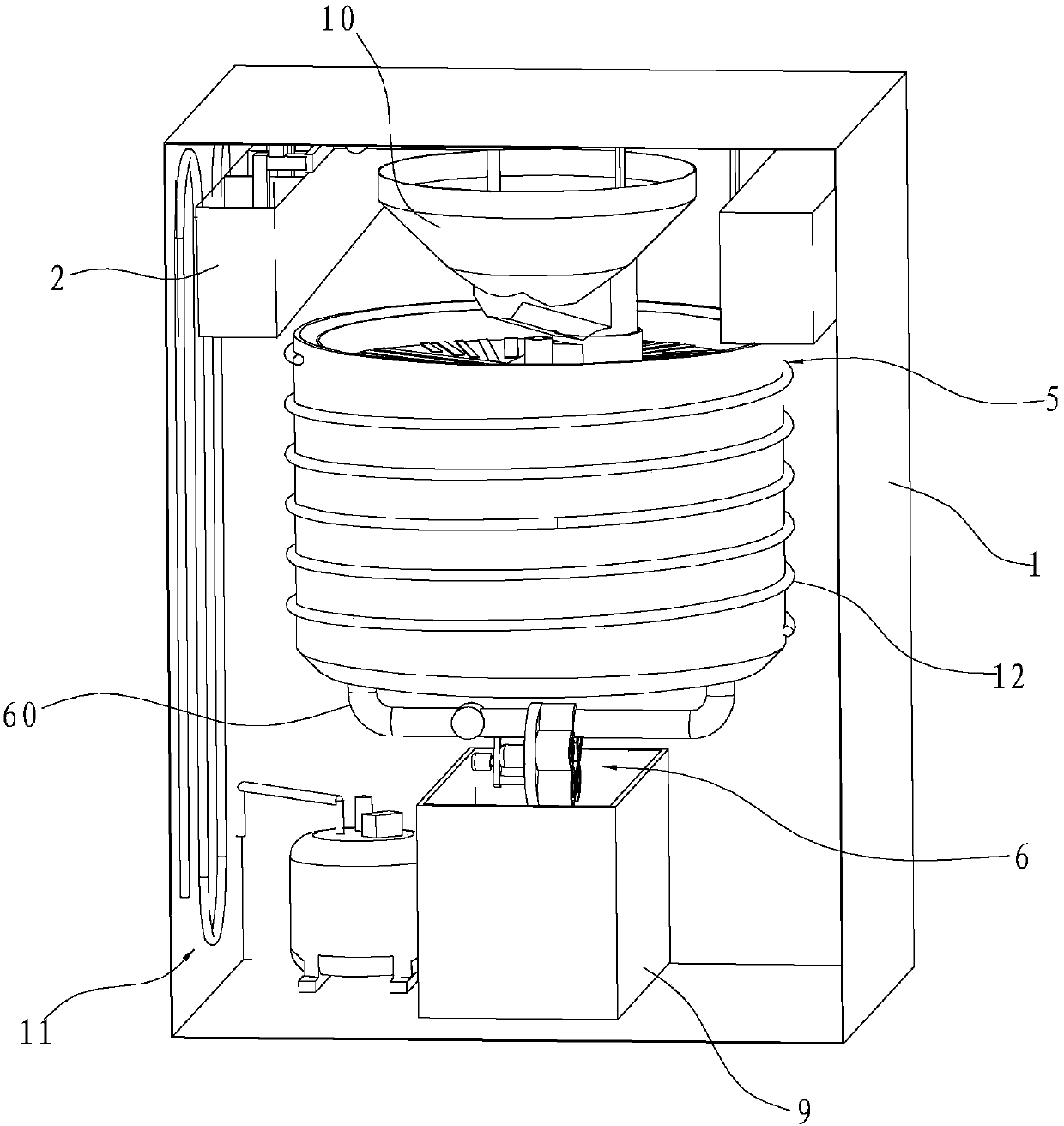

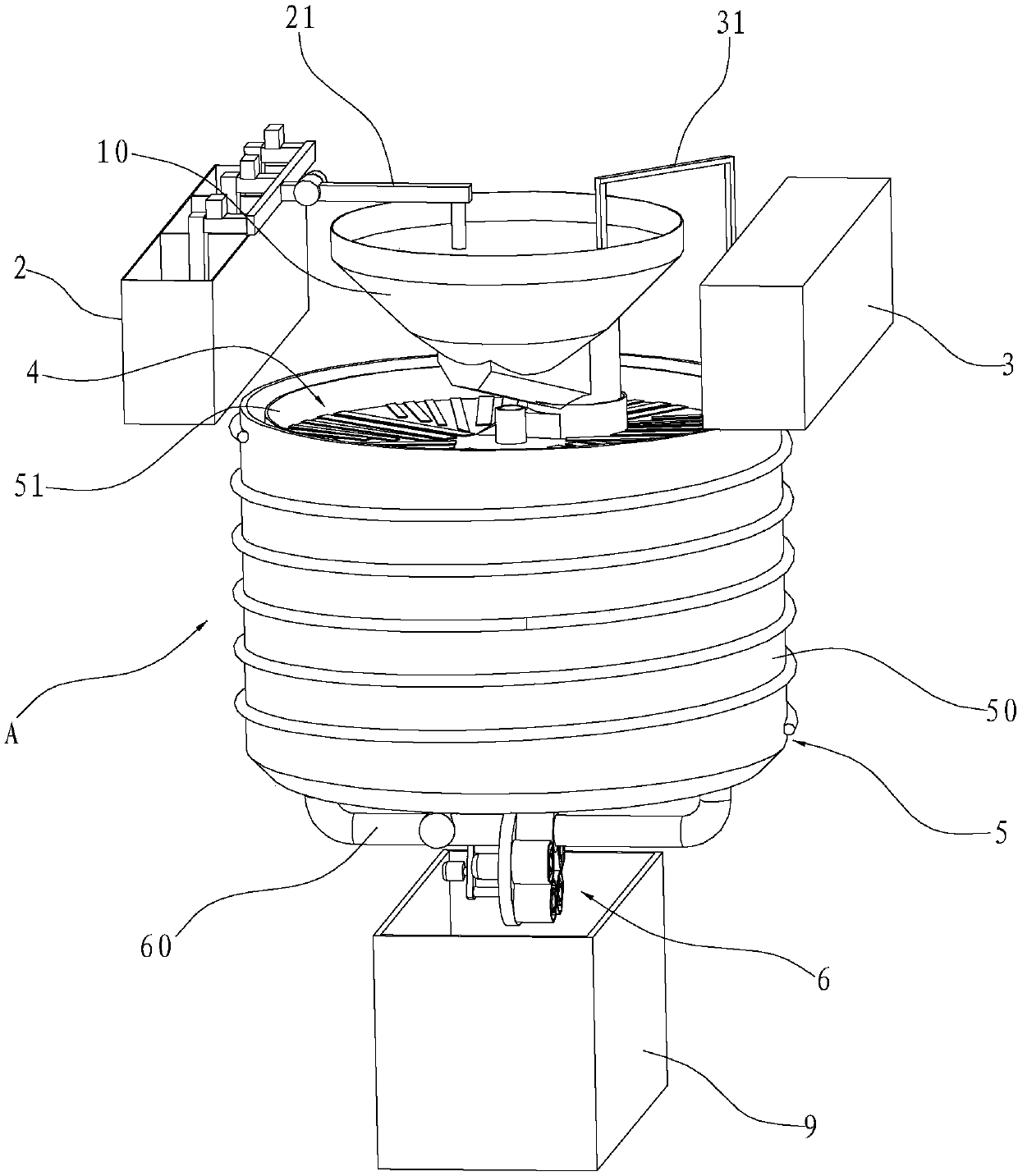

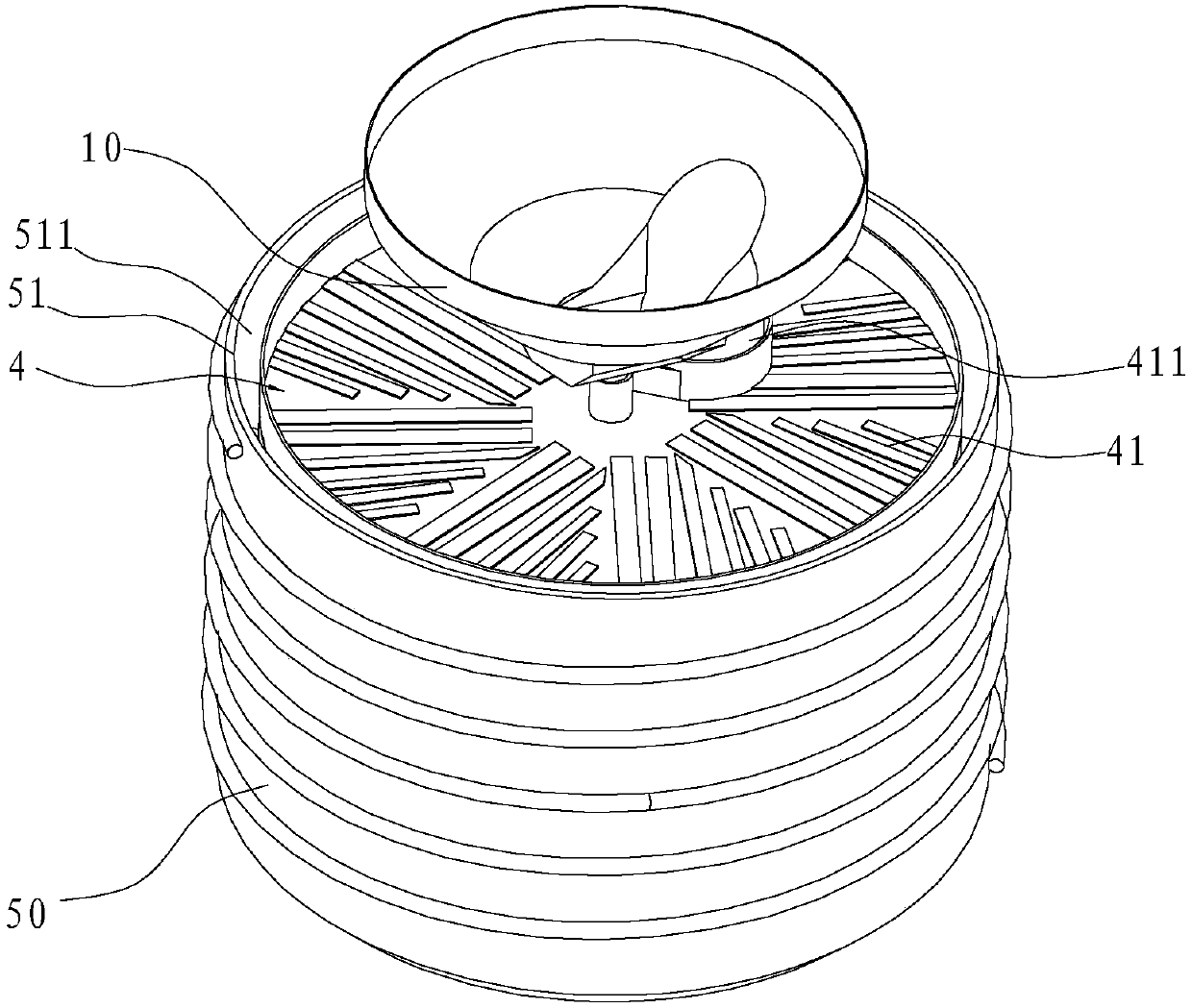

Fermentation machine with residue removing function

PendingCN109988703AGreat tasteGood experienceBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryFermentation

