Patents

Literature

482 results about "High pressure oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gaseous oxygen system whose cylinders have oxygen at a pressure between 1000 and 2000 psi. In liquid oxygen systems, a high-pressure oxygen system is one with a pressure of 300 psi or higher.

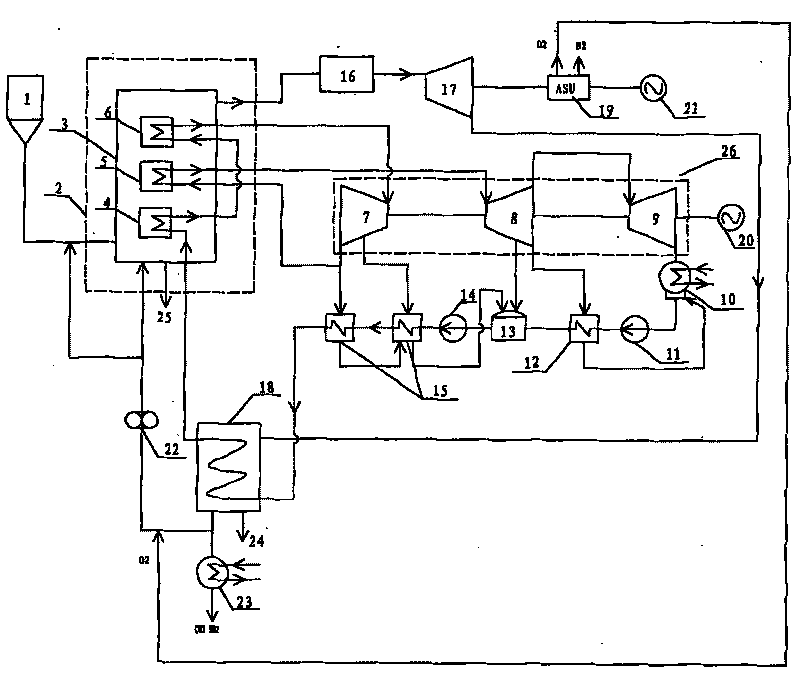

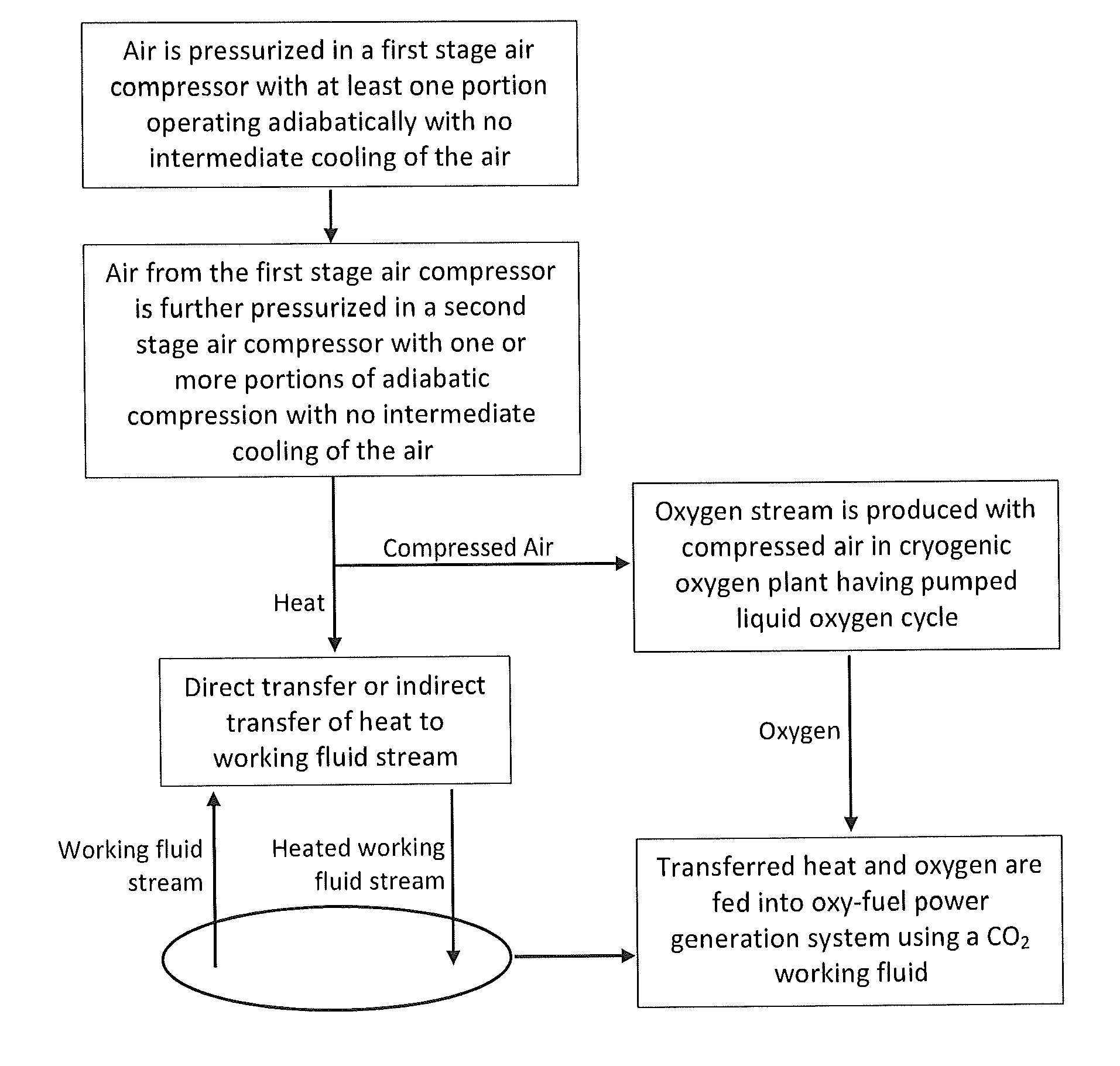

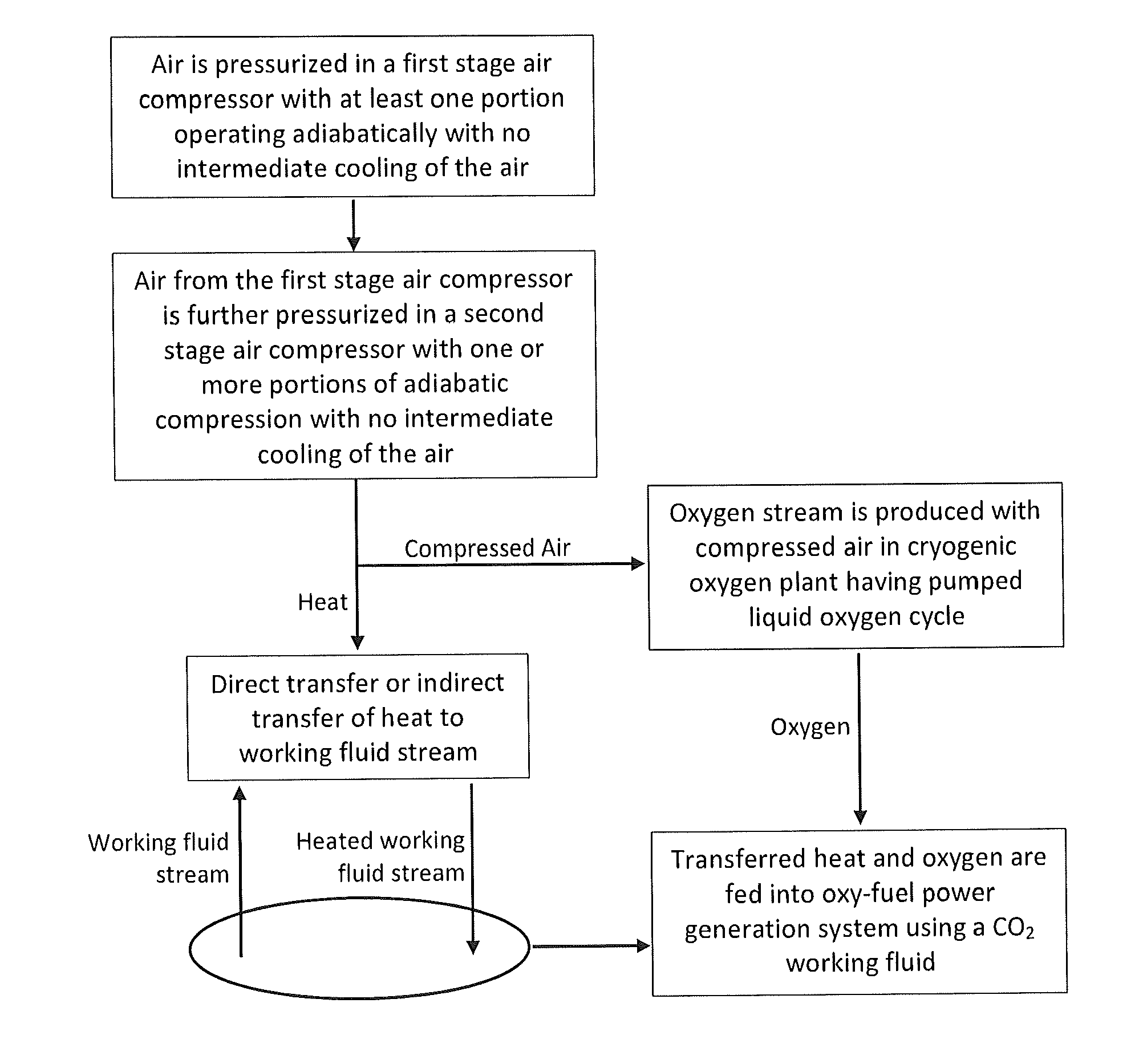

Cryogenic air separation method and system

ActiveUS20120237881A1Increase pressureEfficient productionSolidificationLiquefactionAir compressionWorking fluid

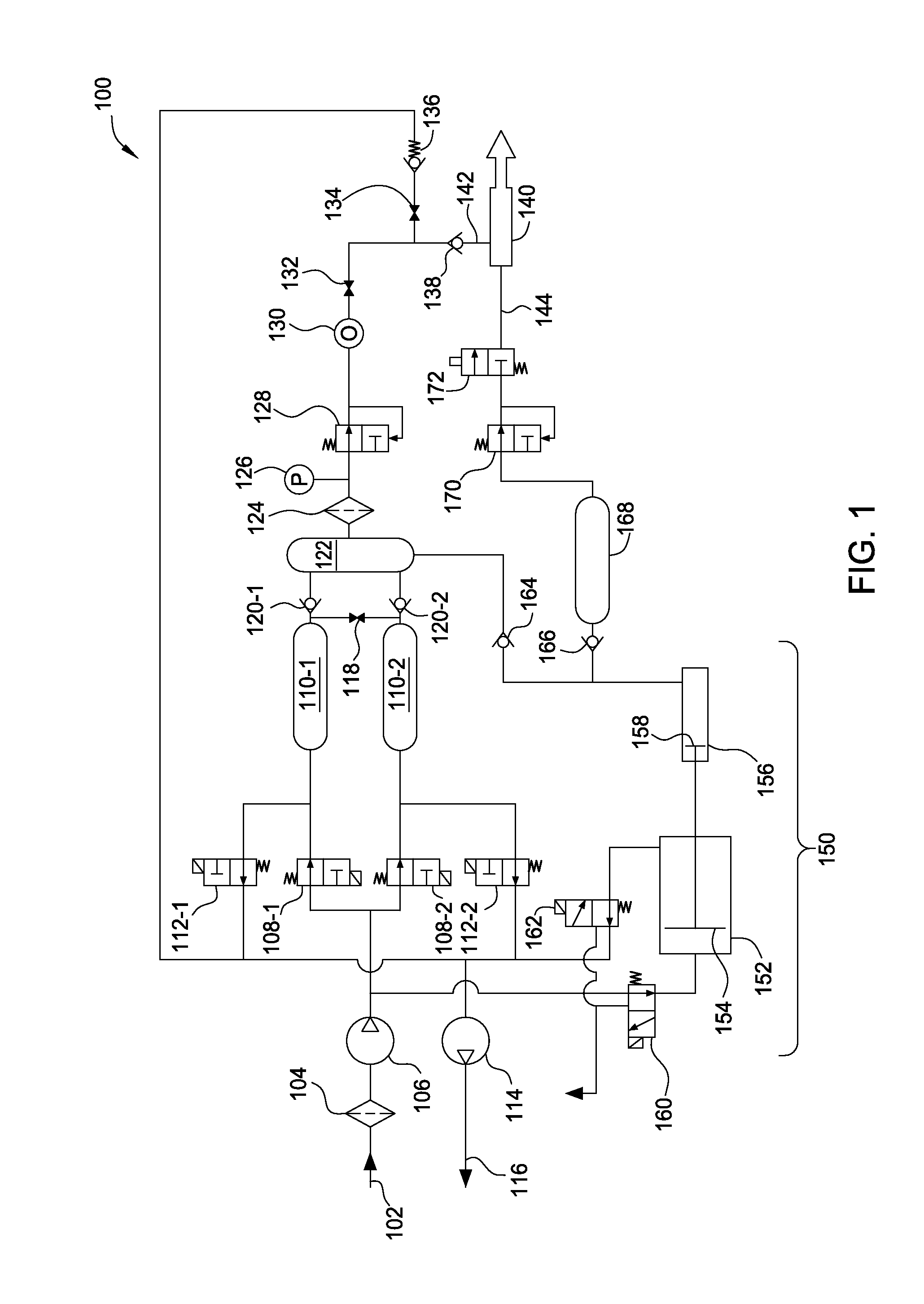

The present invention relates to a cryogenic air separation process that provides high pressure oxygen for an oxy-fired combustion of a fuel (e.g., a carbonaceous fuel). The air separation process can be directly integrated into a closed cycle power production process utilizing a working fluid, such as CO2. Beneficially, the air separation process can eliminate the need for inter-cooling between air compression stages and rather provide for recycling the adiabatic heat of compression into a process step in a further methods wherein an additional heat supply is beneficial.

Owner:8 RIVERS CAPTTAL LLC

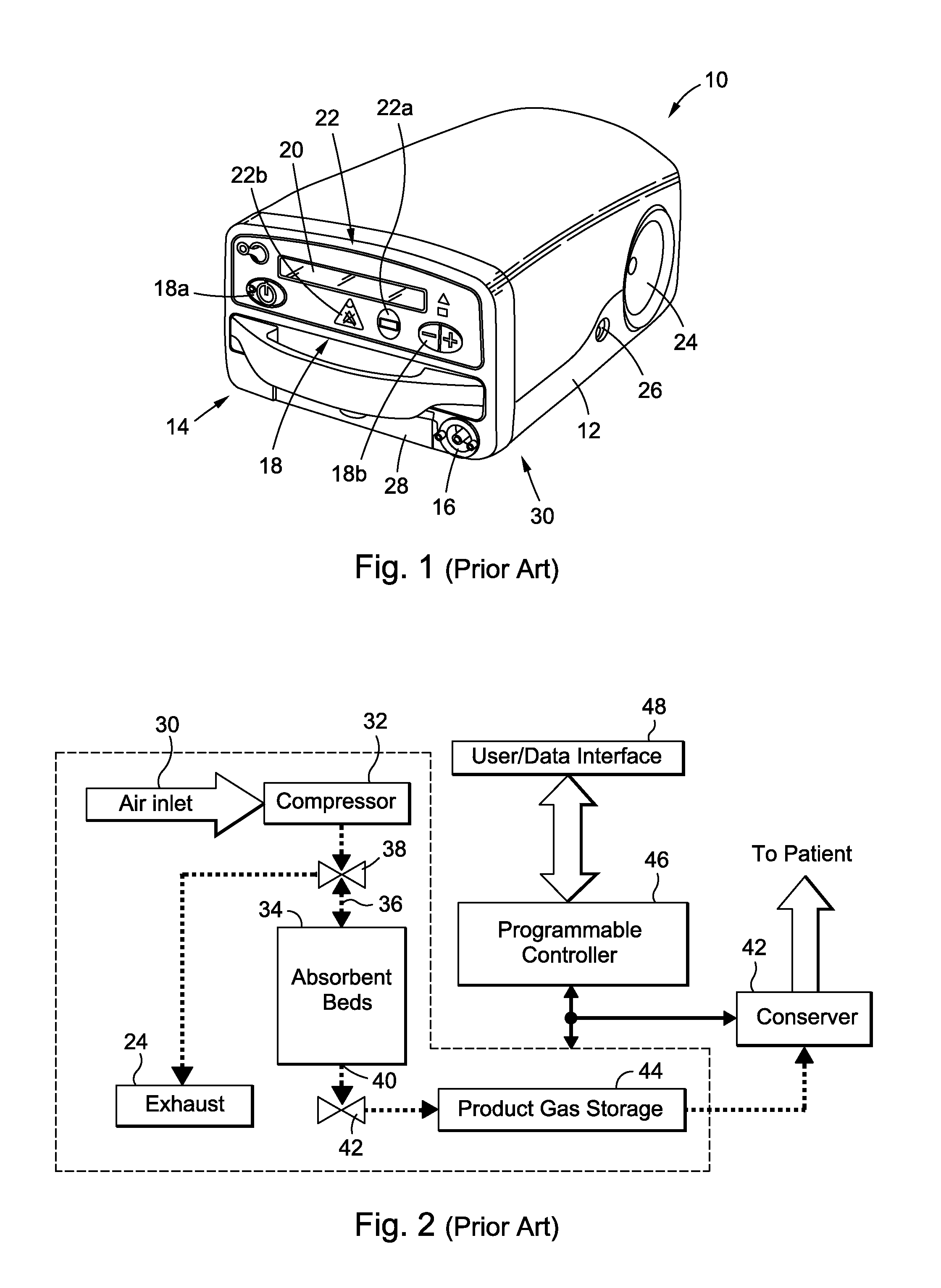

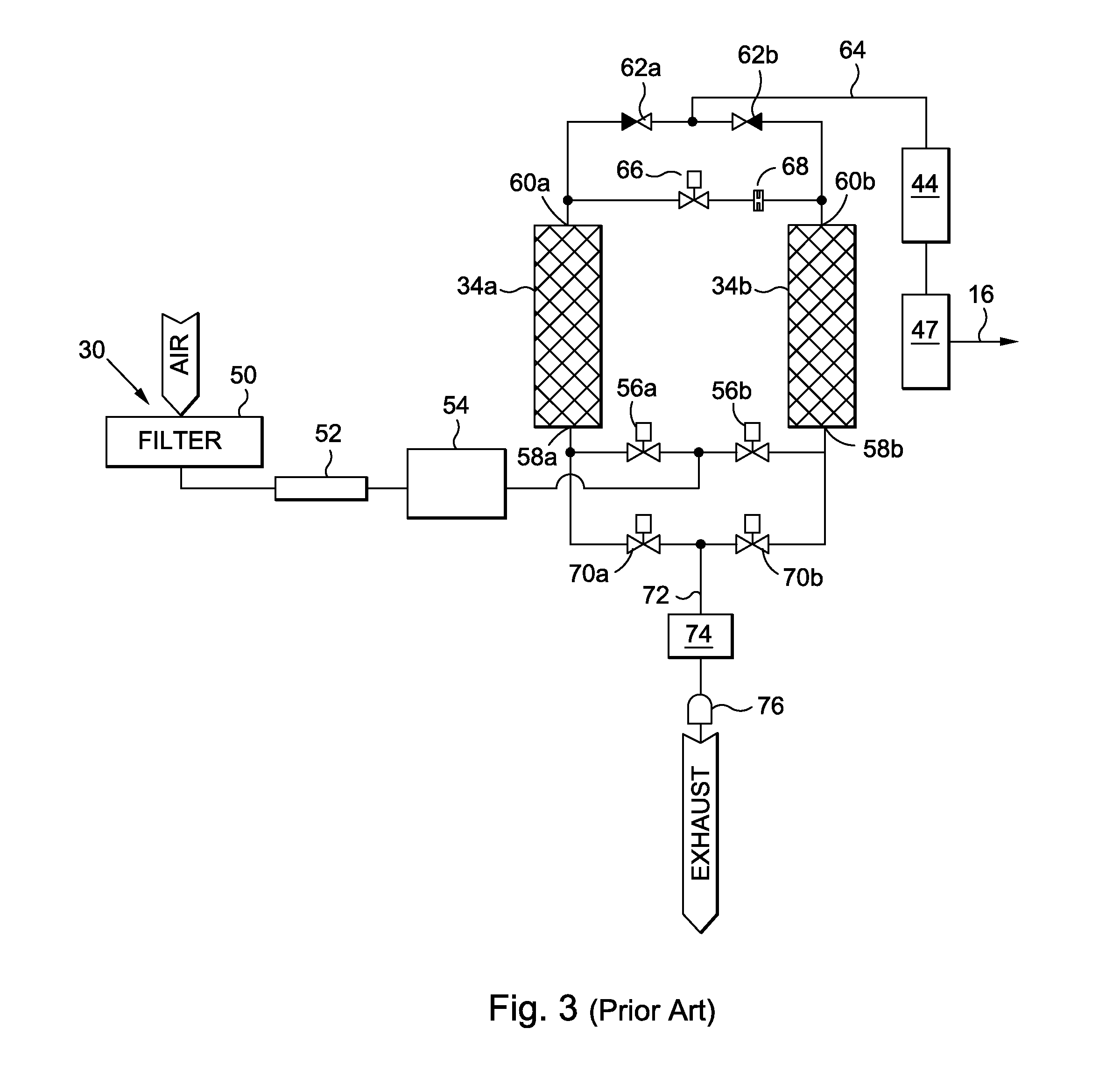

Oxygen generator with storage and conservation modes

ActiveUS20060062707A1Reduce decreaseIncrease productionCombination devicesAuxillary pretreatmentElectronic controllerEngineering

