Patents

Literature

167 results about "Sodium cyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

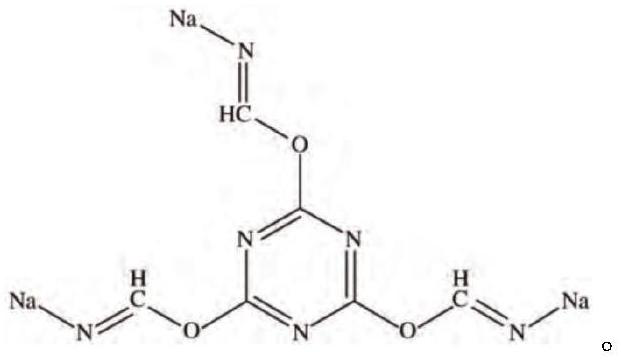

Sodium cyanate (NaOCN) is a white crystalline solid that adopts a body centered rhombohedral crystal lattice structure (trigonal crystal system) at room temperature.

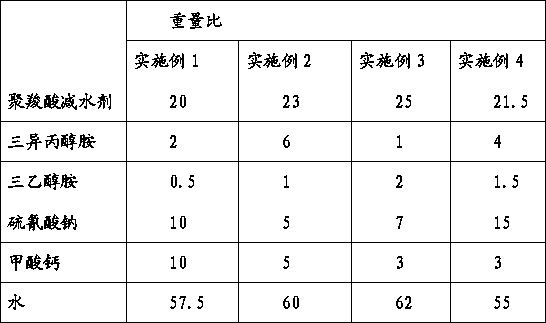

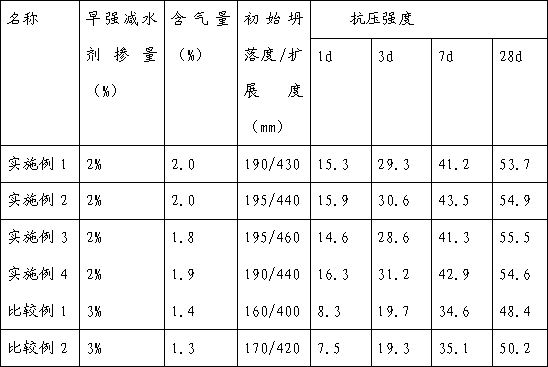

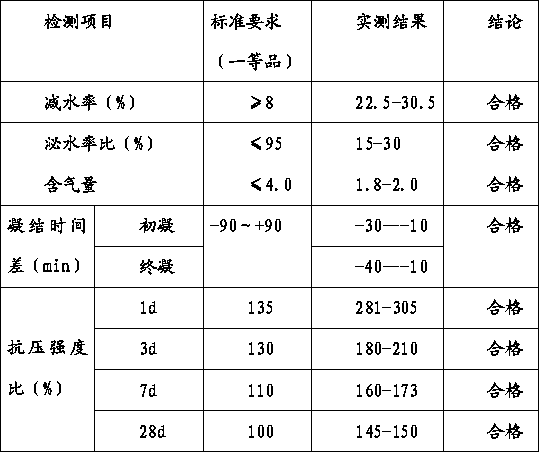

Early-strength water reducer for recycled aggregate concrete

The invention provides an early-strength water reducer for recycled aggregate concrete, which is suitable for the field of building materials. The the early-strength water reducer comprises the following raw materials by weight percent: 20-25% of a polycarboxylic acid water reducer, 1-6% of tri-isopropanolamine, 0.5-2% of triethanolamine, 5-15% of sodium sulfocyanate, 3-10% of calcium formate, and 42-70.5% of water. The early-strength water reducer provided by the invention is low in dosage, good in early-strength effect, free from chloride ions, resistant to the corrosion of steel bars, suitable for recycled concrete, and capable of enhancing the early strength of a recycled concrete product and improving the peaceability of a recycled concrete mixture.

Owner:北京新奥混凝土集团有限公司

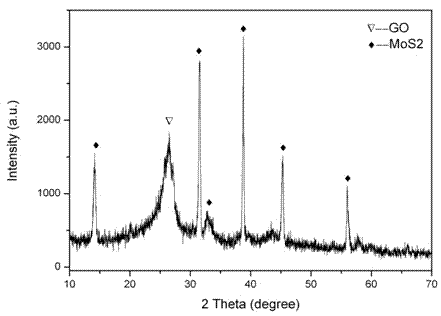

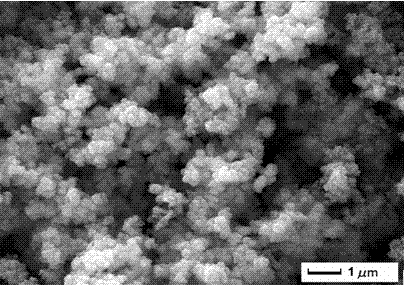

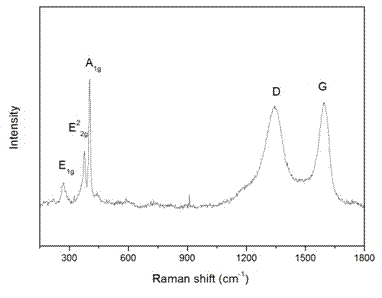

Graphene/metal oxide semiconductor (MoS2) nano self-lubricating composite material and preparation method thereof

InactiveCN102807907AImprove friction performanceSimple manufacturing methodAdditivesSodium thiocyanateSodium cyanate

The invention relates to metal oxide semiconductor 2 (MoS2), in particular to a graphene / MoS2 nano self-lubricating composite material and a preparation method thereof. The composite material is prepared through the following steps that: graphene oxide nanosheets are placed into mixed solution which is formed by molybdate, sodium thiocyanate, sodium chloride and deionized water to obtain mixed solution 1, the pH value of the mixed solution 1 is adjusted through hydrogen chloride (HCl) and sodium hydroxide (NaOH) to 1 to 6, the mixed solution 1 is transferred to a hydrothermal reactor which is lined with polytetrafluoroethylene after being ultrasonically treated and uniformly mixed, the mixed solution 1 has hydrothermal reaction under 180 to 200 DEG C after the reactor is well sealed, products are centrifuged and collected after 24 to 48 hours, the products are washed by the deionized water and the absolute ethyl alcohol, and the dried products are heat treated for 2 hours under 800 to 900 DEG C under the protection of the nitrogen (N2) / hydrogen (H2) atmosphere to obtain the graphene / MoS2 nano self-lubricating composite material.

Owner:JIANGSU UNIV

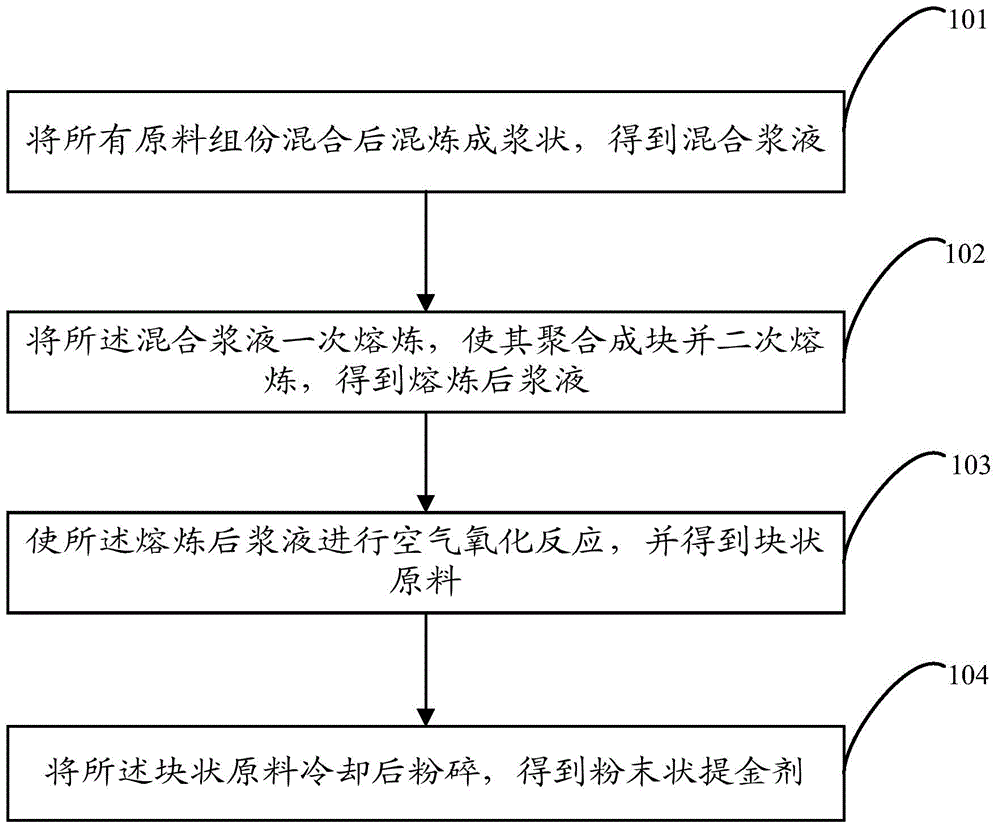

Preparation method of environment-friendly type precious metal beneficiation agent

ActiveCN103937986AAvoid pollutionEfficient leachingProcess efficiency improvementLead saltSodium cyanide

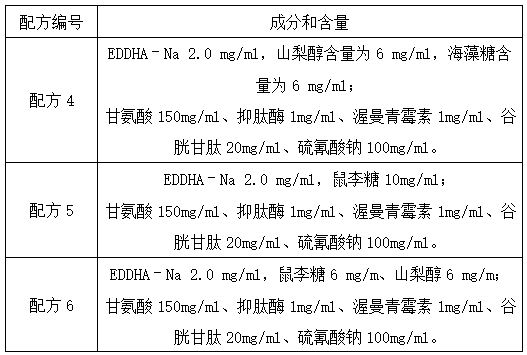

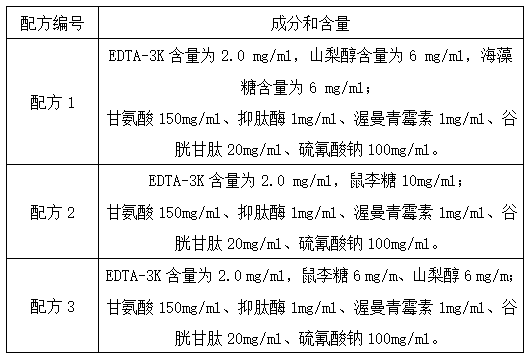

The invention relates to a preparation method of a low-toxic environment-friendly type novel precious metal beneficiation agent. Raw materials of the low-toxic environment-friendly type novel precious metal beneficiation agent comprise a cyanate, sodium hydroxide, sodium sulfate, sodium ferrocyanide, a bromide, and a lead salt. The preparation method comprises following steps: sodium cyanate, sodium hydroxide, sodium sulfate, and sodium ferrocyanide are mixed at a certain ratio; an obtained mixture is delivered into a smelting pot which is heated to be slightly red, and is heated to 650 to 750 DEG C so as to obtain a fused material, temperature is maintained to be 750 DEG C for 30 to 50min of reaction, and then an obtained product is collected and cooled; the obtained product is smashed, the bromide and the lead salt are added for stirring, and the environment-friendly type precious metal beneficiation agent is obtained via combination. The environment-friendly type precious metal beneficiation agent can be widely used for precious metal beneficiation metallurgy of nonferrous metals ores, contains no hypertoxic compounds, is safe for human and animal, and is friendly to the environment. Compared with other metal beneficiation agents, the environment-friendly type precious metal beneficiation agent is excellent in effects, stable in performance, and low in production cost; the preparation method is simple; and environmental protection can be realized.