The invention relates to a fermentation machine with a residue removing function. The fermentation machine comprises a casing. A fermenting tank arranged in the casing comprises a tank body. A residuedischarging tube communicated with an inner cavity of the tank body is connected to the bottom of the tank body. The free end of the residue discharging tube is closed or is communicated with the inner cavity of the tank body. A residue discharging device for removing residues in fermentation liquid in the tank body is arranged on the residue discharging tube. Compared with the prior art, the fermentation machine has the advantages that the residue discharging device is arranged in the fermentation machine, the residues in the fermentation liquid in the fermenting tank can be removed by the residue discharging device when the fermentation liquid passes through the residue discharging device, automatic residue discharging is realized, the taste of prepared fermented food is good, and accordingly, users can have good user experience.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

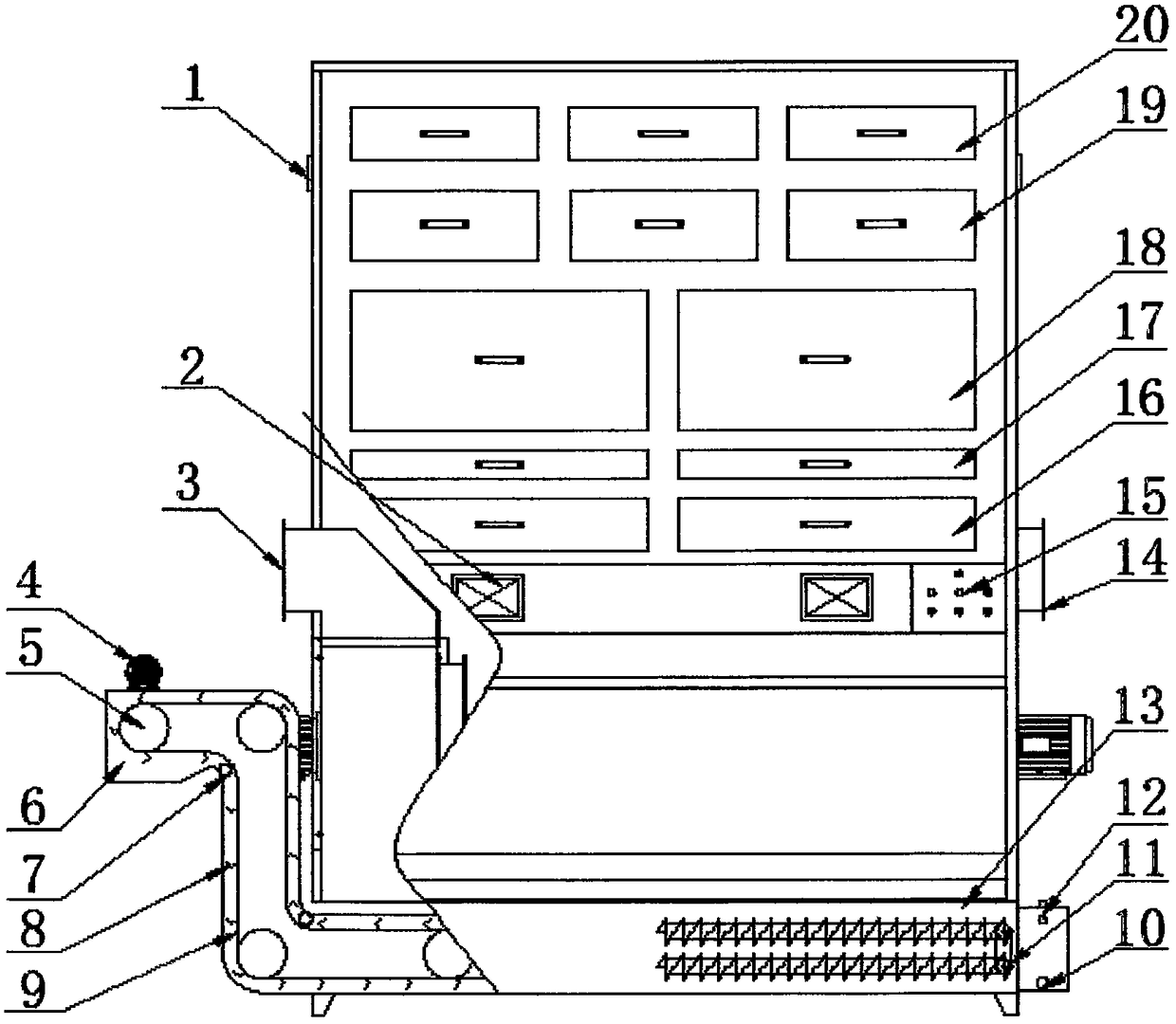

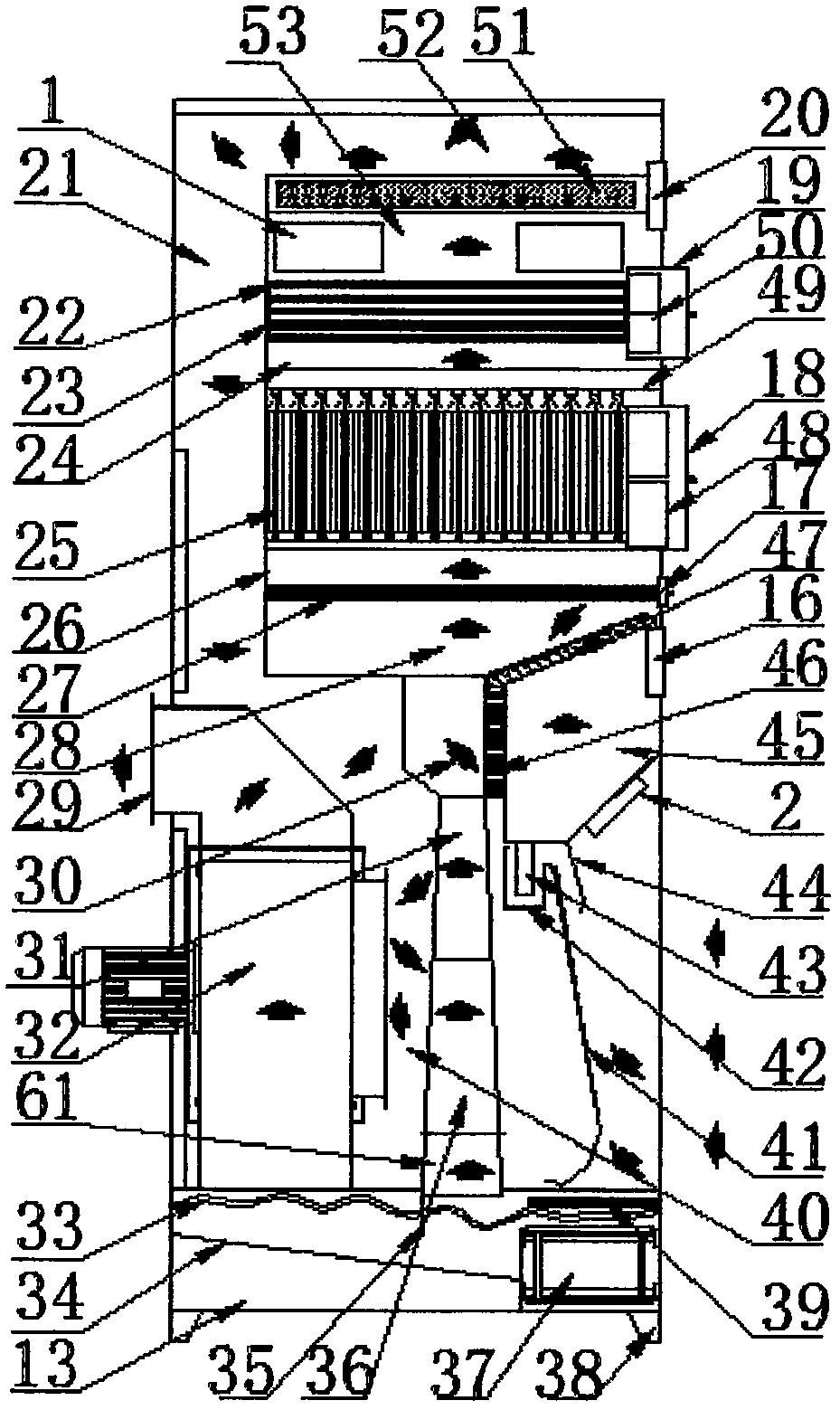

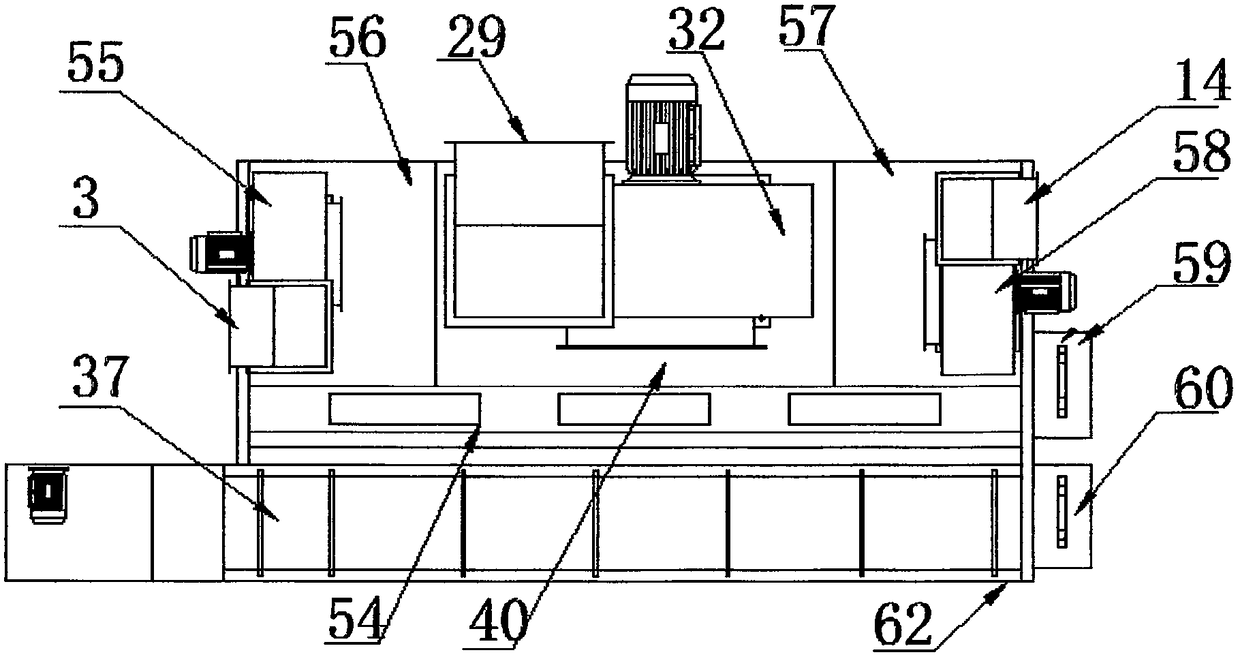

Paint spraying, dust removing and organic waste gas purifying integrated machine

PendingCN108525480AEasy accessEasy to collectCombination devicesGas treatmentAir filtrationActivated carbon

The invention discloses a paint spraying, dust removing and organic waste gas purifying integrated machine. The paint spraying, dust removing and organic waste gas purifying integrated machine comprises a wind-powered water lifting port, a wind-powered water lifting zone, a wind-powered water lifting buffer zone, an up-and-down boiling wind-powered water lifting, dust removing and purifying zone,a wind-powered water lifting, dust removing and purifying channel with a smaller upper part and a bigger lower part, a condensed water deflector, a collected water buffer zone, a sewer pipe, a water returning tank, an environment-friendly water curtain, a circulating water pool, a uniform-air filtration zone, a low-temperature plasma cracking purification zone, a photocatalytic oxidation purification zone, an activated carbon steady zone, a purified gas discharging zone and a purified gas negative pressure channel. The V-shaped screen water filtering and slag scraping device of the paint spraying, dust removing and organic waste gas purifying integrated machine can completely scrape, fish and clean slag in the water pool, so that automatic slag cleaning, discharging and packaging can be achieved; and the wind-powered water lifting, dust removing and purifying channel with the smaller upper part and the bigger lower part is designed according to the characteristics of fluid motion, andan air inlet is large, then slowly shrinks and becomes very small when the air inlet reaches the wind-powered water lifting port, so that dust-free water vapor can quickly enter the water lifting buffer zone conveniently, collection and purification of dust is facilitated, a water bloom and the water vapor can fully collide and contact with the dust in a boiling manner, and the working efficiencyis improved.

