Vertical band sawing machine

A band sawing machine and vertical technology, applied in the field of sawing machines, can solve the problems of wasting labor costs, affecting cutting accuracy, lack of heat dissipation and residue cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

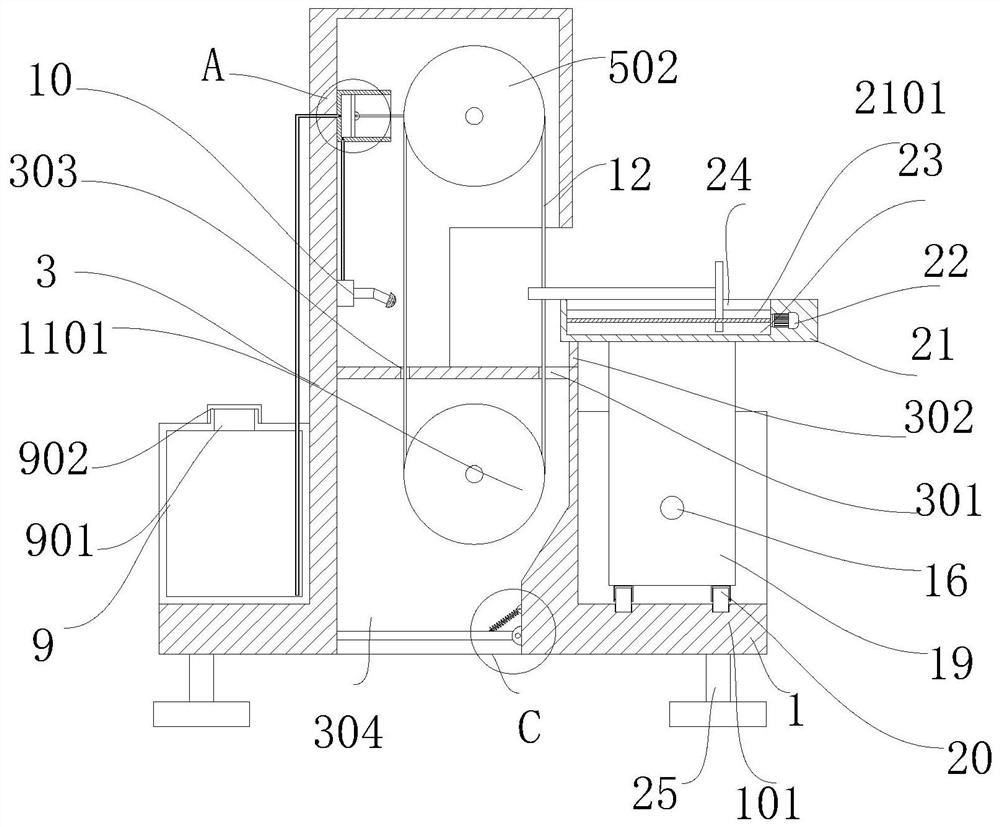

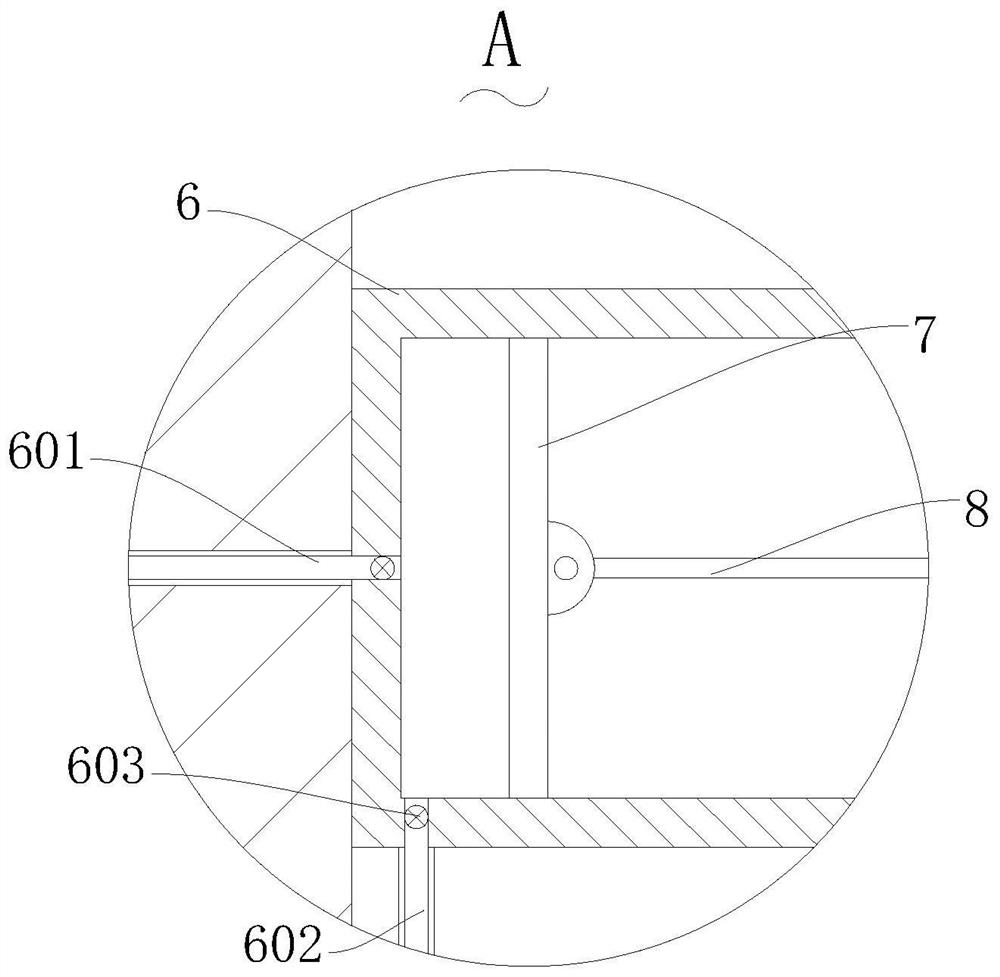

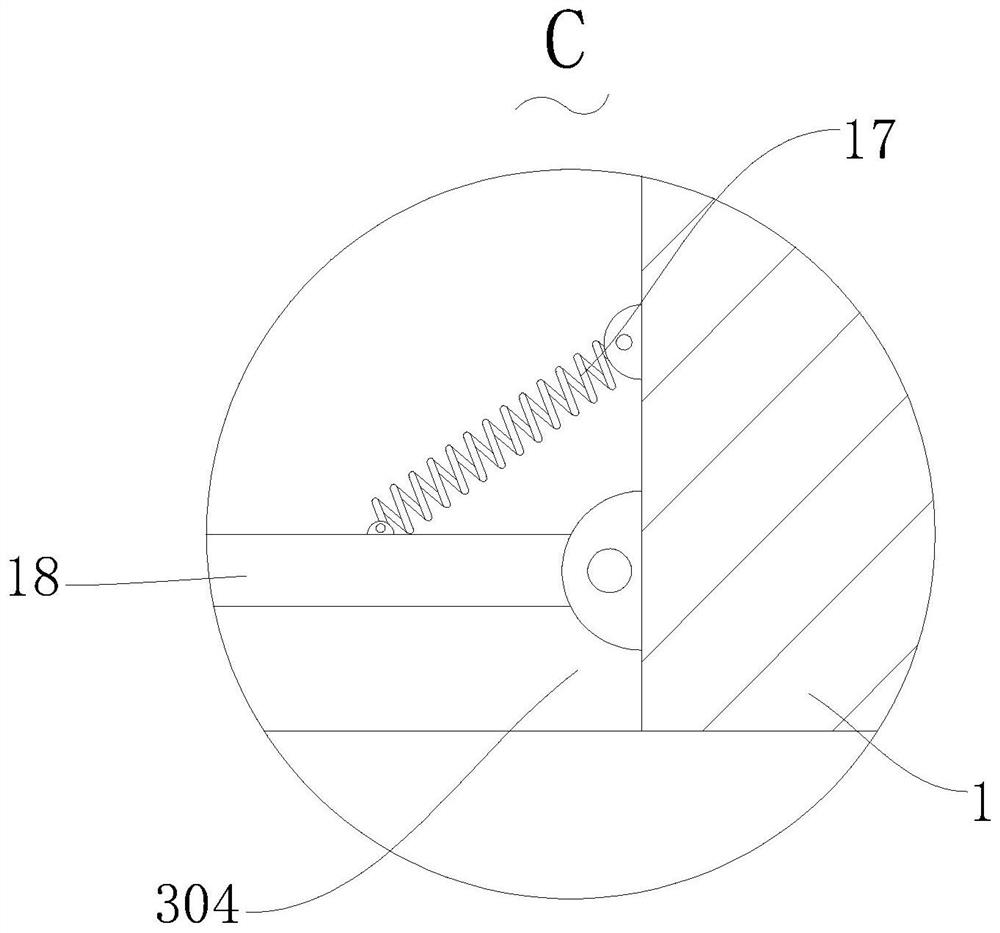

[0034] refer to figure 1 , Figure 4 and Figure 6, a vertical band sawing machine, comprising a base 1, the outer wall of the base 1 is fixedly connected with a casing 3, the inner wall of the casing 3 is fixedly connected with a first motor 4, the output end of the first motor 4 is fixedly connected with a first rotating shaft 5, and the first rotating shaft 5 A first pulley 501, a first belt reel 502 and a crankshaft 503 are fixedly connected to the top, a second rotating shaft 11 is rotatably connected to the inner wall of the casing 3, and a second belt reel 1101 and a first gear 1102 are fixedly connected to the second rotating shaft 11. A saw band 12 is sleeved on the belt reel 502 and the second reel 1101, the casing 3 is