Owner:广西河池鑫银环保科技有限公司

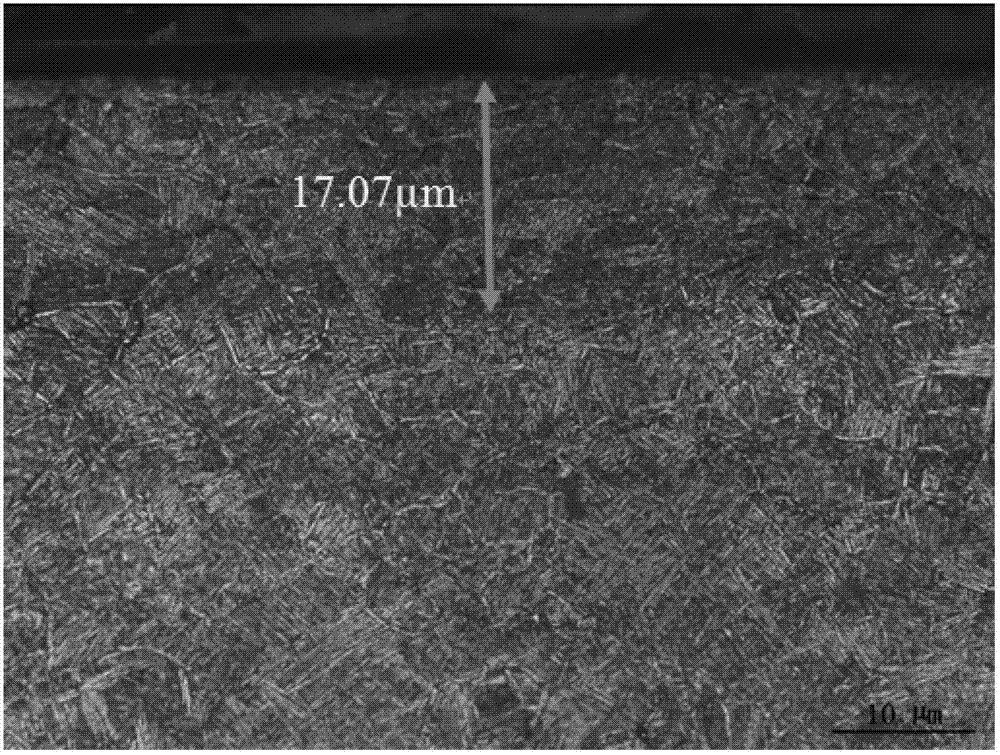

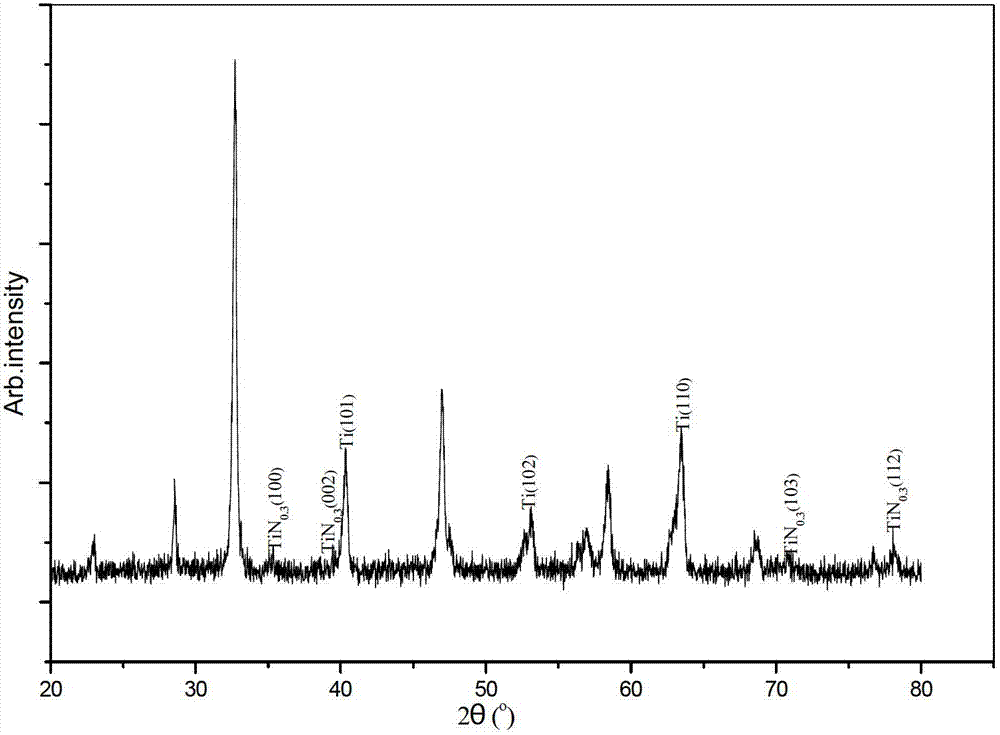

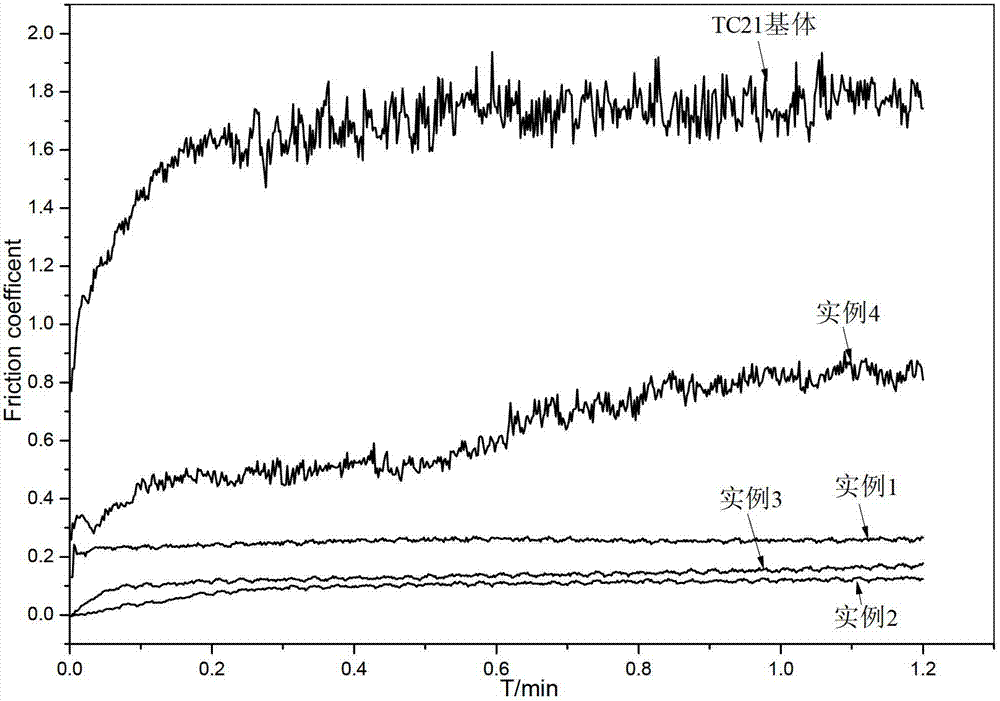

Low-temperature surface nitriding method of titanium alloy

ActiveCN102965613ASimple processImprove controllabilitySolid state diffusion coatingPtru catalystSand blasting

The invention discloses a low-temperature surface nitriding method of a titanium alloy, and belongs to the technical field of metal surface heat treatment and modification. The low-temperature surface nitriding method is characterized by comprising the following steps of: firstly, carrying out sand blasting cleaning on the surface of the titanium alloy, then carrying out chemical mechanical lapping and polishing, then mixing powder crystal sodium cyanate (NaCNO) and granular crystal potassium cyanate (KCNO) and rare earth CeO2 powder in a certain proportion so as to obtain a nitriding reagent, placing the nitriding reagent and the treated titanium alloy in a crucible for compacting and sealing, then drying, and placing the crucible in a high-temperature furnace for heating, wherein NaCNO and KCNO are used as nitriding sources, and rare earth CeO2 is used as a catalyst. According to the low-temperature surface nitriding method, a TiN 0.3-1 nitriding layer is formed on the surface of the titanium alloy TC21, the friction coefficient of the surface of the titanium alloy is remarkably reduced, the surface hardness is increased, and the surface property is enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

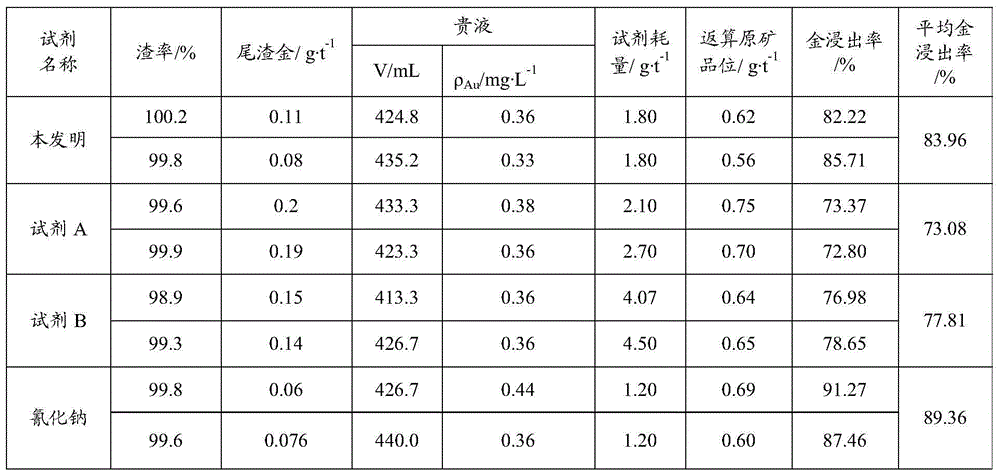

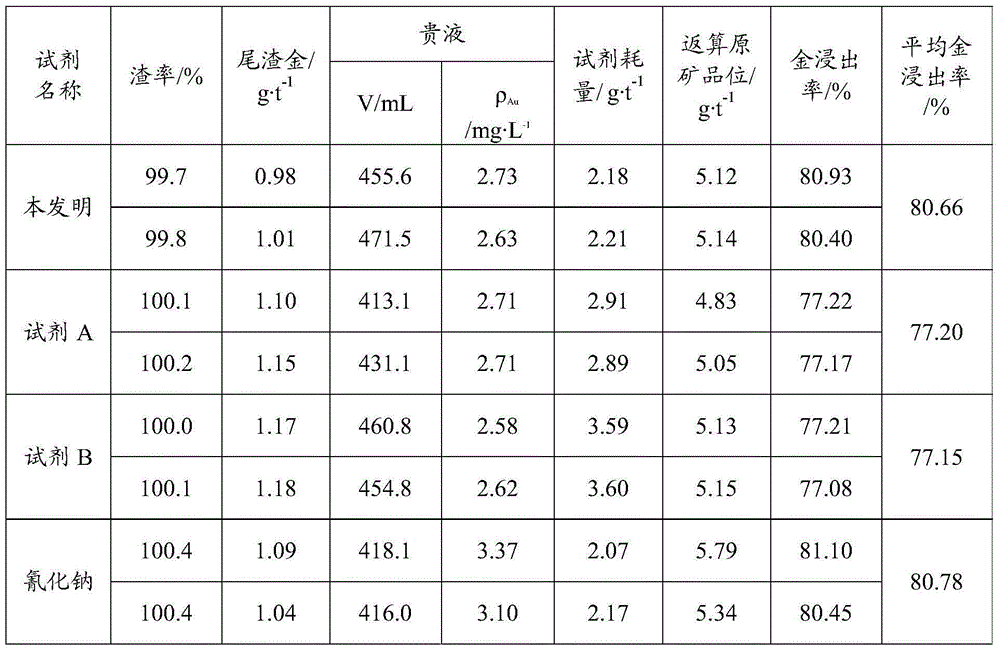

Gold extracting agent and preparation method thereof

The invention provides a gold extracting agent and a preparation method thereof, and belongs to the technical field of gold extraction. The gold extracting agent comprises the raw material components in parts by weight: 12-12.4 parts of sodium hexametaphosphate, 7-7.4 parts of sodium cyanate, 9.4-9.8 parts of sodium ferrocyanide, 10.3-10.7 of sodium sulfide, 13.3-13.7 parts of sulphur, 10.4-10.8 parts of sodium bromide, 6.3-6.7 parts of sodium chloride, 8.2-8.6 parts of manganese dioxide, 11.8-12.2 parts of urea, and 9.3-9.7 parts of industrial sodium carbonate. The gold extracting agent is alkaline, and has the advantages of low toxicity, environmental protection, short leaching time and convenient transportation and keeping and the like; in addition, the gold extracting rate is high; and the gold extracting agent is quite suitable for use as a novel gold extracting agent for heap leaching, pond leaching and carbon paste production processes of micro-fine particle gold-containing oxidized ores.

Owner:圣的新材料(长兴)有限公司

Salt bath formula for treating high-speed steel air conditioning compressor blade by salt bath nitriding treatment and treatment method

ActiveCN101871087ARaise the concentration ratioLow melting pointSolid state diffusion coatingAir conditioningSodium cyanate

The invention relates to a salt bath formula for treating a high-speed steel air conditioning compressor blade by salt bath nitriding treatment and a treatment method. The salt bath formula comprises the following compositions in percentage by weight: 15-25 percent of potassium cyanate, 5-20 percent of sodium cyanate, 3-10 percent of lithium carbonate, 8-20 percent of sodium carbonate, 10-40 percent of potassium carbonate and 1-10 percent of sodium chloride. The invention has the advantages that because Li ions and Cl ions are added in the formula, the melting point of salt bath is lowered, and nitridation can be carried out under lower temperature; the activity is favorable, and good appearance and good diffusion layer thickness can be achieved without introducing ammonia; and the K / Na concentration proportion is enhanced, and a white layer is not easy to form on the surface of a workpiece.

Owner:SHANGHAI JIANGKAI METAL SURFACE TREATMENT TECH +1

Preparation method of special antibacterial wool fiber for wool hat

InactiveCN107974828ASoft touchFeel smoothPhysical treatmentBiochemical fibre treatmentThioureaUltraviolet lights

The invention discloses a preparation method of a special antibacterial wool fiber for a wool hat. The preparation method comprises the steps of dipping the wool fiber in acetone, airing after washing, adding into a mixed aqueous solution of sodium cyanate and hydrogen peroxide, airing after dipping, and irradiating through an ultraviolet light to obtain a pretreated wool fiber; adding thiourea, urea and butyl titanate into absolute ethyl alcohol for mixing, adjusting a pH value, adding deionized water for stirring until a Tyndall effect occurs, standing for ageing, drying, grinding, and calcining to obtain modified nanometer titania; adding chitosan into an acetic acid aqueous solution, adjusting a pH value, adding the modified nanometer titania, adjusting a system pH value, adding glutaraldehyde after temperature rising, standing for reacting, centrifuging, washing, and drying to obtain modified chitosan; adding the modified chitosan, a plant extract, beta-cyclodextrin and a silane coupling agent KH-550 into the deionized water, and stirring to obtain an antibacterial solution; adding the pretreated wool fiber into the antibacterial solution for padding processing, and baking after drying.

