Patents

Literature

268results about "Travelling grate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

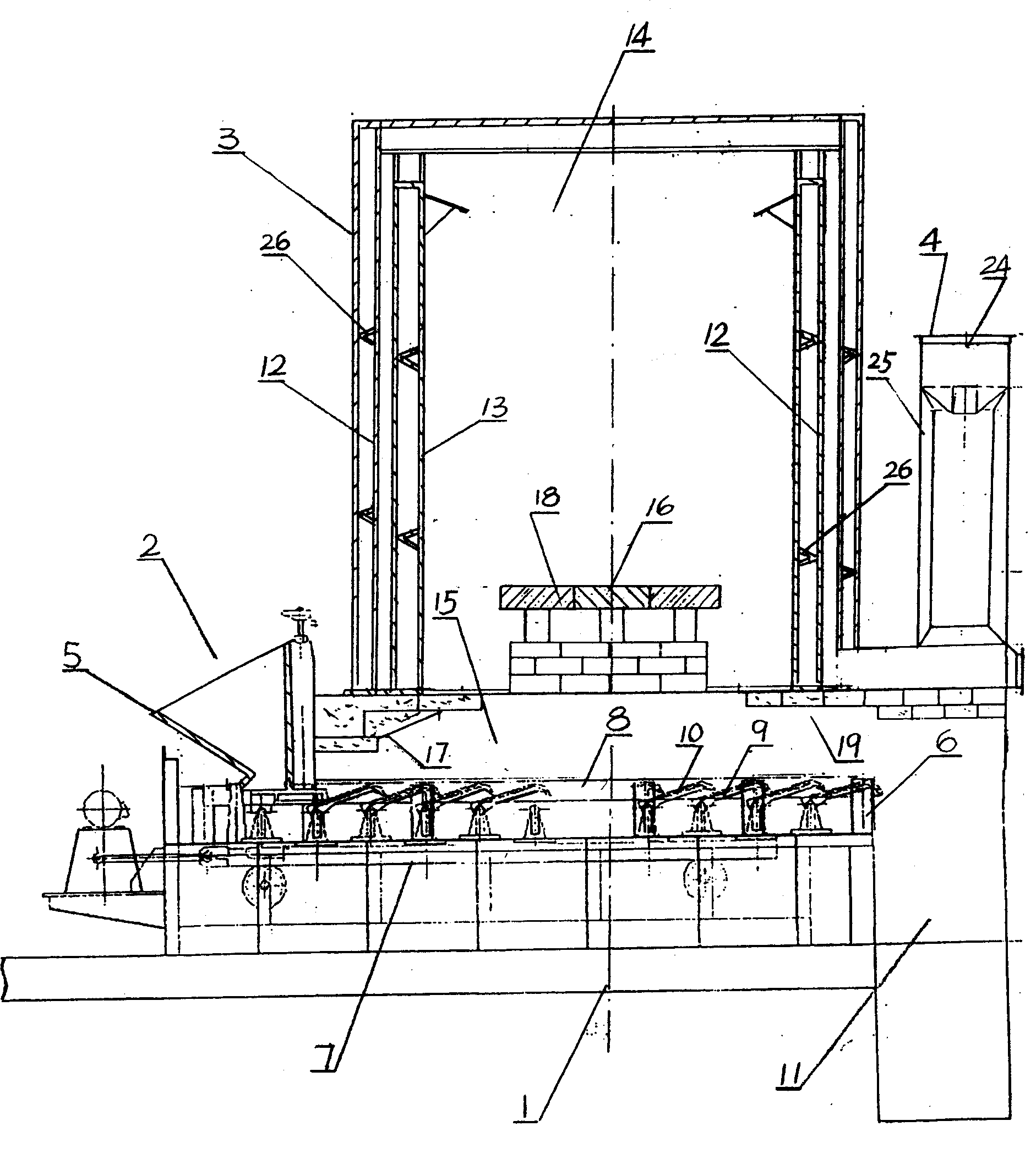

Domestic refuse incinerator

InactiveCN1375656AAids in mashingReduce heat burn rateTravelling grateIncinerator apparatusAir volumeLitter

Owner:屠柏锐 +2

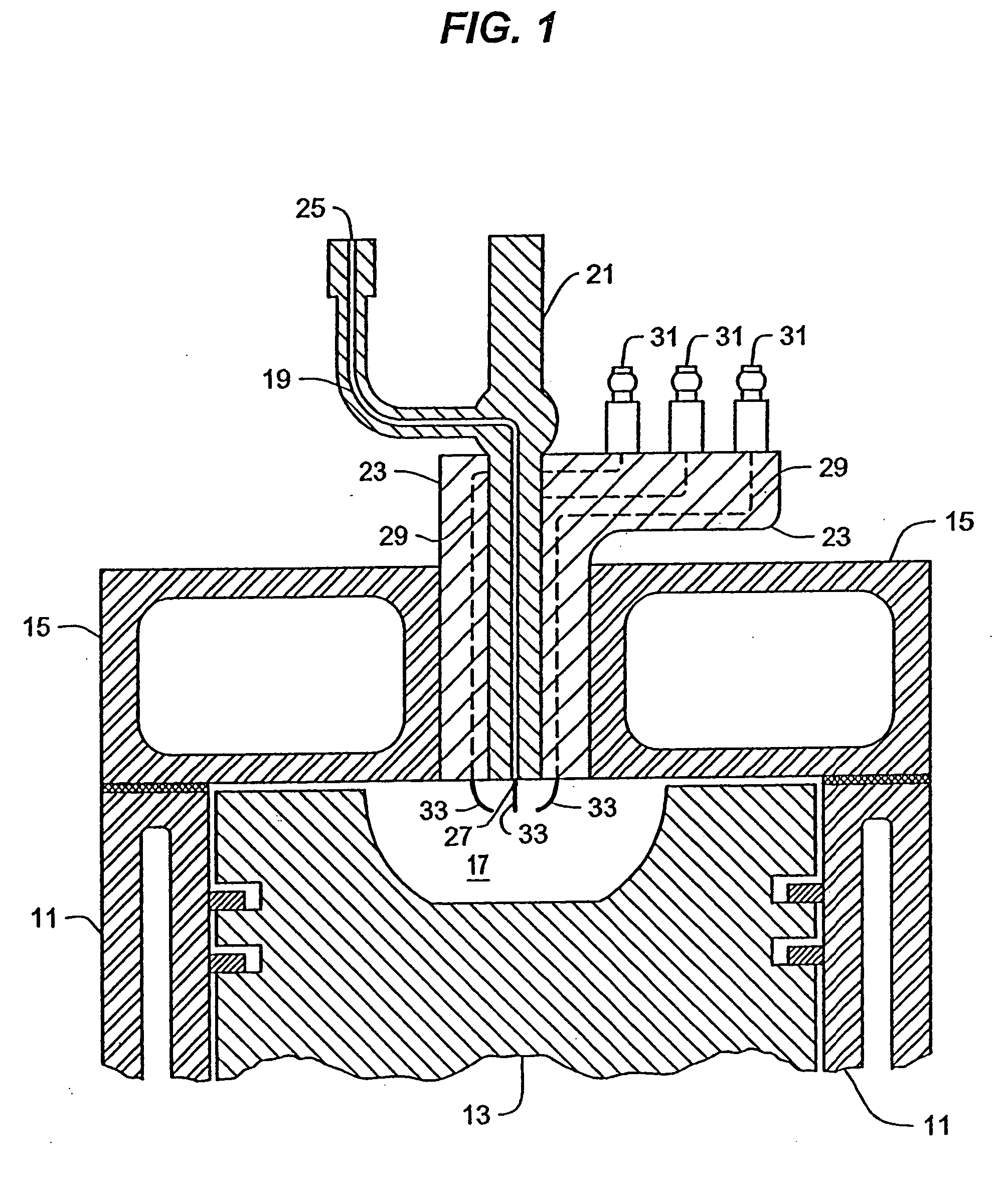

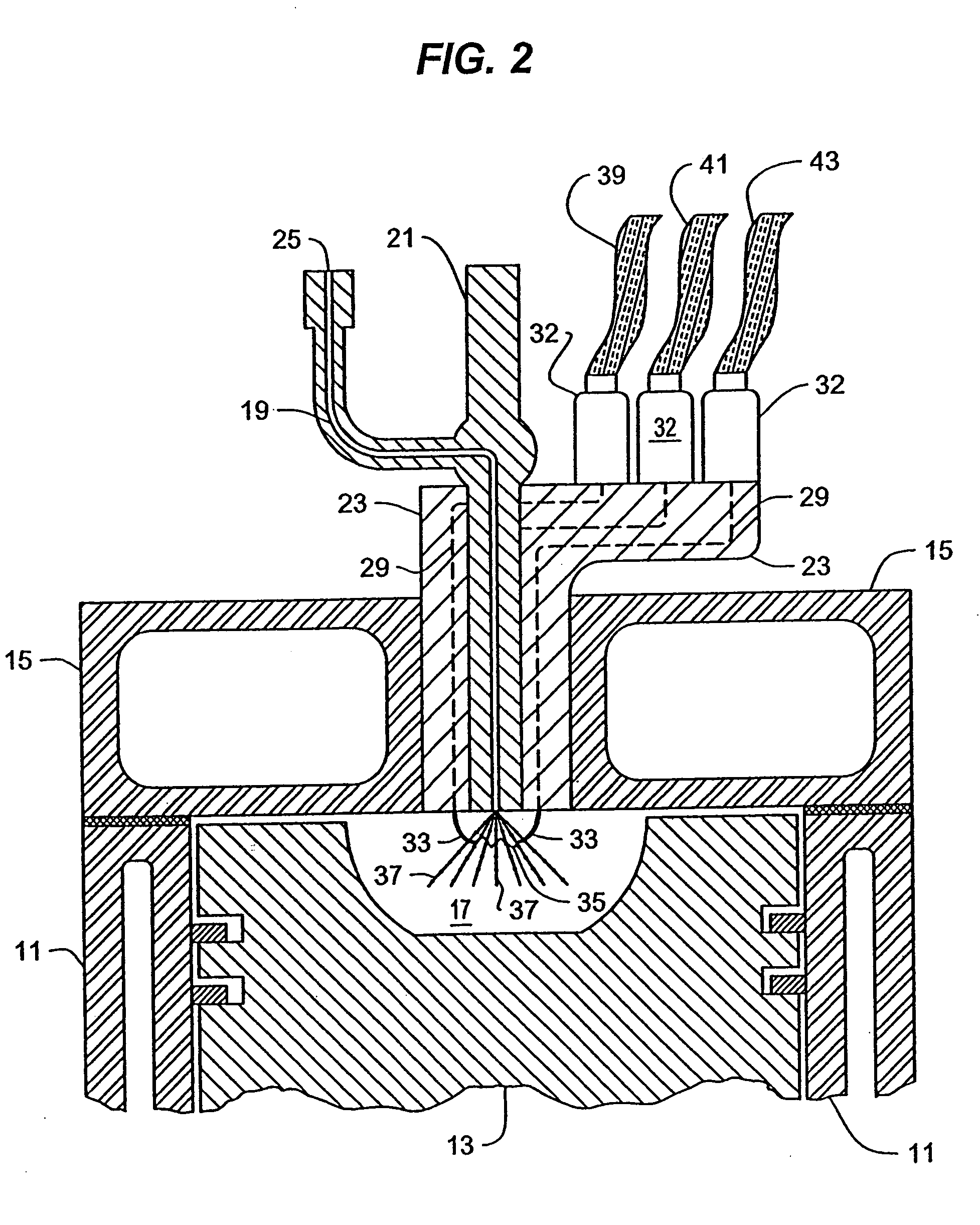

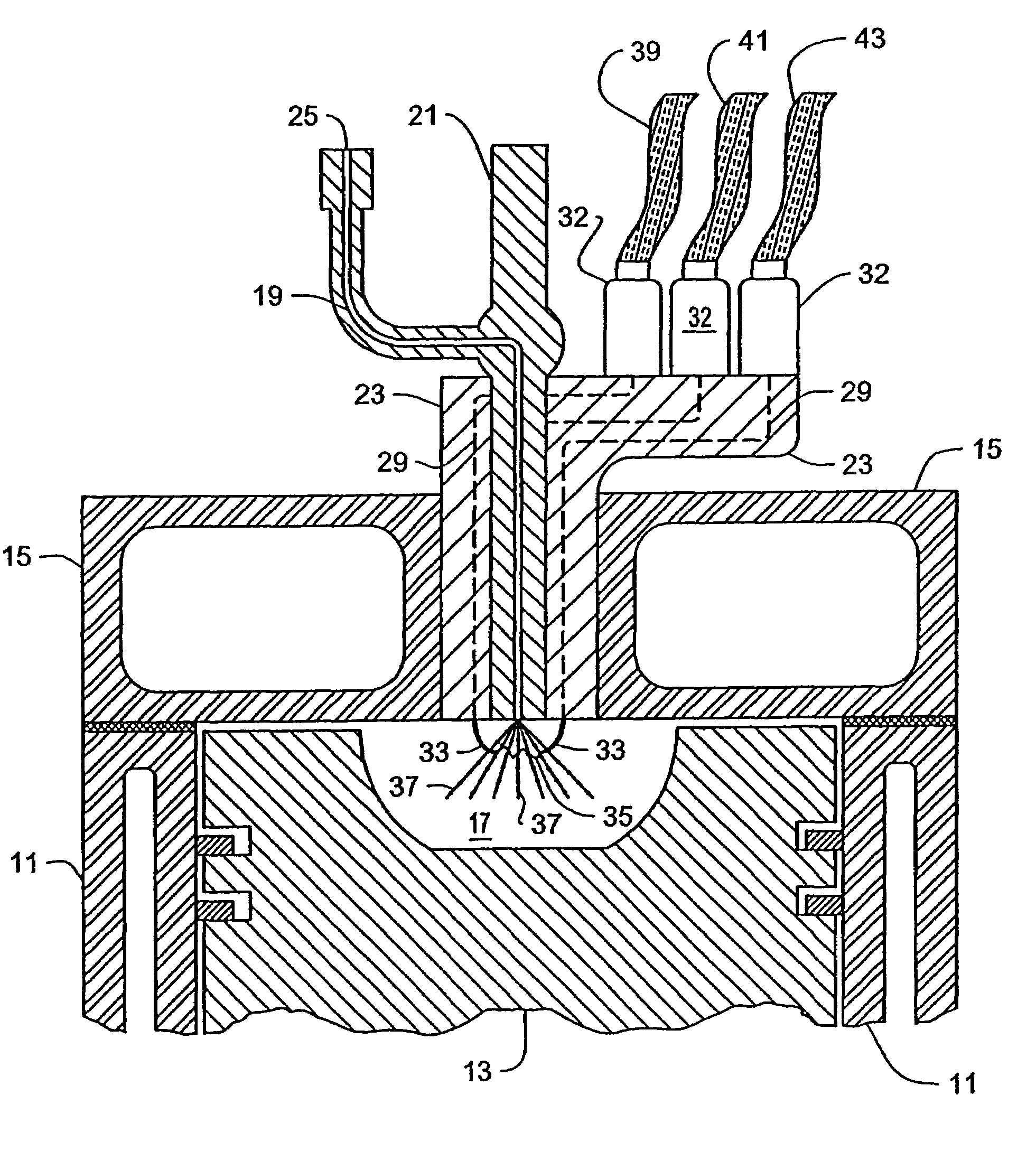

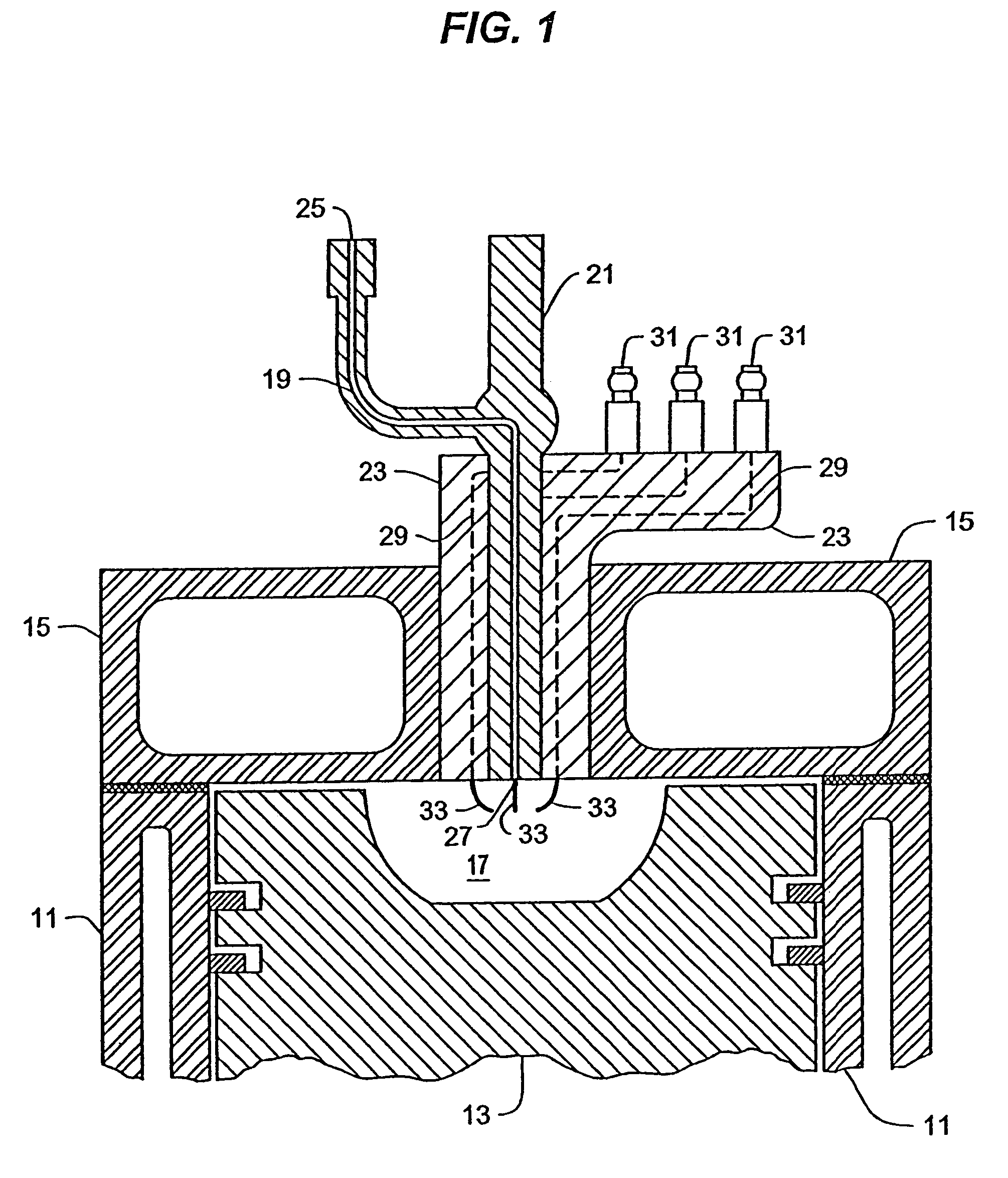

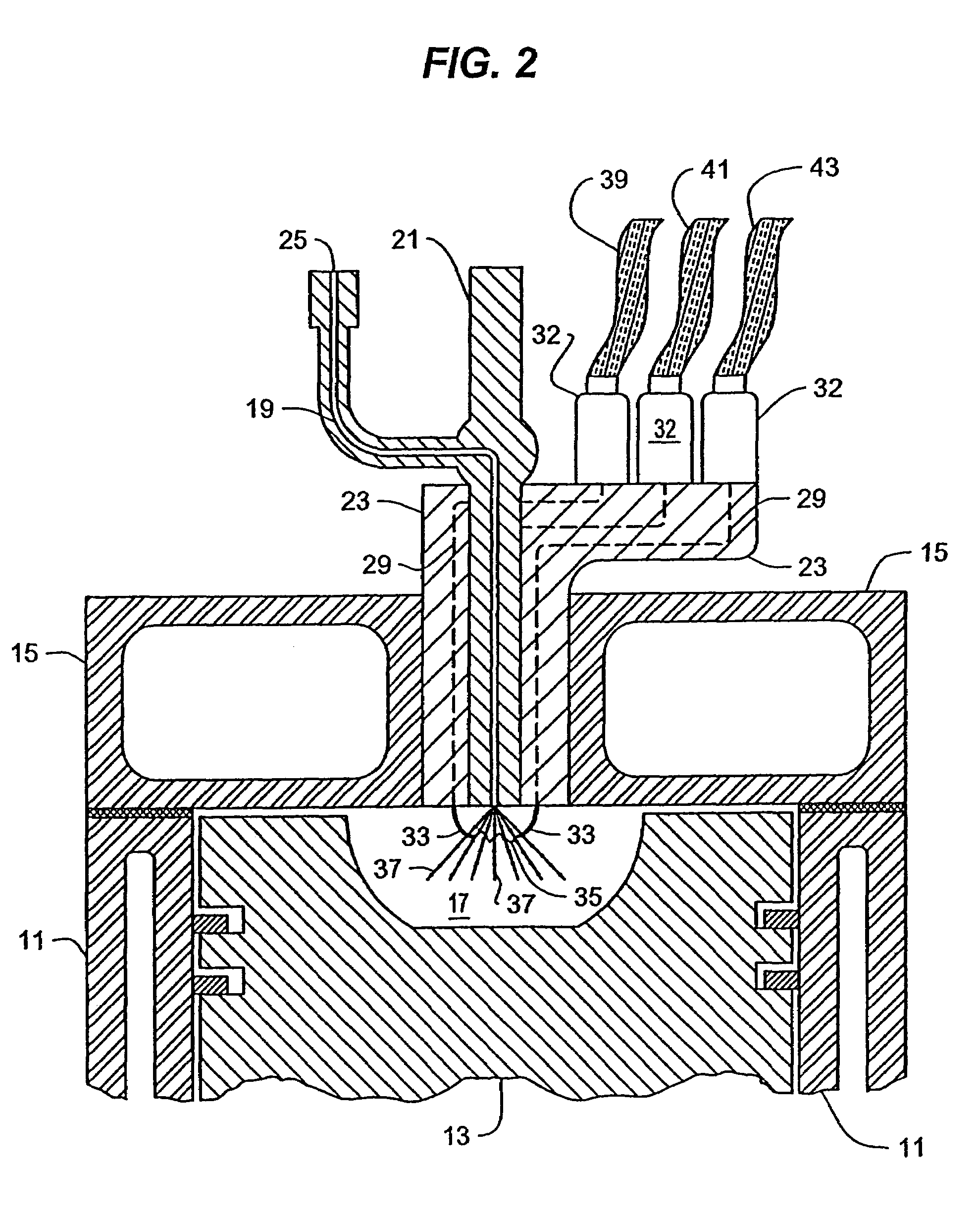

Furnace using plasma ignition system for hydrocarbon combustion

InactiveUS20050208446A1Improve fuel efficiencyMany timesBurnersInternal combustion piston enginesCombustorFuel efficiency

An apparatus and method for the creation, placement and control of an area of electrical ionization within an internal combustion engine combustion chamber or a fuel burner for a furnace is disclosed. A furnace includes a fuel source, a fuel burner, a plasma nozzle and igniter assembly, and the associated housing and flue structures. The plasma nozzle and igniter assembly is arranged so that the fuel sprayed out from the nozzle into the combustion area passes through or in close proximity to the area of plasma ionization. A fuel burner equipped with this electrical ionization device has its fuel efficiency enhanced by the complete and immediate combustion of substantially all of the fuel that passes through the area of plasma ionization. Exhaust gas recirculation using this system is also disclosed.

