A kind of molten steel alloying device and alloying method of rotating injection powder

A molten steel alloying and rotary blowing technology, applied in the field of iron and steel metallurgy, can solve the problems of large molten steel temperature drop during melting time, low alloy yield, long alloying time, etc. Alloying temperature drop, high uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

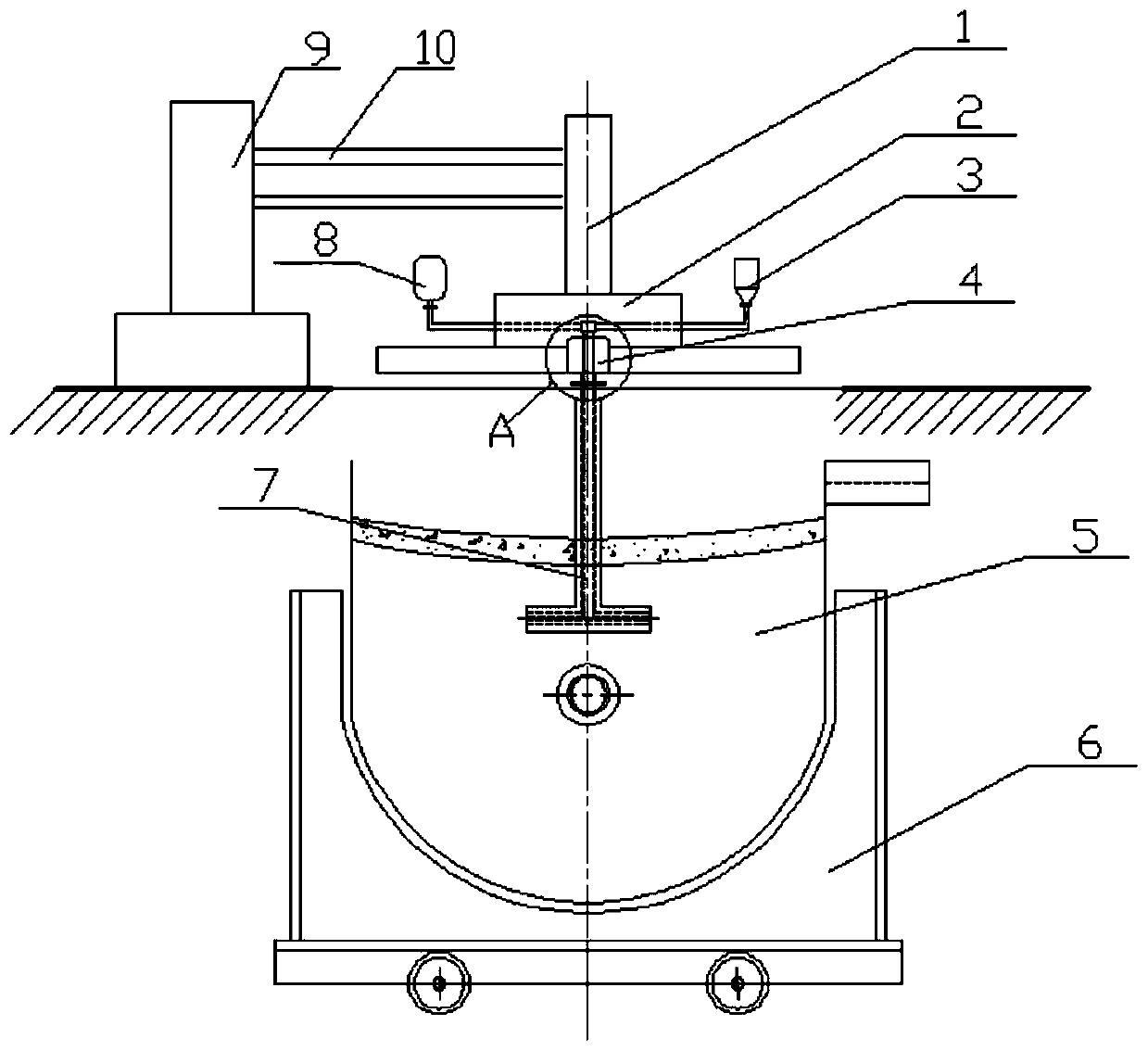

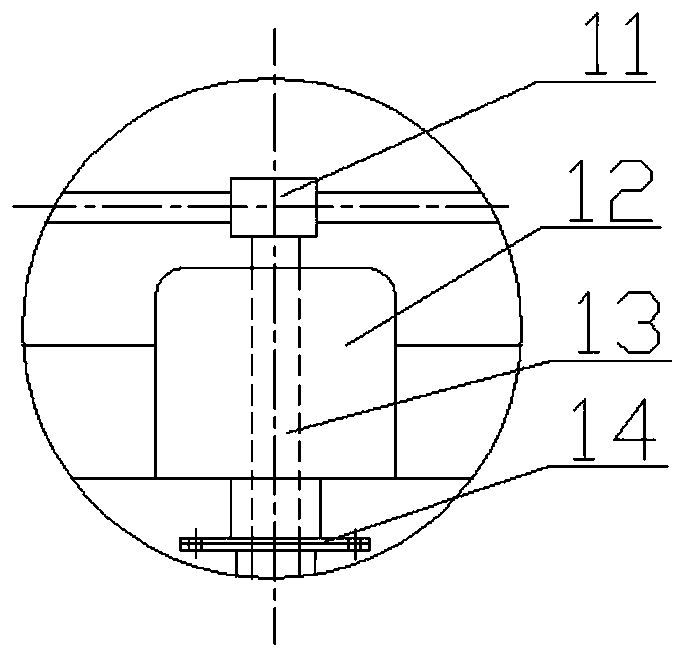

[0026] Adopt the present invention to carry out alloying test, and the maximum diameter of anti-splashing device 2 is 110% of the outer diameter of tank mouth of molten steel tank 5, and the refractory material wrapped on the outside of powder spray gun 7 has a length of refractory material that is 1 / 2 of the total length of the powder spray gun; The injection system 8 sprays nitrogen with a purity of more than 99.9% and a pressure of 0.4 MPa into the molten steel through the powder spray gun 7, and at the same time opens the elevator 9 to lower the powder spray gun 7 of the externally wrapped refractory material to 400 mm from the bottom of the molten steel tank 5. When the powder spray gun 7 reaches the working position, the rotating device 4 is turned on, and the rotation speed is 10 rpm. At the same time, the feeding system 3 is started to spray the total amount of alloy to be added into the molten steel through the powder spray gun 7. The alloy particle size 0.09mm, adjust...

Embodiment 2

[0028]Adopt the present invention to carry out alloying test, and the maximum diameter of anti-splashing device 2 is 120% of the outer diameter of tank mouth of molten steel tank 5, and the refractory material of dust spray gun 7 external wrapping is 2 / 3 of the total length