Owner:安徽中福毛纺制帽有限公司

Sodium cyanate gold leaching technology

Owner:FUJIAN SHUANGQISHAN MINING +1

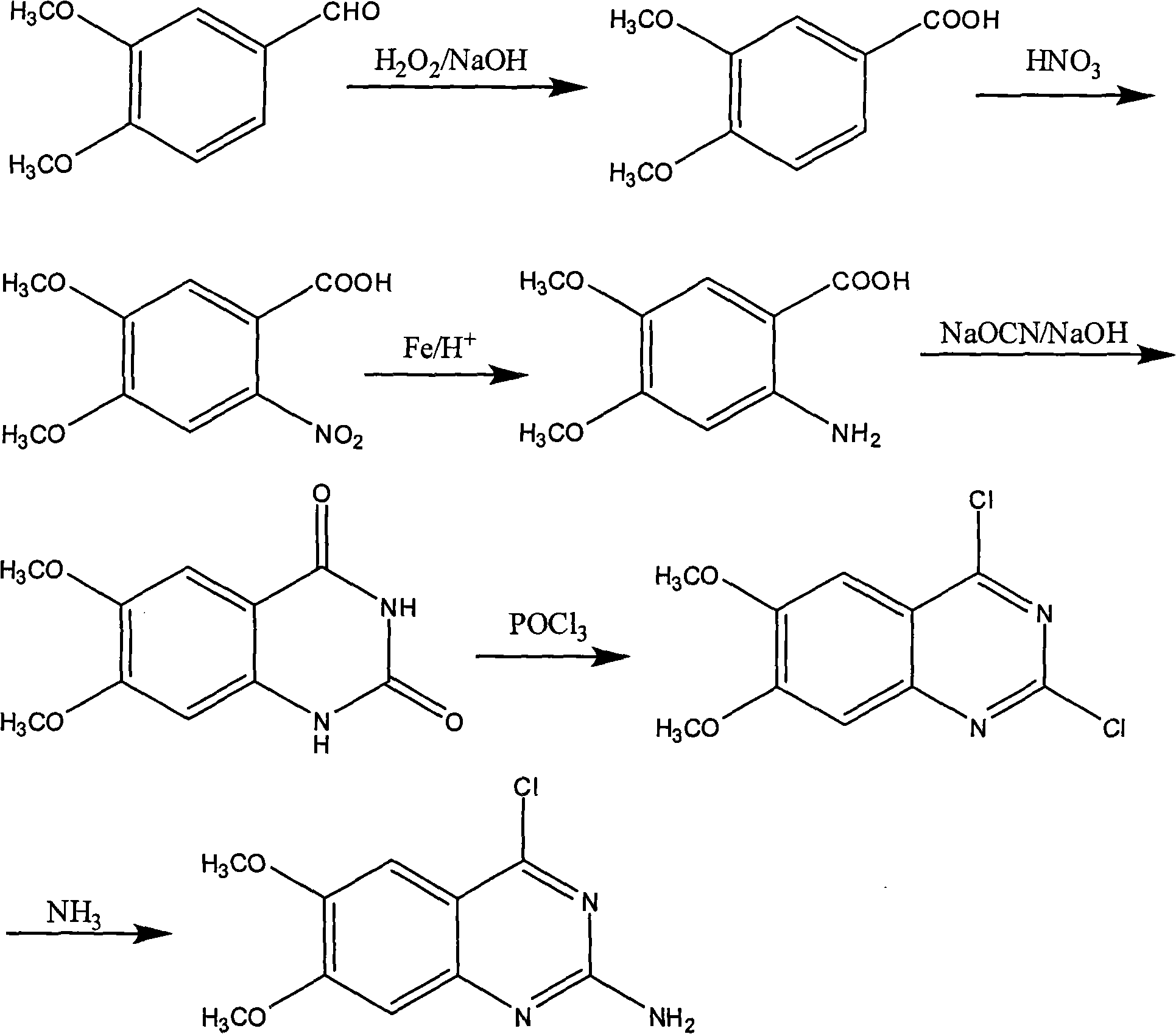

Preparation of 2-chlorin-4-amido-6,7-dimethoxy quinazoline

The invention discloses a preparation method of 2-chloro-4-amido-6,7-dimethoxy quinazoline. The preparation method comprises the following steps: 3,4-dimethoxy benzaldehyde is taken as an initial raw material, then the following reactions are sequentially carried out: oxidizing reaction between the 3,4-dimethoxy benzaldehyde and oxydol, nitration reaction between the 3,4-dimethoxy benzaldehyde and nitric acid, reduction reaction of the 3,4-dimethoxy benzaldehyde and hydrogen ion obtained by iron powder and hydrochloric acid, reaction between the 3,4-dimethoxy benzaldehyde and sodium cyanate, chlorination reaction between the 3,4-dimethoxy benzaldehyde and phosphorus oxychloride, ammoniation reaction between the 3,4-dimethoxy benzaldehyde and ammonia liquor, etc., then the 2-chloro-4-amido-6,7-dimethoxy quinazoline is obtained. The synthetic method takes the commercialized 3,4-dimethoxy benzaldehyde as the initial raw material, and potassium permanganate is not used in the oxidizing reaction process, organic solvents (glacial acetic acid, DMF) are not used in the refining process, the noxious solvent N, N-amino dimethylbenzene or the organic solvent N, N-dimethyl formamide with high boiling point is not used in the chlorination process, so the use amounts of the organic solvents and the phosphorus oxychloride are reduced, thus reducing the production cost, simplifying the production process, protecting the health of operators, reducing 'three wastes' pollution, protecting the environment and greatly improving the reaction yield and the production efficiency.

Owner:CHONGQING WORLD HAORUI PHARM CHEM

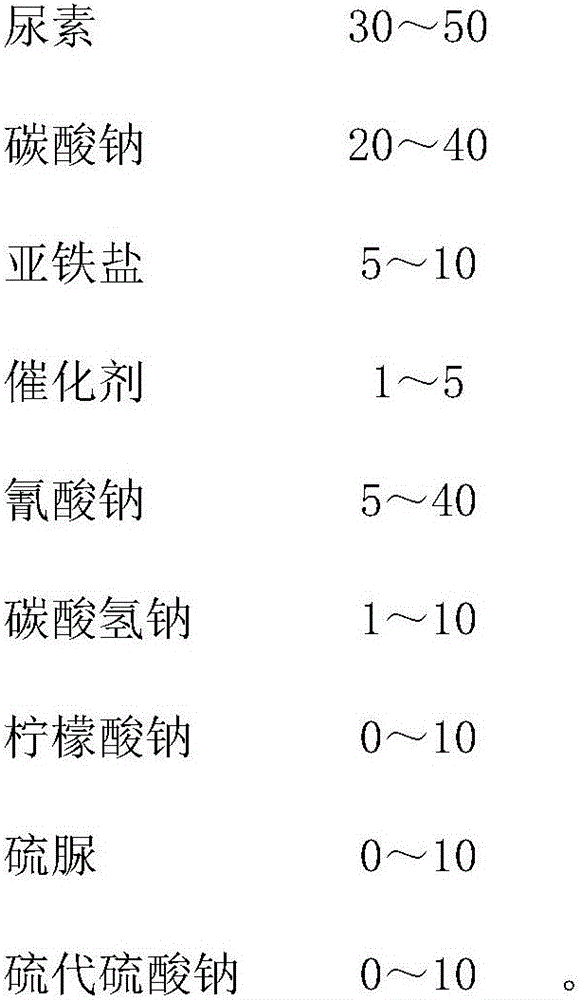

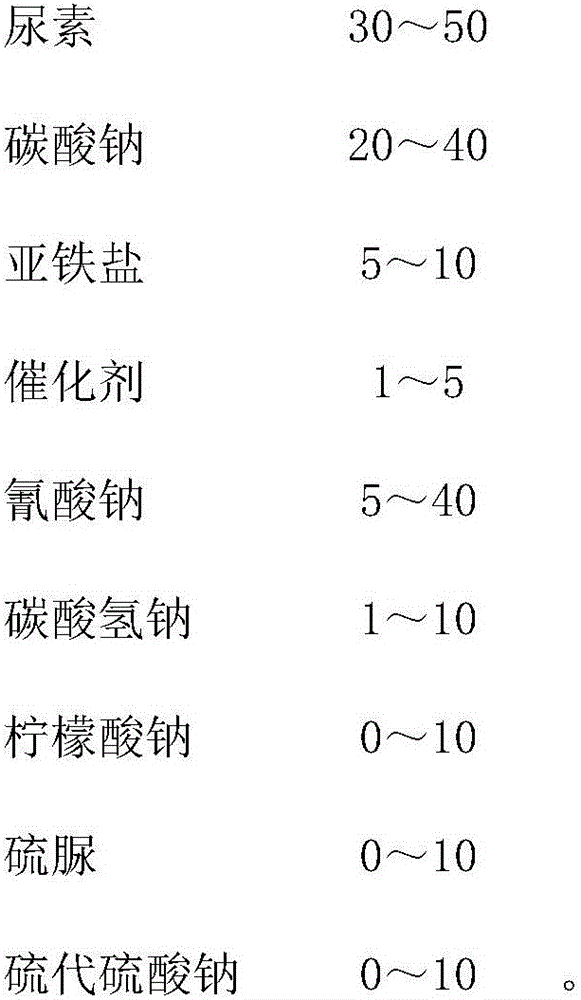

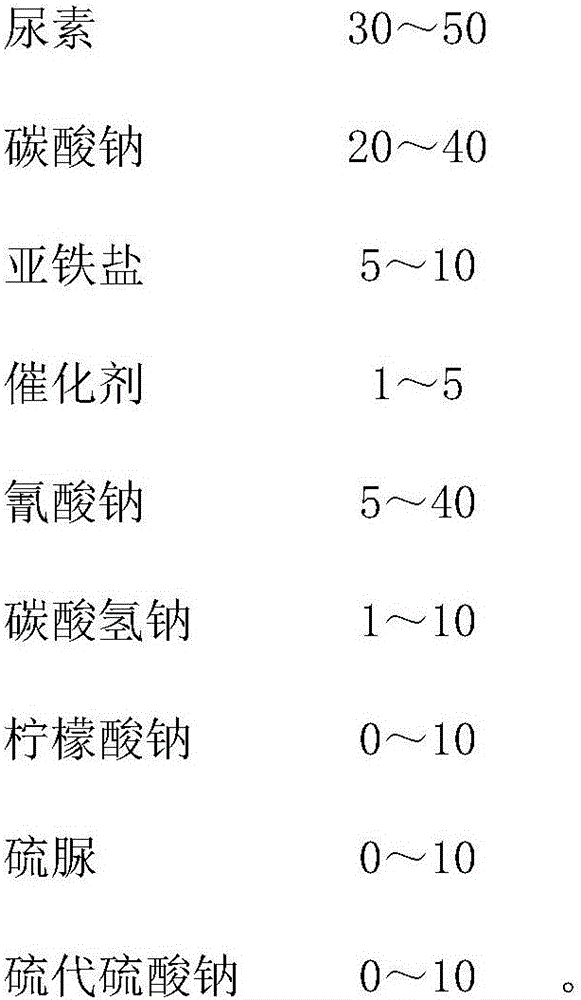

Low-toxicity environment-friendly gold mineral separation agent and preparation method thereof

InactiveCN106399712AExtract impactImprove leaching effectProcess efficiency improvementSodium bicarbonateThiourea

The invention relates to a low-toxicity environment-friendly gold mineral separation agent. Urea, sodium carbonate, ferrite, catalysts, sodium cyanate and sodium bicarbonate are adopted as main raw materials, and sodium citrate, thiourea and sodium thiosulfate are selectively added. After reactions of certain steps, the finished product is obtained. In the low-toxicity environment-friendly gold mineral separation agent, sodium cyanide with highly toxic hazards is not used, iron, nickel and carbon catalysts are used for catalyst reactions in the technology process, and the reaction time is shortened; by means of filtering measures, produced unmelted impurities are removed, and the effects of the impurities on gold extraction are avoided; in a product formula, multiple mineral separation ingredients and inhibitors, decomposing agents and the like for mineral harmful impurities are matched, and an obvious leaching effect is achieved for ores difficult to treat; and by means of a special two-time charging manner, the recovery rate of the product is increased.

Owner:金霖控股(北京)股份有限公司

Antibacterial mildew-resistant finishing agent for wool caps

InactiveCN107829295AReduce yellowingAvoid yellowingLight resistant fibresWrinkle resistant fibresAminosilochromeGlutaminase

The invention discloses an antibacterial mildew-resistant finishing agent for wool caps. The antibacterial mildew-resistant finishing agent comprises, by weight, 2-10 parts of sodium cyanate, 2-10 parts of hydrogen peroxide, 10-35 parts of modified chitosan, 2-10 parts of eucommia extract, 3-9 parts of bamboo leaf extract, 1-5 parts of cortex dictamni extract, 2-10 parts of pomegranate peel extract, 3-16 parts of radix lithospermi extract, 3-18 parts of beta-cyclodextrin, 0.1-1.2 parts of transglutaminase, 1-5 parts of amino siloxane, 2-10 parts of citric acid and 2-4 parts of hydrophilic surfactant. The antibacterial mildew-resistant finishing agent can endow the wool caps with excellent antibacterial performance and mildew resistance, feltability of the wool caps is lowered, and the woolcaps are enabled to be soft in hand feel and gentle in gloss.

