Patents

Literature

336results about How to "Fast leaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling copper, nickel, chromium, zinc and iron from plating sludge

The invention relates to a method for recycling copper, nickel, chromium, zinc and iron from plating sludge, belonging to the technical field of chemical engineering and metallurgy. The method comprises the following steps: acid leaching, vulcanizing for separation and enrichment, hot-pressure leaching, extracting for separation, hot-press oxidizing chromium, purifying chromium solution, extracting ferric chloride and the like. The method has obvious advantages of strong adaptability to different kinds of plating sludge, high utilization of metal resources, high value-added content of product,less process waste residue, thorough deintoxication and the like.

Owner:YANGZHOU NINGDA NOBLE METAL CO LTD

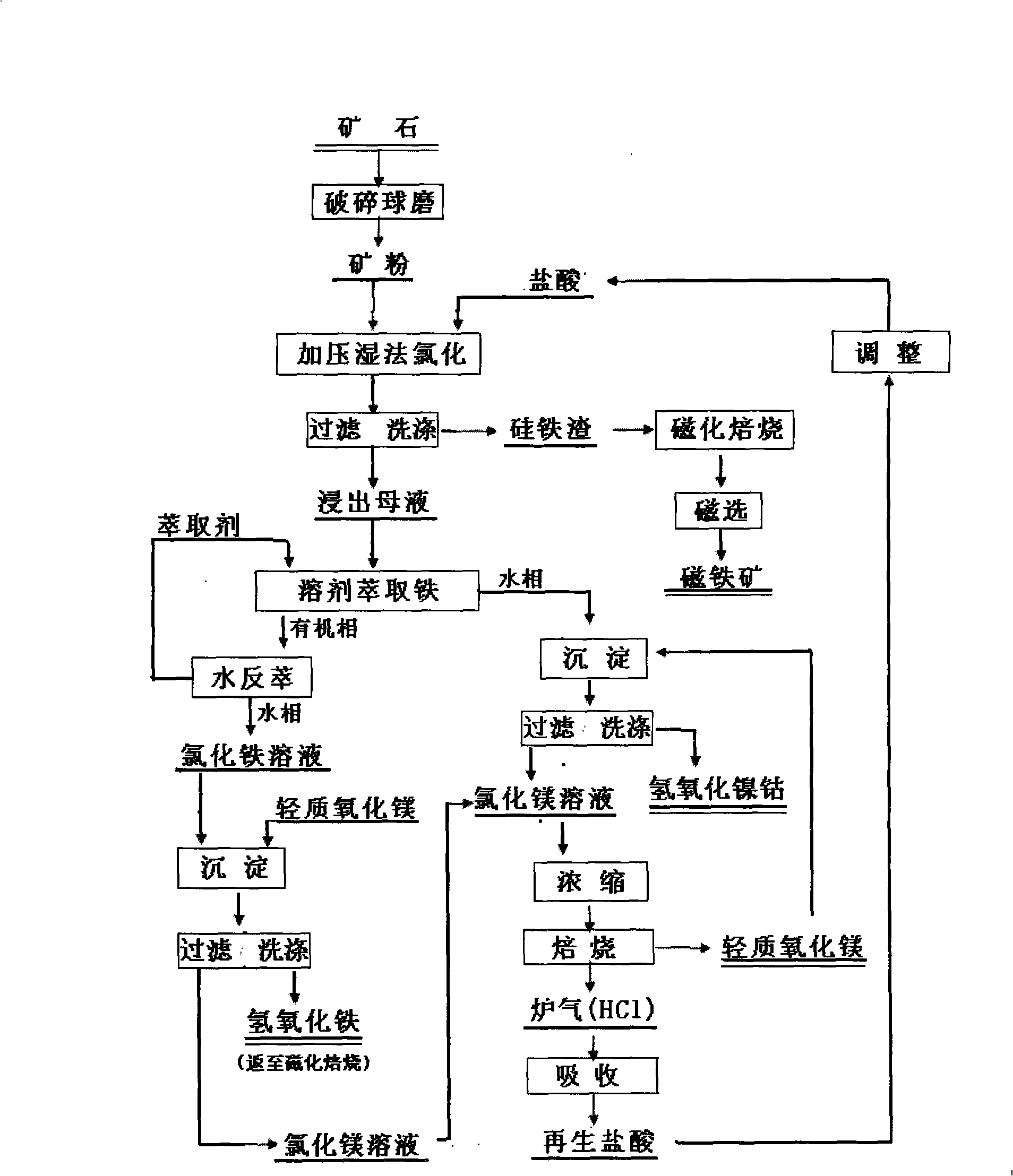

Process for comprehensively developing and utilizing nickel, cobalt, iron and magnesium from laterite-nickel ore

The invention relates to a method for compressively developing and utilizing nickel and cobalt in a lateritic nickel ore. The lateritic nickel ore is used as the raw material; the technical flows of mining, defibrination and ore preparation, pressurizing and wet chlorinating extraction, separating the nickel (cobalt) and iron by extraction, hydrolyzing magnesium chloride with a high temperature, magnetizing and roasting the extracted slag, magnetically separating, etc., and the like, are adopted to extract the middle product of the nickel and cobalt, recycle the light magnesium chloride and the materials used for pudding. The invention is mainly characterized in that the nickel and cobalt in the lateritic nickel ore is firstly and selectively dissolved and extracted by using the pressurized muriatic acid; a depositing method is used on the nickel and cobalt in a liquid to obtain the middle product; the mother liquid after the nickel is deposited is hydrolyzed by high temperature to obtain the light magnesium chloride and the chlorine hydride is recycled to obtain the muriatic acid; a material used for pudding is obtained after the extracted slag is reduced, magnetized, roasted and weakly separated in a magnetic way; the recycling muriatic acid enters the working period of extraction, thereby leading the muriatic acid to closely circulate. The method of the invention comprehensively recycles nickel and cobalt, magnesium and iron and has the advantages of high nickel and cobalt extraction rate, low cost, less investment and closed muriatic acid circulation. The whole technique is simple, clean, environmental friendly and is applicable for industrial production with large scale in particular.

Owner:CENT SOUTH UNIV

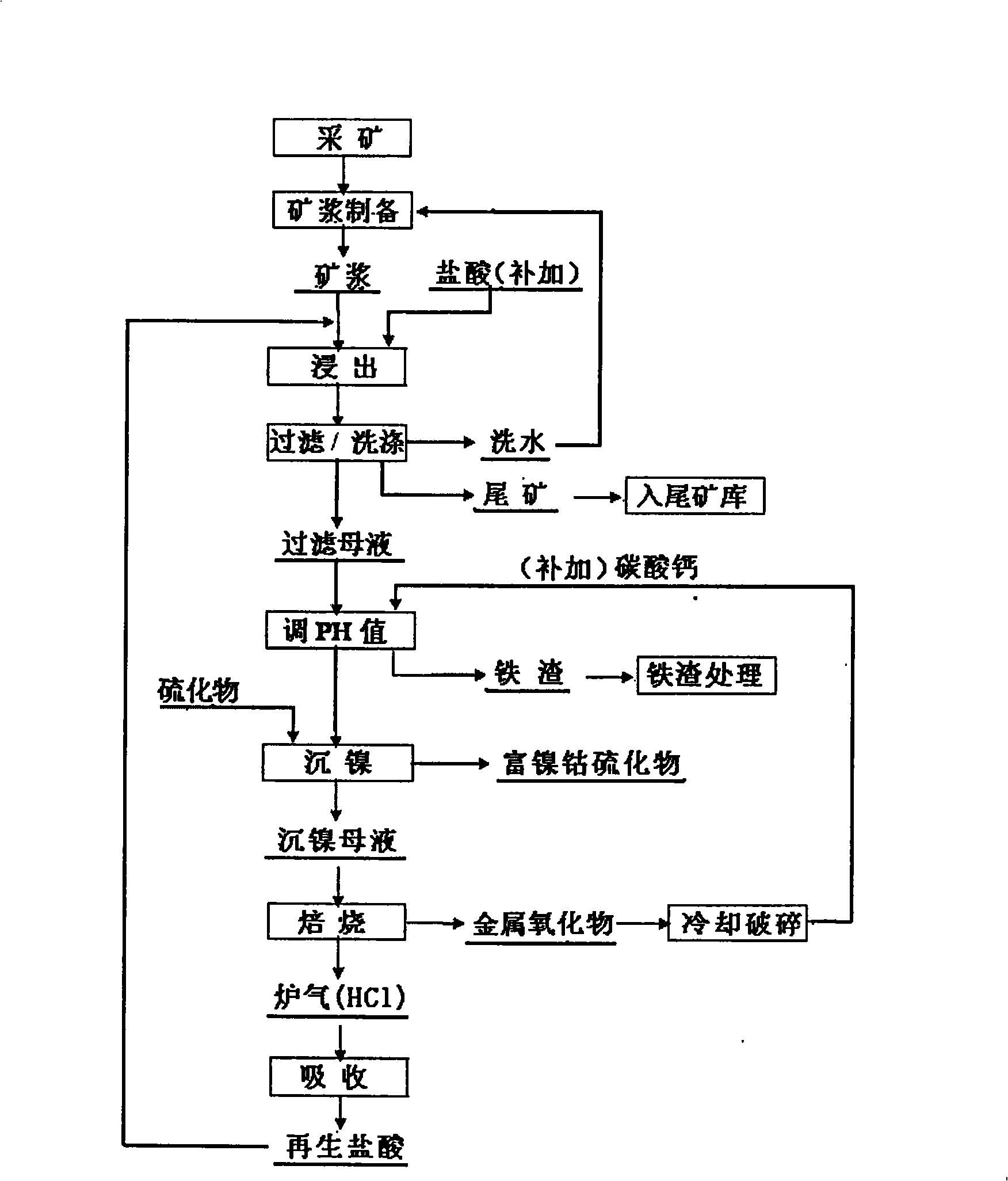

Process for extracting nickel and cobalt from laterite-nickel ore

InactiveCN101338374ARealize closed loop recyclingImprove leaching rateProcess efficiency improvementMetal chlorideSlurry

The invention discloses a method for extracting nickel and cobalt from a lateritic nickel ore which includes the steps of: (1) preparing the slurry of the ore: cracking the ores and preparing the slurry; (2) dipping the ores with muriatic acid: adding the muriatic acid in the slurry of the ore to carry out stirring and extraction under a normal pressure; (3) separating the solid and liquid; (4) neutralizing an extraction liquid; (4) sulfurizing and depositing the nickel; (6) regenerating the muriatic acid: the mother deposition liquid after nickel depositing is concentrated and roasted, the metal chloride in the mother liquid is hydrolyzed into chlorine hydride and metal oxide; the chlorine hydride after being absorbed by water obtains the regenerated muriatic acid and return to the working procedure of ore extraction; the metal oxide after being cracked and grinded returns to the working procedure of neutralizing. The method of the invention has a simple flow and an environment protective technique; the application range to resources is large; besides, the extraction speed is fast; the impurity removing capacity is high; the extraction rate of the nickel and cobalt is high; the method realizes the closed circulation of HCl and the comprehensive utilization of the resources.

Owner:CENT SOUTH UNIV

Method for quickly leaching gold and silver by using mixed leaching agent

The invention discloses a method for quickly leaching gold and silver by using a mixed leaching agent, which comprises the following steps of: crushing gold-containing pyrite smelting slag, a sulfide-containing visible gold ore or / and a gold-containing oxidized ore serving as raw materials, conditioning the raw materials with water to form slurry, adding ammonium thiocyanate, thiocarbamide, urea and an oxidant, namely manganese dioxide or ferric chloride, into the ore slurry and stirring and leaching the mixed slurry to leach the gold and silver out. The method has the advantage that: the mixed leaching agent formed by adding the urea into the ammonium thiocyanate can quickly leach the gold and the silver out of the sulphur and arsen-containing gold ore by adding the urea with a low cost, particularly the gold and the silver which are contained in pyrolusite can be leached out with a lower cost. At the same time, beneficial elements in the ores can be comprehensively used.