Owner:章鹏飞

Conical ash control valve with automatic slag poking function

PendingCN112696521AImprove liquidityImprove dredging efficiencyFluidized bed combustionOperating means/releasing devices for valvesBoiler slagProcess engineering

The invention discloses a conical ash control valve with an automatic slag poking function. The conical ash control valve comprises a valve seat provided with a boiler slag removal opening and a valve body provided with an ash control valve discharging opening, and further comprises a valve rod and a slag poking rod, wherein the valve rod slidably penetrates through the valve body; the slag poking rod penetrates through the valve rod; the slag poking rod can move along the axis of the valve rod; the slag poking rod crushes blocky materials in the boiler slag removal opening through back-and-forth stretching; a compressed air channel is arranged in the slag poking rod; a plurality of purging holes communicated with the compressed air channel are arranged in the head of the slag poking rod; and compressed air purged out of the purging holes is used for enhancing the flowability of the crushed materials. The slag poking rod stretches back and forth to complete material stirring, ash accumulated at the boiler slag removal opening is loosened and separated or large slag blocks are broken, meanwhile, the slag poking rod sprays high-pressure gas through the purging holes to continuously purge broken ash near the boiler slag removal opening, the fluidity of the ash is enhanced, and the purpose of automatic slag poking is achieved.

Owner:SICHUAN LONGLINKECHUANG ENERGY SAVING & ENVIRONMENT PROTECTING CO LTD

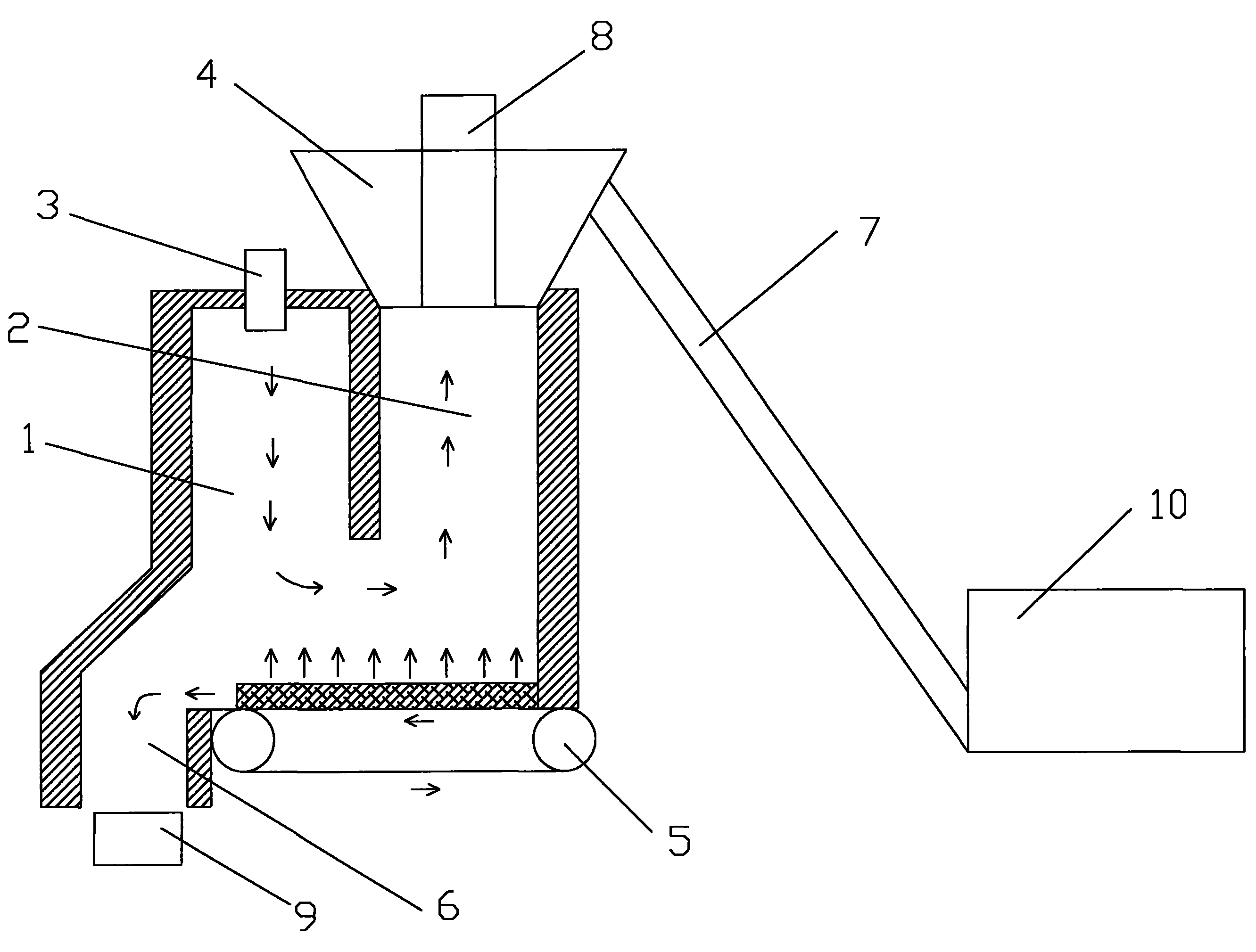

Dynamic continuous organic solid waste gas-carbon oil cogeneration device

InactiveCN105778955AAvoid condensationIncrease productionProductsReagentsEffective lengthCogeneration

The invention discloses a dynamic continuous organic solid waste gas-carbon oil cogeneration device. The device comprises a sealed reaction main body structure as well as a first bed board panel and a second bed board panel which are distributed in the cavity of the reaction main body structure, the device body is provided with a continuous feeding mechanism used for conveying to-be-treated materials to the first bed board panel to be subjected to pyrolysis treatment, a scraper chain mechanism is arranged inside the reaction main body structure, and an oil gas outlet used for conveying oil gas generated through pyrolysis reaction to a condenser to be condensed into fuel oil and a solid residue outlet used for discharging waste residue produced through pyrolysis out the device body are formed in the reaction main body structure. The device disclosed by the invention is provided with an upper pyrolysis bed board and a lower pyrolysis bed board, and organic solid waste incompletely cracked on a first layer is transferred on to the lower pyrolysis bed board by virtue of a movable scraper chain to be continuously pyrolyzed until pyrolysis is fully completed, so that pyrolysis efficiency is improved, effective length of equipment is shortened, and floor area of the equipment is reduced.