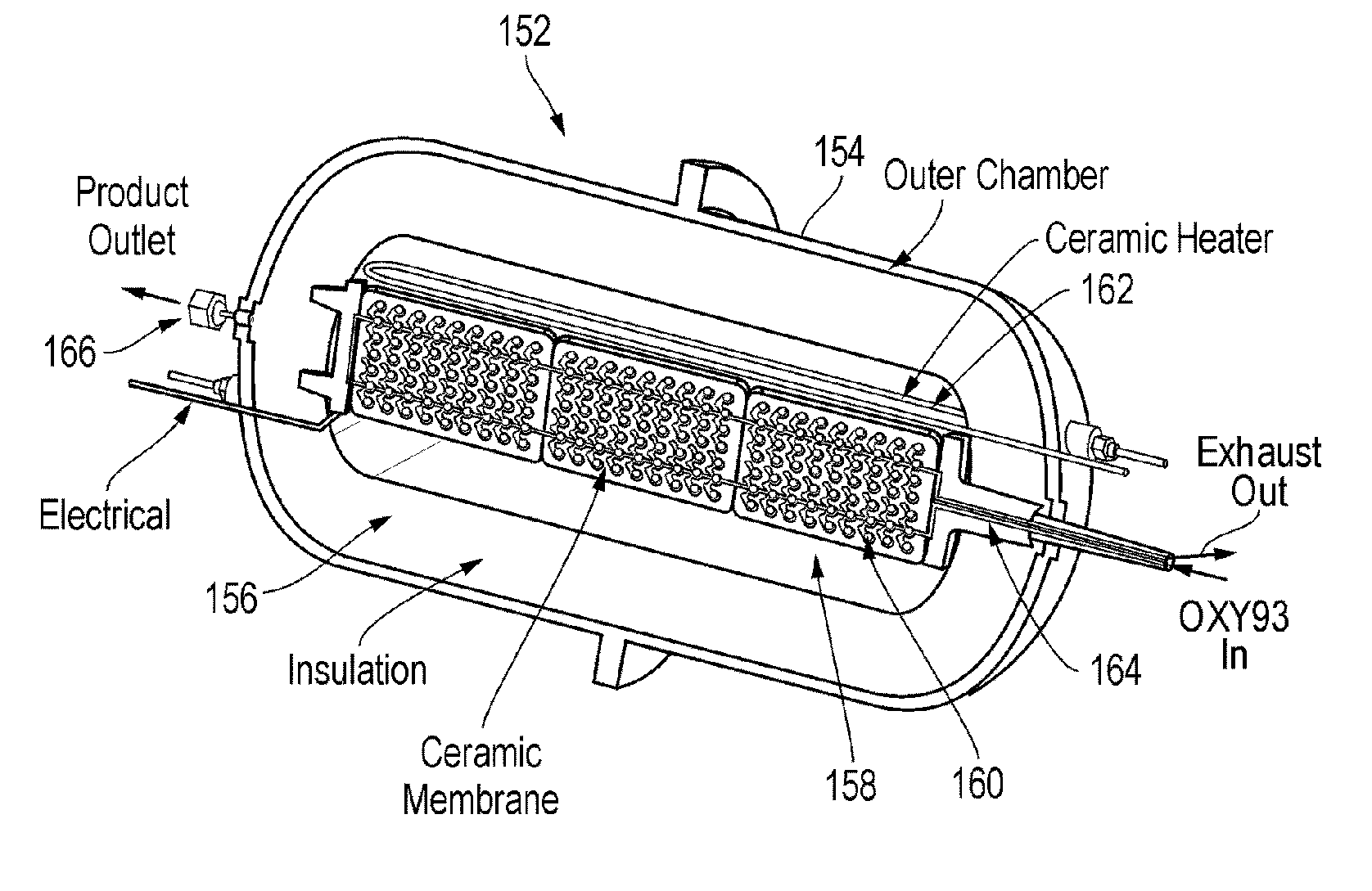

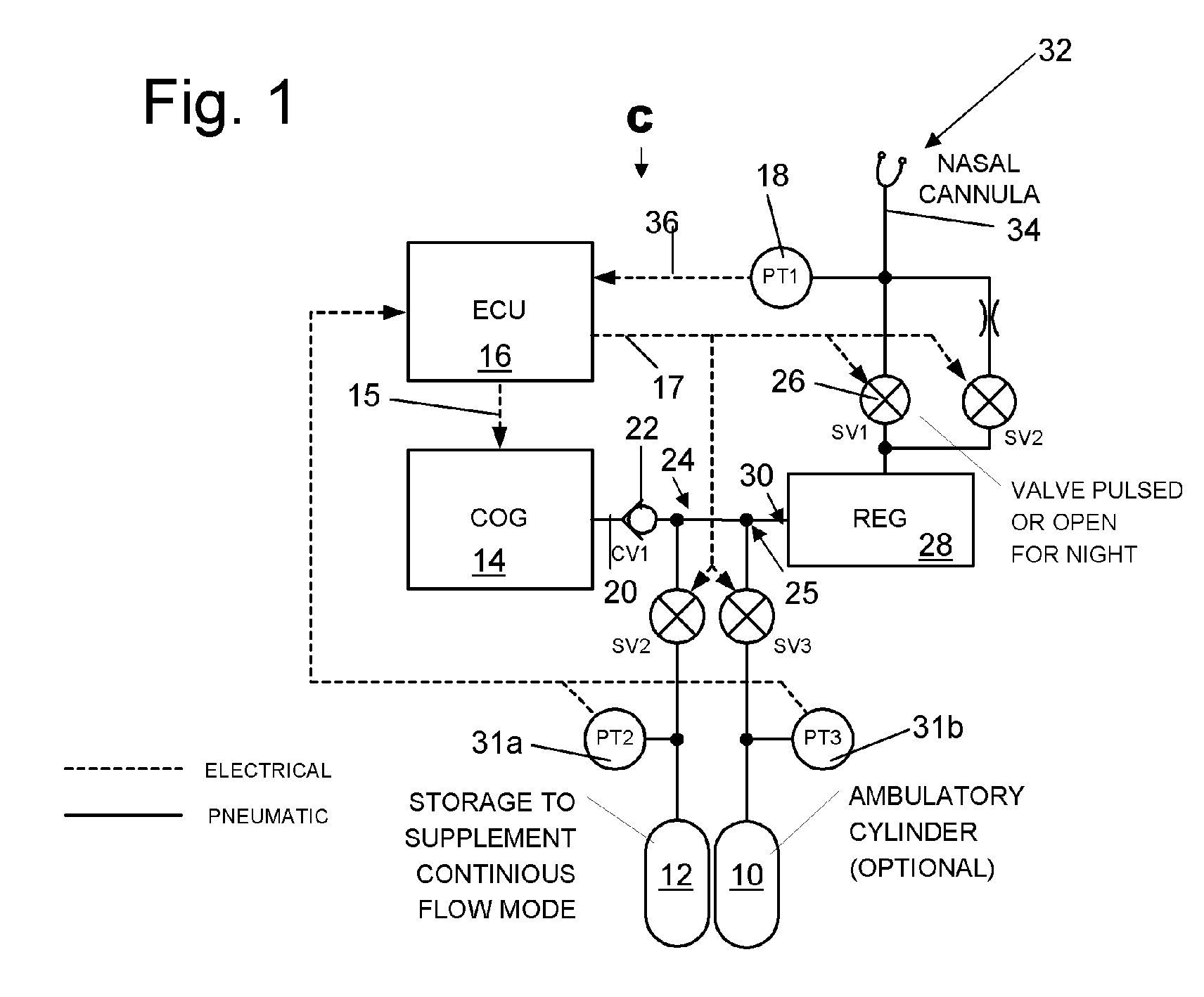

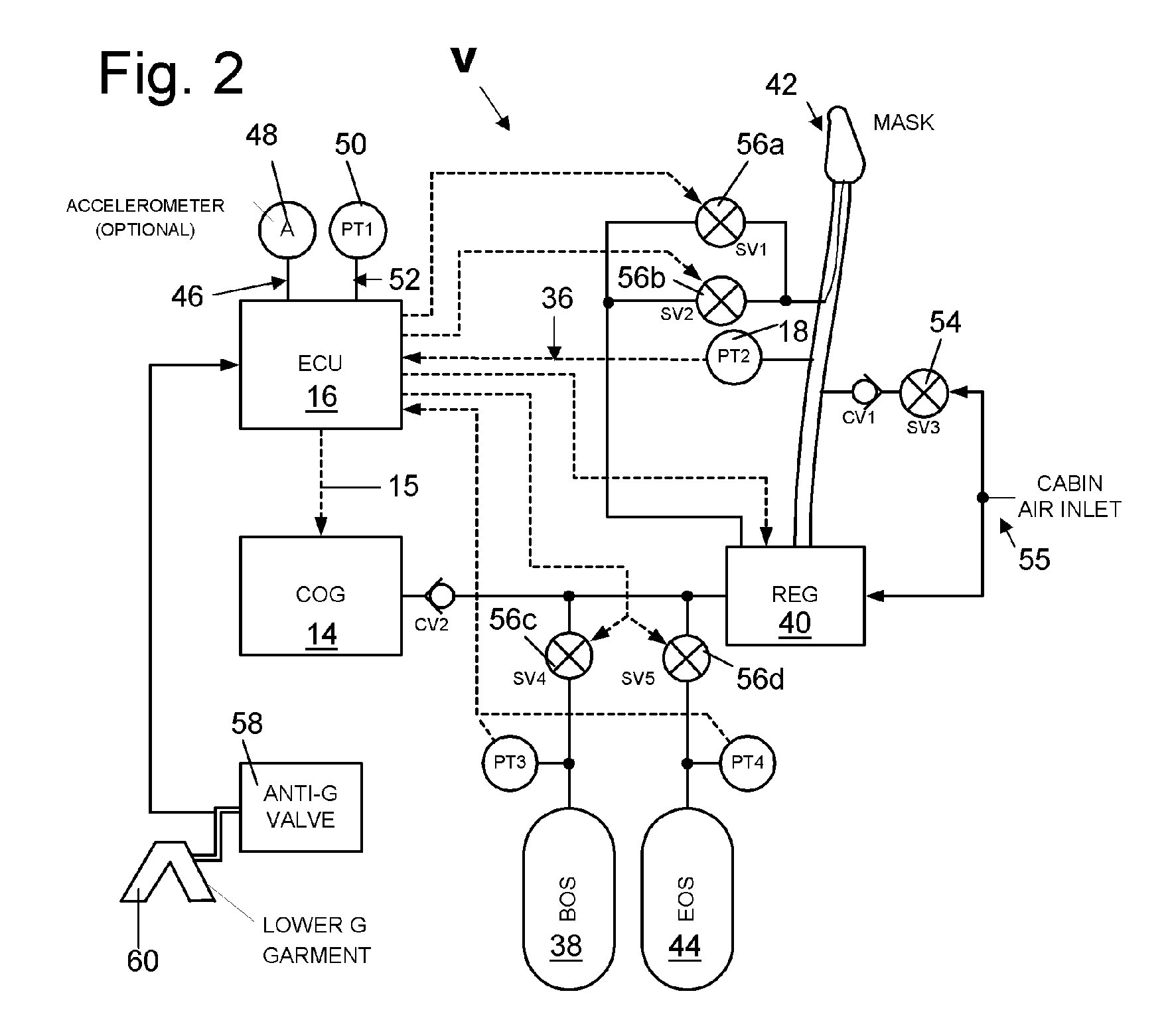

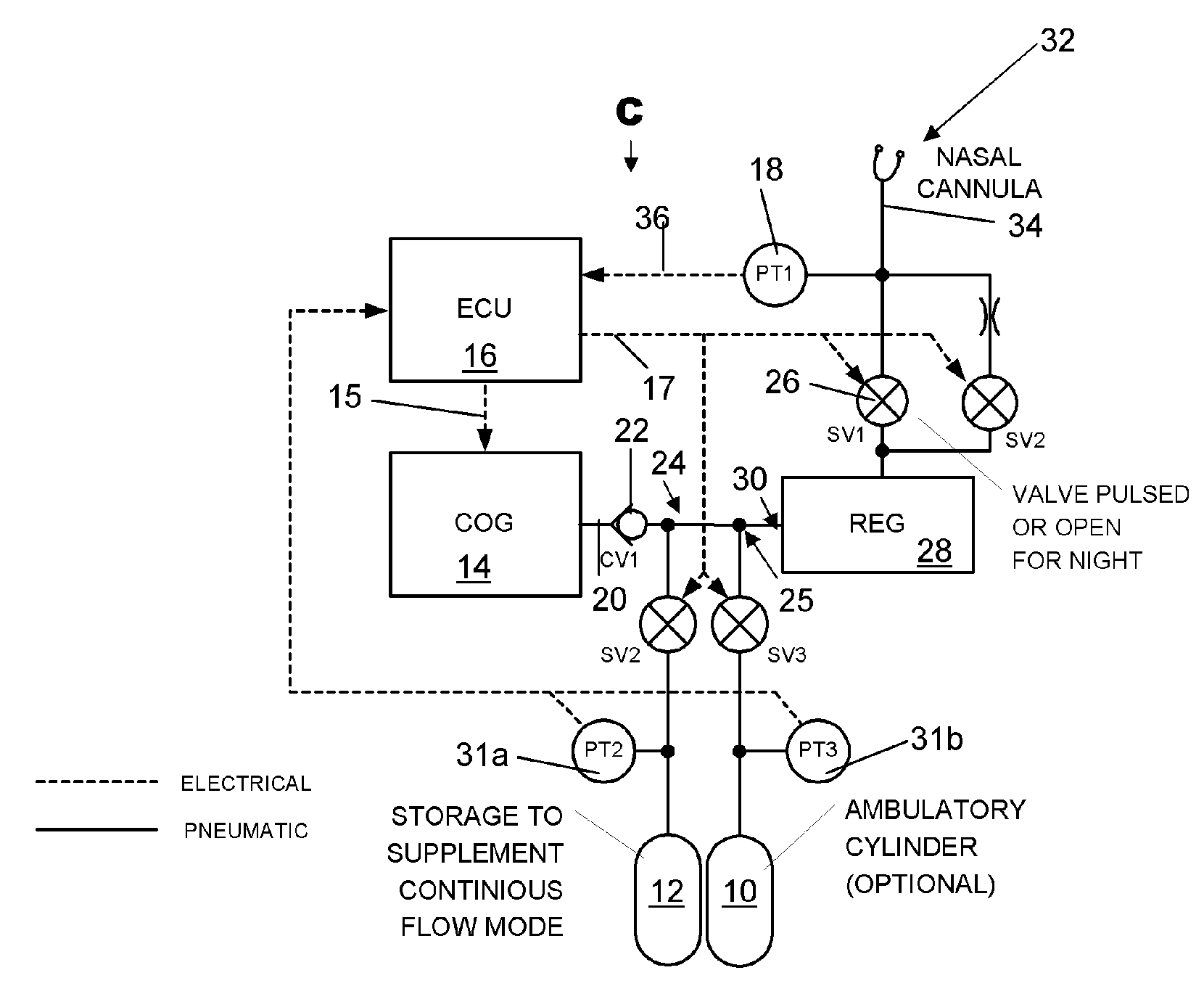

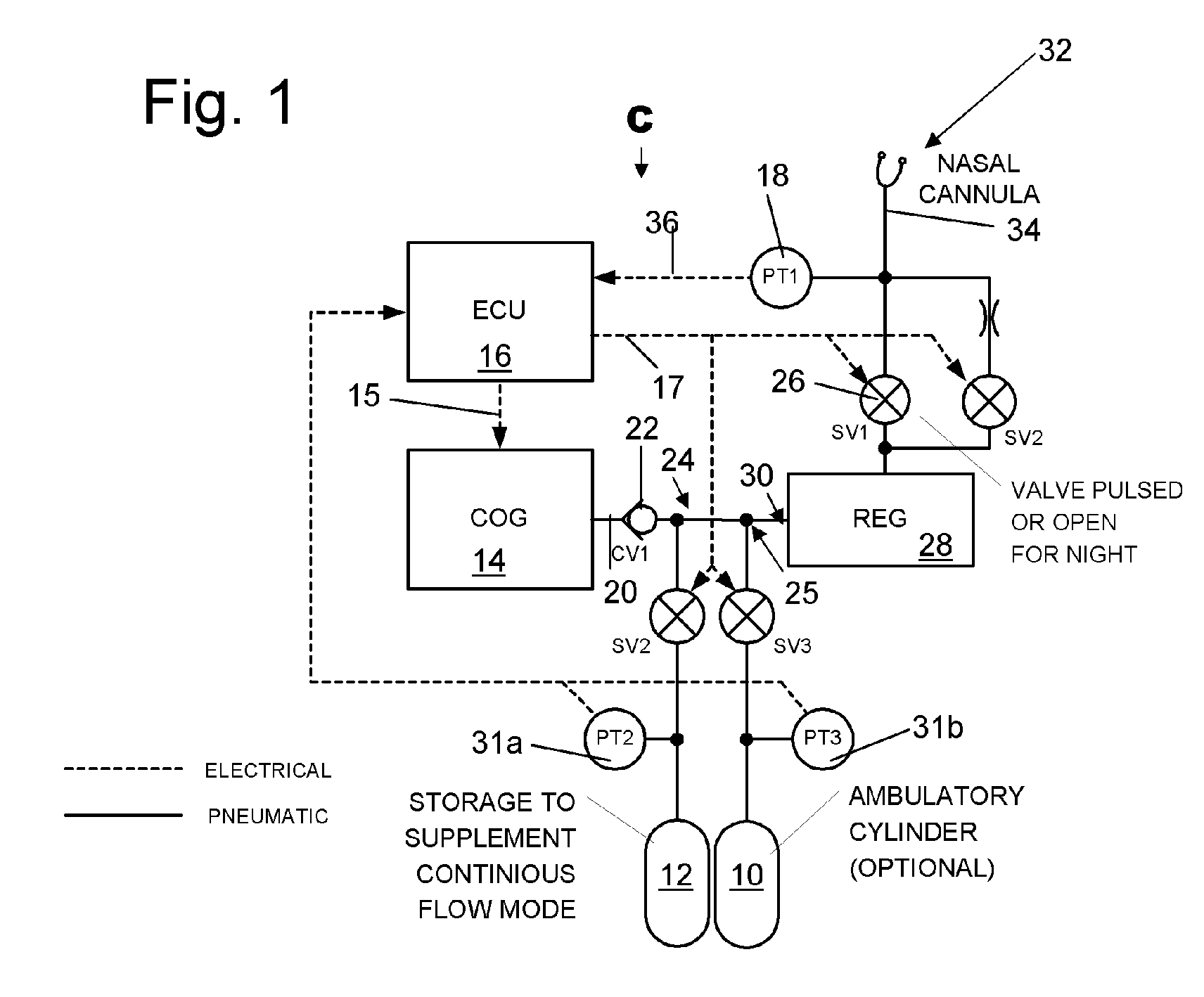

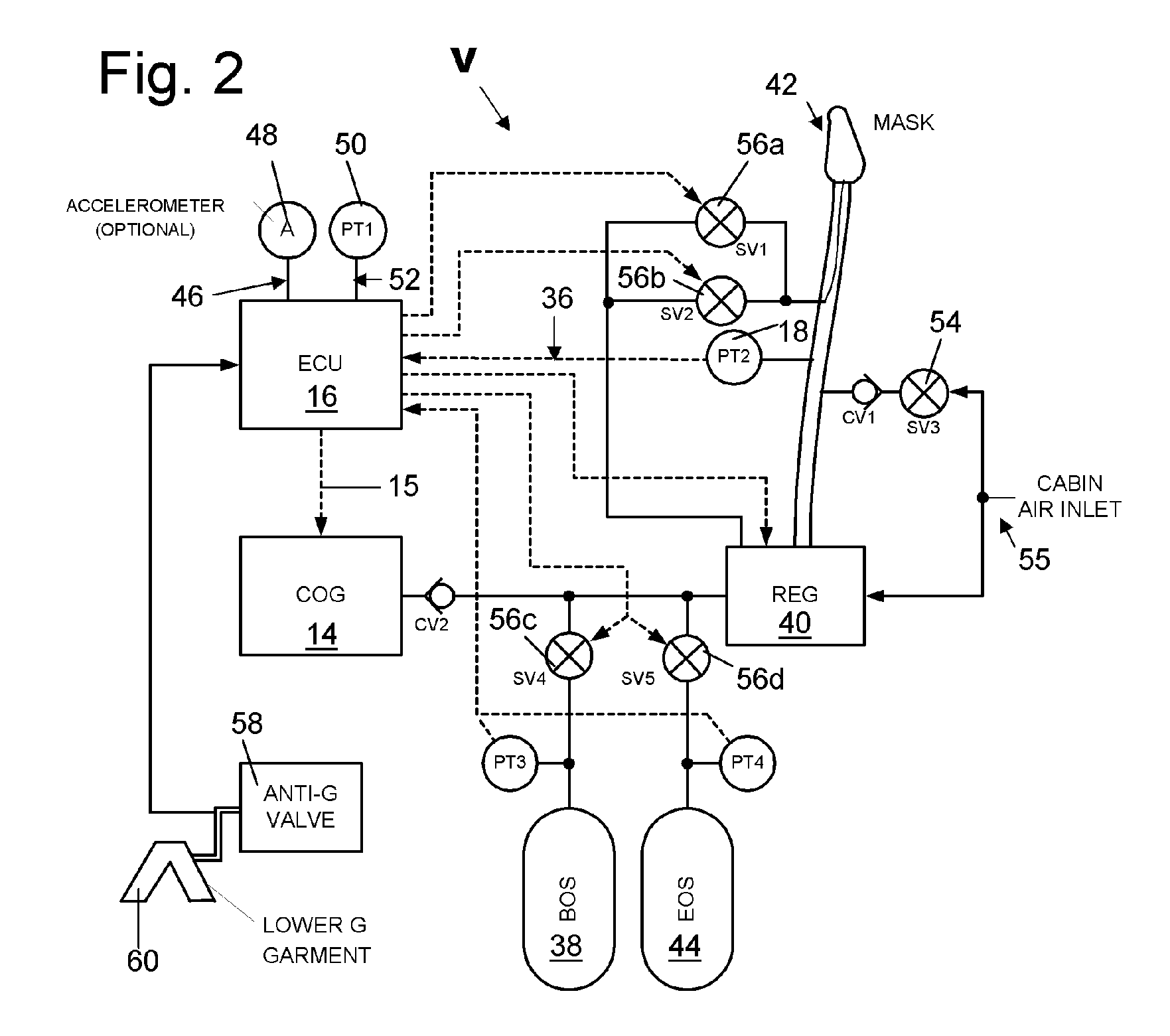

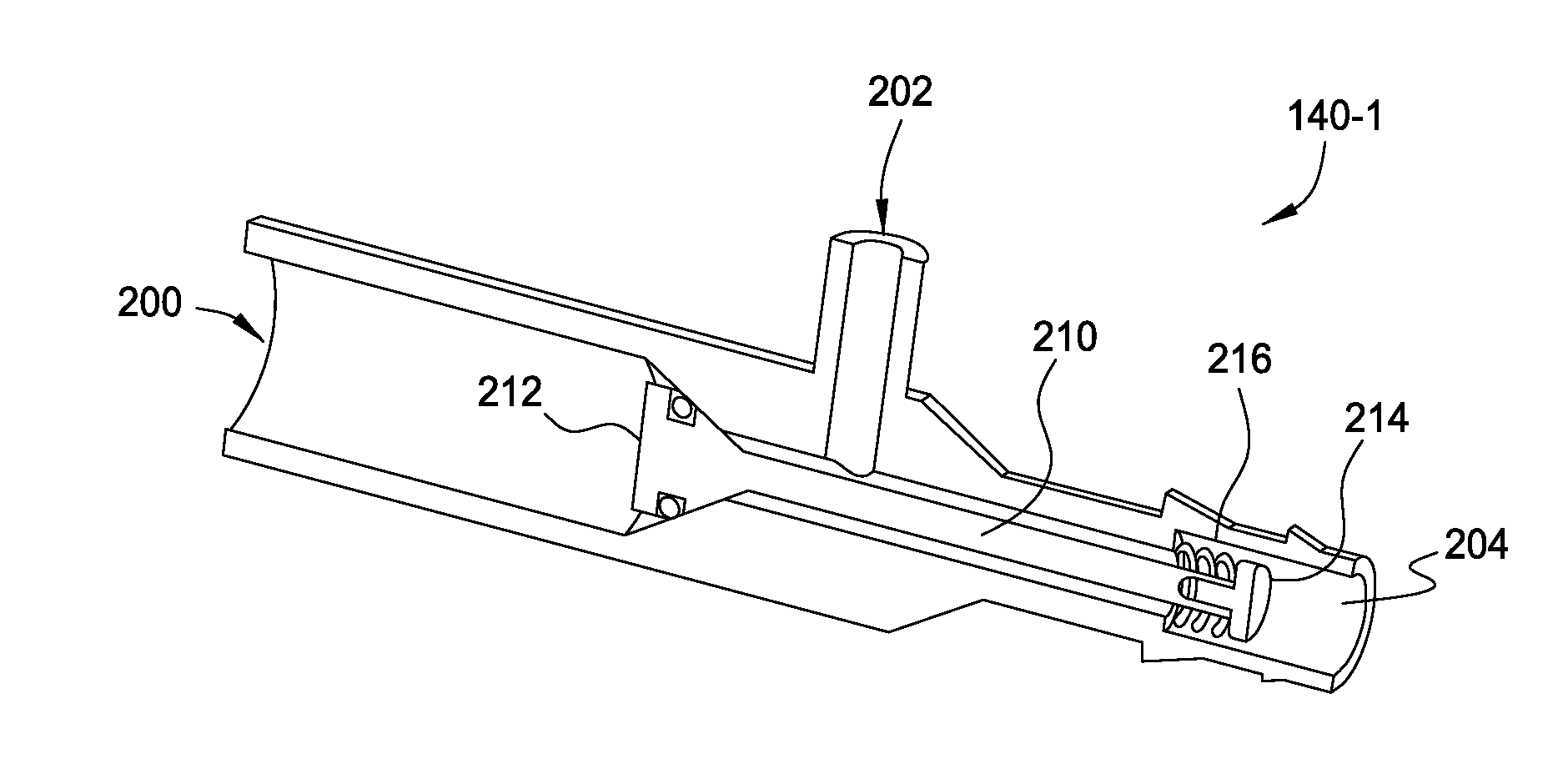

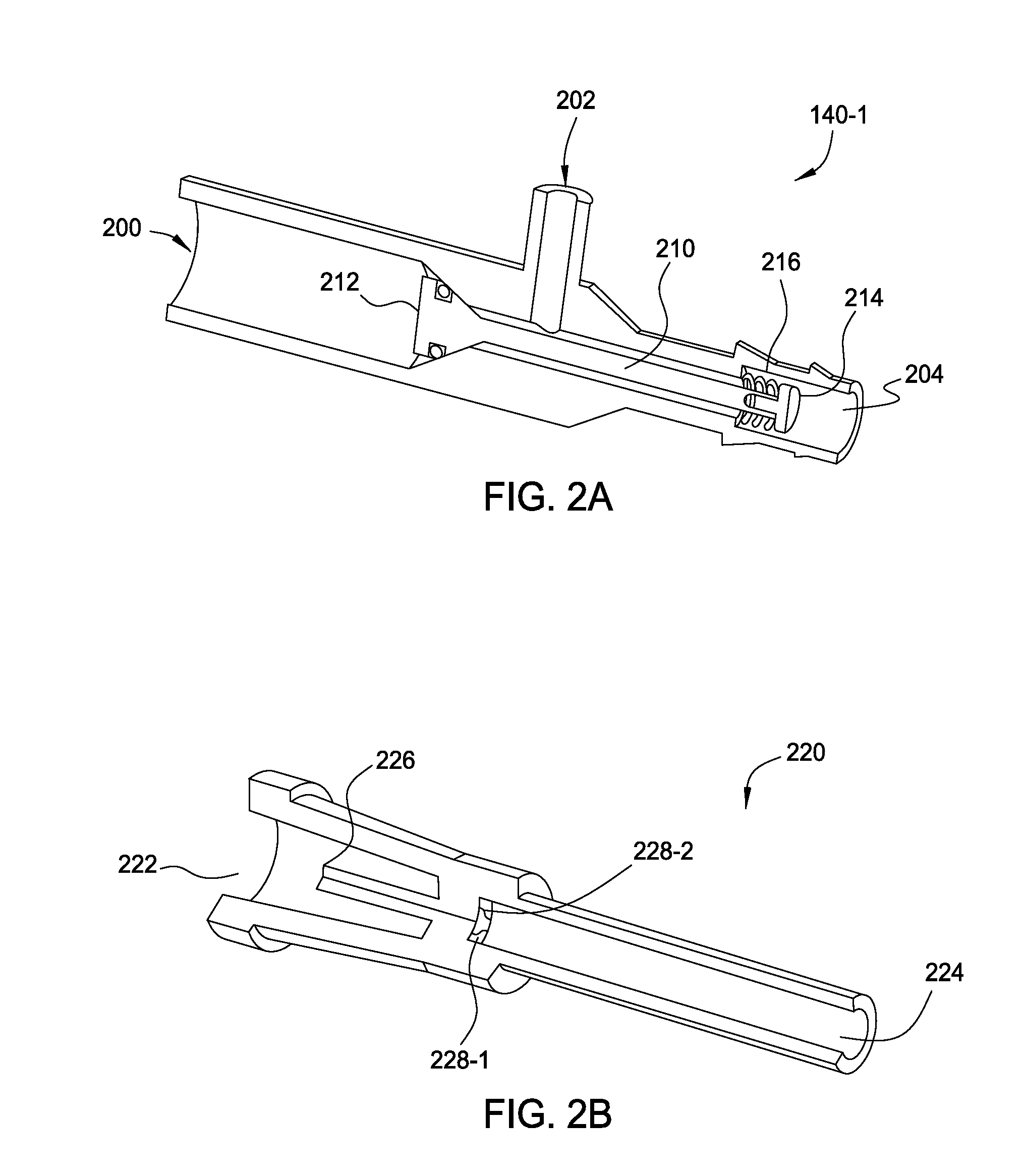

An electronic controller (16) controls the operation of an electrochemical oxygen generating system (14) producing a desired gas. The product gas is fed to a storage unit (12) or a regulator (28) and pulsing valve (28) controlling the gas flow to a user. A two-stage system (180) combines a low pressure 100 and a high pressure (150) gas generating subsystems. The low pressure subsystem (100) uses IMAT's (106) to pump oxygen from ambient air to generate a low-pressure. The high pressure subsystem (150) uses IMAT's (160) to pump oxygen to high-pressure oxygen storage devices (194).

Owner:COBHAM MISSION SYST DAVENPORT LSS INC

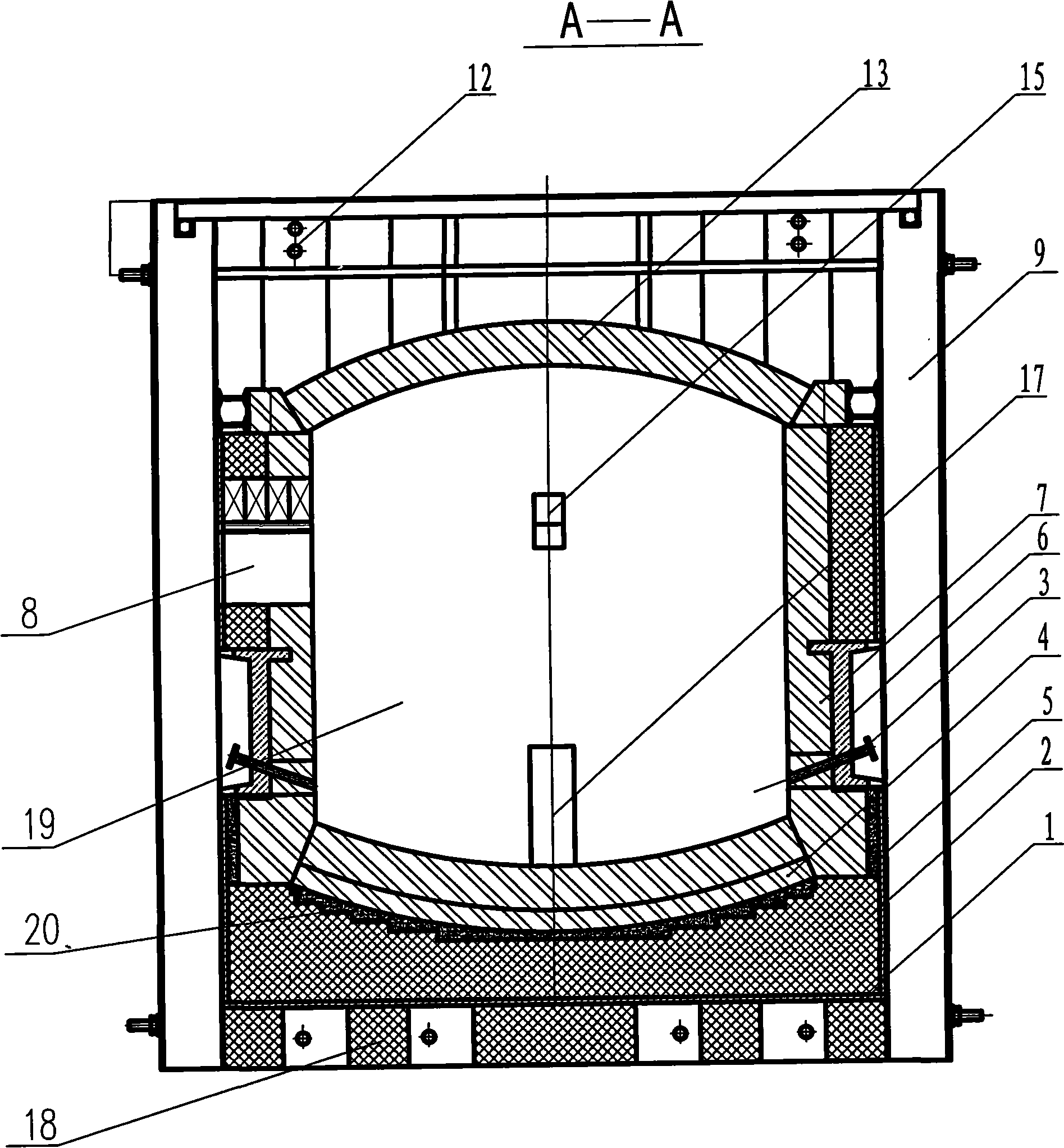

Living environment control system in coal mine underground movable lifesaving cabin

InactiveCN101825000AIncrease effective spaceReduce volumeSafety equipmentsAir cycleOperating instruction