Owner:梁伟基 +1

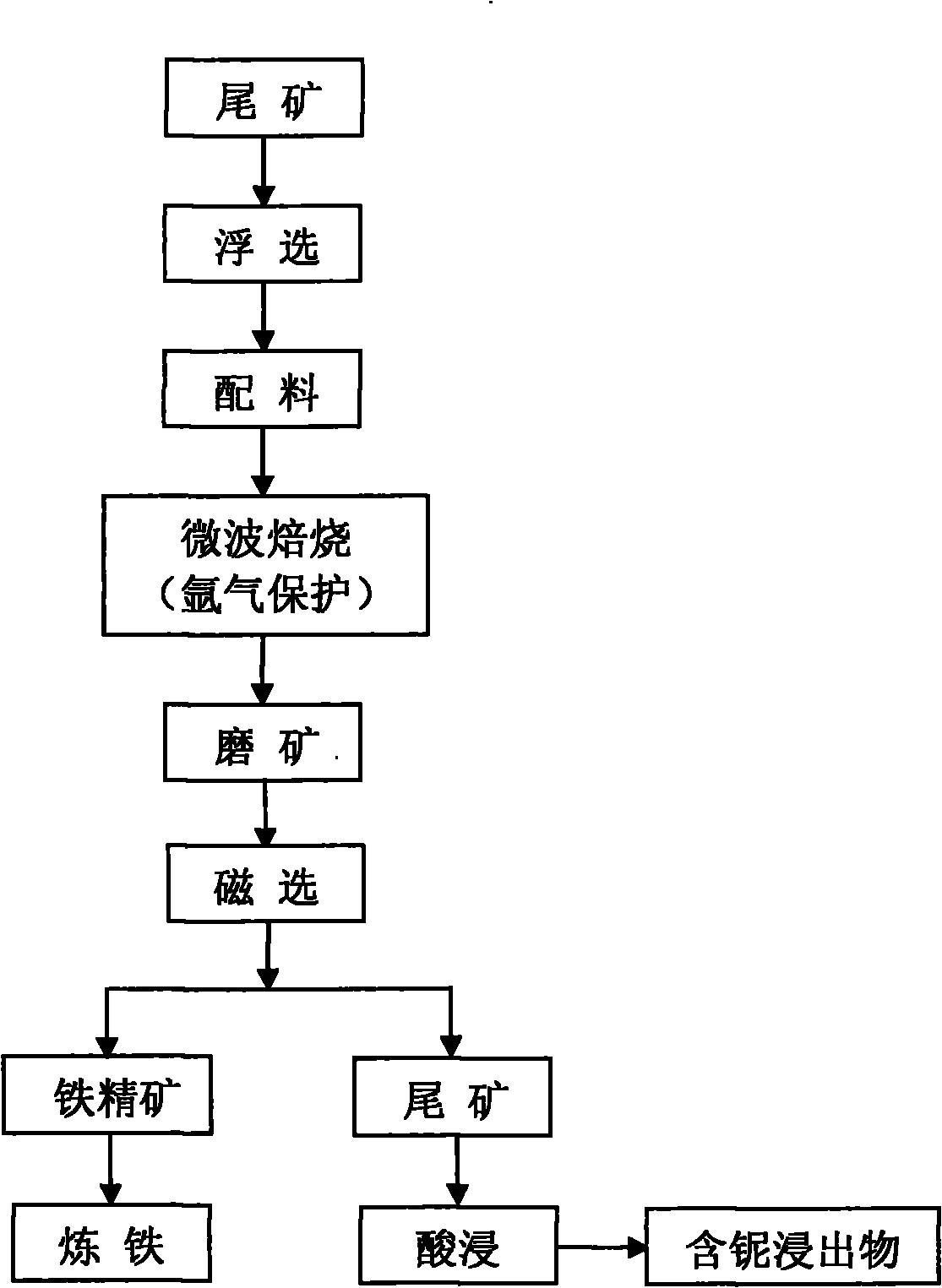

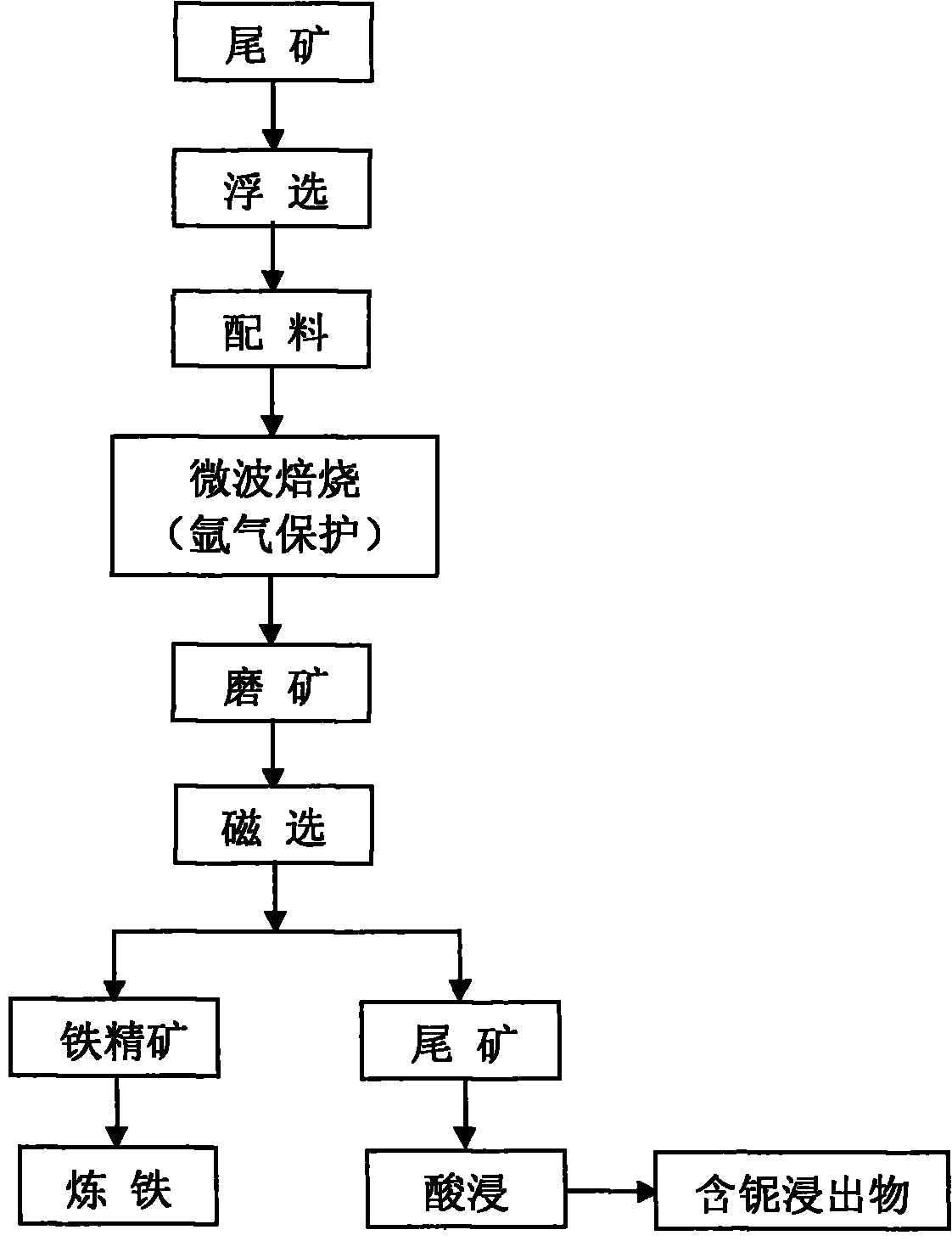

Method for extracting niobium from tailings

The invention relates to a method for extracting niobium from tailings, belonging to the technical field of mineral extraction metallurgy. The method includes the steps as follows: (1) treating the tailings with a flotation method so as to float out iron and niobium minerals from the tailings; (2) using a microwave magnetizing-roasting method and adding carbonaceous reducing agent in the floated minerals so as to convert the haematite in the minerals into magnetite; (3) separating the magnetite out from the roasted minerals by adopting a low-intensity magnetic separation method, thus enriching the niobium minerals in the tailings subjected to magnetic separation; and (4) leaching the obtained niobium minerals out in a high-pressure kettle with concentrated acid so as to obtain niobium-containing extract. The method flow is short, flotation agent types are few and the flotation effect is good; the mineral roasting time is short, the consumption quantity of reducing agent is less and the cost is low; the content of hazardous elements such as S, P and the like in the magnetite obtained by low-intensity magnetic separation is low simultaneously when niobium is enriched, niobium is an excellent material for making iron with a blast furnace, and environment pollution caused by the tailings is solved to a large extent.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

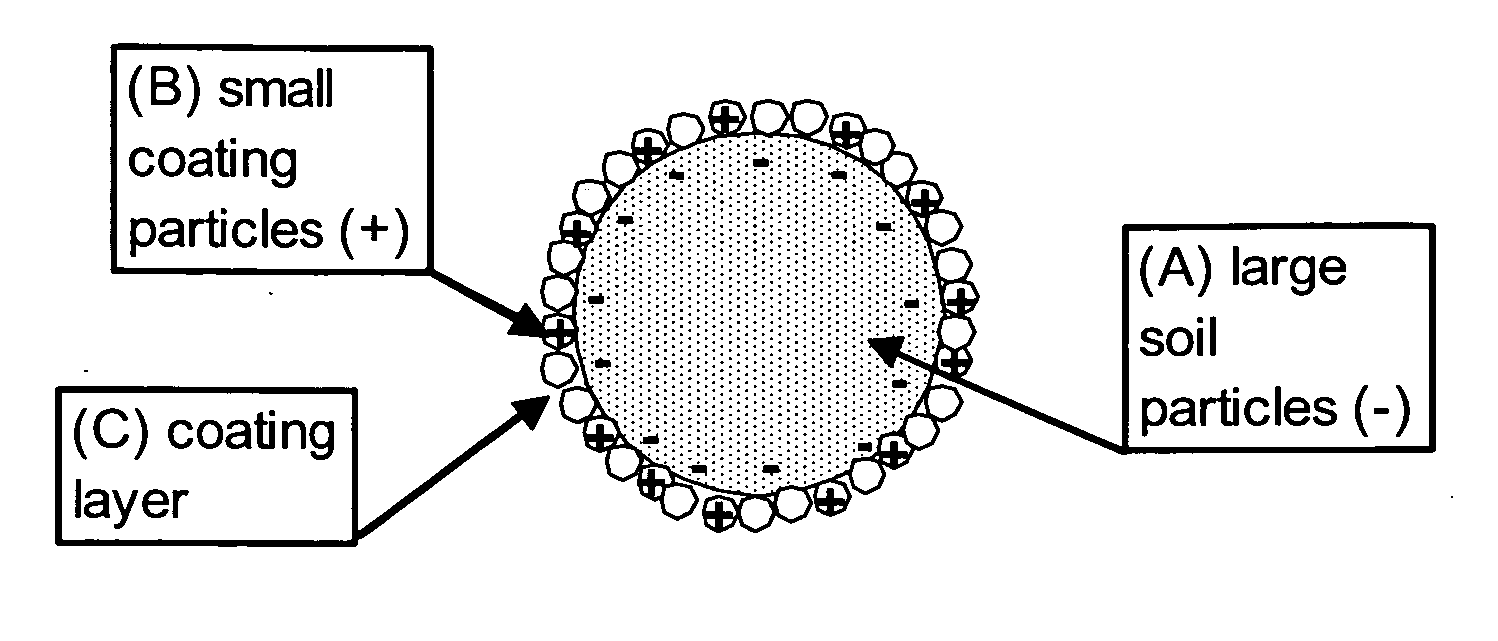

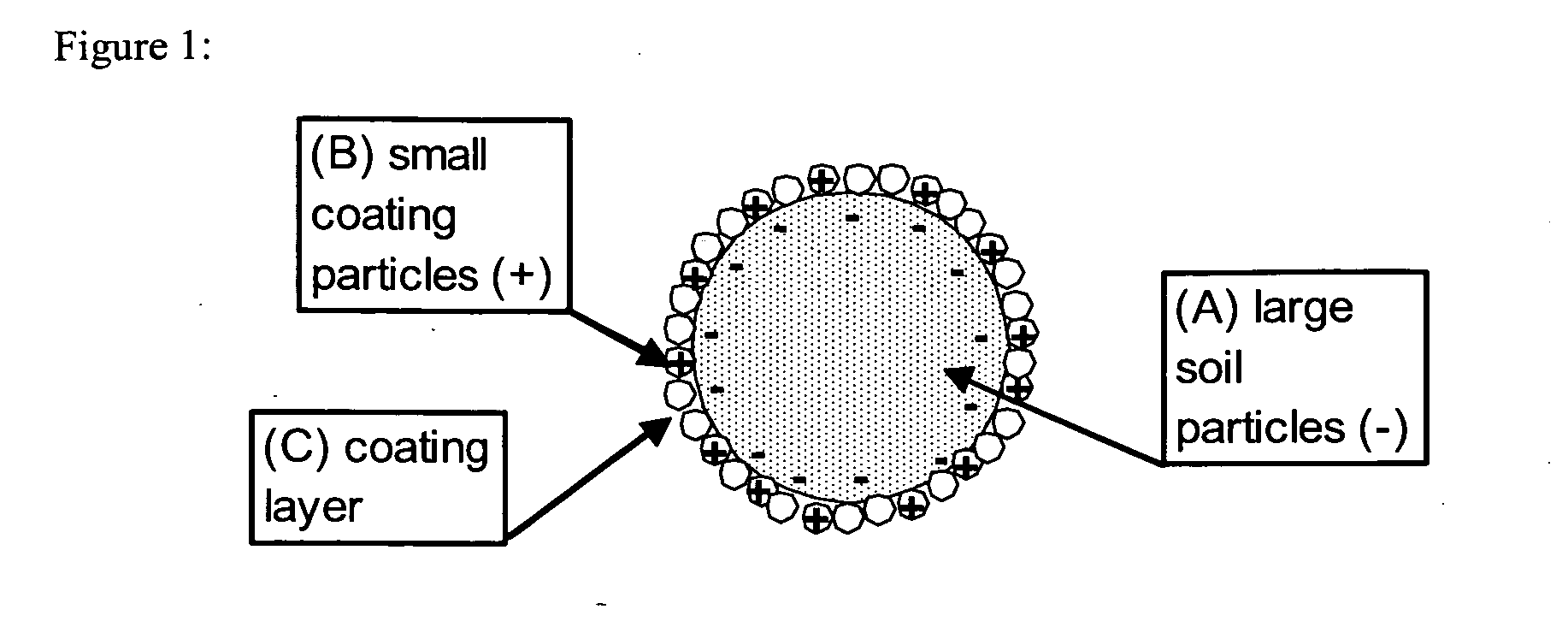

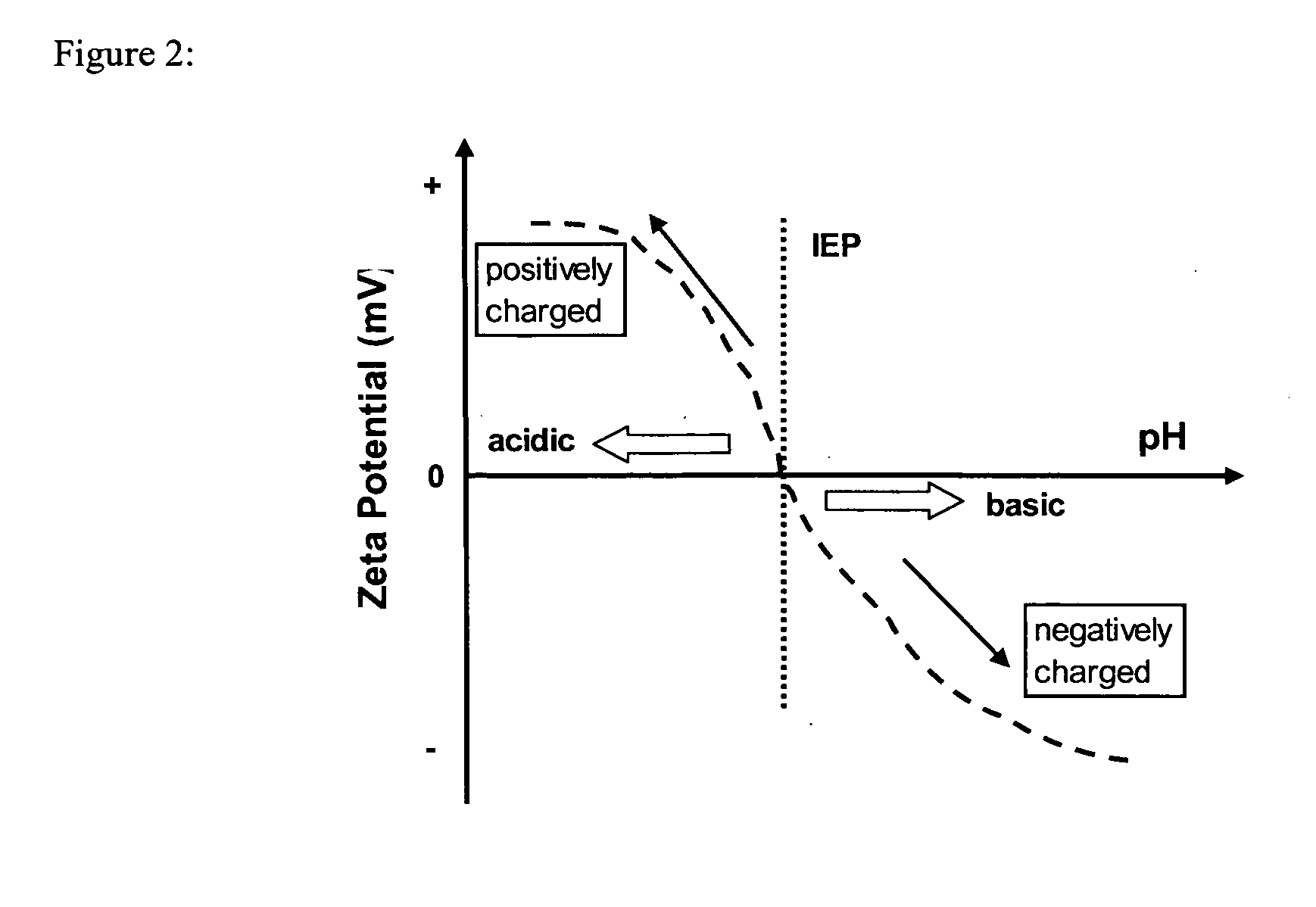

Soil remediation through surface modification

InactiveUS20110044761A1Increase productivityLong-terms robustnessContaminated soil reclamationLayered/coated fertilisersFreezing thawingSoil remediation