Owner:大连杜尔环保科技有限公司

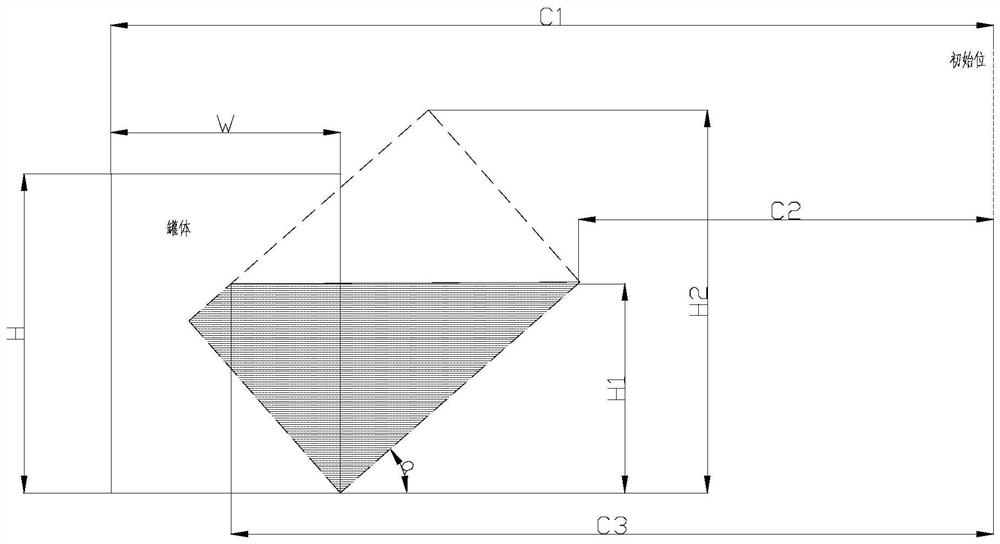

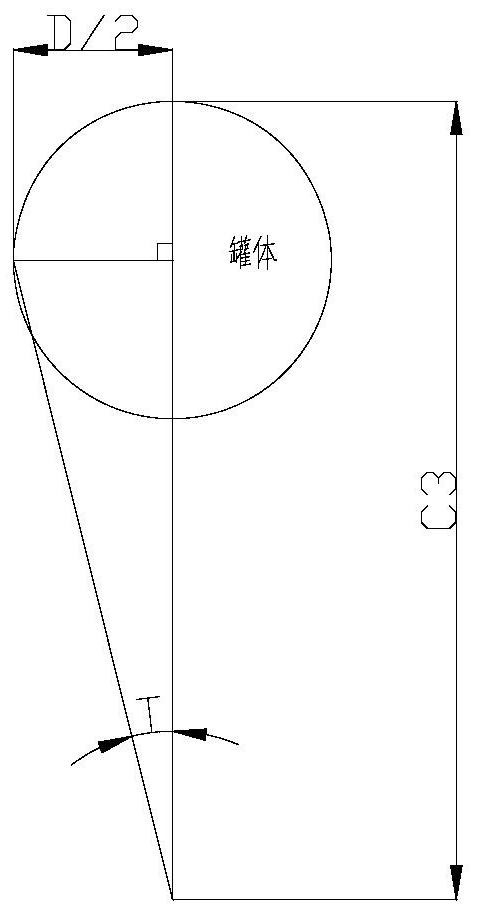

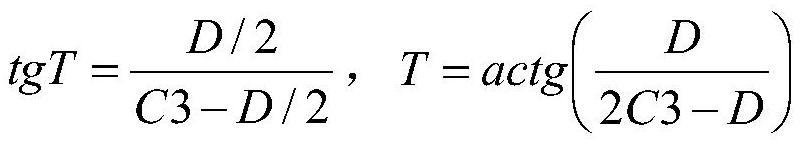

Three-dimensional positioning method for automatic slagging-off of desulfurized molten iron

InactiveCN112795727AAvoid good times and bad timesReduce workloadSteel manufacturing process aspectsIncreasing energy efficiencyMetallurgyOriginal data

The invention provides a three-dimensional positioning method for automatic slagging-off of desulfurized molten iron. The method comprises the following steps of establishing an original data model, calculating the minimum lifting height H1, the maximum lifting height H2, the minimum extension distance C2, the maximum extension distance C3 and the rotation angle value T of a slagging-off machine, and sequentially controlling the lifting height, the rotation angle and the extension length of the slagging-off machine according to the calculated data to carry out automatic slagging-off operation. The situation that errors are too large during manual operation and the slagging-off effect is sometimes good or sometimes bad is avoided, the influence of personal errors on the slagging-off effect is reduced, the inclination angle of a tank body during slagging-off is determined, three-dimensional coordinates needing to act of the slagging-off machine are calculated through a certain method, and the slagging-off operation is carried out according to the set coordinates; and meanwhile, the three-dimensional coordinates are continuously changed, an area needing slagging-off is determined, automation of the slagging-off process is achieved, manual participation is reduced, the slagging-off efficiency is improved, the workload of workers is reduced, and harm caused by molten iron spray explosion to operators in the slagging-off process is reduced.

Owner:ANGANG STEEL CO LTD

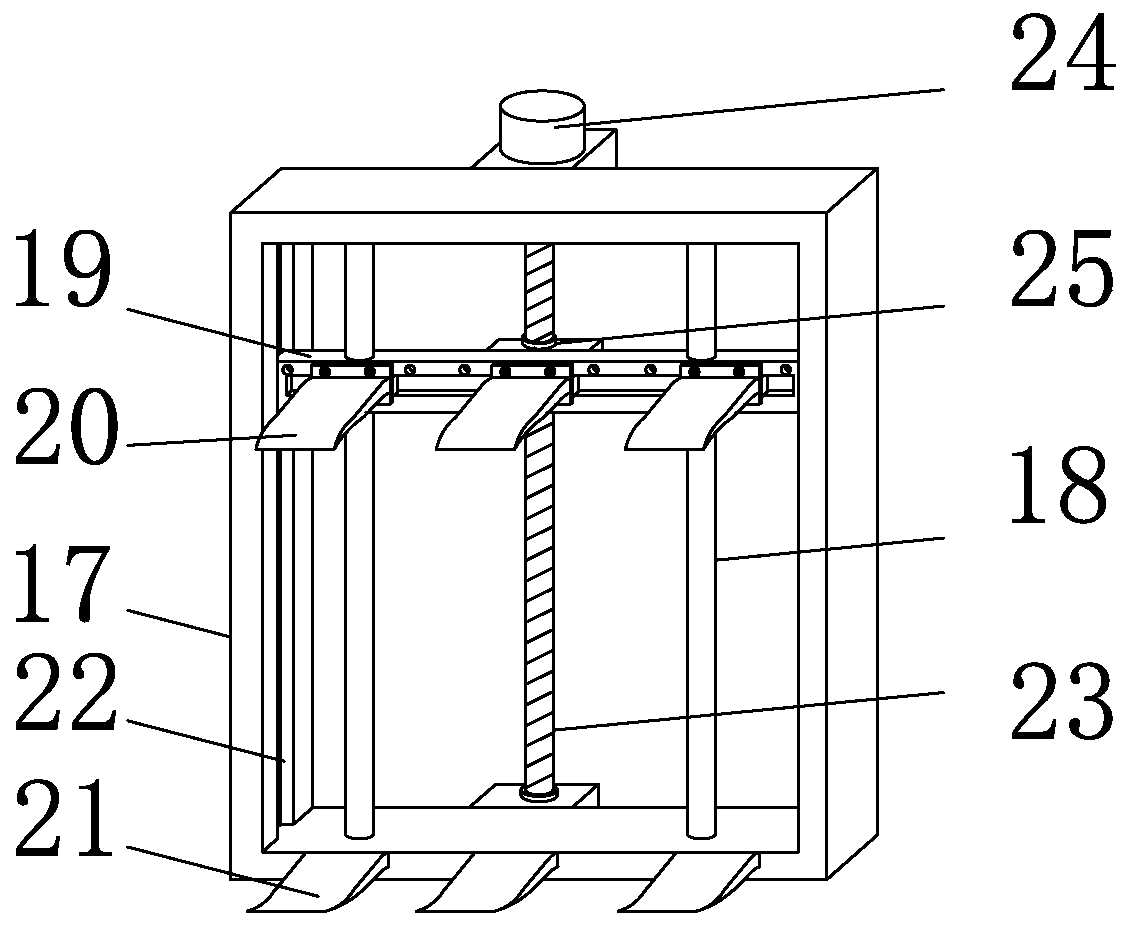

Sewage treatment device with automatic deslagging function

InactiveCN112479417AReduce or reduce the contentRealize slaggingTreatment involving filtrationMultistage water/sewage treatmentWastewaterSewage

The invention relates to the technical field of sewage treatment, in particular to a sewage treatment device with an automatic deslagging function. A servo motor is adopted to drive a first bevel gearto rotate, based on rotation of the bevel gear, the first bevel gear drives a third bevel gear to drive a stirring shaft to rotate, then the stirring shaft drives a first-class stirring rod to conduct stirring in a stirring tank, thus sewage and chemicals are mixed, a reaction is accelerated to generate solid sediments, the content of pollutants in the wastewater is reduced, and solid sediments are blocked by a filter screen and left on the filter screen. The first bevel gear drives a second bevel gear to drive a hollow shaft to rotate, a jacking assembly acts on an amplifying assembly, and then a fifth bevel gear drives the rotating shaft to rotate forwards and backwards through a transmission assembly, so that the rotating shaft drives a scraping plate to swing in a reciprocating mode through a first connecting rod; and when the scraping plate swings anticlockwise, residues on the filter screen are scraped and pushed to a residue discharging pipe to be discharged, and automatic residue removing and discharging are achieved.

Owner:安徽智晟通讯科技有限公司

Automatic slag falling double closed carbon disulfide gasification reactor

ActiveCN105197930BClosed tightlyIncrease gasification rateCarbon compoundsFailure rateDischarge efficiency

Owner:陵川县金丰科技股份有限公司

Fire grate suitable for large particle solid fuels

InactiveCN106122987ARealize automatic blankingRealize automatic focus breakingTravelling grateSlagSolid fuel

The invention discloses a fire grate suitable for large-grain solid fuels, and provides a fire grate capable of automatically breaking coke and having the function of automatic cleaning. It is composed of a stepped fixed furnace bar and a stepped movable furnace bar. The furnace bar base of the stepped fixed furnace bar is composed of the upper first fuel sliding area, the middle first fuel main combustion area and the lower first slag discharge area; The first fuel main combustion area is stepped; the grate body of the stepped active grate is composed of the upper second fuel sliding area, the middle second fuel main burning area and the lower second slagging area, the second fuel sliding There is a rocking support groove matched with the rocker below the zone; the second fuel main combustion zone is stepped. The stepped solid grate and the stepped movable grate are arranged side by side; the first fuel main combustion zone in the stepped fixed grate and the second fuel main combustion zone in the stepped movable grate have the same stepped structure and form a stove Fuel main combustion zone. Automatic feeding is realized, avoiding coking in a large area.

