Beneficiation reagent, synthesis method and method for comprehensively utilizing generated waste gases

A kind of beneficiation agent and agent technology, which is applied in the field of precious metal extraction, can solve the problems of low utilization rate of backwater, high comprehensive cost, unsafety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

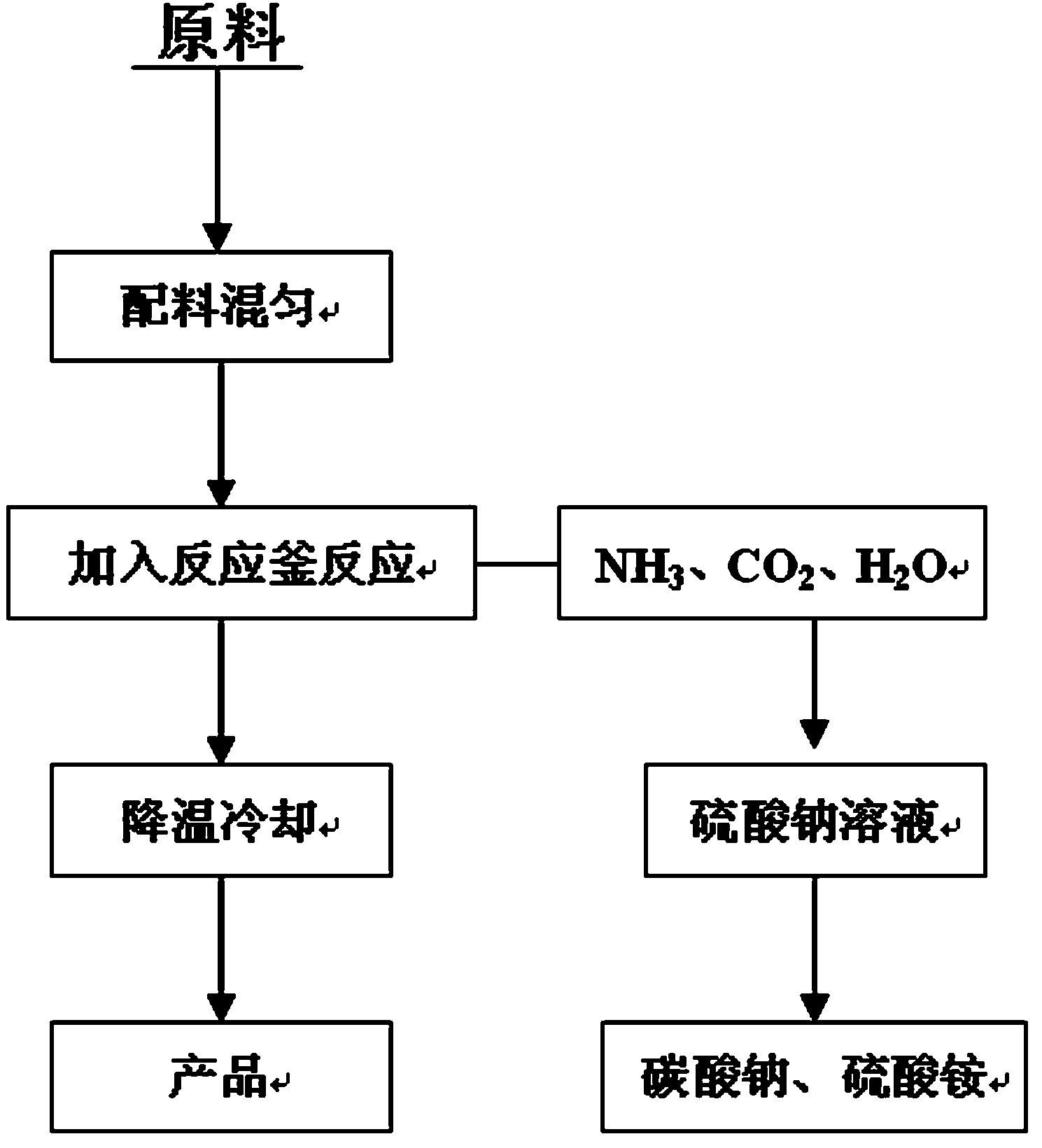

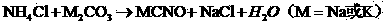

Method used

Image

Examples

Embodiment 6

[0054] Embodiment 6: In parts by weight, 500 parts of ammonium chloride, 40 parts of strong alkali, 360 parts of urea, 650 parts of sodium carbonate, 500 parts of yellow blood salt potassium, 10 parts of potassium sulfide, 50 parts of lime nitrogen, 100 parts of carbon, cyanic acid The mixture of 100 parts of sodium is added into the reaction kettle, heated rapidly to 500-900°C, and then reacted at this temperature for half an hour, and the product is obtained after cooling down. Then use this product to carry out immersion gold test, and the test results are shown in Table 1.

Embodiment 7

[0055] Embodiment 7: In parts by weight, 700 parts of ammonium chloride, 80 parts of strong alkali, 500 parts of urea, 650 parts of sodium carbonate, 50 parts of yellow blood salt potassium, 5 parts of potassium sulfide, and 100 parts of sodium cyanate are added to the reaction kettle. Rapidly heat up to 500-800°C, then react at this temperature for half an hour, and obtain the product after cooling down. Then use this product to carry out immersion gold test, and the test results are shown in Table 1.

Embodiment 8

[0056] Embodiment 8: In parts by weight, 700 parts of ammonium chloride, 160 parts of strong alkali, 700 parts of urea, 650 parts of sodium carbonate, 500 parts of yellow blood salt potassium, 10 parts of potassium sulfide, 50 parts of lime nitrogen, 100 parts of carbon, cyanic acid Add the mixture of 300 parts of sodium into the reaction kettle, heat it rapidly to 500-1000°C, then react at this temperature for half an hour, and get the product after cooling down. Then use this product to carry out immersion gold test, and the test results are shown in Table 1.

[0057] From the test data of each example in Table 4 below, it is shown that the medicament has a complex composition capable of leaching gold, wherein cyanide plays an auxiliary role in leaching. After the gold leaching is completed, the residual amount of cyanide in the wastewater is small, which is harmful to the environment and operation. , transportation, etc., and finally can obtain good economic and environme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com