Owner:安徽中福毛纺制帽有限公司

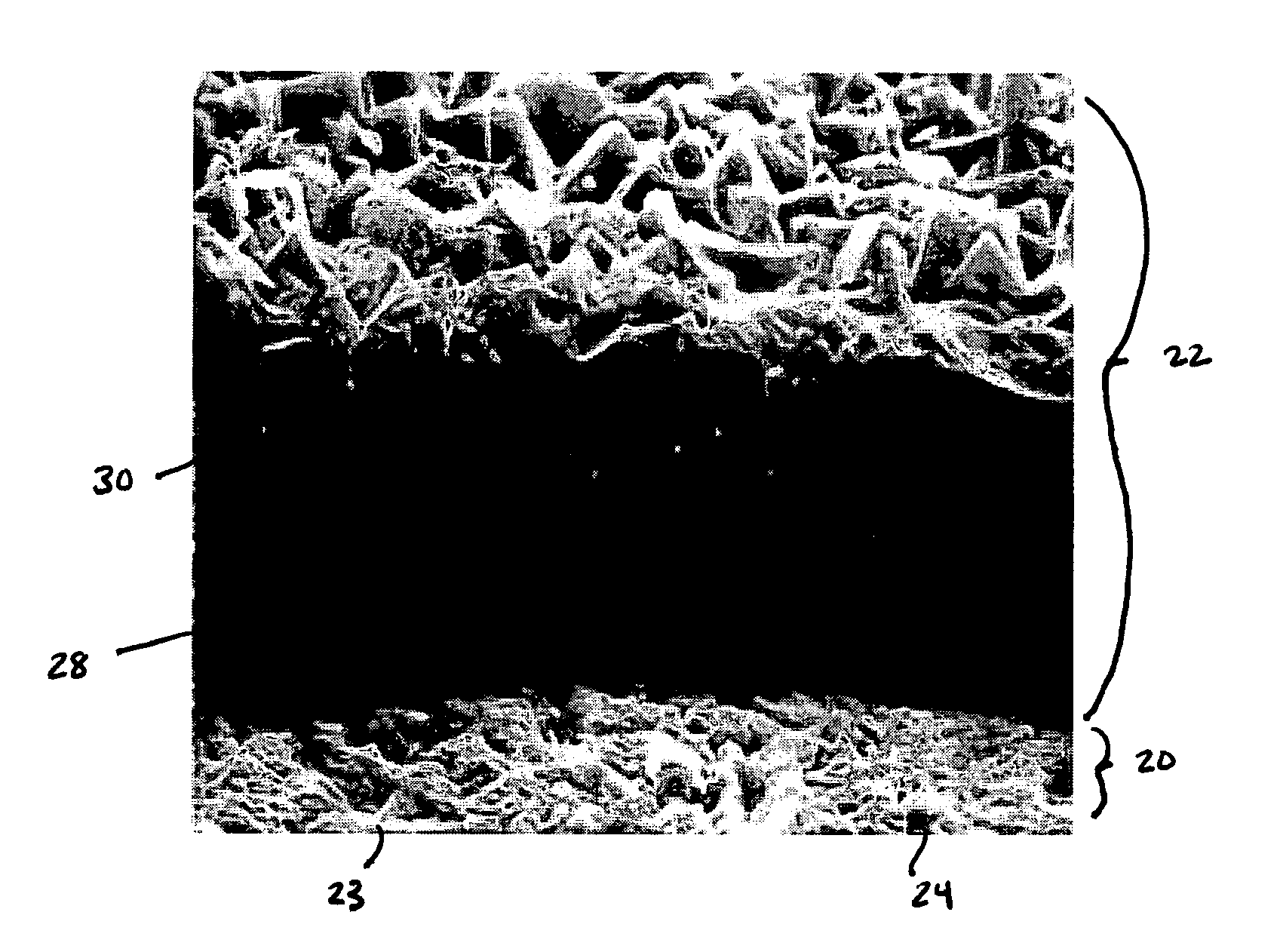

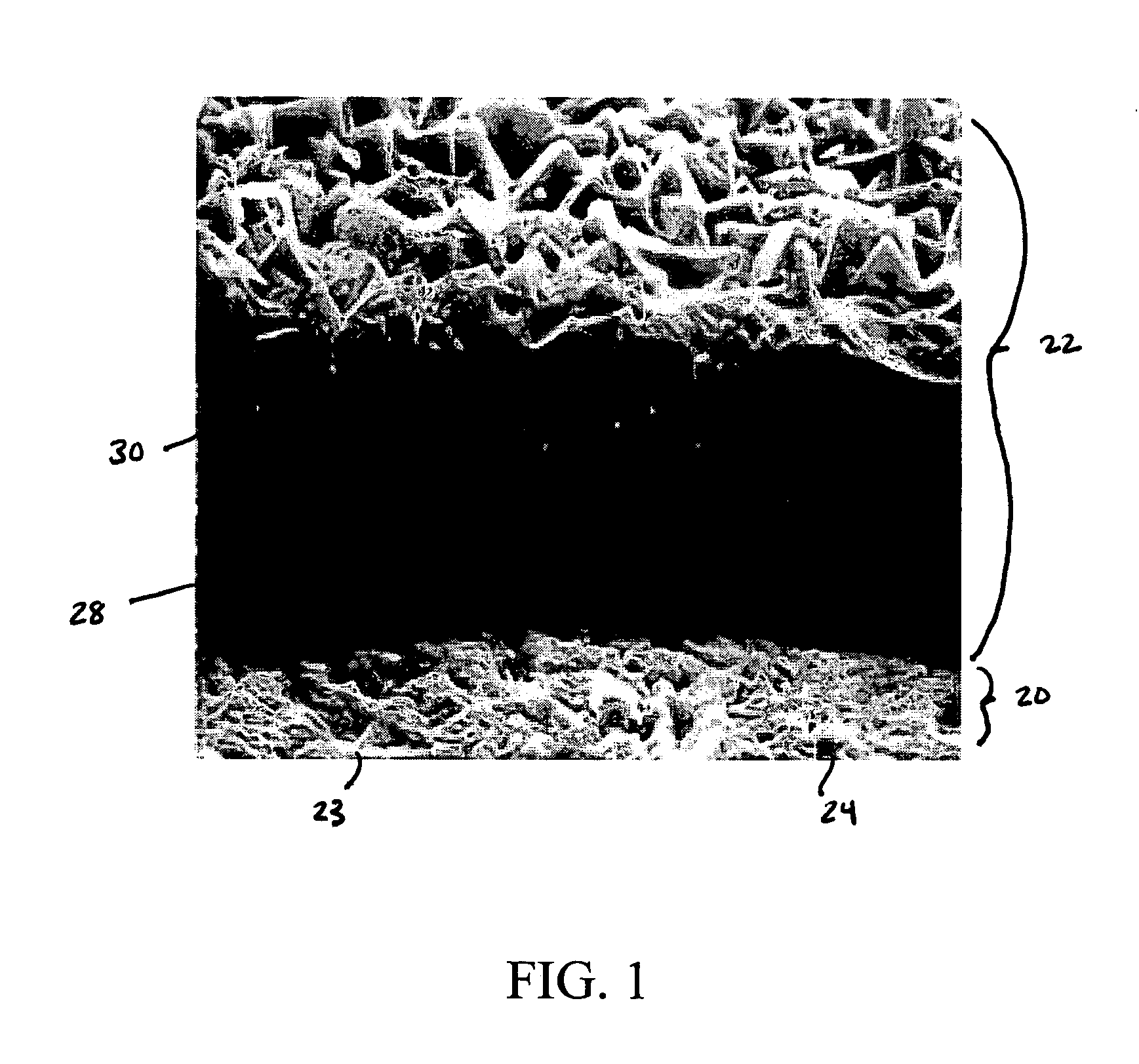

Process for diffusing titanium and nitride into a material having a coating thereon

InactiveUS7438769B2Improve propertiesImprove adhesionHot-dipping/immersion processesPretreated surfacesElectrolysisTitanium

A method for diffusing titanium and nitride into a base material having a coating thereon using conventional surface treatments or coatings. The method generally includes the steps of providing a base material having a coating thereon; providing a salt bath which includes sodium dioxide and a salt selected from the group consisting of sodium cyanate and potassium cyanate; dispersing metallic titanium formed by electrolysis of a titanium compound in the bath; heating the salt bath to a temperature ranging from about 430° C. to about 670° C.; and soaking the base material in the salt bath for a time of from about 10 minutes to about 24 hours. In accordance with another aspect of the present invention, titanium and nitride may be diffused into a base material without a coating. The treated base material may further be treated with conventional surface treatments or coatings.

Owner:KO PHILOS JONGHO +1

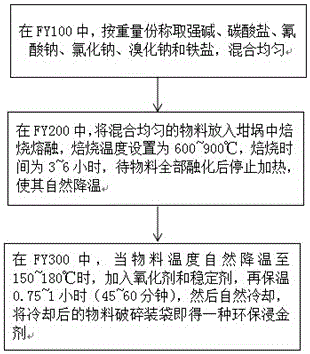

Environmental-protection gold leaching agent and preparation method thereof

InactiveCN105950884AIncrease profitEmission reductionProcess efficiency improvementEnvironmental resistanceIron salts

The invention relates to the technical field of gold extraction, and particularly relates to an environmental-protection gold leaching agent and a preparation method thereof; the gold leaching agent is composed of the following raw materials in parts by weight: 8-15 parts of a strong alkali, 4-16 parts of carbonate, 12-30 parts of sodium cyanate, 3-6 parts of sodium chloride, 2-8 parts of sodium bromide, 6-22 parts of an iron salt, 2-4 parts of an oxidant, and 3-6 parts of a stabilizer. The gold leaching agent can completely replace cyanide for gold leaching, and is non-toxic and harmless; moreover, the synthesis process is simple, the utilization rate of the raw materials is higher, the waste gas emission load is low, and waste gas has no influence on the environment after being absorbed by a spray tower; the oxidant and the stabilizer are added in the product, so the product is guaranteed to have better gold leaching performance, can handle primary ores, oxidized ores and ores with more harmful impurities, and has wider adaptability.

Owner:天津华勘矿业选冶技术开发有限公司

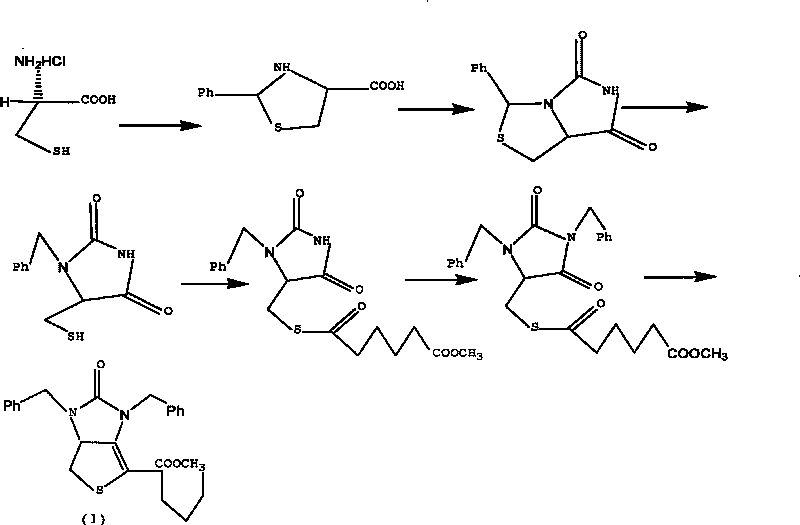

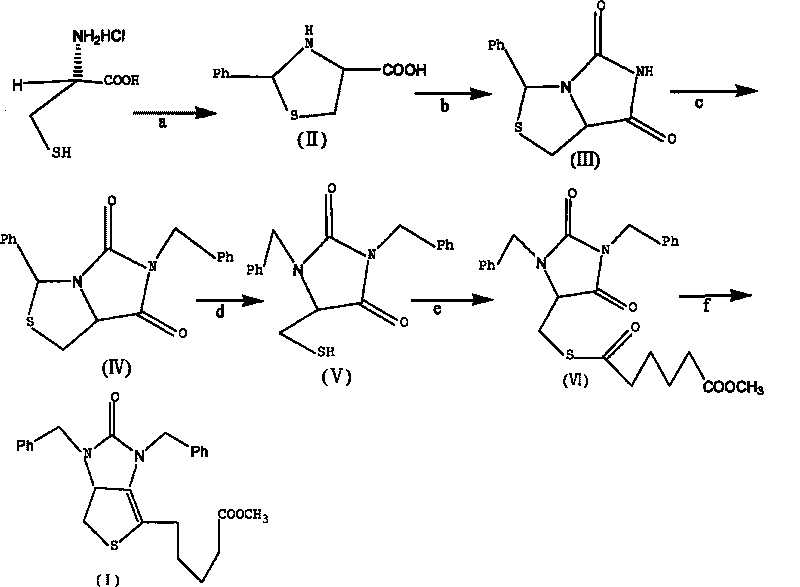

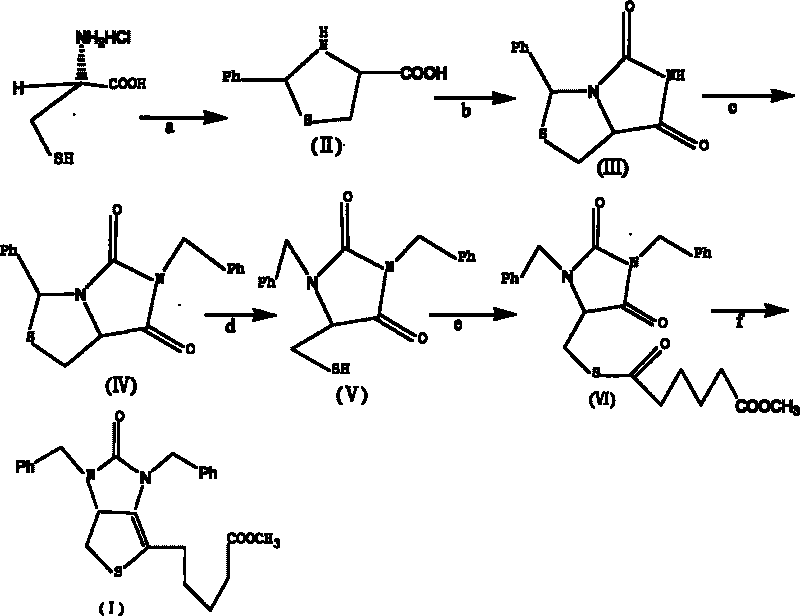

Method for preparing D-(+)-biotin intermediate

ActiveCN101735242AEasy to buyIncreased riskOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsBenzoyl bromideBenzaldehyde

The invention provides a method for preparing a D-(+)-biotin intermediate. The method comprises the steps of: taking L-cysteine monohydrochloride as a starting material; using benzaldehyde and sodium cyanate as a ring closure reagent to synthesize (7aR)-3-phenyl-6-benzyl-1H, 3H-imidazo[1, 5-C]thiazole-(6H, 7aH)-5, 7-dione through the cyclization; then utilizing benzyl bromide to perform benzyl protection on N atoms; then taking zinc as a reducing agent to perform ring-opening synthesis on N, N-dibenzyl-L-sulfhydryl hydantoin; introducing a side chain through an esterification reaction with monomethyl adipate acyl chloride; and taking titanium as the reducing agent to perform reductive ring closure to generate the intermediate. According to the method, the cheap and readily available sodium cyanate is used as the ring closure reagent to replace sodium isocyanate which is toxic and difficult to purchase in an original method, reaction conditions are optimized and reaction order is adjusted, so the disadvantages of harsh reaction conditions and low yield in the original method of ring opening first and then benzyl protection are overcome by the method of performing benzyl protection on the N atoms of an imidazole part first and then performing ring opening; and the total yield reaches 34.0-38.0 percent.