Composition and process of surface modification of soil particles by coating to improve fertility, better moisture and nutrients retention, flooding resistance, and longer freeze-thaw-freeze cycle life.

Owner:CHANG YUN FENG

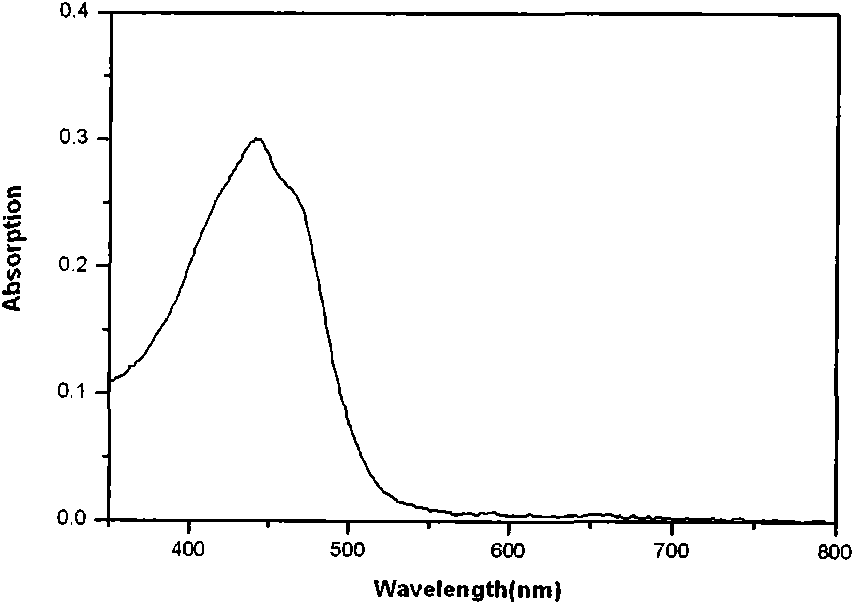

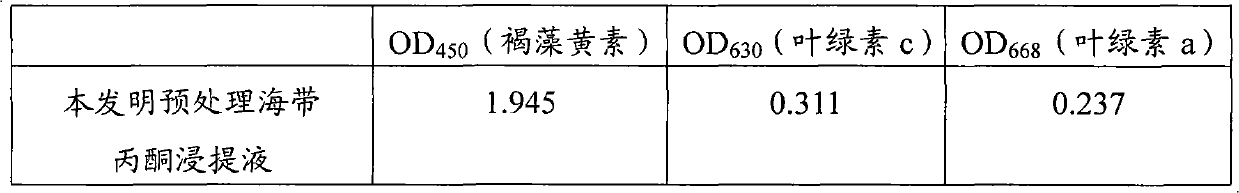

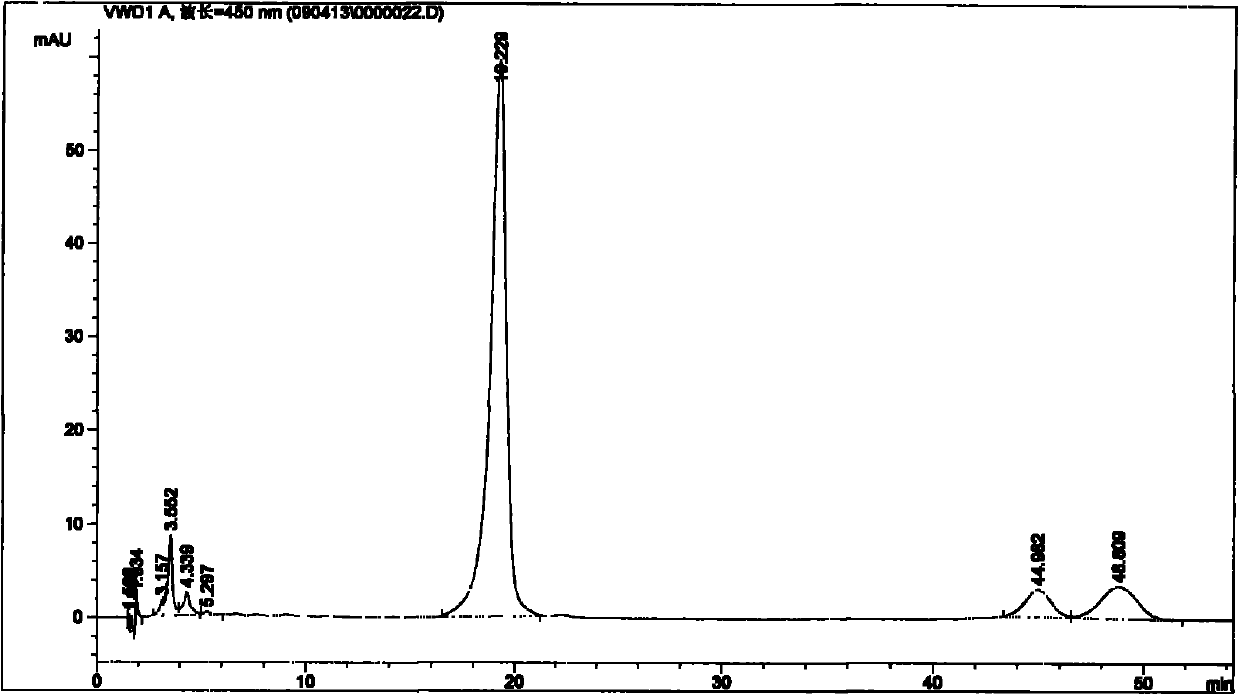

Method for extracting fucoxanthin from brown algae

The invention relates to a method for extracting fucoxanthin from brown algae. The method comprises the following steps of: performing water swelling pretreatment on the crushed brown algae, and leaching the brown algae by using a water-soluble organic solvent; purifying fucoxanthin in leaching solution by adopting an extraction method and twice column chromatography in turn; and finally, further purifying to obtain a fucoxanthin standard substance with the purity of over 90 percent or over 99 percent through preparative thin-layer chromatography or preparative high performance liquid chromatography. The method for extracting the fucoxanthin has the advantages of simple, economic and efficient technology, and capacity of providing an experimental basis for industrial production of the fucoxanthin and improvement of industrial utilization rate of the algae.

Owner:秦皇岛惠恩生物技术有限公司

Method of recycling metals from wasted lithium ion batteries

InactiveCN107293820AFast leachingReduce dosageWaste accumulators reclaimingBattery recyclingElectrochemical responseSodium-ion battery

The invention relates to the technical field of recovery of wasted lithium ion batteries, and particularly provides a method of recycling metals from wasted lithium ion batteries. The method includes the following steps: 1) recycling a cathode waste material of the lithium ion batteries, and processing the cathode waste material into electrode sheets; 2) with the electrode sheets as a cathode and an inert electrode as a counter electrode, performing an electrochemical reaction in an acidic electrolyte to leach-out metals, thus forming a solution containing metal ions; 3) regulating the pH of the solution to 9-10, fully stirring the solution, performing centrifugation to obtain a supernatant, adding 1,2,4,5-benzenetetracarboxylic acid to the supernatant, and performing a hydrothermal reaction at 100-160 DEG C for 5-12 h to form a metal organic composite material, wherein the metal is Ni and / or Co. Through the electrochemical method, metals in the cathode is leached out, wherein completeness of leaching is guaranteed; meanwhile, the leached metals are coordinated with organic substances to form a new lithium ion battery cathode or a positive pole of a super-capacitor. The method develops a new application direction of valuable metals in wasted cathodes.

Owner:广州盘太能源科技有限公司

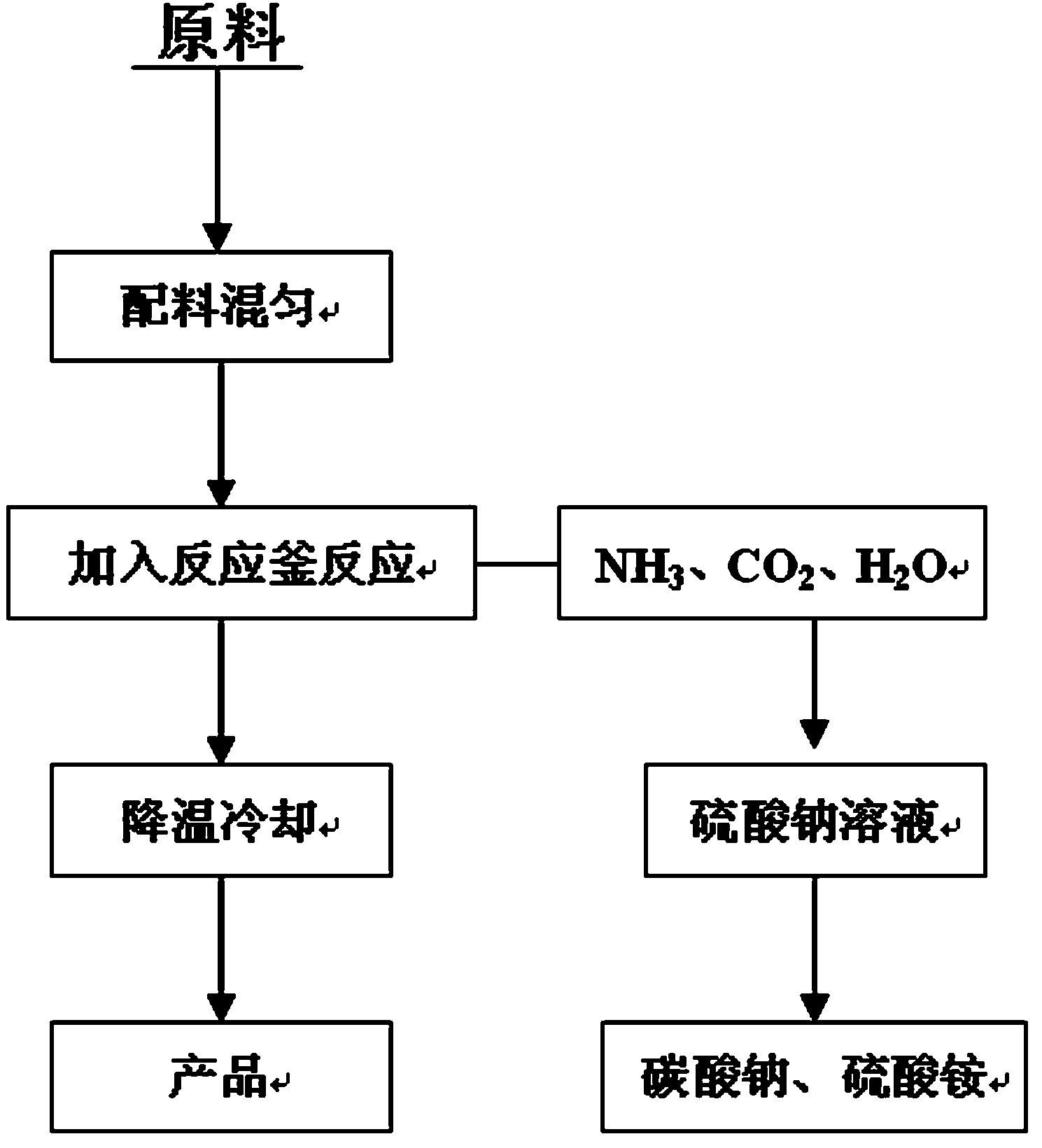

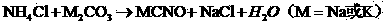

Beneficiation reagent, synthesis method and method for comprehensively utilizing generated waste gases

The invention discloses a beneficiation reagent, a synthesis method and a method for comprehensively utilizing generated waste gases. The beneficiation reagent is formed by solid-phase synthesis of inorganic or organic raw materials and comprises the following raw materials in parts by weight: 300 to 700 parts of a nitrogen-containing compound, 500 to 800 parts of chlorine salt, 400 to 650 parts of carbonate, 80 to 160 parts of strong alkali, 50 to 500 parts of cyanide complex double salt, 0 to 300 parts of cyanate, 5 to 20 parts of potassium sulfide, 50 to 200 parts of carbon and 0 to 100 parts of lime nitrogen. The beneficiation reagent is prepared by the following steps: mixing the raw materials uniformly; adding the mixed raw materials into a reaction kettle; quickly heating to 500 to 1,200 DEG C; maintaining high temperature for 1 to 2 hours; and cooling and crushing to obtain the product. Ammonia gas and carbon dioxide generated in a synthesis process are absorbed by a sodium sulfate solution to generate byproducts sodium carbonate and ammonium sulfate. The invention has the advantages of low production cost, simple operation, low toxicity and easy control. The product can be widely applied to leaching of noble metals such as gold oxide ores and silver oxide ores, floatation inhibitors and metal heat treatment and electroplating industries.