Owner:JAYNE MICHAEL E

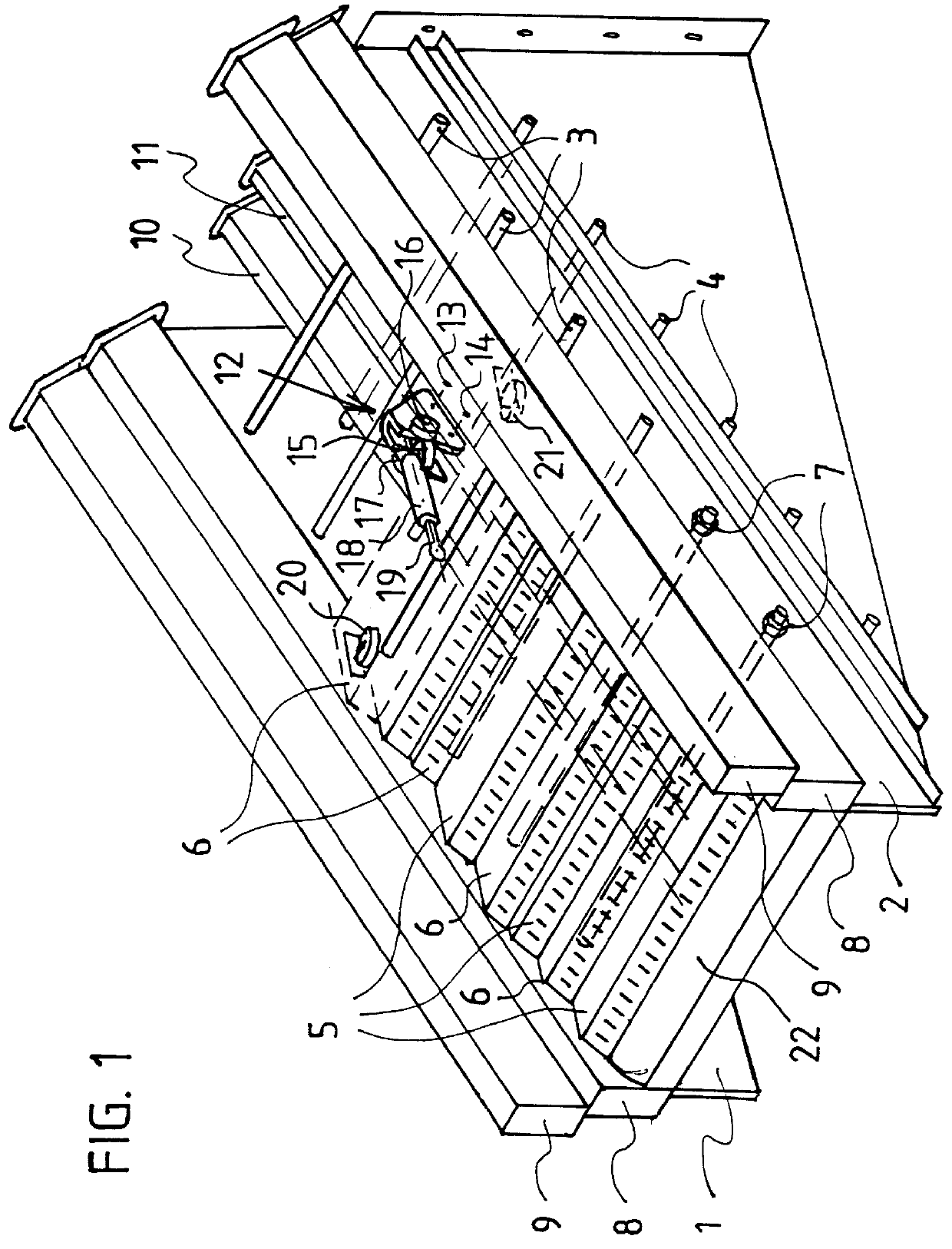

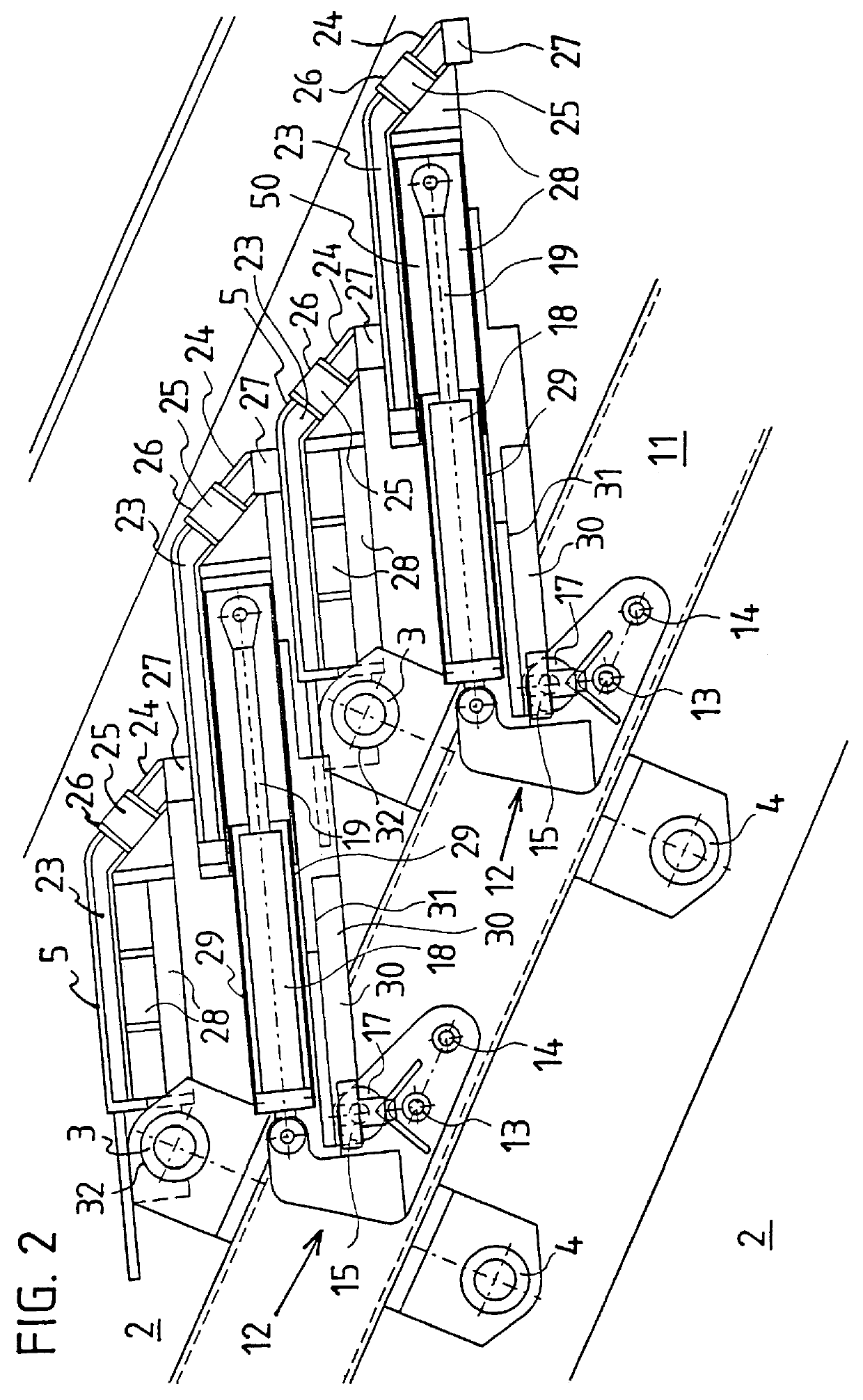

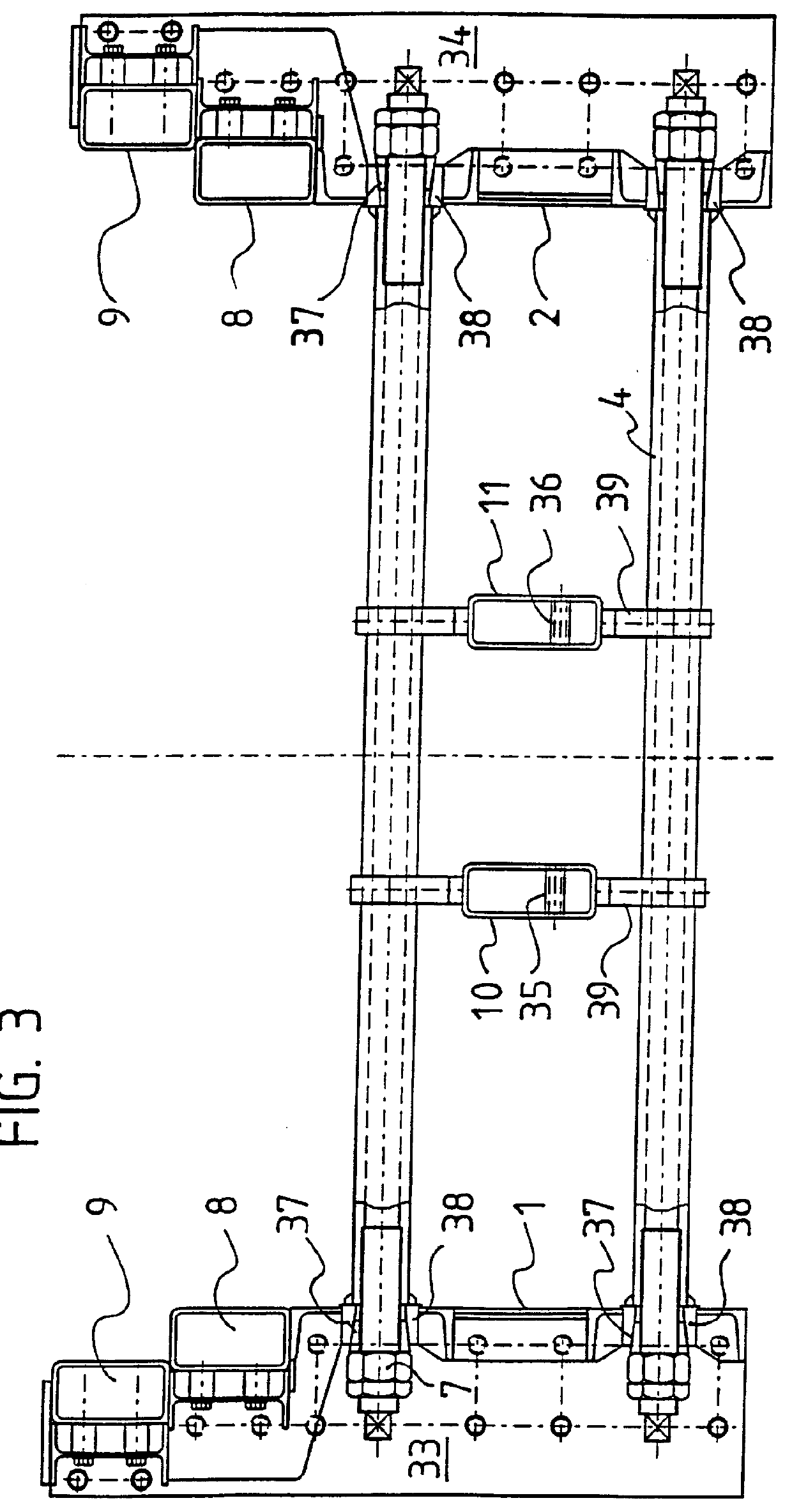

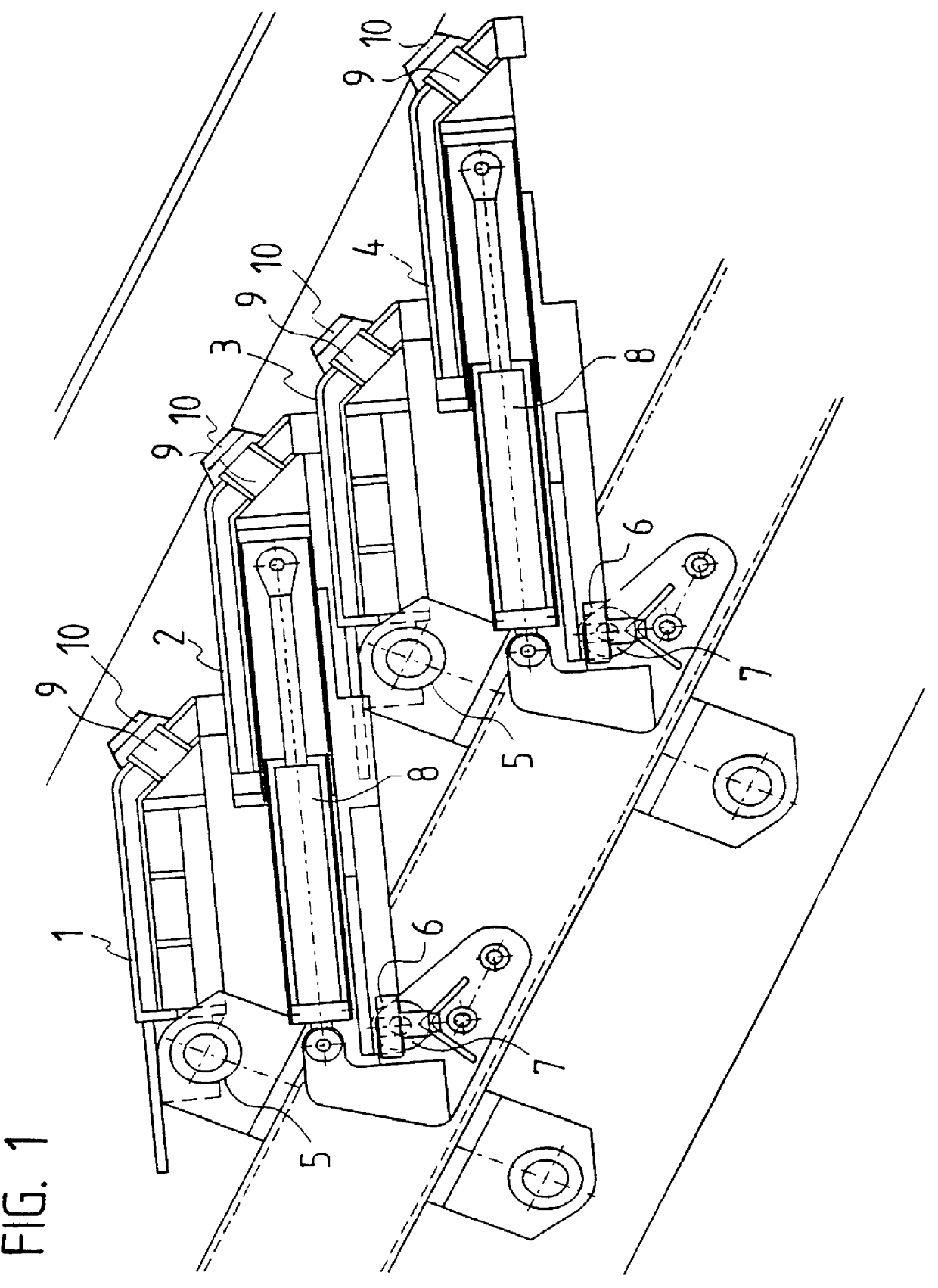

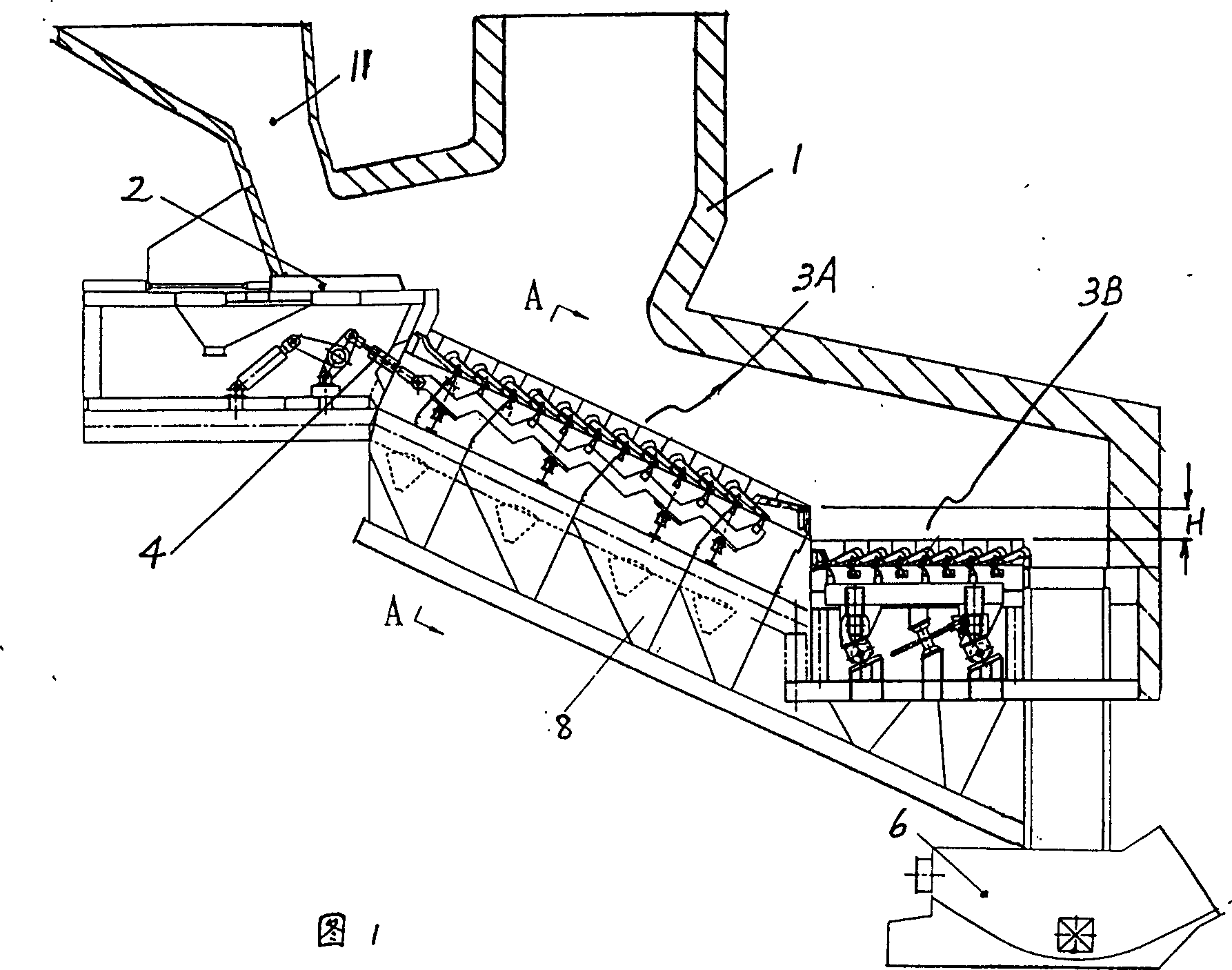

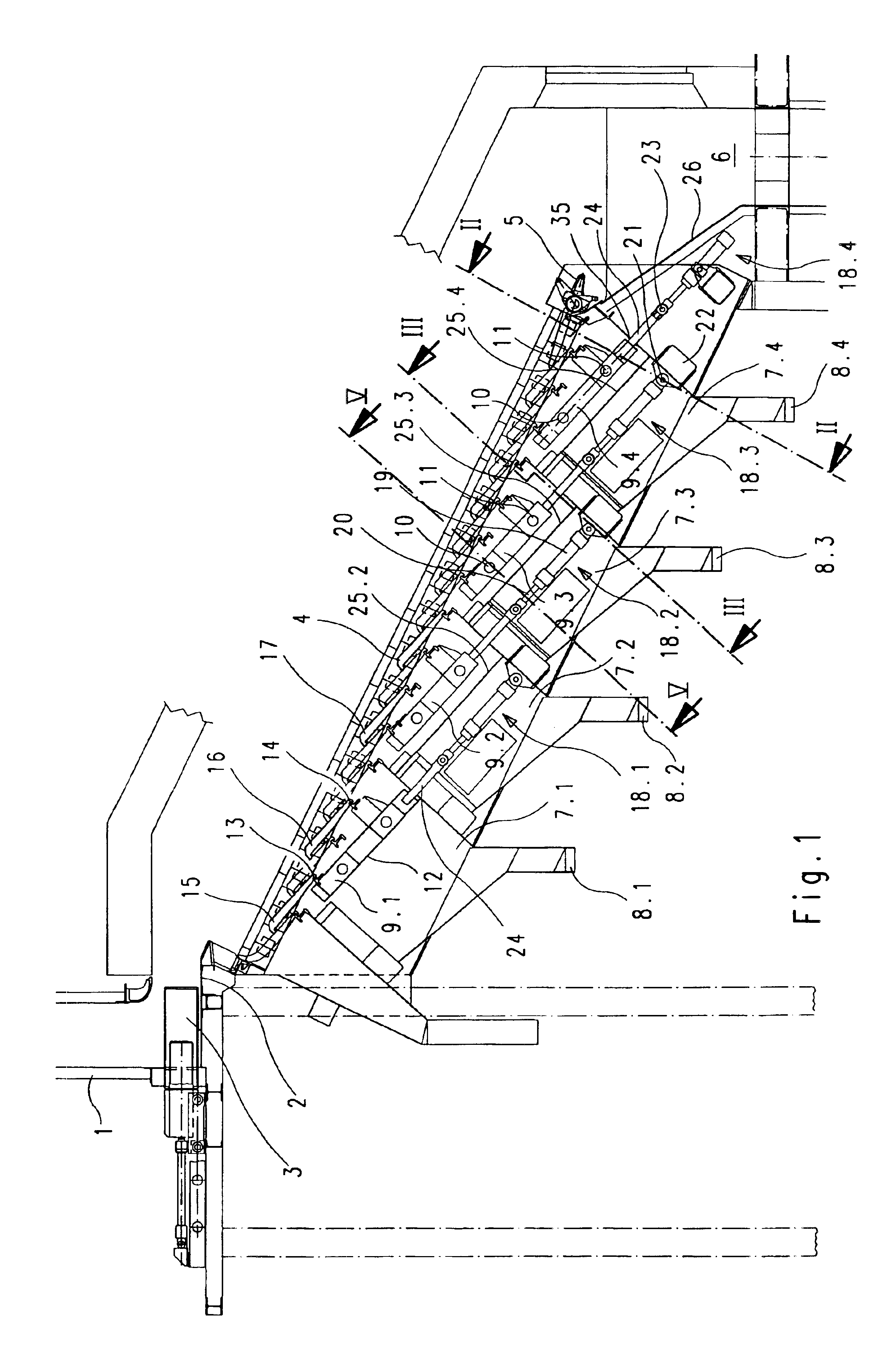

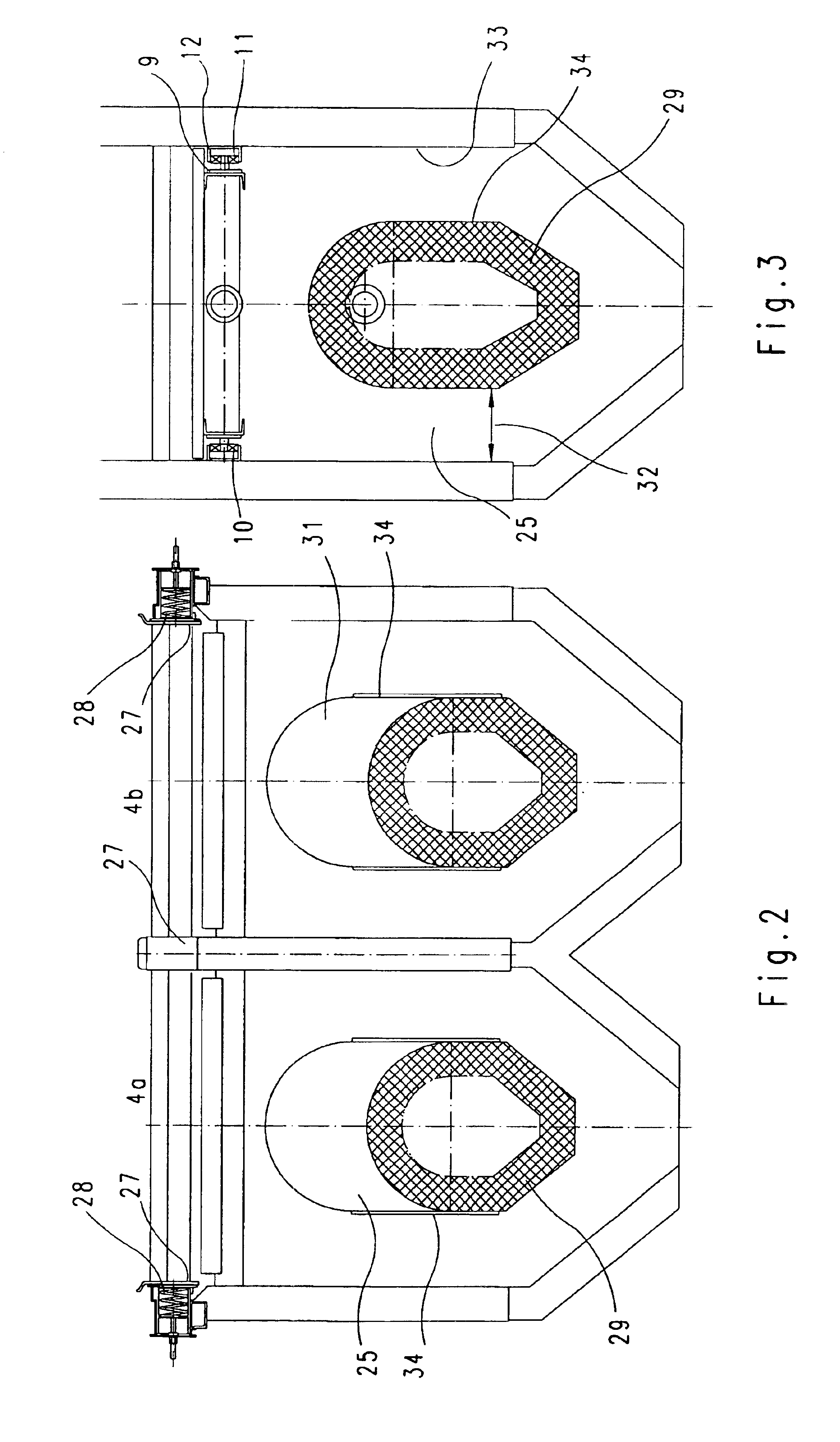

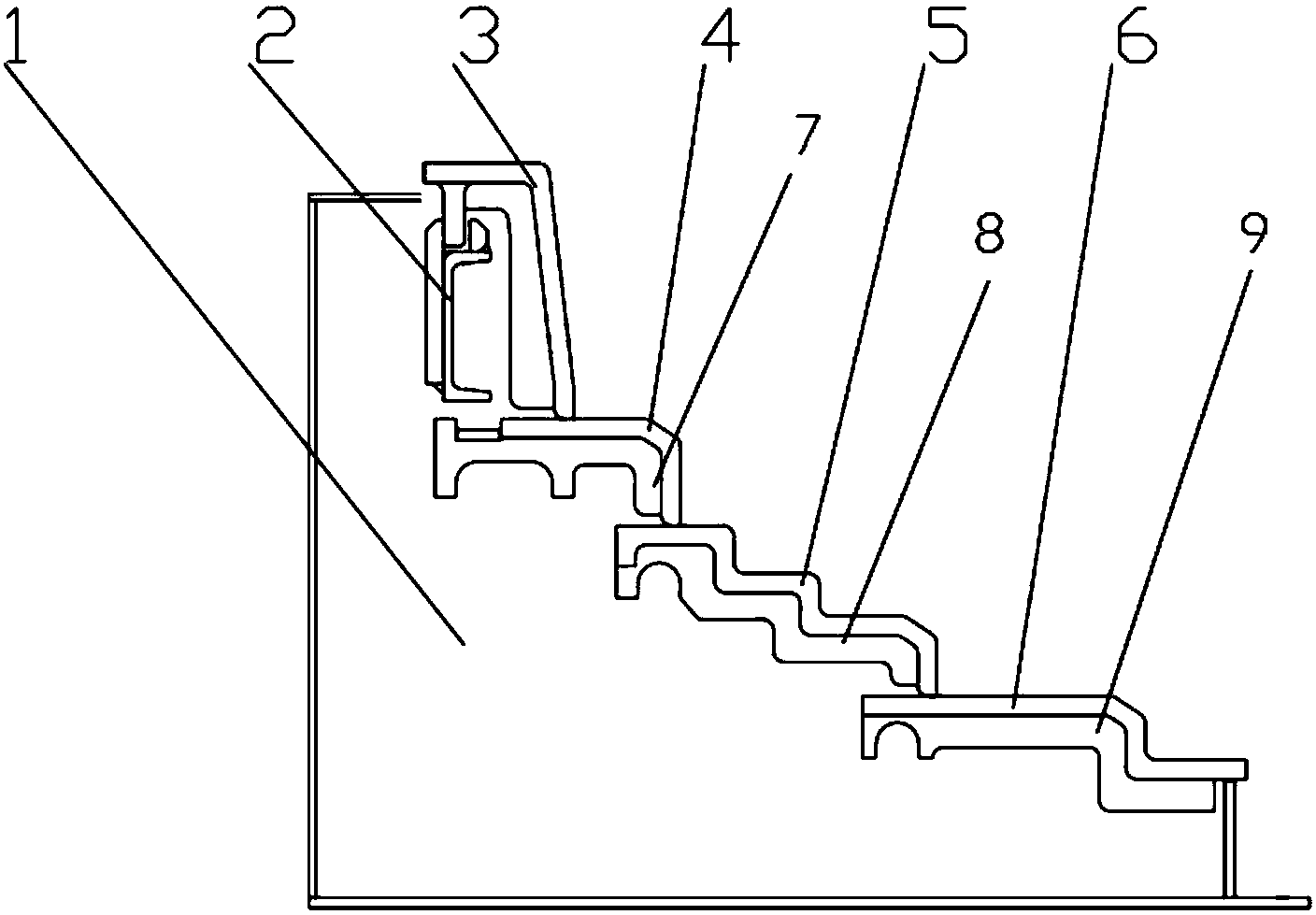

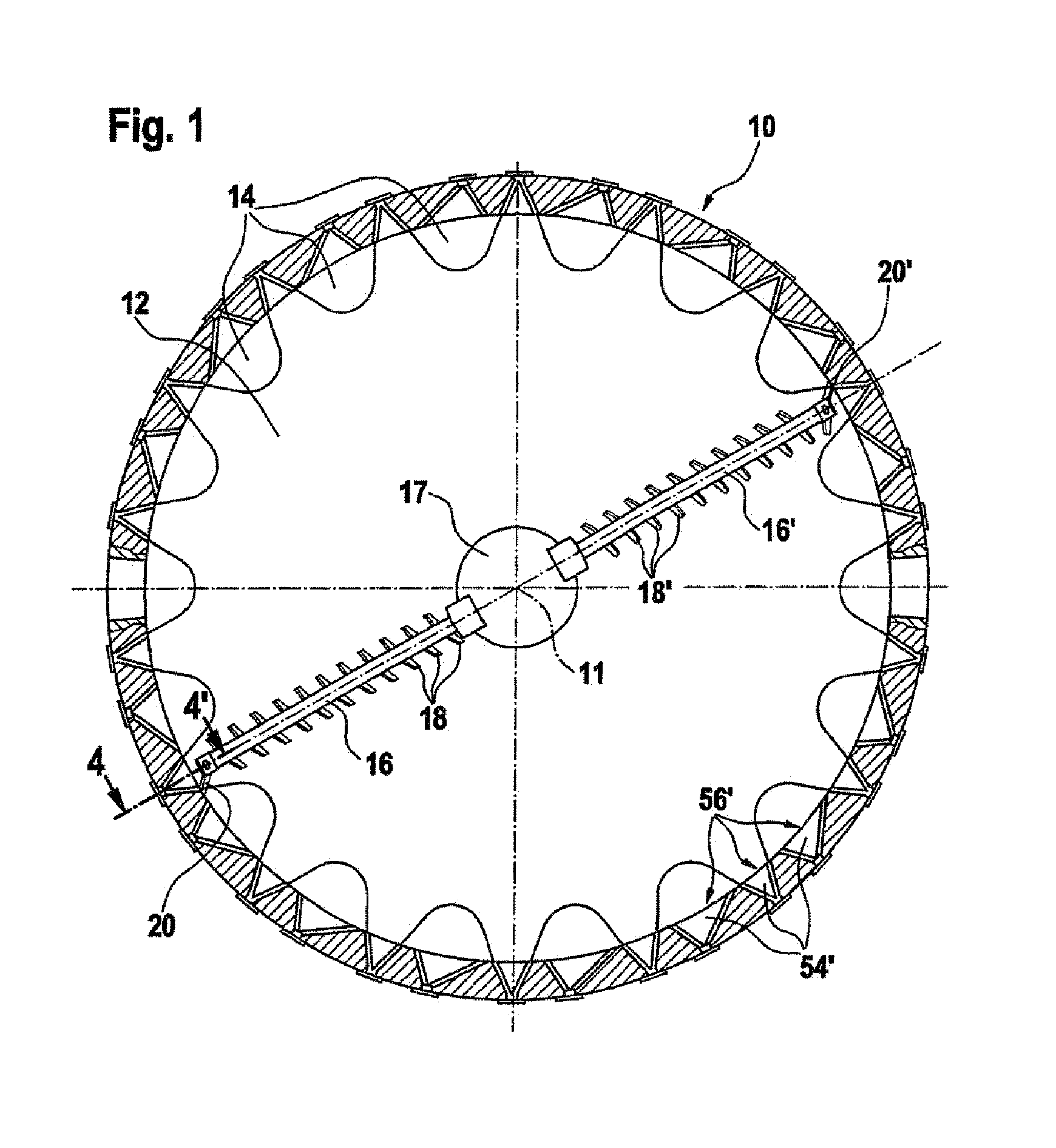

Water-cooled thrust combustion grate

A thrust combustion grate for burning refuse having altemately stationary (5) and movable (6) hollow grate plates (5,6) in a stairway formation, that rest on each other with their front underedge. The grate plates extend across the entire width of the grateway. The movable grate plates (6) are each driven by a hydraulic cylinder-piston unit (18,19). To the sides, the grateway is limited by panels of water-cooled conduits (8,9), which, in the longitudinal direction, each consist of at least two sections sealingly flanged together. The panels are rigidly screwed to each other by a plurality of horizontally disposed distancing bars (3,4) running perpendicular thereto. Running between the panels are two additional conduits (10,11) flanged together in the same way, for feeding primary air and cooling water, which are fixed to certain individual distancing bars (3,4). The back sides of the stationary grate plates (5) each rest on one distancing bar (3) while the back sides of the movable grate plates (6) rest on at least one steel roller (16,17) with a horizontal axis, with each side of their front sides being guided along a steel roller (20,21) whose axis runs perpendicular to the grate plate (6). The front portions of the grate plates (6) form by primary air slots (25).