The invention discloses a living environment control system in a coal mine underground movable lifesaving cabin, comprising a lift support system and an air-conditioning system, wherein the life support system is composed of an air circulating system, an air purification system and an oxygen regenerator; the air-conditioning system has a refrigerating system, a phase-change material cold accumulation system and a heat exchange system; and the invention has simple structure and convenient use, miners can enter into the cabin to start the living environment control system of the movable lifesaving cabin according to the requirements of operating instructions when a mining accident happens, and the lift support system adopts a proven aerospace and submarine oxygen regeneration principle to work stably and reliably. High pressure oxygen cylinder with explosion risk can be saved in the cabin, thus reducing the shockproof requirement on the cabin and greatly reducing the volume of a CO2 absorption device; and the refrigerating system in the air-conditioning system is characterized by adopting no transmission parts (vortex tube refrigeration) or less transmission parts (turbo-expander refrigerator) and having no power demand, thus avoiding depending on power in the traditional refrigeration mode.

Owner:HENAN UNIV OF URBAN CONSTR

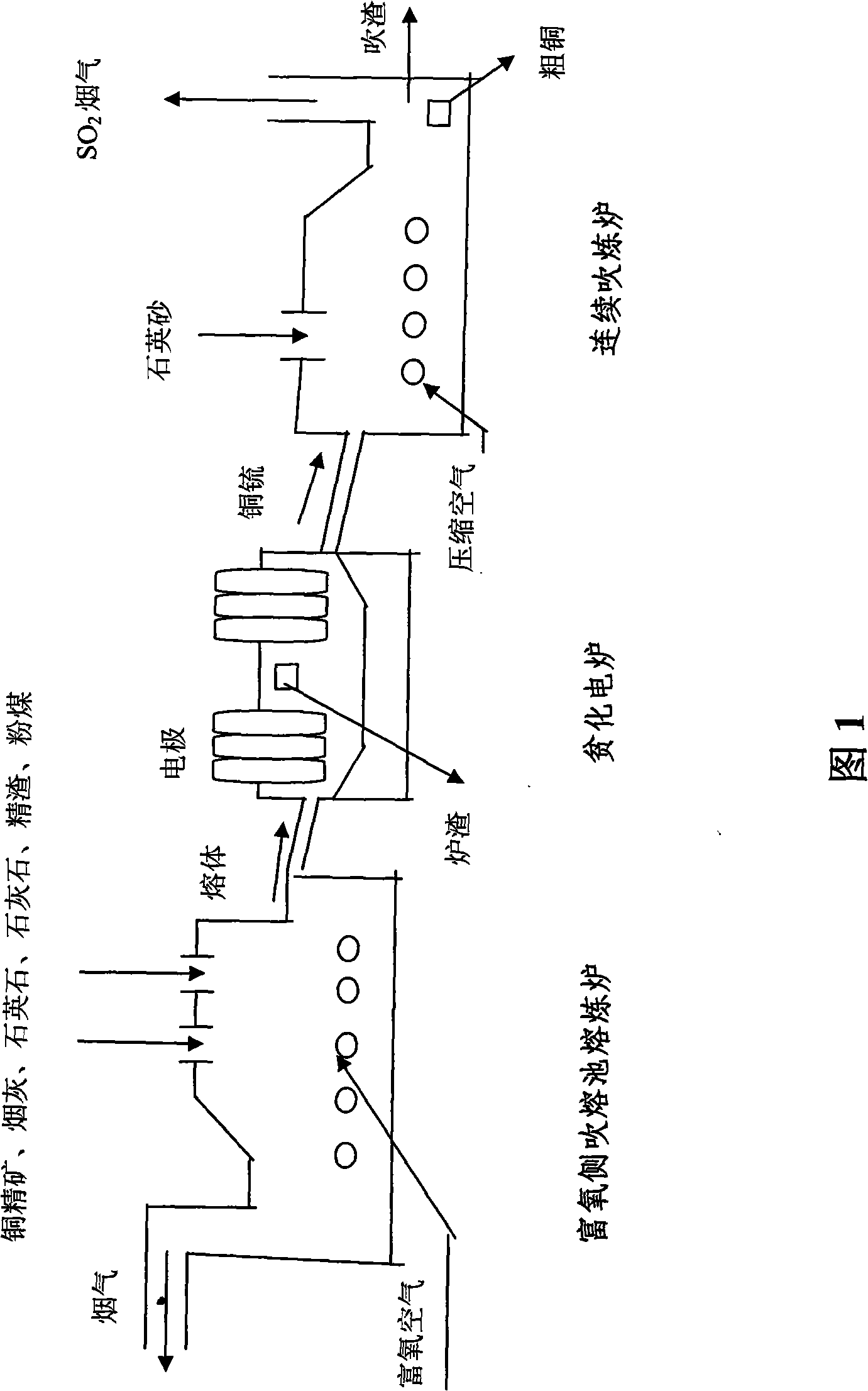

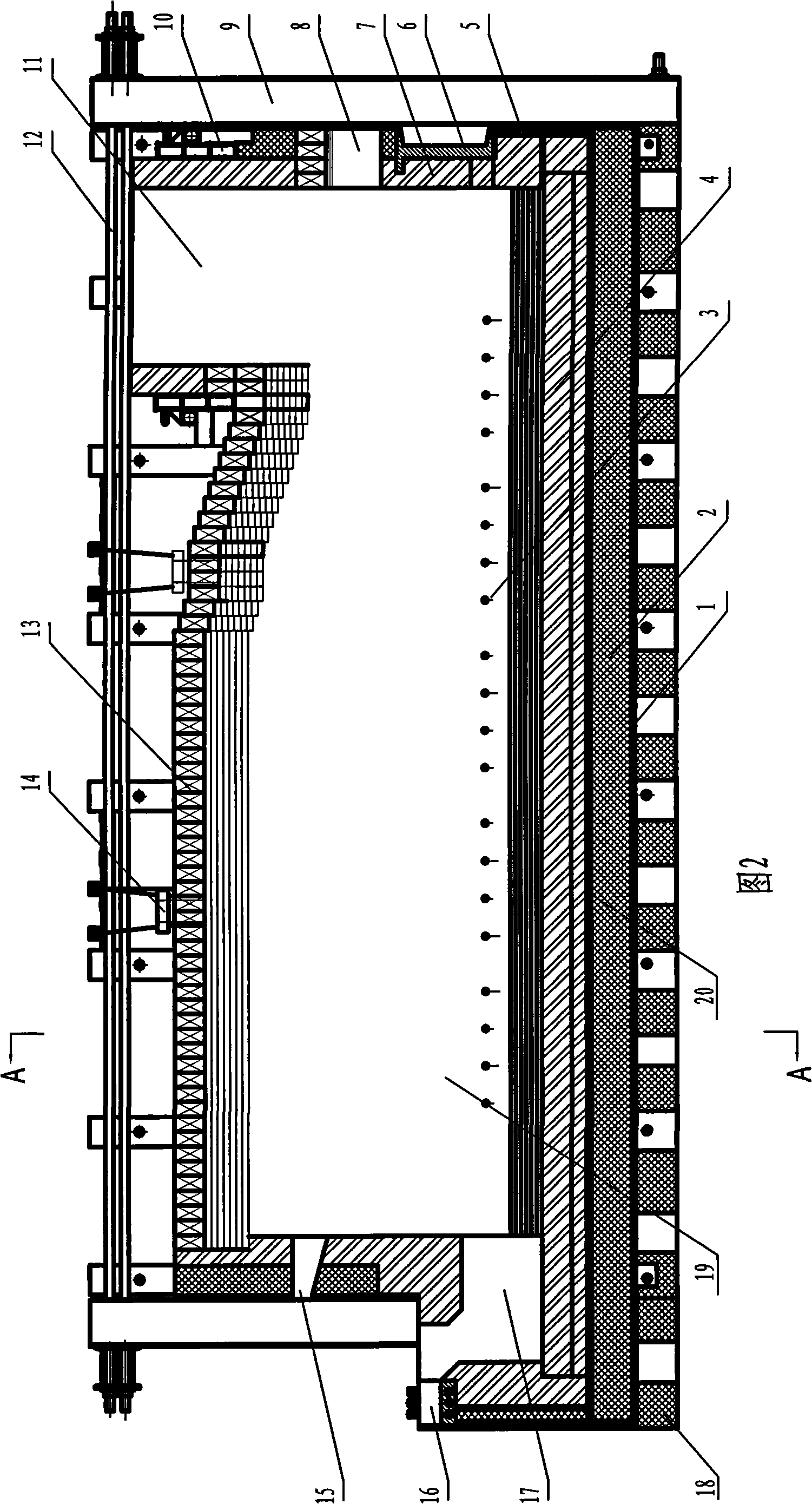

Manufacturing technique for oxygen-enriched side blowing molten pool raw copper smelting and special equipment thereof