Owner:TIANJIN JUNENG BOILER MFG CO LTD

Twin auger feeder

ActiveCN103697460BImprove ventilationPrevent flashbackSolid fuel combustionLump/pulverulent fuel feeder/distributionCombustion chamberSlag

Owner:郑文虎

A hydraulic cylinder with flexible vortex power, automatic slag removal and no backlog

InactiveCN105179366BRealize flexible vortex booster startAchieving Buffer StillnessFluid-pressure actuatorsHydraulic cylinderSlag

The invention provides a flexible scroll power-assisted, automatic slag cleaning and no backlog hydraulic cylinder, which mainly includes a cylinder barrel, an end cover A, an end cover B, a piston rod, a piston, a buffer block, a guide sleeve and a buffer pad. Its characteristics are that the piston with spiral flow channel can play a flexible vortex assistance, and the buffer block with the slag cleaning flow channel can automatically remove the slag. The invention realizes the flexible vortex force-increasing start when the piston rod extends and the buffer stillness when retracting through the blind hole of the round table with the spiral flow channel; automatic slag removal is realized through the slag cleaning flow channel on the buffer block; The 45° inclined annular oil channel on the upper side realizes the buffering stillness without backlog when the piston rod is extended and the acceleration start when retracting.

Owner:UNIV OF JINAN

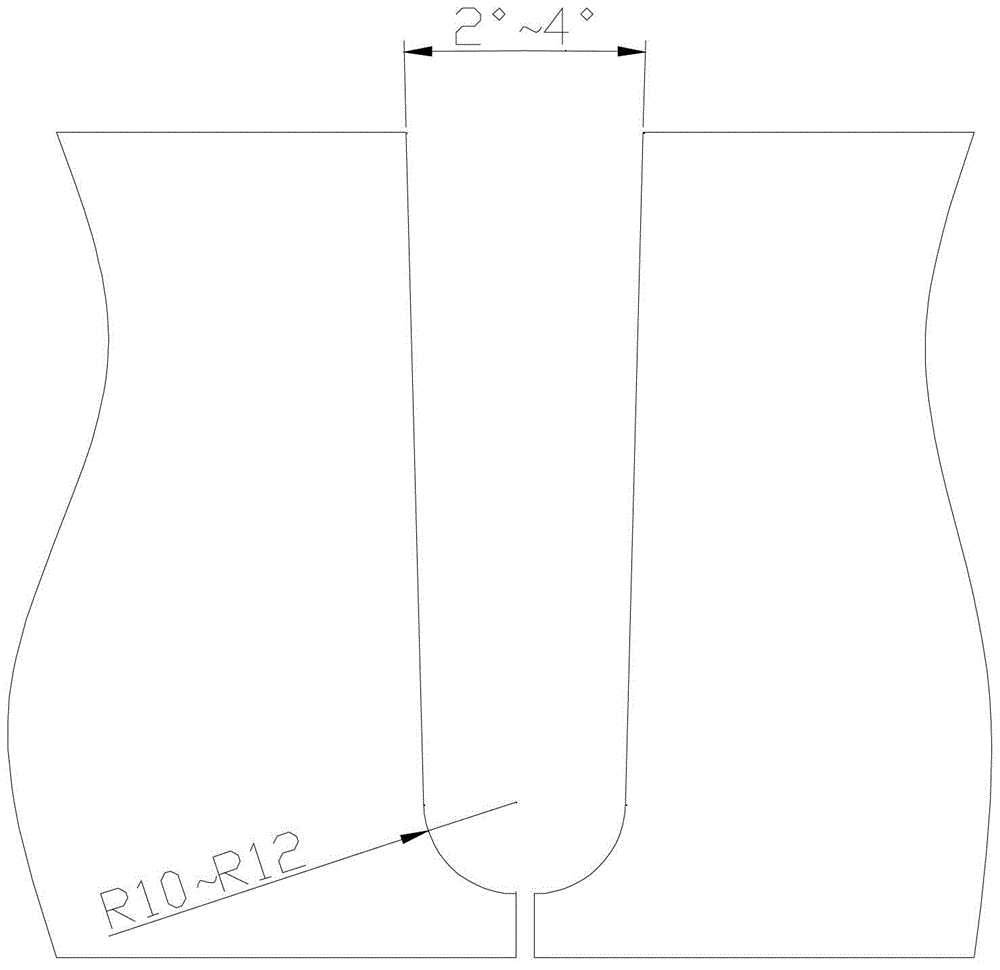

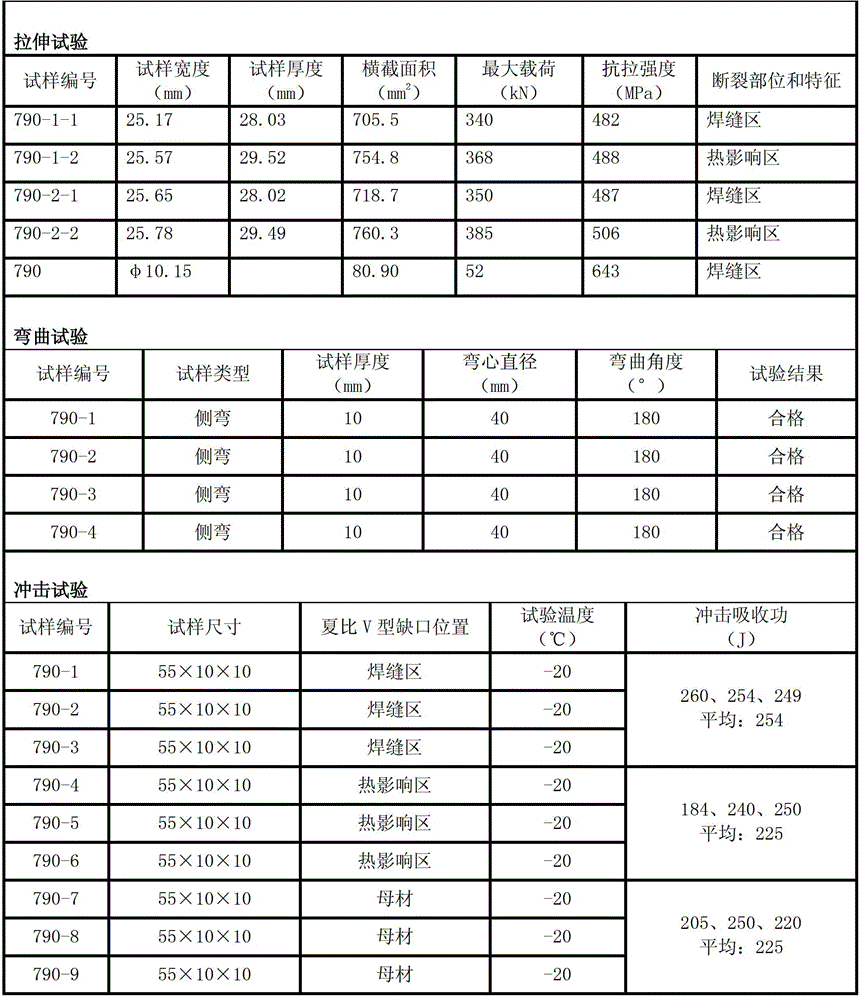

A welding process for thick-walled beams and columns of marine engineering equipment

ActiveCN103433697BImprove work efficiencySave welding materialArc welding apparatusNon destructiveCrack resistance

The invention discloses a process of welding thick-walled beam columns of marine engineering equipment, which includes the following steps: blanking, groove machining, preheating before welding, filling layer welding, post heat treatment and non-destructive inspection. The longitudinal seam grooves and circumferential seam grooves of the thick-walled beam columns are narrow U-shaped; narrow-gap submerged arc welding is adopted as filling layer welding, and interlayer temperature is controlled at 150 DEG C to 250 DEG C during welding. Since the grooves are narrow U-shaped and narrow and narrow-gap submerged arc welding is adopted, not only can working efficiency be increased, but also welding materials can be saved, and compared with conventional welding processes, the process can save 40 percent of welding materials; and meanwhile, the invention decreases welding stress, improves the comprehensive mechanical properties of welded joints, and enhances the crack resistance of welded joints.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Slag driving device on side edge of zinc pot

The invention discloses a slag driving device on the side edge of a zinc pot, and relates to the field of zinc pot automatic slag driving equipment. An oil axial translation mechanism, a lifting mechanism, a first lateral translation mechanism and a slag driving device body are arranged on one side of a zinc liquid pool of the zinc pot, and the axial translation mechanism is used for driving the slag driving device body to move in the axial direction of the zinc liquid pool; the lifting mechanism is used for driving the slag driving device body to ascend and descend, so that the slag driving device body can descend below the liquid level of the zinc liquid pool; and the first lateral translation mechanism is used for driving the slag driving device body to move in the lateral direction of the zinc liquid pool. Through the synergistic effect of the axial translation mechanism, the lifting mechanism and the first lateral translation mechanism, the slag driving device body is used for gathering zinc slag in the zinc liquid pool to a designated position in the movement direction, then through the synergistic effect of a front-end mechanical arm, a V-shaped area chain type slag driving device and a rear-end mechanical arm, manual slag salvaging can be completely replaced, and full-automatic slag salvaging is achieved.