Owner:DOIKOS INVESTIMENTS LTD

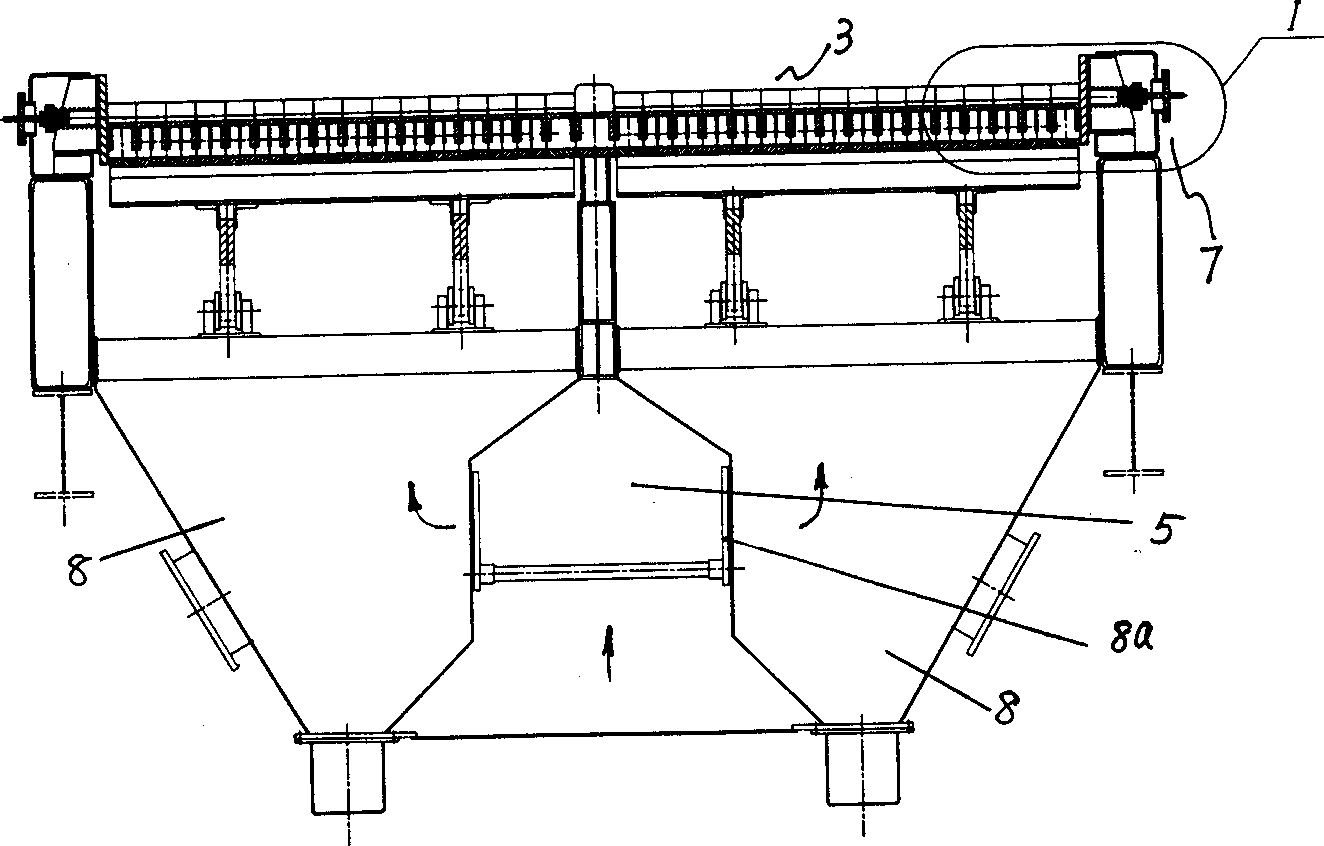

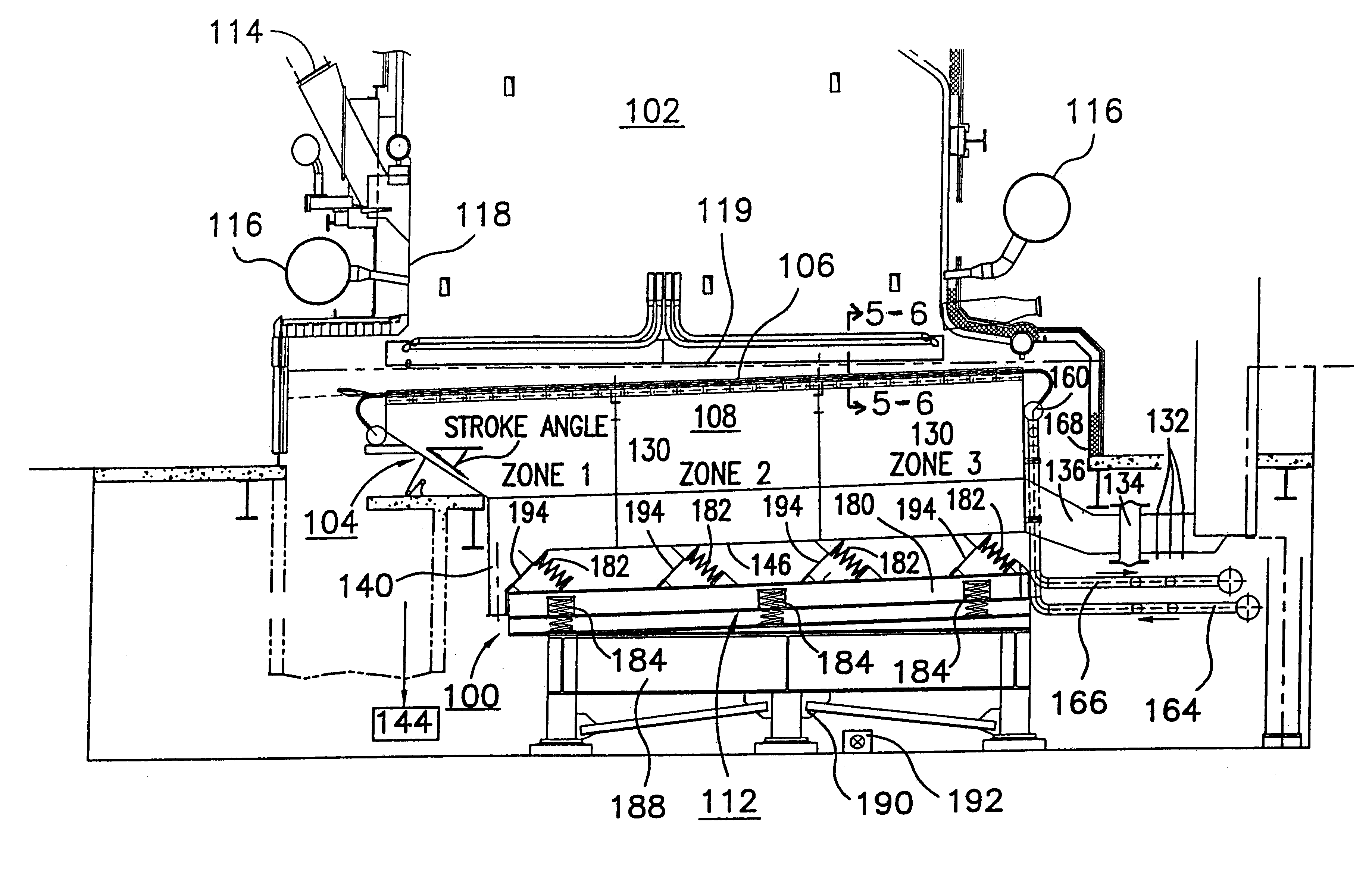

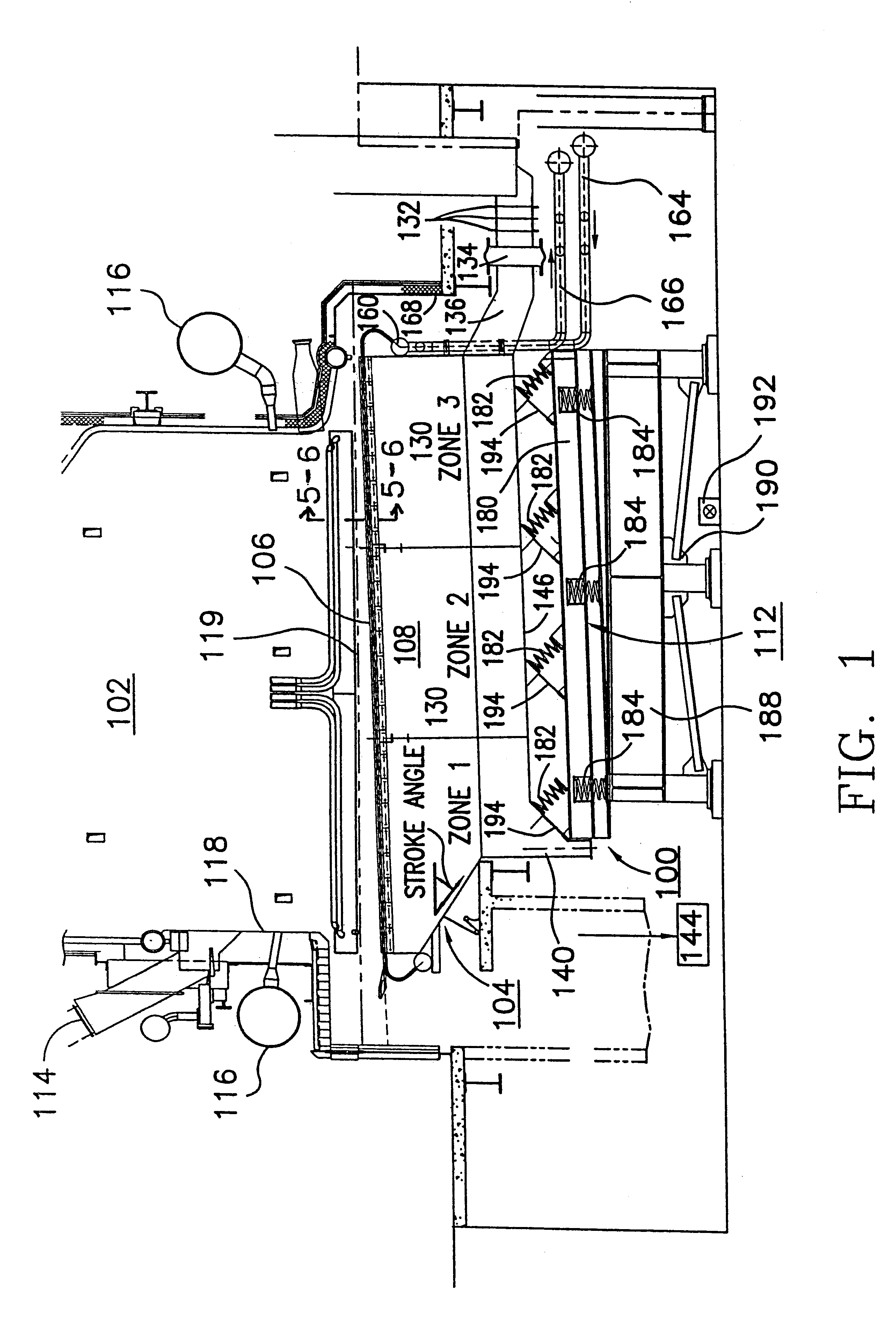

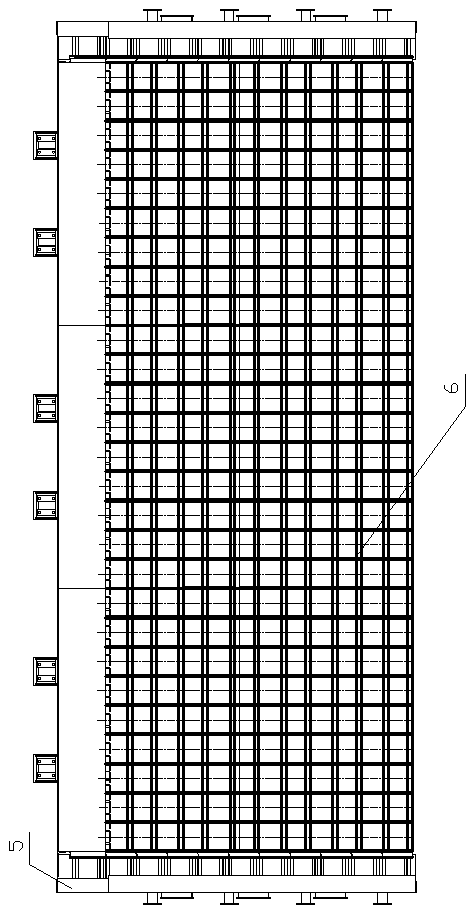

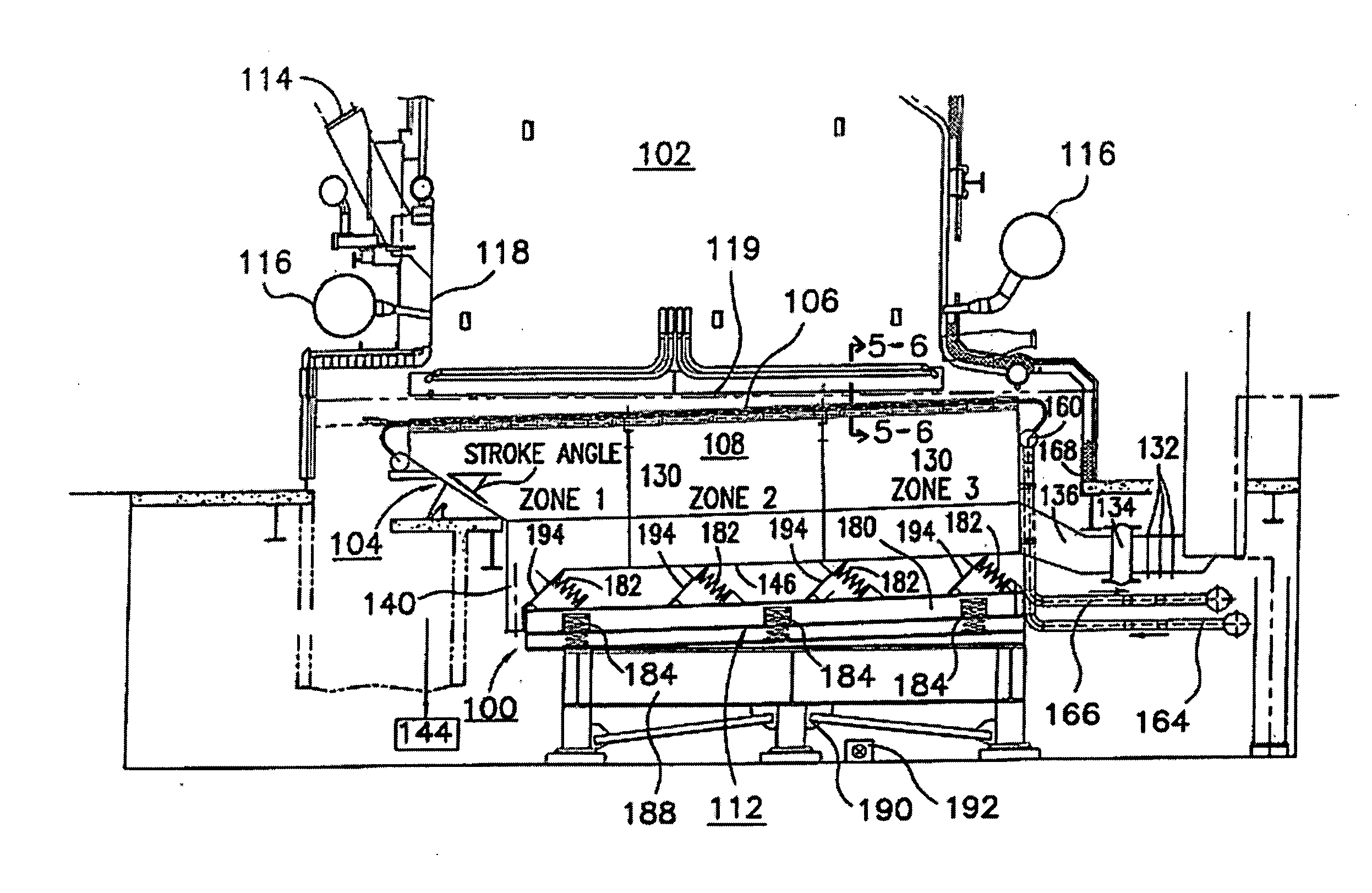

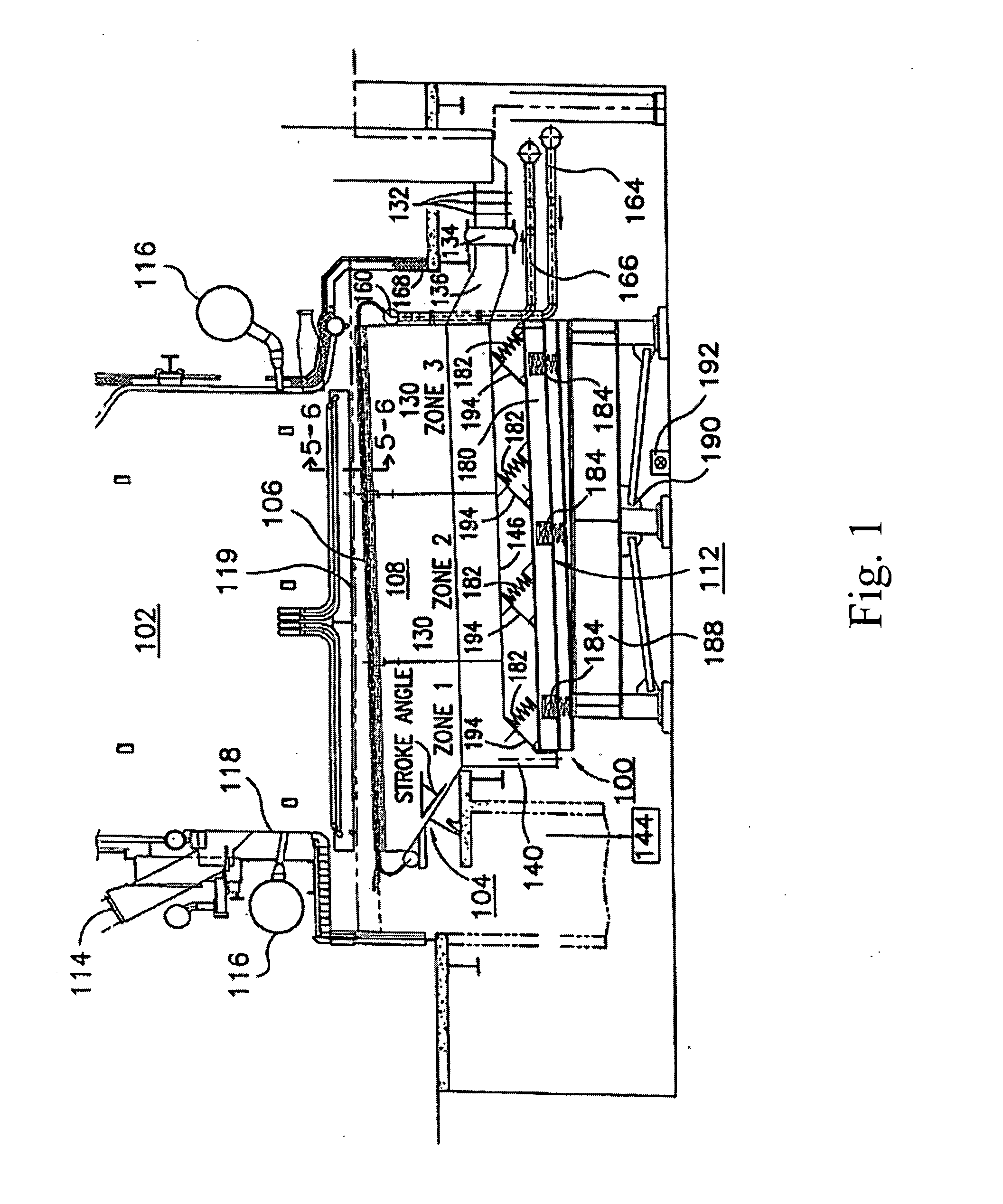

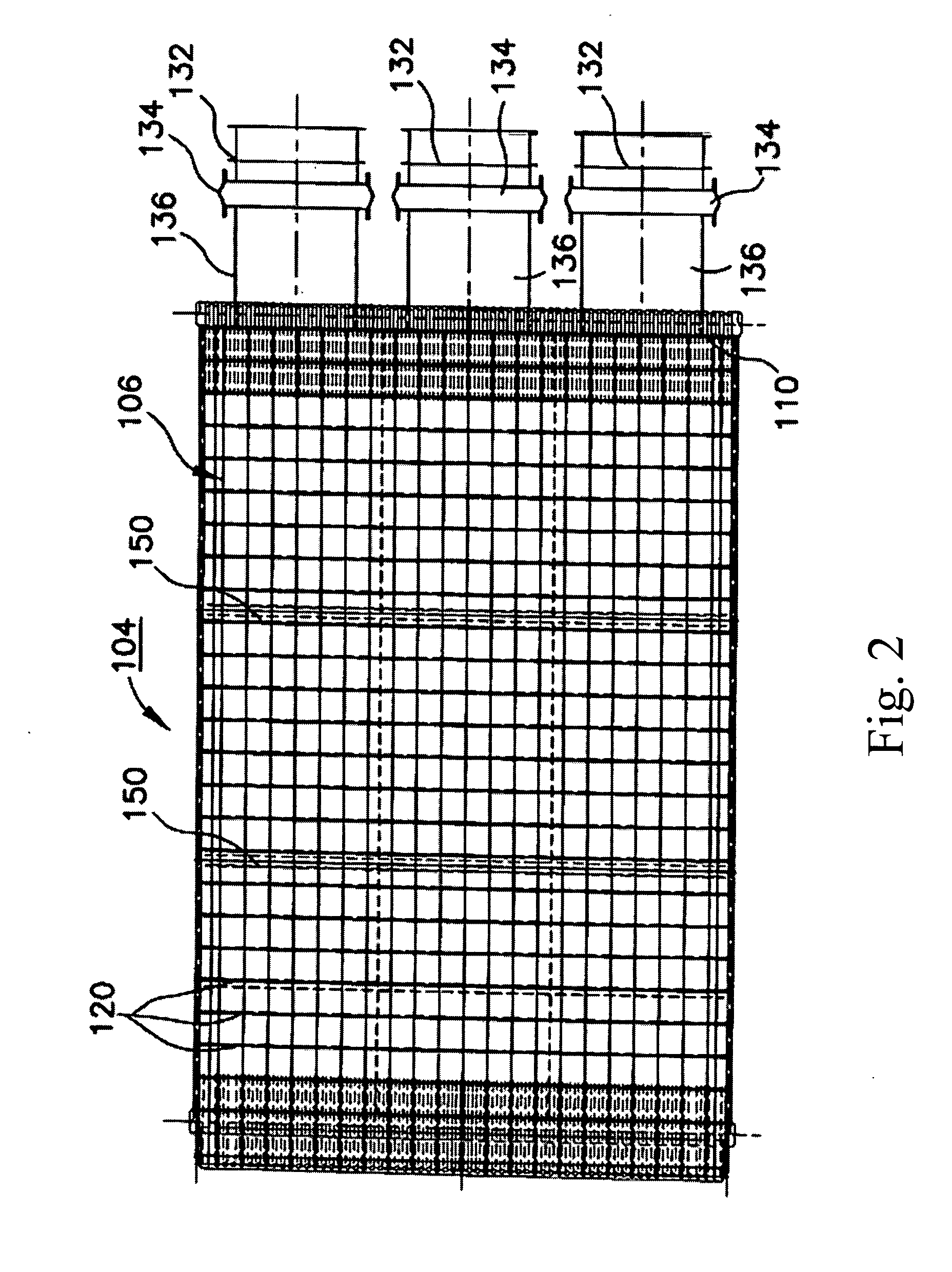

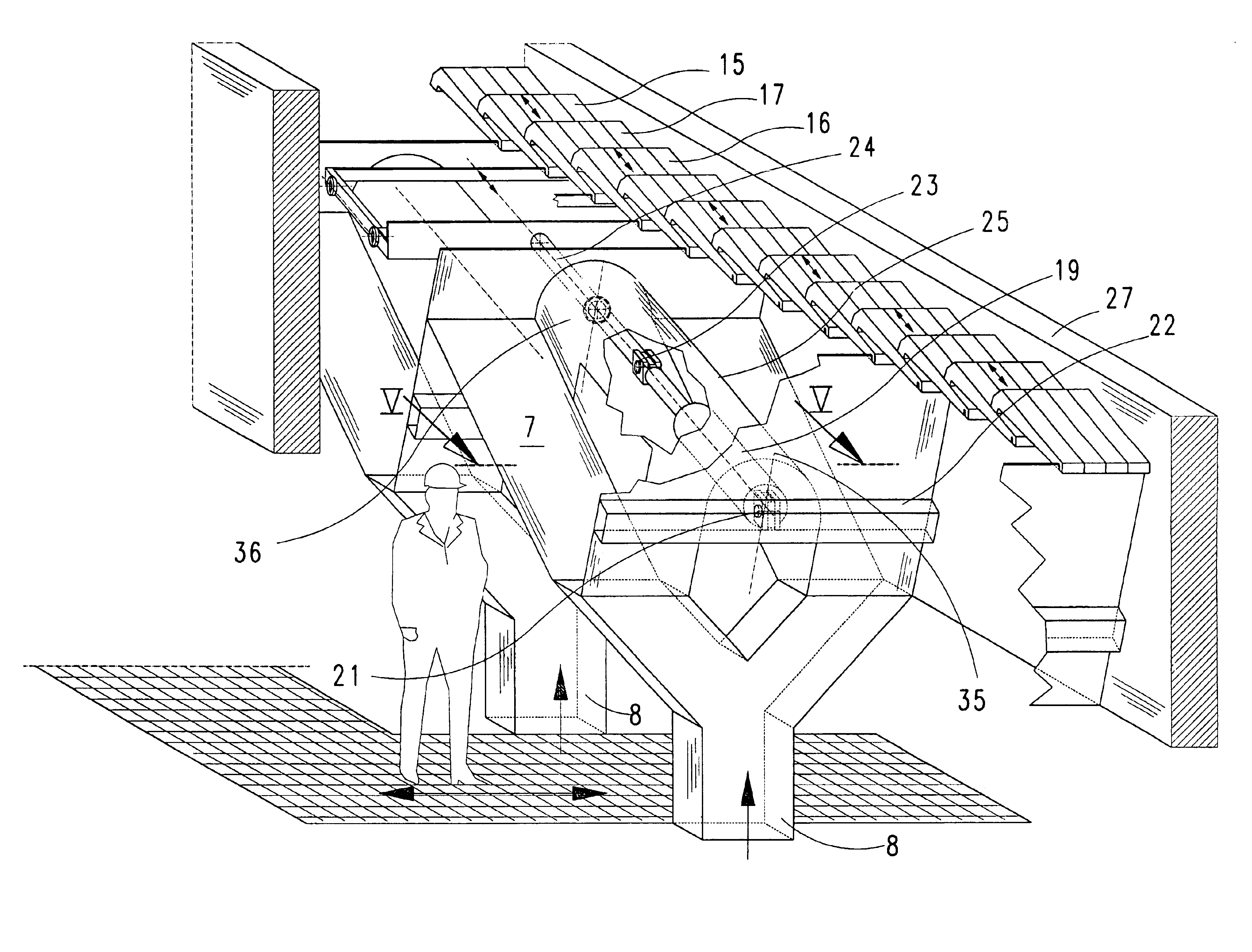

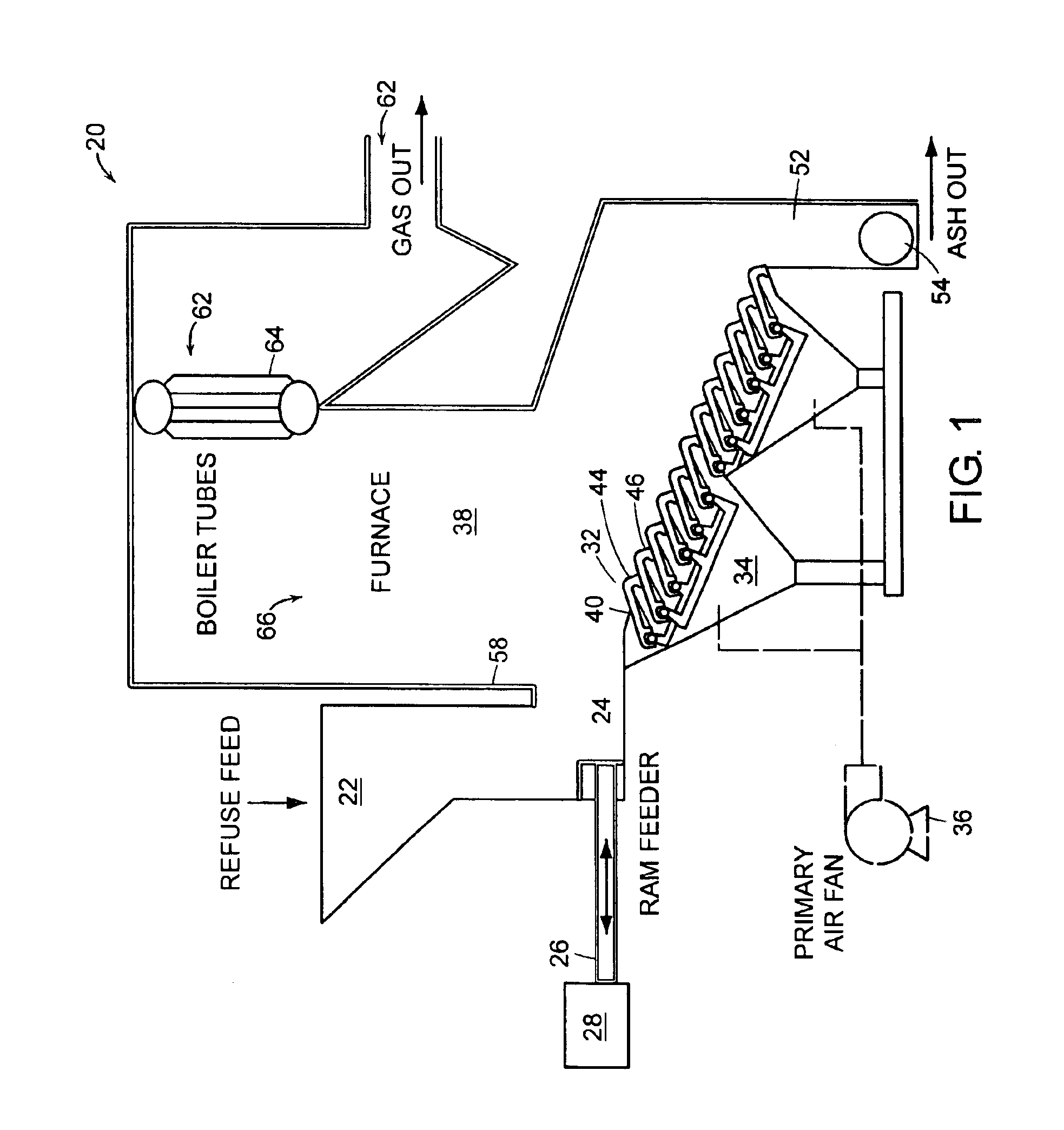

Water-cooled oscillating grate system

InactiveUS6220190B1Minimize under grate air leakageEffective and efficient and reliable operationHollow bar grateSpeed sensing governorsCombustionWater source

An integral water-cooled, air permeated, vibrating grate system for combusting biomass and other fuels in a boiler includes a grate top surface having air-flow apertures extending therethrough. The grate top surface is supported by a plurality of water-cooling pipes which arc coupled to a water supply. An enclosed air plenum unit is positioned under and attached directly to the grate top surface. The air plenum unit is coupled to an air supply for providing combustion air through the top grate surface air-flow apertures. The air plenum unit includes multiple zones, each of which zones has an associated air flow control damper so that the flow of combustion air can be controlled. Ash siftings formed on the grate top surface when the biomass or other fuel is combusted fall into the air plenum unit and flow toward at least one ash-siftings discharge opening at a discharge end of the air plenum when the grate top surface and the air plenum is vibrated. The grate top surface and the air plenum are vibrated together by a vibratory drive-isolation assembly which includes a longitudinally extending counterbalance member. A plurality of drive springs are supported by the counterbalance member. The drive springs are distributed across the width and the length of the top grate surface and at least one vibratory motor or mechanism is associated with the counterbalance member so that the vibration can be adjustably controlled.