Owner:安徽泰格生物技术股份有限公司

Salt bath formula for treating stainless air conditioning compressor blade by salt bath nitriding treatment and treatment method

ActiveCN101871088ALow melting pointHigh activitySolid state diffusion coatingPotassium hydroxideAir conditioning

The invention relates to a salt bath formula for treating a stainless air conditioning compressor blade by salt bath nitriding treatment and a treatment method. The salt bath formula comprises the following compositions in percentage by weight: 5-20 percent of potassium cyanate, 15-25 percent of sodium cyanate, 3-10 percent of lithium carbonate, 8-25 percent of sodium carbonate, 10-30 percent of potassium carbonate, 1-3 percent of sodium hydroxide, 1-5 percent of potassium hydroxide and 1-15 percent of sodium chloride or sodium fluoride. The invention has the advantages that because Li ions and Cl ions are added in the formula, a melting point of salt bath is lowered, and nitridation can be carried out under lower temperature; the activity is favorable, and good appearance and good diffusion layer thickness can be achieved without introducing ammonia; and air cooling can be adopted after salt bath nitridation without adopting the traditional oil cooling mode.

Owner:SHANGHAI JIANGKAI METAL SURFACE TREATMENT TECH +1

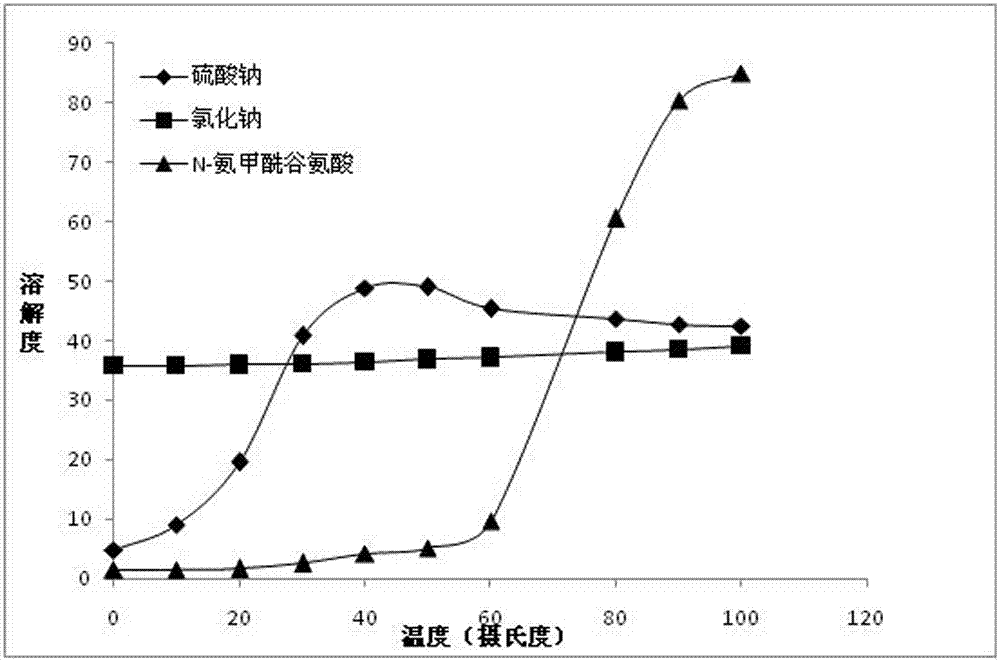

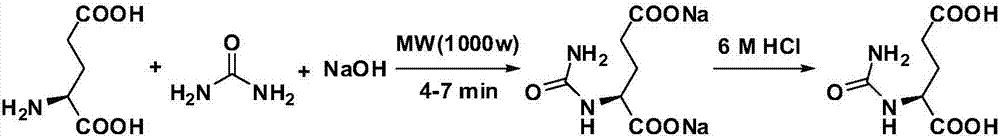

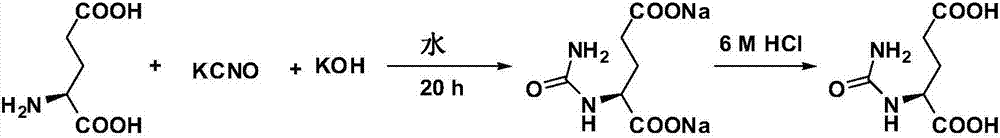

Synthesis and post-treatment method of high-purity N-carbamylglutamic acid

ActiveCN107033035ASolve the problems of high cost, low purity and complicated processEasy to separateUrea derivatives preparationOrganic compound preparationCarbamylglutamic acidFiltration

The invention discloses a synthesis and post-treatment method of high-purity N-carbamylglutamic acid and belongs to the field of organic chemistry and fine chemical engineering. According to the method, sodium glutamate and sodium cyanate are adopted as raw materials to prepare N-carbamoyl sodium glutamate, acidification is performed with sulfuric acid after reaction is completed, then heating is performed to 40-50 DEG C, and filtration is performed to obtain a high-purity product after even stirring; a mother solution is cooled to 0-5 DEG C, a byproduct sodium sulfate decahydrate is obtained through filtration, the mother solution is regulated to be neutral with a sodium hydroxide solution for recycled usage. The problems of high cost, low purity, difficult wastewater treatment and the like in the N-carbamylglutamic acid production process are solved, the product purity is up to 99% or above, and a feasible way is provided for industrial production of the N-carbamylglutamic acid.

Owner:内蒙古天翊生物科技有限公司

Process for diffusing titanium and nitride into a material having a coating thereon and products produced thereby

InactiveUS20070243398A1Improve propertiesImprove adhesionHot-dipping/immersion processesPretreated surfacesElectrolysisTitanium

A method for diffusing titanium and nitride into a base material having a coating thereon using conventional surface treatments or coatings. The method generally includes the steps of providing a base material having a coating thereon; providing a salt bath which includes sodium dioxide and a salt selected from the group consisting of sodium cyanate and potassium cyanate; dispersing metallic titanium formed by electrolysis of a titanium compound in the bath; heating the salt bath to a temperature ranging from about 430° C. to about 670° C.; and soaking the base material in the salt bath for a time of from about 10 minutes to about 24 hours. In accordance with another aspect of the present invention, titanium and nitride may be diffused into a base material without a coating. The treated base material may further be treated with conventional surface treatments or coatings.

Owner:KO PHILOS JONGHO +1

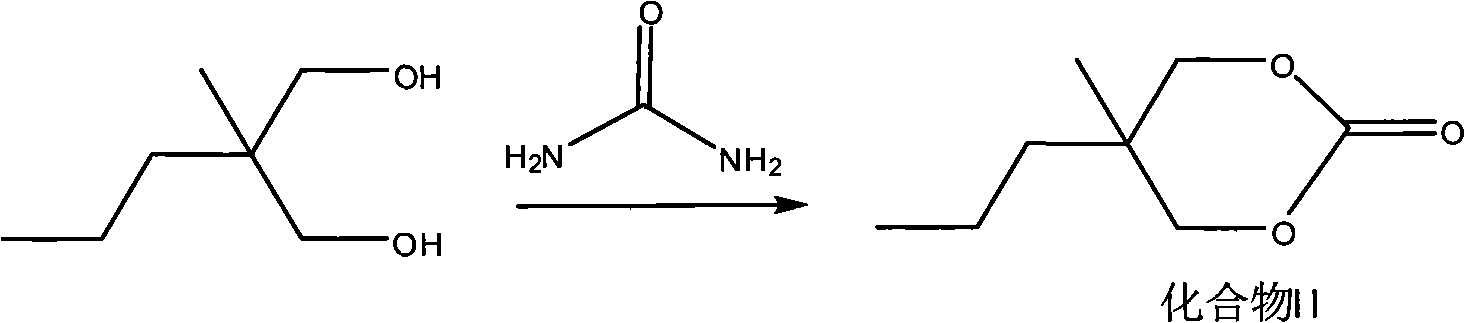

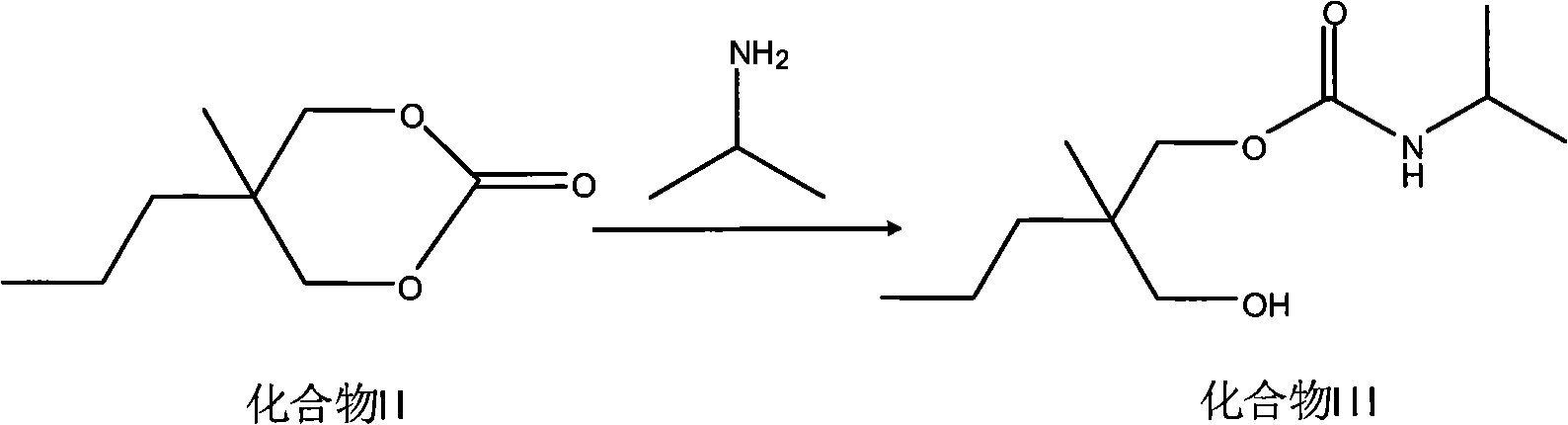

Method for synthesizing 5-methyl-5-propyl-1,3-dioxane-2-ketone and carisoprodol

InactiveCN101289441AIncrease profitReduce consumptionCarbamic acid derivatives preparationOrganic compound preparationKetoneIsopropylamine

The invention discloses a synthetic method for 5-methyl-5-propyl-1, 3-dioxane-2-ketone and carisoprodol, which uses 2-methyl-2-propyl-1, 3-propanediol as an original material, and the 5-methyl-5-propyl-1,3-dioxane-2-ketone can be generated through a condensation reaction with urea under the catalysis of activated metal oxide; the obtained 5-methyl-5-propyl-1, 3-dioxane-2-ketone is ammonolyzed with isopropylamine, and 2-methyl-2-ethyl-3-hydroxypropyl-N-isopropylcarbamate can be prepared; the 2-methyl-2-ethyl-3-hydroxypropyl-N-isopropylcarbamate reacts with sodium cyanate, and the carisoprodol is prepared. The synthetic method for the 5-methyl-5-propyl-1, 3-dioxane-2-ketone and the carisoprodol is cheap and easily available in raw material, simple in preparation technology and more economical.

Owner:CHONGQING ENSKY CHEM

Environment-friendly high-efficiency gold leaching agent synthesis method

ActiveCN109797290AIncrease profitPromote generationProcess efficiency improvementEnvironmental resistanceIron salts

The invention discloses an environment-friendly high-efficiency gold leaching agent synthesis method. The environment-friendly high-efficiency gold leaching agent synthesis method comprises the specific steps that iron salt, sodium cyanate and sodium carbonate are mixed and placed in a reactor, the reaction atmosphere is controlled according to the volume ratio of N2: CO2: O2 being [5-25]:[5-30]:[45-90], slowly heating is carried out to reach 400-900 DEG C, the temperature is kept for 10-50min, and cooling is carried out to normal temperature to obtain an environment-friendly high-efficiency gold leaching agent; and the mass ratio of iron salt, sodium cyanate and sodium carbonate is [2-30]:[40-85]:[5-40]. According to the environment-friendly high-efficiency gold leaching agent synthesis method, by controlling the reaction atmosphere, the metathesis reaction in the high-temperature process can be effectively reduced, the utilization rate of reactants is greatly improved, the generationof cyanate is promoted, the chelation of cyanate and iron salt is catalyzed, the generation of cyanide is inhibited, so that the total cyanide concentration in gold leaching tail liquid is greatly reduced, and the leaching rate is ensured.

