Method for pre-treating high-impurity copper anode slime rich in noble metals

A technology of anode slime and impurity copper, which is applied in the direction of improving process efficiency, can solve the problems of unfavorable extraction of precious metals, increased costs, and low production efficiency, and achieves the effects of simplified purification process, reduced production cost, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

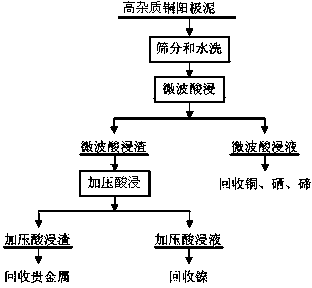

Image

Examples

Embodiment 1

[0022] (1) Microwave acid leaching: Add water to the high-impurity copper anode slime for rough slurry adjustment, sieve out sand impurities with a particle diameter greater than 5mm, drain the water, and add 500g of copper anode slime to the drained copper anode slime The sulfuric acid slurry of / L obtains the copper anode mud slurry, and controls the weight concentration of copper anode mud in the copper anode mud slurry at 30%;

[0023] Put the copper anode slurry in the microwave reaction furnace, add the oxidant H 2 o 2 , H 2 o 2 The dosage is 2.5molH 2 o 2 / L slurry, the microwave frequency is 2450MHz, the microwave heating power is 500w, acid leaching is carried out in a microwave reaction furnace for 20min, and then solid-liquid separation is carried out to obtain microwave acid leaching residue and microwave acid leaching solution, which are recovered from the microwave acid leaching solution copper, selenium and tellurium;

[0024] (2) Pressure acid leaching: a...

Embodiment 2

[0028] (1) Microwave acid leaching: Add water to the high-impurity copper anode slime for coarse slurry adjustment, sieve out sand impurities with a particle diameter greater than 5mm, drain the water, and add 400g of copper anode slime to the drained copper anode slime The sulfuric acid slurry of / L obtains the copper anode mud slurry, and controls the weight concentration of copper anode mud in the copper anode mud slurry at 20%;

[0029] Put the copper anode slurry in the microwave reaction furnace, add the oxidant H 2 o 2 , H 2 o 2 The dosage is 5molH 2 o 2 / L slurry, the microwave frequency is 2450MHz, the microwave heating power is 1000w, acid leaching is carried out in a microwave reaction furnace for 30min, and then solid-liquid separation is carried out to obtain microwave acid leaching residue and microwave acid leaching solution, which are recovered from the microwave acid leaching solution copper, selenium and tellurium;

[0030] (2) Pressure acid leaching: a...

Embodiment 3

[0034](1) Microwave acid leaching: Add water to the high-impurity copper anode slime for rough slurry adjustment, sieve out sand impurities with a particle diameter greater than 5mm, drain the water, and add 250g of copper anode slime to the drained copper anode slime The sulfuric acid slurry of / L obtains the copper anode mud slurry, and controls the weight concentration of copper anode mud in the copper anode mud slurry at 10%;

[0035] Put the copper anode slurry in the microwave reaction furnace, add the oxidant H 2 o 2 , H 2 o 2 The dosage is 3molH 2 o 2 / L slurry, the microwave frequency is 2450MHz, the microwave heating power is 300w, acid leaching is carried out in a microwave reaction furnace for 30min, and then solid-liquid separation is carried out to obtain microwave acid leaching residue and microwave acid leaching solution, which are recovered from the microwave acid leaching solution copper, selenium and tellurium;

[0036] (2) Pressure acid leaching: add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com