Owner:RILEY STOKER

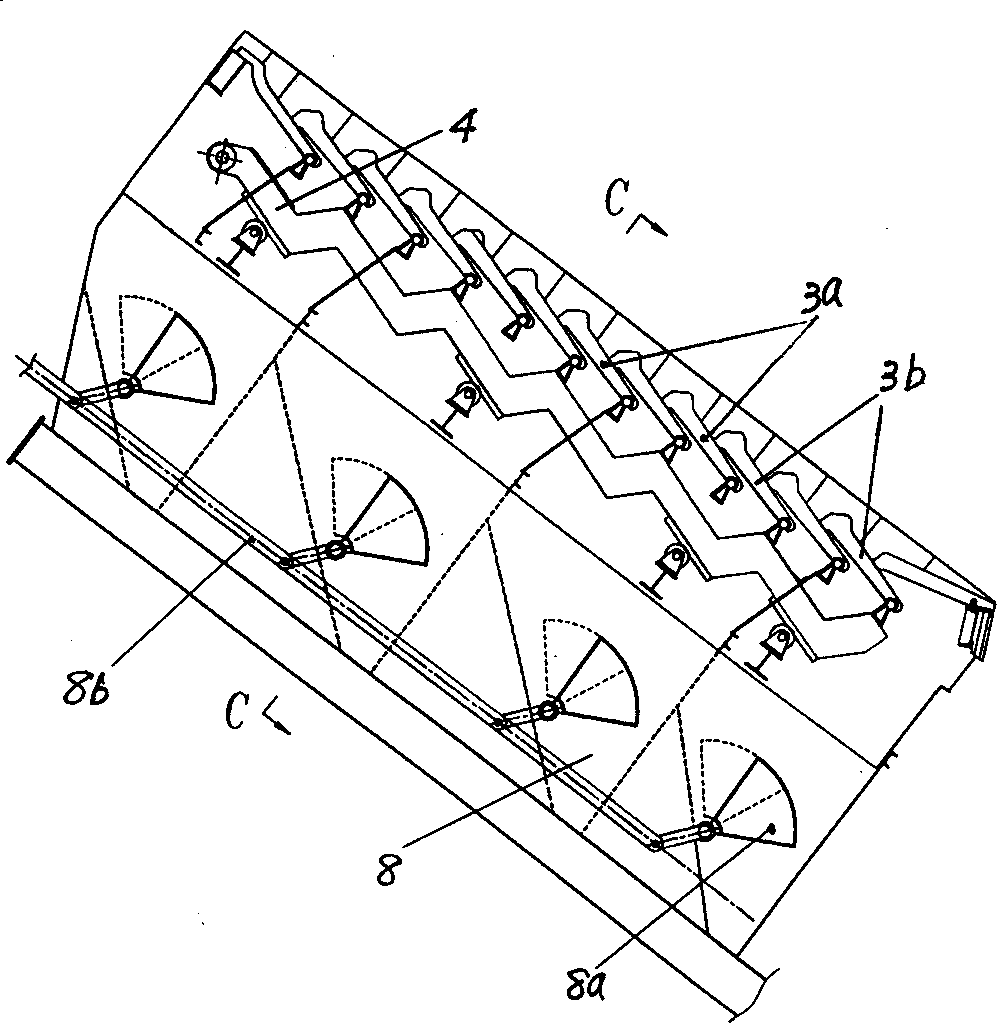

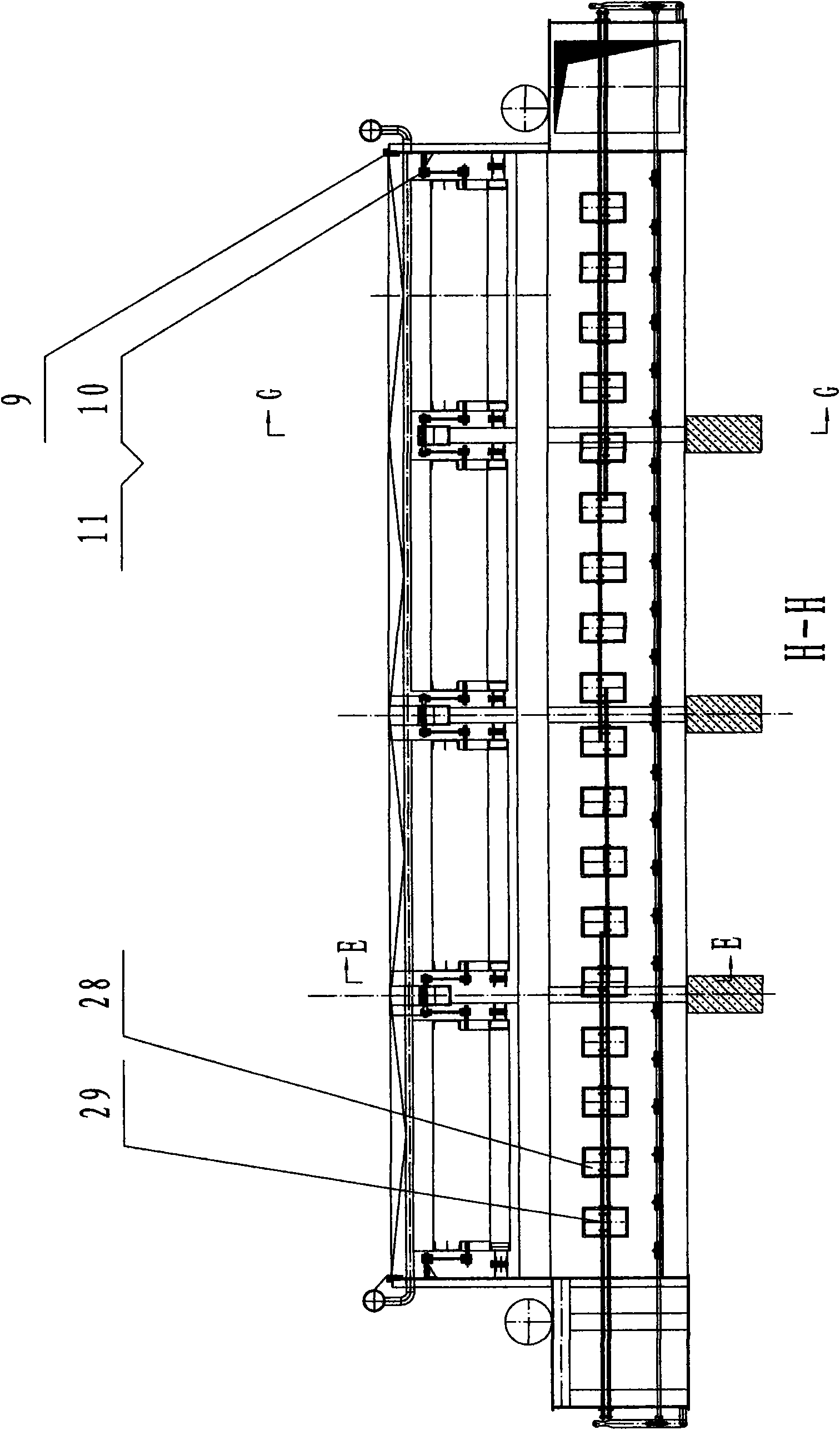

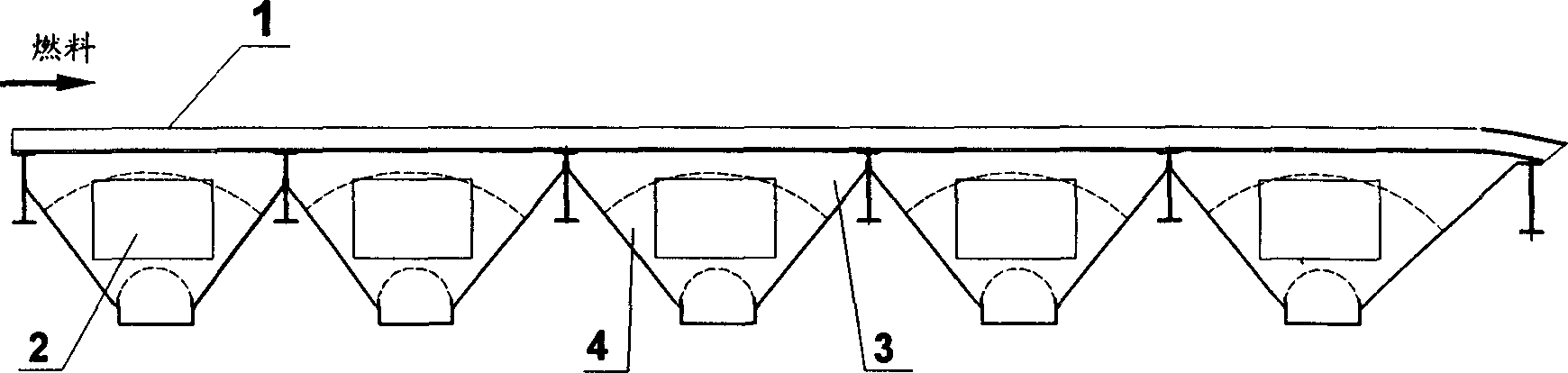

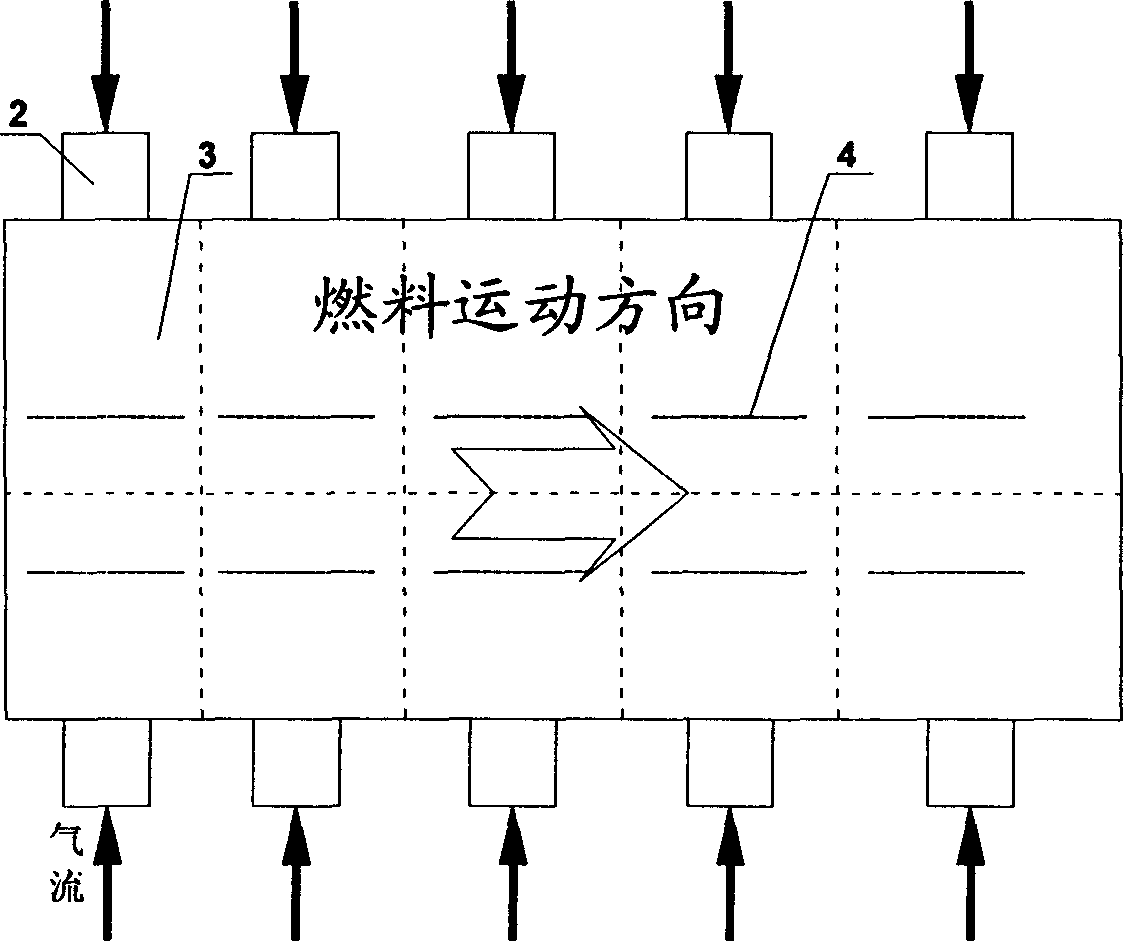

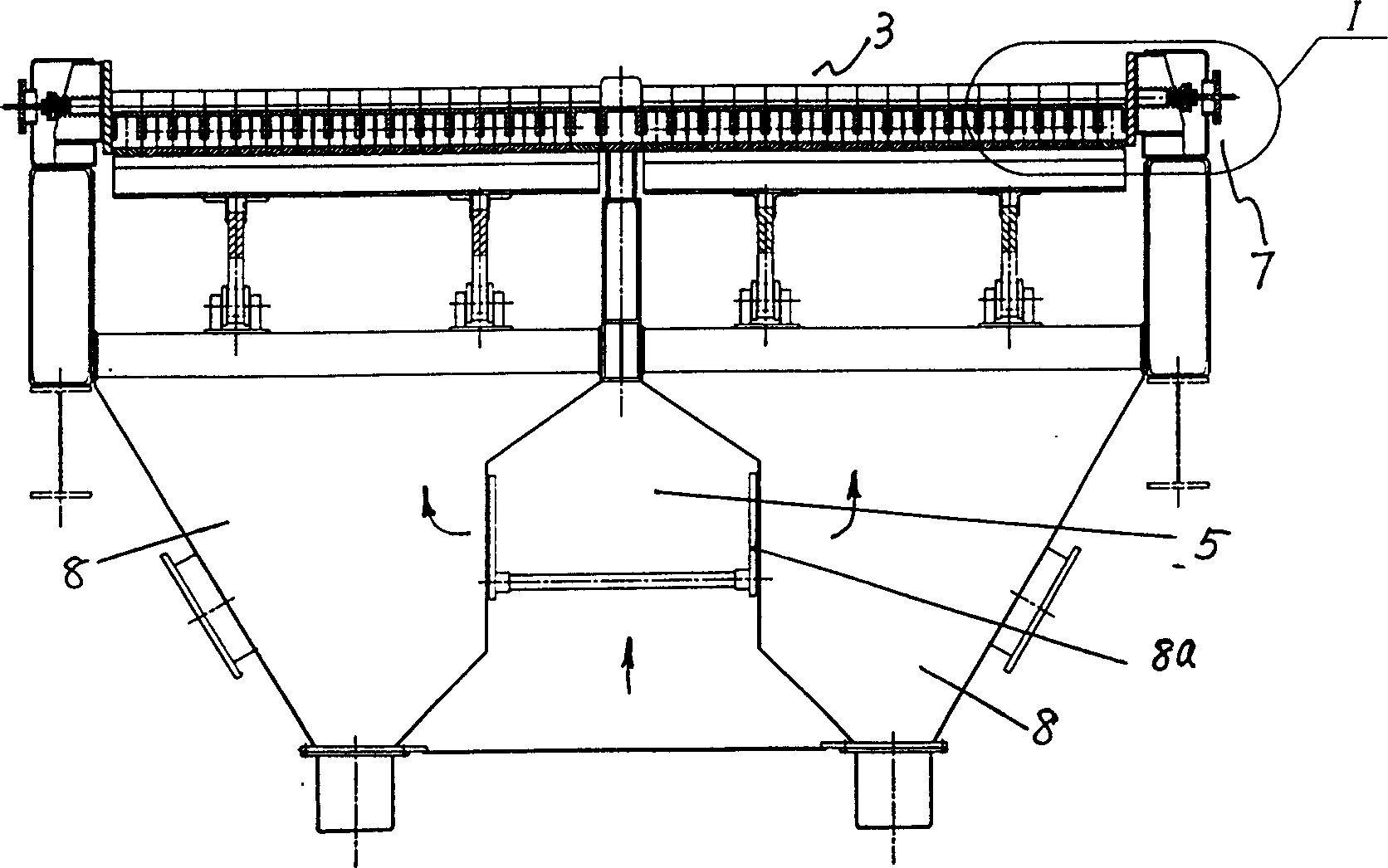

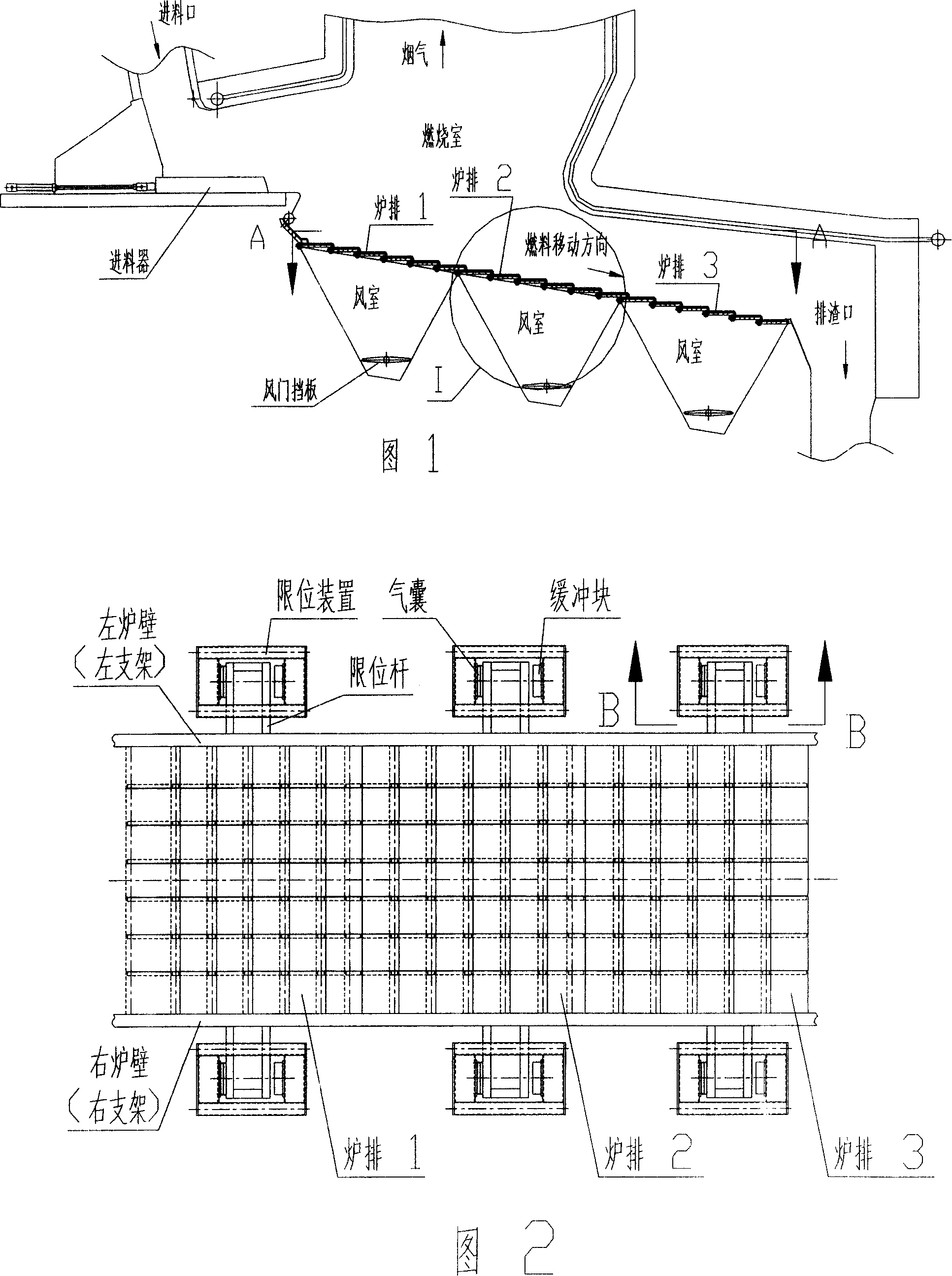

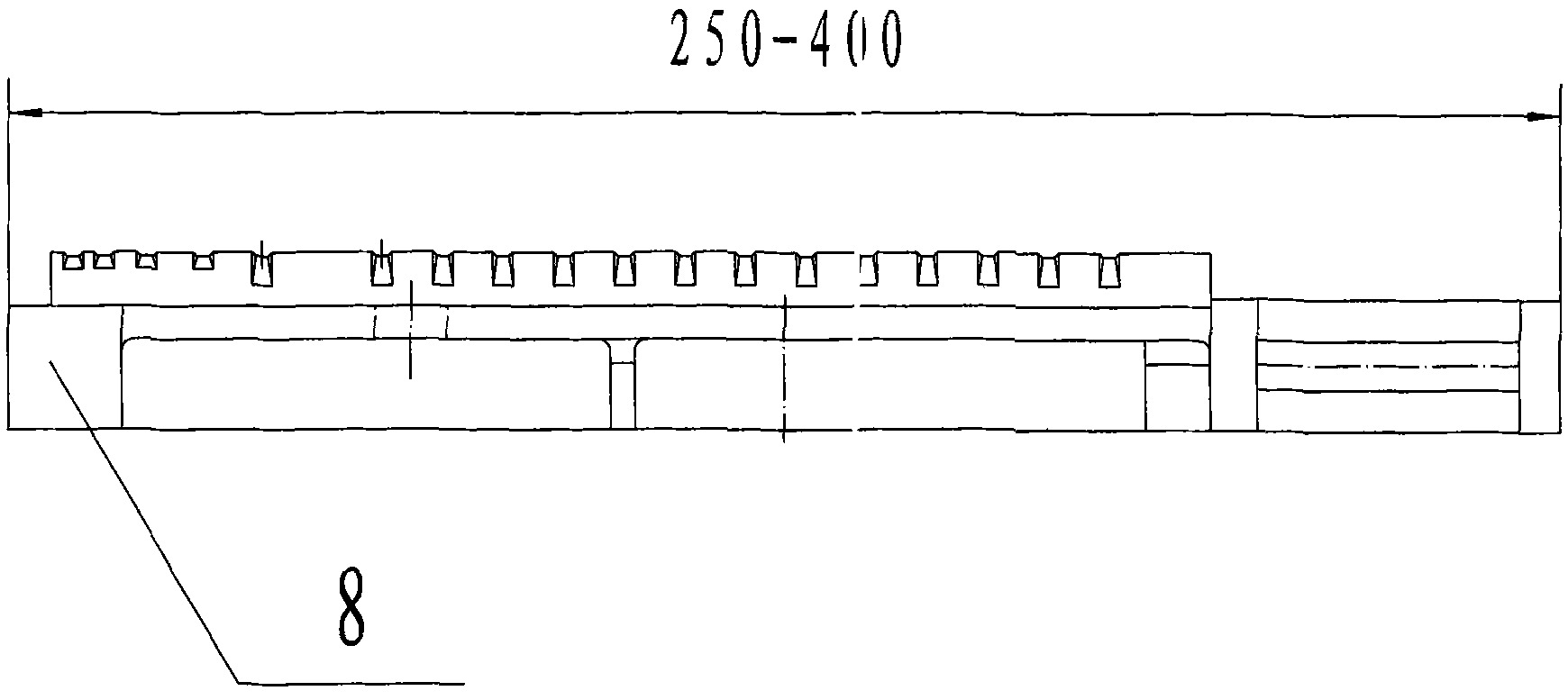

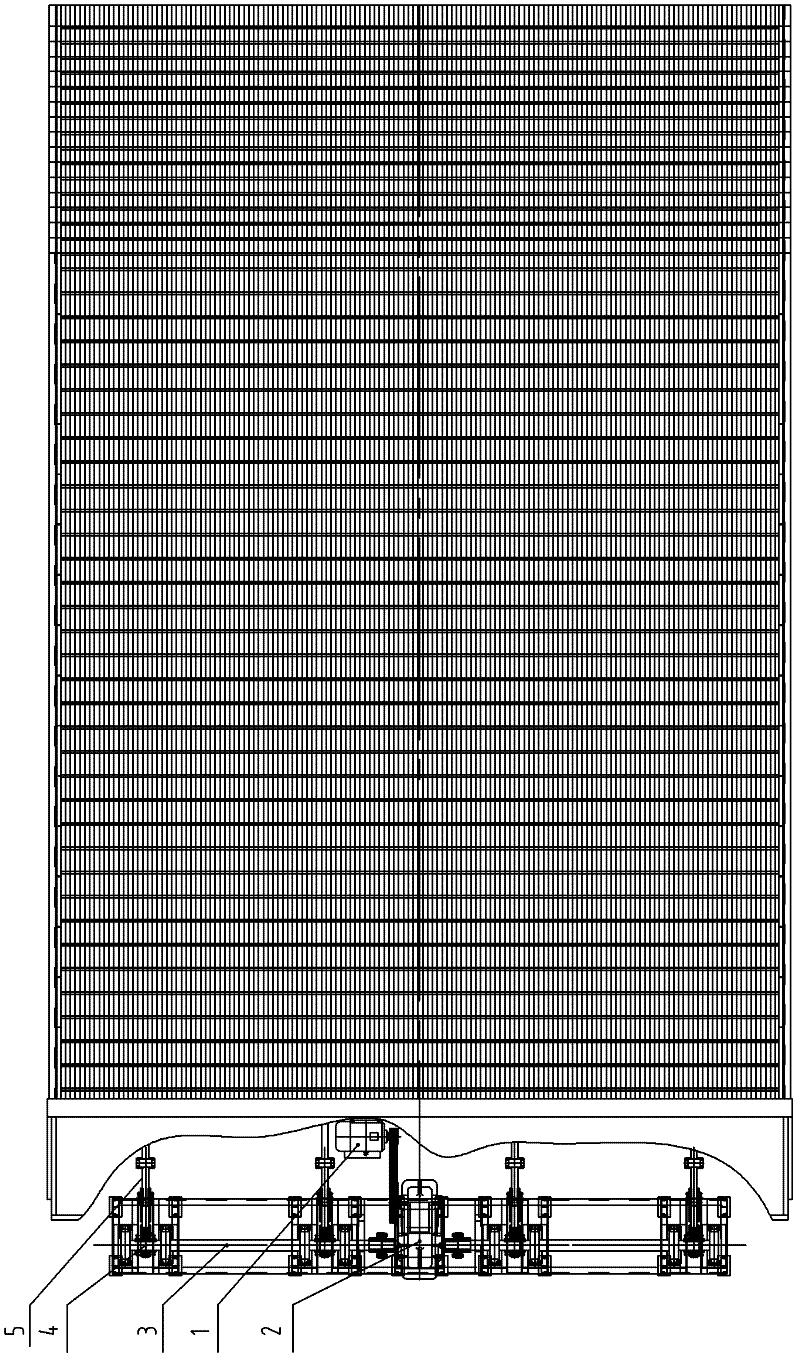

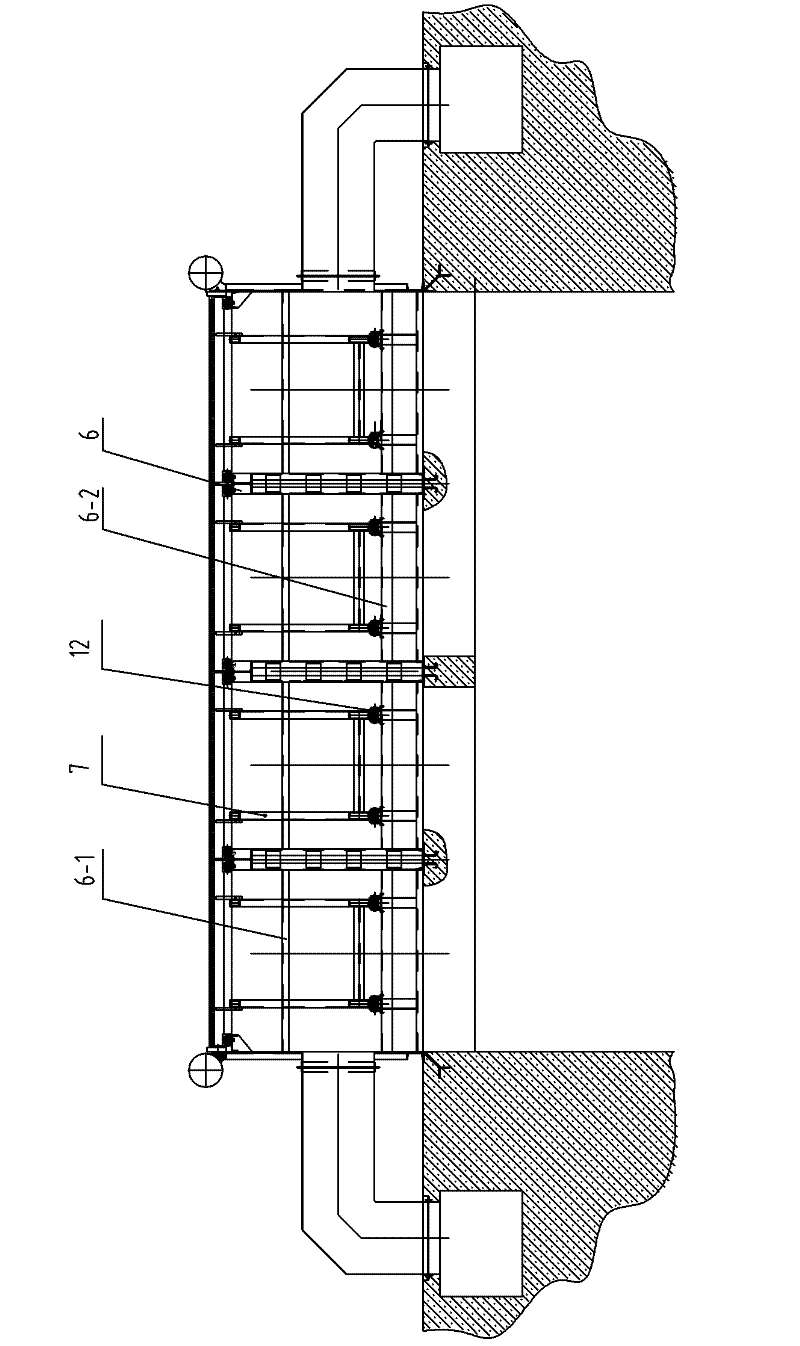

Isobaric air supplying and suspension active propelling unit for novel large reciprocating grate

InactiveCN101603692ASolve Design StructureSolve load-bearingTravelling grateAir/fuel supply for combustionCombustionMathematical model

The invention relates to a novel large scale isobaric air supplying and suspension active propelling unit for a reciprocating grate, which utilizes aerodynamic principle and principle of mechanics and belongs to the technical field of F23L industrial air supplying of international patent classification. In order to implement an isobaric air supplying and suspension active propelling unit on a large scale industry reciprocating grate with the power of 14MW-700MW, a new task, a new subject knowledge combination and a new mathematical model concept are generated. Digital module combination is not limited by the large scale reciprocating grate boiler and the continuously developed and widened lateral width dimension thereof, and the oscillating reciprocating motion of suspension and the sealing of dynamic independent air chamber are implemented on the large scale reciprocating grate boiler in order to realize isobaric air supplying random chaining regulation and control and central control required by transverse and longitudinal combustion under the major fluctuation operation condition; difficult problems, such as bearing load, synchronous reciprocating motion and the like of the reciprocating grate consisting of multiple groups of independent units under the state of super width dimension are solved. Making the large scale reciprocating grate boiler achieve the goals of energy saving and high-efficiency combustion under set conditions becomes the core of the invention.

Owner:王聪会 +1

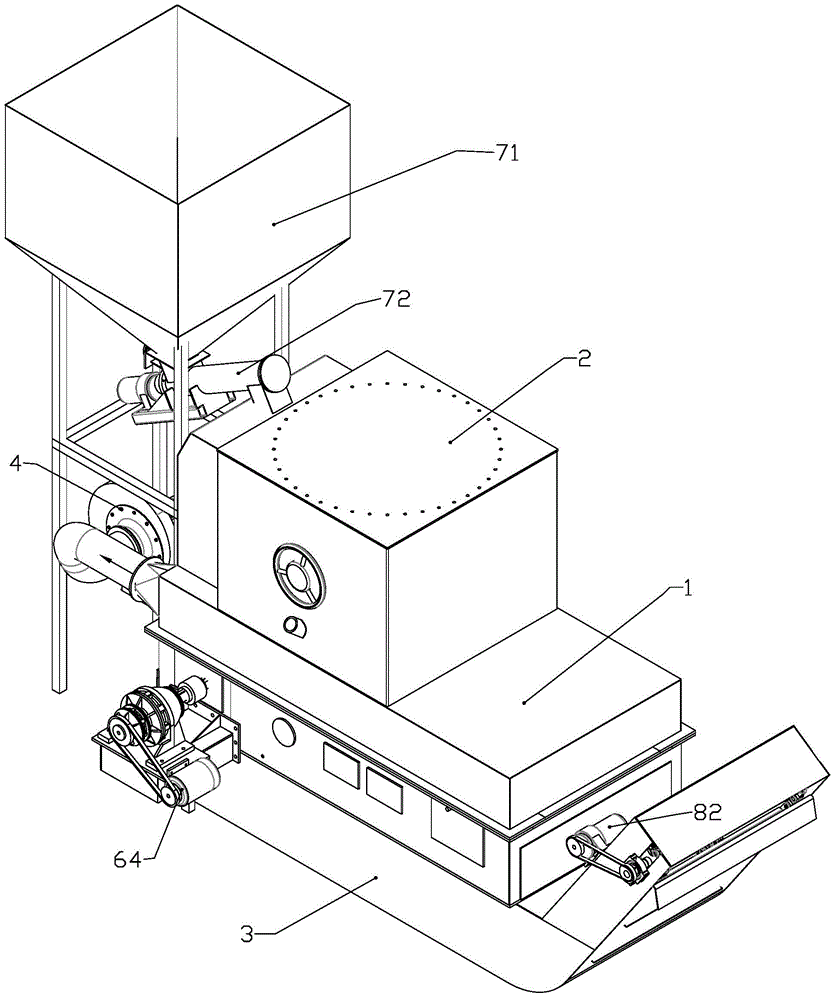

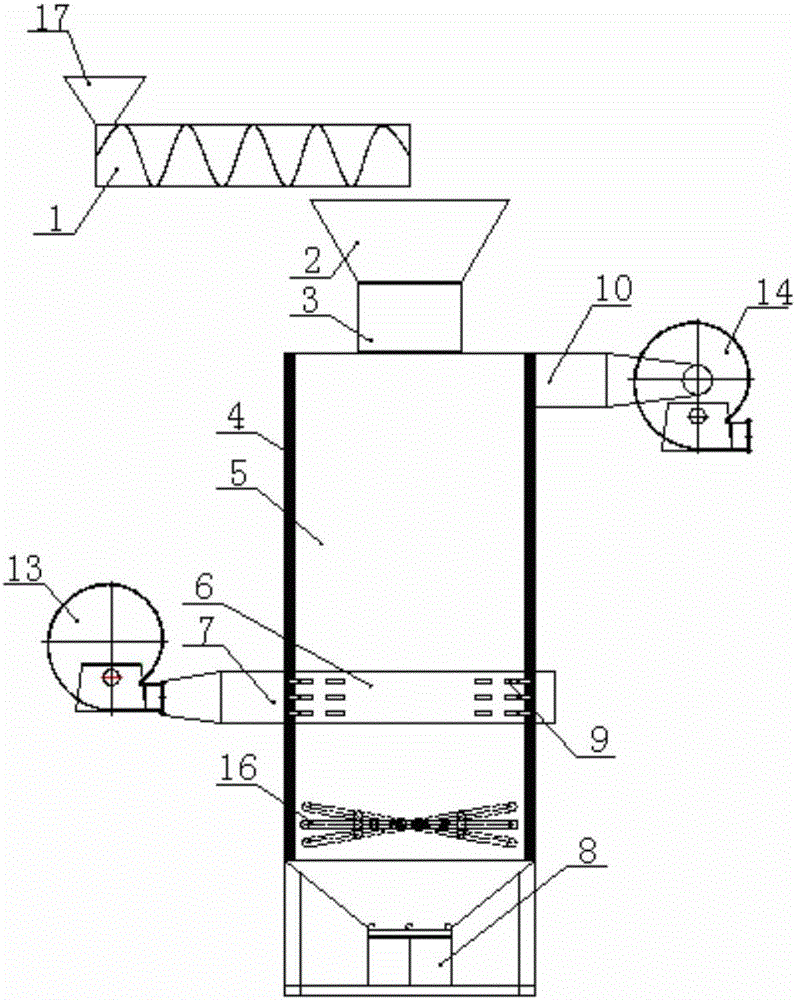

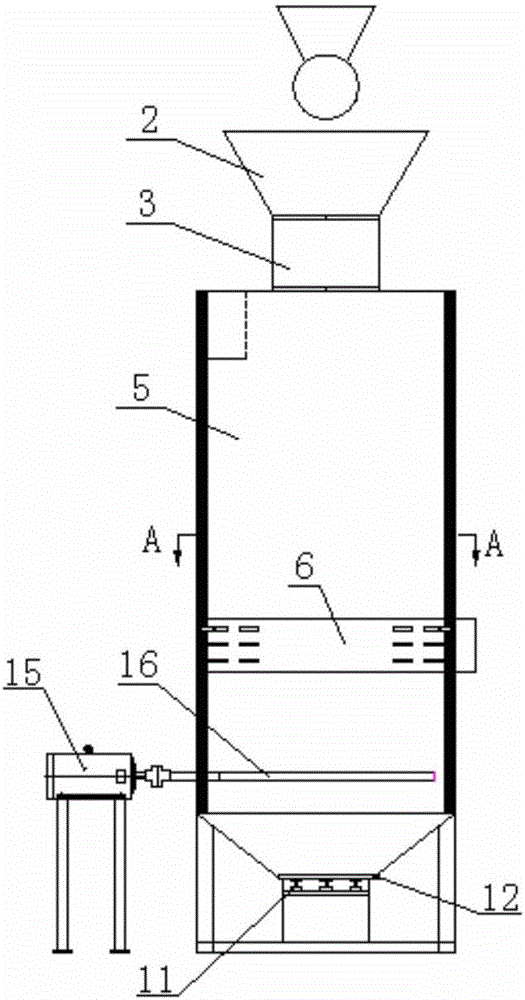

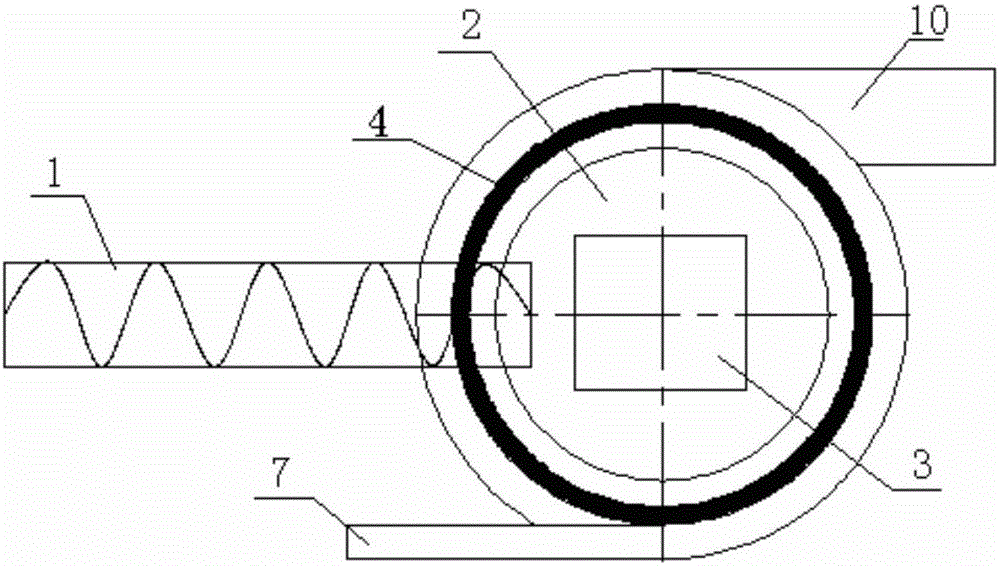

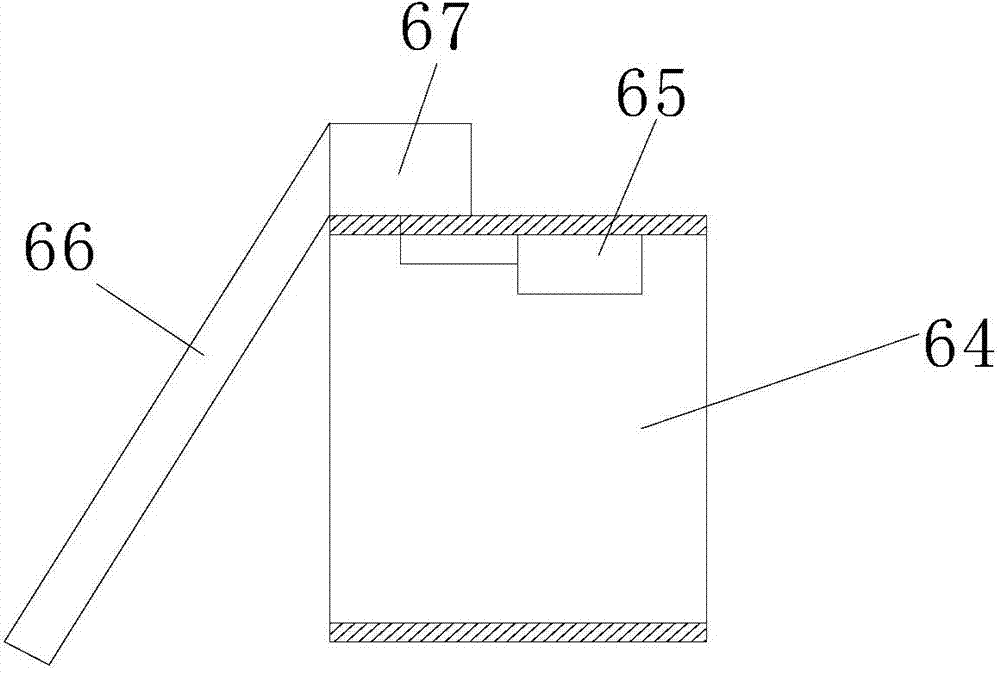

Biomass particle burner and use method thereof

ActiveCN104791767ADon't leakImprove utilizationTravelling grateSolid fuel combustionThermal energyCombustion chamber

The invention discloses a biomass particle burner and a use method thereof. The biomass particle burner comprises an ash chamber located at the lower portion, a burning chamber located at the middle and a flame chamber located at the upper portion, which cut through mutually from bottom to top, wherein the periphery of the burning chamber is provided with air channels capable of conducting pre-heating utilization and thermal insulation, and the biomass particle burner is further provided with the ash chamber, an automatic feeding portion, an air circulating portion and an automatic ash discharging portion. Meanwhile, the use method of the biomass particle burner is introduced. According to the biomass particle burner and the use method thereof, unique design is conducted on an air channel system, the thermal energy utilization is high, compared with a furnace with the same calorific value, the whole optimization is good, the volume is small, the energy consumption is low, and the thermal loss is low.