InactiveCN101275185ALess investmentReduce energy consumptionRotary drum furnacesCrucible furnacesMelting tankHigh pressure oxygen

The invention disclose a production process for melting blister copper in a bath by side-blowing of oxygen enrichment and special apparatuses thereof, the process comprises the steps of melting concentrate of copper, diluting the slug and air refining copper matte, which is to say, adding the material comprising copper, quartz, limestone and fine coal into the furnace of bath and blowing the high pressure oxygen enrichment air into the furnace, the formed copper matte, slug are ceaselessly flowed into a diluting electric furnace, manufacturing acid after recycling waste heat by smoke gas at high temperature; overheating the slug through an electrode and separating the slug from copper matte to obtain the diluted slug and copper matte which is fed into the continuously-air-refining furnace through a chute slipway; reacting the copper matte with arenaceous quartz under the effect of compressed air to obtain the blister copper, performing mineral dressing to the air-refined slug, manufacturing the acid with SO<2>; the invention has less process investment, high heat utilization rate, low energy consumption, good effect of environmental protection, compact apparatus structure, small occupied area, great processing ability, light sticking in air flue, simple operations, diverse measures in adjusting the condition of furnace which is easy to control, high level of mechanization and low labor intensity.

Owner:YANTAI PENGHUI COPPER IND

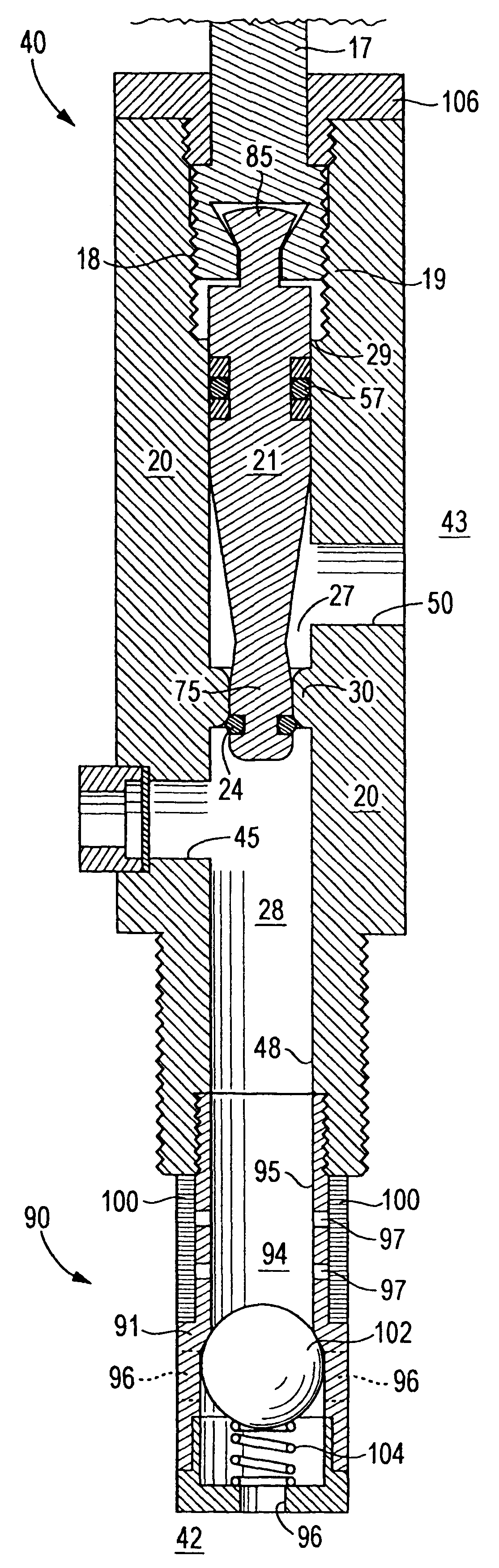

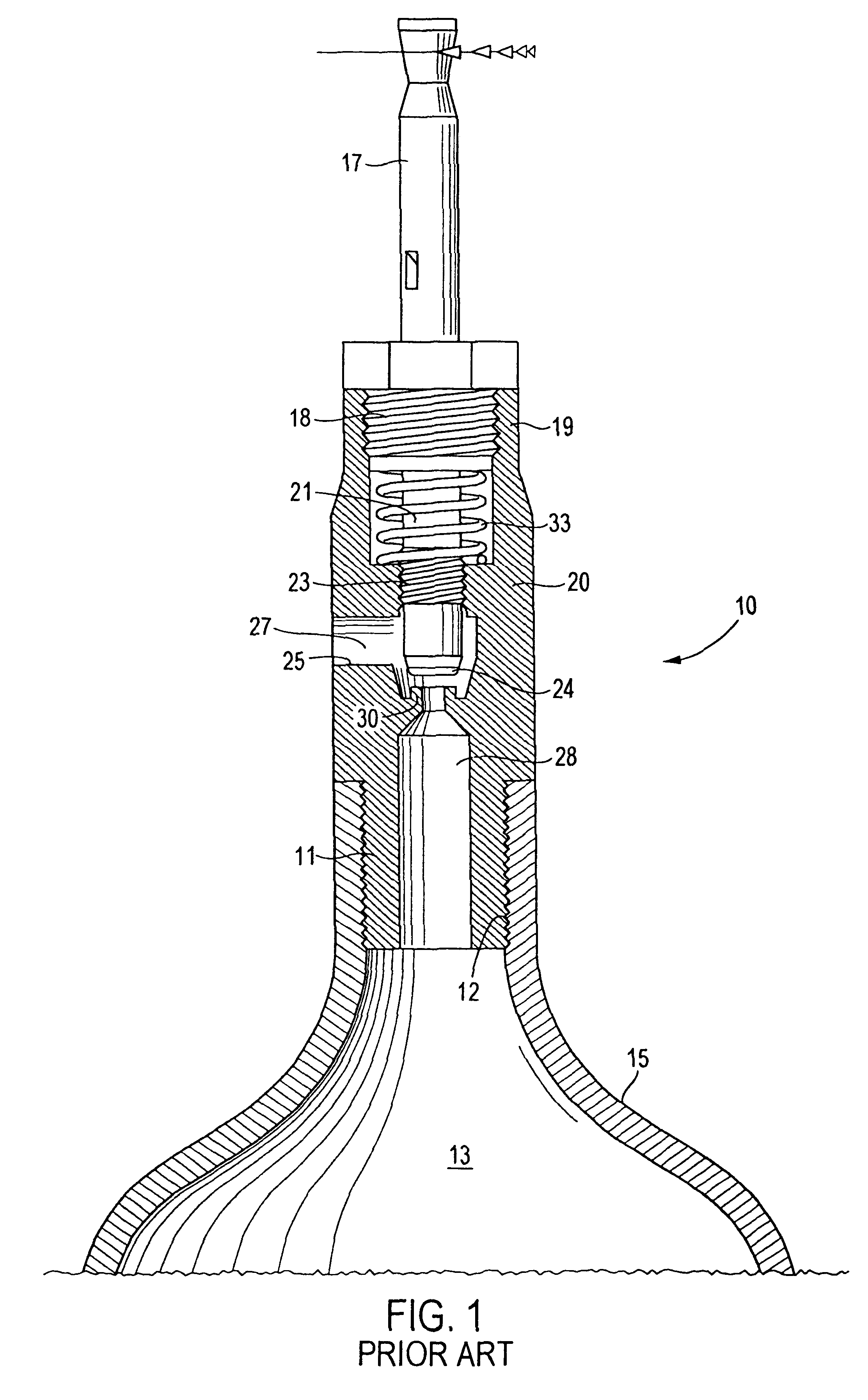

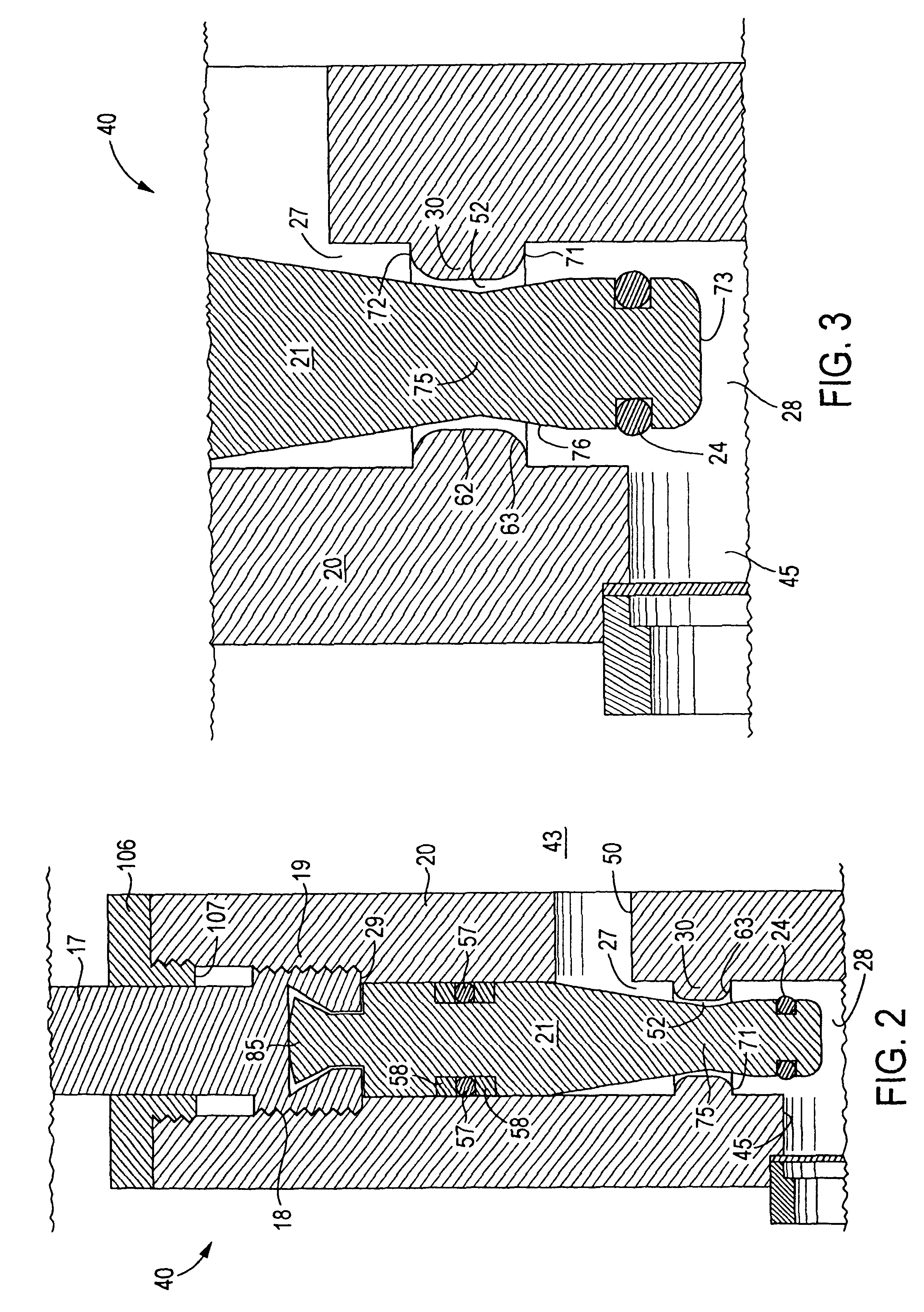

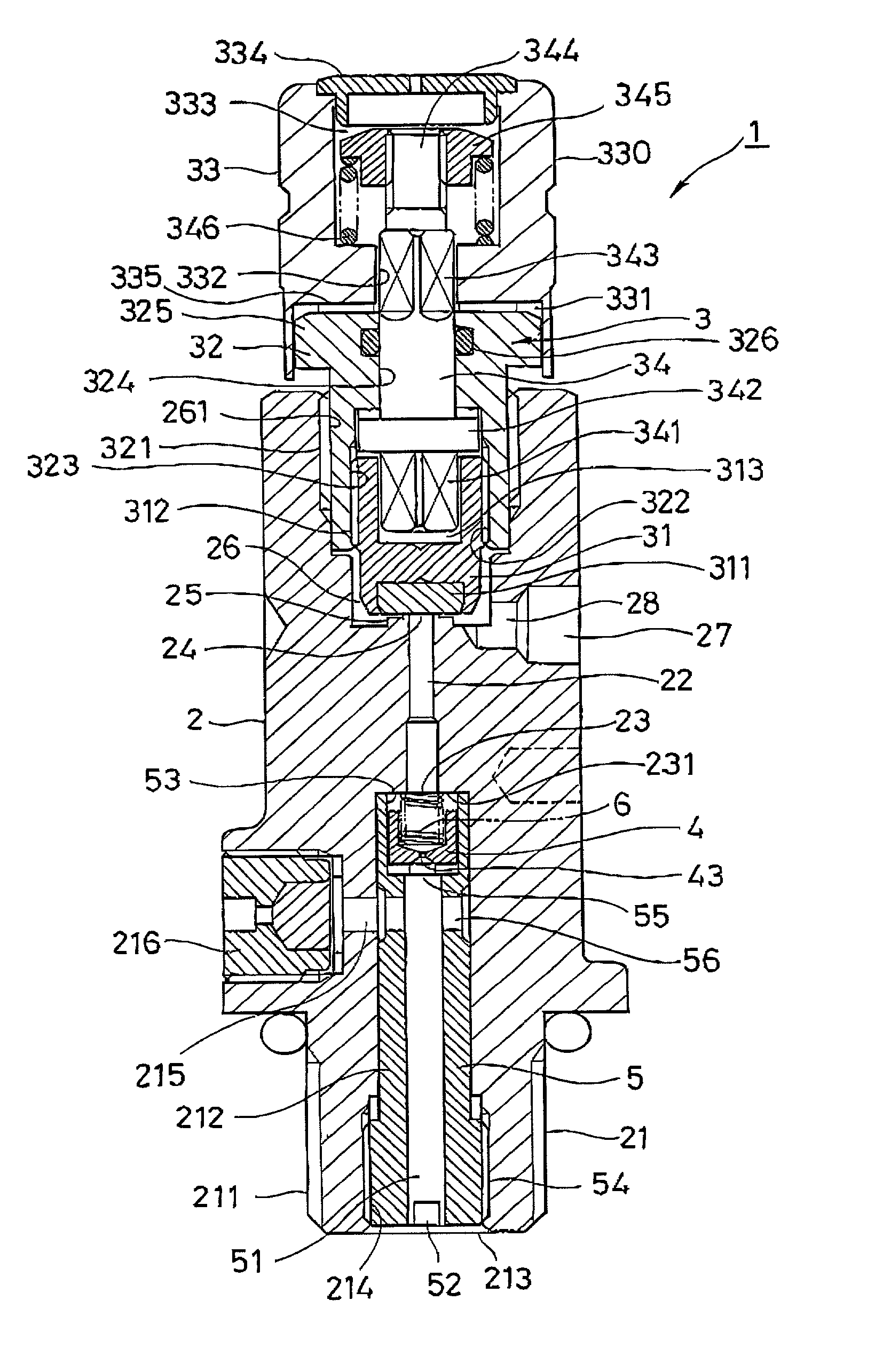

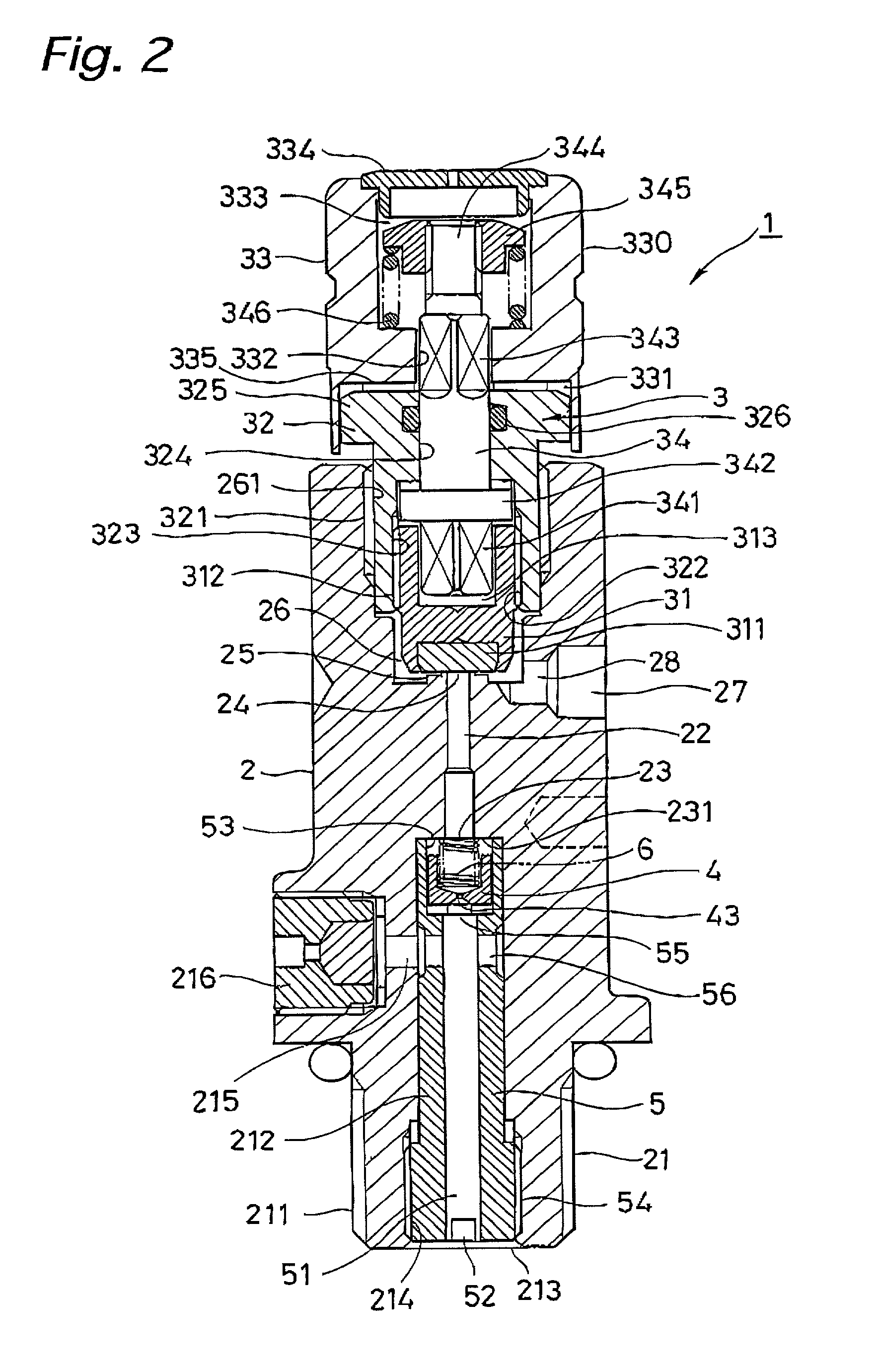

Cylinder valve and bayonet check-filter with excess-flow protection feature

InactiveUS6607007B1Reduce the risk of fireLower potentialFunctional valve typesContainer filling methodsOxygen systemHigh pressure oxygen

A valve apparatus especially well-suited for use in gaseous oxygen delivery systems. A valve apparatus is provided that substantially reduces the risk of fire in high-pressure oxygen systems. The apparatus is particularly well-suited for use as a plug valve on ordinary cylinder containers, but may be beneficially used in any pressurized gas system, particularly oxygen systems such as those encountered in many industrial facilities. The wetted portion of the valve is isolated from threaded portions to prevent particulate contamination of the gas stream. The valve seat is located to protect it from direct impact of high-velocity gas streams. The inventive valve, and its associated inventive check-filter and excess-flow prevention features, reduces the potential for hazardous combustion at valve points within oxygen delivery systems.