Owner:YUNNAN KEENLY NEW MATERIAL

Extraction process for lychee seed saponin

The invention discloses an extraction process for lychee seed saponin. The process comprises the following steps: 1) lychee seeds are pulverized, a certain amount of lychee seed powder is weighted and is soaked with water, and combinative enzyme reagent, which accounts for 1 to 2 percent of the weight of the lychee seed powder, is added in for enzymolysis treatment; 2) ethanol solution is added in for ultrasonic extraction, so as to obtain ultrasonic extracting solution; 3) filtering treatment and vacuum concentration treatment are conducted to the ultrasonic extracting solution, so as to obtain lychee seed saponin coarse extractive; and 4) macroporous adsorption resin is adopted to sublimate the lychee seed saponin coarse extractive, so as to obtain the lychee seed saponin. In the process, cell walls are softened and degraded through enzymes; with the combination of ultrasonic cavitation, the cell walls are fully destroyed, and the dissolution of active ingredients is accelerated and increased; and through the nonpolar macroporous adsorption resin, saponin ingredients of the lychee seeds are concentrated and separated, so as to prepare the high-content lychee seed saponin. The process has the advantages of time and labor conservation, lower cost and the like.

Owner:GUANGZHOU HOSPITAL OF TRADITIONAL CHINESE MEDICINE

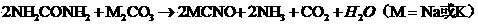

Method for increasing content of rare saponin in ginseng raw material by explosion of steam

The invention relates to a method for preparing raw materials containing rare ginsenoside Rg3, Rh2 and the like for medicines, foods and healthcare products through process steps of wetting, steam explosion and the like of an acid reagent by taking ginseng, American ginseng, ginseng stem leaves and ginseng stem leaves as raw materials. The method disclosed by the invention has advanced process and is simple and feasible, the products prepared by the method disclosed by the invention contain the rare ginsenoside Rg3, Rh2 and the like, and the leaching rate of effective elements is high, the leaching is rapid, and effective elements are easy to be absorbed by human bodies. The products can be applied to the medicines, the foods and the healthcare products directly or after being simply processed.

Owner:JILIN AGRICULTURAL UNIV

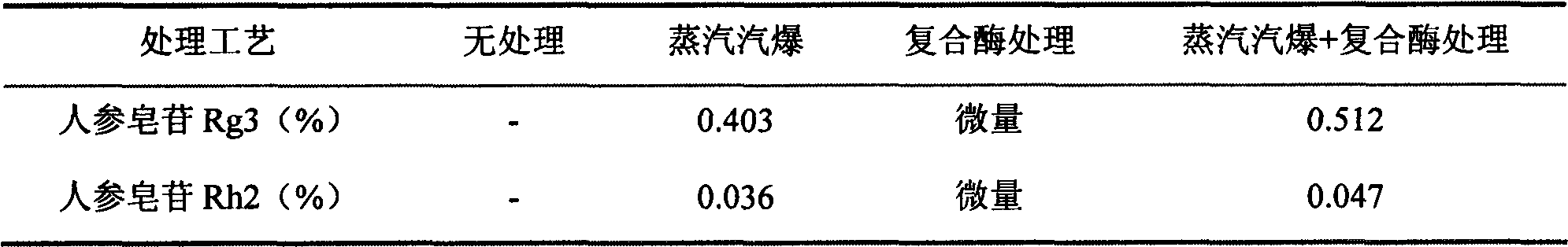

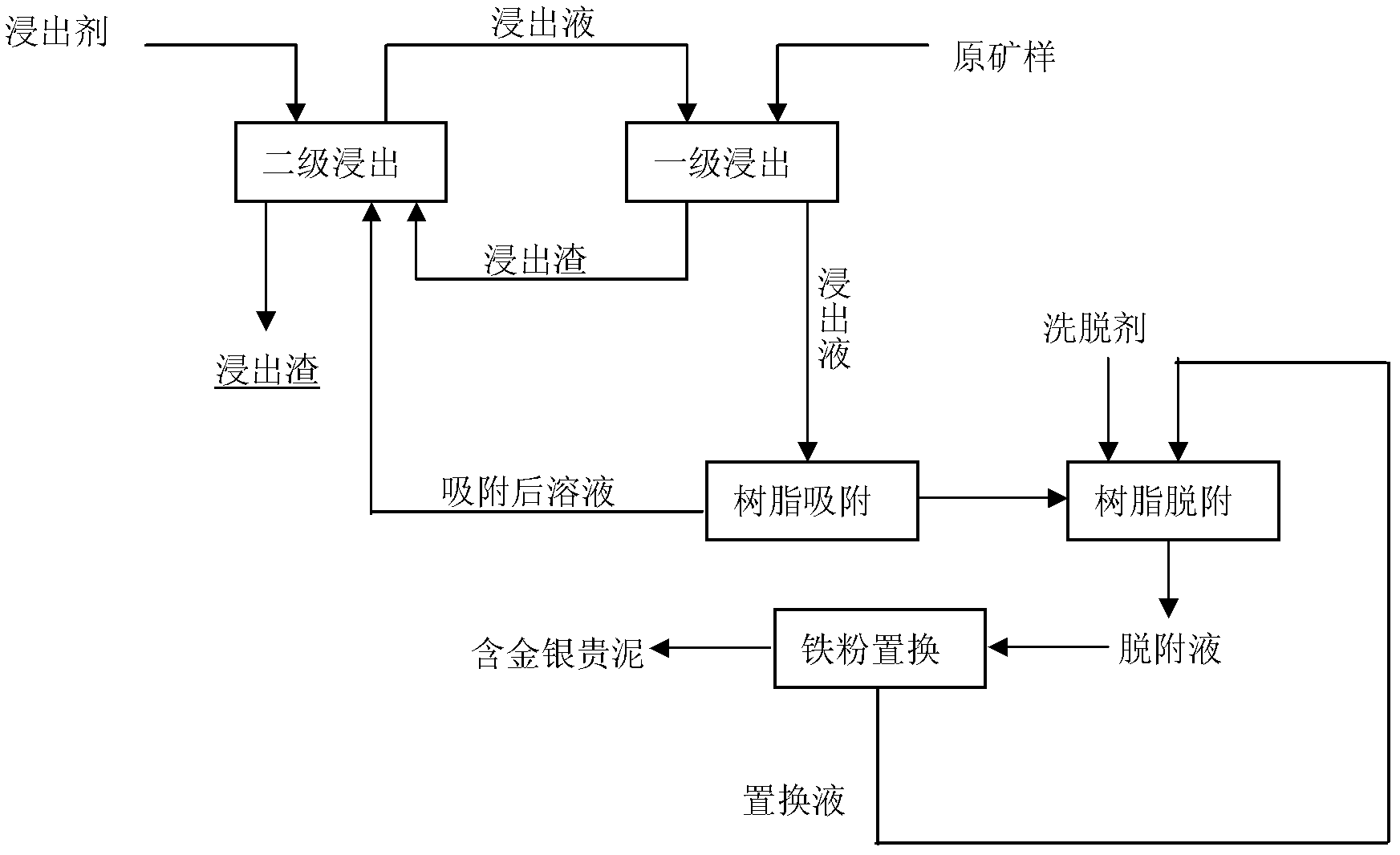

Method for extracting gold and/or silver from sulfuric acid slag

The invention discloses a method for extracting gold and / or silver from sulfuric acid slag. The method comprises the following steps: performing multi-stage countercurrent leaching on sulfuric acid slag containing gold and silver by using an acidic thiourea solution; adsorbing a leachate by using an ester-based thiourea resin column; and after elution of a dilute acid, performing replacement and reduction by using iron to obtain noble mud containing gold and silver. The adsorption solution and the replacement solution can respectively return to a former process to be used as a leaching agent and an eluting agent; and in the operating process, wastewater and waste residues are not discharged, so that the method has remarkable environmental and economic benefits.