Owner:ZIJIN MINING GROUP

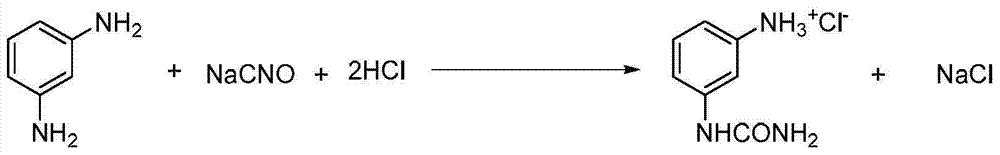

Clean production process of m-carbamidoaniline hydrochloride

ActiveCN103539705AEmission reductionAvoid reactionUrea derivatives preparationOrganic compound preparationReaction temperatureSodium cyanate

The invention discloses a clean production process of m-carbamidoaniline hydrochloride. The clean production process comprises the following steps of: dissolving m-phenylenediamine into a sodium chloride salt water reaction system; adding an auxiliary agent into the reaction system; controlling a reaction temperature at -5 DEG C to 25 DEG C; then adding sodium cyanate and hydrochloric acid for reaction; and after the reaction is completed, carrying out post-treatment on a resulting substance to obtain m-carbamidoaniline hydrochloride, wherein the auxiliary agent is nitric acid or nitrate. According to the clean production process, salt water, instead of pure water, is used as base water, m-carbamidoaniline hydrochloride produced in the reaction can be separated out in time by using salt precipitation effects of sodium chloride, a byproduct diurea is not generated, the purity of the obtained m-carbamidoaniline hydrochloride is more than 98%, the yield is more than 95%, the content is 75%-80%, the sewage quantity is reduced by 50%, and the process is simple and high in automation degree.

Owner:ZHEJIANG RUNTU INST

Environment-friendly gold leaching agent and preparation process thereof

The invention discloses an environment-friendly gold leaching agent, which comprises the following components in parts by mass: 20-60 parts of urea, 5-20 parts of thiourea, 8-40 parts of sodium cyanate, tetraoxide 5-25 parts of triiron, 5-30 parts of sodium carbonate, 20-30 parts of sodium hydroxide. The environment-friendly leaching agent of the present invention comprehensively utilizes the cooperation between sulfur urine and iron ions, the coordination of nitrogen atoms in urea and Au3+ to produce a new mixture, and the reaction of urea and salts to generate soluble gold cyanate. The multiple action mechanisms of gold make it electrochemically react with the gold in the ore under the environment of the inhibitory control agent, thus becoming a new type of gold leaching agent with fast gold leaching speed, good leaching effect and high recovery rate of gold in the ore dressing agent. Environmentally friendly leaching agent.

Owner:张韬 +1

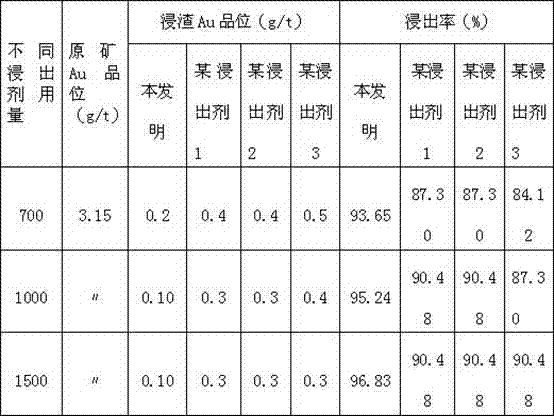

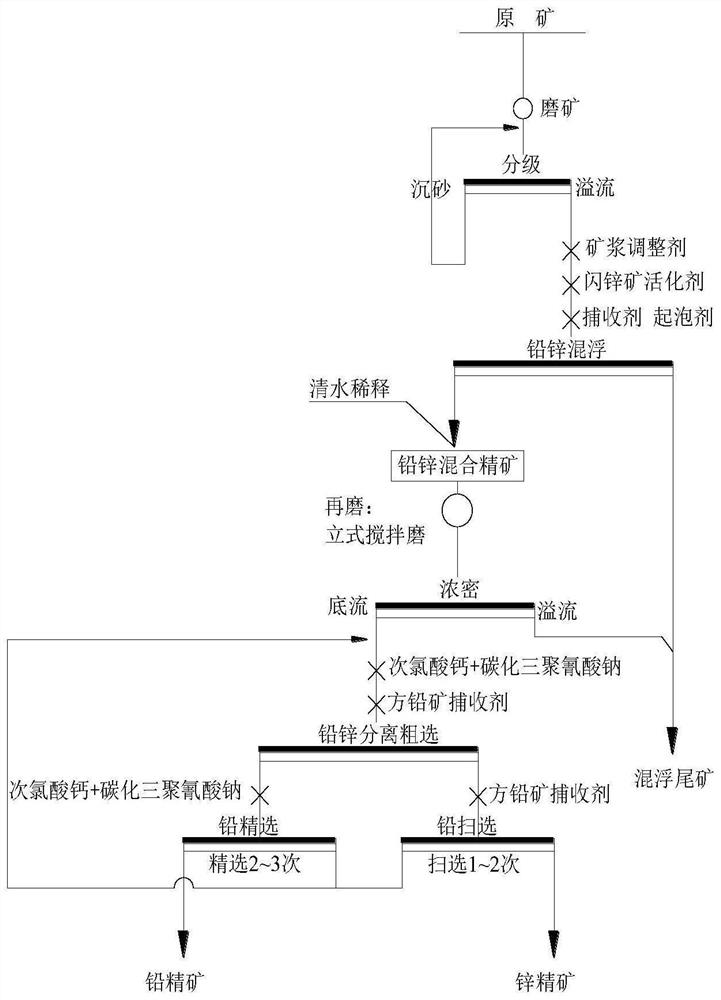

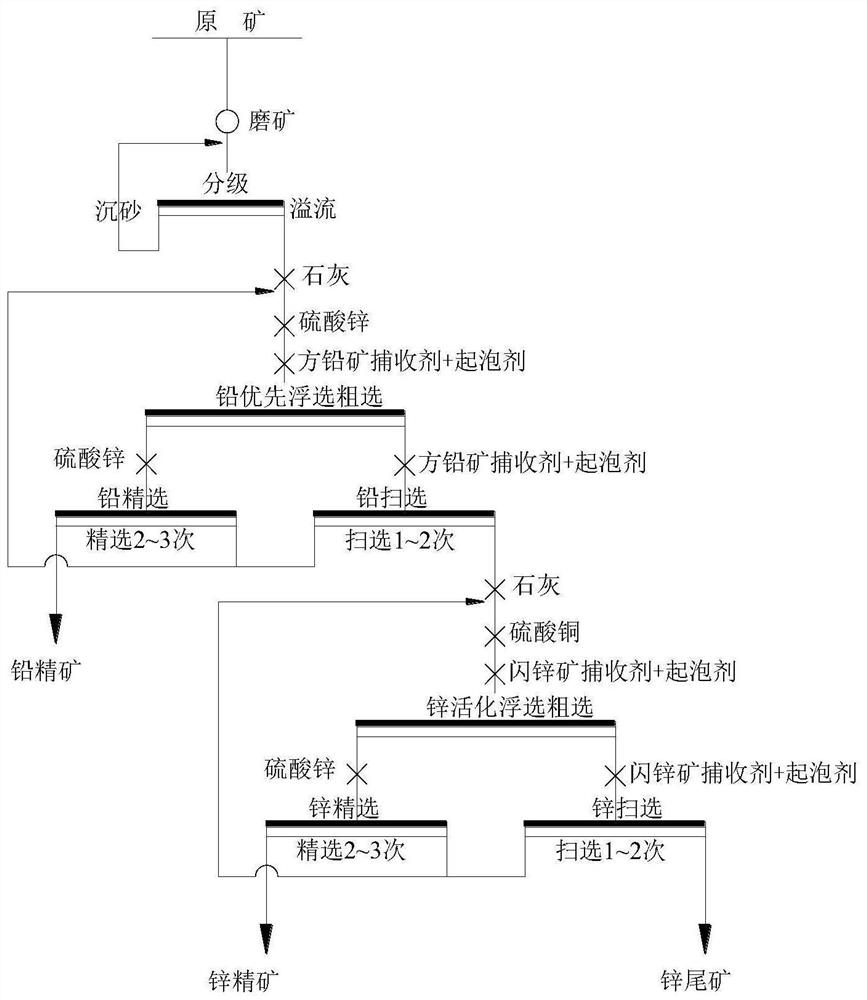

Flotation separation method of refractory lead-zinc sulfide ore and sphalerite inhibitor of refractory lead-zinc sulfide ore

The invention discloses a flotation separation method of refractory lead-zinc sulfide ore and a sphalerite inhibitor of the refractory lead-zinc sulfide ore, the sphalerite inhibitor is a composition of calcium hypochlorite and carbonized sodium cyanurate, the mass ratio of calcium hypochlorite to carbonized sodium cyanurate is 1: (2 to 4), and the inhibitor composition can have a strong inhibition effect on sphalerite. The invention further provides a flotation separation method of the refractory lead-zinc sulfide ore, the refractory lead-zinc sulfide ore is subjected to ore grinding and grading treatment and size mixing, a sphalerite activating agent, a flotation collecting agent and a foaming agent are added, then inflation flotation is conducted, lead-zinc bulk concentrate dense underflow is obtained through regrinding and thickening, and the sphalerite inhibitor and a galena collecting agent are added for flotation separation; and the separated lead rough concentrate is subjected to sphalerite inhibition and repeated concentration to obtain lead concentrate, the galena collecting agent is added into the separated lead rough concentrate for repeated lead scavenging to obtain zinc concentrate, and therefore the refractory lead-zinc sulfide ore is economically and efficiently separated and enriched, and the method has wide industrial application prospects.

