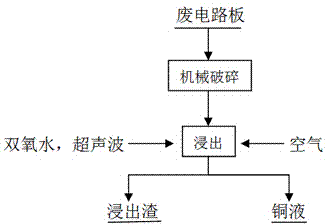

Method for recovering copper from waste circuit board

A technology for waste circuit boards and ore pulp, applied in the field of hydrometallurgy, can solve the problems of complicated extraction process of metal copper, difficult to achieve large-scale application, increase of processing cost, etc. The effect of reducing recovery costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 10 grams of a copper-clad circuit board with a copper content of 20.38%, and mechanically crush it to below 200 mesh; at a solid-to-liquid ratio of 1:3, a stirrer speed of 200r / min, a reaction temperature of 25°C, and an air volume of 12m 3 / h, ammonium chloride concentration 1mol / L, ammonia water 1 mol / L, turn on the ultrasonic wave, power 60W, add 1L / t hydrogen peroxide every 20min, ultrasonic enhanced oxidation leaching for 1 hour, the leaching of metal copper in waste copper circuit boards The rate is 98.19%.

Embodiment 2

[0033] Take 10 grams of a copper-clad circuit board with a copper content of 20.98%, and mechanically crush it to below 200 mesh; at a solid-liquid ratio of 1:8, a stirrer speed of 800r / min, and a reaction temperature of 25°C, the amount of air introduced is 12m 3 / h, ammonium chloride concentration 5mol / L, ammonia water 4 mol / L, turn on the ultrasonic wave, power 120W, add 3L / t hydrogen peroxide every 20min, ultrasonic enhanced oxidation leaching for 4 hours; leaching of metal copper in waste copper circuit boards The rate is 99.53%.

Embodiment 3

[0035] Take 10 grams of a copper-clad circuit board with a copper content of 19.58%, and mechanically crush it to below 200 mesh; at a solid-liquid ratio of 1:5, a stirrer speed of 600r / min, a reaction temperature of 25°C, and an air volume of 10m 3 / h, ammonium chloride concentration 3mol / L, ammonia water 2 mol / L, turn on the ultrasonic wave, power 180 W, add 2L / t hydrogen peroxide every 20min, ultrasonic enhanced oxidation leaching for 2 hours; The leaching rate is 98.62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com