Owner:CENT SOUTH UNIV

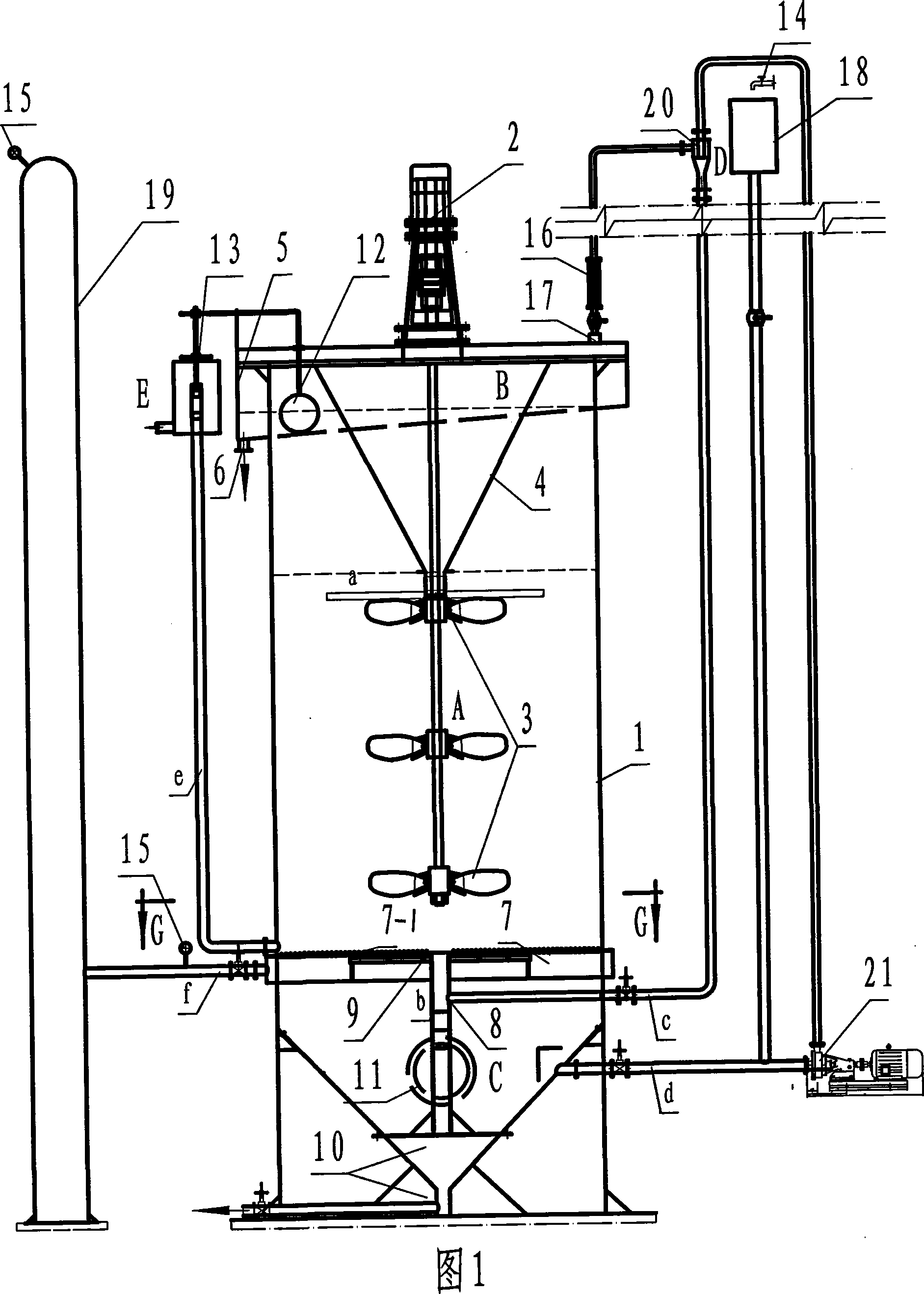

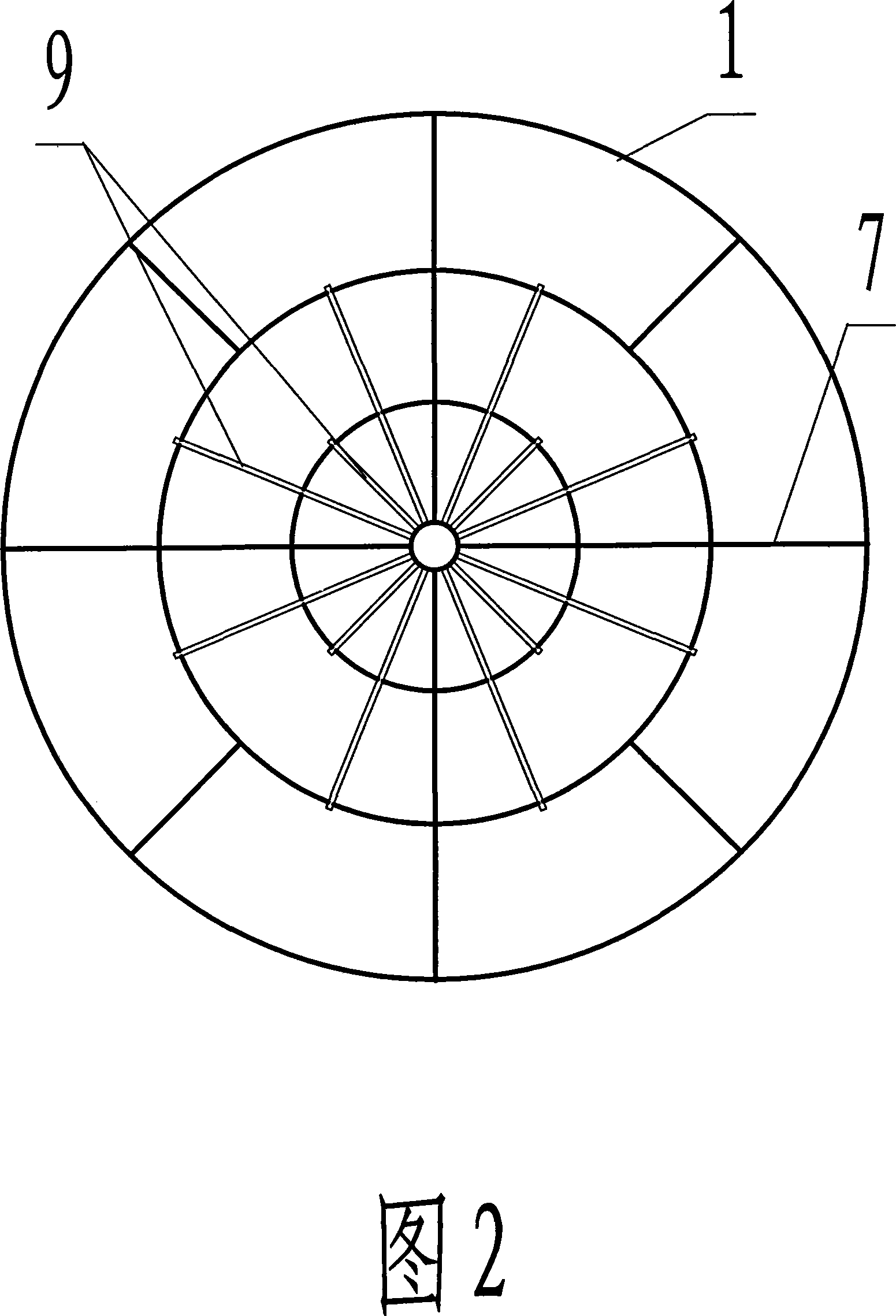

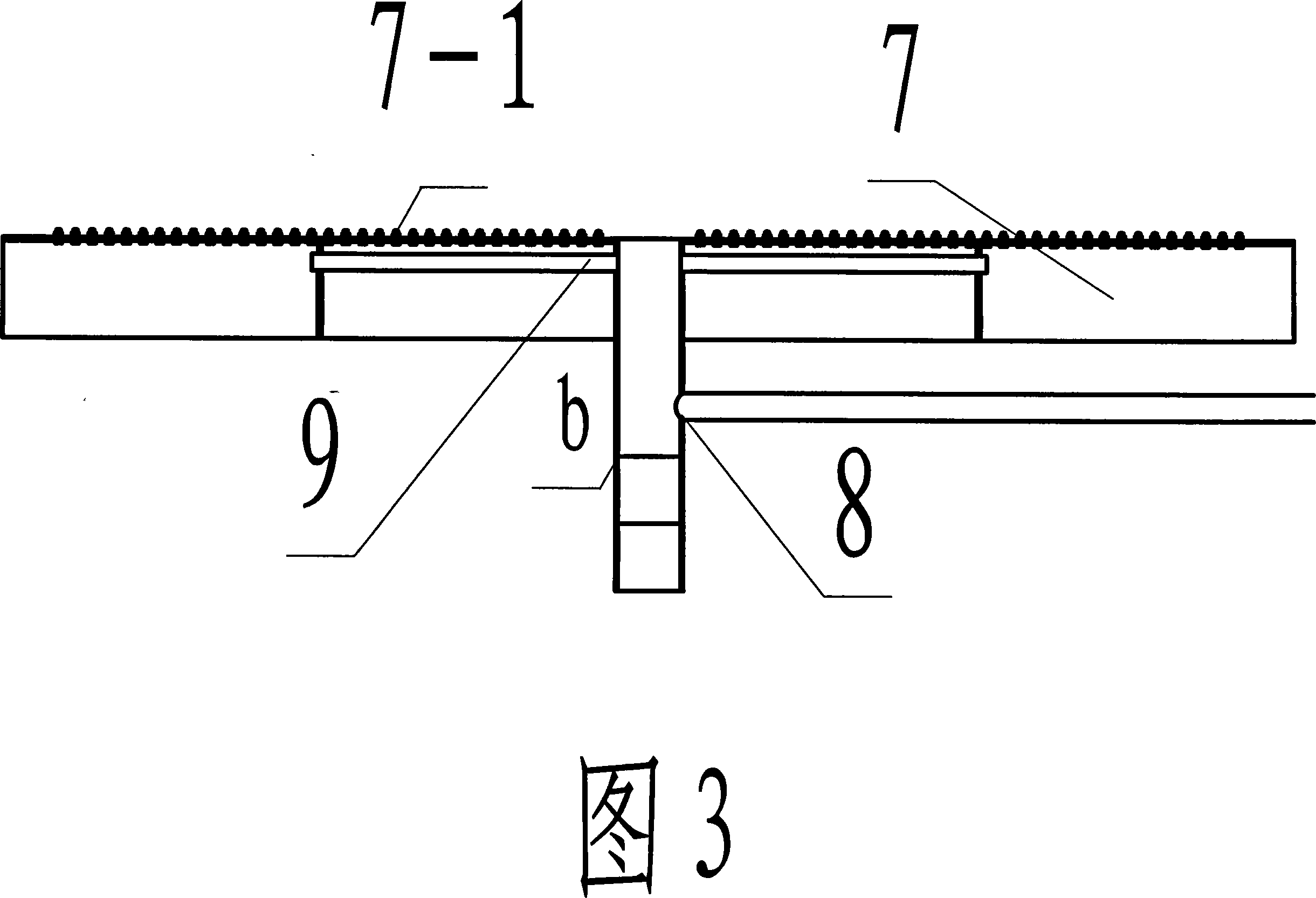

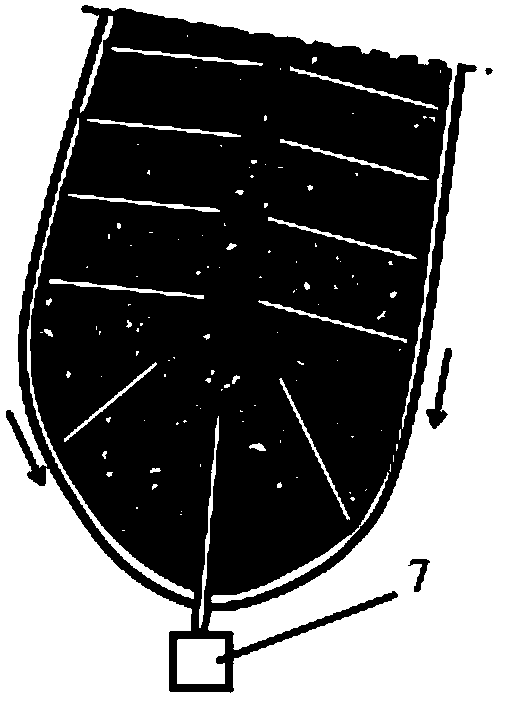

Novel technics of metallurgy mineral dressing flotation air inflation and special equipment

InactiveCN101081379AEnhanced mixing effectImprove flotation recoveryFlotationAutomatic controlMicrobubbles

The present invention discloses inflated metallurgical floatation process and apparatus, and features the completely covered microbubble inflating in the self balanced water separated microbubble generating and inflating mode. The apparatus includes a main machine, a bubble overflowing system, a microbubble generating separator, a microbubble generating system, an automatic mineral slurry regulating mechanism to control the liquid level, etc. Inside the floatation column, leaching tank and oxidation tank, great amount of microbubbles are generated in the bottom and flown in the opposite direction to the falling mineral slurry so as to raise the stirring effect, form stable floating bubble layer, speed oxygen dissolution, increase oxygen utilizing rate, enhance oxidizing leaching and raise floatation recovering rate.

Owner:王树芳

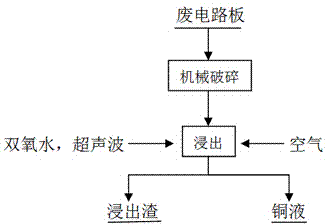

Method for recovering copper from waste circuit board

InactiveCN104745824ALow impurity contentReduce recycling costsProcess efficiency improvementResource utilizationHydrometallurgy

The invention discloses a method for recovering copper from a waste circuit board and belongs to the technical field of hydrometallurgy. The method comprises the following steps: firstly crushing the waste circuit board into powder, fully mixing the powder, an ammonia water solution, an ammonium chloride solution and water to obtain ore pulp, introducing air into the ore pulp, and carrying out ultrasonic wave intensified leaching under a stirring condition; and periodically adding hydrogen peroxide in the intensified leaching process so as to leach copper from the waste circuit board, wherein the leaching rate of copper from the waste circuit board leached in 1 hour reaches over 98%. The method disclosed by the invention realizes resource utilization of effective components of the waste circuit board and moreover, the method has the advantages of being environment-friendly, mild in reaction and short in technological process, the production cost can be lowered and the metal copper recovery rate is high, and the method is suitable for recovering valuable metals in the waste circuit board.

Owner:KUNMING UNIV OF SCI & TECH

Method for leaching and recovering metal from lithium ion battery anode wastes based on electrochemical method

ActiveCN106785174AReduce dosageEmission reductionWaste accumulators reclaimingBattery recyclingScrapNickel

The invention discloses a method for leaching and recovering metal from lithium ion battery anode wastes based on an electrochemical method. The method comprises the steps of compacting lithium ionanode waste powder into a flake shape as a negative electrode, adopting an inert electrode as a counter electrode, adopting a solution containing H<+>, K<+> and / or Na<+> as an electrolyte solution, and carrying out electrochemical reduction leaching under direct voltage to obtain an electrolyte solution containing metal ions. Compared with traditional acid leaching (acid plus a reducing agent), according to the method, the acid dosage is greatly reduced, the leaching time is short, the operation can be carried out at normal temperature, the leaching efficiency of metal in a manganese-nickel-cobalt ternary cathode material is greatly improved, the method is simple to operate, and wide in industrial prospect, and the cost is low.