Owner:LUXFER INC

Oxygen generator with storage and conservation modes

ActiveUS7694674B2Withstanding stressIncrease pressureCombination devicesAuxillary pretreatmentElectronic controllerProduct gas

Owner:COBHAM MISSION SYST DAVENPORT LSS INC

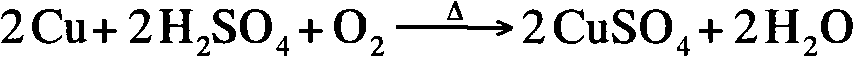

Oxidative pressure acid leaching method for processing purified waste residue in zinc hydrometallurgy process

ActiveCN101550485AFast leachingHigh recovery rateProcess efficiency improvementHigh pressure oxygenHydrometallurgy

The invention relates to an oxidative pressure acid leaching method for processing the purified residue generated in the zinc hydrometallurgy process. The method comprises the following steps: the copper-cadmium residue generated during the copper-cadmium removal and the nickel-cobalt residue generated during the nickel-cobalt removal is replaced, i.e., the residue from the purification of zinc is leached with sulfuric acid in an acid-resistant high pressure autoclave under the condition that the high-pressure oxygen is introduced in. Compared with the commonly-used direct acid solution method, the method has the advantages of high leaching rate, high processing speed, no poisonous and harmful gas and iron removal during the leaching process, and the like, can obviously improve the prior process conditions, reduce the pollution andthe production cost and also provides a new method for processing the other waste residues containing heavy metal.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

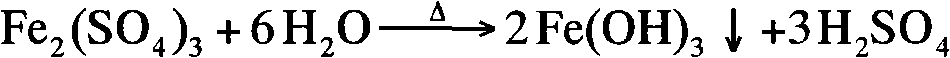

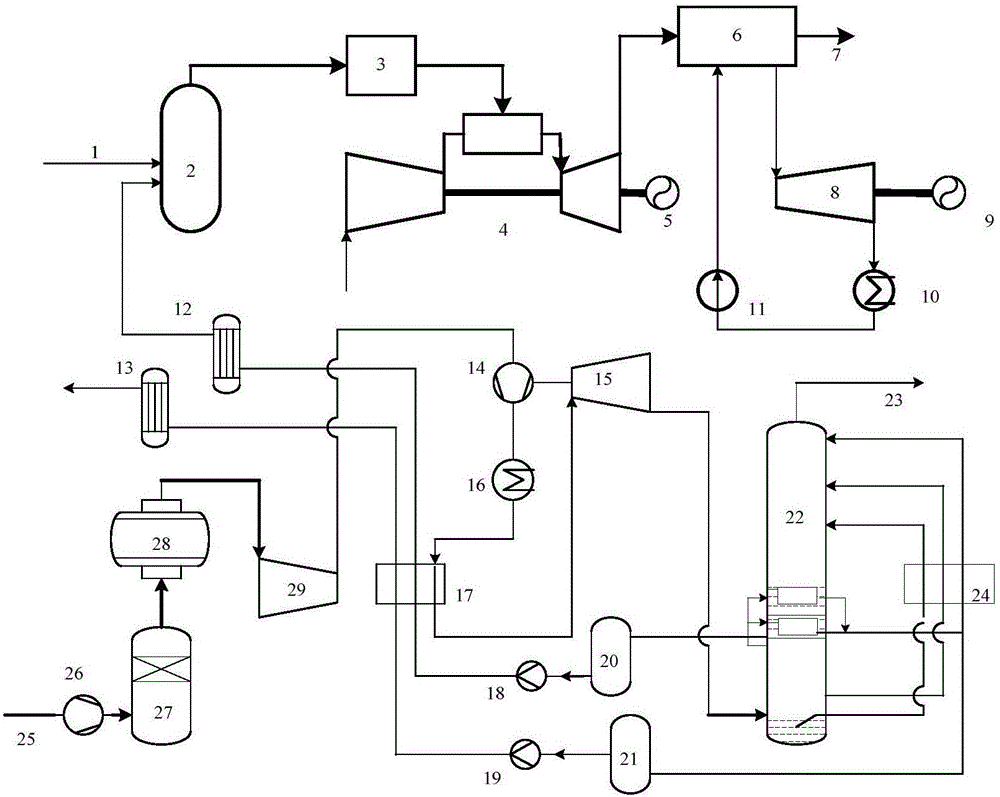

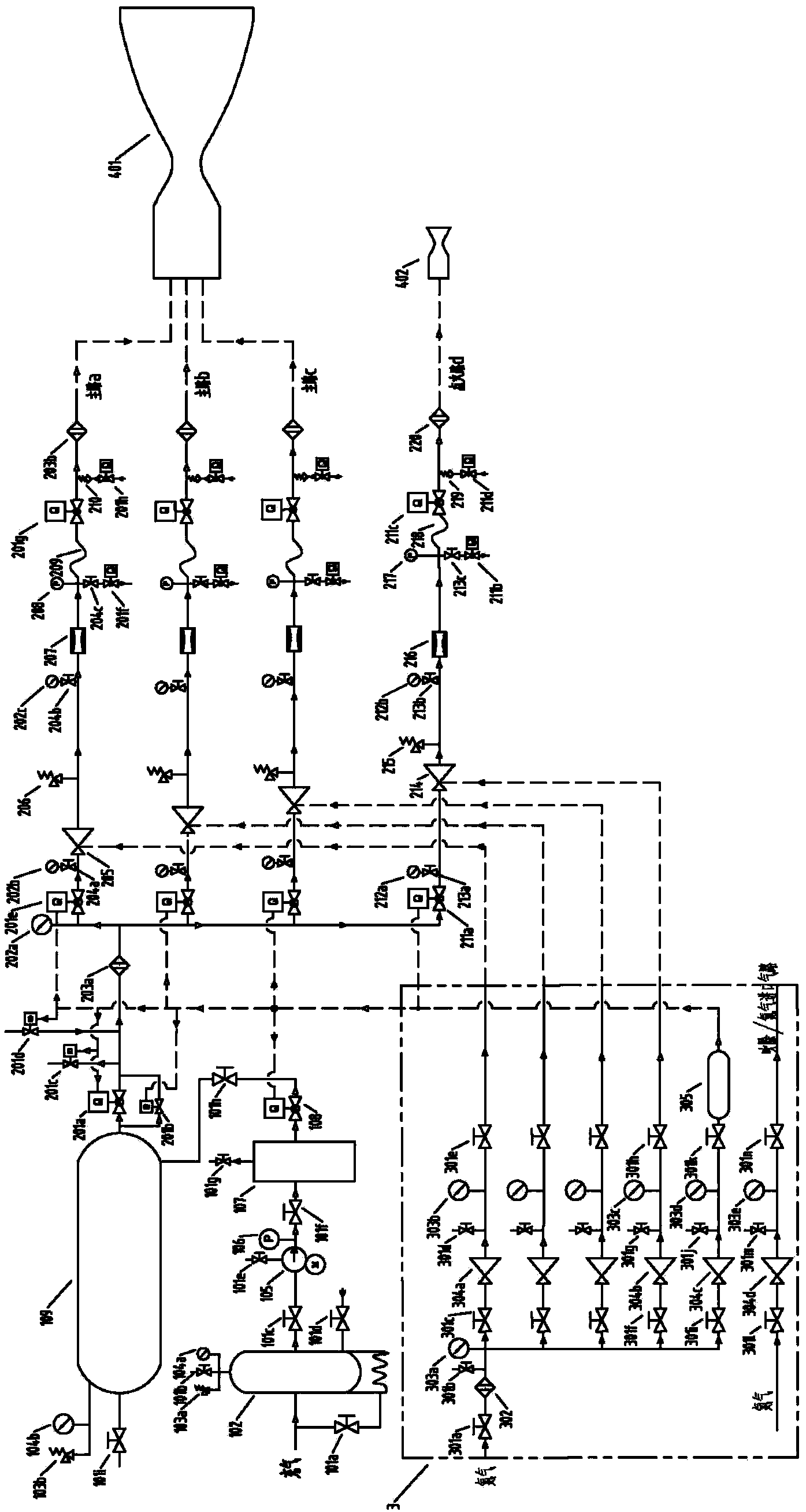

IGCC power station peak regulating device achieving energy storage through air separation system and method

ActiveCN106285944AOvercome the disadvantages of slow load changing speed and poor peak-shaving ability of power gridQuickly meet peak shaving needsSolidificationLiquefactionComing outHigh pressure oxygen

The invention discloses an IGCC power station peak regulating device achieving energy storage through an air separation system and a method. The device comprises a gasification furnace, a synthesis gas purification unit, a gas turbine power generation system, a waste heat boiler system and a steam turbine power generation system; oxygen needed by the gasification furnace is supplied by the air separation system; the air separation system comprises an air cooling and compressing system which supplies cooling air to a rectifying tower and can achieve variable frequency regulation, air in the rectifying tower is separated into nitrogen and oxygen, nitrogen and oxygen are stored in a liquid nitrogen storage tank and a liquid oxygen storage tank respectively, the liquid oxygen storage tank is connected with an oxygen heater through a liquid oxygen pump and a cold box, and high-pressure oxygen coming out from the oxygen heater is delivered to the gasification furnace. According to the device and method, the defects that an IGCC power generation system is low in load varying speed and poor in power grid peak regulating capacity are overcome, the capability of quickly regulating the IGCC output power is achieved through the storage capacity of the air separation system, and the whole-plant output power can be increased and decreased by within 20% most quickly in a short time.

Owner:CHINA HUANENG GRP CO LTD +1

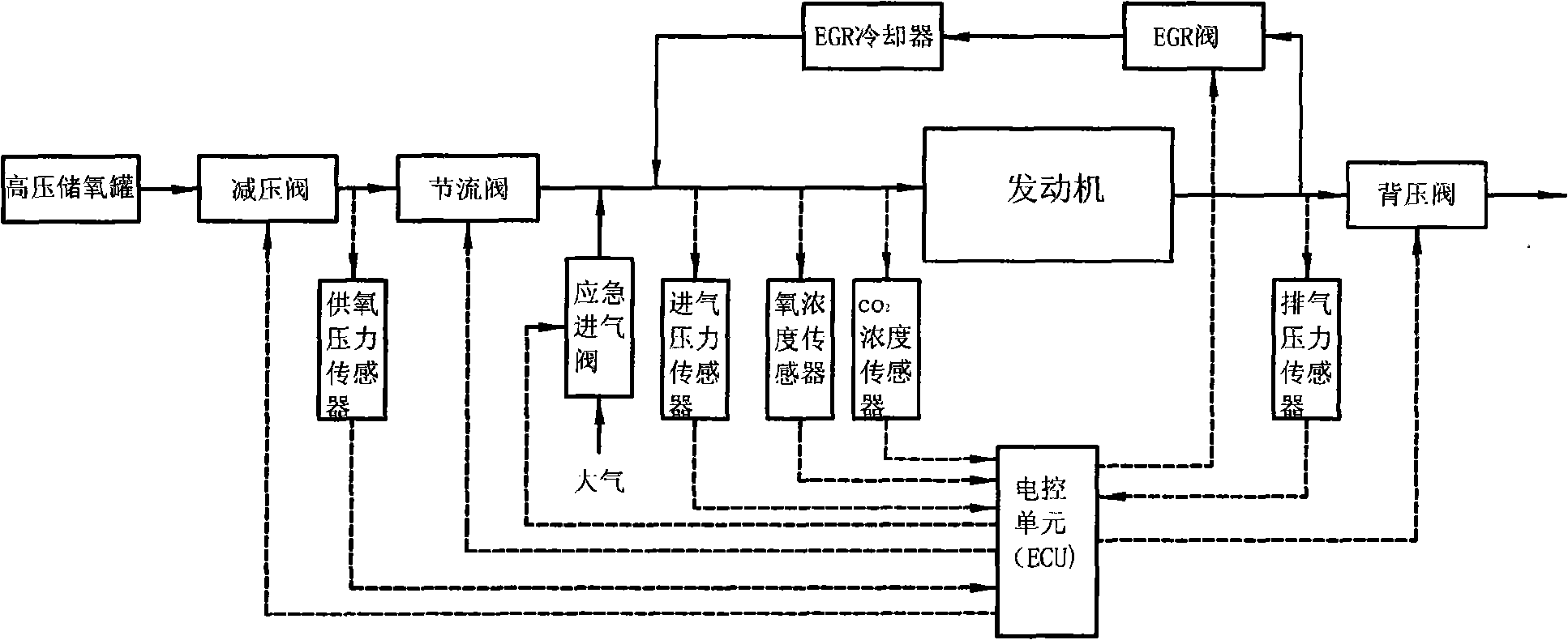

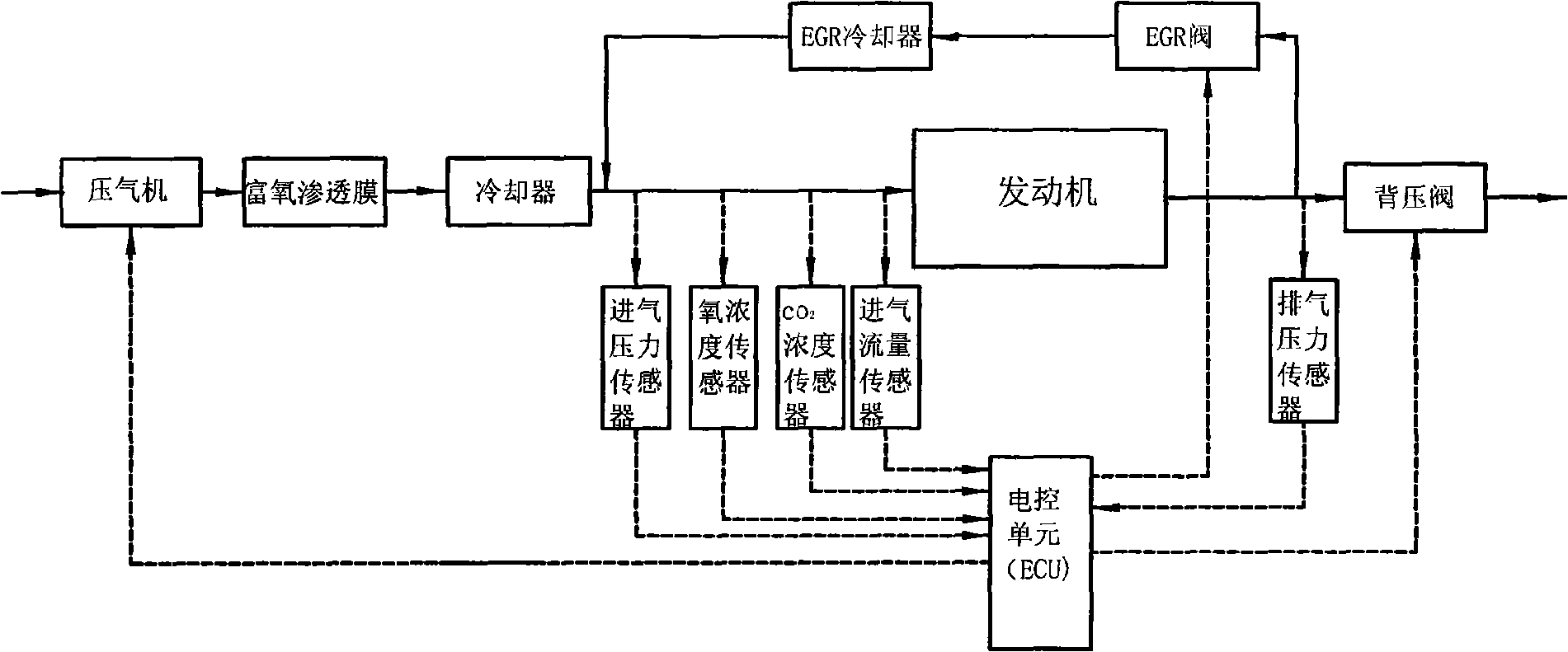

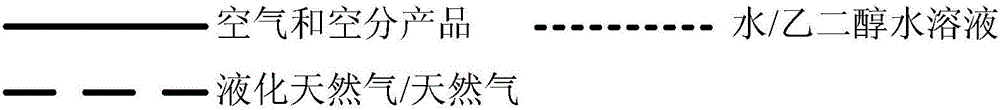

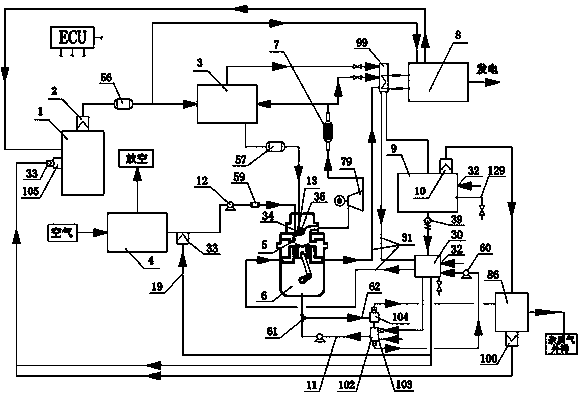

Automobile pure oxygen combustion engine system

InactiveCN101526035AOxygen-enriched combustionControl the combustion processElectrical controlMachines/enginesExternal combustion engineClosed loop

The invention relates to an automobile pure oxygen combustion engine system which comprises an internal combustion engine and a gas recirculation system, and adopts a high pressure oxygen storage tank or a membrane separation oxygenerator to form a pure oxygen gas supply system for providing the pure oxygen; EGR waste gas of a vehicle EGR system is mixed with the pure oxygen, and then the mixed gas is taken as the inlet gas of the engine, so that engine oxygen-enriched combustion can be realized; while the emission of granules in a diesel engine is reduced, the discharge of nitrogen oxide of the diesel engine can be effectively reduced, thus reaching the strict discharge standard; furthermore, automatic closed-loop control can be carried out by using the ECU, and the oxygen content can be accurately controlled, thus controlling the combustion process of the engine and realizing ultra-low emission.

