Method of using active persulphate for processing difficult-biodegradability organic waste water

A technology for activating persulfate and organic waste water, applied in oxidation water/sewage treatment, light water/sewage treatment, etc., can solve problems such as hindering the application of thermally activated persulfate, complex heating system, serious heat loss, etc. Start and stop heating quickly, no secondary pollution, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Treatment example of low concentration organic wastewater golden orange II solution.

[0015] Get 250mL of the golden orange II solution of printing and dyeing wastewater, the concentration is 20mg / L; the amount of sodium persulfate is 0.034g (10:1 with the golden orange II molar ratio); first put the sodium persulfate into the reaction container filled with the golden orange II solution After mixing and dissolving, it is placed in a microwave generator with a frequency of 2450 MHz and a power of 800 W for 2-8 minutes to complete radiation heating.

[0016] Experimental results

Embodiment 2

[0019] An example of the treatment of high-concentration organic wastewater golden orange II solution.

[0020] Get 250mL of printing and dyeing wastewater Golden Orange II solution, the concentration is 1000mg / L; the amount of sodium persulfate is 4.247g (molar ratio with Golden Orange II is 25:1); first put sodium persulfate into the reaction container filled with Golden Orange II solution , after mixing and dissolving, put it in the above-mentioned microwave generator and heat it for 2-8 minutes to complete.

[0021] Experimental results

Embodiment 3

[0024] Catalyst added to the treatment example of high-concentration organic wastewater golden orange II solution.

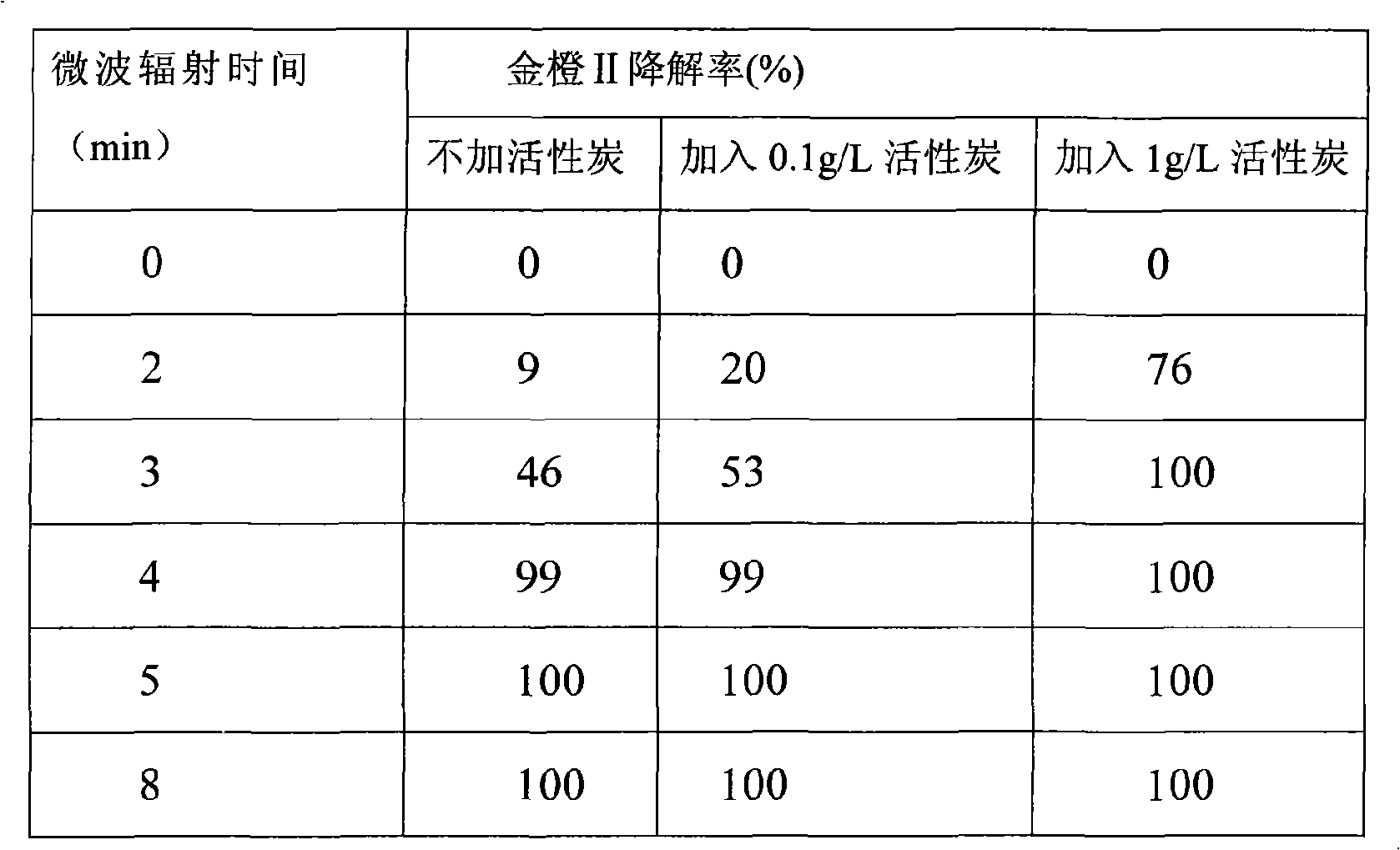

[0025] Take 250mL of printing and dyeing wastewater golden orange II solution, the concentration is 500mg / L; the amount of sodium persulfate is 4.247g (molar ratio to golden orange II is 50:1); add catalyst activated carbon 0.025g, 0.25g; put sodium persulfate and activated carbon first Put it into the reaction vessel containing the golden orange II solution, mix it, place it in the above-mentioned microwave generator and heat it by radiation for 2-8 minutes, and then complete.

[0026] Experimental results

[0027]

[0028] Obviously, the degradation rate of Golden Orange II was further improved after adding catalyst activated carbon before microwave activation of sodium persulfate to treat organic wastewater Golden Orange II solution.

[0029] Above-mentioned microwave generator can be refitted with domestic microwave oven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com