Owner:武汉斯蒂尔派科技有限公司

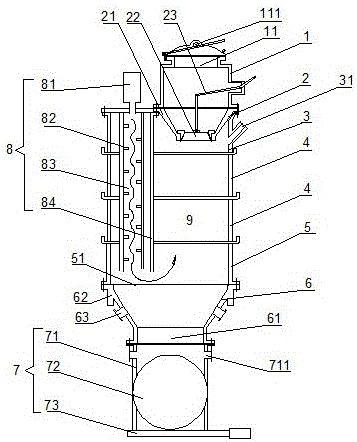

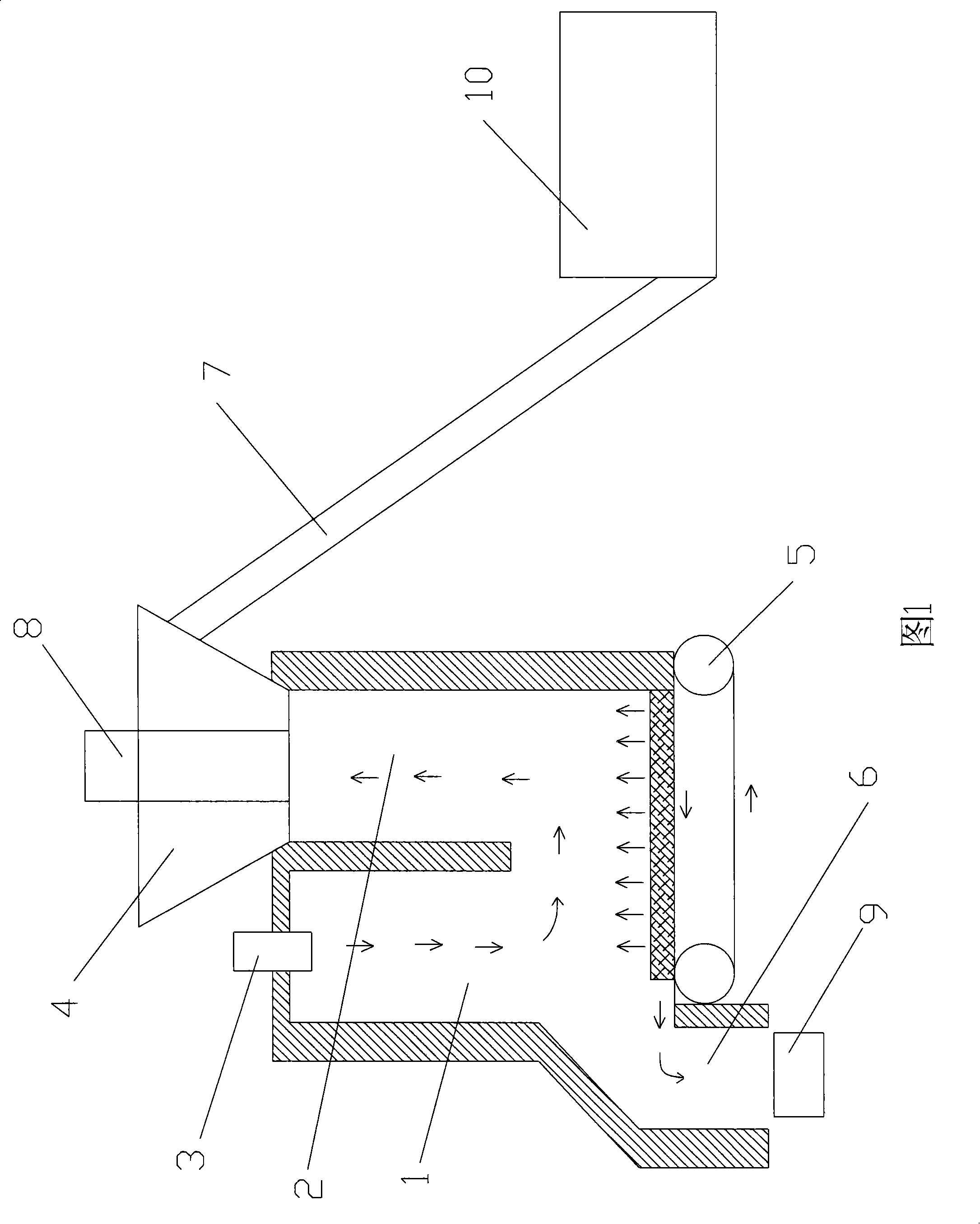

Cold tea tailing processing equipment and processing technique thereof

InactiveCN101270876BNo need to deal withSolve fire problemsIncinerator apparatusCombustion chamberCombustor

The invention is a processing device for the cool tea scrap and the processing technique. The processing device for the cool tea scrap of the invention comprises a combustion chamber (1) and a preheating and drying chamber for the cool tea scrap (2), which are in parallel arrangement; the lower part of the cool tea scrap is communicated with the lower part of the preheating and drying chamber forthe cool tea scrap (2); a combustor (3) is mounted on the combustion chamber (1); a dissemination machine (4) of the cool tea scrap is mounted on the upper part of the preheating and drying chamber for the cool tea scrap (2); the rotational bands (5) for the bearing of the combustion of the cool tea scrap are mounted at the lower parts of the combustion chamber (1) and the preheating and drying chamber for the cool tea scrap (2); an ash discharge outlet (6) is mounted between the side wall of the combustion chamber (1) and the tail part of the rotational band (5). The invention has a simple structure of the processing device, which is convenient to use; the processing technique of the invention combines the layer combustion of the cool tea scrap with the suspension combustion, which solves the ignition and burning-out problems of the cool tea scrap skillfully; the processing technique of the invention can not only reclaim a large amount of energy but also realize the volume reduction treatment for the waste without the discharging of the pollutants; the invention has both great social and economic benefits.

Owner:GUANGDONG UNIV OF TECH

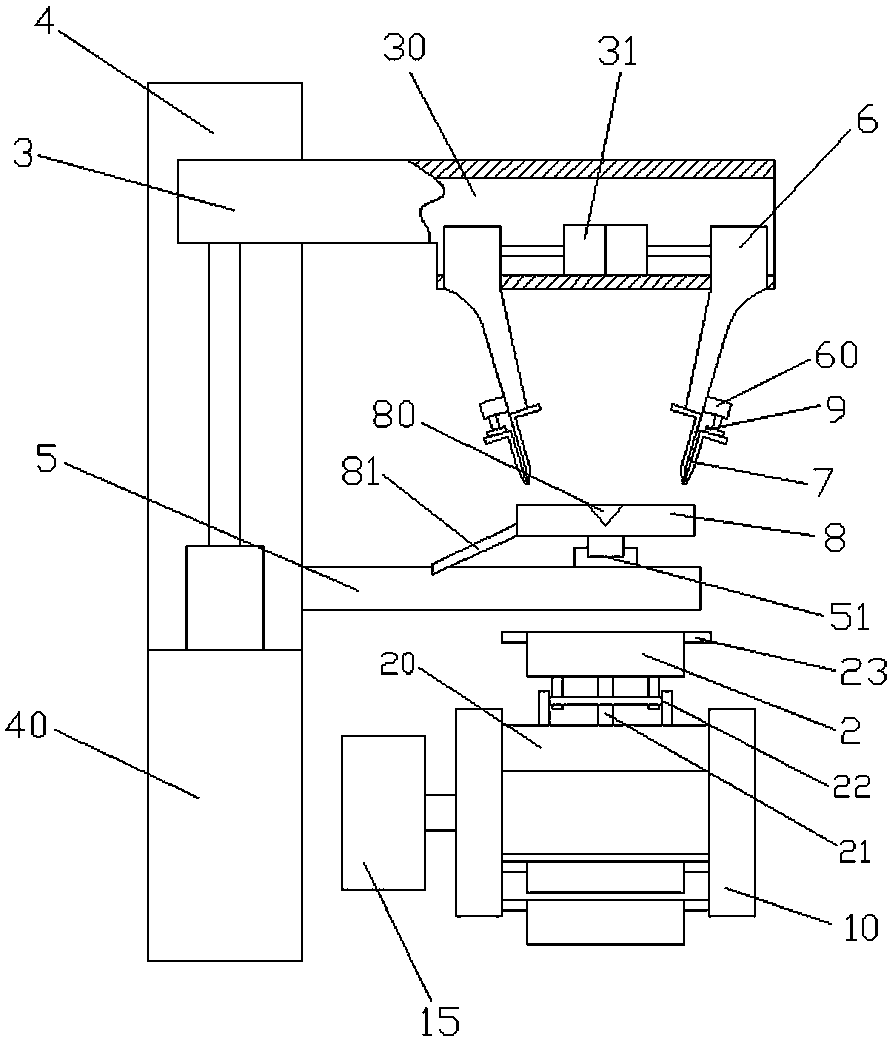

Efficient scraping off and deslagging method for zinc alloy ingot casting

The invention relates to an efficient scraping off and deslagging method for zinc alloy ingot casting. The method comprises the following steps: firstly, a conveying device conveys a mold containing zinc alloy ingot casting liquid to the position under telescopic scraping-off plates; secondly, a lifting mechanism drives the scraping-off plates to move downwards to be attached to the end of the mold, the scraping-off plates stretch out downwards and are inserted into the zinc alloy ingot casting liquid, the two scraping-off plates oppositely move, slag on the surface of the zinc alloy ingot casting liquid is collected to the middle from the two ends and is clamped, and the lifting mechanism drives the scraping-off plates and the slag to move upwards to the initial height; thirdly, a slag groove moves to the position under the scraping-off plate in the transverse direction, the two scraping-off plates move in the opposite direction while retracting upwards, the slag falls into the slag groove under the gravity effect and the effect of a discharging plate, the slag groove moves to the initial position in the reverse direction, and scraping off and deslagging are completed. The method is reasonable in design and simple in use, the deslagging efficiency is effectively improved, and the manual labor amount is reduced.

Owner:福建龙翌合金有限公司

Feeding combustion device with automatic residue elimination function

InactiveCN109631086AEfficient separationImprove combustion qualityDomestic stoves or rangesLighting and heating apparatusSpiral bladeEngineering

The invention discloses a feeding combustion device with an automatic residue elimination function, and aims at providing a feeding combustion device with an automatic residue elimination function andcapable of effectively separating particle powder generated in a combustion process in time to realize automatic residue elimination, so that the combustion quality of biomass particles is improved.The feeding combustion device with the automatic residue elimination function comprises a feeding device and a combustion device, wherein the feeding device comprises a lower feeding barrel, a lower feeding packing auger rotationally arranged in the lower feeding barrel, a lower feeding barrel charge port formed in the outer side surface of the lower feeding barrel, and a lower feeding barrel discharge port formed in the outer side surface of the lower feeding barrel; spiral blades on the lower feeding packing auger comprise forward-propulsion spiral blades and reverse-propulsion spiral blades; the forward-propulsion spiral blades and the reverse-propulsion spiral blades are located at the two opposite sides of the lower feeding barrel discharge port; and the combustion device comprises acombustion bowl located above the lower feeding barrel discharge port, a material guide barrel through port formed in the bottom surface of the combustion bowl, and a material guide barrel connectingthe combustion bowl with the lower feeding barrel discharge port.

