A low-nitrogen swirl pulverized coal burner with fuel-saving/gas ignition and stable combustion

A pulverized coal burner and burner technology, which are applied to burners, burners, combustion methods and other directions for burning powder fuel, can solve the problem of low nitrogen and stable combustion performance of the entire row of swirl burners, and do not have low nitrogen combustion. The performance and structure of the equipment and the poor adaptability of coal types have achieved the effect of strong adaptability to coal types, wide practicability and strong adaptability to coal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

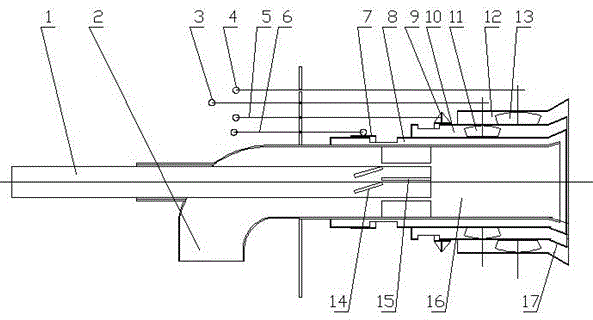

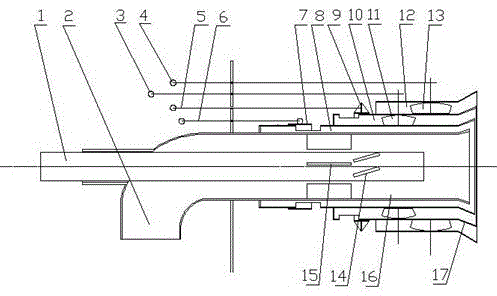

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0013] The fuel-saving / gas ignition and stable combustion low-nitrogen swirl pulverized coal burner of the present invention is mainly composed of an oil / gas burner 1, a primary air channel 2, a damper, an adjustment rod, a secondary air inlet pipe 8, and a secondary air flow in the swirl flow. The air inlet pipe 10, the secondary air inlet pipe 12 outside the swirl flow and the swirl flow blades are formed. The oil / gas burner 1 extends into the primary air channel 2, and the outer wall of the horizontal pipe section of the primary air channel 2 is provided with a guide sleeve that allows the oil / gas burner 1 to enter the primary air channel 2 and move back and forth. The axis line of the gas burner 1 coincides with the axis line of the horizontal pipe section of the primary air channel 2 . The outlet ends of the primary air channel 2, the secondary air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com