Owner:CENT SOUTH UNIV +1

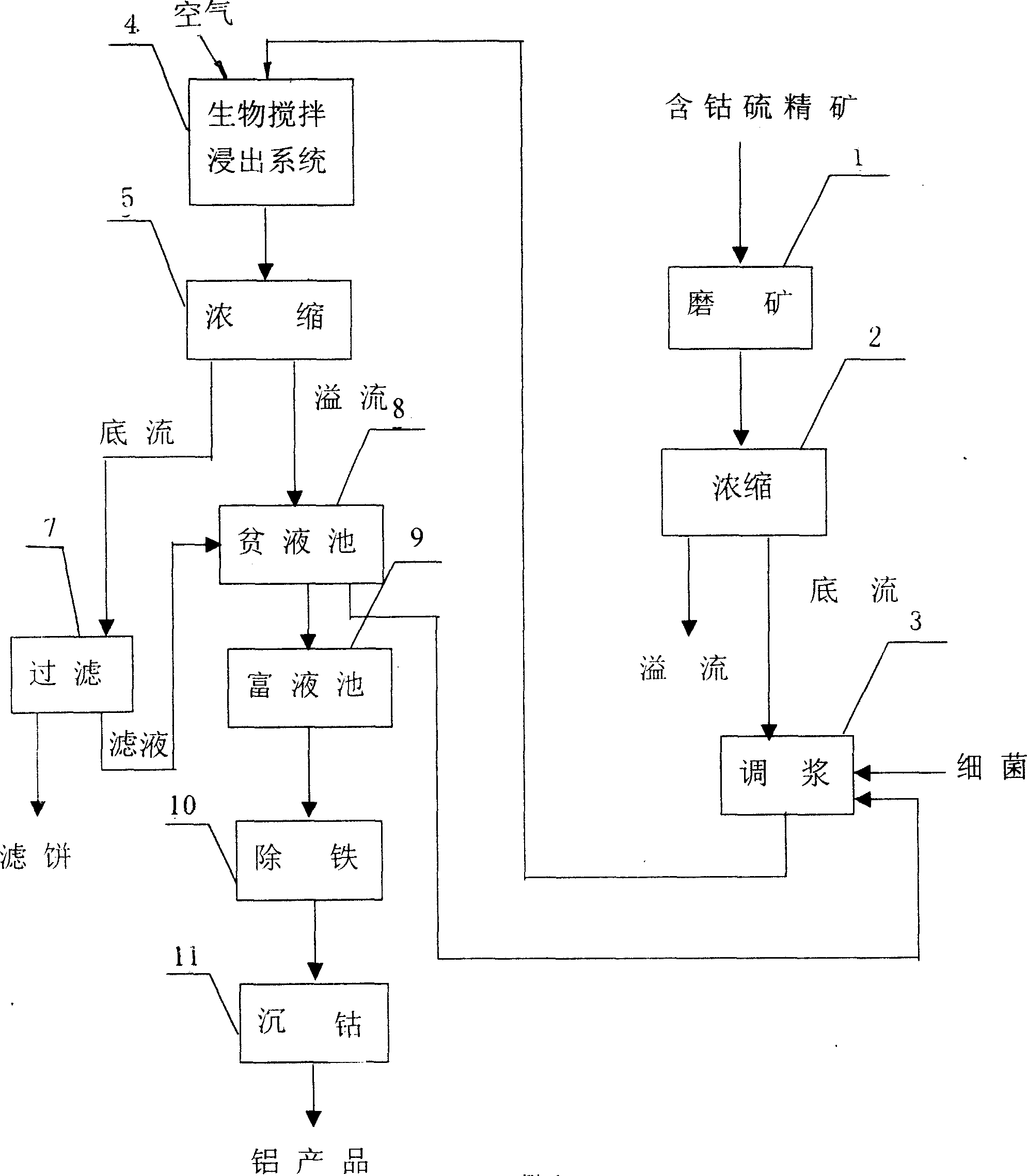

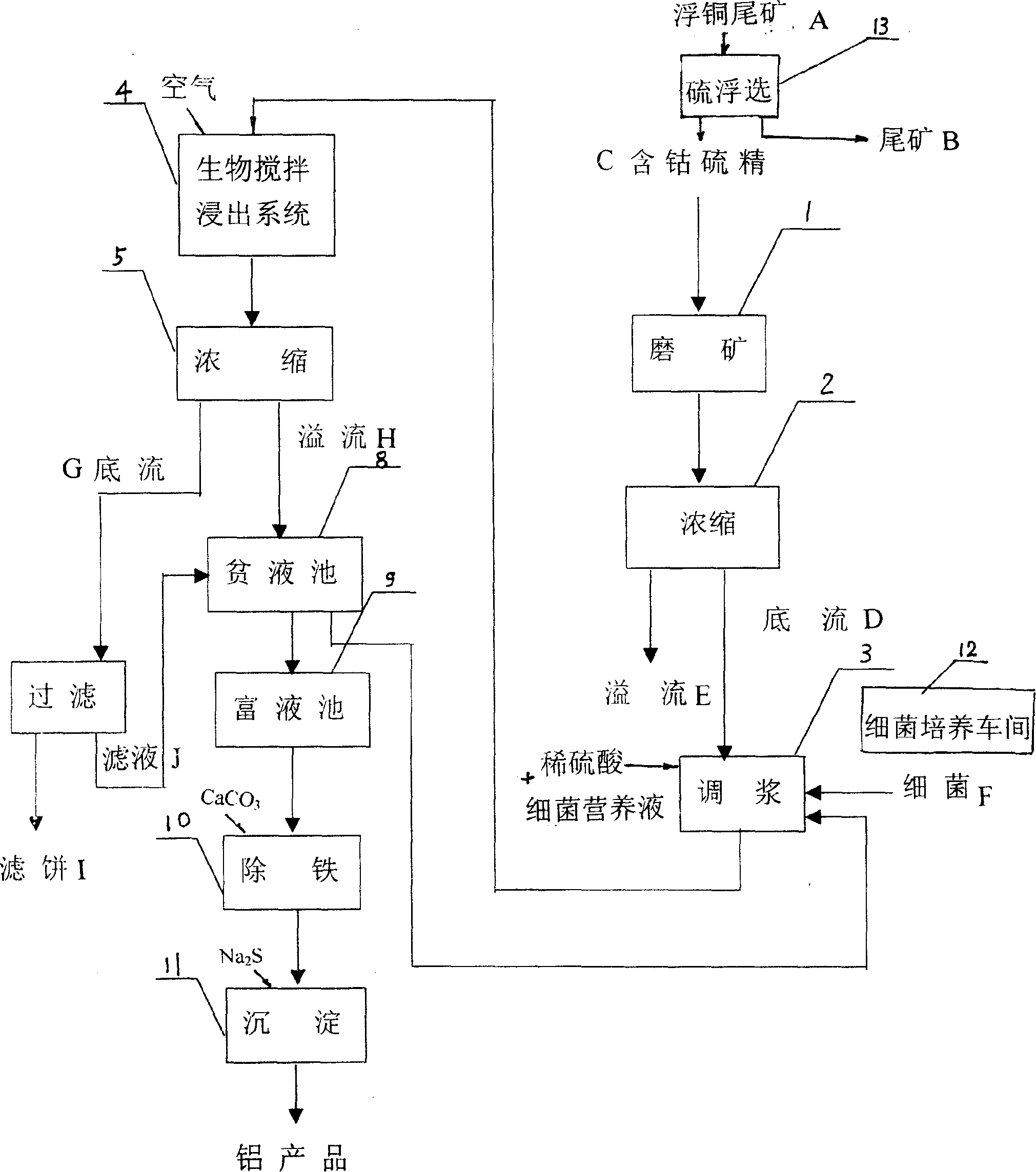

Biological stirring cobalt-dipping technique for concentrate containing cobalt and sulfur

InactiveCN101191152AFast leachingEfficient recyclingMicroorganismsProcess efficiency improvementGramOre concentrate

The invention relates to a biological mixing cobalt leaching novel technique for cobaltiferous sulfide ore concentrates. Cobalt sulphate which can be sold in the market are produced after procedures of fine grinding, washing and reagent removal, conditioning, biological mixing and leaching, solid-liquid separation, iron removal, cobalt precipitation and so on of the cobaltiferous sulfide ore concentrates. During the leaching process, the temperature of 40 to 55 DEG C, the PH value of 1.2 to 1.8 and certain ferrum concentration (1 to 15 grams per liter) in a system are needed to maintain in order to keep high activity of bacteria. The invention has the advantages of capability of fully utilizing mineral resources, improvement of comprehensive utilization level of mines, conservation of cost and improvement of profit, and is particularly suitable for development of cobaltiferous sulfide ore resources in remote areas.

Owner:有研资源环境技术研究院(北京)有限公司

Cordyceps glossy ganoderma teabag and making method thereof

The invention discloses a cordyceps glossy ganoderma teabag and a making method thereof. The method comprises the following steps of: extracting glossy ganoderma sporophore and fomes japonica sporophore through hot water; mixing the hot water extraction liquid with cordyceps sporophore particles so that the cordyceps sporophore particles absorb the hot water extraction liquid containing the nutrient contents of glossy ganoderma and fomes japonica; and then, drying, uniformly stirring, portioning and bagging to prepare cordyceps glossy ganoderma teabags. The making method of the invention not only overcomes the defect that cordyceps glossy ganoderma teabags are hardly prepared because a common automatic teabag packaging machine cannot package crushed glossy ganoderma sporophore in flocculence is directly used in the prior art, but also solves the problem of glossy ganoderma quantifying difficulty in a teabag production process of the prior art and ensures that the active ingredients of the glossy ganoderma and the fomes japonica in the cordyceps glossy ganoderma teabag can be rapidly socked out. The cordyceps glossy ganoderma teabag is a teabag with higher health action.

Owner:GUANGDONG INST OF APPLIED BIOLOGICAL RESOURCES

Microwave-assisting method for fast leaching vanadium in stone coal vanadium ore

The invention discloses a microwave-assisting method for fast leaching vanadium in stone coal vanadium ore. The method adopts a microwave generating device as a heating source, a leaching agent is heated to about 100 DEG C for leaching, and the frequency of microwave is 0.3 GHz to 300 GHz. The method adopts raw materials of stone coal vanadium ore and other slag-containing vanadium such as fly ash containing vanadium, converter slag and the like, a microwave radiant type heating manner is adopted to heat the mineral aggregate fast and selectively, microwave energy is transferred by depending on the dielectric property of the mineral aggregate, heat is produced, and the aim of leaching vanadium is achieved by using the action of microwave activated molecules. The method can improve the leaching speed of vanadium in mineral greatly and has the advantages of short process, short period, high efficiency and high resource comprehensive utilization rate, and the method is suitable for all processes of leaching vanadium in vanadium ore by using a solution.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Honeysuckle green tea and production method thereof

ActiveCN104222399AAvoid destructionOvercome the problems of dull color and poor product qualityTea extractionMicrowaveBud

The invention relates to a honeysuckle green tea and a production method thereof. The method comprises picking honeysuckle buds of the three-green period, radiating the buds through a film with infrared rays of the rate of power of 5kW for 20-30 seconds and then water-removing the buds through microwaves for 2 minutes at a temperature of 80-90 DEG C, and during the microwave water-removing process, adjusting the moisture removal according to the color and the water content of the water-removed buds; timely blowing and cooling the water-removed buds for 20-30 minutes; rolling the buds for 8-10 minutes in a gentle and short-time mode; drying the buds through microwaves for 2-3 minutes at a temperature of 80-85 DEG C; flavoring the buds for 30-60 minutes to obtain the honeysuckle green tea. The honeysuckle green tea comprehensively improves the appearance and the color as well as internal qualities such as fragrance and taste of honeysuckle substituting tea and accordingly is a novel honeysuckle green tea product integrating high quality, health care and ornamental value.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

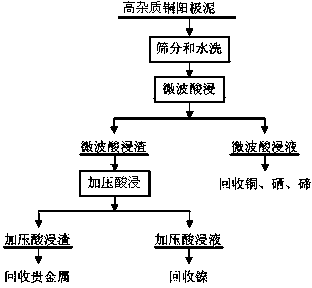

Method for pre-treating high-impurity copper anode slime rich in noble metals

ActiveCN103509953ASimple purification processHigh recovery rateProcess efficiency improvementSeleniumCopper

The invention belongs to the field of hydrometallurgy of non-ferrous metals, and particularly relates to a method for pre-treating high-impurity copper anode slime rich in noble metals. The method comprises the following special steps: adding sulfuric acid in the dried copper anode slime to mix size, placing in a microwave reactor, carrying out the microwave acid leaching for 5-30 min, performing the solid-liquid separation to obtain microwave acid leaching slag and a microwave acid leaching solution, adding dilute sulphuric acid in the microwave acid leaching slag to mix size, placing the microwave acid leaching sizing agent in a high-pressure reaction kettle under the pressure of 0.8-1.2 MPa after oxygen introducing, carrying out pressure acid leaching for 4-6 h to obtain pressure acid leaching slag and a pressure acid leaching solution, recovering gold and silver from the pressure acid leaching slag, and recovering nickel from the pressure acid leaching solution. The method adopting the technical scheme improves the recovery rate of copper, selenium, tellurium and nickel in the impurity copper anode slime, shortens the processing time of the copper anode slime, increases the processing capacity of the copper anode slime, enables the trend of the noble metals to be reasonable and concentrated, and is favorable for comprehensive recovery.

Owner:NORTHEASTERN UNIV

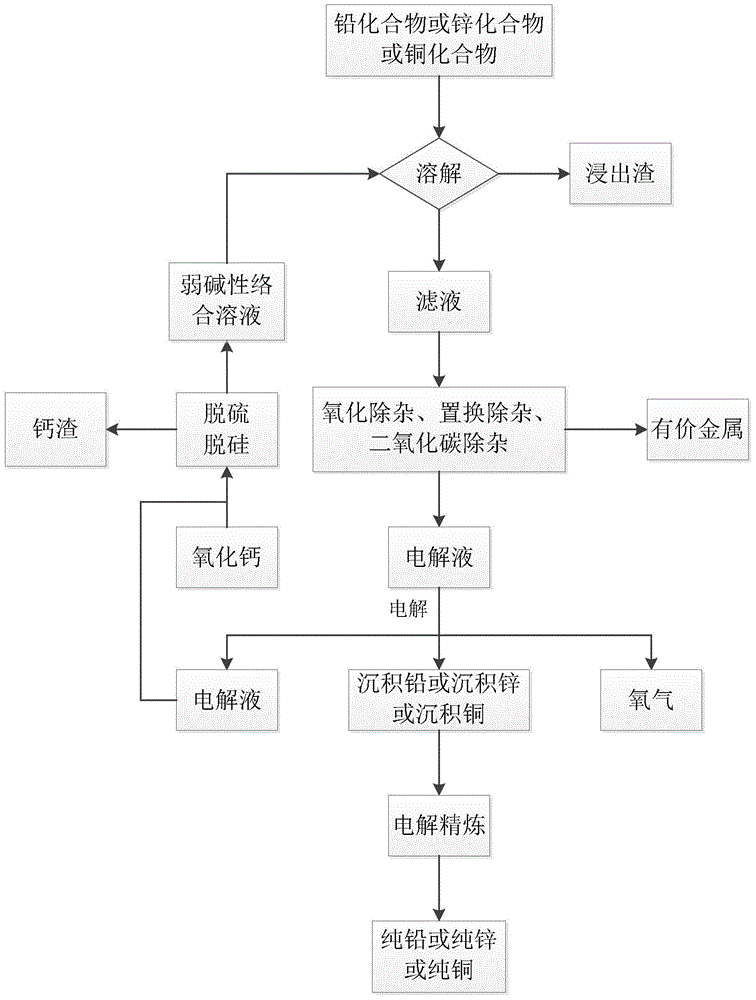

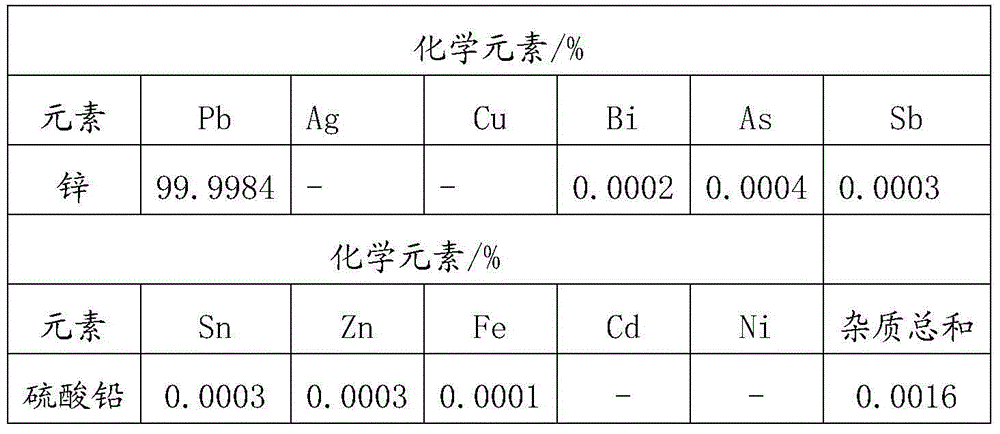

Method for electrolyzing metals through wet method

InactiveCN105274565AImprove leaching rateIncrease profitPhotography auxillary processesProcess efficiency improvementElectrolysisOxygen

The invention provides a process for electrolyzing and refining lead, zinc and copper through a wet method. The process includes the specific steps that an alkalescent complexing solution with high complexing capacity is selected as a leaching solution and all valuable metals are leached out; impurities of the leaching solution are removed through a metal replacement mode; deposited lead or deposited zinc or deposited copper and oxygen are obtained through an electrolytic method; then the solution is subjected to desulfuration and desilicication through calcium oxide or calcium hydroxide; and finally, the lead or the zinc or the copper is obtained after being refined. The alkalescent complexing solution is adopted for leaching and electrolyzing, so that the problems that the leaching rate is low and metal silicates and ferrates are hard to dissolve in terms of current metal smelting with the wet method are solved. Compounds of calcium or barium are adopted for desulfuration of metal sulfates, so that the problem of high desulfuration cost caused by current desulfuration through sodium carbonate or sodium hydroxide is solved. The potential of hydrogen (pH) value of the alkalescent complexing solution is controlled to be 7.5-13.5, the electrolytic voltage is substantially lowered, and the energy consumption is effectively reduced.