Owner:ZHEJIANG ZHONGLI TOOL MFG

A kind of molten steel alloying device and alloying method of rotating injection powder

The invention discloses a molten steel alloying device adopting rotary injection of powder, and an alloying method. According to the molten steel alloying device adopting rotary injection of powder, multipoint simultaneous alloying can be achieved by using an inverted T-shaped powder gun; the rotary injection alloy powder method is used for alloying, the alloying temperature can be reduced, and the alloying time is shortened; the alloy yield is improved effectively, and the alloy elements after alloying are high in uniformity; a feeding system and an injection system can be controlled automatically and adjusted on line; and the powder gun is prevented from being blocked effectively, and automatic deslagging of the powder gun can be achieved.

Owner:ANGANG STEEL CO LTD

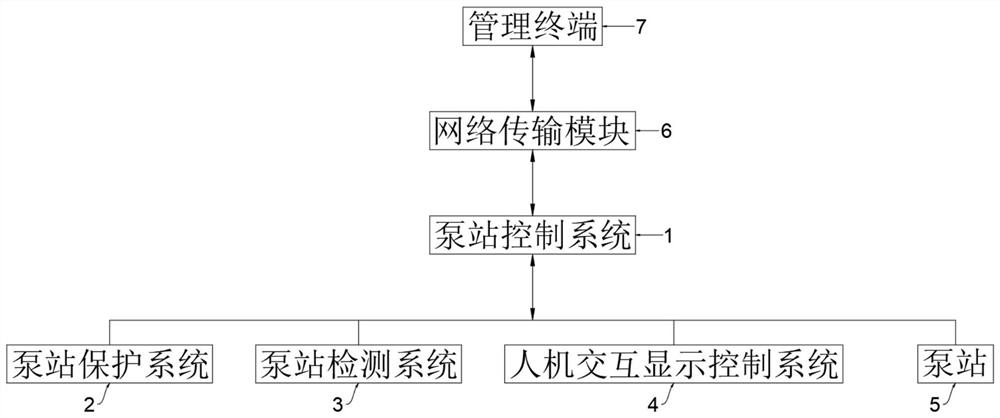

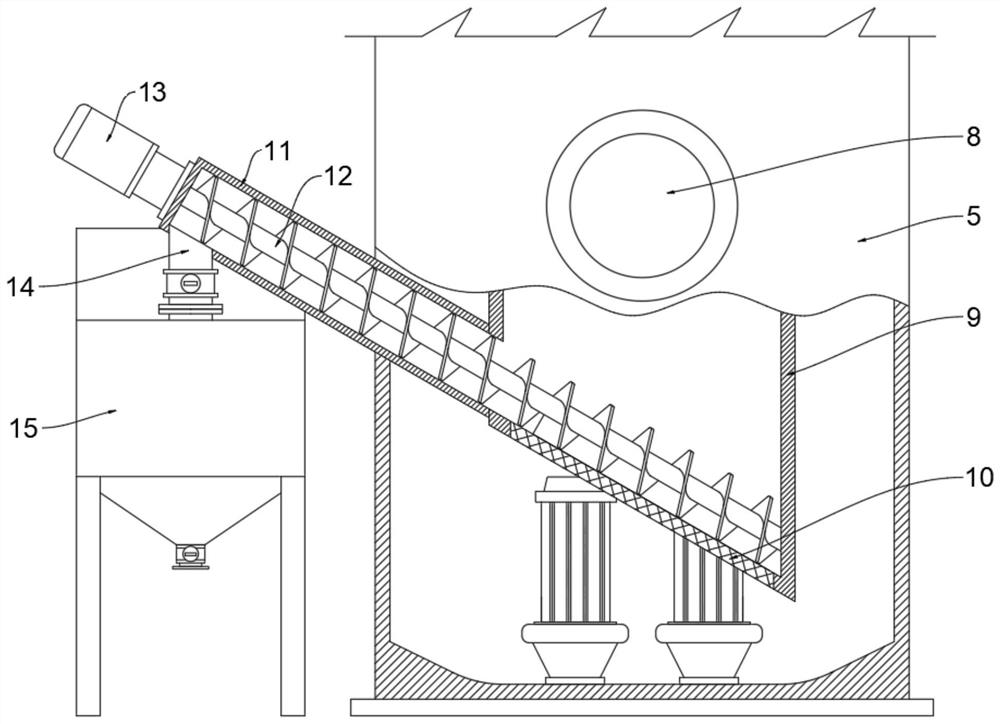

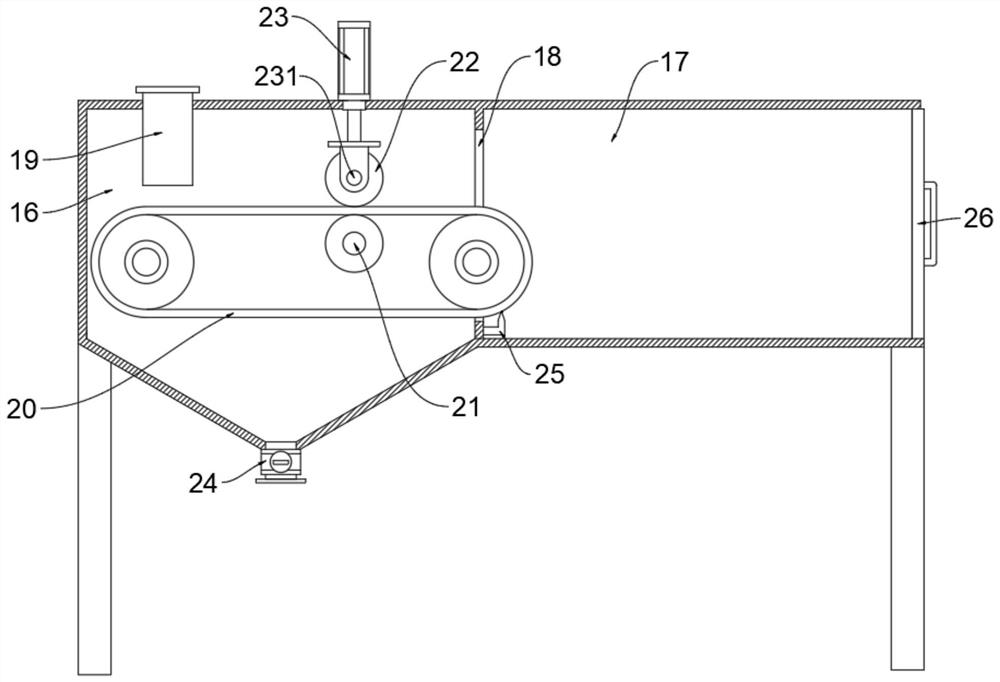

Integrated intelligent pump station control system

InactiveCN113050527AComprehensive protectionExtended service lifeProgramme controlComputer controlElectric energyStandby power

The invention discloses an integrated intelligent pump station control system, relates to the related field of sewage treatment, and aims to solve the problems that an existing integrated intelligent pump station control system is not comprehensive enough, the use is not convenient enough, and the actual work needs cannot be met. The pump station control system is bidirectionally connected with a pump station protection system, a pump station detection system, a man-machine interaction display control system, a pump station and a network transmission module, wherein the network transmission module is bidirectionally connected with a management terminal, the pump station protection system comprises a remote start-stop module, a standby power supply module, a humidity alarm module and a smoke alarm module, the pump station detection system comprises a pressure monitoring module, a flow monitoring module, an electric energy monitoring module, a water level monitoring module and a water quality monitoring module, a water inlet pipe is arranged at one end of the pump station, and a filter box is installed below one end of the water inlet pipe.

Owner:安徽皖水水务发展有限公司

Vertical band sawing machine

InactiveCN112828394ARealize automatic slag removalReduce labor burdenMetal sawing devicesMaintainance and safety accessoriesGear wheelElectric machinery

The invention relates to the technical field of sawing machines, and particularly discloses a vertical band sawing machine which comprises a base. A shell fixedly connected to the outer wall of the base, a first motor fixedly connected to the inner wall of the shell, a first rotating shaft fixedly connected to the output end of the first motor, and a first belt wheel, a first belt disc and a crankshaft fixedly connected to the first rotating shaft. The inner wall of the shell is rotatably connected with a second rotating shaft, the second rotating shaft is fixedly connected with a second tape reel and a first gear, the first tape reel and the second tape reel are sleeved with a saw band, the shell is provided with a water cooling mechanism, the outer wall of the shell is fixedly connected with a baffle, and the inner wall of the shell is provided with a cleaning mechanism. The vertical band sawing machine is easy to operate and has the heat dissipation and residue cleaning functions, meanwhile, a movable workbench is used for replacing manual material moving for cutting, the cutting precision is guaranteed, the labor burden of a user is relieved, the production efficiency is improved, and the service life of a saw belt is prolonged.

Owner:张嘉乐

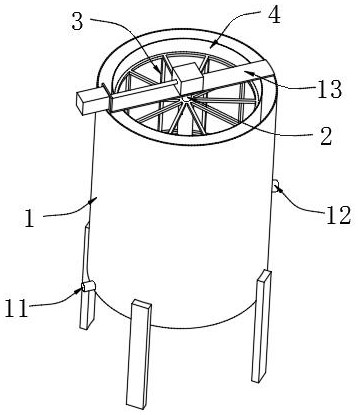

Honey extracting, filtering and residue removing all-in-one machine

The invention provides a honey extracting, filtering and residue removing all-in-one machine. The honey extracting, filtering and residue removing all-in-one machine comprises a honey extracting cylinder, a rotating shaft, a honey extracting frame, a first filter cylinder and a second filter cylinder, and a honey outlet and a residue outlet are formed in the outer wall of the honey extracting cylinder; the honey extracting frame sleeves the upper part of the periphery of the rotating shaft; the first filter cylinder is arranged between the outer wall of the honey extracting frame and the inner wall of the honey extracting cylinder; the lower diameter of the first filter cylinder is gradually reduced and connected with the bottom surface of the honey extracting cylinder; the second filter cylinder is arranged at the lower portion of the honey extracting frame in a sleeving manner and is accommodated in the first filter cylinder, the bottom of the second filter cylinder is fixedly connected with the bottom surface of the honey extracting cylinder, and a residue discharging pipe is arranged on the outer wall of the top of the second filter cylinder, obliquely extends downwards, penetrates through the first filter cylinder and then is communicated with the residue outlet; and a spiral piece is further arranged in the second filter cylinder and sleeves the periphery of the rotating shaft. Honey impurities centrifugally separated from honeycombs are filtered out by arranging the first filter cylinder, a spiral conveying channel is formed by the second filter cylinder and the spiral piece, so that the honey impurities are spirally conveyed upwards from the bottom of the honey extracting cylinder and discharged through the residue discharging pipe and the residue outlet, and automatic residue removal is achieved.