provided with a water-cooling mechanism, the outer wall of the casing 3 is fixedly connected with a baffle 302, the inner wall of the casing 3 is provided with a cleaning mechanism, and the outer wall of the base 1 is fixedly connected with a Fixed ...

Embodiment 2

[0045] refer to figure 1 , figure 2 and Figure 4 , a vertical band sawing machine, comprising a base 1, the outer wall of the base 1 is fixedly connected with a casing 3, the inner wall of the casing 3 is fixedly connected with a first motor 4, the output end of the first motor 4 is fixedly connected with a first rotating shaft 5, and the first rotating shaft 5 A first pulley 501, a first belt reel 502 and a crankshaft 503 are fixedly connected to the top, a second rotating shaft 11 is rotatably connected to the inner wall of the casing 3, and a second belt reel 1101 and a first gear 1102 are fixedly connected to the second rotating shaft 11. A saw band 12 is sleeved on the belt reel 502 and the second reel 1101, the casing 3 is provided with a water-cooling mechanism, the outer wall of the casing 3 is fixedly connected with a baffle 302, the inner wall of the casing 3 is provided with a cleaning mechanism, and the outer wall of the base 1 is fixedly connected with a Fixed...

Embodiment 3

[0056] refer to figure 1 , image 3 and Figure 5 , a vertical band sawing machine, comprising a base 1, the outer wall of the base 1 is fixedly connected with a casing 3, the inner wall of the casing 3 is fixedly connected with a first motor 4, the output end of the first motor 4 is fixedly connected with a first rotating shaft 5, and the first rotating shaft 5 A first pulley 501, a first belt reel 502 and a crankshaft 503 are fixedly connected to the top, a second rotating shaft 11 is rotatably connected to the inner wall of the casing 3, and a second belt reel 1101 and a first gear 1102 are fixedly connected to the second rotating shaft 11. A saw band 12 is sleeved on the belt reel 502 and the second reel 1101, the casing 3 is provided with a water-cooling mechanism, the outer wall of the casing 3 is fixedly connected with a baffle 302, the inner wall of the casing 3 is provided with a cleaning mechanism, and the outer wall of the base 1 is fixedly connected with a Fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com