Method for extracting niobium from tailings

A tailings and mineral technology, applied in the field of niobium extraction, can solve the problems of high power consumption and high cost, and achieve the effects of high heating efficiency, fast heating speed and high leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

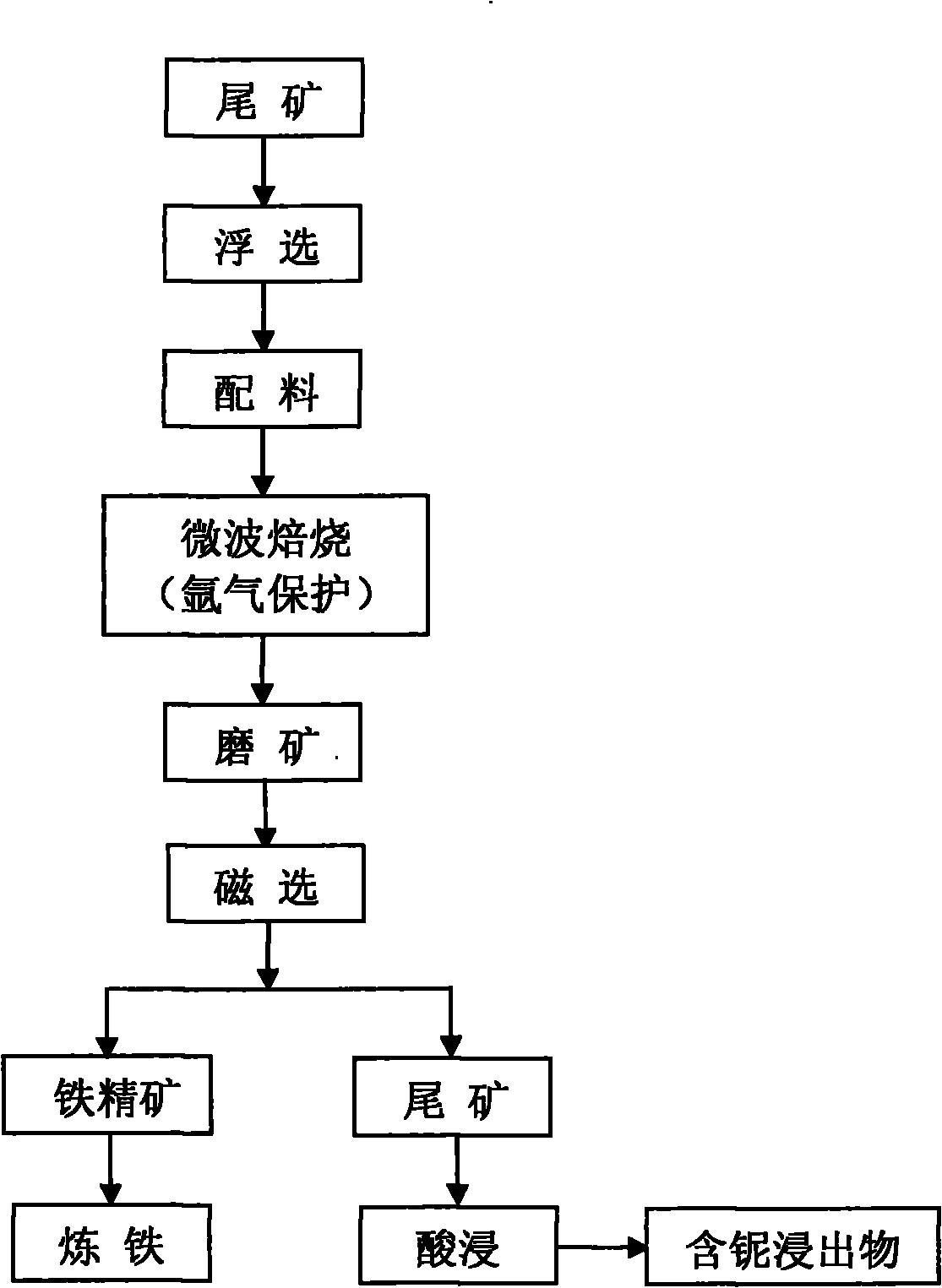

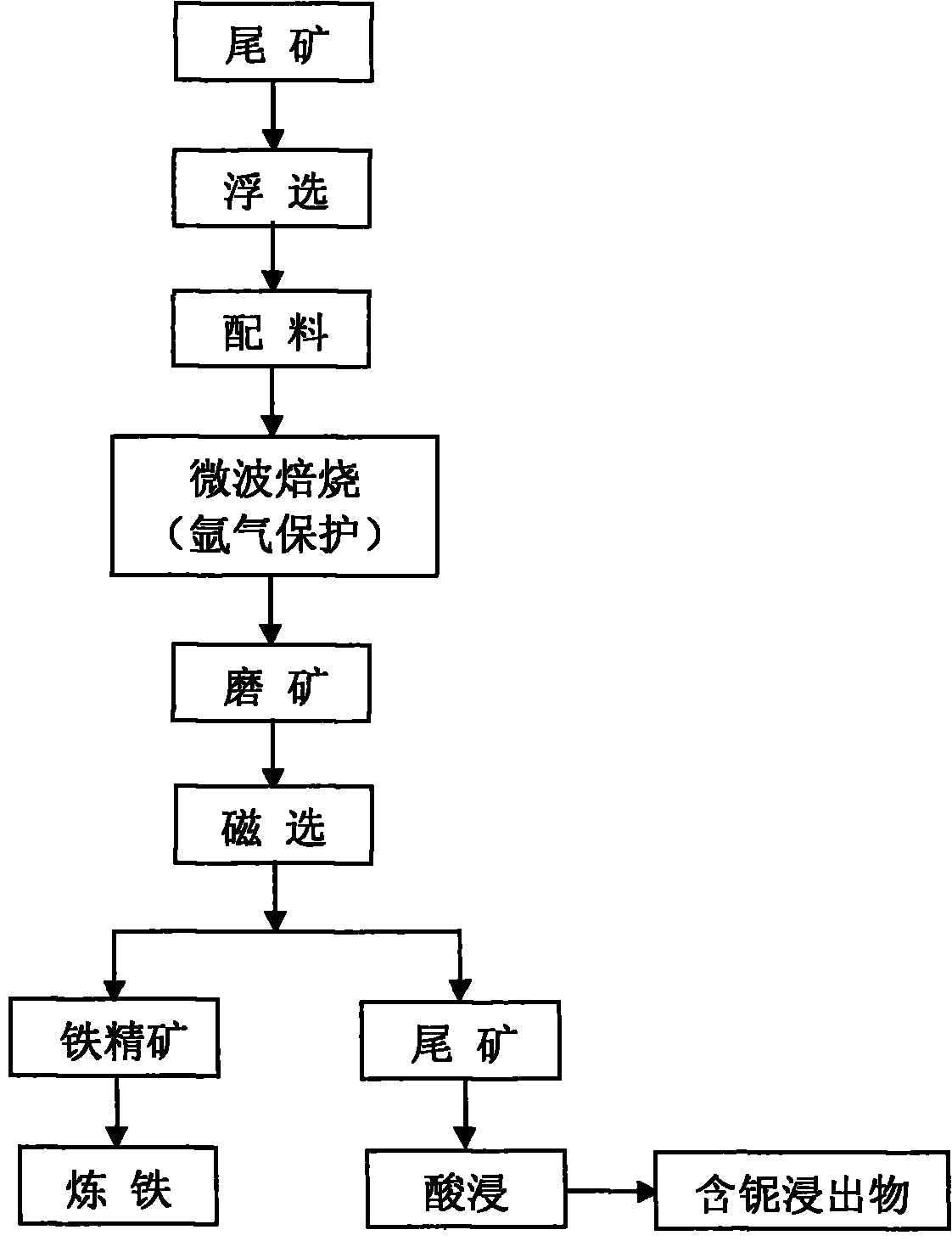

[0026] The crude niobium concentrate is gradually processed under the process conditions given in the "microwave magnetization roasting-weak magnetic separation-acid leaching" method.

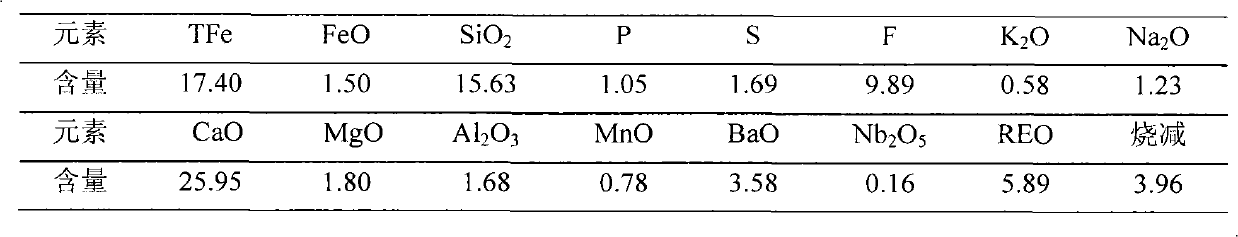

[0027] The tailings in this example come from Baotou Steel Concentrator, and its composition is shown in Table 1.

[0028] Table 1 The multi-element analysis results of flotation rare earth tailings in Baotou Steel, %

[0029]

[0030] The flotation method is used to treat the tailings, and minerals with an iron grade of 49.4-54.1% and a niobium content of 0.16-0.25% can be extracted. According to the amount of carbonaceous reductant added is 1.85% of the total amount of coarse niobium iron concentrate, and the protective gas is introduced during the reduction process. The flow rate is 2-5L / min. Roasting for 20 minutes, the roasting temperature is 650°C, the roasted product is finely ground to 400 mesh, and magnetically separated in a weak magnetic tube with a magnetic field of 80KA / m. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com