Internal combustion steam boosting take-off unit of airplane

An aircraft and booster technology, applied in aircraft parts, auxiliary power equipment, transportation and packaging, etc., can solve the problems of huge mass, insufficient power, low efficiency, etc., to achieve high output power, increased fuel capacity, high pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

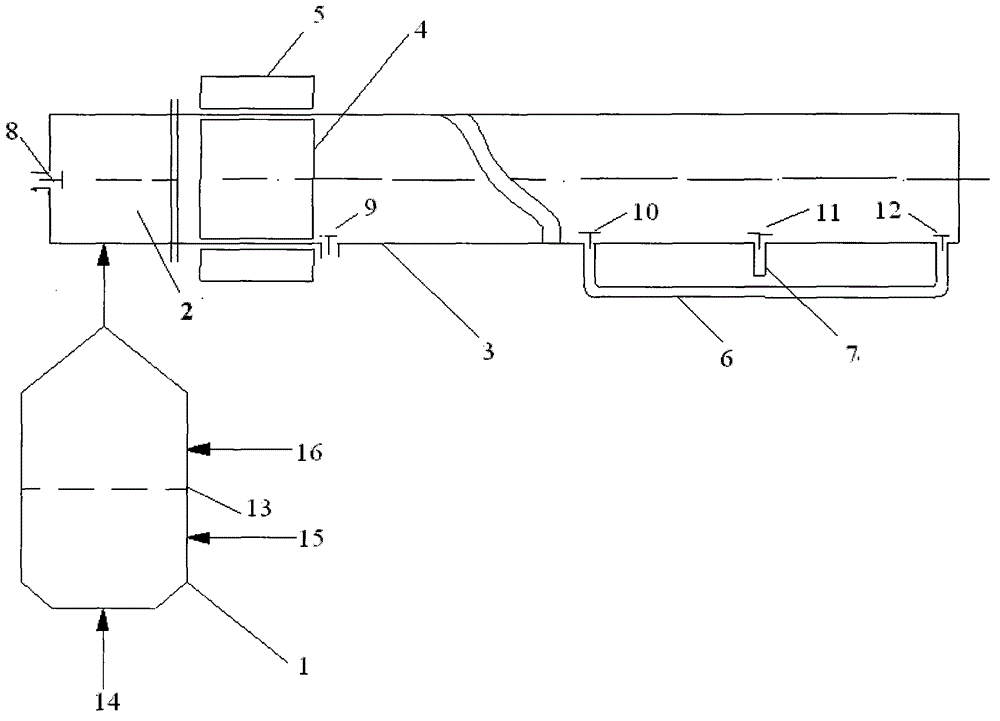

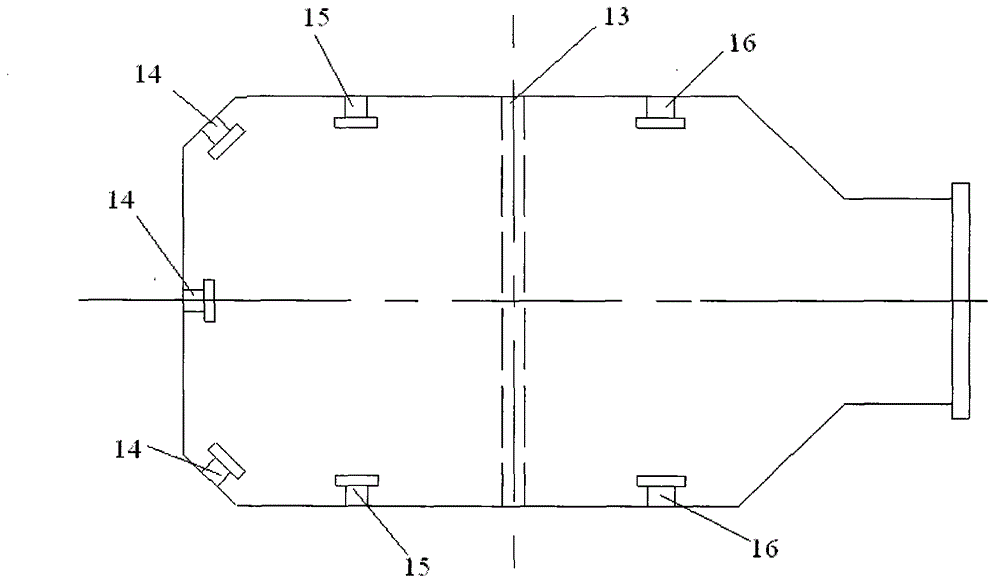

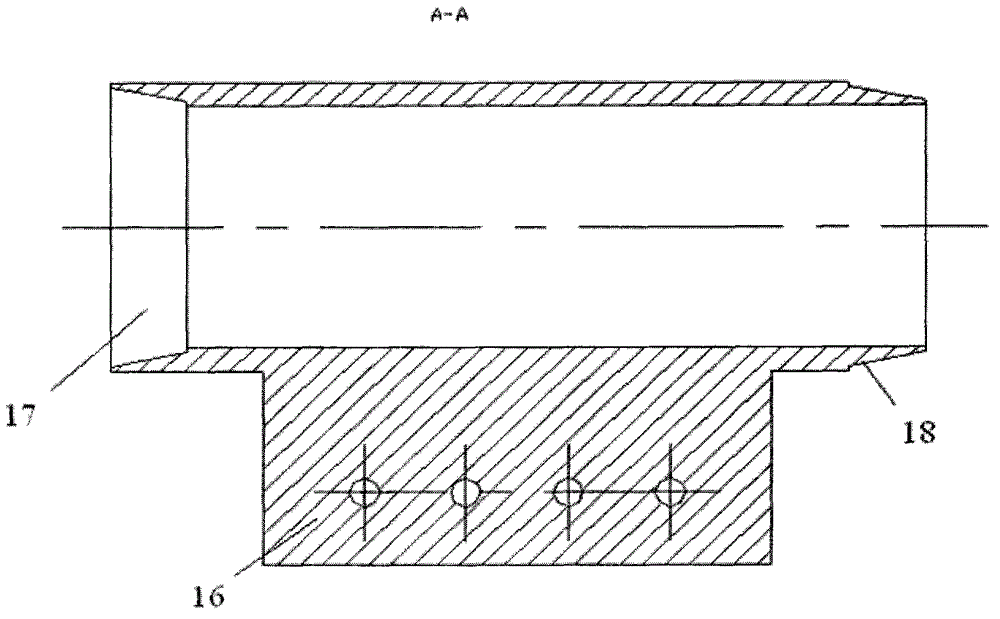

[0042] As a device for catapult take-off of aircraft carrier aircraft, internal combustion steam aircraft booster launcher, such as figure 1 As shown, it includes a combustion chamber 1, a balance chamber 2, a cylinder 3, an electromagnetic piston 4, an electromagnetic collar 5, a vent pipe 6 and a vent pipe 7; the outlet of the combustion chamber 1 is connected to the balance chamber 2 through a pipeline; the electromagnetic piston 4 is in The inside of the cylinder 3 can slide and move; the electromagnetic collar 5 is set on the outside of the cylinder 3; the electromagnetic collar 5 follows the electromagnetic force of the electromagnetic piston 4; there are 4 valves on the side wall of the cylinder 3; Combustion chamber 1 is a cylinder, such as figure 2 As shown, there is a catalyst net 13 in the middle, and there are oil injection holes 14 and air injection holes 15 at the bottom, and high-pressure fuel (enters the combustion chamber 1 through the oil injection holes 14)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com