A welding process for thick-walled beams and columns of marine engineering equipment

A marine engineering and welding process technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high consumption of welding materials, easy generation of cracks and pores, and wide groove, so as to save welding materials and improve welding quality The effect of controlling and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A welding process for thick-walled beams and columns of marine engineering equipment in the present invention comprises the following steps:

[0020] 1) Selection of welding wire: You can choose the corresponding welding wire according to the difference of welding beams and columns (plates), usually choose H08A or H10Mn2, in this embodiment, choose H08A.

[0021] 2) Cutting and blanking.

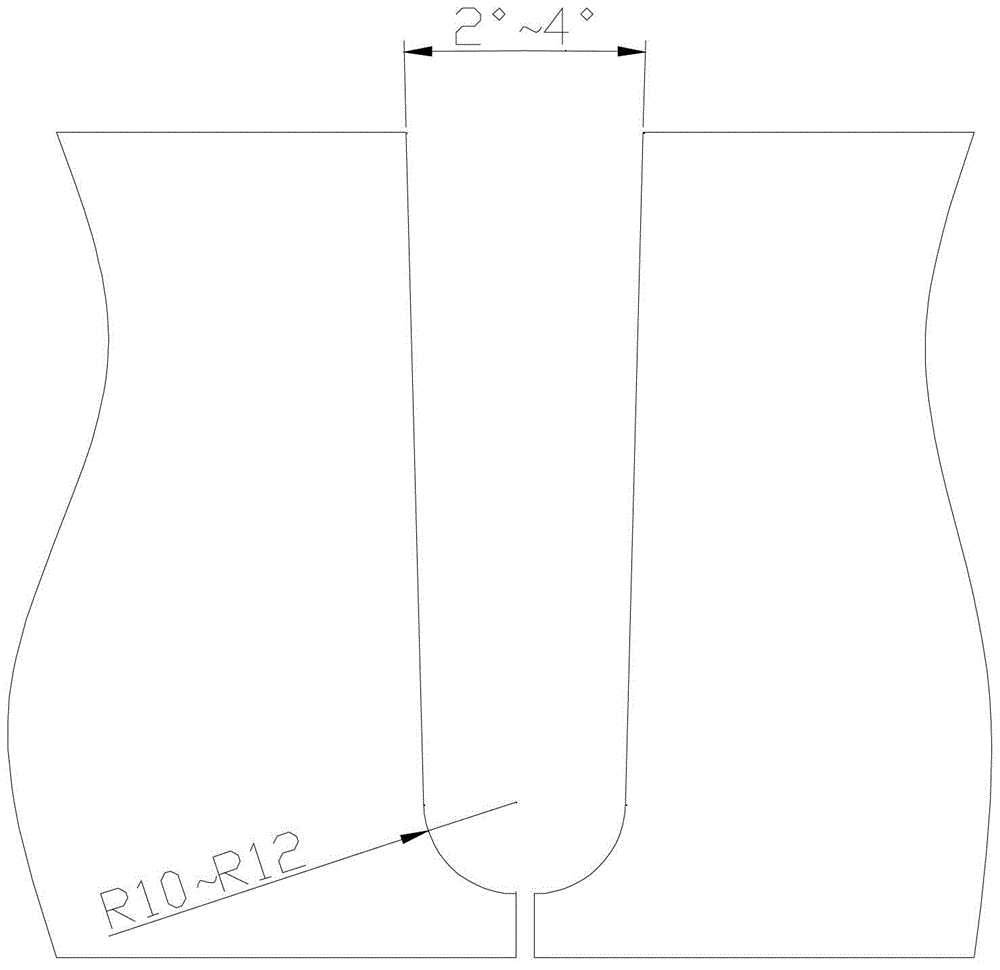

[0022] 3) Groove processing: For the welding groove of thick-walled beams and columns, the longitudinal seam can be processed into a narrow U shape by using a planer or milling machine, and the circular seam can be processed into a narrow U shape by a vertical lathe. The angle of the U-shaped groove is 2°, and the arc radius of the bottom of the groove is 10mm.

[0023] 4) Preheating before welding: Before preheating, remove the oxide layer, slag, water, oil and other impurities on the groove surface and both sides; before welding, use flame heating or electric heating to weld Carry...

Embodiment 2

[0028] A welding process for thick-walled beams and columns of marine engineering equipment in the present invention comprises the following steps:

[0029] 1) Selection of welding wire: The corresponding welding wire can be selected according to the difference of welding beams and columns (plates), usually H08A or H10Mn2 is selected, and in this embodiment, H10Mn2 is selected.

[0030] 2) Cutting and blanking.

[0031] 3) Groove processing: For the welding groove of thick-walled beams and columns, the longitudinal seam can be processed into a narrow U shape by using a planer or milling machine, and the circular seam can be processed into a narrow U shape by a vertical lathe. The angle of the U-shaped groove is 4°, and the arc radius of the bottom of the groove is 12mm.

[0032] 4) Preheating before welding: Before preheating, remove the oxide layer, slag, water, oil and other impurities on the groove surface and both sides; before welding, use flame heating or electric heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com