Owner:山东宇龙机械有限公司

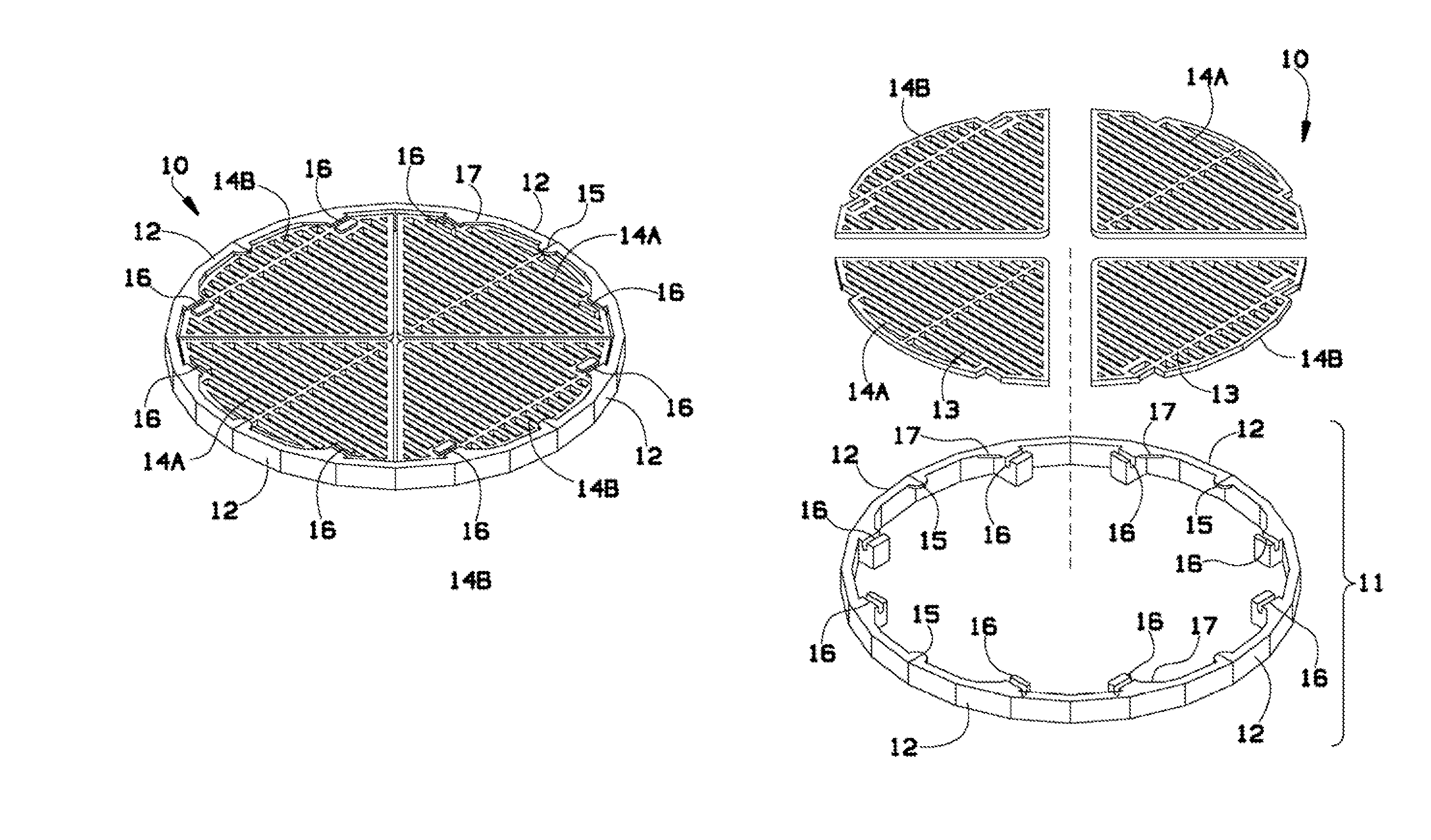

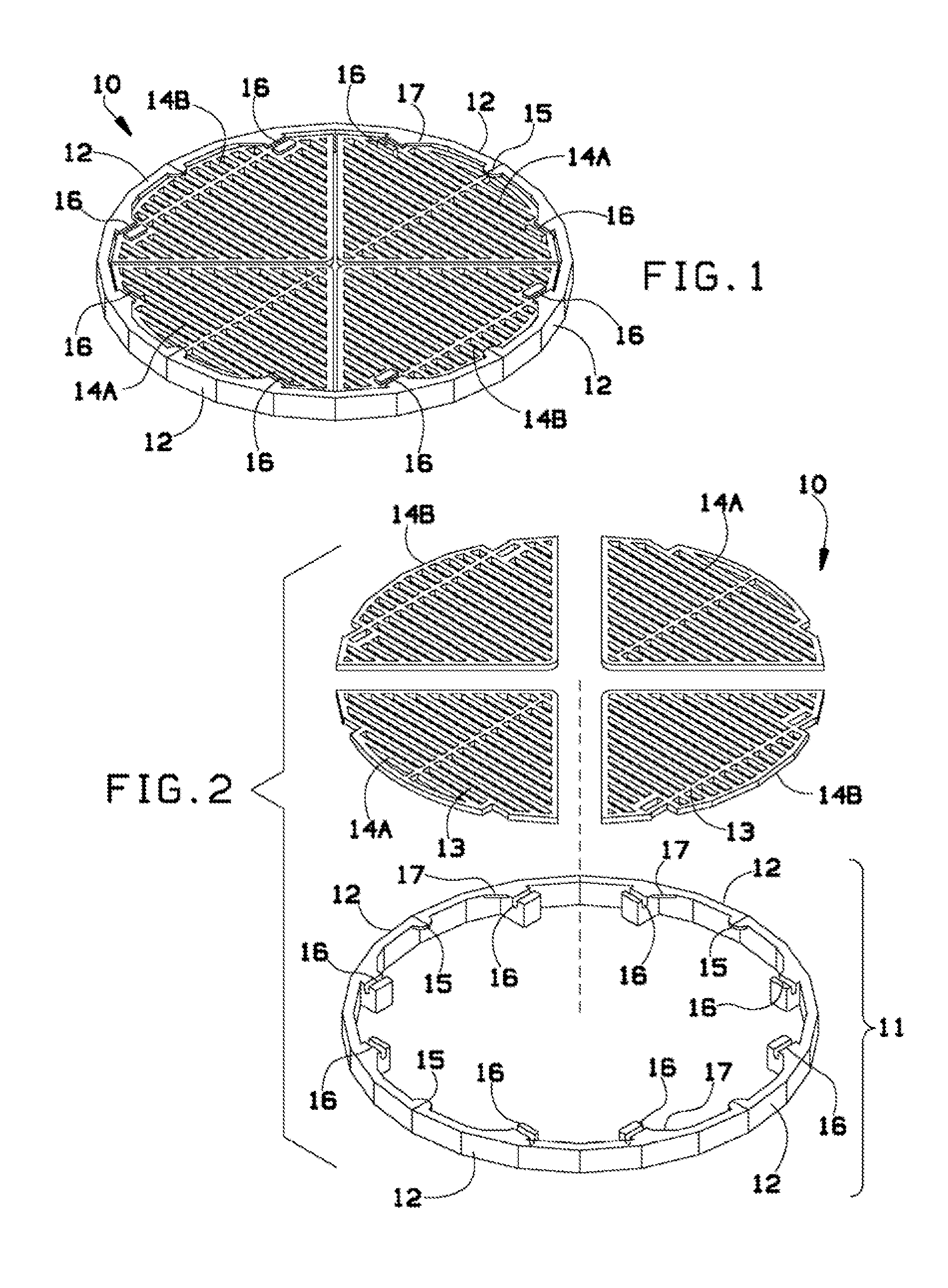

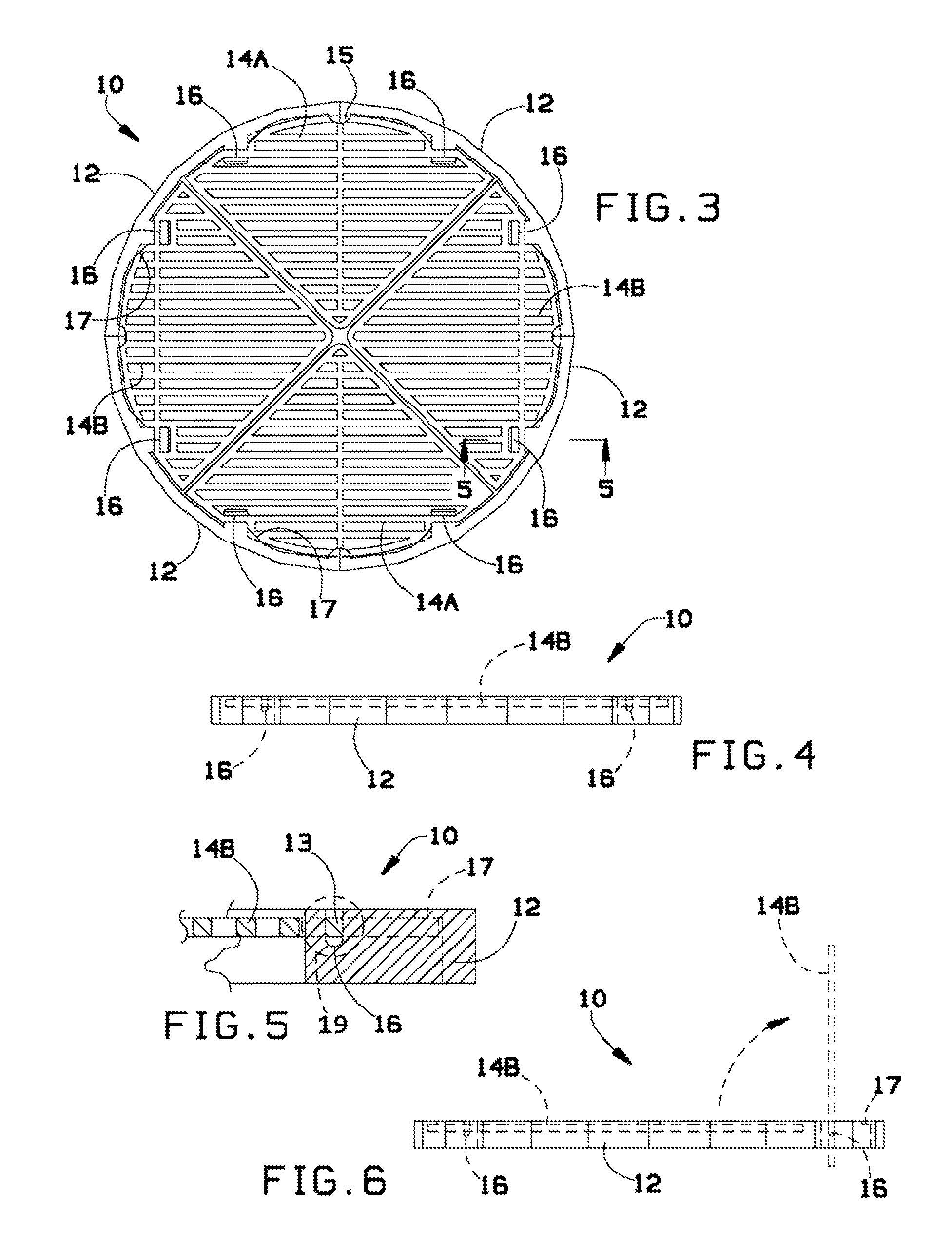

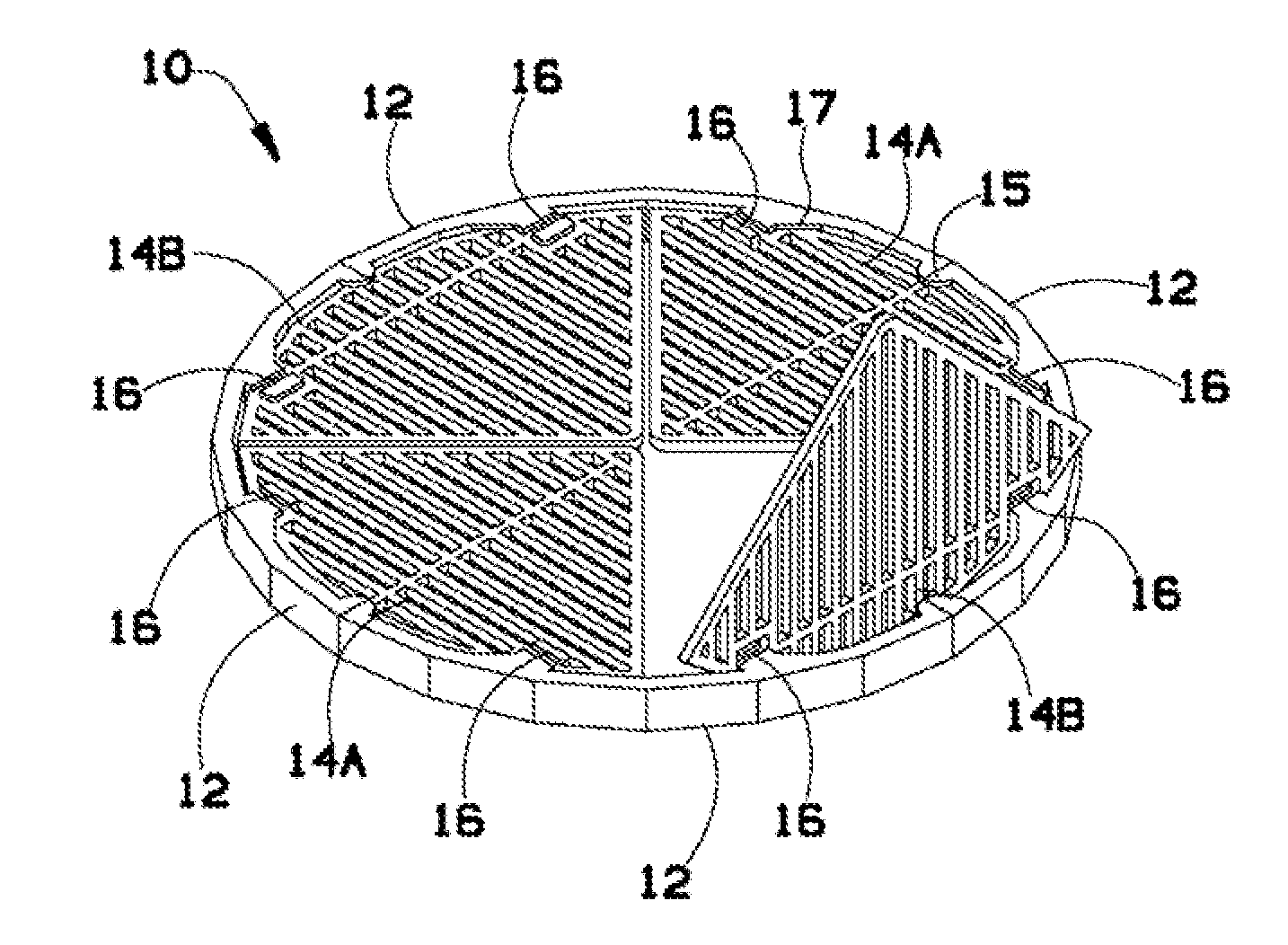

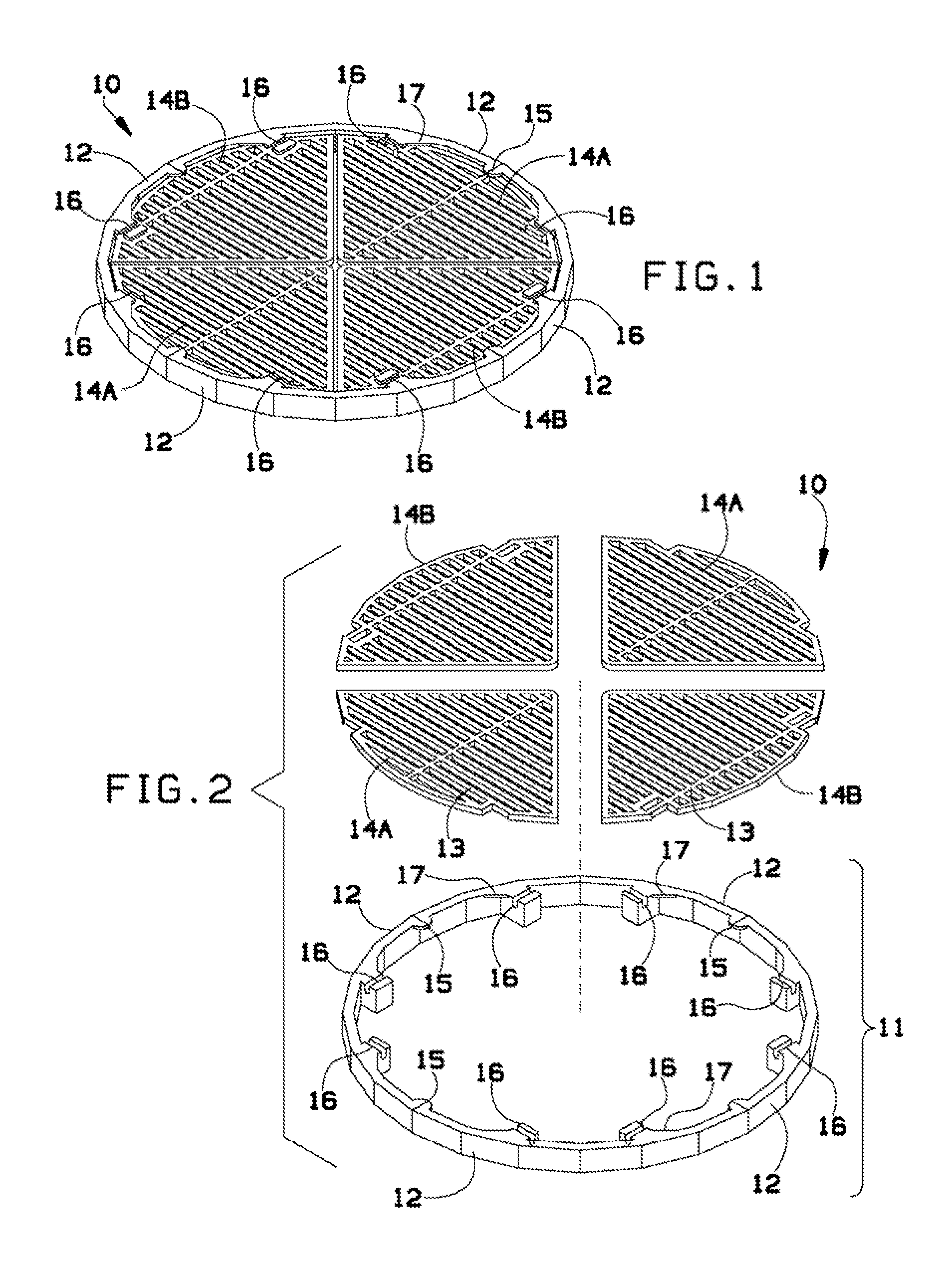

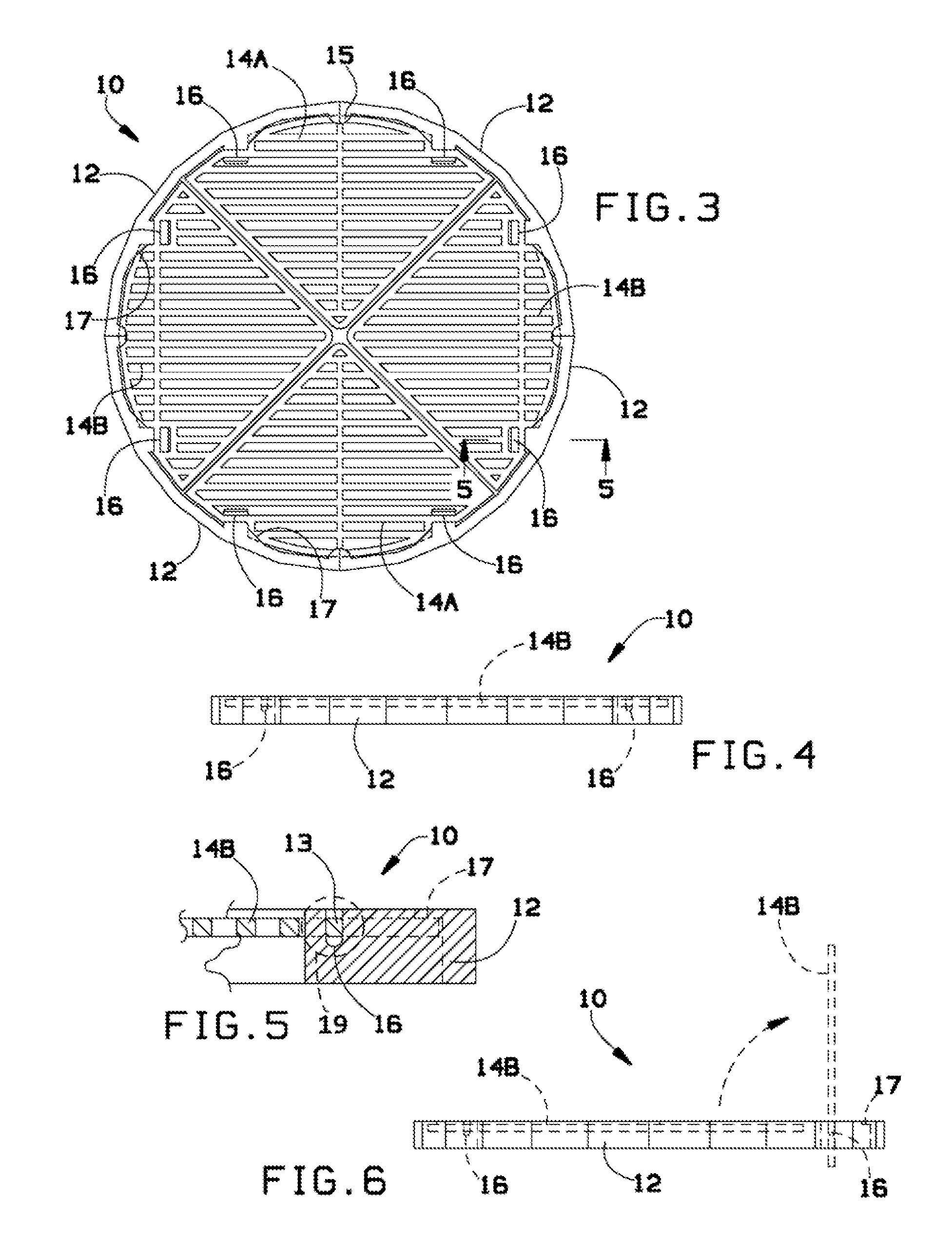

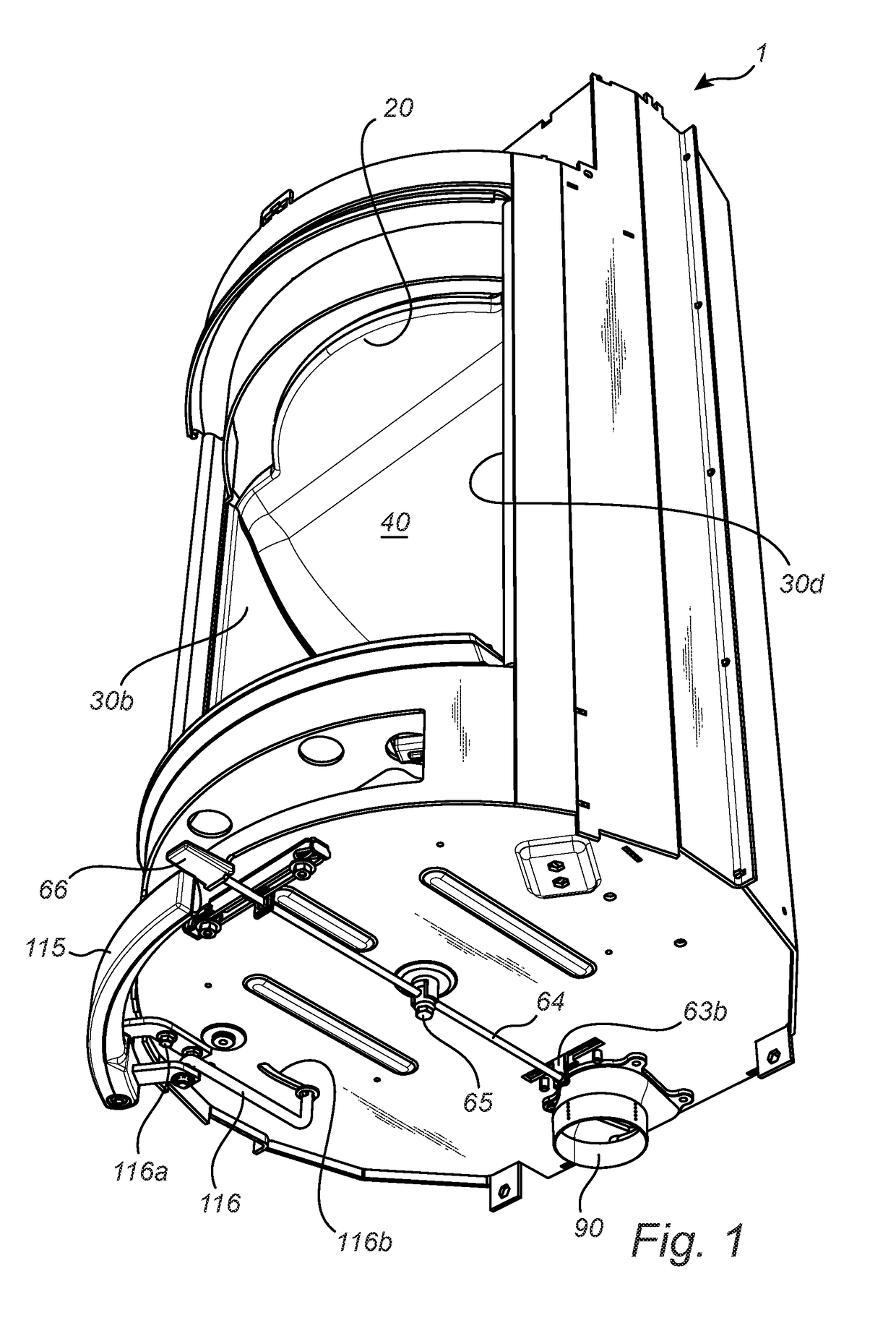

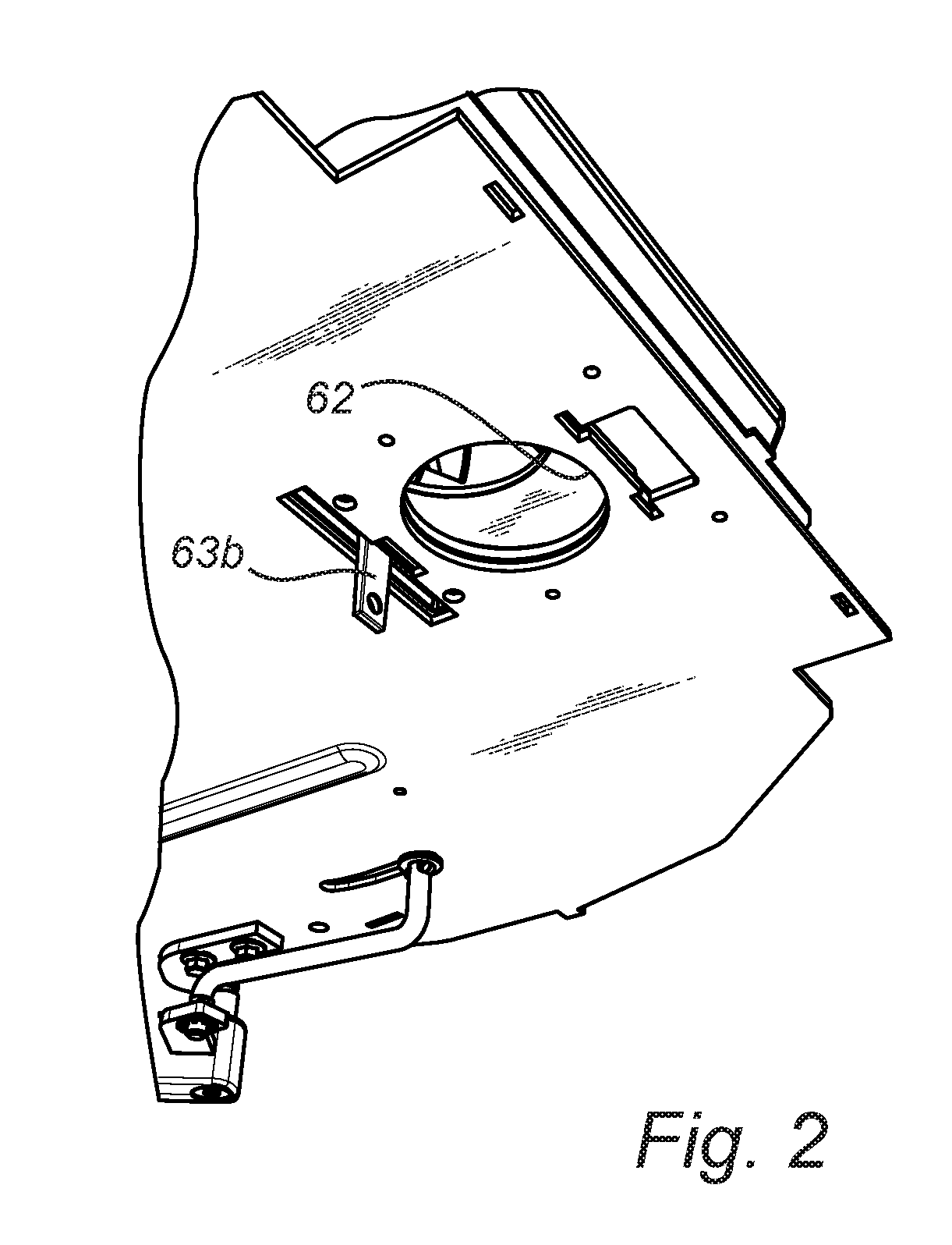

Modular-hinged grilling grate system

A modular-hinged grilling grate system may include a modular outer support structure and at least one attachable swivel grill grate section.

Owner:BURKLE ROLF

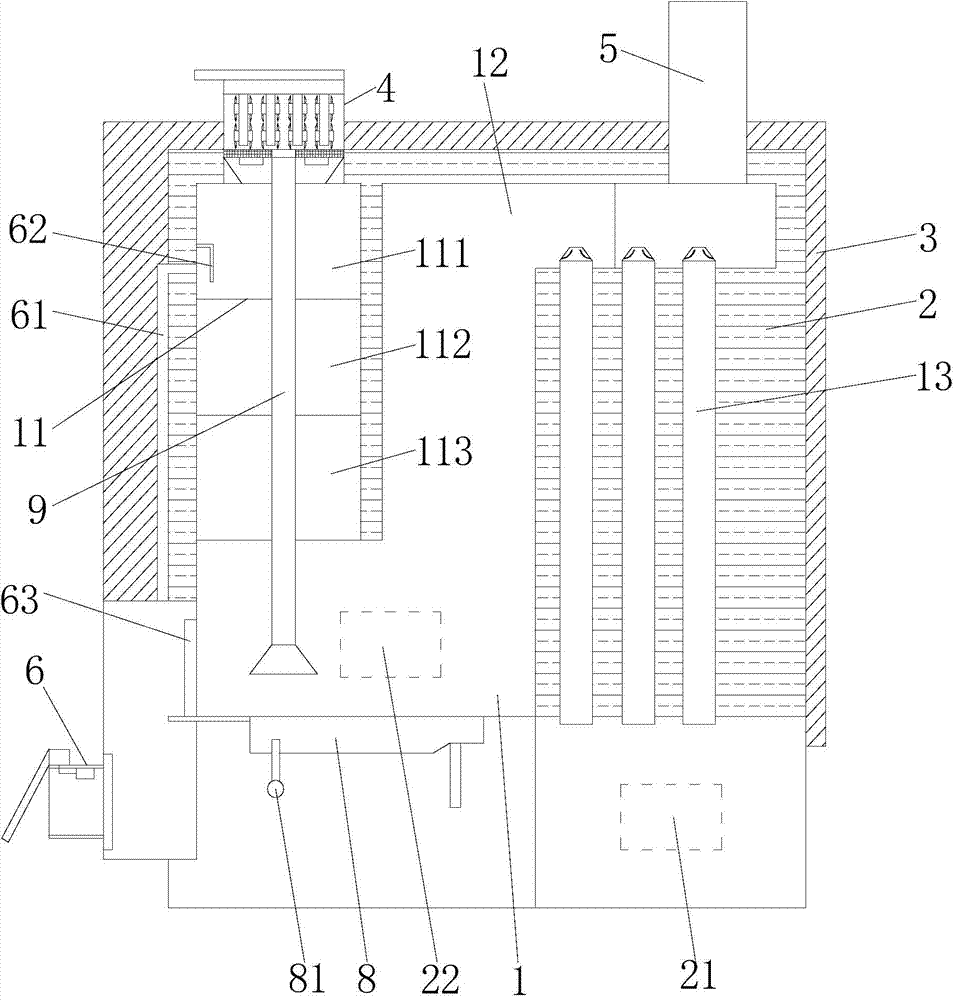

Household garbage incinerator

ActiveCN106122975AUniform temperature distributionIncrease temperatureTravelling grateBlast-producing apparatusCombustionSlag

The invention discloses a household garbage incinerator. A furnace door is arranged at the top of a furnace cavity of the incinerator. Materials are put into the furnace cavity through a feeding system. At least two rows of fire grates used for carrying garbage are arranged in the furnace cavity. The garbage entering the furnace cavity is dried and combusted on the fire grates. A slag discharging and dust removing door is arranged at the bottom of the furnace cavity. A plurality of injection pipes are arranged on the side wall of the furnace cavity. The injection pipes are connected with an air blower and used for injecting air to the interior of the furnace cavity. An exhaust port is formed in the top of the furnace cavity, arranged in the tangential direction of the furnace cavity, connected with an induced draft fan and used for pumping smoke in the furnace cavity. According to the household garbage incinerator, the movable fire grates are adopted, layered combustion is achieved, the garbage is evenly distributed, and the purpose of controlling the combustion condition in the incinerator can be achieved by controlling the induced air amount and air blowing amount. Through the arrangement of the injection pipes, the smoke temperature in the incinerator can be distributed more evenly, the retention time of the smoke is greatly prolonged, harmful matter such as dioxin can be completely decomposed, and sufficient combustion of the garbage is achieved.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