Owner:北京中金瑞丰环保科技有限公司

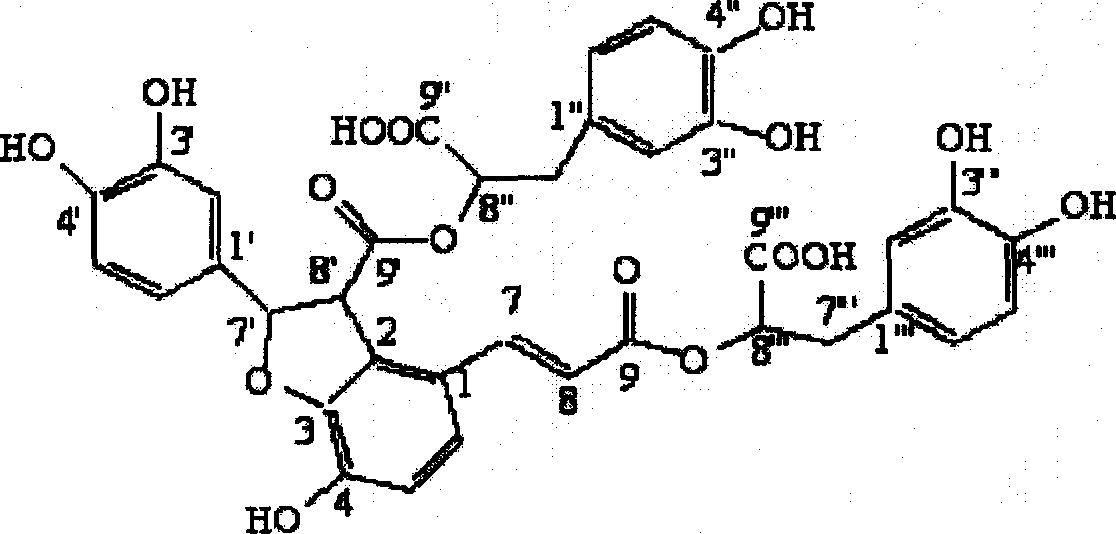

Method for purifying salvianolic acid B

InactiveCN1876641AFast leachingAvoid degradation and contaminationOrganic active ingredientsOrganic chemistryPolyamideChemistry

The invention relates the method of extracting purification pellet phenolic acid B from Sage plant, especially extracting purification pellet phenolic acid B from salvia miltiorrhizae. The method comprises the following steps: treating the salvia miltiorrhizae in microwave field for 1-10 minutes, adding water, or disintegrating salvia miltiorrhizae to 10-60 mesh, and adding water, treating it in microwave field for 1- 20 minutes, centrifuging, removing deposition, then carrying out chromatography with polyamide, removing impurity with water and 20-50% alcohol, washing pellet phenolic acid B with 60-80% alcohol, decompressing, thickening, freezing, drying and getting pellet phenolic acid B whose purify is above 95%. The invention has the advantages of simple technology, low cost, high purify and stable quality.

Owner:DALIAN UNIV OF TECH

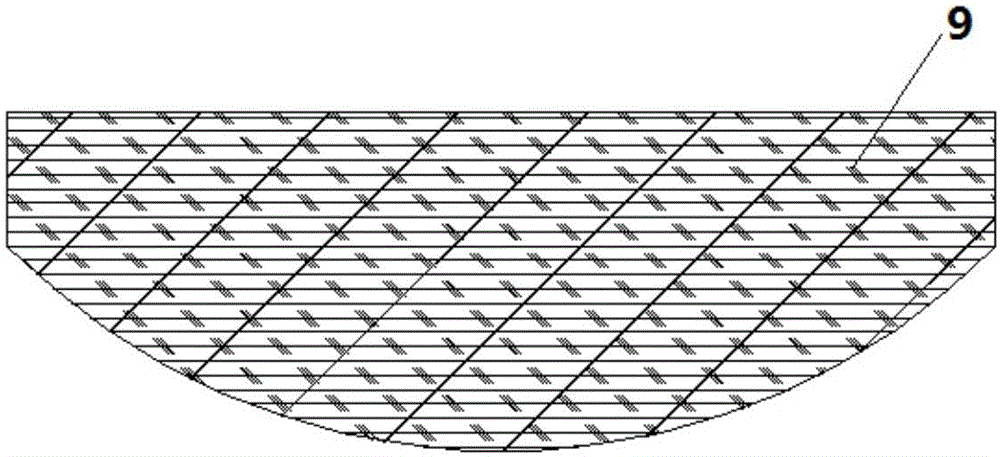

Production method and product of structured flexible conductive porous material

InactiveCN106750500AControllable pore sizeHigh porosity interconnection ratePorosityConductive materials

The invention discloses a preparation method of a structured flexible conductive porous material. The preparation method comprises the following steps: designing a structured mold according to the real requirement; successively adding filling particles and polydimethylsiloxane prepolymer into the mold, and preparing a flexible porous material with a structured appearance; and rapidly and sufficiently filling the structured flexible porous material with a conductive material to obtain the structured flexible conductive porous material. The invention also discloses a structured flexible conductive porous material prepared by using the method. The preparation method integrates the technologies such as structured molding, grading and screening of the filling particles, surface trace fusion curing and negative-pressure permeation promotion of the filling particles and the like, so that the prepared flexible conductive porous material has the structured appearance, a porosity of the flexible porous material is controllable, the pore interconnection rate is relatively high, the filling particle is sufficient to leach, and the overall preparation speed is increased by two to three times compared with the traditional method.

Owner:HUAZHONG UNIV OF SCI & TECH

Flower-fruit tea and preparation method thereof

The invention relates to a flower-fruit tea and a preparation method thereof. The flower-fruit tea is characterized by comprising a 1.8g of flower bag and a bag of 3.2g of filter-bag medicine package, wherein, the flower bag is prepared by blending dry chrysanthemum, honeysuckle, roselle, lophatherum gracile and globeflower; and the filter-bag medicine package takes dried roselle, fructus gardeniae, liquorice, mint, oroxylum indicum, boat-fruited sterculia seed, myrobalan and balloonflower as raw materials, which are smashed and pelletized to obtain the filter-bag medicine package. In the invention, no flavour and fragrance need to be added, thus reserving the original flavor and the natural properties of flowers and fruits; the flower-fruit tea can recuperate body and mind, relieve dried eyes, subtract yellow sweat, dispel wind and heat from the body, clear pharynx and benefit throat, purge fire and cool blood, lead the body to be joyful and healthy, and can be backwashed repeatedly.

Owner:安徽方敏医药科技股份有限公司

Blueberry green tea bag

The invention discloses a blueberry green tea bag. The blueberry green tea bag comprises a brewing bag and blueberry green tea sealed in the brewing bag, the blueberry green tea is prepared by fresh blueberry leaves, and the processing procedures include fresh leaf picking, water-removing, a first rolling, stir-frying, a second rolling, drying and the like. The blueberry green tea bag has the advantages that the blueberry green tea bag is free of caffeine, the brewing is convenient, the leaching speed of soluble matters in tea-leaf is fast, the leaching is thorough, brewed tea water tastes fresh and fragrant, the color of the tea water is pleasant, the tea is rich in tea polyphenol and anthocyanin, and the blueberry green tea bag has heath care effects of anticancer, preventing cardiovascular and cerebrovascular diseases, restraining free radicals, antianaphylaxis, improving human body comprehensive immunity, and the like.

Owner:开原景隆现代农业综合开发有限公司

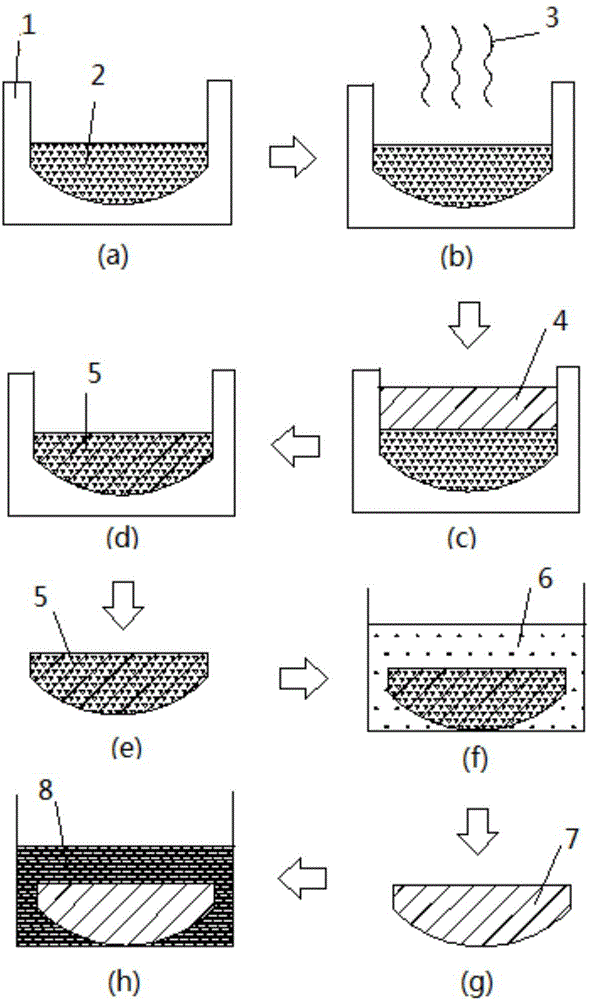

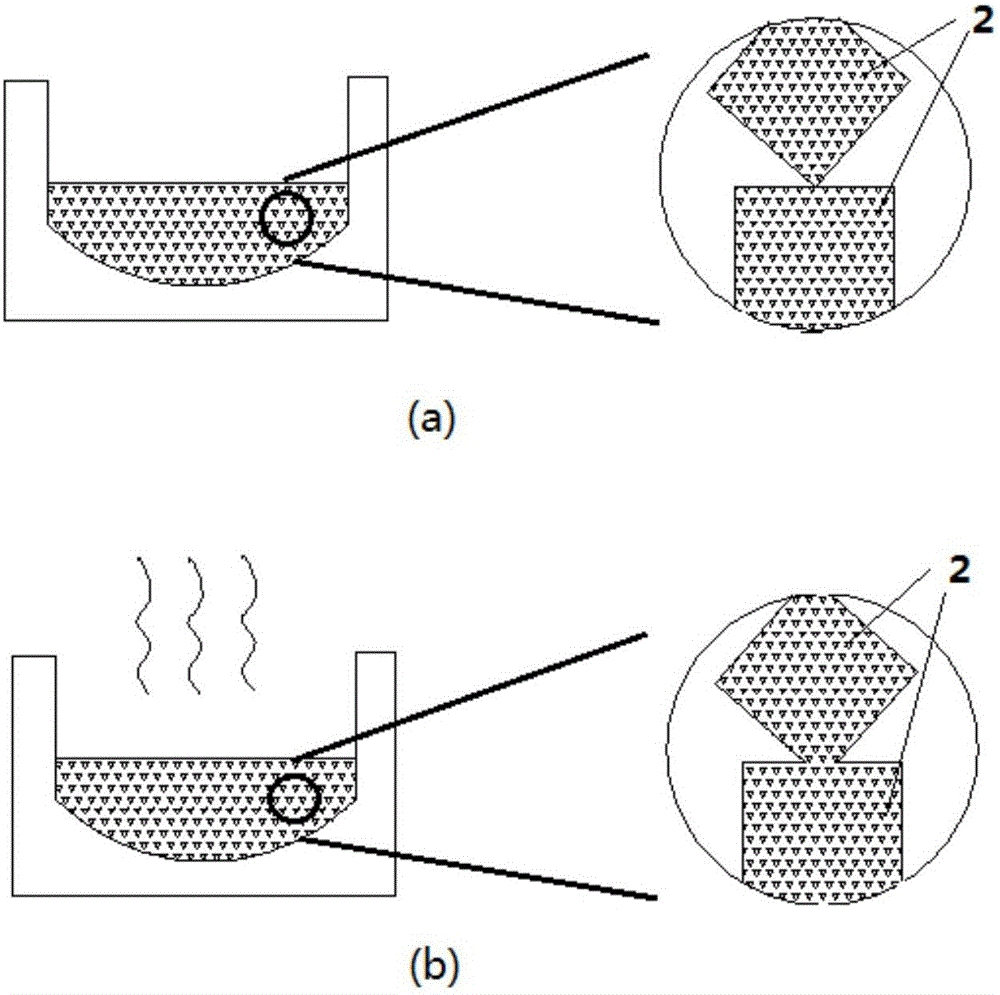

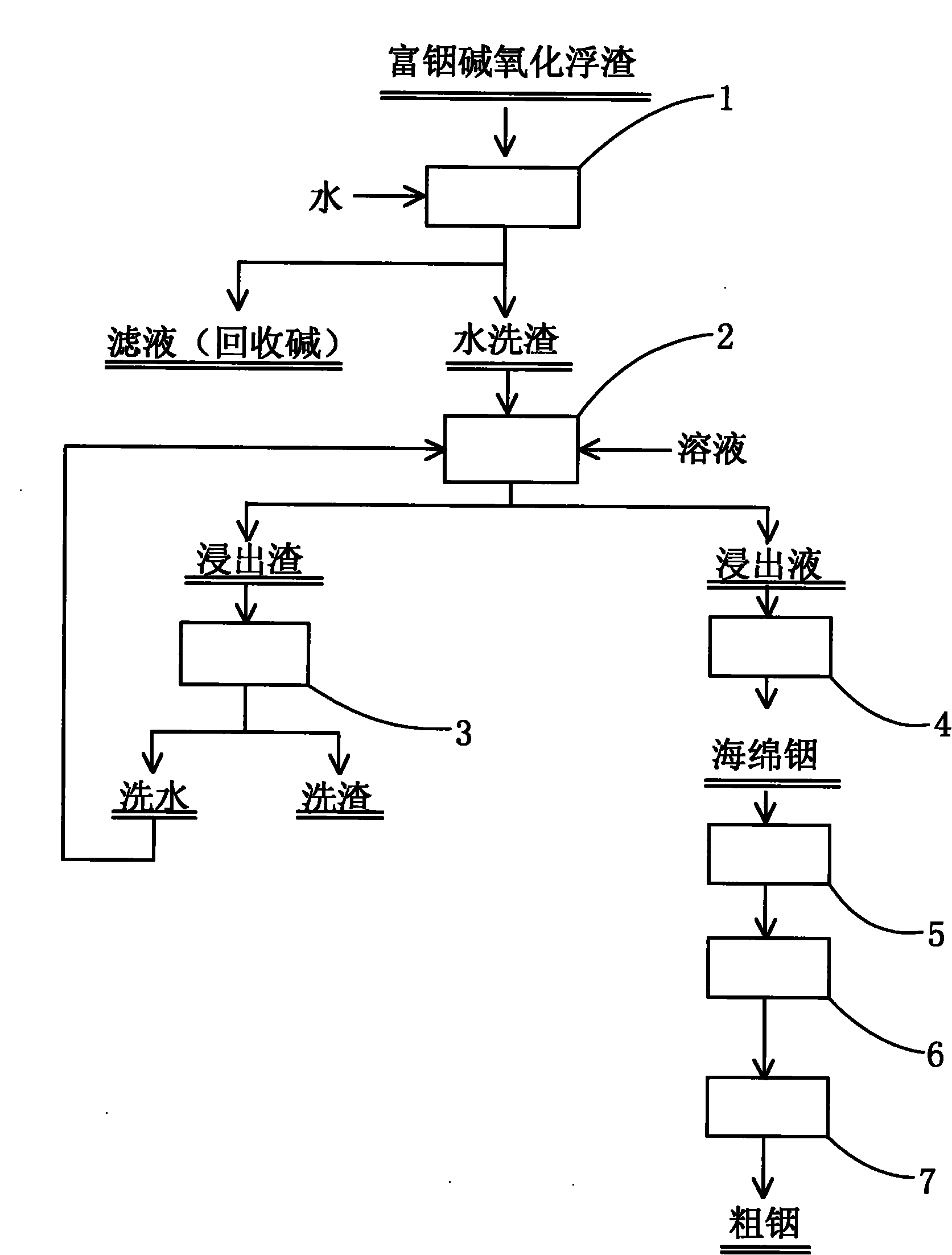

Method for extracting indium from alkali oxidation scum rich in indium

InactiveCN101831550AImprove leaching rateLow impurity contentProcess efficiency improvementIndiumReaction temperature

The invention relates to a method for extracting indium from alkali oxidation scum rich in the indium. Crude indium is obtained through the following working procedures of: (1) washing the alkali oxidation scum rich in the indium by using water; (2) washing by using water and leaching; (3) washing leached scum by using water; (4) displacing aluminum in leaching liquor; (5) briquetting indium sponges; (6) smelting briquetted alkali; and (7) removing cadmium and thallium in the smelting material. In the method, a solvent consisting of sulfuric acid and chlorides is used for leaching the alkali oxidation scum rich in the indium at a time, and the leaching rate of the indium can reach higher than 99.5 percent. Compared with traditional secondary dilute sulfuric acid counter current leaching, the method has the advantages of short process flow, high leaching speed, low reaction temperature, simple operation, low content of leaching liquid impurities, high indium leaching rate, and the like and is suitable to being applied to extracting metal indium from crude lead alkali oxidation scum rich in the indium.