Owner:TIANJIN UNIV

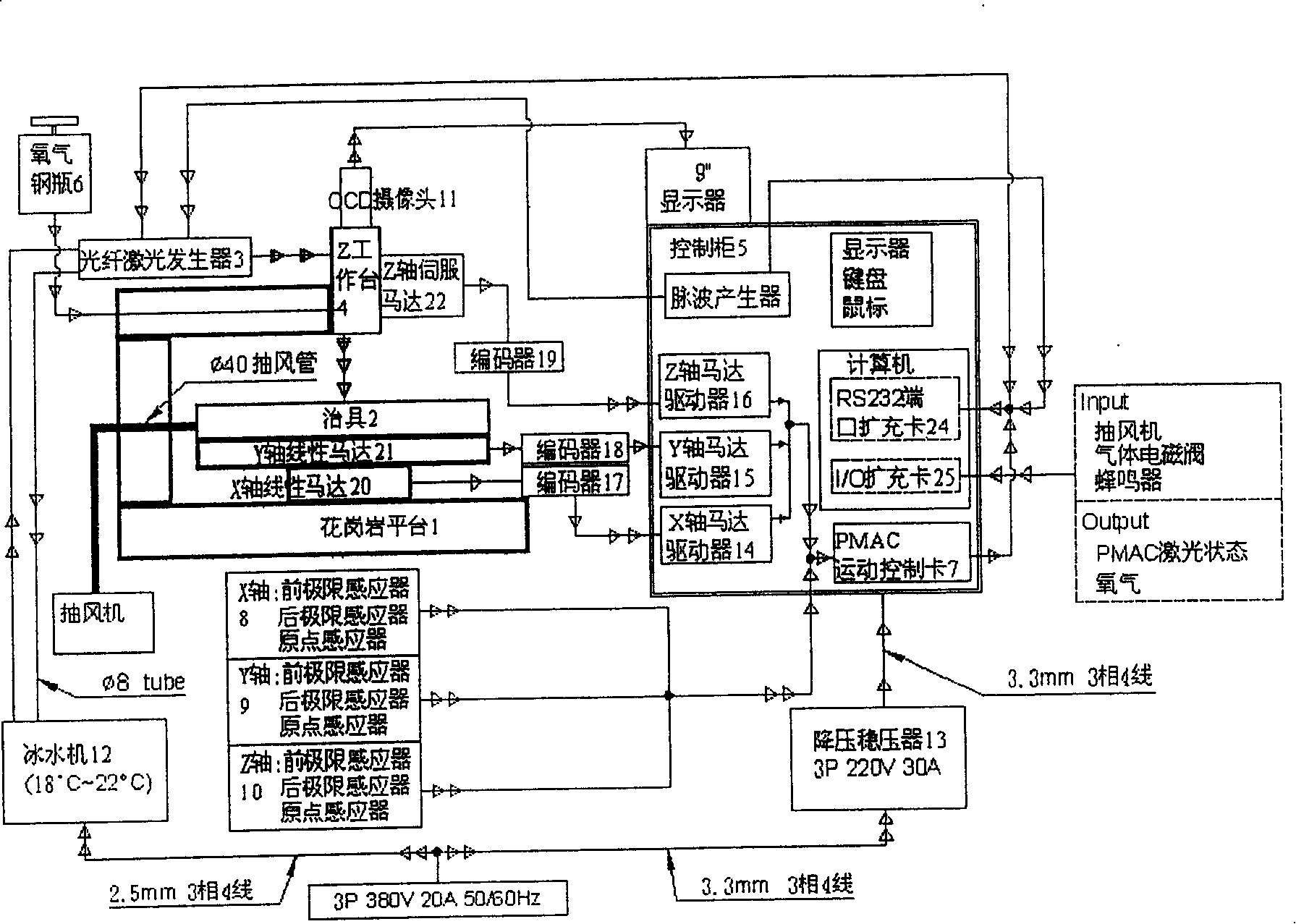

Laser cutting device

InactiveCN101190476AEasy CalibrationImprove cutting accuracyLaser detailsLarge fixed membersMetallic materialsHigh pressure oxygen

The invention discloses a laser cutting device, comprising a laser cutting head system, an X-Y workbench and a granite workbench of counterweight and a workpiece clamping mechanism. The laser cutting head system comprises a laser generator, a Z workbench and a control cabinet. The invention is characterized in that the X-Y workbench adopts a sliding block to carry out limitless circular restricted linear motion on a linear sliding track through steel balls between the sliding block and the linear sliding track; the laser generator is an optical fiber generator; the laser cutting head system also comprises a high-pressure oxygen nozzle at the circumference of the laser beam; when cutting, the oxygen flow basically coaxial with the laser beam is spouted out from the cutting head. The invention has the advantages of high cutting precision, high processing efficiency, low manufacture cost, low application cost, simple optical path correction, conveniently implementing miniaturization, being suitable for the cutting process of most of metal and non-metal material, also having the functions of sign marking, carving, punching, etc., and being widely applicable to industries of mechanism, steel, automobile, shipping, petrochemicals, cases and cabinets, and packages.

Owner:SHENZHEN MUSEN TECH

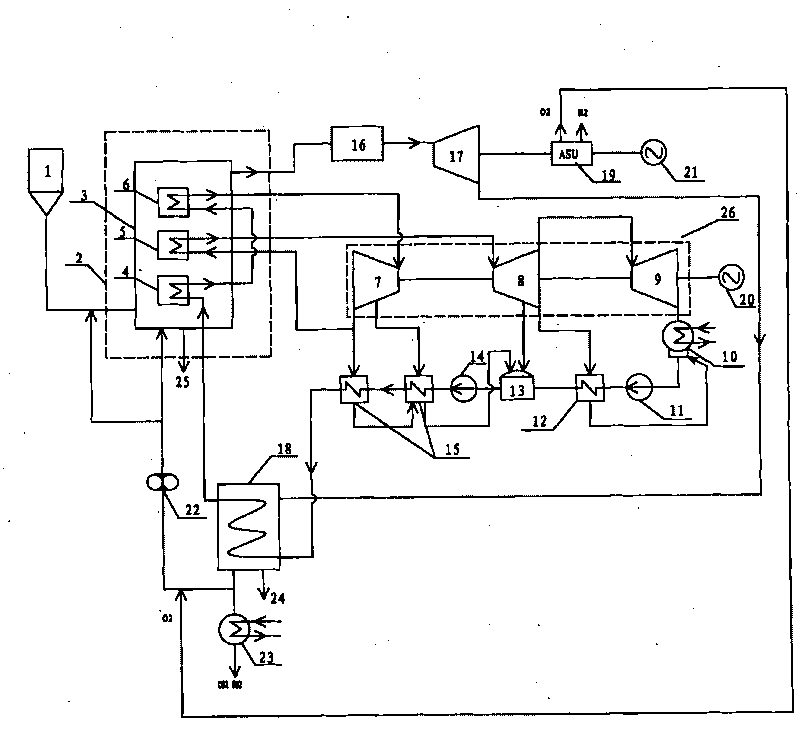

Combined cycle generation system of high-pressure oxygen-enriched combustion fluidized bed

InactiveCN101761915ASmall sizeHigh outputFluidized bed combustionSteam generation plantsLiquid waterTrapping

The invention relates to a combined cycle generation system of a high-pressure oxygen-enriched combustion fluidized bed, which is used for solving the problem of economy of oxygen-enriched combustion. The invention has the technical scheme that the combined cycle generation system of the high-pressure oxygen-enriched combustion fluidized bed comprises a working medium circulating system, an oxygen gas supply and flue gas recirculation system and a fuel conveying device, wherein the overall process of the whole system from the oxygen preparation of air separation, the combustion and the heat exchange of a boiler, the work applying of a high-pressure gas turbine until the CO2 trapping of flue gas is persistently finished at high pressure, and the compression energy consumption and the decompression loss are greatly reduced. The invention can condense water in the flue gas which is unserviceable originally in combustion at normal pressure into liquid water, thereby utilizing the released latent heat of vaporization, which lowers the flue gas loss to about 1%, enhances the efficiency of the boiler greatly and can also enhance the output of the gas turbine by about 3-5%. Because of high pressure in an exhaust-heat boiler, liquid-state CO2 can be obtained only by cooling the flue gas to about 25 DEG C through cooling water. Compared with a normal-pressure oxygen-enriched combustion mode adopting multistage compression and refrigeration, the energy saving of the invention is larger.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Cryogenic air separation method and system

The present invention relates to a cryogenic air separation process that provides high pressure oxygen for an oxy-fired combustion of a fuel (e.g., a carbonaceous fuel). The air separation process can be directly integrated into a closed cycle power production process utilizing a working fluid, such as CO2. Beneficially, the air separation process can eliminate the need for inter-cooling between air compression stages and rather provide for recycling the adiabatic heat of compression into a process step in a further methods wherein an additional heat supply is beneficial.

Owner:8 RIVERS CAPTTAL LLC

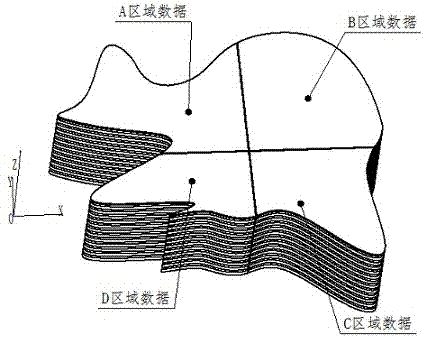

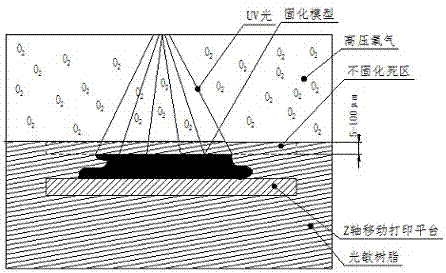

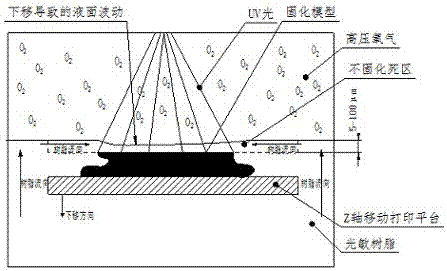

Large-format rapid 3D printing method and device based on DLP photo-curing

PendingCN107283825AFast Stereocuring 3D PrintingAdditive manufacturing apparatusManufacturing environment conditioningHigh pressure oxygenProjection system

The invention provides a large-format rapid 3D printing method and device based on DLP photo-curing. The large-format rapid 3D printing method based on DLP photo-curing comprises the steps that four groups of DLP projection system components are adopted to constitute a large-sized format projection system ( the large-format projection system for short), the large-format projection system is controlled by a computer to continuously play UV images of 365-405 nm layer by layer, the UV images enable photosensitive resin to be cured layer by layer, a Z-axis printing platform descends layer by layer, and then a three-dimensional object is formed through such reciprocating iteration. The large-format projection system is placed on the upper portion of the whole device system, a seal component cavity is arranged on the lower portion, the upper portion of the seal component cavity restrains generation of bubbles through high-pressure oxygen and forms a curing dead zone, under the action of the dead zone and the high-pressure oxygen, the liquid level can be kept stable; and meanwhile, under the action of a balance box and a liquid level laser ranger, on the premise of not lowering the precision, the large-format rapid 3D printing device greatly improves the printing speed and the printing format.

Owner:南京壹千零壹号自动化科技有限公司

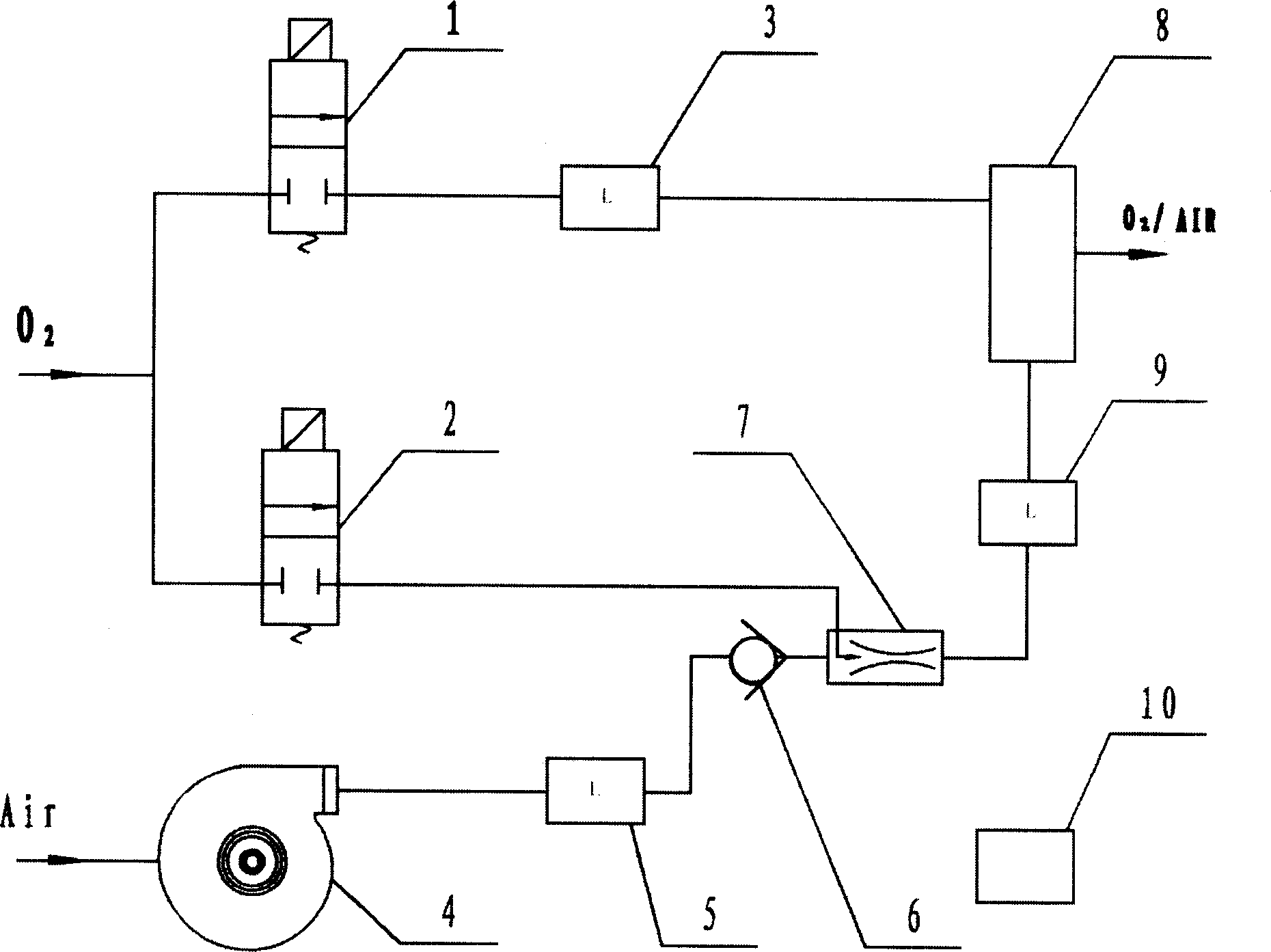

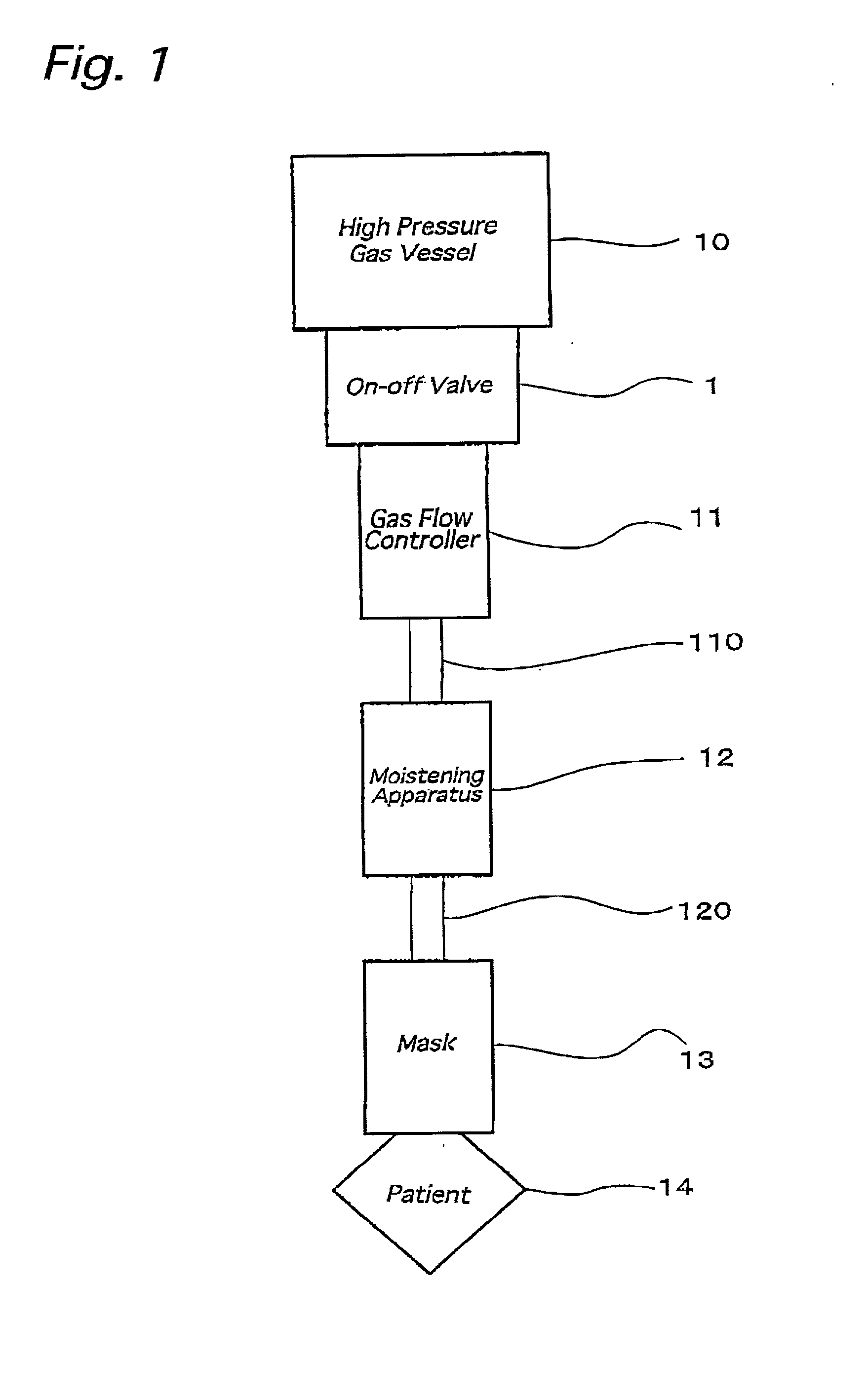

Non-compressed air mixing system of intelligent respirator

An air-oxygen mixing system for the intelligent respiratory machine without compressed air features that the one-way valve, flow sensor and turbine pressurizer are sequentially installed at the air inlet of Venturi device, the electric proportional valve is connected to the high-pressure inlet of Venturi device for controlling the flow of high-pressure oxygen, and another oxygen channel with electric proportional valve and flow sensor is mixed with the mixed gas from Venturi device in the air mixer for supplying the air-oxygen mixture to patient.

Owner:江苏蓝韵凯泰医疗设备有限公司

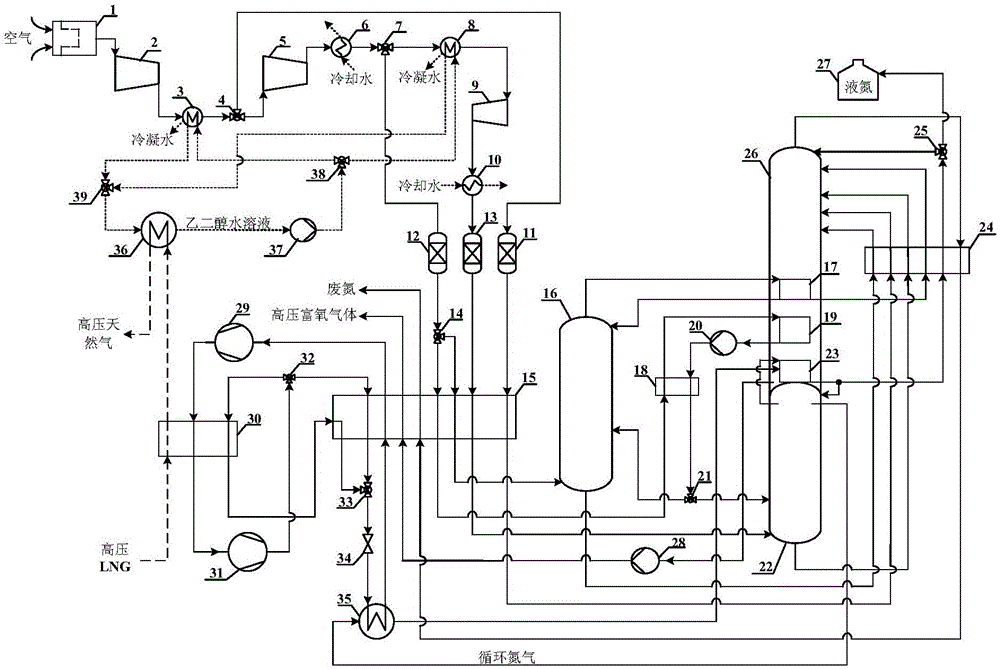

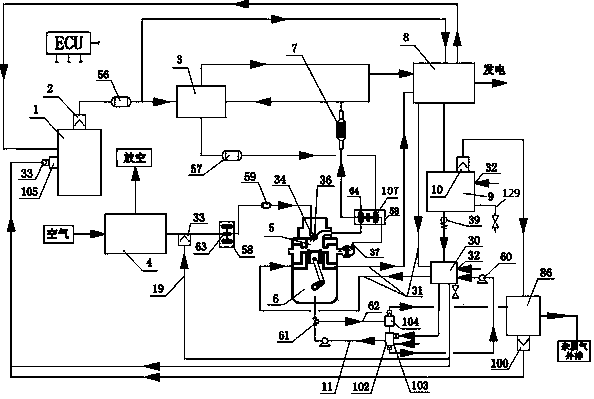

Air separation method utilizing liquefied natural gas cold energy to produce high pressure oxygen rich gas

ActiveCN105783424AReduce power consumptionLow investment costSolidificationLiquefactionHigh pressure oxygenEngineering

The invention belongs to the technical field of liquefied natural gas cold energy utilization, and particularly relates to an air separation method utilizing liquefied natural gas cold energy to produce a high pressure oxygen rich gas. The method specifically comprises the steps of (1) air compression and purification; (2) air liquefaction; (3) air rectification; and (4) LNG cold energy utilization. According to the air separation method, on one hand, a medium pressure tower and a medium pressure air condenser are additionally arranged for performing heat integration with a low pressure tower on the basis of a conventional double-tower air separation process, so that a part of raw air can be separated after being compressed to medium pressure, and the power consumption of an air compressor is greatly reduced; and circulating nitrogen is adopted as an intermediate medium, and the liquefied natural gas cold energy is utilized to condensate nitrogen at the tower top of a high pressure tower to provide cold energy for the air separation process, so that through utilizing the method, a quite high oxygen extraction rate is achieved, the liquefied natural gas is prevented from leaking and entering an air rectification unit, and the safety performance of a system is high.