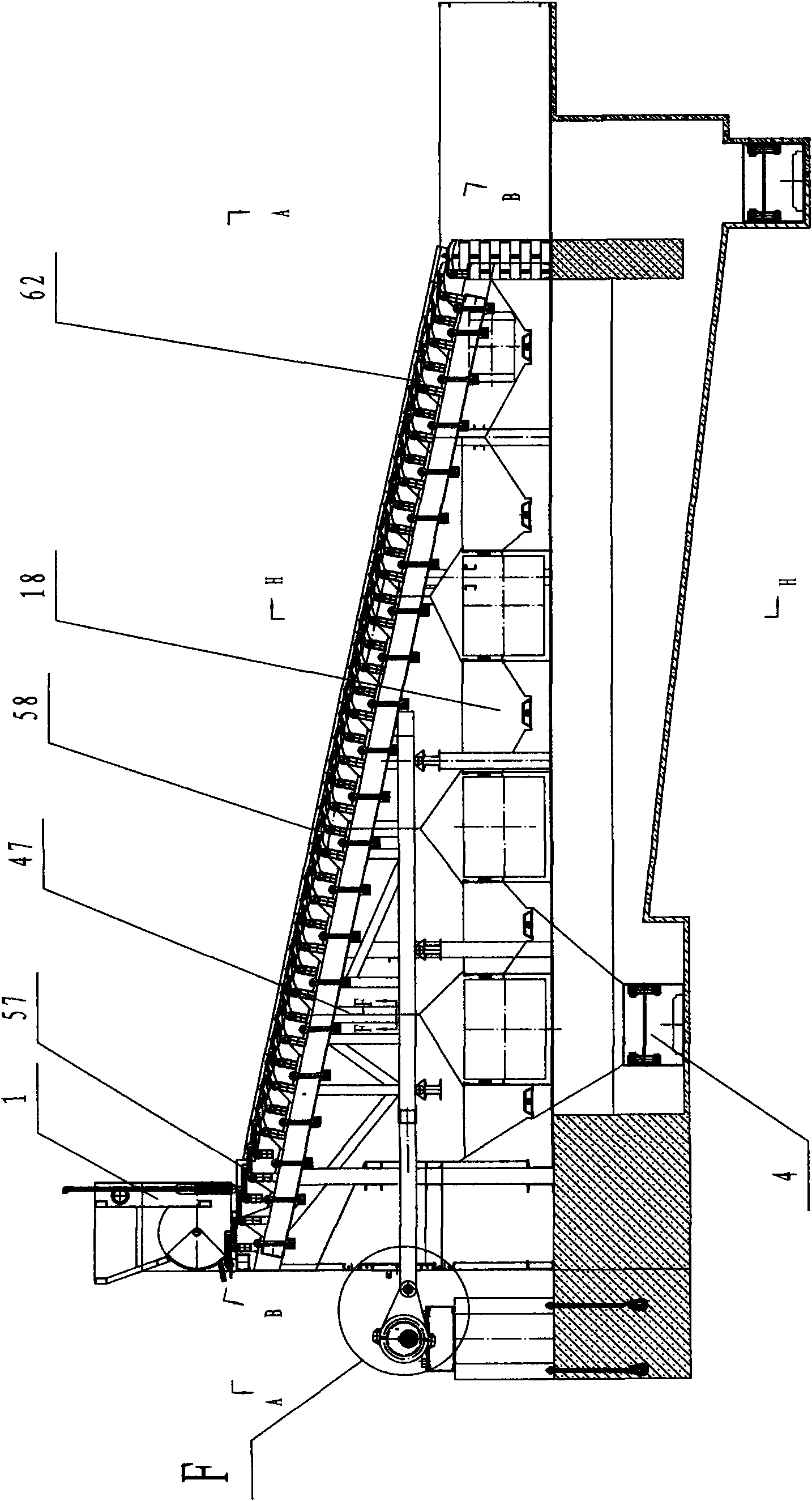

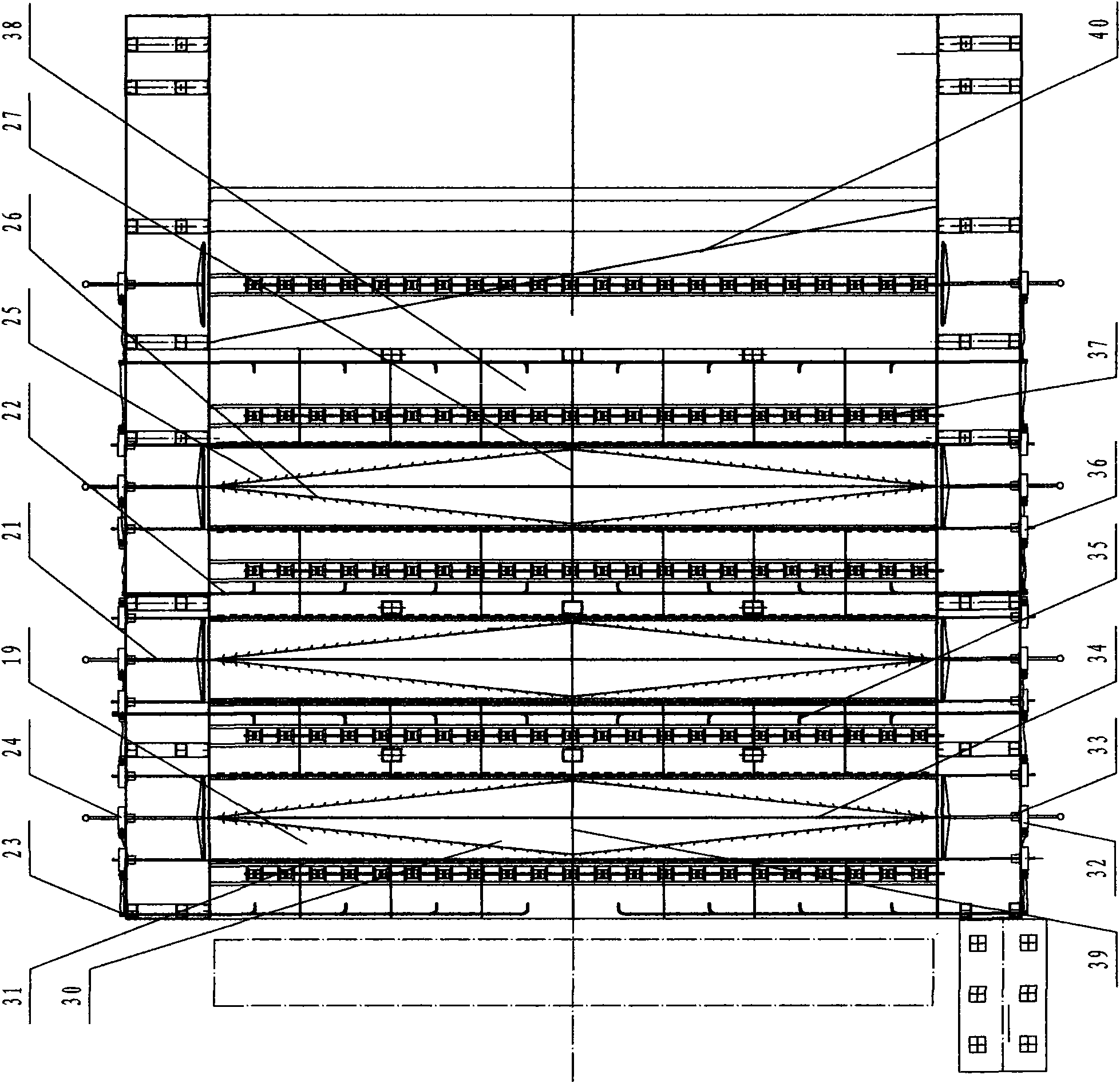

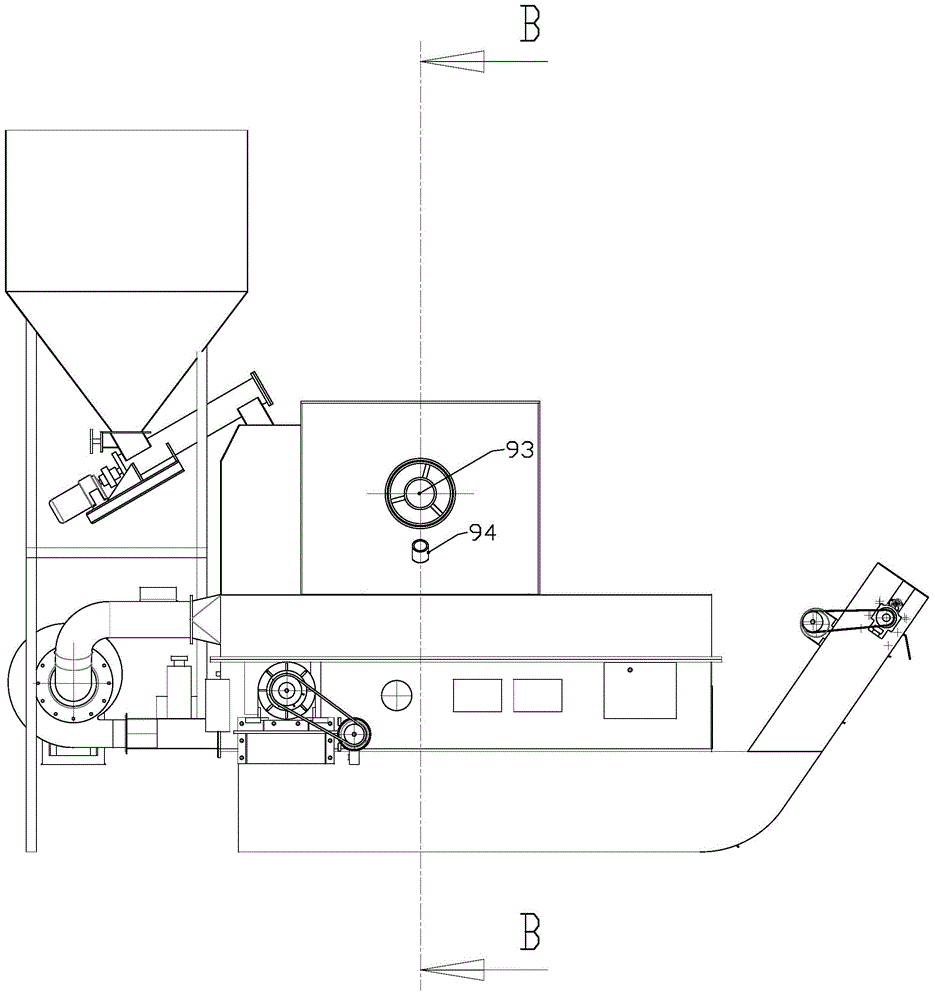

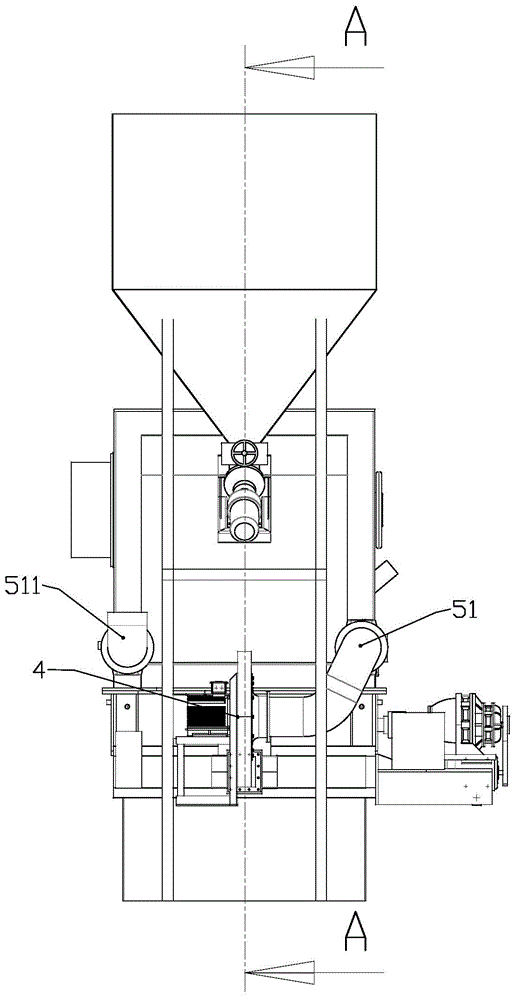

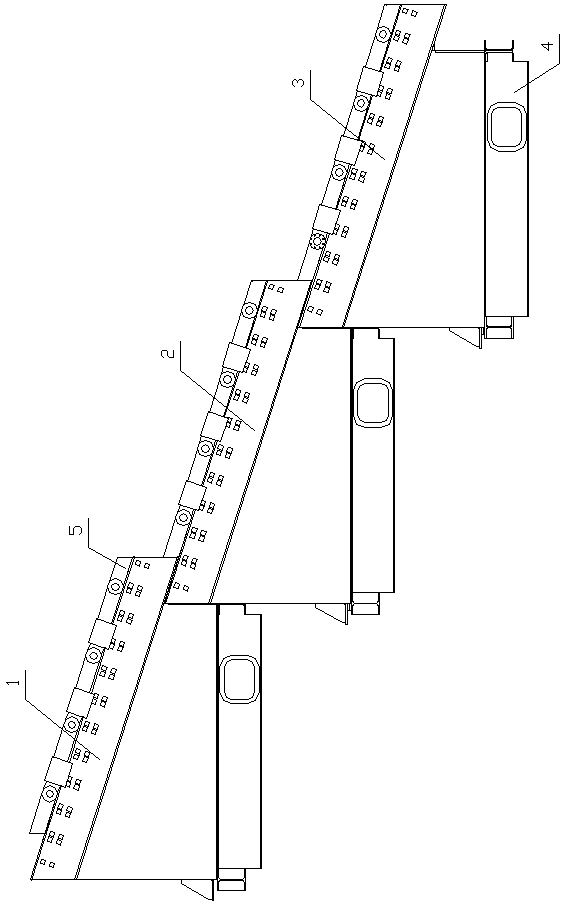

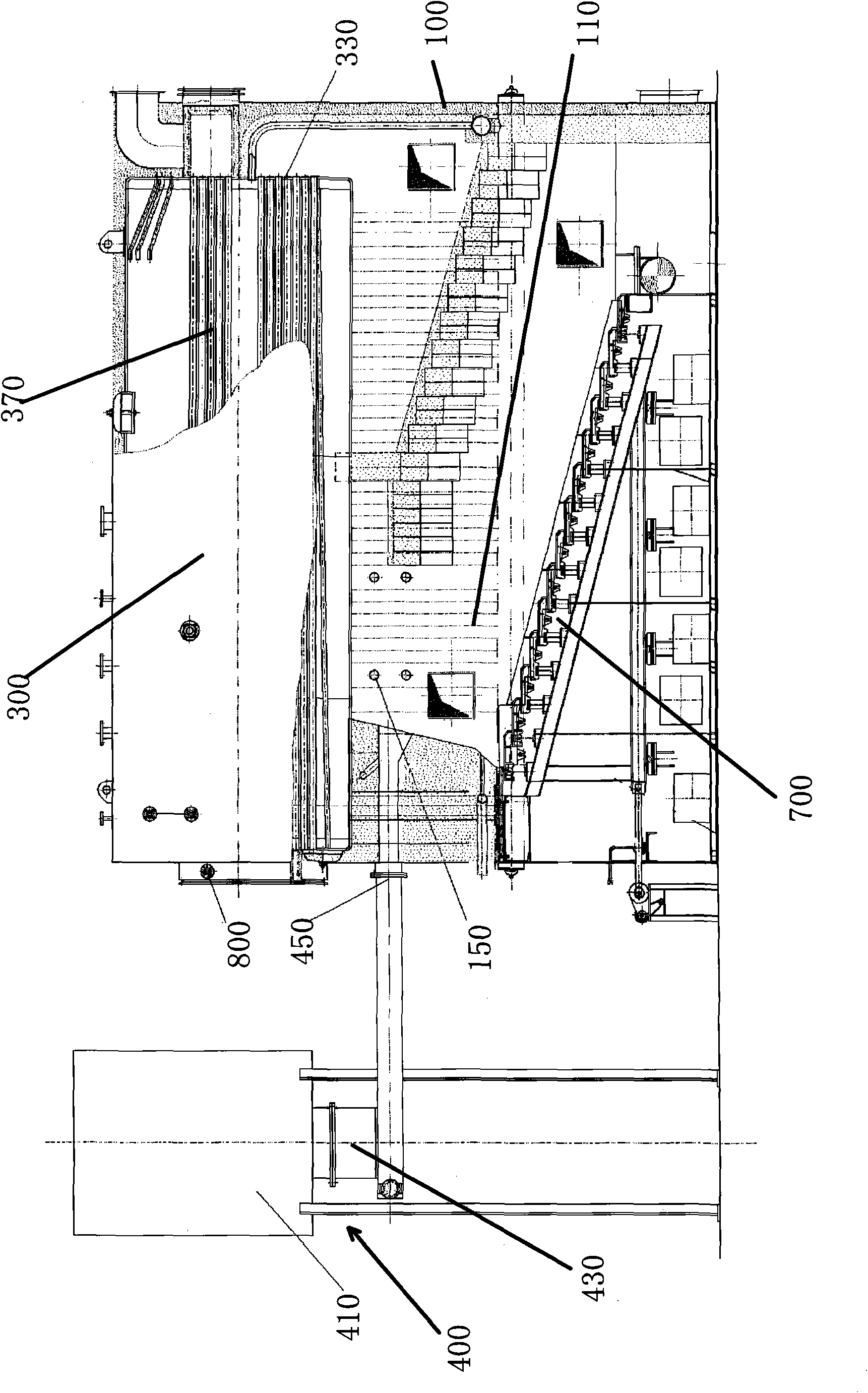

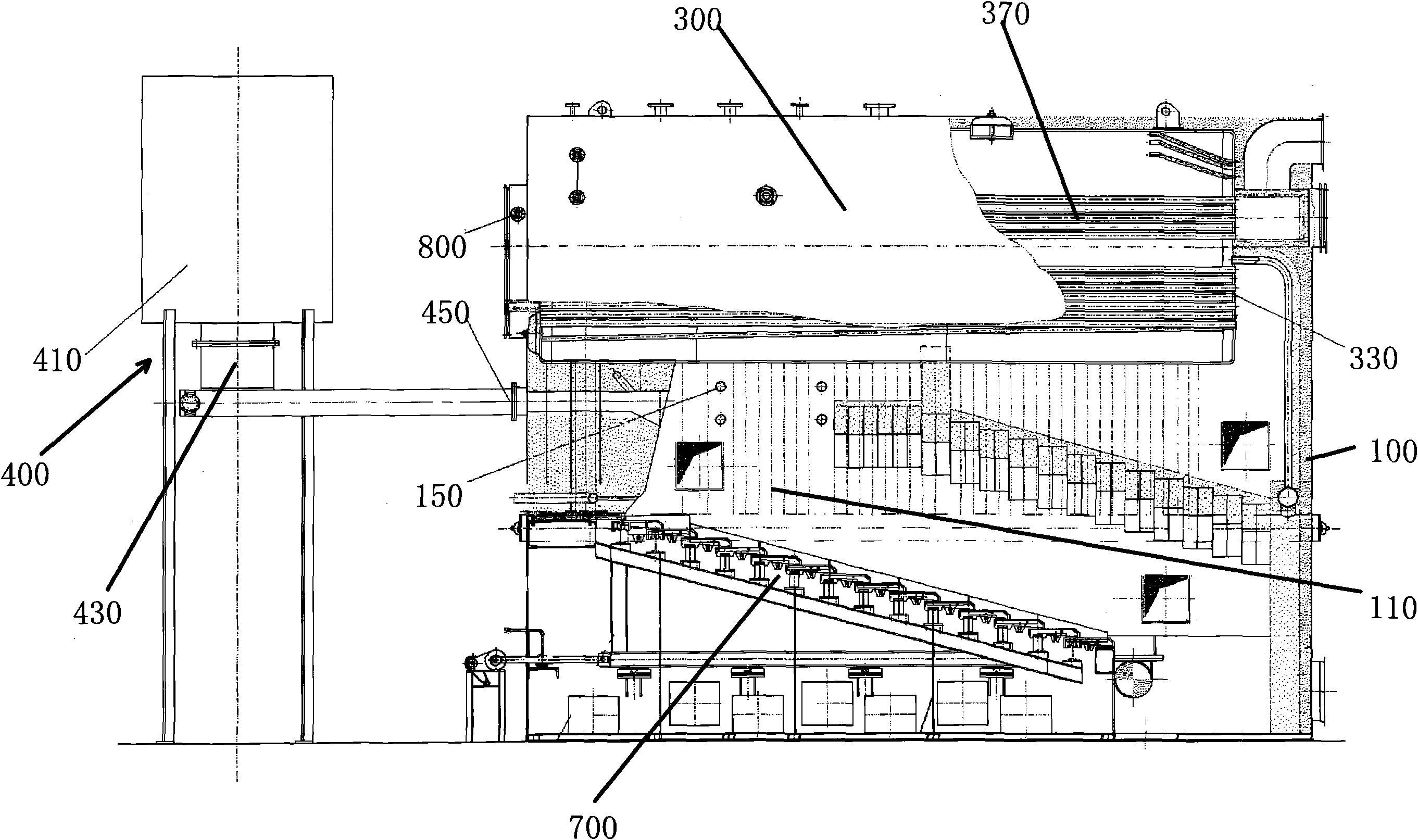

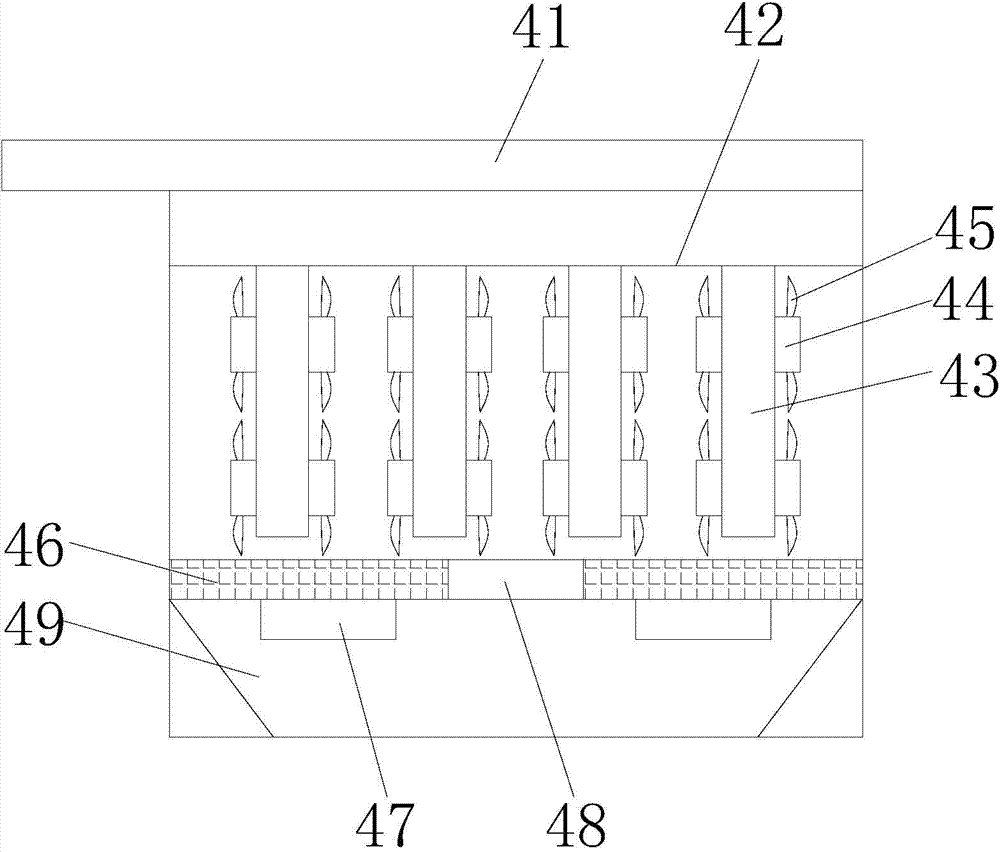

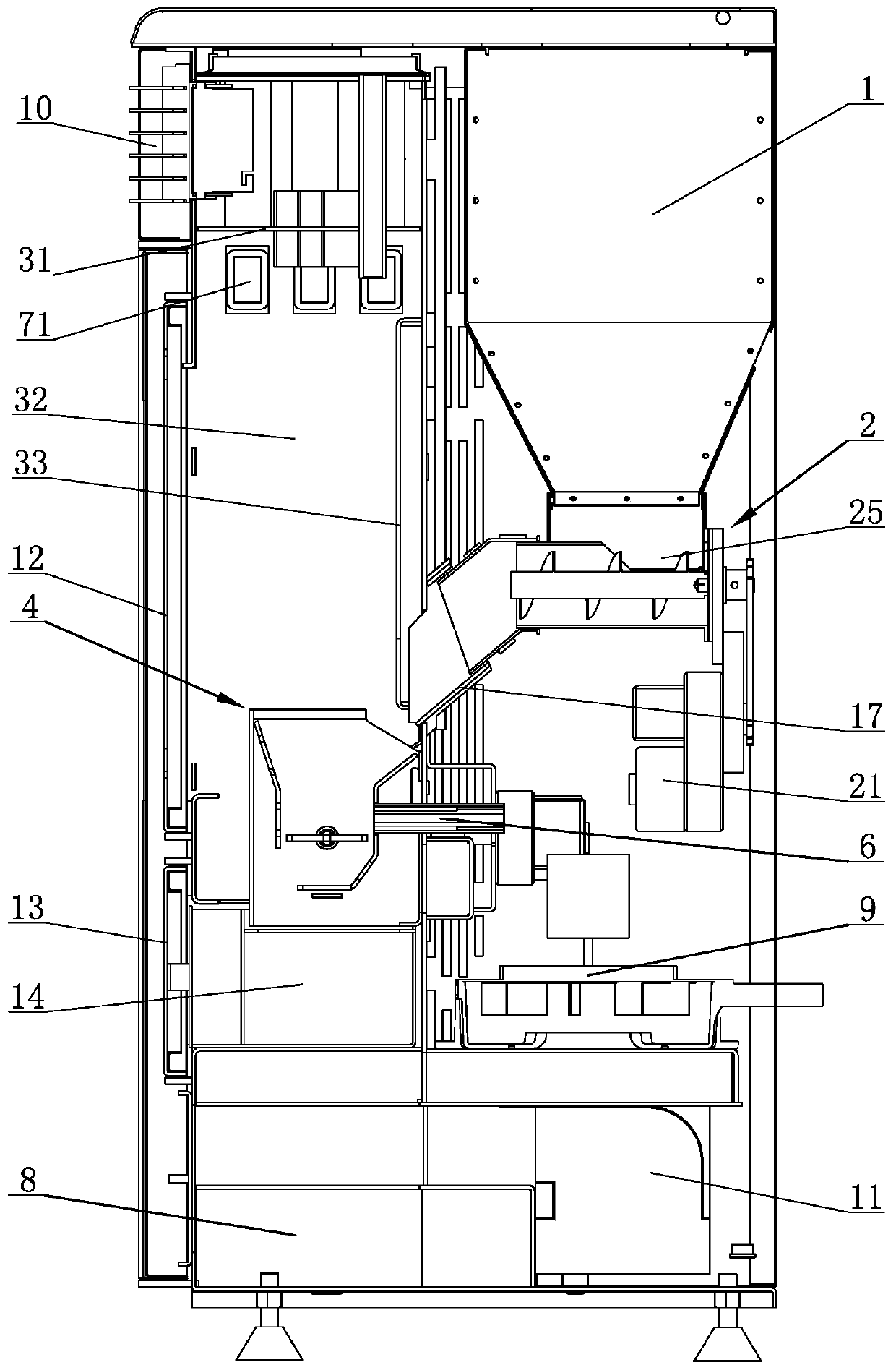

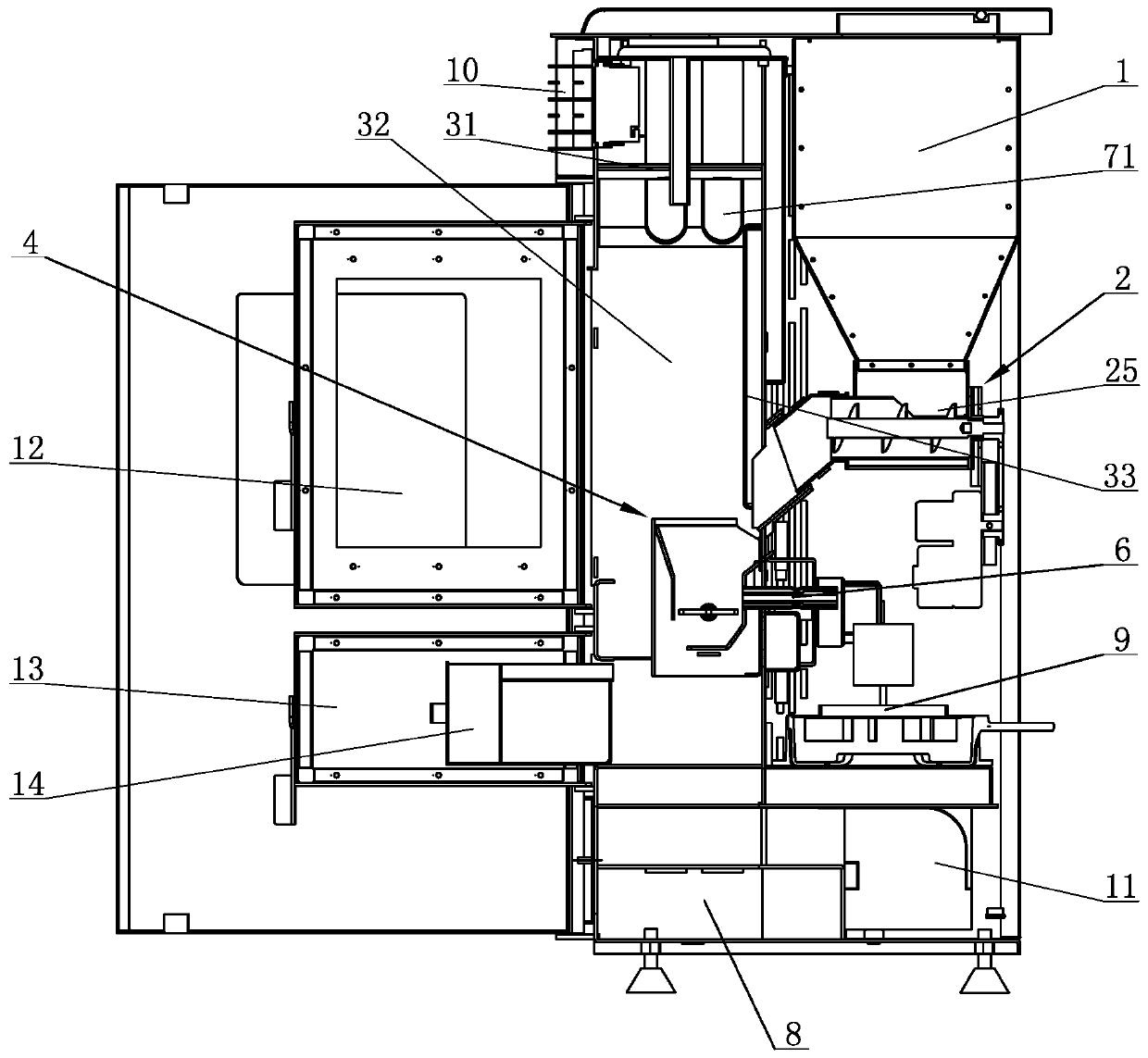

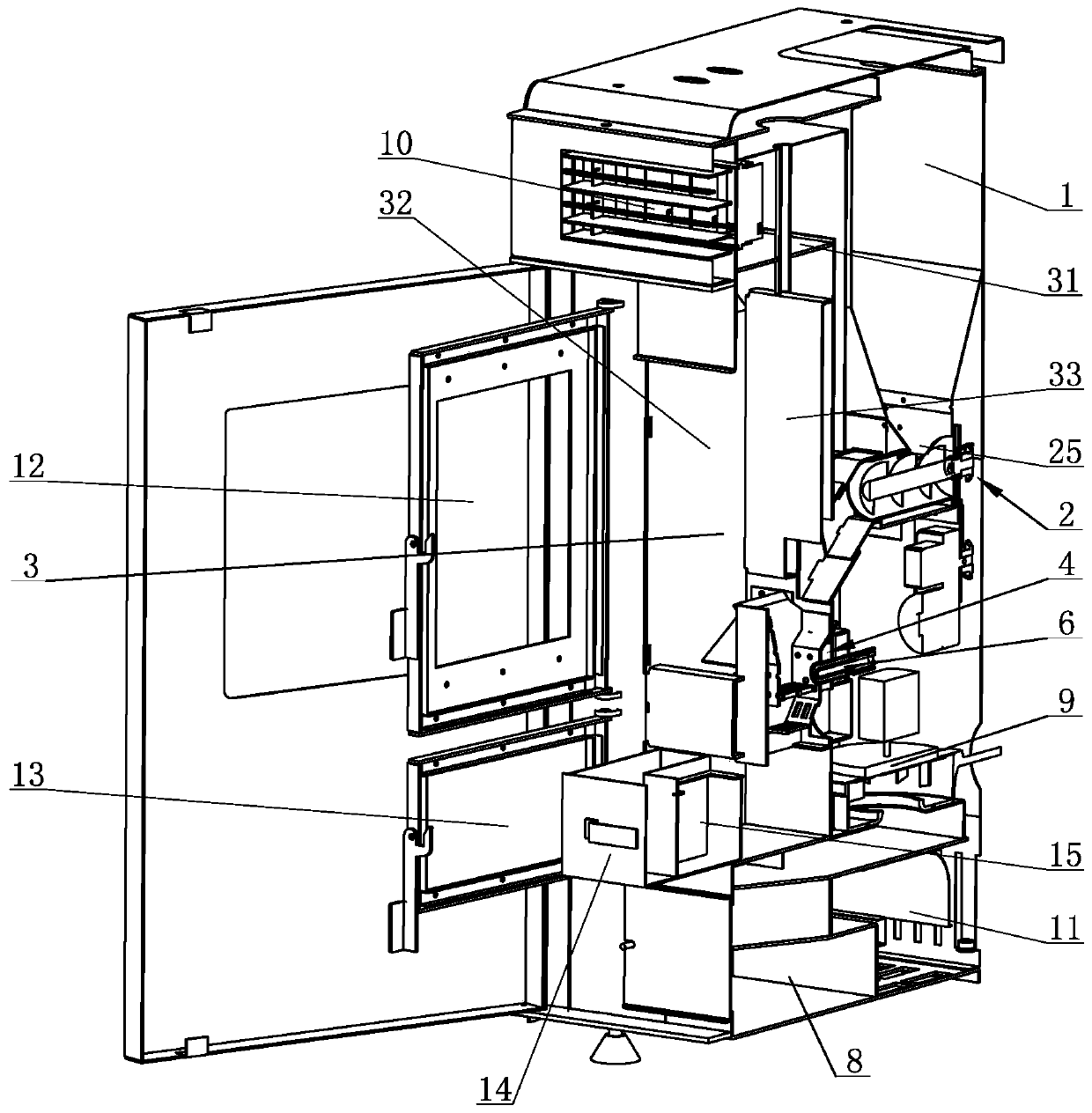

Large-scale domestic waste incineration grate furnace

ActiveCN106196077AChange processing powerAbility to operate independentlyTravelling grateIncinerator apparatusCombustionLitter

The invention relates to a large-scale domestic waste incineration grate furnace and relates to the field of waste incineration equipment. The large-scale domestic waste incineration grate furnace comprises a drying section grate, a combustion section grate and a burnout section grate which are arranged in a stepped manner. The drying section grate, the combustion section grate and the burnout section grate are of the same modular structure and each comprises a grate support frame. Side frame bodies are symmetrically arranged on the two sides of each grate support frame, and multiple modular incineration grate units which are arranged in a stepped manner are arranged on the portion, between the side frame bodies, of each grate support frame. A modular design is adopted for each of the grate support frames, the side frame bodies and the modular incineration grate units of the drying section grate, the combustion section grate and the burnout section grate. The domestic waste treatment capacity of the incineration units is changed by changing the number of the modular units, each modular unit has independent operating capacity, and the structural size of the large-scale domestic waste incineration grate furnace can be adjusted and altered according to the actual demands.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD +1

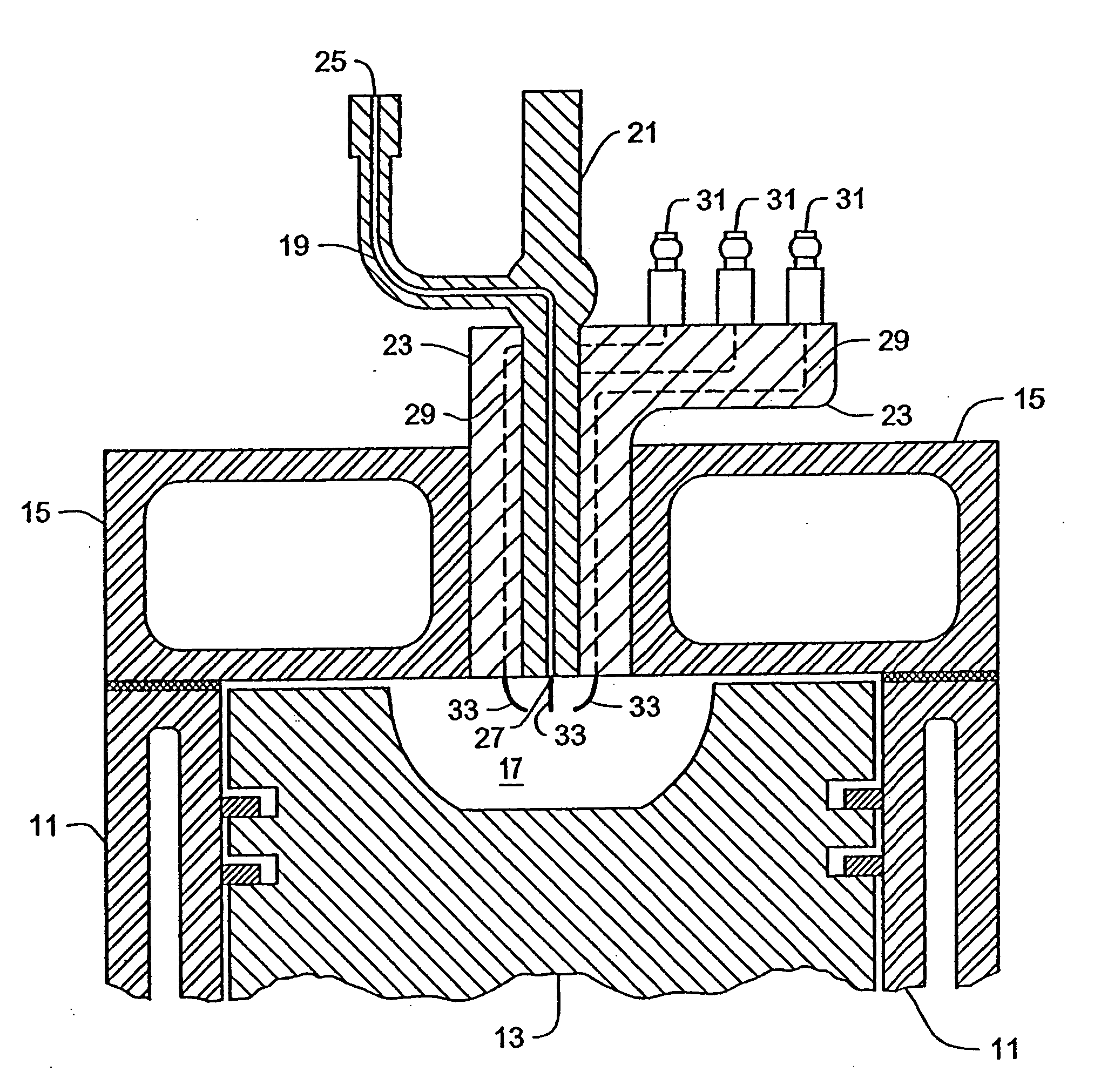

Furnace using plasma ignition system for hydrocarbon combustion

InactiveUS7435082B2Promote combustionImprove efficiencyBurnersInternal combustion piston enginesCombustorFuel efficiency

An apparatus and method for the creation, placement and control of an area of electrical ionization within an internal combustion engine combustion chamber or a fuel burner for a furnace is disclosed. A furnace includes a fuel source, a fuel burner, a plasma nozzle and igniter assembly, and the associated housing and flue structures. The plasma nozzle and igniter assembly is arranged so that the fuel sprayed out from the nozzle into the combustion area passes through or in close proximity to the area of plasma ionization. A fuel burner equipped with this electrical ionization device has its fuel efficiency enhanced by the complete and immediate combustion of substantially all of the fuel that passes through the area of plasma ionization. Exhaust gas recirculation using this system is also disclosed.

Owner:JAYNE MICHAEL E

Blowing system of chain boiler with sectorial blow homogenating plate

InactiveCN1424538AReduce carbon contentReduce primary air volumeTravelling grateAir/fuel supply for combustionAir volumeDistribution system

A air distribution system in chain with fan shaped plate to make air even for boiler includes air chamber, fire grate and wind introducing pipe. According to structure and feature of the air chamber, the fan shaped plate to make air even and to be suitable to the air chamber will be designed and erected in different locations of the air chamber, but it will not knock against with dust collector set at bottom of the air chamber with its plane in vertical to direction of air flowing. The present invention can decrease air flow deviation along with width direction of the boiler a lot so as to decrease air amount of once a time for raising combustion temperature in the boiler and the boiler efficiency.

Owner:SHANGHAI JIAO TONG UNIV

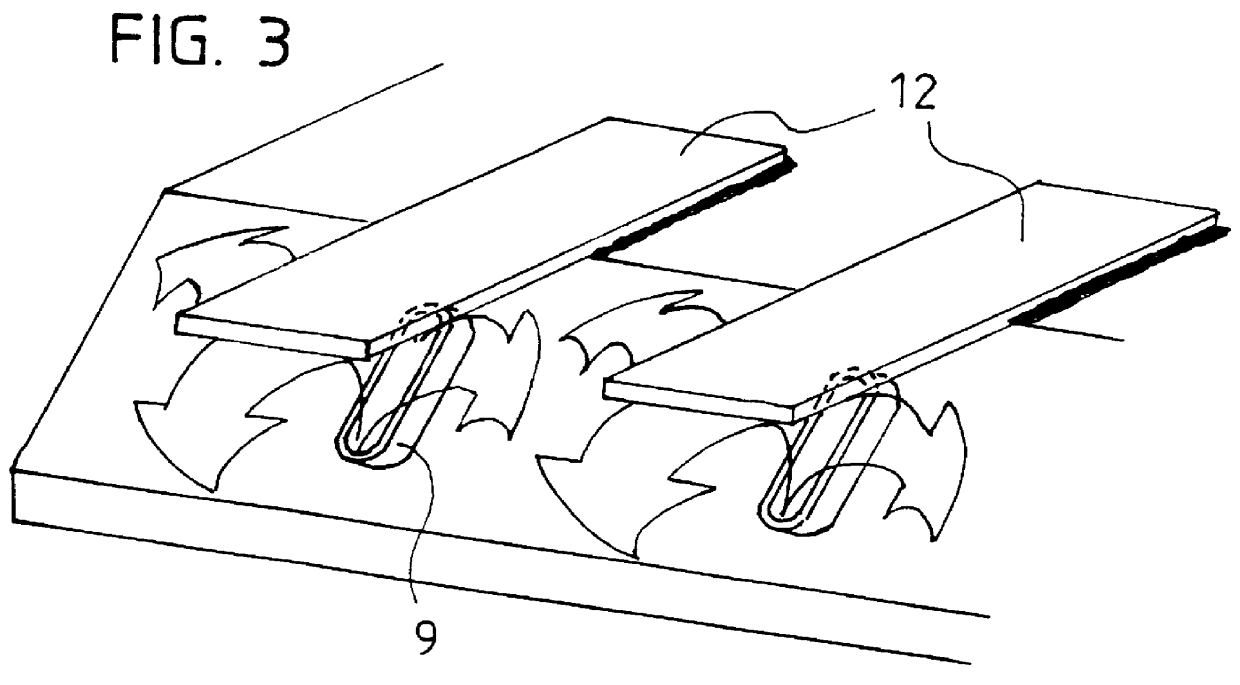

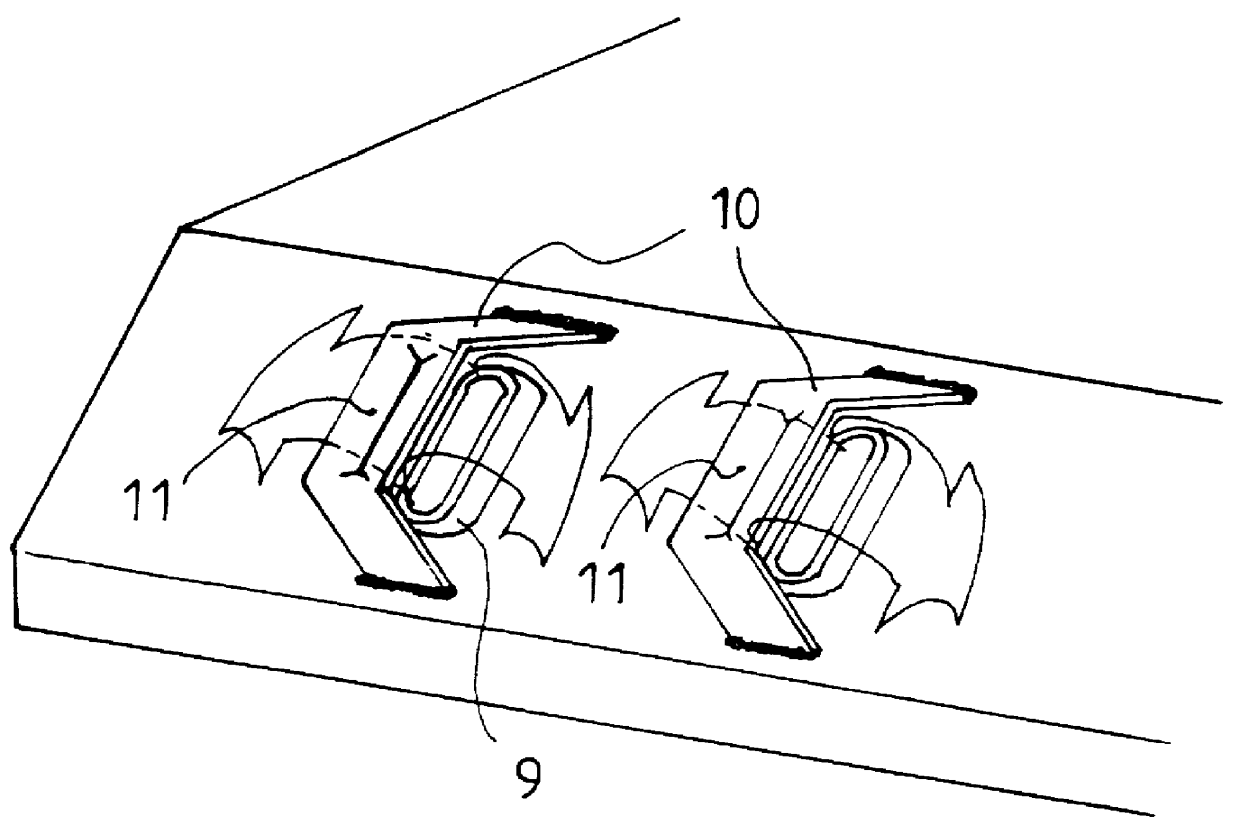

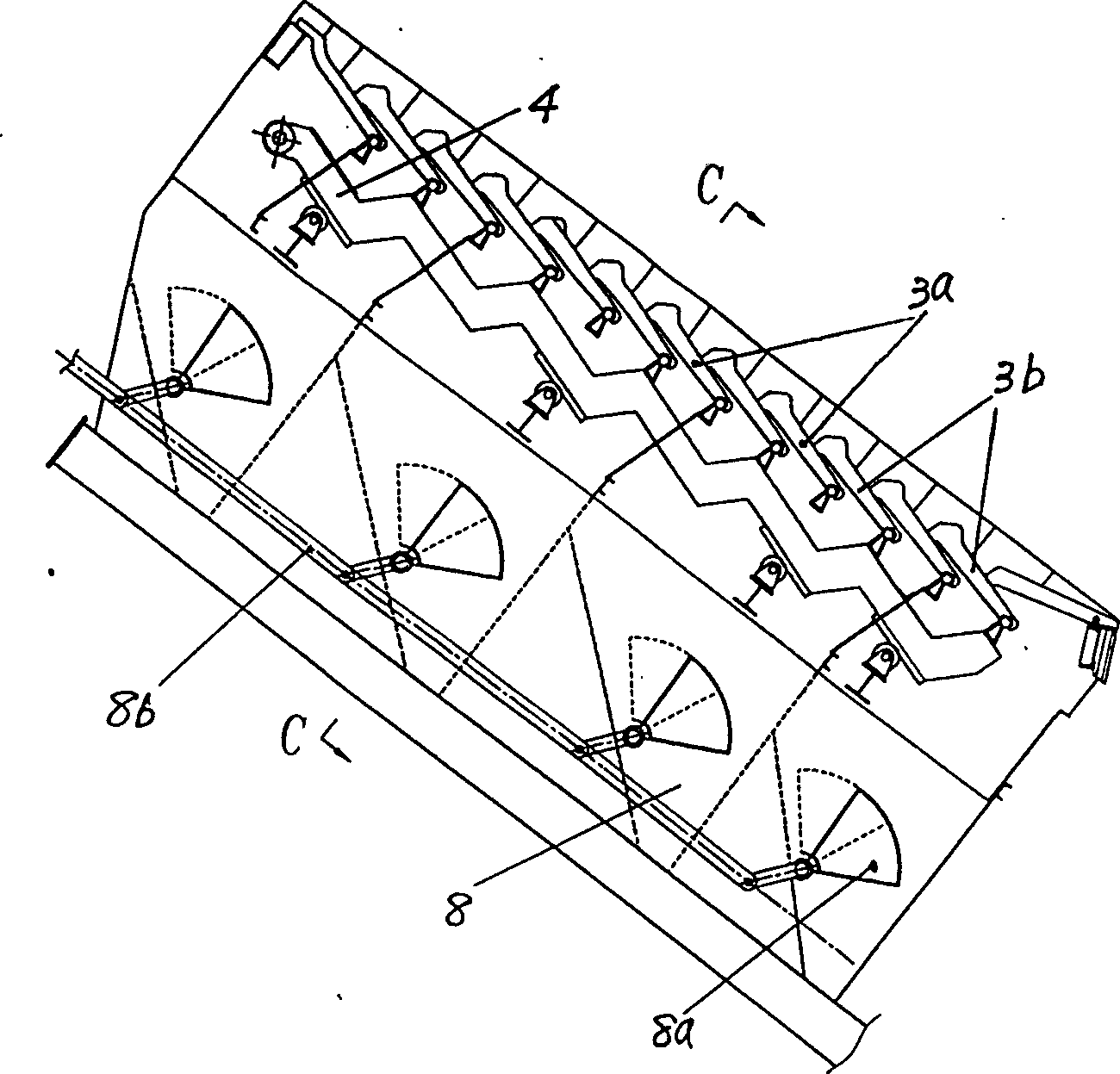

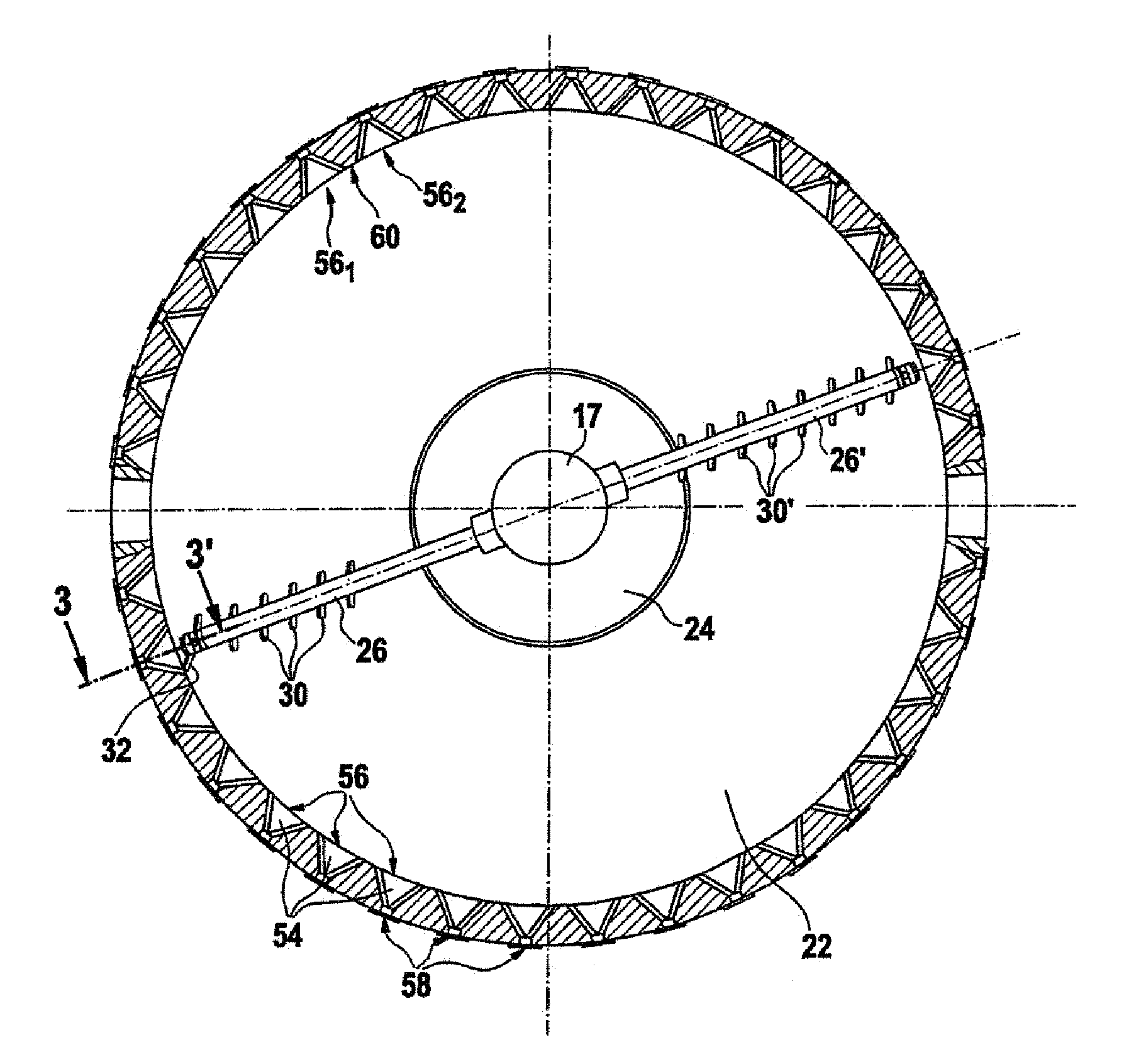

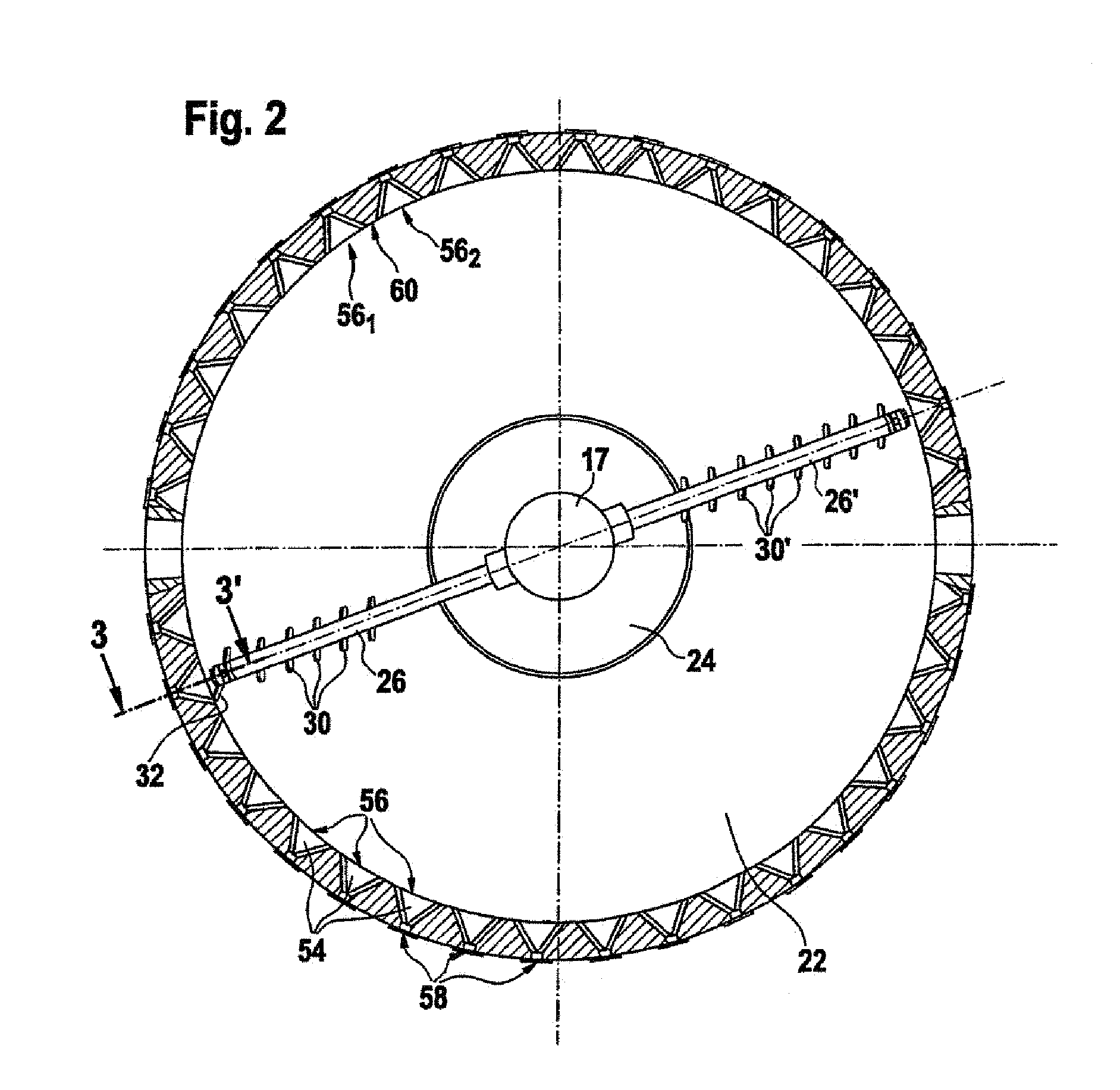

Process for incinerating solids on a water-cooled thrust combustion grate, and a grate plate and grate for accomplishing the process

A process wherein primary air supplied to the combustion bed through the thrust combustion grate is deflected after exiting from a surface of the thrust combustion grate by deflector elements mounted on the surface of the thrust combustion grate. The grate required for this purpose has grate plates made from a permeable hollow element with connection pieces for supplying and draining cooling water, with primary air supply ducts that run through the grate plate from a bottom to a top. Deflector elements against which the primary air exiting the outlet is intended to impact, are disposed over openings of the primary air supply ducts.