Owner:巫溪县驰小乐农业科技有限公司

Coating for high temperature devices or containers, and preparation method thereof

InactiveCN110272288ARealize automatic slag removalHigh temperature resistantEtchingO-Phosphoric Acid

The invention discloses a coating for high temperature devices or containers, and a preparation method thereof. The coating is prepared from, by weight, 40-50 parts of marbles, 40-50 parts of magnesia, 2-3 parts of zirconia, 2-6 parts of anhydrous phosphoric acid, 0.5-3 parts of calcium aluminate cement, 0.03-0.2 part of washing powder, 0.2-0.8 part of waste newspaper and 30-50 parts of water. Compared with coatings in the prior art, the product of the invention has resistance to high temperatures, oxidation and molten slag and liquid metal etching, has a moderate bonding strength, can effectively solve the problem of adhesion of molten slag and liquid metals of metallurgy and casting to furnace bodies and containers, and realizes the automatic slag removal of nondestructive devices.

Owner:焦作诺尔曼炉业有限公司

High-efficiency scraping and slag removal method for zinc alloy ingot casting

The invention relates to an efficient scraping off and deslagging method for zinc alloy ingot casting. The method comprises the following steps: firstly, a conveying device conveys a mold containing zinc alloy ingot casting liquid to the position under telescopic scraping-off plates; secondly, a lifting mechanism drives the scraping-off plates to move downwards to be attached to the end of the mold, the scraping-off plates stretch out downwards and are inserted into the zinc alloy ingot casting liquid, the two scraping-off plates oppositely move, slag on the surface of the zinc alloy ingot casting liquid is collected to the middle from the two ends and is clamped, and the lifting mechanism drives the scraping-off plates and the slag to move upwards to the initial height; thirdly, a slag groove moves to the position under the scraping-off plate in the transverse direction, the two scraping-off plates move in the opposite direction while retracting upwards, the slag falls into the slag groove under the gravity effect and the effect of a discharging plate, the slag groove moves to the initial position in the reverse direction, and scraping off and deslagging are completed. The method is reasonable in design and simple in use, the deslagging efficiency is effectively improved, and the manual labor amount is reduced.

Owner:福建龙翌合金有限公司

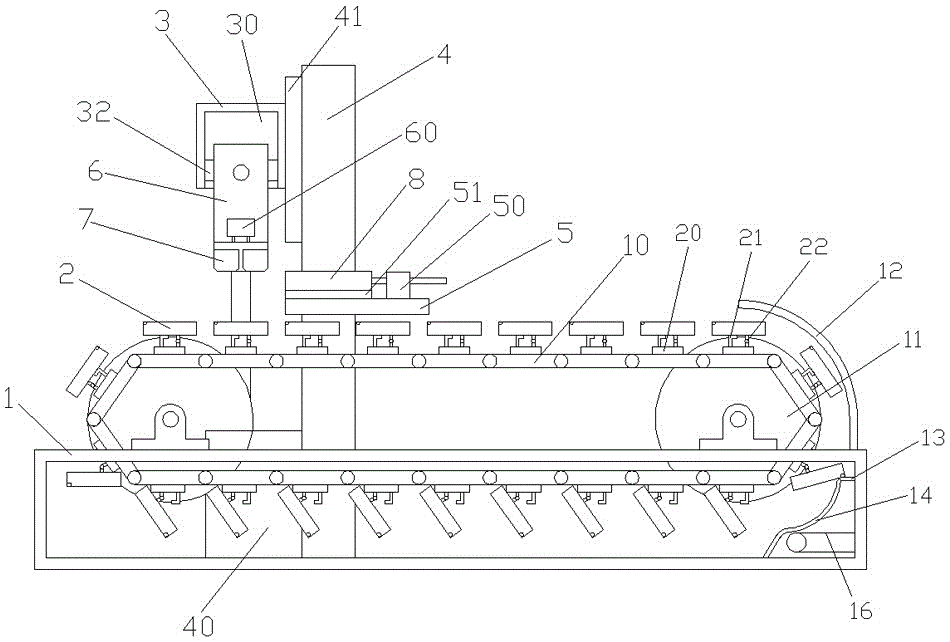

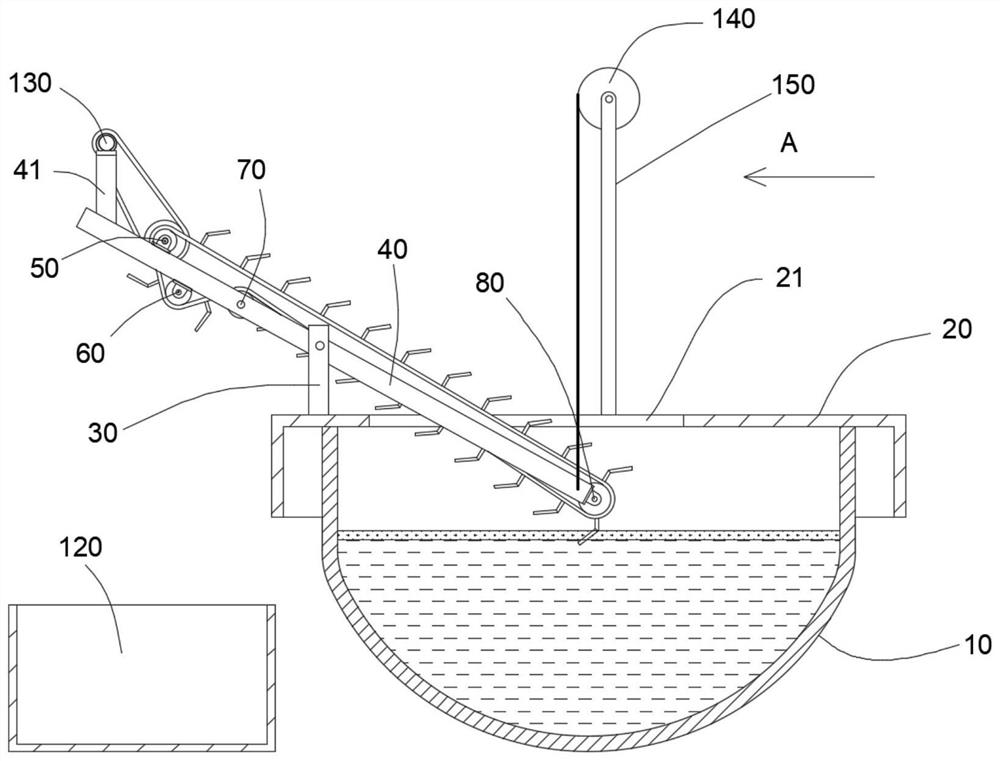

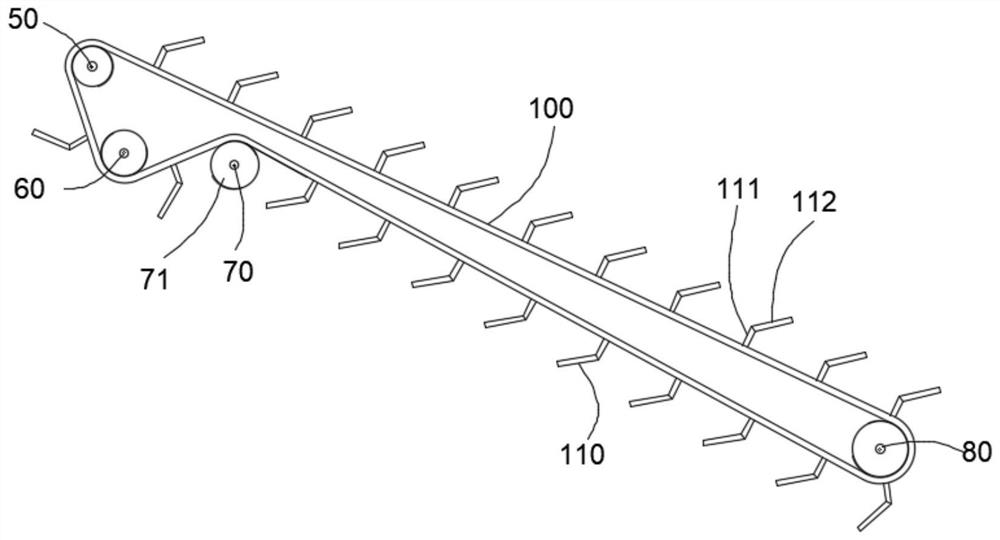

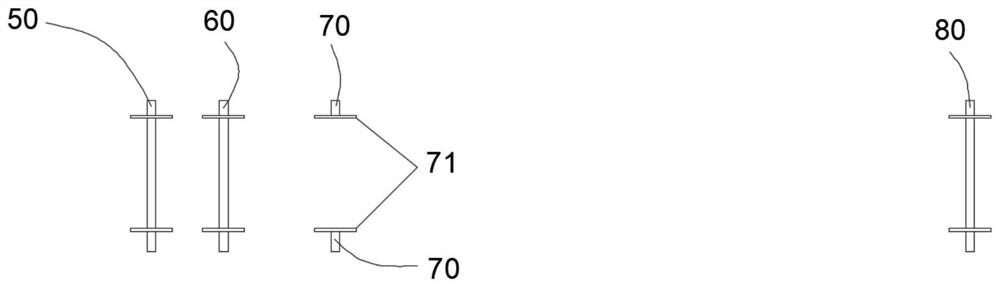

Slag salvaging machine

PendingCN113624016ARealize automatic slag removalRealize dumpingCharge manipulationSlagElectric machinery

The invention relates to the technical field of molten metal surface slag salvaging, in particular to a slag salvaging machine which is provided with two rotatable chains, a plurality of shovel plates are uniformly fixed on the chains, the chains obliquely and downwards extend into a melting pot, a motor is arranged to drive the chains to rotate, the shovel plates on the chains sequentially sweep over molten lead and salvage dross of the molten lead in the melting pot, and the effect of automatic slag salvaging is achieved.

Owner:李想

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com