of powder spray gun; The injection system 8 sprays nitrogen with a purity of more than 99.9% and a pressure of 0.5 MPa into the molten steel through the powder spray gun 7, and at the same time opens the elevator 9 to lower the externally wrapped refractory material powder spray gun 7 to 450 mm from the bottom of the molten steel tank 5. When the powder spray gun 7 reaches the working position, turn on the rotating device 4, the rotation speed is 20 rpm, and start the feeding system 3 at the same time to spray the total amount of alloy that needs to be added into the molten steel through the powder spray gun 7, and the alloy particle size 0.106mm, adjust the injection system 8 to adjust the pressure to the w...

Embodiment 3

[0030] Adopt the present invention to carry out alloying test, the maximum diameter of anti-splashing device 2 is 130% of the outer diameter of tank mouth of molten steel tank 5, and the outer wrapping refractory material of powder spraying gun 7 has the length of refractory material being 2 / 3 of the total length of powder spraying gun; Injection system 8 sprays nitrogen with a purity of more than 99.9% and a pressure of 0.6 MPa into the molten steel through the powder spray gun 7, and at the same time opens the elevator 9 to lower the externally wrapped refractory material powder spray gun 7 to 500 mm from the bottom of the molten steel tank 5. When the powder spray gun 7 reaches the working position, turn on the rotating device 4, the rotation speed is 30 rpm, and start the feeding system 3 at the same time to spray the total amount of alloy that needs to be added into the molten steel through the powder spray gun 7, and the alloy particle size 0.125mm, adjust the injection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com