Owner:DOIKOS INVESTIMENTS LTD

Modular-hinged grilling grate system

A modular-hinged grilling grate system may include a modular outer support structure and at least one attachable swivel grill grate section.

Owner:BURKLE ROLF

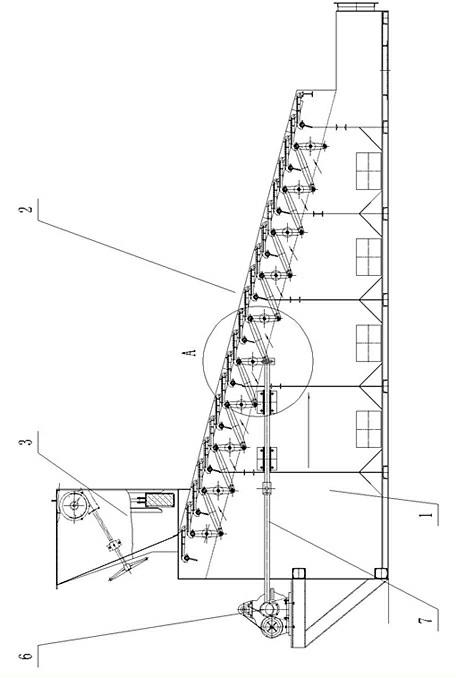

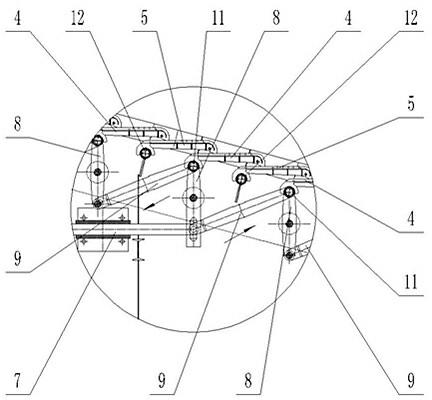

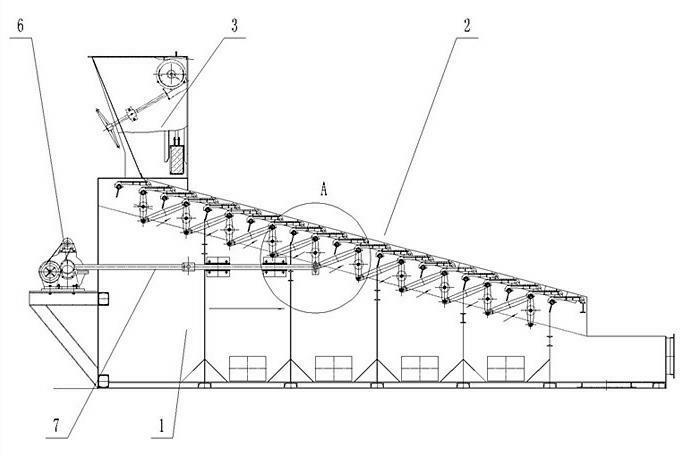

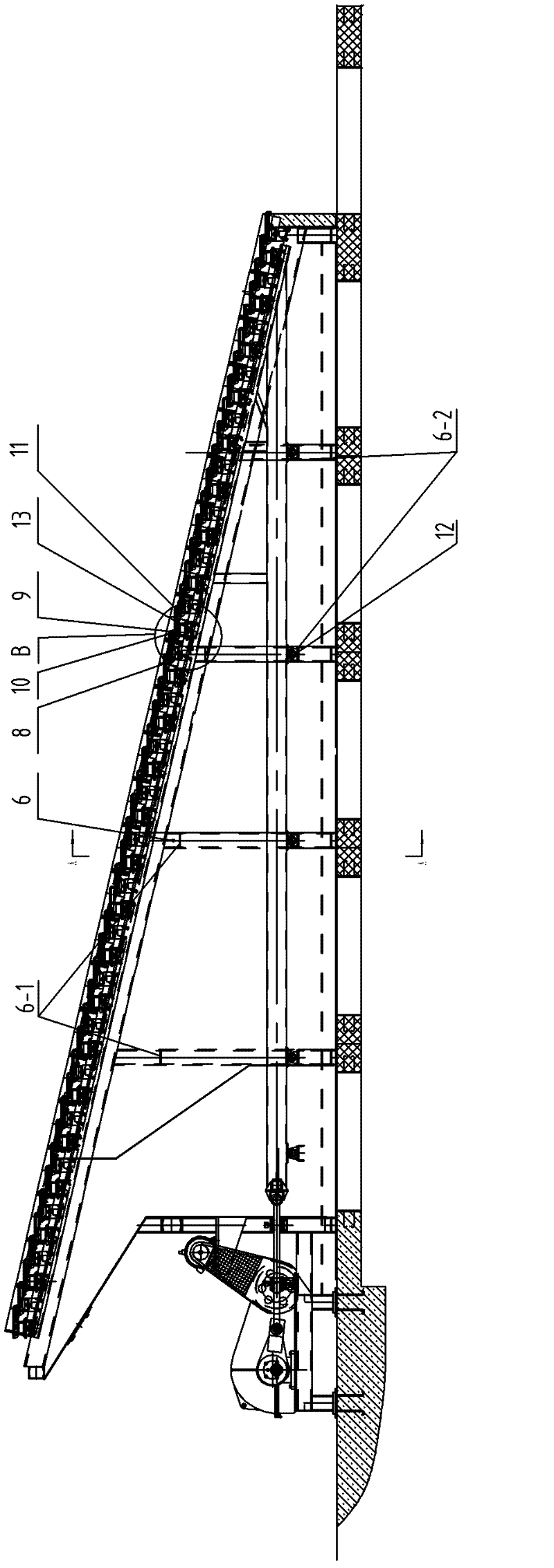

Vertical reciprocating grate

InactiveCN101858602AImprove ventilationImprove combustion effectTravelling grateCombustionReciprocating motion

The invention relates to a vertical reciprocating grate, aiming at solving the technical problems that when the grate is transmitted back and forth, the working surface of the grate is in the form of a horizontal flat slope or a flat slope with a small slope angle; accumulated continuous layered distribution is formed on the working face of the grate during the fuel operation period, and fuel operation is realized only by the thrust generated by reciprocating motion of mobile grate sheets relative to fixed grate sheets, thus leading long fuel ignition time, easy generation of lag and coking, and large ventilation resistance, and reducing the combustion effect of a boiler. The technical scheme of the invention is as follows: the vertical reciprocating grate comprises a fixed grate sheet support, a mobile grate sheet support, fixed grate sheets, mobile grate sheets and a reflecting arch, wherein, the fixed grate sheet support and the mobile grate sheet support are vertical support bodies the front sides of which are inclined, the working surface of the reciprocating grate composed of the fixed grate sheets and the mobile grate sheets is in a stepped shape, and the reflecting arch is of a vertical structure and correspondingly matched with the stepped working surface.

Owner:黑龙江双锅锅炉股份有限公司

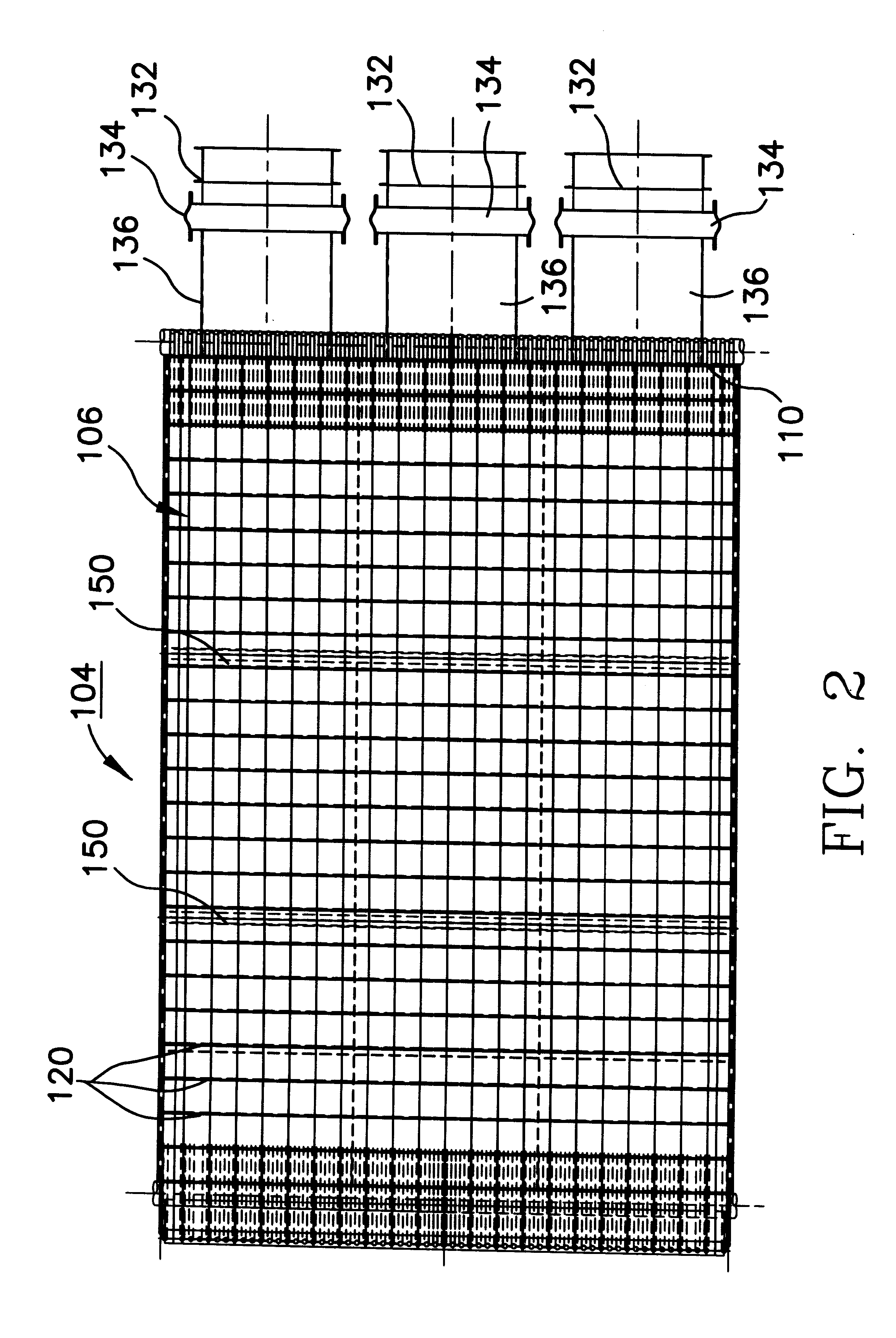

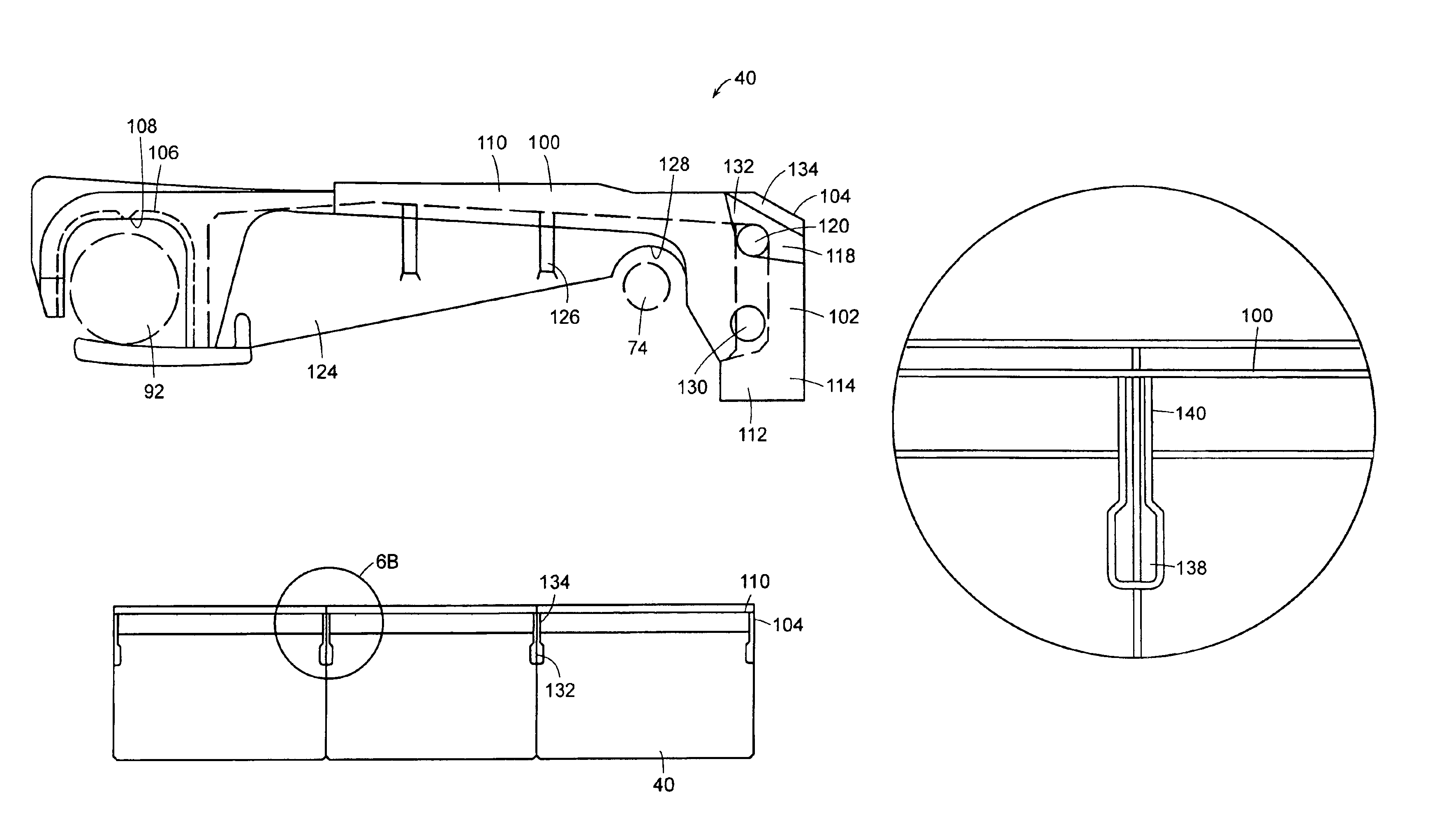

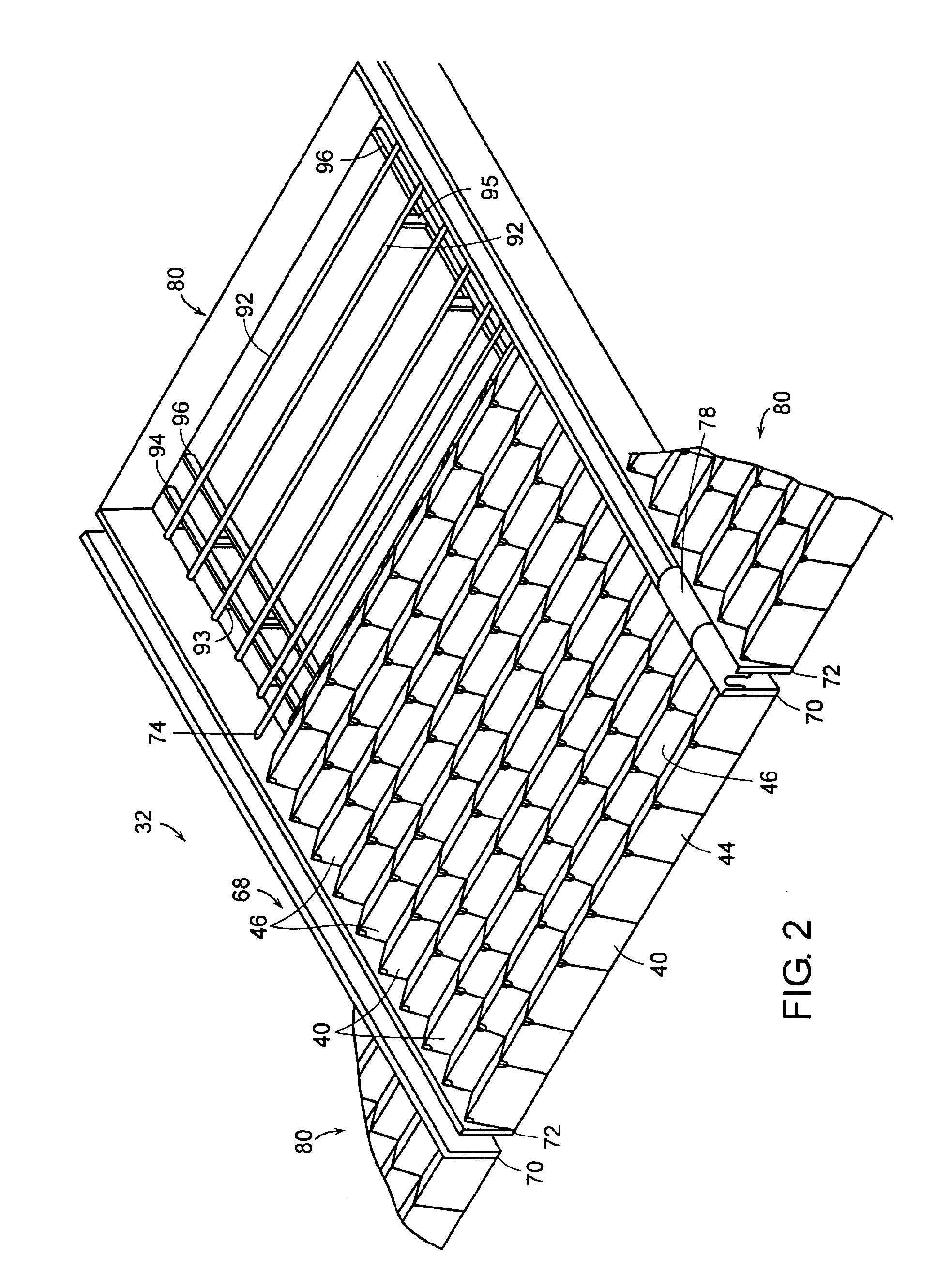

Grating system and sidewall seal arrangement for oscillating grate stoker

InactiveUS20080276843A1Obstruct passageGood vibration isolationSievingSolid bar grateGratingCombustion

The invention includes a grate system for a boiler. The grate system includes a grate unit and a side header guard. The grate unit supports fuel during combustion thereof, and has an upper surface, a lower surface, and upturned lateral edges. The side header guard is arranged along a side wall of the boiler and has upwardly and downwardly projecting fin portions. The upwardly projecting fin portion is adapted and configured to extend over and protect the boiler side wall from abrasion by fuel. The downwardly projecting fin portion is adapted and configured to extend over the upturned lateral edge of the grate unit, inhibiting passage of fuel therebetween.

Owner:RILEY STOKER

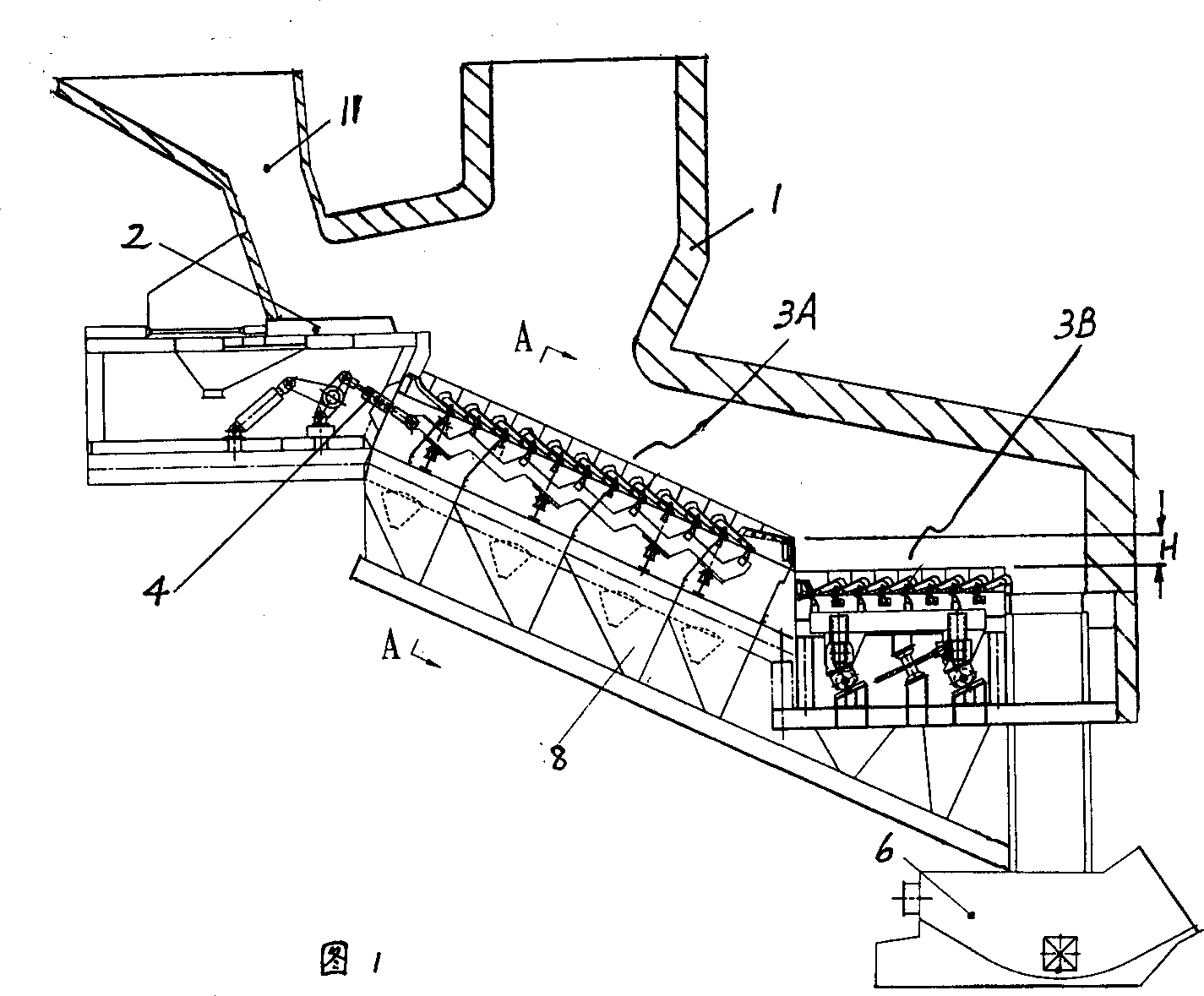

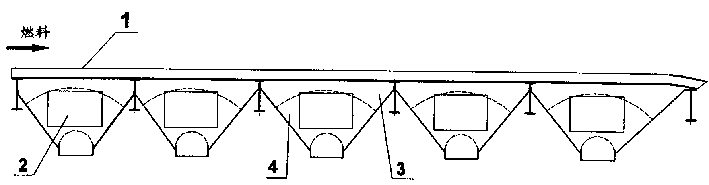

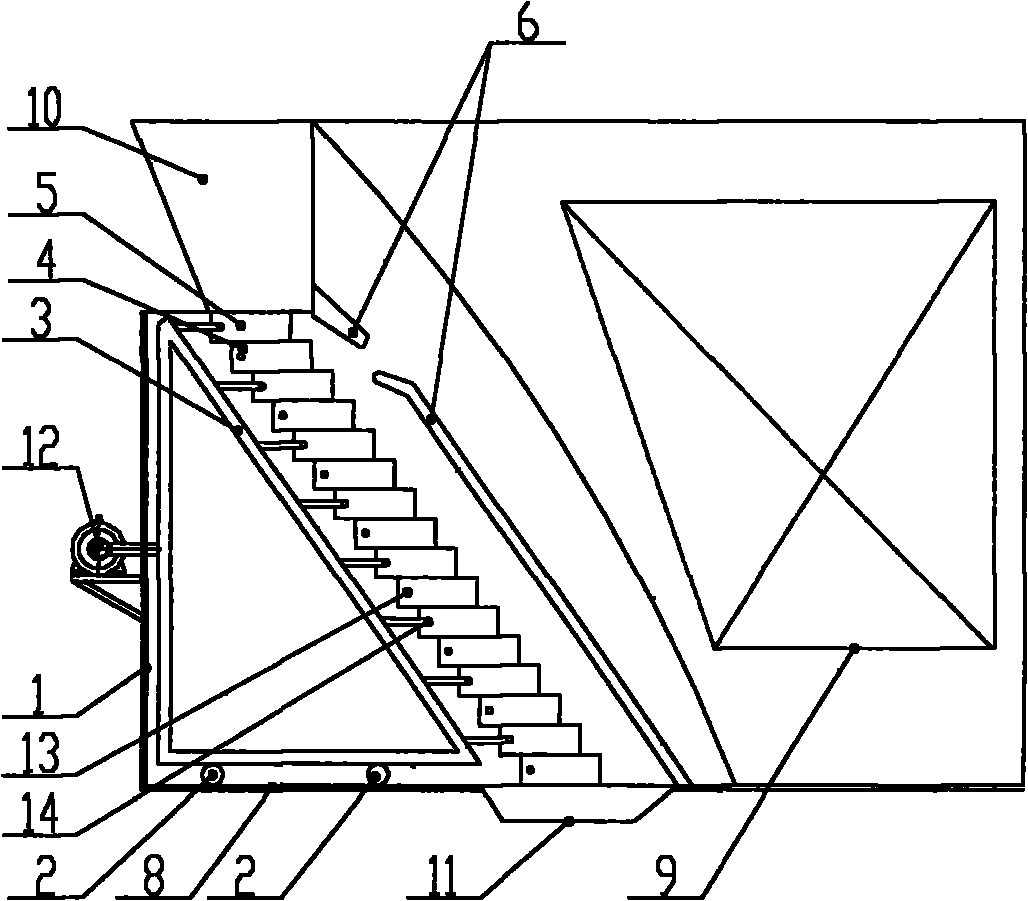

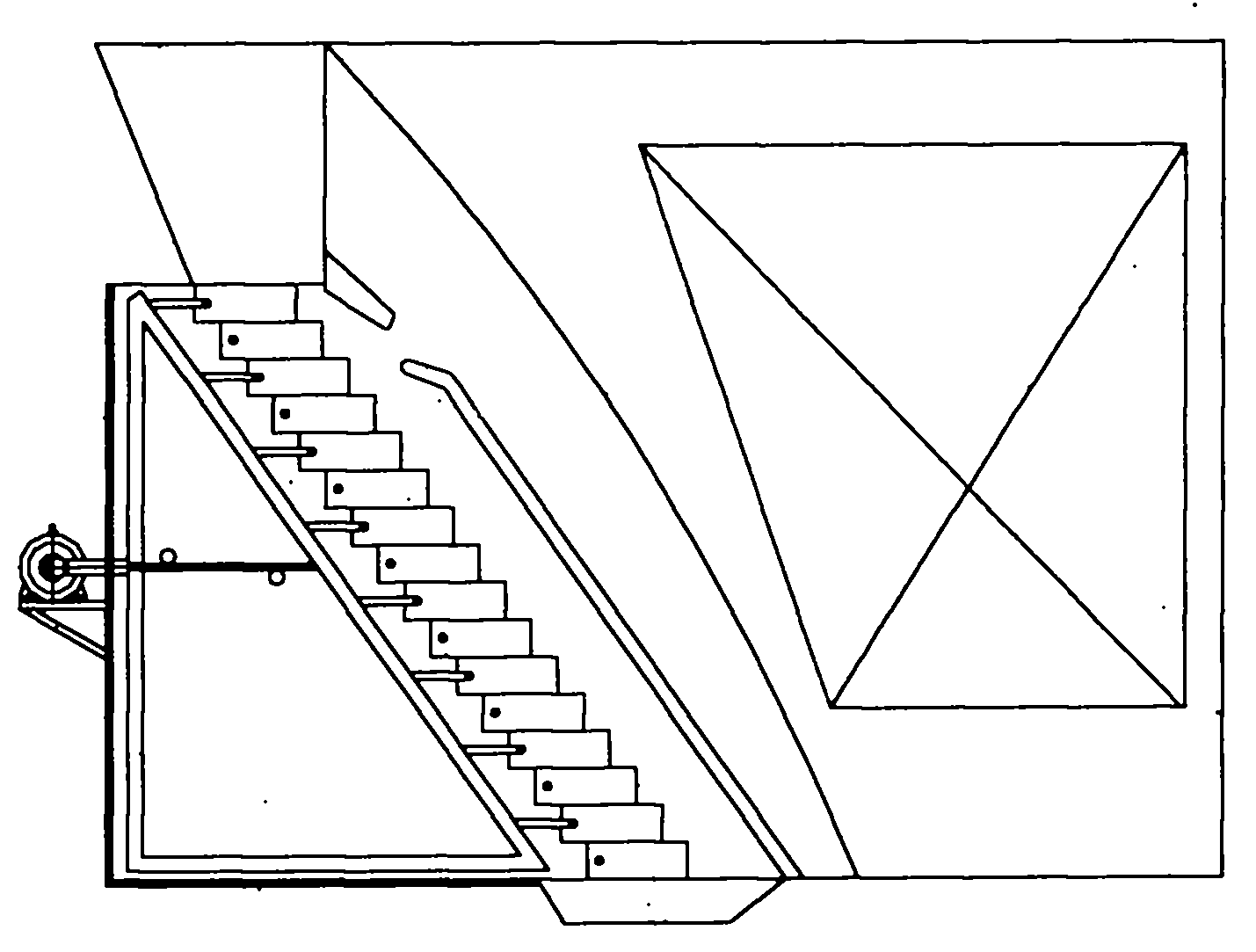

Domestic refuse incinerator

InactiveCN1162646CImprove mashing effectChange the ventilation sectionTravelling grateIncinerator apparatusAir volumeLitter

The domestic refuse incinerator is characterized by that two-stage reciprocating grate, it is suitable for incinerating low-calority high water content and non-sorted domestic refuse, it comprises furnace body with bunker, feeding machine, fire grate, air chamber positioned under the grate and ash-discharge hole, in which said fire grate comprises fixed grate segments fixed on the furnace body and movable grate segments connected on the reciprocating bar. Said fire grate can be divided into two portions of front-stage grate and rear-stage grate, between them there is a position head with a certain height, said fire grate can make refuse automatically be turned, stirred and crushed, and its air intake can be regulated conveniently, and the refuse can be fully incinerated.

Owner:屠柏锐 +2

Novel reciprocating furnace grate

The invention discloses a novel reciprocating furnace grate. A plurality of furnace grate bars which are stacked and crossed are arranged at the upper end of a furnace grate shell in a stepped manner; and a coaling bucket is arranged above the furnace grate at the highest horizontal height. The novel reciprocating furnace grate is characterized in that the furnace grate bar is divided into a movable bar and a fixed bar which are arranged at intervals, wherein the movable bar is hinged on a movable beam; the fixed bar is hinged on a fixed beam; a driving device is arranged in the furnace grate shell; the output end of the driving device is a drive rod which can move transversely in a reciprocation way; the end part of the drive rod is hinged with the movable arm and an inclined connecting rod; the centre of the movable arm is hinged on the furnace grate shell; the top end of the movable arm is also hinged with one movable beam; the hinged point is also hinged with the other inclined connecting rod; the other end of the inclined connecting rod is hinged with the lower part of the adjacent primary movable arm; each pair of movable bar and movable beam corresponds to one group of matched movable arm and inclined connecting rod. The novel reciprocating furnace grate is simple in structure and smart in design, and can effectively guarantee that coal briquettes are fully burned.

Owner:DALIAN HUIYING MACHINERY

Steam boiler capable of burning biomass

InactiveCN101881433AHigh heat resistanceBig spaceTravelling grateAir/fuel supply for combustionCombustionHearth

The invention discloses a steam boiler capable of burning biomass, comprising a boiler body, a loading system and a vapour-water pipe system, wherein the boiler body is provided with a hearth in which the biomass fuel burns so as to release heat and a heat exchange device positioned above the hearth; the loading system is connected with the boiler body so as to convey the biomass fuel to the hearth for burning; the vapour-water pipe system is connected with the heat exchange device so as to exchange heat generated by the burning of the biomass; the hearth is internally provided with a reciprocal grate which downward slopes relatively to the level in an angle of inclination of 5-25 degrees from the end of the hearth close to the loading system to the far end far away from the loading system so as to enable the biomass fuel falling on the fire grate to be pushed and extruded and to roll relatively to the fire grate. In the invention, the fire grate moves relatively to fuel, the fuel is constantly extruded in the process of being pushed so as to damage coke and ash shells; and the fuel rolls slowly, thereby enabling the material layer to be loosened and facilitating full combustion.

Owner:GUANGZHOU DEVOTION THERMAL TECH

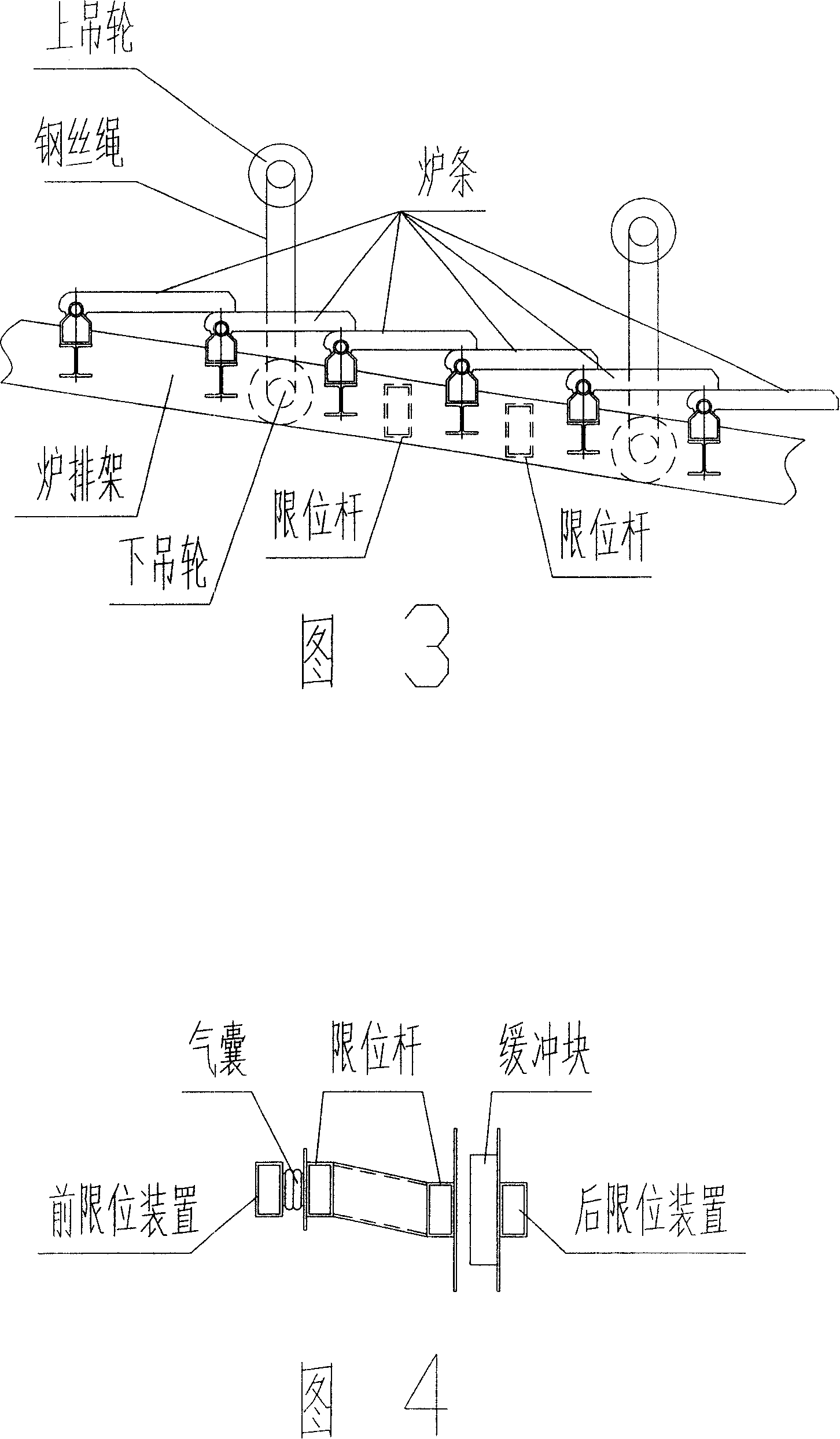

Vibrating high burn-out grate

InactiveCN101149152AReduce gapImprove combustion efficiencyRevolving grateTravelling grateCombustion chamberSlag

This invention is a vibrating high burnout grate. The fire bar is fixed at the grate surface. The grate is suspended on the furnace wall through steel wire and can move a little backwards. The air chamber in vibration device provides driving force for grate to move. The anterior end of grate is material feeding opening. The posterior end is slag-off opening. The superior end is combustion chamber. The inferior end is air chamber. This invention has high combustion efficiency and long life span.

