Movable type molten copper refining, deslagging and stirring device

A stirring device and mobile technology, which is applied in the field of copper water refining, slag removal, and stirring devices, can solve the problems of affecting the refining effect, prone to oxidation reaction, uniformity of stirring, and unsatisfactory slag removal effect, etc., to achieve The effect of adding refining agents in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

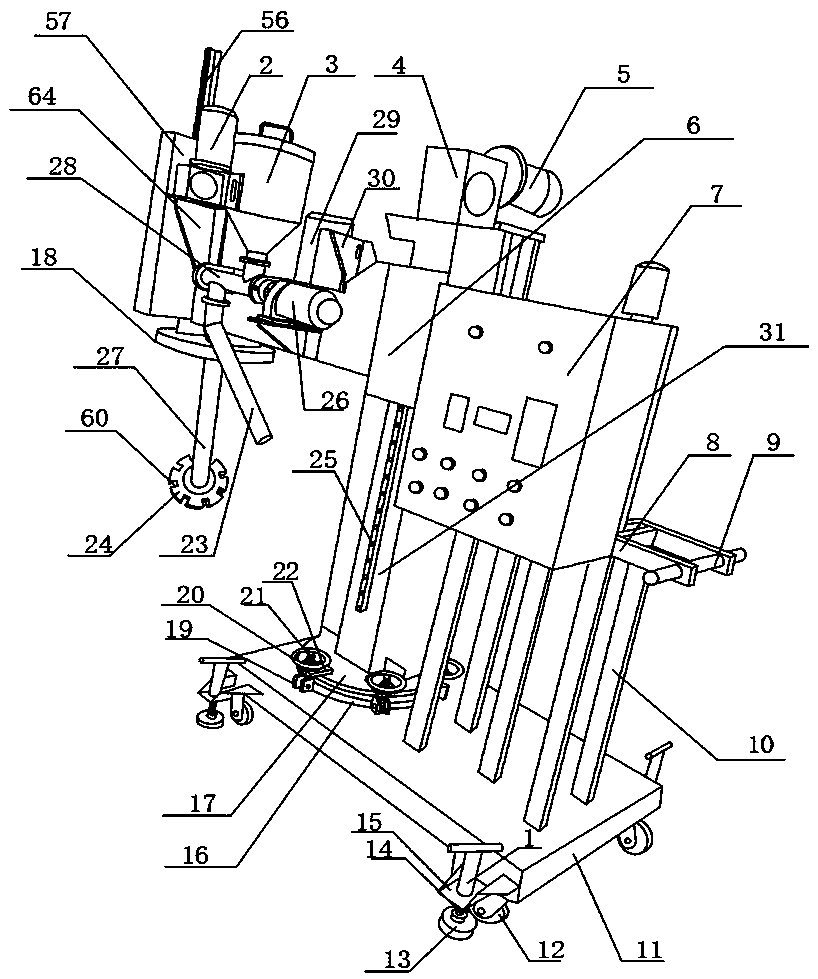

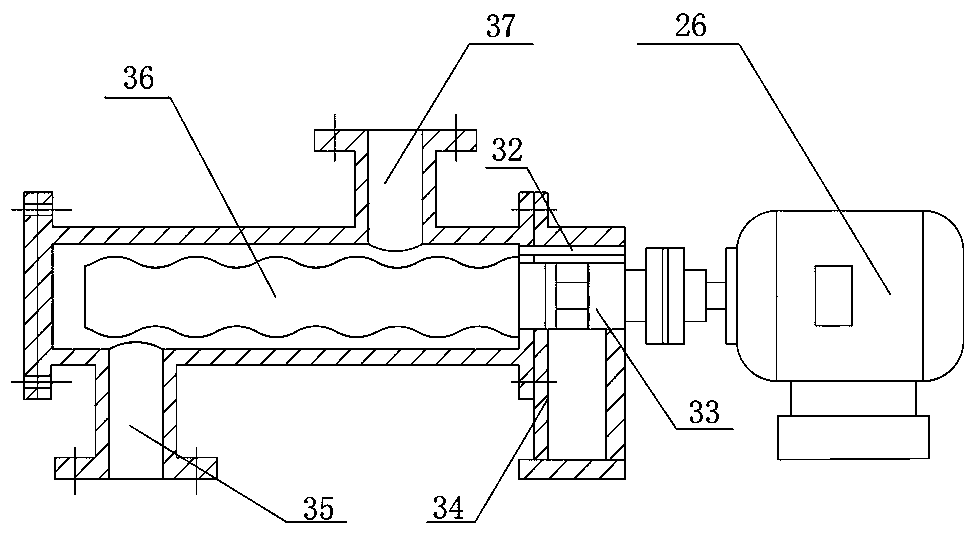

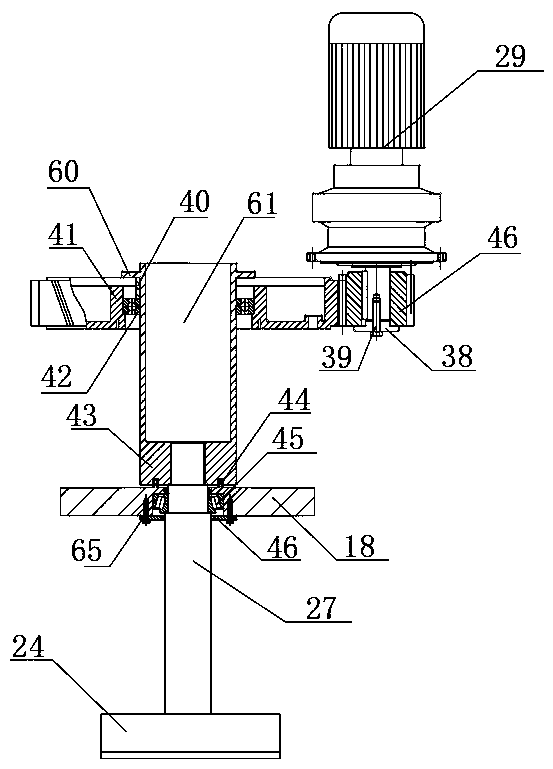

[0026] See attached Figure 1-8 A kind of mobile copper water refining, slag removal, stirring device comprises: mobile platform 11, and mobile platform 11 is equipped with copper water refining agent adding device through mounting bracket 6, and copper water refining agent adding device comprises the base 34 that connects mounting bracket 6, The base 34 is provided with a shaft coupling 33 and a high-pressure intake pipe 32, the two ends of the shaft coupling 33 are respectively connected to the main shaft of the second motor 26 and the stirring screw 36, the stirring screw 36 is installed in the body of the refining tube 28, and the refining tube 28 The side is connected to the refining agent storage tank 3 through the first connecting pipe 37, and the lower side of the refining pipe 28 is connected to the refining agent output inclined pipe 23 through the second connecting pipe 35, and the refining agent in the refining agent storage tank 3 is passed through the stirring scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com