Reciprocating mechanical fire grate with improved combustion stabilization capability under layered combustion down-firing mode

A reciprocating motion and mechanical grate technology, applied in the direction of combustion method, combustion equipment, mobile grate, etc., can solve the problems of reducing the effect of decoupling combustion, increasing the amount of smoke leakage from coal scuttle and furnace door, and delaying ignition. Achieve the effects of improving decoupling combustion performance, improving stable combustion ability, and reducing design height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

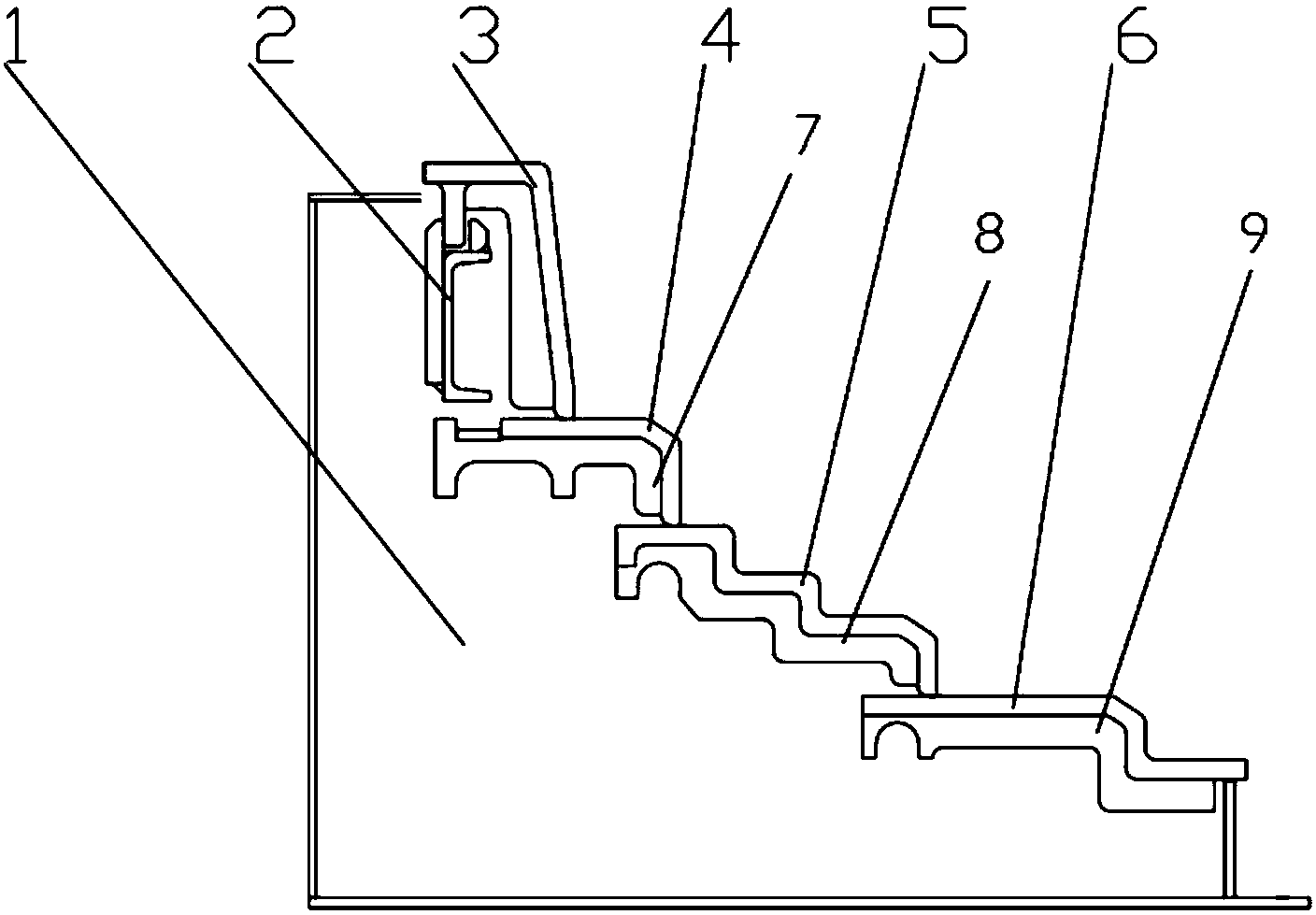

[0027] Such as figure 1 As shown, the reciprocating mechanical fire grate of the present invention that improves the ignition stability under layered combustion, and the reciprocating mechanical fire grate that improves the ignition stability of the layered combustion of the present invention include: from top to bottom The upper fixed grate piece 3, the upper movable grate piece 4, the lower movable grate piece 5 and the lower fixed grate piece 6 are arranged in the same shape, and the upper movable grate piece 4 and the lower movable grate piece 5 reciprocate through the driving device; wherein, the upper movable The speed, stroke, and width of the working face in the moving direction of the fire grate 4 are smaller than the movable fire grate 5 at the bottom. The upper fixed grate 3, the upper movable grate 4, the lower movable gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com