Manufacturing technique for oxygen-enriched side blowing molten pool raw copper smelting and special equipment thereof

A melting pool smelting and production process technology, applied in crucible furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problems of aggravating environmental pollution caused by the discharge of coal-fired flue gas, high energy consumption of closed blast furnaces, and high energy consumption of depletion processes. Achieve the effect of being convenient for large-scale production, good environmental protection effect and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

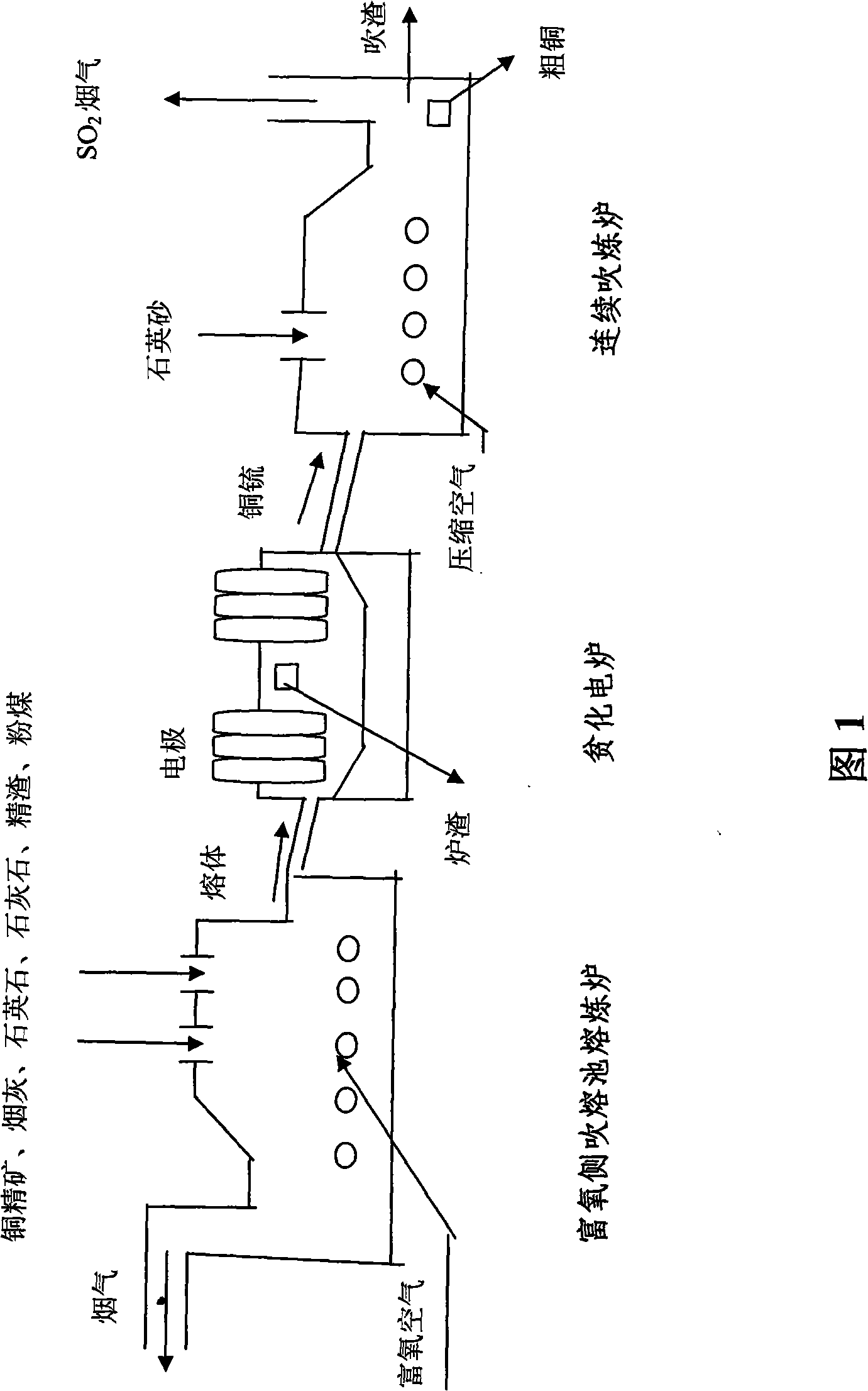

[0044] Embodiment 1: a kind of production technique (referring to Fig. 1) of smelting blister copper in oxygen-enriched side-blown molten pool, comprises the steps:

[0045] Copper concentrate smelting:

[0046] According to weight percentage, 75% of copper concentrate, 1% of soot, 6% of fine slag, 8% of quartz stone, 4% of limestone, and 6% of pulverized coal are mixed evenly and then fed into the side-blown furnace from the furnace top feed port through the feed belt. High-pressure (0.18Mpa) oxygen-enriched air (oxygen concentration 45%) is blown into the wind eye to form a violent agitation for the melt in the molten pool, and the mass and heat transfer processes in the molten pool are carried out rapidly, completing a series of chemical reactions and forming Copper matte (grade 65%), slag and high-temperature flue gas (1100°C-1200°C), copper matte and slag flow into the depleted electric furnace continuously through the chute, and the high-temperature flue gas recovers was...

Embodiment 2

[0051] Embodiment 2: a kind of production technique (referring to Fig. 1) of smelting blister copper in oxygen-enriched side-blown molten pool, comprises the steps:

[0052] Copper concentrate smelting:

[0053] According to weight percentage, 80% of copper concentrate, 2% of soot, 2% of fine slag, 4% of quartz stone, 5% of limestone, and 7% of pulverized coal are mixed evenly and fed into the side-blowing furnace through the feeding belt through the feeding port on the top of the furnace. High-pressure (0.17Mpa) oxygen-enriched air (oxygen concentration 38%) is blown into the wind eye to form a violent agitation for the melt in the molten pool, and the mass and heat transfer processes in the molten pool are carried out rapidly, completing a series of chemical reactions and forming Copper matte (grade 58%), slag and high-temperature flue gas (1100°C-1200°C), copper matte and slag flow into the depleted electric furnace continuously through the chute, and high-temperature flue ...

Embodiment 3

[0058] Embodiment 3: a kind of production technology (referring to Fig. 1) of smelting blister copper in oxygen-enriched side-blown molten pool, comprises the steps:

[0059] Copper concentrate smelting:

[0060] 85% of copper concentrate, 4% of quartz stone, 5% of limestone, and 6% of pulverized coal are mixed according to weight percentage. ) Oxygen-enriched air (oxygen concentration 30%) forms violent stirring for the melt in the molten pool, the mass transfer and heat transfer process in the molten pool proceeds rapidly, completes a series of chemical reactions, and forms copper matte (grade 50%), slag And high-temperature flue gas (1100°C-1200°C), copper matte and slag flow into the depleted electric furnace continuously from the chute, and the high-temperature flue gas recovers waste heat and sends it to acid production.

[0061] Slag depletion:

[0062] After the copper matte and slag flow into the depleted electric furnace, the slag is clarified and separated from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com