High-efficiency scraping and slag removal method for zinc alloy ingot casting

A zinc alloy and skin scraping technology, which is applied in casting equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of slag dripping, heavy manual labor, and low efficiency of slag removal, and achieve reduced labor and automation High, good slag removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

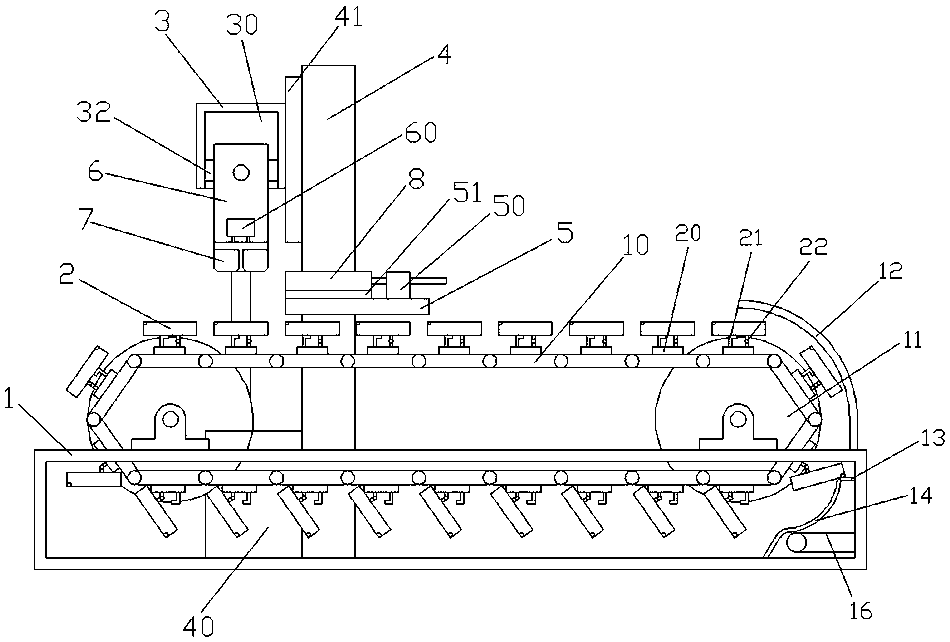

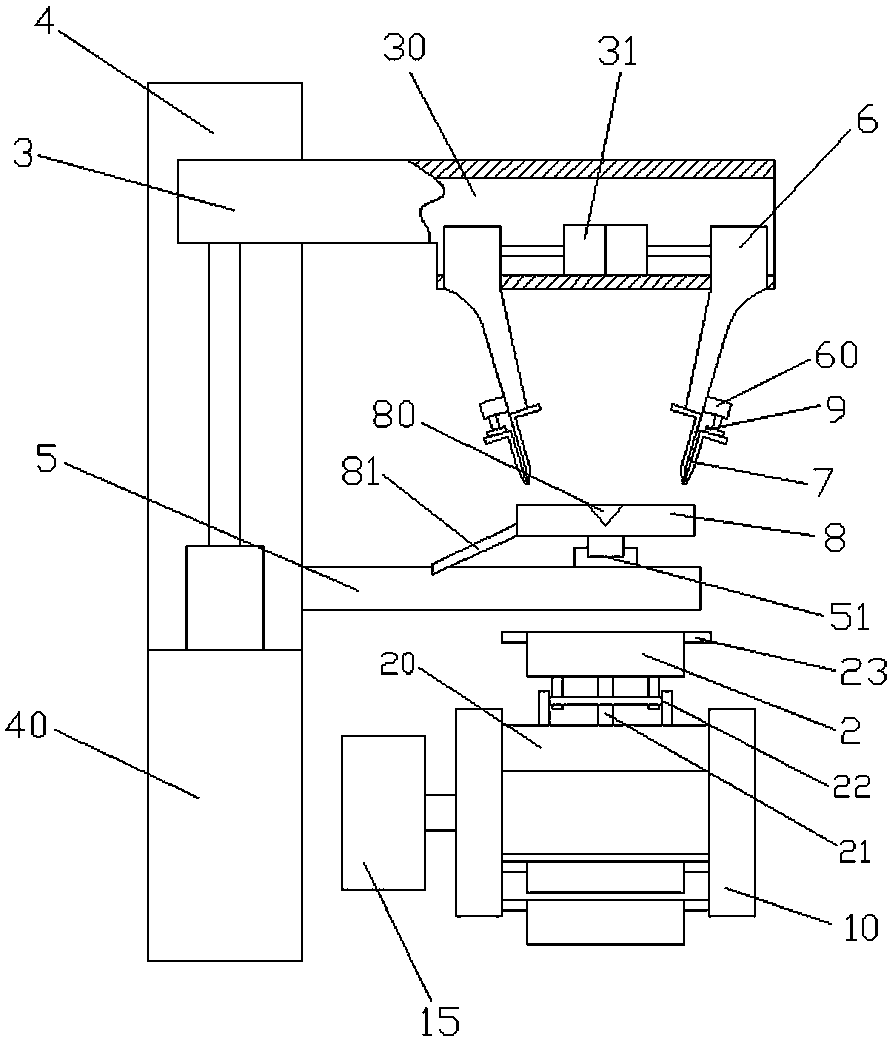

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] Such as Figure 1-2 As shown, the zinc alloy ingot casting high-efficiency scraping and slag removal method of the present invention comprises the following steps:

[0023] (1) The conveying device conveys the forming mold containing the zinc alloy ingot casting liquid to the right below the retractable scraper;

[0024] (2) The lifting mechanism drives the scraper to move down to close to the end of the forming mold, the scraper extends downward and is inserted into the zinc alloy ingot casting liquid, and the two scrapers move towards each other, and the zinc alloy ingot casting liquid The slag of the skin is scraped from both ends to the middle and clamped, and the lifting mechanism drives the scraper and the slag to move upward to the initial height;

[0025] (3) The slag tank moves horizontally to directly below the scra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com