Owner:HULUDAO ZINC IND CO LTD

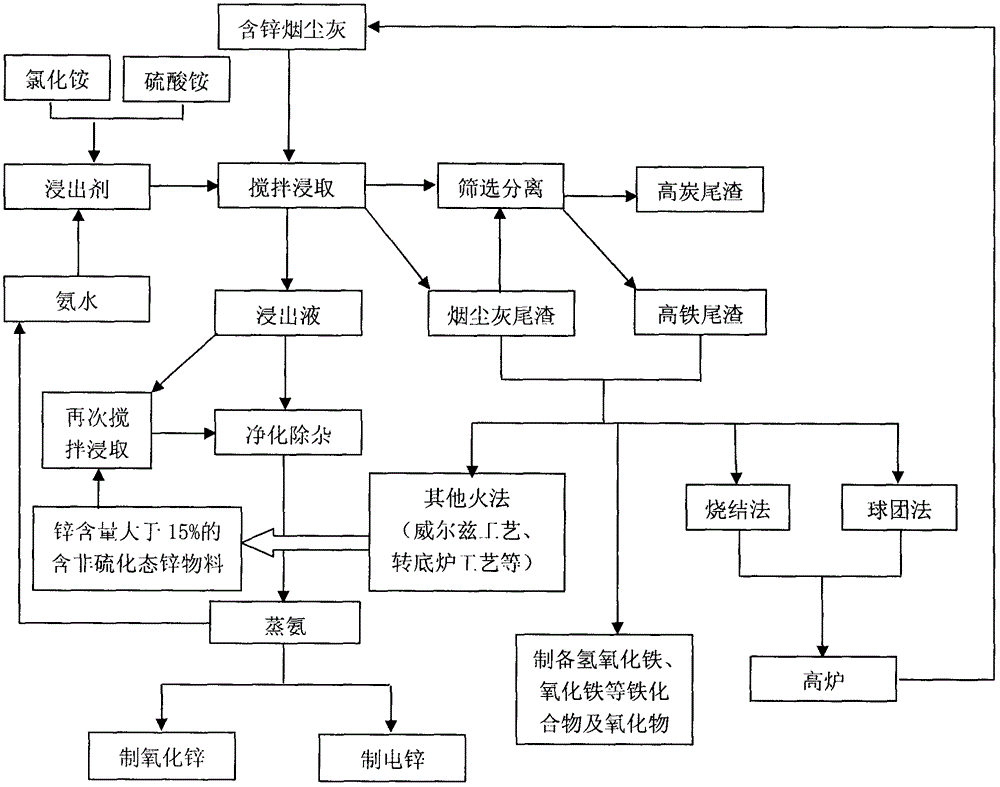

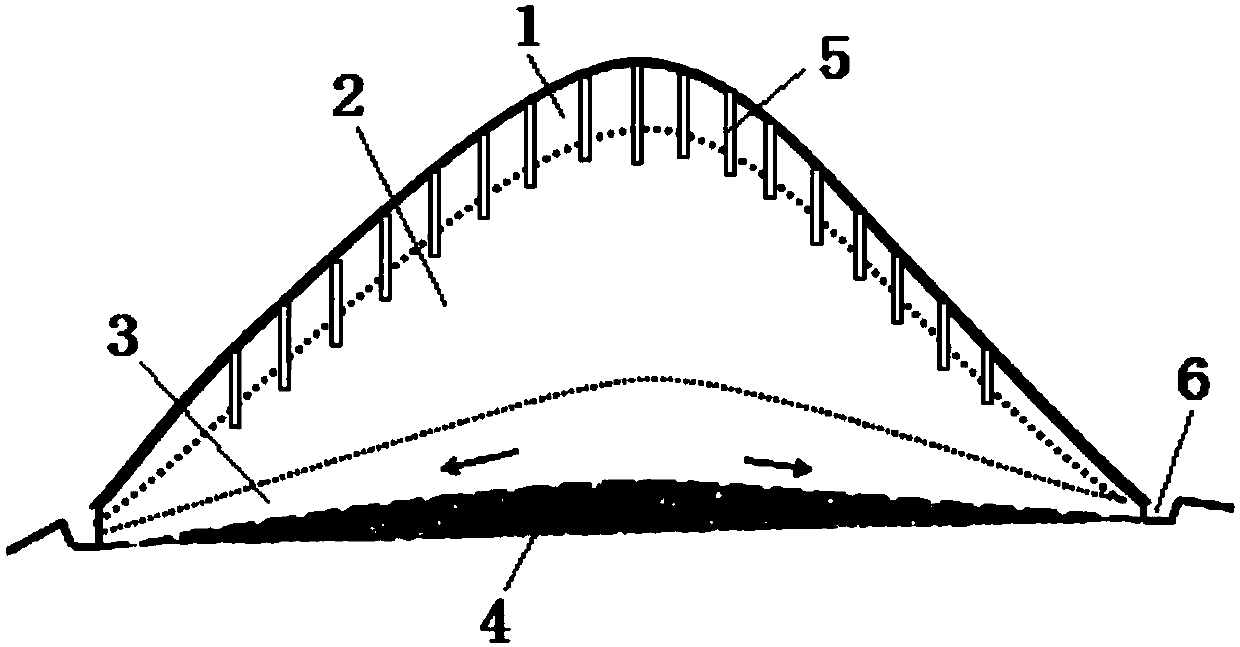

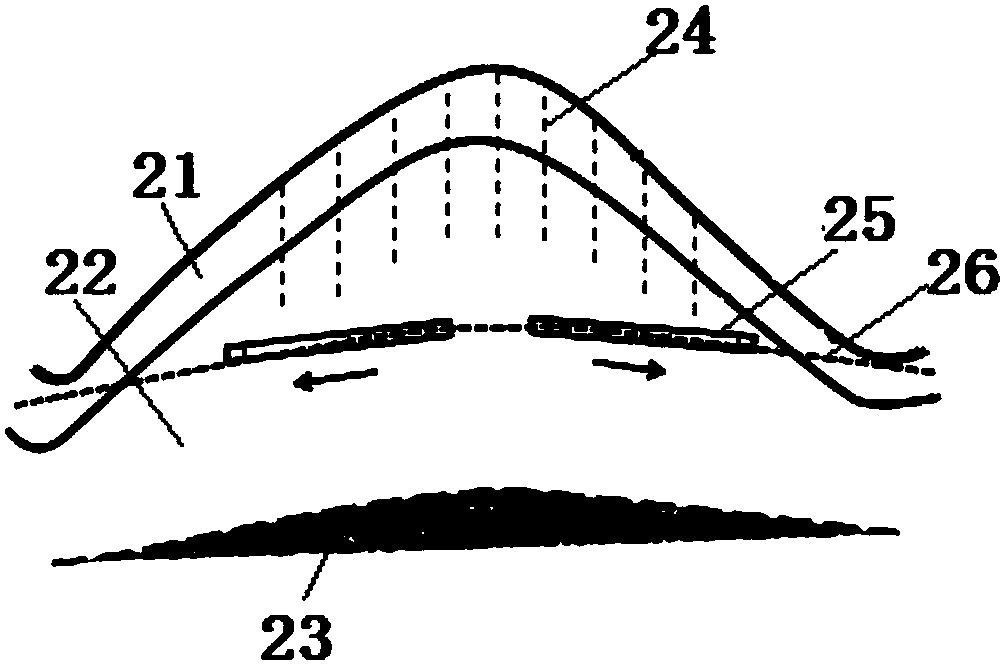

Utilizing method of zinc-containing dust ash of steel plant

InactiveCN106119556AIncrease concentrationSolve the problem of continuous enrichmentPhotography auxillary processesZinc oxides/hydroxidesEnvironmental resistanceAmmonia

The invention relates to a utilizing method for producing zinc oxide products by utilizing zinc-containing dust ash of a steel plant and recycling ferric carbon for returning to smelting. Zinc in the dust ash is leached by use of an ammonia method; materials which have the zinc content greater than 15% and contain non-vulcanized zinc are added for increasing the concentration of a zinc solution; leachate is purified, cleaned and subjected to ammonia distilling, and zinc oxide is prepared after electrolytic zinc preparation or zinc deposition; and original dust ash tailings or screened dust ash tailings are sent into a blast furnace for smelting, or a conventional pyrogenic process is adopted for recycling ferric carbon from the original dust ash tailings or the screened dust ash tailings, and collected secondary zinc oxide dust ash is used for the front end leaching, so that the zinc concentration of the leachate is increased. The utilizing method can be applicable to dust ash, with the zinc content as lower as 4% or even lower, of the steel plant; by use of a conventional method, the zinc extraction rate and the removing rate of harmful substances including alkali metal, fluorine and chlorine are both above 90%; the dust ash tailing recovery process is high in equipment adaptability, and appropriate treatment processes can be chosen according to existing equipment; and efficiency is high, the environment is protected, and comprehensive cyclic utilization of the zinc-containing dust ash is achieved.

Owner:李果

Ion-type rare-earth ore ammonium-free environment-friendly exploitation technique

InactiveCN108034842ANo pollution in the processPollution meetsProcess efficiency improvementEnvironmental resistanceIon exchange

The invention discloses an ion-type rare-earth ore ammonium-free environment-friendly exploitation technique. The ion-type rare-earth ore ammonium-free environment-friendly exploitation technique comprises the following steps that an ammonium-free ore leaching agent with a certain concentration is injected through liquid injecting holes distributed in a stope to be subjected to an ion exchanging reaction with rare-earth ores so as to obtain mother liquid enriched in rare-earth positive ions; the mother liquid seeps and gathers into liquid collecting engineering such as matching of ore-layer natural water partition bottom plates or artificial liquid collecting roadways with liquid collecting flow guiding holes; and then the mother liquid is conveyed to a hydrometallurgy workshop through a main conveying pipeline, ammonium-free agents are used for impurity removal and precipitation to obtain rare-earth carbonate, and supernatant liquid is circulated back to a liquid preparation pool andthen subjected to pH valve adjustment and agent adding, and returns to the stope to serve as a new ammonium-free ore leaching agent. The ion-type rare-earth ore ammonium-free environment-friendly exploitation technique has the advantages that ammonium is avoided in the overall process, and environmental friendliness is achieved on soil and water bodies; production waste water is circularly and comprehensively utilized, and harmful waste discharging is avoided; and the leaching rate, liquid collecting rate and precipitating rate of the rare-earth ions are high, and the resource mining comprehensive recovery rate is increased.

Owner:五矿勘查开发有限公司

Method for producing biodiesel

InactiveCN102703135AImprove ergonomicsHigh extraction rateFatty acid esterificationBiofuelsSolventChemistry

The invention discloses a method for directly producing biodiesel from plant oilseeds by microwave irradiation. The method includes using plant oilseeds as raw material, using alkane solvent and low carbon alcohol solvent as double-liquid-phase mixed solvent, using acid or alkali as catalyst, and performing oil extraction and transesterification in a 2450MHz or 915MHz microwave reactor. Strict water limitation on the oilseeds is not required in the method, oil production process and biodiesel production process are simplified into a simple process, and accordingly production efficiency is improved, production cost of the biodiesel is lower than that of raw oil, cost control in biodiesel production can be broken through, and investment is reduced greatly.

Owner:BEIJING GUOLIYUAN POLYMER SCI & TECH R & D CENT

Technology for producing extract solution from baical skullcap root

InactiveCN101693001AImprove inner qualitySimple methodCosmetic preparationsToilet preparationsBaical Skullcap RootBULK ACTIVE INGREDIENT

The invention discloses a technology for producing extract solution from baical skullcap root, and the key point of the technical scheme is that the technology for producing the extract solution from the baical skullcap root comprises the steps of smashing, stirring, mixing, heating, boiling, pressure-filtering, stirring, mixing, heating, soaking, smashing, beating, pressure-filtering and canning, thereby obtaining a finished product of the extract solution from the baical skullcap root. The technology for producing the extract solution from the baical skullcap root for extracting flavonoid compounds is characterized by simple method, fast leaching speed, high extraction rate of active ingredients and no need of purification and separation, the extract solution from the baical skullcap root is a natural, high-efficient and multifunctional additive for cosmetics which integrates the multiple effects of removing freckles, whitening, sun-screening, anti-allergy, anti-inflammation and anti-aging into a whole and can be directly used in sunscreen cream, mask, cream and other cosmetics, thereby not only improving the internal quality of the extract solution from the baical skullcap root, but also greatly saving the production cost. The technology for producing the extract solution from the baical skullcap root is applicable to producing the extract solution from the baical skullcap root and the extract solution from Chinese herbal medicines.

Owner:许庆华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com