Owner:刘沪滨

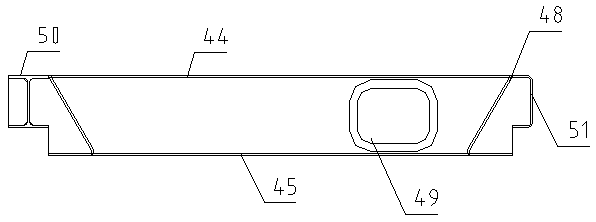

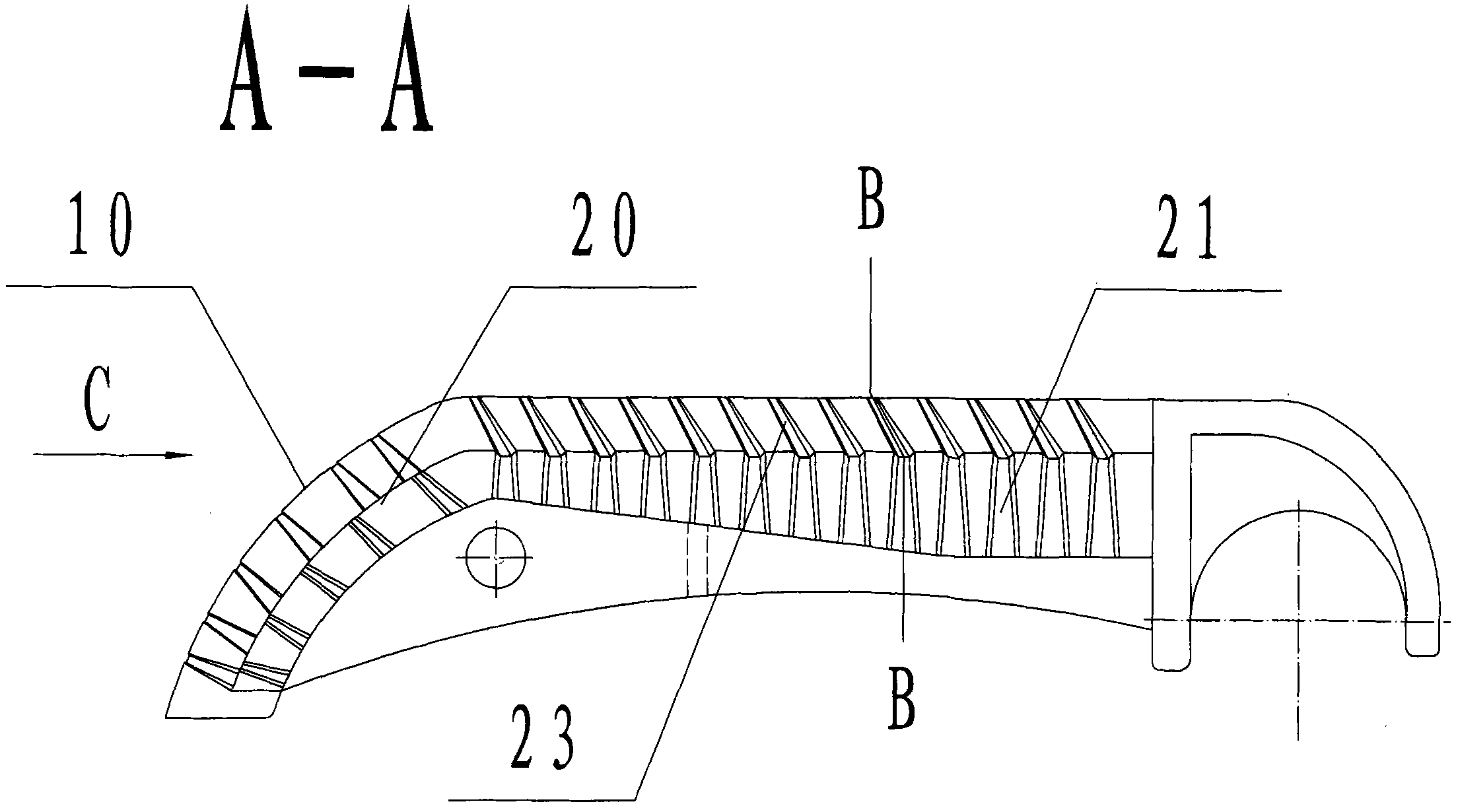

Non-coal leaking front air-outlet reciprocating grate segment for large suspension-type reciprocating grate

InactiveCN101776274AChange air coolingChange cooling conditionsTravelling grateCombustionEngineering

The invention relates to a non-coal leaking front air-outlet reciprocating grate segment for a large suspension-type reciprocating grate, in particular to a non-coal leaking front air-outlet reciprocating grate segment which uses the principle of aerodynamics, is used on a 14-700MW large suspension-type industrial reciprocating grate boiler with an angle of inclination of 12 to 25 degrees, and belongs to the technical field of International Patent Classification F23H coal fired boilers. Orienting to the future, being used for the development of large or very large reciprocating grate boilers and solving the problems of no restriction by the random working condition changes of combustion air supply and the implementation of equal pressure air supply and the combustion air distribution of a grate segment crack air outlet and becoming the focus of large-scale development and research, the non-coal leaking front air-outlet reciprocating grate segment fully adopts the design of a variable cross section ventilation slot structure, a cross section is reduced along the ventilation direction, so that the combustion air flows to the grate crack outlet through the variable cross section ventilation slot and a ventilation dynamic back-pressure chamber, thereby changing the ventilation dynamic airflow of the ventilation dynamic back-pressure chamber and balancing the static pressure. The combustion air dynamic pressure is realized in the narrow strip structure of the grate segment, the combined encryption crack of the grate segment and a secondary control combustion air supply process, and the static pressure is kept balanced; and the combustion air equal pressure balanced air distribution is realized on the grate segment crack outlet, and directly actioned on a combustion coal layer.

Owner:王聪会 +1

Biomass molding fuel combustion boiler

ActiveCN104515128AIncrease temperatureLower combustion temperatureSolid fuel combustionTravelling grateInsulation layerSlag

The invention discloses a biomass molding fuel combustion boiler. The biomass molding fuel combustion boiler comprises a hearth, a water cooling wall layer and a heat insulation layer, wherein the water cooling wall layer covers the outer side of the hearth; the heat insulation layer covers the outer side of the water cooling wall layer; a feeding hole and a chimney are mounted at the top of the hearth; a charging door is mounted on the feeding hole; a crushing device is mounted in the feeding hole; a plurality of rotary shafts are arranged in the crushing device; each rotary shaft is provided with a rotary head; each rotary head is provided with a crushing blade; a mesh screen is mounted at the bottom of the crushing device; a vibration motor is mounted at the bottom of the mesh screen; a through hole is formed in the mesh screen; the hearth is provided with a gasification region and a combustion region; a water cooling wall layer is arranged between the gasification region and the combustion region; the combustion region is internally provided with a plurality of fire pipes; the water cooling wall layer is arranged between the adjacent two fire pipes; a fire grate is mounted under the gasification region and a rotary shaft is mounted on the fire grate. By the aid of the biomass molding fuel combustion boiler, the combustion temperature of fixed carbon is reduced, slag is not easily formed by ash and fireproof materials are arranged at the periphery of the combustion region, so that the temperature of the combustion region can be improved.

Owner:泾县凡泽科技服务有限公司

Grate furnace

A grate furnace with a grate includes grate steps made of grate elements lying next to one another. Every second grate step in the longitudinal direction of the grate can be driven for carrying out stoking movements and the grate steps in each case lying therebetween are stationary. Drive devices for driving the moveable grates are arranged in housing chambers and are in this way protected against impairment caused by material falling through the grate. A certain section of the housing chamber is open toward the bottom so that it is accessible even during operation of the grate furnace.

Owner:MARTIN GMBH FUR UMWELT UND ENERGIETECHNIK

Heating furnace adopting biomass particles

PendingCN109915816AWon't go outGuaranteed burning stateTravelling grateSolid fuel combustionCombustion chamberSlag

The invention discloses a heating furnace adopting biomass particles. The heating furnace comprises a burning chamber, a burning container located inside the burning chamber and a feeding device for conveying materials inside a bin to the burning container; the burning container comprises a burning box; a rotating fire grate and a fixed fire grate are arranged in the burning box; the rotating firegrate is located above the fixed fire grate and is rotationally mounted in the burning box; the fixed fire grate is fixed to the burning box; and a slag discharging opening is reserved between the fixed fire grate and the burning box and is used for discharging coke slag on the fixed fire grate through rotation of the rotating fire grate. During coke cleaning, the rotating fire grate rotates by 180 degrees in the fixed direction, the coke slag on the rotating fire grate and the burning biomass particles are thoroughly overturned onto the fixed fire grate, the biomass particles are burned continuously on the fixed fire grate, the biomass particles falling onto the rotating fire grate newly are ignited, when the rotating fire grate is overturned by 180 degrees again, the coke slag is pushedout of the slag discharging opening, and the flame cannot be extinguished in the coke cleaning process, so that nonstop coke cleaning is realized, and thorough coke cleaning is achieved; and variousbiomass particles can be used by the heating furnace.

Owner:范建书

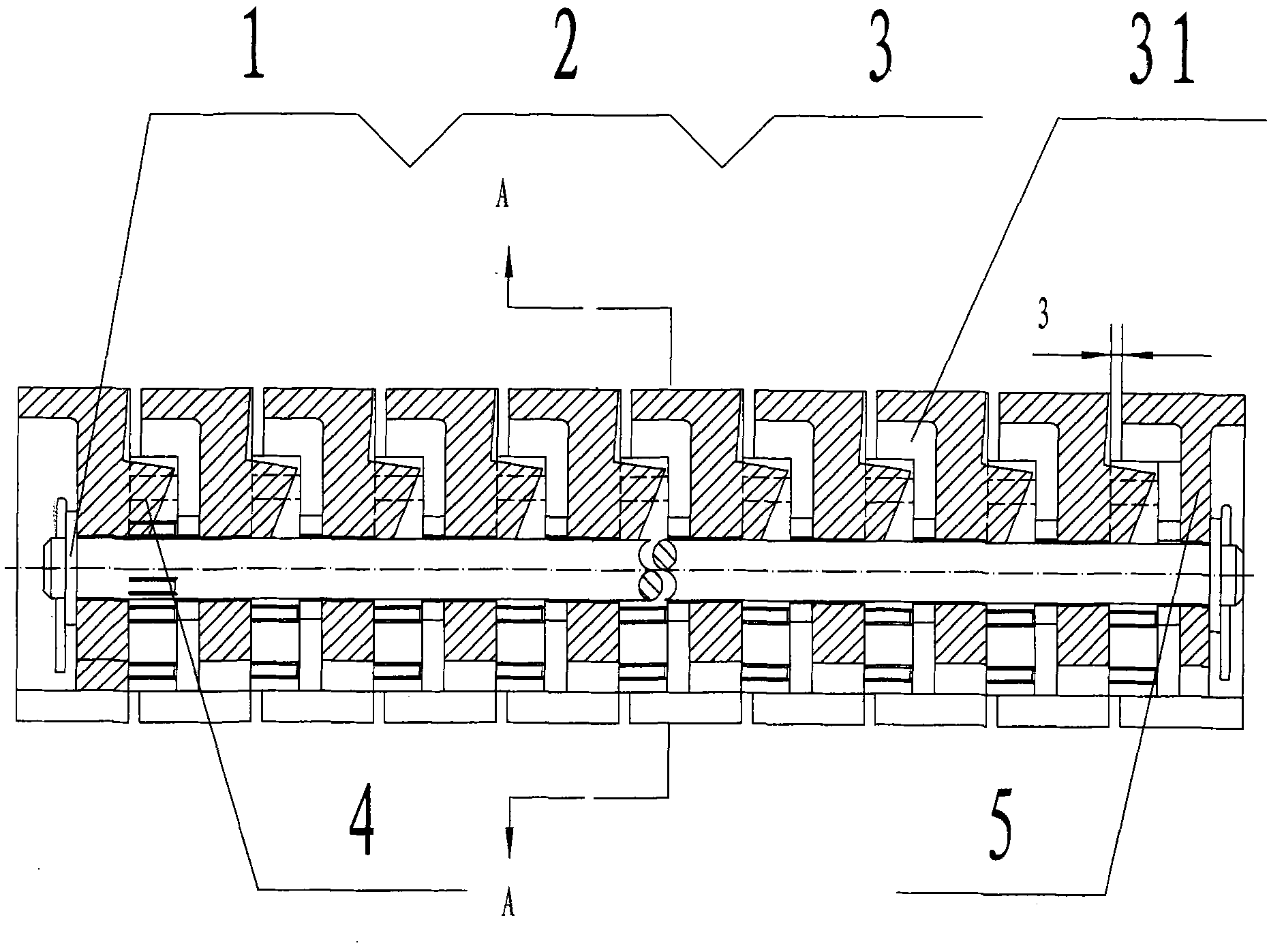

Reciprocating mechanical fire grate with improved combustion stabilization capability under layered combustion down-firing mode

ActiveCN103453535AImprove ignition stabilityImprove combustion stabilityTravelling grateCombustionReciprocating motion

The invention belongs to the field of raw coal combustion equipment and provides a reciprocating mechanical fire grate with improved combustion stabilization capability under a layered combustion down-firing mode. The reciprocating mechanical fire grate comprises an upper fixed fire grate segment (3), an upper movable fire grate segment (4), a lower movable fire grate segment (5) and a lower fixed fire grate segment (6) which are arranged in a step shape from top to bottom, wherein the upper movable fire grate segment (4) and the lower movable fire grate segment (5) reciprocate by virtue of a driving device; the reciprocating speed and stroke of the upper movable fire grate segment (4) are less than those of the lower movable fire grate segment (5); the end part of one side, facing toward the fuel moving direction, of the upper movable fire grate segment (4) is not overlapped with the end part of one side, facing toward the fuel moving direction, of the lower movable fire grate segment (5). According to the reciprocating mechanical fire grate, a mode that the movement of reciprocating fire grates and movable fire grate segments is progressively increased is adopted, so that stable combustion of combusted coal at the initial stage of firing is ensured, flameout does not occurs, and heat load of combustion is ensured.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Coal burning hot air furnace with horizontal-reciprocating grate

InactiveCN101498503AImprove combustion conditionsHigh thermal efficiencyAir heatersTravelling grateCold airFlue gas

The invention relates to a horizontal reciprocating push grate (6) which comprises a heat-insulating long furnace chamber (1), at least one fuel inlet (2) and a waste residue outlet and is connected with the fuel inlet (2) to support fuel and form a combustion process. The upper space of the horizontal reciprocating push grate is provided with a heat exchanger (3) with a plurality of layers of annular metal barrel bodies forming clapboards. The heat exchanger is supported by the upper end face of the furnace chamber, the barrel-shaped clapboard at the innermost layer of the exchanger forms the lower part of a cavity, a group of upwardly raising furnace arches (16) are arranged between the cavity and a hearth cavity which is arranged in the furnace chamber and includes the upper part of the horizontal reciprocating push grate, the furnace arches (16) extend along the long direction of the furnace chamber, the furnace arches (16) are provided with holes to communicate the upper cavity with the lower hearth cavity, the metal barrel body clapboards of the heat exchanger form flue gas passages and hot air passages, which are separated from each other, high-temperature flue gas generated in the hearth heats the clapboards while being discharged outsides through the flue gas passages, and required hot air can be obtained by exchanging the heat by the heated clapboards and the cold air fed by a ventilator. The invention is widely applicable, can fully burn low-quality soft coal and has good effect in smoke and dust elimination.

Owner:四川省南充蚕具研究有限公司

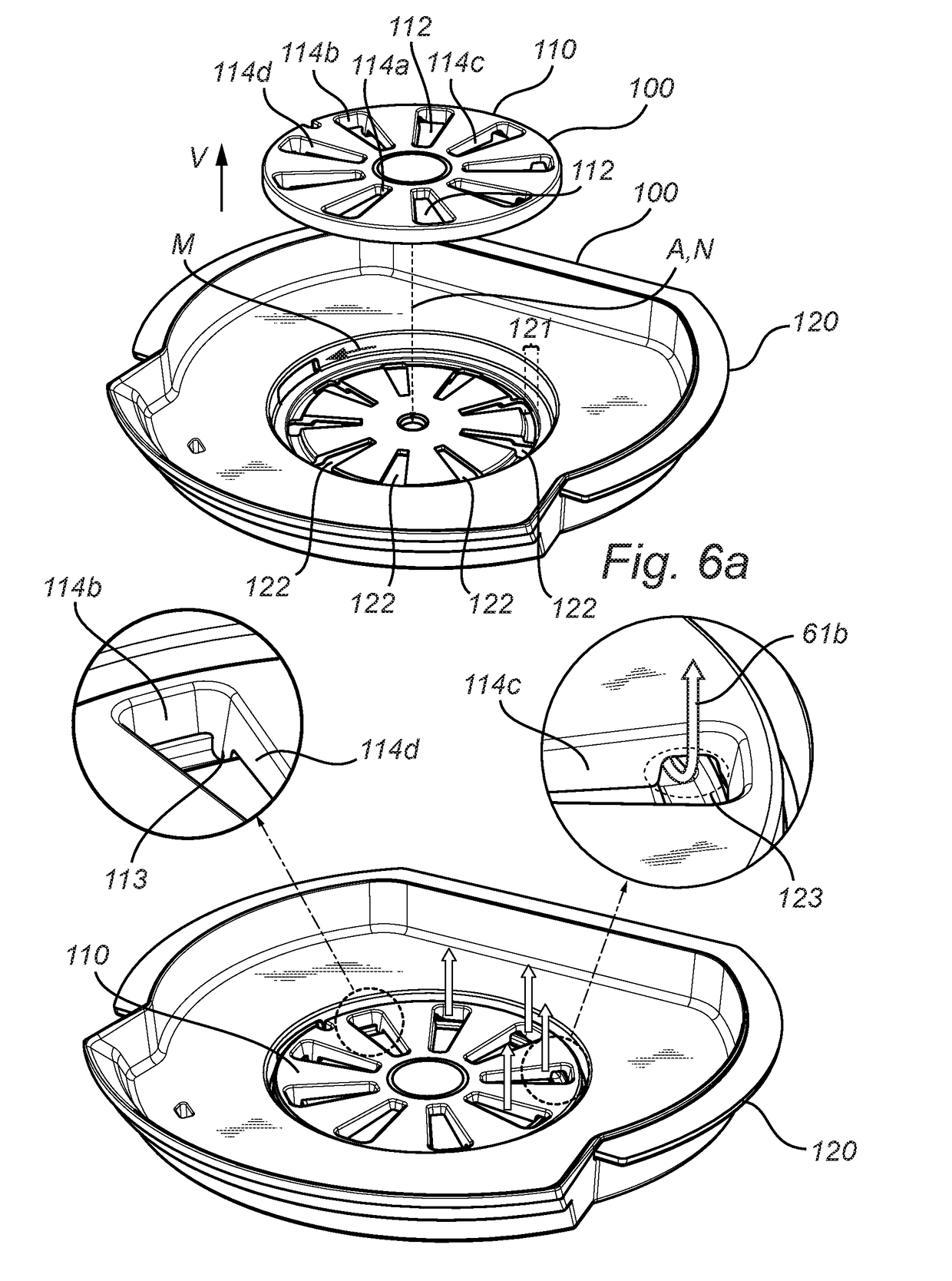

Stove

ActiveUS20170363325A1Simple to provideCompact solutionMechanical apparatusAir supply regulationCombustion chamberMajor and minor

A stove for indoor use includes a housing having a bottom wall, a top wall and one or more side walls defining a combustion chamber adapted to retain a fire, and an air supply system for supplying air to the combustion chamber. The air supply system includes a primary air conduit for supplying air to the combustion chamber from below through the bottom wall and a secondary air conduit for supplying air to the combustion chamber from above. A valve is arranged in the primary air conduit or in a branching between the primary and secondary air conduits. The valve is controlled by a bimetal whereby the valve is in a maximum open position when the prevailing temperature is below a first predetermined temperature during start-up of a fire and in a maximum closed position when the prevailing temperature is above a second predetermined temperature after start-up of the fire.

Owner:NIBE

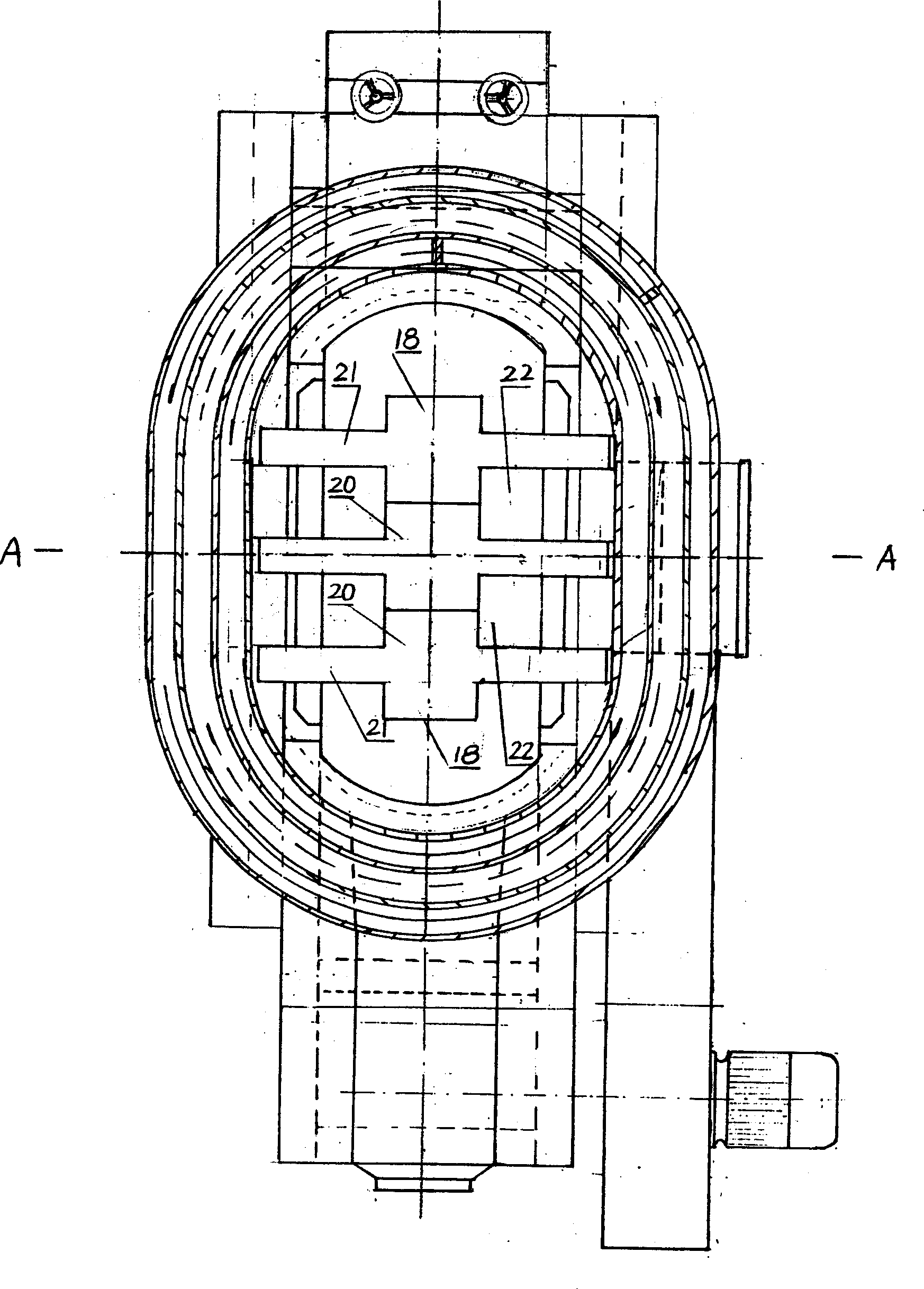

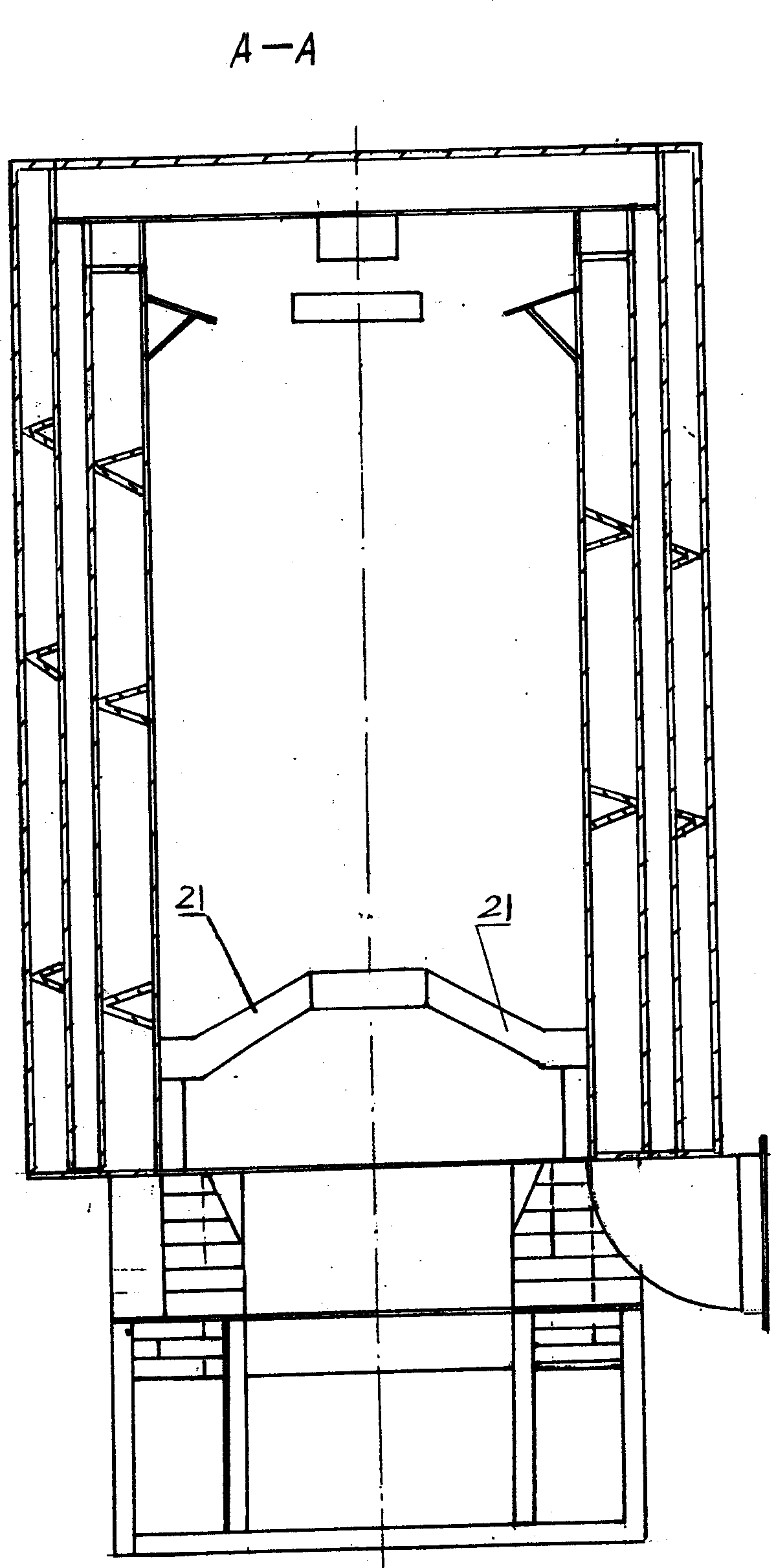

Multi-frame reciprocating grate

InactiveCN102506436AAlleviate the phenomenon of uneven forceStable operating conditionsTravelling grateMultiple frameDrive shaft

The invention provides a multi-frame reciprocating grate, relating to a reciprocating grate and aiming at the problem that the abnormal operation of a large-capacity boiler is affected when connection between a grate frame and a grate beam of a reciprocating grate used in the large-capacity boiler at present. According to the invention, an output end of a motor is in transmission connection with an input end of a speed reducer, an output end of the speed reducer is in transmission connection with a transmission shaft, each eccentric wheel is in transmission connection with one end of a push-pull rod, the other end of the push-pull rod is in transmission connection with a corresponding movable grate frame, the movable grate frame is arranged in a fixed grate frame, a fixed grate beam and a movable grate beam are spaced from each other, the movable grate frame is in rolling connection with the fixed grate frame through a plurality of movable grate frame rollers, the fixed grate frame is provided with a plurality of cross beams, a bracket is arranged at the lower part of each cross beam and each movable grate beam roller is arranged in the corresponding bracket and is in rolling connection with the corresponding bracket. The multi-frame reciprocating grate is applicable to a large reciprocating grate boiler.

Owner:HARBIN INST OF TECH

Multiple-hearth furnace

The inventive multi-level furnace comprises a furnace wall delimiting a cylindrical space having a vertical axis, a plurality of beds defining the levels inside said cylindrical space and at least one scraping arm which is provided with a wall scraper and associated with the bed in such a way that it is rotatable about the vertical axis of the furnace. During scraping arm rotation, said wall scraper defines a scraped area on the internal surface of the furnace wall which comprises a plurality of wall cavities forming a row of access openings in the scraped area, thereby making it possible to avoid the formation of a hardened crust adhered to the internal surface of the furnace wall and to develop braking shocks in the scraping arm.

Owner:PAUL WURTH SA

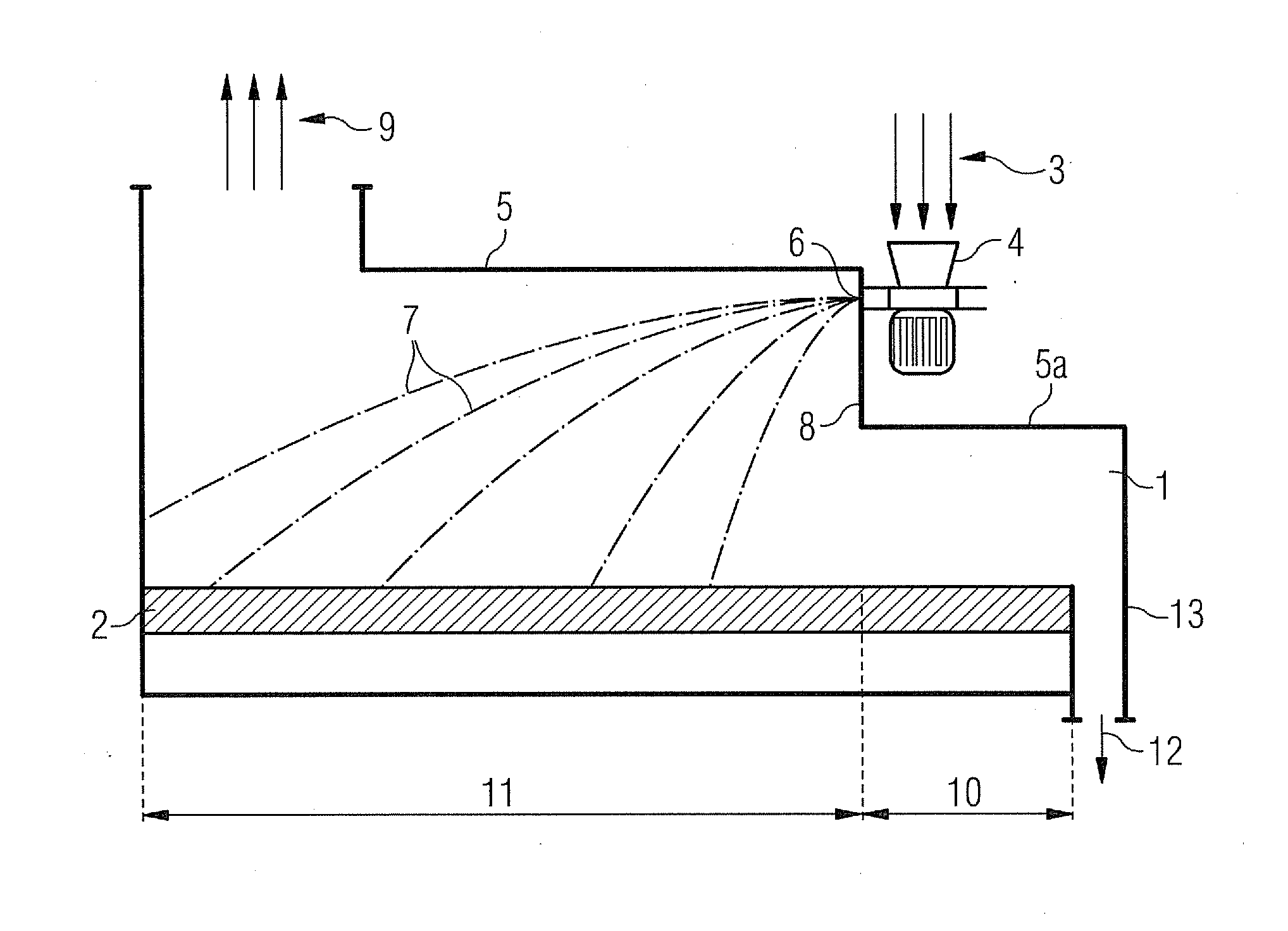

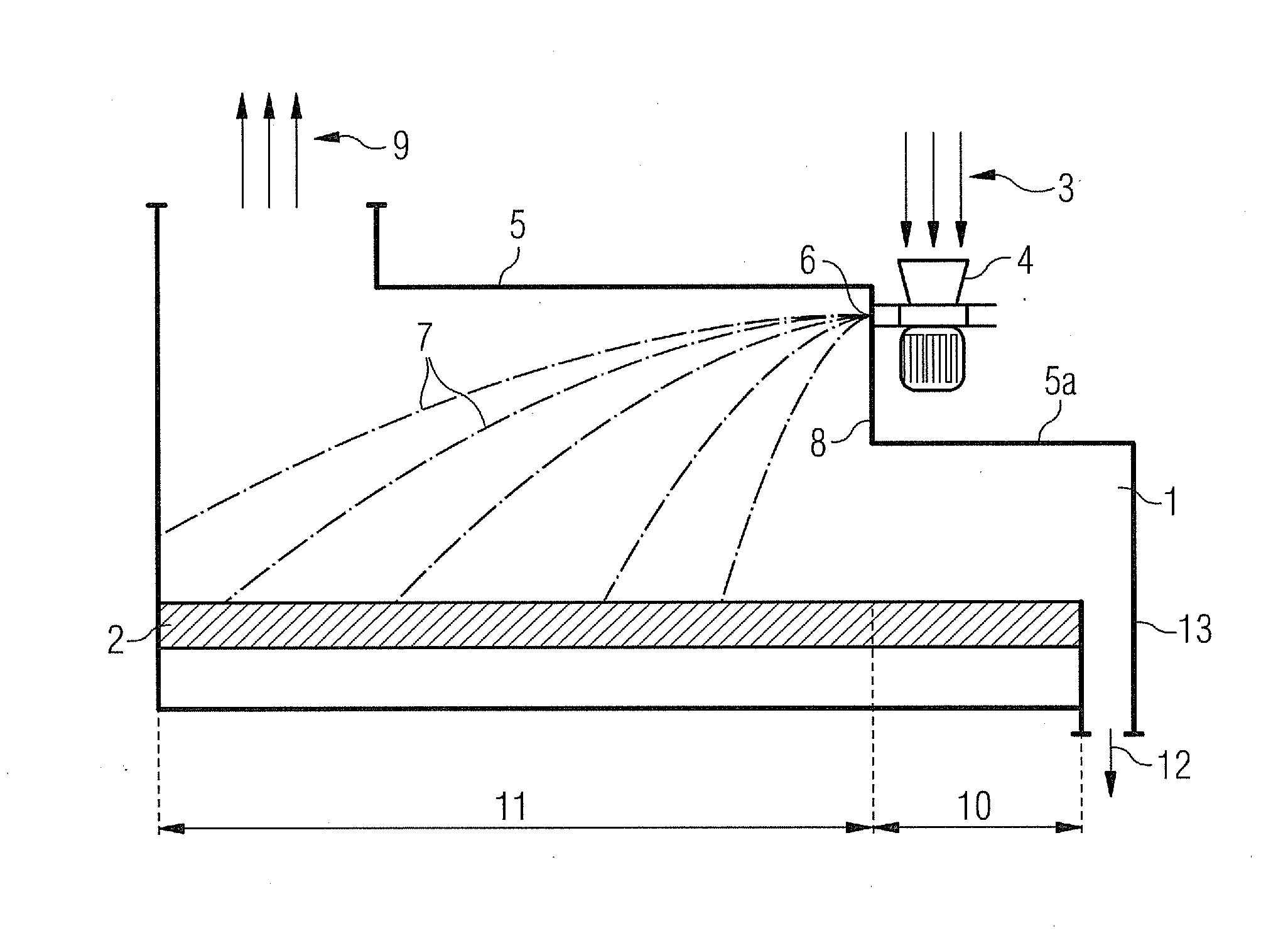

Method for mechanical stoking in firing installations and firing installation

InactiveUS20100323310A1Reduction in residual carbon content of ashComplete combustionFuel supply regulationInclined grateCombustion chamberEngineering

A method for mechanical stoking in firing installations and a firing installation is provided. Fuel is applied to a grate using a mechanical stoker, the grate being disposed in a firing chamber, wherein the mechanical stoker is oriented opposite a delivery direction of the grate. The fuel is introduced directly below a firing chamber ceiling, viewed in the delivery direction of the grate before the end of the grate such that a burnout zone, which does not have fresh fuel applied thereto, is created on the grate between the mechanical stoker and the end of the grate.

Owner:SIEMENS AG OESTERR

Grate block for a refuse incineration grate

InactiveUS6964237B2Minimizes cutting through trashEasy to moveSolid bar grateHollow bar grateLitterEngineering

Owner:HEPP MARK P

Popular searches

Electric spark igniters Combustion using gaseous and pulverulent fuel Combustion using liquid and pulverulent fuel Fuel injection apparatus Rocking grate Combustion using lump and gaseous fuel Combustion using lump and liquid fuel Combustion using liquid and gaseous fuel Combustion using lump and pulverulent fuel Ignition sparking plugs

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com