Owner:GUANGXI ZHONGJIN LINGNAN MINING CO LTD +1

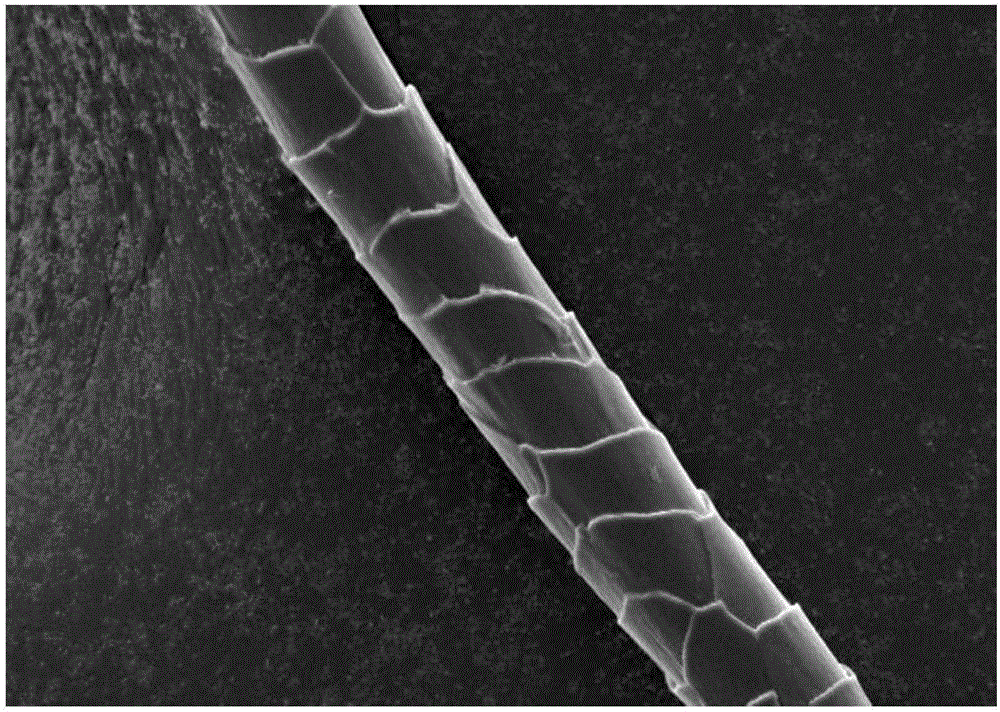

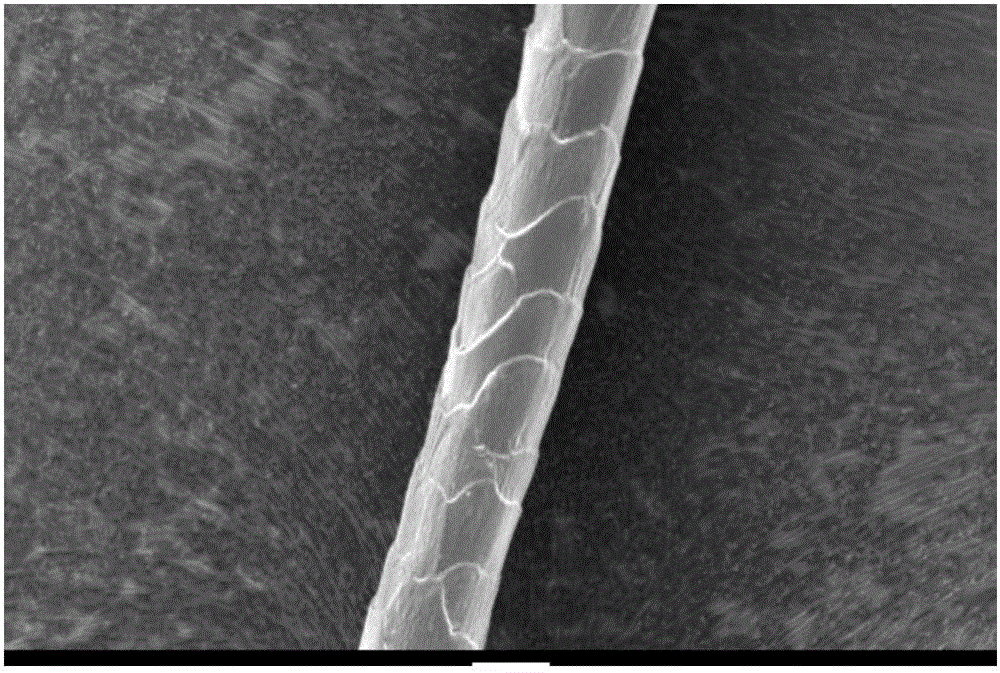

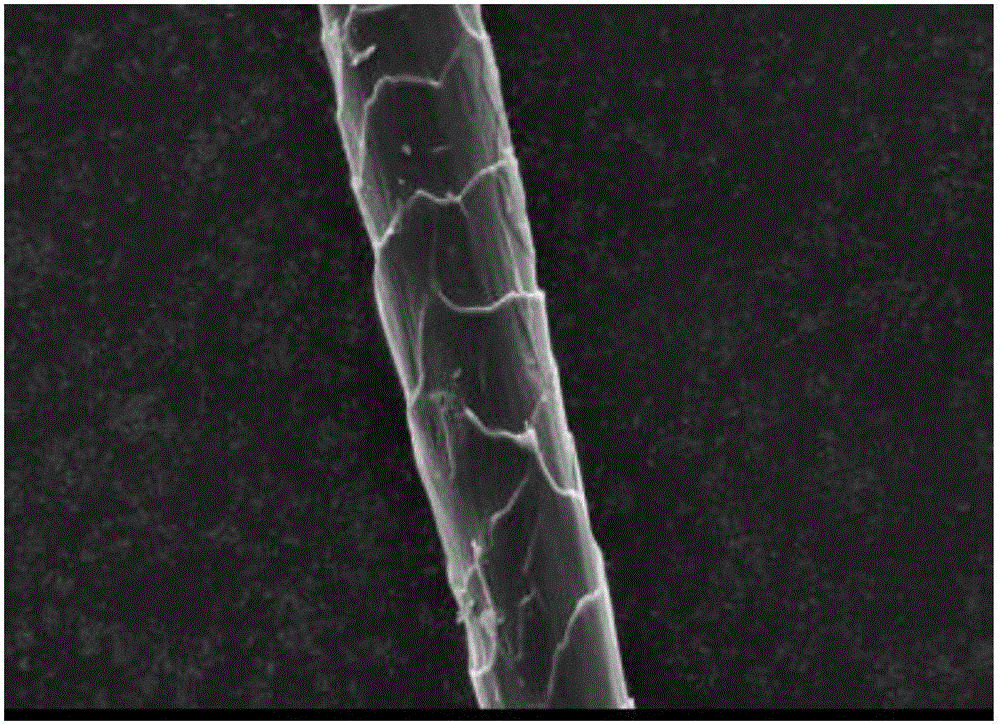

Wool fiber surface modification method

InactiveCN106637922AFast corrosionPlay a regulatory roleBiochemical treatment with enzymes/microorganismsAnimal fibresYarnPyrophosphate

A wool surface scale modification method adopts wool loose fiber, wool top, wool yarns or wool garment as wool to-be-treated products and is conducted according to the following steps sequentially: a, preparing treatment liquid; taking sodium cyanate, sodium pyrophosphate, hydrogen peroxide at the concentration of 30 percent and the balance of water, wherein in the prepared treatment liquid, the liquid sodium cyanate concentrate is 1 to 20 g / L, the sodium pyrophosphate concentration is 0 to 20 g / L and the hydrogen peroxide concentration is 10 to 70 g / L; and b, soaking the wool to-be-treated product in the above treatment liquid at the mass ratio of the to-be-treated wool to the treatment liquid being 1:15 to 1:25, maintaining the temperature of the treatment liquid at 30 to 70 DEG C, and performing oscillation in an ultrasonic oscillating instrument for 10 to 60 minutes.

Owner:ZHEJIANG LANBAO WOOL SPINNING GROUP

Special anti-wrinkle flame retardant finishing agent of wool hat

InactiveCN107938356AGuaranteed StrengthAvoid yellowingBiochemical fibre treatmentAnimal fibresWrinkle skinRare earth

The invention discloses a special anti-wrinkle flame retardant finishing agent of a wool hat. The finishing agent comprises the following raw materials in parts by weight: 20-38 parts of waterborne polyurethane emulsion, 2-10 parts of organic silicon emulsion, 1-5 parts of sodium cyanate, 3-8 parts of hydrogen peroxide, 1-5 parts of dicyandiamide, 2-10 parts of chitosan, 3-10 parts of mixed plantextracting solution, 2-10 parts of beta-cyclodextrin, 0.1-0.8 parts of cyclodextrin, 1-5 parts of organic acid, 1-4 parts of oxidized alginate, 2-10 parts of oxidized sodium carboxymethyl cellulose, 2-10 parts of rare earth oxide sol, 1-4 parts of hexa(4-aminophenoxy)cyclotriphosphazene and 1-5 parts of a hydrophilic surfactant. The special anti-wrinkle flame retardant finishing agent provided bythe invention has the advantage that the wool hat can be endowed with excellent wrinkle resistance and fire retardance.

Owner:安徽中福毛纺制帽有限公司

Blood virus RAN protective agent and blood sampling tube

ActiveCN109679946AAvoid degradationAvoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsSodium thiocyanatePollution

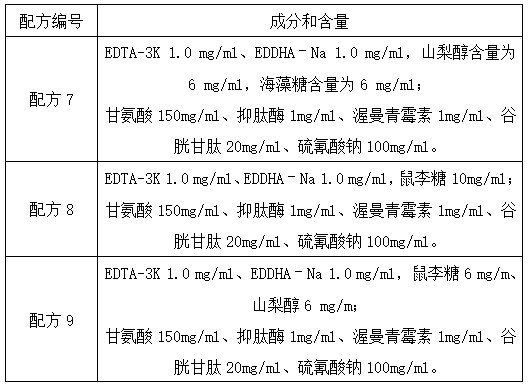

The invention provides a blood virus RAN protective agent and a blood sampling tube. The blood virus RAN protective agent is prepared by dissolving the following components in DEPC (diethyl pyrocarbonate) solution 100-500mg / ml glycine, 1-5mg / ml aprotinin, 1-5mg / ml wortmannin, 10-40mg / ml glutathione, 100-500mg / ml sodium thiocyanate, 1-3mg / ml anticoagulant and 5-20mg / ml membrane protective agent. The blood virus RAN protective agent provided by the invention is capable of supplying long-term protection to virus RNA in blood under room temperature, preventing degradation and pollution of virus RNA and effectively guaranteeing accuracy and validity of blood sample.

Owner:NINGBO AJCORE BIOSCIENCES INC

Environment-friendly gold and silver leaching agent and preparation method thereof

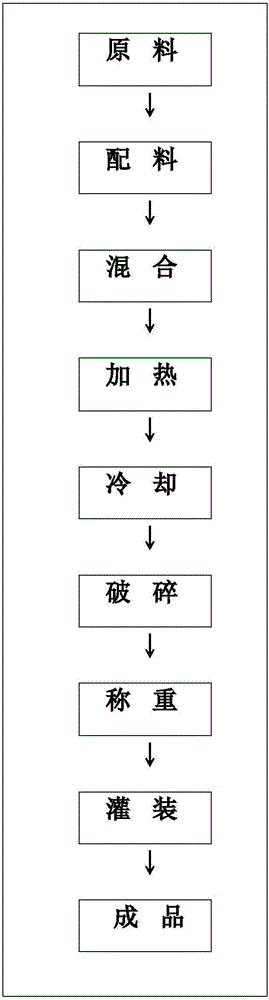

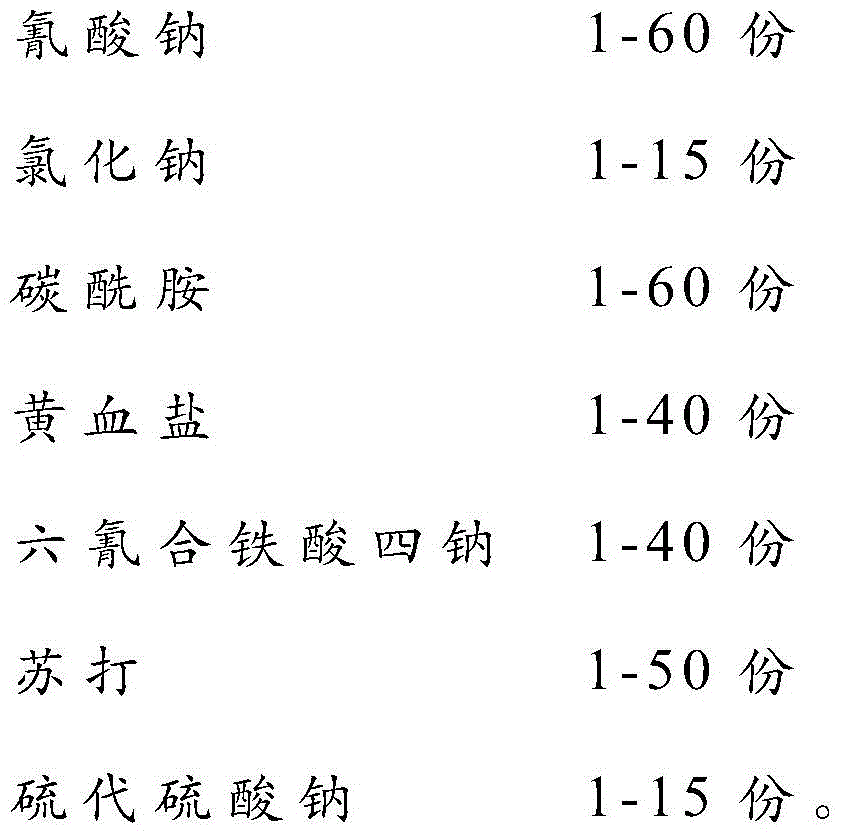

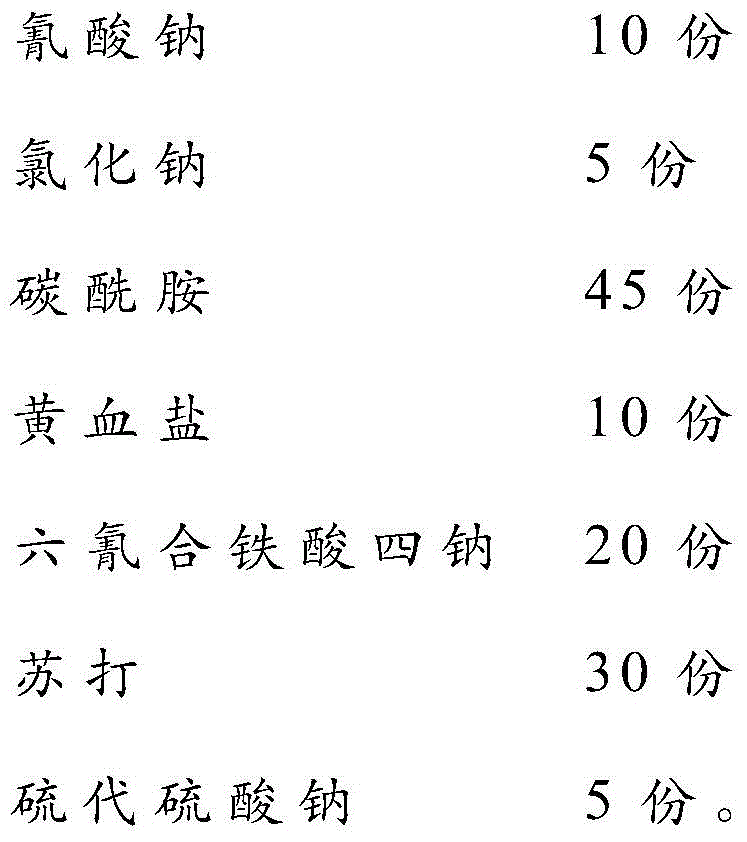

ActiveCN105671312ALeachability is stableFast leachingProcess efficiency improvementEcological environmentCrusher

The invention discloses an environment-friendly gold and silver leaching agent and a preparation method thereof. The leaching agent is prepared from, by weight, 1-60 parts of sodium cyanate, 1-15 parts of sodium chloride, 1-60 parts of carbamide, 1-40 parts of potassium ferrocyanide, 1-40 parts of tetrasodium hexacyanoferrate, 1-50 parts of soda and 1-15 parts of sodium thiosulfate. The preparation method of the leaching agent comprises the steps that the materials are prepared according to a proportion, and added into a mixing agitator to be evenly stirred, and then the mixture enters a stainless steel reaction still to be subjected to a high-temperature reaction for 3.5 h to 5.5 h at the temperature of 450 DEG C to 860 DEG C; and the mixture is crushed into the size of 0.1 cm to 2 cm through a crusher after being discharged and cooled, and the product is weighed and filled to from a finished product after being inspected to be qualified. According to the environment-friendly gold and silver leaching agent, no harmful or toxic ingredients are included in the product, the leaching rate is high, the applicable mine types are wide, and the raw materials are easy to buy; the technological process of production is short, cost is low, and the product quality is easy to control; and the leaching agent is nonhazardous to production personnel and livestock, and pollution to the ecological environment is avoided.