Owner:JINAN UNIVERSITY

Oxygen direct-injection pure-hydrogen combustion engine and power system thereof

ActiveCN108443010AIncrease diversityIncrease flexibilityCellsHydrogenVapor–liquid separatorHigh pressure oxygen

The invention relates to an oxygen direct-injection pure-hydrogen combustion engine and a power system thereof. The oxygen direct-injection pure-hydrogen combustion engine comprises a hydrogen fuel engine body, a magnesium hydride storage tank, a pressure swing adsorption oxygenerator, a three-way catalyst, a tail gas waste heat utilization unit and a hydrogen purification unit. The magnesium hydride storage tank is connected to a hydrogen opening of the hydrogen fuel engine body through a low-pressure hydrogen buffering tank, and the pressure swing adsorption oxygenerator is connected to an oxygen nozzle of the hydrogen fuel engine body through a high-pressure oxygen buffering tank. Exhausting holes of the hydrogen fuel engine body are connected to the three-way catalyst through a tail gas expander or a turbocharging unit, and an outlet of the three-way catalyst is connected to a gas-liquid separator through a kelaipu unit / combined type kelaipu unit. A gas outlet of the gas-liquid separator is connected to a steam inlet of the magnesium hydride storage tank through the hydrogen purification unit, and a water outlet of the gas-liquid separator is connected to a cooling water tank.The oxygen direct-injection pure-hydrogen combustion engine is combined with the kelaipu unit / combined type kelaipu unit through the hydrogen fuel engine body, tail gas waste heat of the engine body is fully utilized, and the heat efficiency of the engine body is improved.

Owner:SHANGHAI KELAIPU ENERGY TECH CO LTD

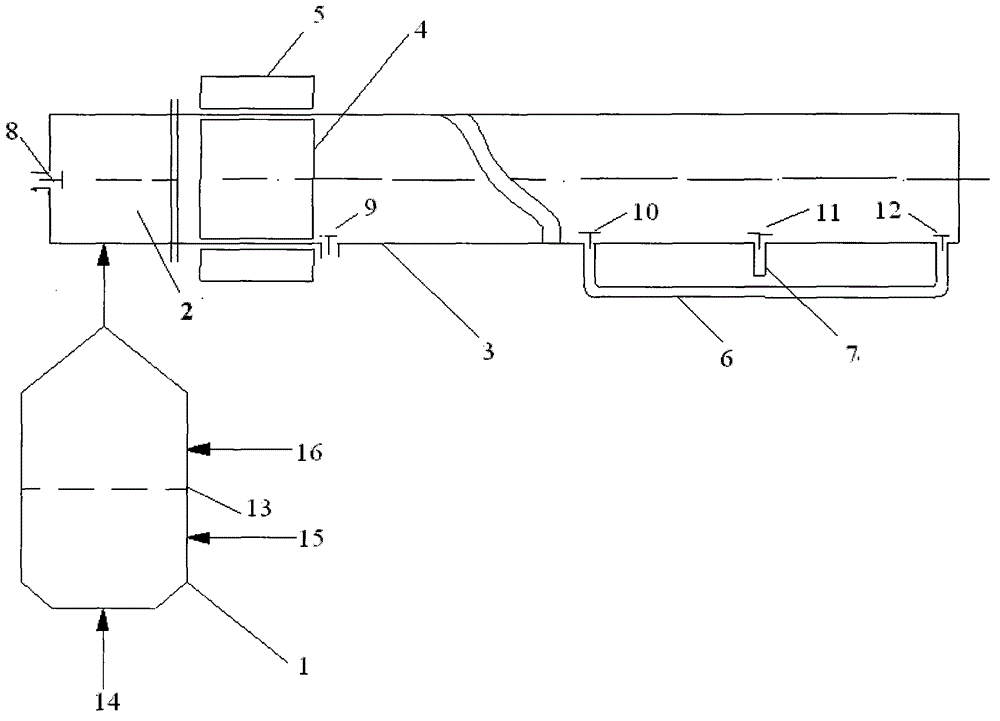

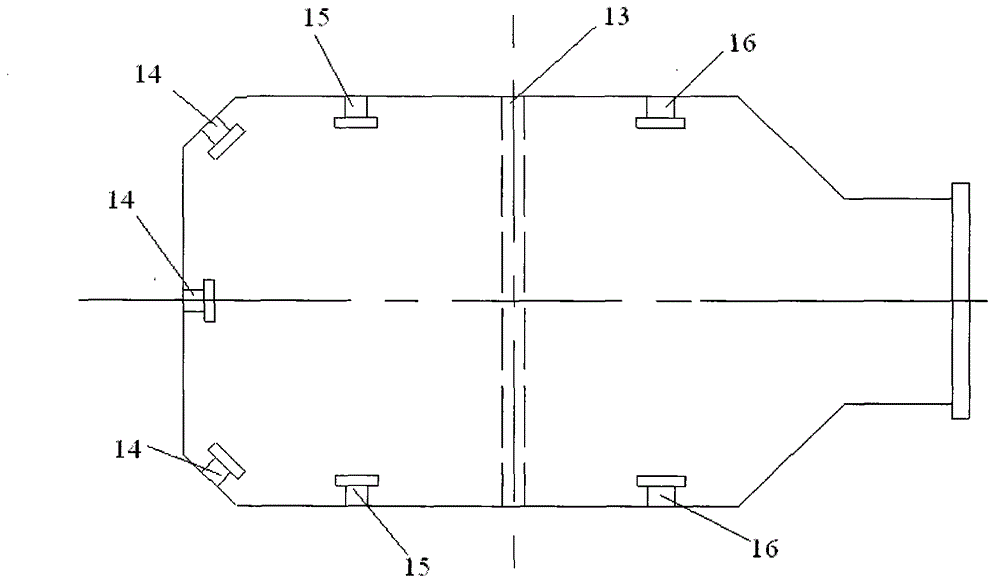

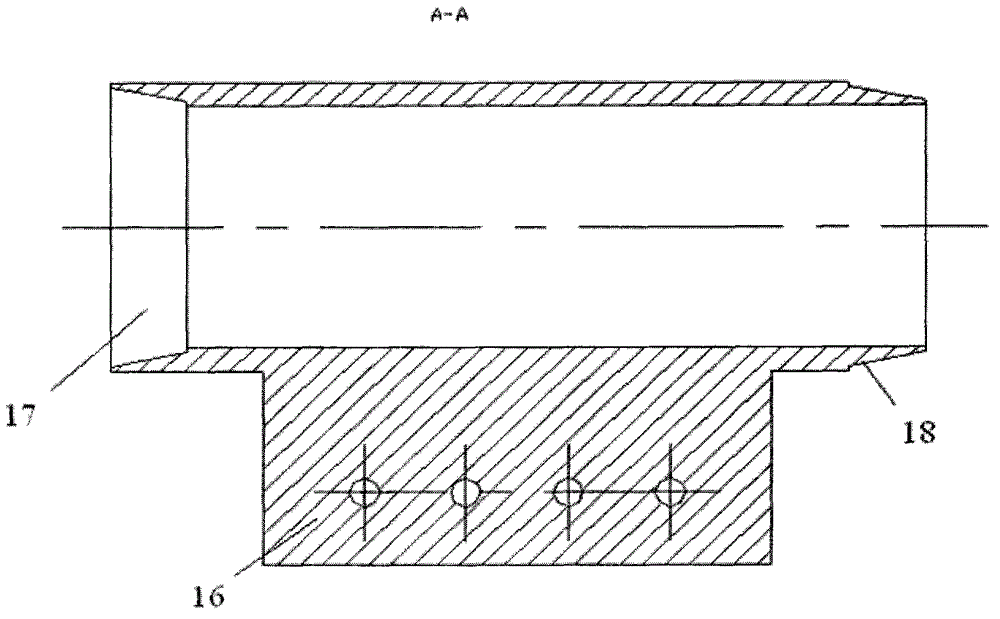

Oxygen supply system for engine reusing test

InactiveCN103486437AIncrease profitReduce flow rateEngine testingContainer filling methodsHigh pressure oxygenHigh pressure

The invention discloses an oxygen supply system for an engine reusing test. The oxygen supply system comprises an oxygen source system, an oxygen transporting system and an oxygen distribution table. In the oxygen source system, a process of preparing oxygen through a liquid oxygen vaporization method is adopted, and the utilization rate of raw liquid oxygen materials is improved. Through the real-time monitoring of a pressure sensor, the whole process can be safely performed. In the oxygen transporting system, measures are taken for control over the flow speed of an oxygen pipeline, a mode of connecting two pneumatic cutoff valves in parallel is adopted, and a small-aperture pneumatic cutoff valve is turned on in advance to be served as a pilot valve. The pressures of two ends of a large-aperture pneumatic cutoff valve are balanced, and the large-aperture pneumatic cutoff valve is turned on, so that a good effect of reducing the flow speed of high-pressure oxygen can be achieved. In the oxygen transporting system, a scheme of three main paths and an ignition path is adopted. A pipeline assembly can be reasonably selected according to test requirements.

Owner:BEIHANG UNIV

Internal combustion steam boosting take-off unit of airplane

InactiveCN102745333AReduce wall thicknessLight in massPower installationsCombustion chamberWater vapor

The invention relates to an internal combustion steam boosting take-off unit of an airplane, and belongs to the technical field of boosting take-off technology of airplanes. The internal combustion steam boosting take-off unit of the airplane comprises a combustion chamber, a balancing chamber, an air cylinder, an electromagnetic piston, an electromagnetic lantern ring, a breather pipe, a blow-off pipe and five valves. The outlet of the combustion chamber is connected with the balancing chamber through a pipeline. The electromagnetic piston is arranged inside the air cylinder and can slide and move. The electromagnetic lantern ring is sleeved outside the air cylinder. The electromagnetic lantern ring follows up under the effect of an electromagnetic force of the electromagnetic piston. A valve is arranged at the left end of the balancing chamber. Four of five valves are arranged on the side wall of the air cylinder. The combustion chamber is provided with a catalyst net, an oil spray hole, a gas injection hole and a water injection hole. High-pressure oil and high-pressure oxygen combust in the combustion chamber to generate gas. High-pressure water enters the combustion chamber through the water injection hole and steam turns into vapor. Then the vapor and the gas enter the balancing chamber to push the electromagnetic piston to move and the electromagnetic lantern ring follows up. The internal combustion steam boosting take-off unit of the airplane provided by the invention is small in electromagnetic energy consumption and light and simple in device. The internal combustion steam boosting take-off unit of the airplane provided by the invention is high in energy conversion ratio, energy-saving, economic and environment-friendly.

Owner:李文铎

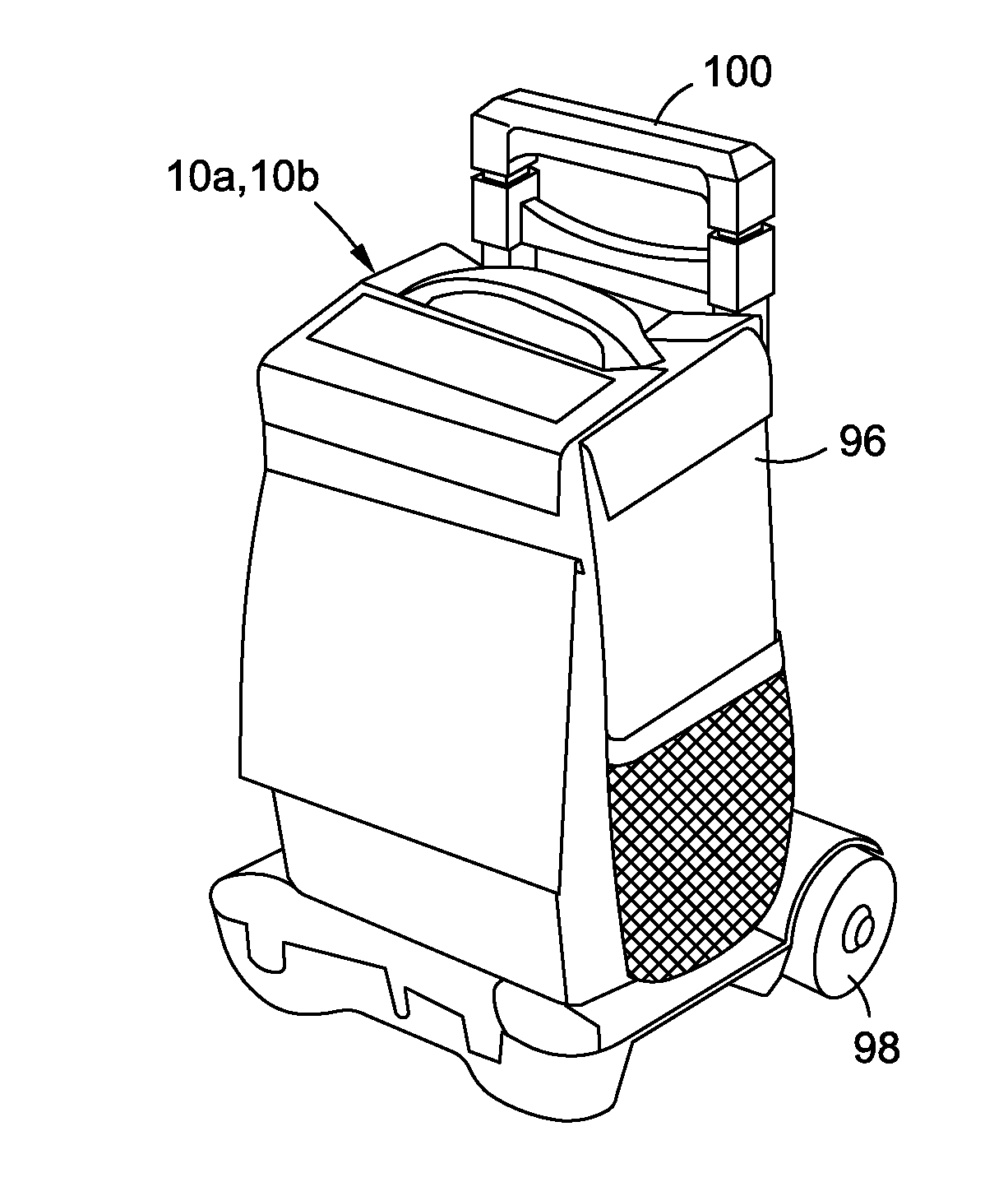

Oxygen concentrator for high pressure oxygen delivery with oxygen circulation loop and improved portability

ActiveUS20150196727A1High flow rateImprove pressure resistanceRespiratorsGas treatmentNitrogenHigh pressure oxygen

A portable oxygen concentrator is disclosed. An output of a high pressure compressor is fluidly coupled to an adsorbent device that increases the concentration of oxygen gas for storage in a high pressure accumulator. The adsorbent device is purged of the collected nitrogen via a valve fluidly coupled to the outlet of the high pressure compressor and the inlet of the adsorbent device. The outlet of the adsorbent device is fluidly coupled to the high pressure accumulator through a first valve. Additionally, a re-circulation loop fluidly couples the outlet of the adsorbent device to a valved inlet of the high pressure compressor.

Owner:BREATHE TECHNOLOGIES INC

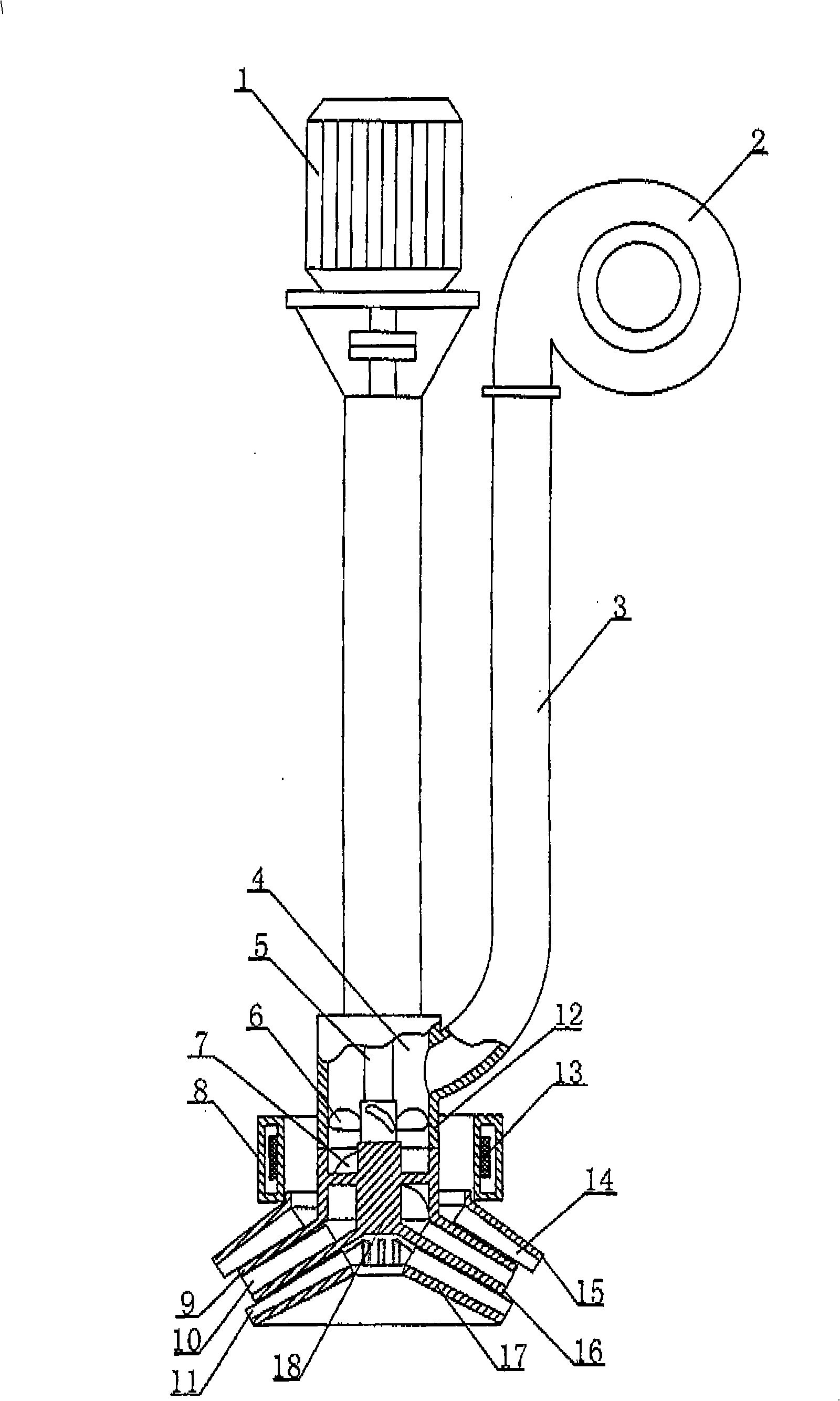

Centrifugal type double-tube activating aeration oxygen increasing machine

InactiveCN101322481AReasonable structural designIncrease pressureWater aerationPisciculture and aquariaDiffusionImpeller

A centrifugal double-barreled activation and aeration automatic aerator comprises a driving device, and is characterized in that the driving device is connected with a main shaft in a driving way, the lower end of the main shaft is provided with a horn mouth type combined centrifugal impeller, an outer coat of a fixing device is installed outside the main shaft at the upper end of the horn mouth type combined centrifugal impeller to form an oxygen gathering chamber that is communicated and provided with an oxygen supply tube, the horn mouth type combined centrifugal impeller is provided with aerobic vanes and water vanes for driving a water body to move. The centrifugal double-barreled activation and aeration automatic aerator has reasonable structural design and exterior high-pressure oxygen supply devices, thereby being capable of obviously improving the air pressure entering the water body, efficiently carrying out enforced down-diffusion for air which enters the water body, efficiently eliminating the aerobic dead angle, improving the oxygen-dissolved saturation degree, and further being capable of increasing air load amount. Air is efficiently enforced and operated to a larger and deeper water body while forming a large-scale aeration convection so that the aeration effect and the aeration scale of the water body is obviously improved. The automatic aerator can be widely applied to aeration of various water bodies in the fields of sewage purification, aquiculture, etc.

Owner:NANTONG TIANYUAN GAS

Spherical iron oxide and ultra-high density drilling fluid adopting spherical iron oxide as weighting agent

InactiveCN106753280AAcid solubleFeed speed controlFerric oxidesDrilling compositionHigh pressure oxygenVolumetric Mass Density

The invention provides spherical iron oxide. The spherical iron oxide is prepared from hematite by high-temperature flame melting, the hematite is conveyed by high-pressure oxygen to main combustion oxygen and natural gas combustion flame at a temperature being 2400 DEG C or higher, the hematite is molten by flames to form dispersed droplets, the droplets rapidly enter a cooling area under the action of negative pressure and are condensed into small spherical particles, and the spherical iron oxide is prepared accordingly. The feeding rate of the hematite is 10-40 Hz, the conveying amount of high-pressure oxygen is 110-190 m<3> / h, the amount of the main combustion oxygen is 550-660 m<3> / h, the consumption of the natural gas is 220-330 m<3> / h, and the oxygen enrichment coefficient is 1.0-1.3. According to ultra-high density drilling fluid adopting the spherical iron oxide as a weighting agent, the ultra-high density drilling fluid is prepared by taking the mixed spherical iron oxide as the weighting agent, and has good rheological property and settling stability, low water loss, high compressive strength and good cementing performance; the density of the drilling fluid is higher than 2.6 g / cm<3>.

Owner:天津泽希矿产加工有限公司

Valve for use in high pressure gas containers

InactiveUS20030131851A1Reduce the amount requiredRespiratorsOperating means/releasing devices for valvesHigh pressure oxygenEngineering

An on-off valve mounted in a high pressurized gas container, which has a holding portion for holding a flow amount controlling member in a path formed in an upper stream side of the body of the valve, and in which a flow amount controlling member is movably held. In the flow amount controlling member, an orifice is formed. When the valve moves into an opening position, a high pressurized oxygen gas is flowed into a valve chamber by gas pressure, the flow amount controlling member moves and closes the path. At this time, the gas flow amount is restricted by the orifice, so that the pressurizing speed of the gas pressure at the down stream side of the orifice becomes slow and then heat generation due to the adiabatic compression is reduced.

Owner:HAMAI INDS

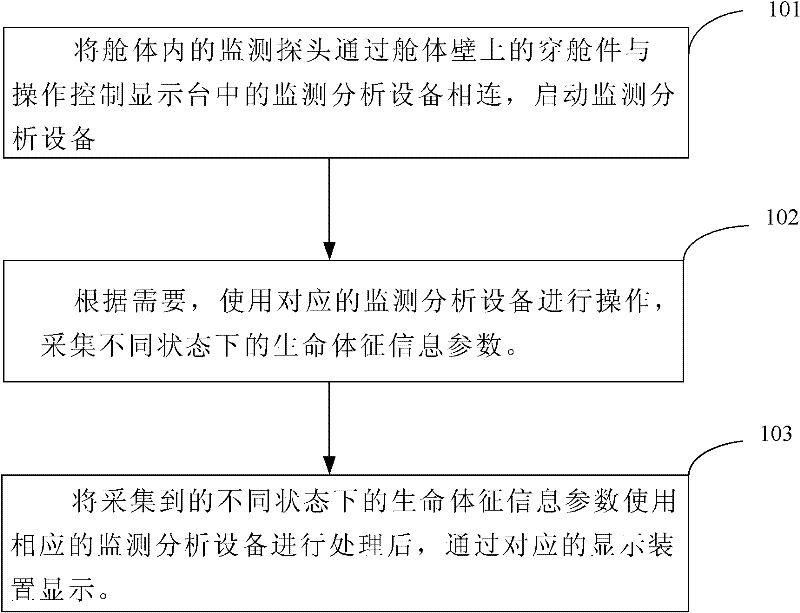

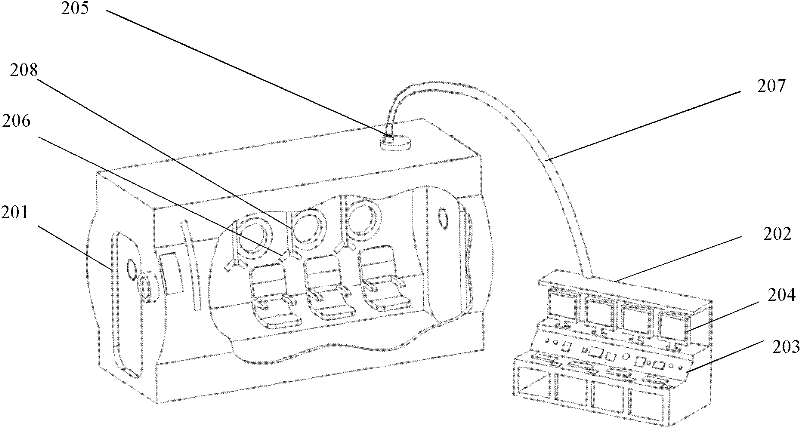

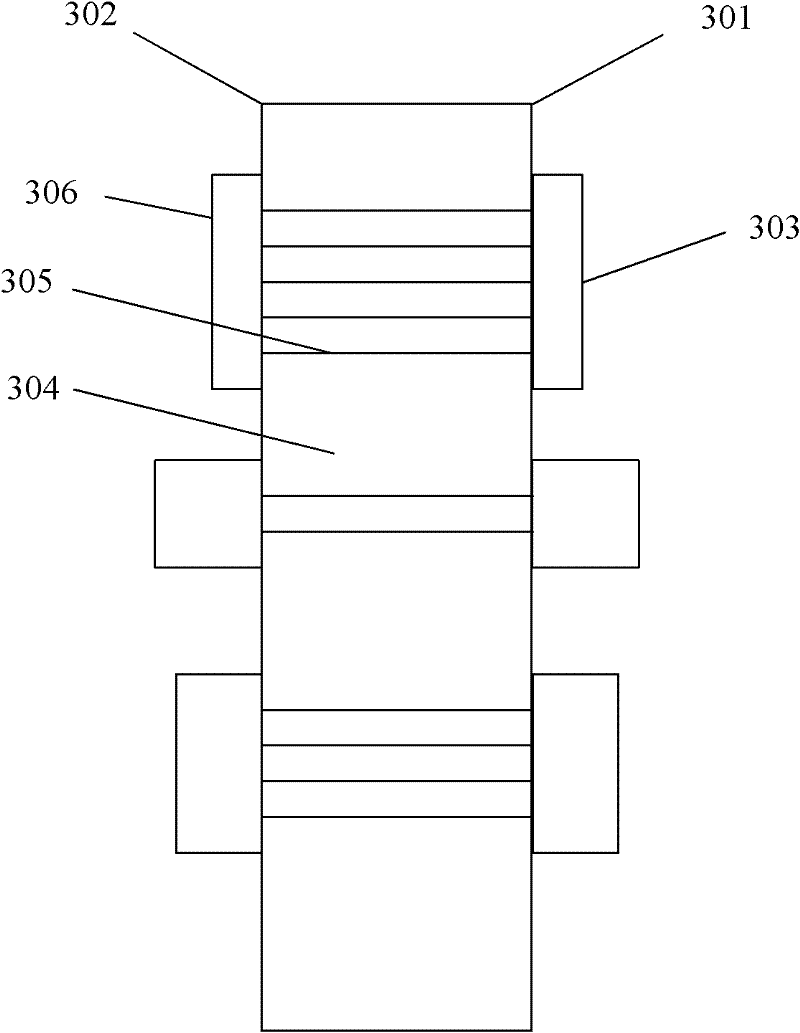

Vital sign monitoring method and system of high pressure oxygen cabin

ActiveCN102335079APrevent atmospheric leakageEnsure rated atmospheric pressureBreathing protectionTreatment roomsDisplay deviceHigh pressure oxygen

The invention discloses a vital sign monitoring method and system of a high pressure oxygen cabin. The vital sign monitoring method comprises the steps of: connecting a monitoring probe in a cabin body with a monitoring and analyzing device in an operation control display platform through a cabin penetrating member on the wall of the cabin body, starting the monitoring and analyzing device; acquiring various vital sign information parameters of a human body under different states by using the corresponding monitoring and analyzing device according to the demands; and displaying the acquired vital sign information parameters of the human body under different states through a corresponding display device. The technical scheme provided by the invention can be used for acquiring the vital sign information parameters of the human body under different states in the high pressure oxygen cabin.

Owner:常骅

Method for melting converter bottom by remaining converter slags

ActiveCN102719596AGuaranteed smelting effectAchieve dynamic balanceManufacturing convertersProcess efficiency improvementDynamic balanceSlag

The invention provides a method for melting a converter bottom by remaining converter slags. The method comprises the steps that: a small amount of slags are left when the converter tapping is finished, high-pressure oxygen is blowed into the converter by an oxygen lance, oxygen blowing time is controlled according to the distance between a oxygen lance nozzle and the converter bottom, temperature of the slags in the converter is heated, weak stirring of the high temperature slags is carried out, and the converter bottom is flushed by by an oxygen stream to achieve a purpose of reducing the height of the converter bottom. According to the invention, the height of a converter bottom of a top-bottom combined blowing converter can be controlled within a preset ideal range, the dynamic balance of the converter bottom can be realized, the top-bottom combined blowing smelting effect is ensured, and the smelting operation and maintenance of the converter body are facilitated; in addition, the smelting time can be shortened, the production cost can be reduced by shortening the converter smelting time by 1-2 min. The method of the invention has simple process and convenient operation, is safe and reliable, and has almost no corrosion to end-point parts of a converter liner such as a ball segment, a trunnion, a slag line, and the like.

Owner:ANGANG STEEL CO LTD

Smelting furnace soot treatment method

InactiveCN105039724AAchieve recyclingHigh purityProcess efficiency improvementSocial benefitsEconomic benefits

The invention relates to a smelting furnace soot treatment method, and belongs to the field of waste resourceful treatment. The smelting furnace soot treatment method comprises the steps of: (1) reductive roasting; (2) high-pressure oxygen leaching; (3) lead recovery; (4) copper recovery; and (5) zinc recovery. The smelting furnace soot treatment method, provided by the invention, can realize total recovery of lead, copper and zinc, so that obtained products are high in purity; meanwhile, the high-pressure oxygen leaching process is adopted to improve the recovery rate of lead, copper and zinc; a wet method is adopted to treat lead to prevent the pollution caused by lead steam; and the social benefit and the economic benefit are higher.

Owner:谭建新

Preparation method of low-loss ferrite bismuth-barium titanate-based piezoelectric ceramic

The invention discloses a low-loss BiFeO3-BaTiO3-based leadless piezoelectric ceramic and a preparation method thereof. The composition general formula of the low-loss BiFeO3-BaTiO3-based leadless piezoelectric ceramic is (1-x)(Bi1-tLat)FeO3-xBa(Ti1-uSnu)O3+0.5%BiMnO3+yBa(Cu1 / 3Nb2 / 3)O3+zLiBiO3+mBa(W1 / 2Cu1 / 2)O3, wherein t, x, u, y, z and m express mole fractions; t is larger than 0 and less than or equal to 0.02; x is larger than or equal to 0.15 and less than or equal to 0.30; u is larger than 0 and less than 0.05; y is larger than 0 and less than 0.05; z is larger than 0 and less than 0.05; m is larger than 0 and less than 0.05. The preparation method comprises the processes of preparing materials according to the composition general formula, ball milling, molding pills, discharging glue, sintering and the like. By adopting the technologies of reduction of sintering temperature, rapid heating and cooling and high pressure oxygen, volatilization of Bi element is reduced, oxygen vacancy is restrained, valence change of Fe<3+> is prevented in the cooling process, and therefore, the purpose of reducing dielectric loss is achieved, the high temperature leadless piezoelectric ceramic with the dielectric loss lower than 0.5% is prepared, and the leadless piezoelectric ceramic can be practically applied to the high temperature piezoelectric field.

Owner:GUILIN UNIV OF ELECTRONIC TECH

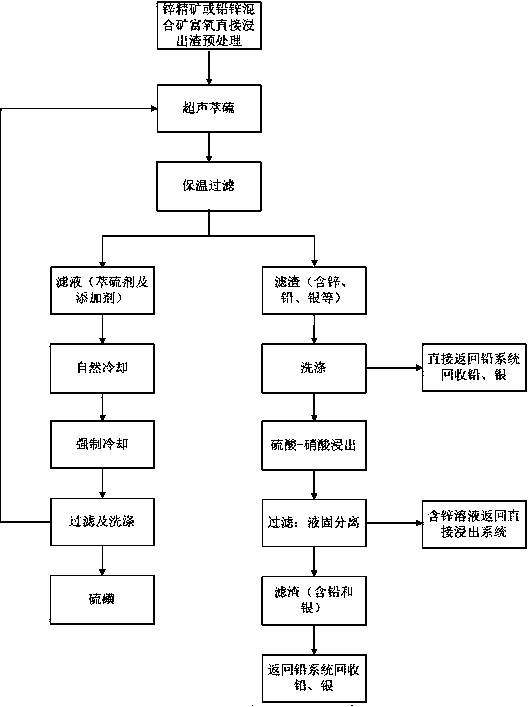

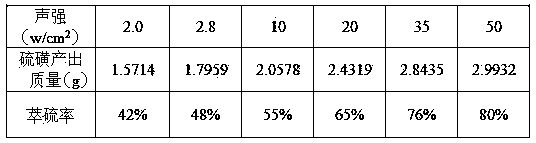

Method for recovering sulfur, lead, zinc and silver from oxygen-rich direct leaching residues of zinc concentrate or lead and zinc mixed ores by virtue of ultrasonic wave intensification

ActiveCN104195344AIncrease throughputReduce processingSulfur compoundsProcess efficiency improvementTetrachloroethyleneSulfur

The invention discloses a method for recovering sulfur, lead, zinc and silver from oxygen-rich direct leaching residues of zinc concentrate or lead and zinc mixed ores by virtue of ultrasonic wave intensification, belonging to the field of comprehensive recycling of non-ferrous metal metallurgy. The method disclosed by the invention comprises the following steps: by using tetrachloroethylene or trichloro ethylene as a solvent, extracting elemental sulfur from the oxygen-rich direct leaching residues of zinc concentrate or lead and zinc mixed ores, which are dried, ground, and sieved by virtue of ultrasonic wave intensification, preserving heat and filtering, after naturally cooling and forcibly cooling the filtrate and filtering to obtain a sulfur product, and returning a regenerated sulfur extraction agent to a sulfur extraction step; and enriching zinc, lead and silver in the residues, wherein the residues can be directly fed to a lead system to recover zinc, lead and silver, or the residues are firstly leached to recover zinc, filter residues are fed to the lead system to recover silver, and zinc-containing filtrate is returned to a direct leaching system. The method disclosed by the invention is simple, energy-saving and high in sulfur recovery rate and product quality. The sulfur extraction process is sealed, so that the method is free from environmental pollution and is particularly suitable for comprehensively utilizing normal pressure / high pressure oxygen-rich direct leaching residues of zinc concentrate or lead and zinc mixed ores.

Owner:株洲起源科技有限责任公司

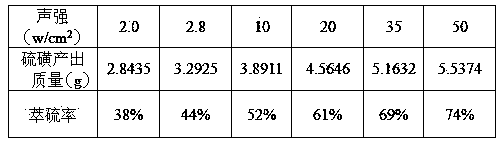

Method for comprehensively recovering cobalt, copper and iron in cobalt-copper alloy

ActiveCN103436708ASmall granularityPowder shape changeFerric oxidesProcess efficiency improvementPregnant leach solutionPtru catalyst

The invention discloses a method for comprehensively recovering cobalt, copper and iron in a cobalt-copper alloy. The method is a full hydrometallurgical process and mainly comprises the following steps of: firstly, performing atomization oxidation on the molten cobalt-copper alloy by adopting high-pressure oxygen or oxygen-rich air to prepare powder; then adding a leaching agent, a catalyst and the cobalt-copper alloy into an autoclave, performing pressurized catalytic oxidative leaching to ensure that cobalt and copper in the cobalt-copper alloy are oxidized and leached out and enter a leach solution in the form of ions, wherein iron in the cobalt-copper alloy is leached, converted and finally remained in leach residues in the form of iron oxide red; finally, separating, purifying and refining the obtained leach solution to respectively obtain a cobalt product and a copper product which meet the international standard, and performing magnetic separation on the leach residues by adopting a strong magnetic separation method to obtain an iron oxide red product meeting the international standard. The method has the advantages of short flow, simplicity in operation, low energy consumption, high metal recovery rate, low cost and the like, and the comprehensive recovery utilization of the high-content iron in the cobalt-copper alloy is realized.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

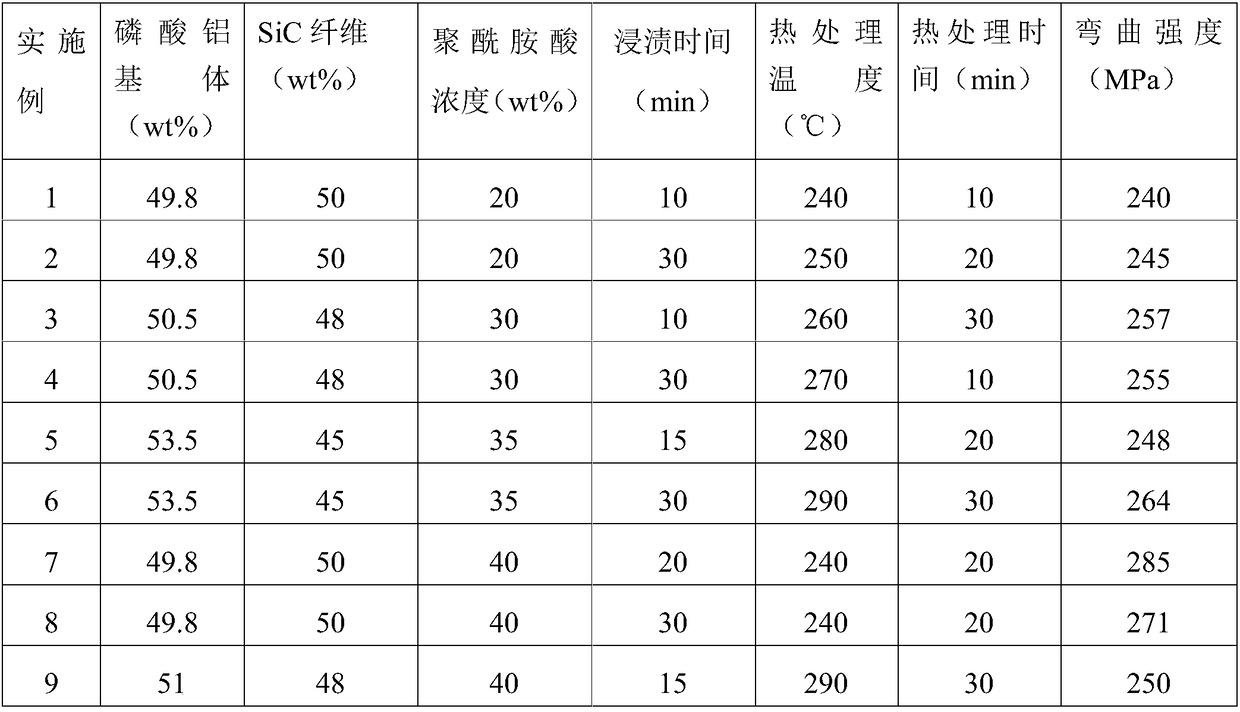

Silicon carbide fiber reinforced aluminium phosphate ceramic-based composite and preparation method thereof

The invention relates to a silicon carbide fiber reinforced aluminium phosphate ceramic-based composite and a preparation method thereof. The silicon carbide fiber reinforced aluminium phosphate ceramic-based composite comprises the following components in percentage by mass of 40% of silicon carbide fiber cloth, 45%-55% of an aluminium phosphate basal body, and 5%-15% of a polyimide resin basal body. The preparation method comprises the preparation steps of putting silicon carbide fiber cloth in a polyamic acid solution for immersing for 10-30min after the silicon carbide fiber cloth is degummed and dried, then taking out the immersed silicon carbide fiber cloth, and performing solidifying to obtain the silicon carbide fiber cloth containing an oxidation resistant coating; uniformly coating an aluminium phosphate sizing agent onto the outer surfaces of the silicon carbide fiber cloth containing the oxidation resistant coating, then stacking up the silicon carbide fiber cloth coated with the aluminium phosphate sizing agent, and then performing vacuum immersing and die pressing, so that the silicon carbide fiber reinforced aluminium phosphate ceramic-based composite is obtained. The combination effect of fibers and the basal body is good, so that the intensity and the tenacity of the composite are improved, and under the high-pressure oxygen-free environment, the composite canalso maintain high mechanical properties.

Owner:QINGHAI UNIVERSITY

Oxygen concentrator for mechanical ventilation

An oxygen concentrator is configured to provide oxygen at either lower pressures or higher pressures. When providing low pressure oxygen, the disclosed oxygen concentrator may be used with a conventional, low pressure oxygen delivery device, such as an oxygen cannula or mask, that is configured to deliver oxygen at approximate source pressures of 5 psig to 8 psig. When providing high pressure oxygen, the disclosed oxygen concentrator may be used with a high pressure oxygen delivery device, such as a low profile nasal cannula, that is configured to deliver oxygen at higher pressures. The disclosed oxygen concentrator is configured to automatically select whether low pressure oxygen or high pressure oxygen should be output to the user based on the type of connector used to couple a delivery device thereto, or based on characteristics of the delivery device itself.

Owner:INOGEN INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com