Owner:张久明

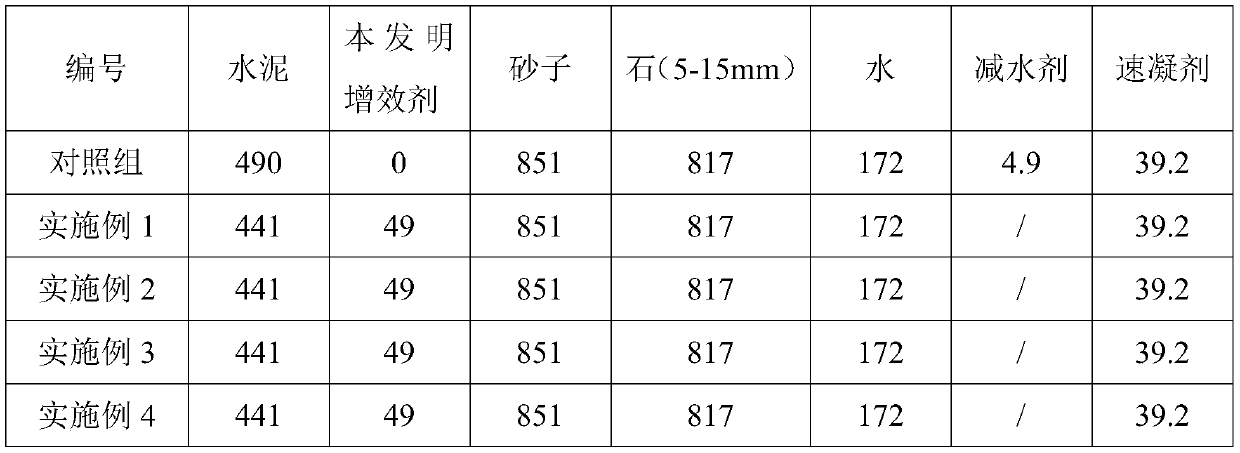

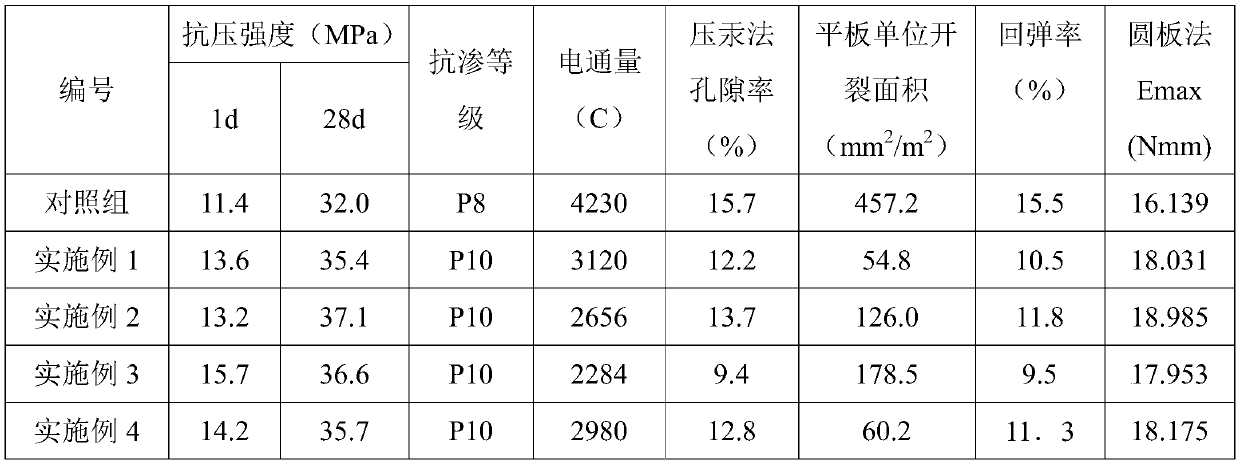

Multi-component composite synergist for shotcrete and preparation method of multi-component composite synergist

The invention provides a multi-component composite synergist for shotcrete and a preparation method of the multi-component composite synergist. The multi-component composite synergist comprises the following components: 20-40% of nanoscale silica fume; 30-50% of modified mineral powder, 10-20% of an expanding agent, 0-5% of a crystal nucleus early strength agent, 1-5% of a fluidizing agent, 1-5% of sodium tripolyphosphate, 0.5-2% of sodium carboxymethyl cellulose, 0.5-2% of sodium gluconate, 5-10% of sodium thiocyanate, 0-0.5% of polypropylene fiber and 0.05-0.2% of an organic silicon defoamer. Compared with the prior art, the working performance and the pumpability of the shotcrete are remarkably improved; the rebound rate and the dust amount of the shotcrete are reduced; the shrinkage ofthe shotcrete is reduced, the pore structure of the shotcrete is improved, and the compactness, strength and cracking resistance of the shotcrete are improved so that the shotcrete has good durability and is non-toxic, pollution-free, simple in production process and zero-emission in production, and belongs to a green and environment-friendly material.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Process for diffusing titanium and nitride into a steel or steel alloy by altering the content of such

InactiveUS20080226831A1Speed up the processLiquid surface applicatorsElectrolysis componentsElectrolysisAlloy

An improved method is provided for diffusing titanium and nitride into a base material comprising a steel or steel alloy. The composition of the base material generally comprises at least one of the following: more than about 1.95% vanadium, less than about 4.1% chromium, and a presence of cobalt. The method generally includes the steps of providing such a base material; providing a salt bath which includes sodium dioxide and a salt selected from the group consisting of sodium cyanate and potassium cyanate; dispersing metallic titanium formed by electrolysis of a titanium compound in the bath; heating the salt bath to a temperature ranging from about 430° C. to about 670° C.; and soaking the base material in the salt bath for a time of from about 10 minutes to about 24 hours.

Owner:KO PHILOS JONGHO +1

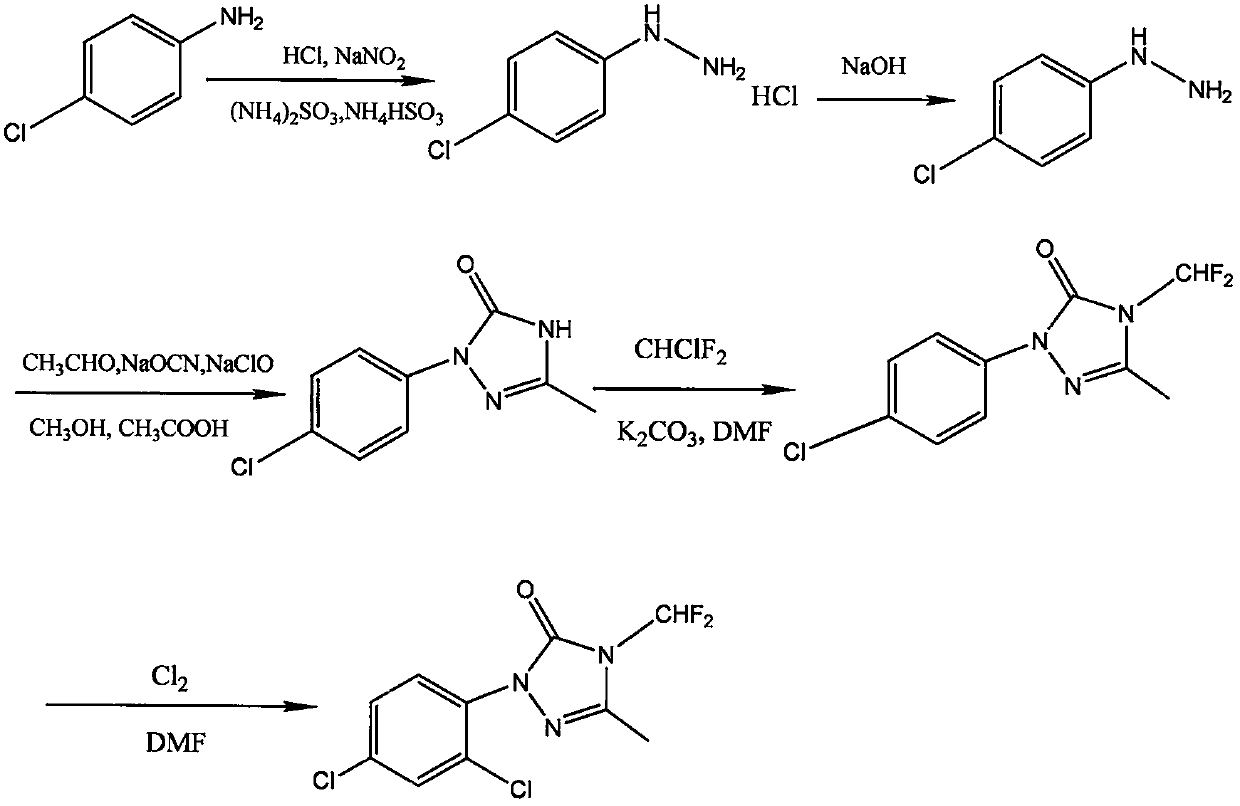

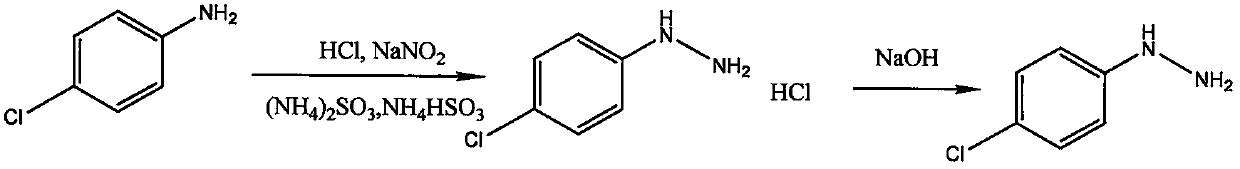

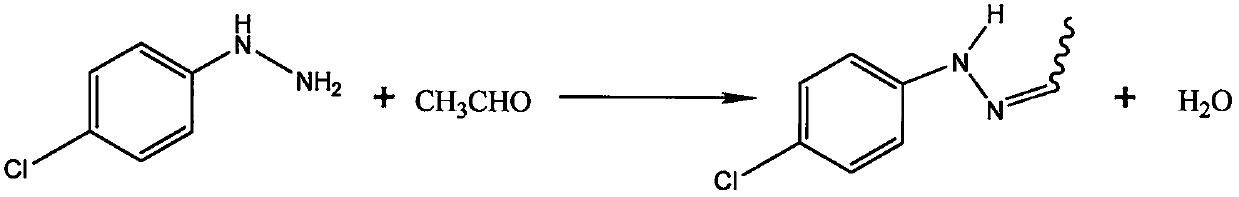

Method for synthesizing 1-(2,4-dichlorophenyl)-3-methyl-4-difluoromethyl-1,2,4-triazole-5-ketone

The invention discloses a method for synthesizing 1-(2,4-dichlorophenyl)-3-methyl-4-difluoromethyl-1,2,4-triazole-5-ketone. The method takes p-chloroaniline as a raw material, through diazotization, reduction, and salt forming, p-chlorophenylhydrazine hydrochloride is synthesized, p-chlorophenylhydrazine is obtained through alkali neutralization, under condition that tert-butyl alcohol is taken asa solvent, chlorophenylhydrazine, acetaldehyde, sodium cyanate and sodium hypochlorite are subjected to condensation, cyclisation and an oxidation reaction to generate 1-p-chlorophenyl-3-methyl-1H-1,2,4-triazole-5-ketone, and the 1-p-chlorophenyl-3-methyl-1H-1,2,4-triazole-5-ketone is subjected to salt forming, reaction with chlorodifluoromethane, and chlorination to obtain the 1-(2,4-dichlorophenyl)-3-methyl-4-difluoromethyl-1,2,4-triazole-5-ketone (a sulfentrazone intermediate). The synthetic method takes p-chloroanniline as the raw material, the synthetic method is realized by only one-time chlorination, steric hindrance for intermediate synthesis is small, and the impurity is low, so that the yield is increased; in addition, the raw materials required by the synthesis route are easilyacquired, the cost is low, the condition is mild, operation is simple, security is high, and the synthesis method is in favor of realizing industrial production.

Owner:连云港世杰农化有限公司

Method for cleanly producing high-purity cyanate at low temperature

ActiveCN102336416ARealize continuous productionSave manpower and material resourcesCyanic/isocyanic acidSocial benefitsSodium cyanate

The invention discloses a method for cleanly producing high-purity cyanate at a low temperature, which comprises the following steps of: mixing urea and carbonate for 10-20 min for standby; adding cyanate bottom materials into a reactor, adding a mixture of the urea and the carbonate after the cyanate bottom materials are preheated to 140-150 DEG C; completely reacting the urea and the carbonate at a temperature of 160-180 DEG C; and obtaining a cyanate product after reacted materials are crushed. The invention also can adopt a continuous production manner. In the invention, potassium cyanate (sodium cyanate) is adopted as bottom materials so as to improve the dispersion of the reacted materials, more completely react the reacted materials, improve the product purity and generate no pollution; the reaction is conducted under the closed low-temperature environment so as to generate no toxic byproducts and greatly improve the safety; and the produced gas almost can be completely recovered without three-waste pollution. The high-purity cyanate has remarkable economic benefit and social benefit.

Owner:HUBEI DELI NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com