Environment-friendly gold and silver leaching agent and preparation method thereof

A leaching agent and environment-friendly technology, applied in the field of environment-friendly gold and silver leaching agent and its preparation, can solve the problems of complex cyanide toxicology, environmental biological and aquatic biological hazards, long leaching time, etc. The effect of improving economic and social benefits and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

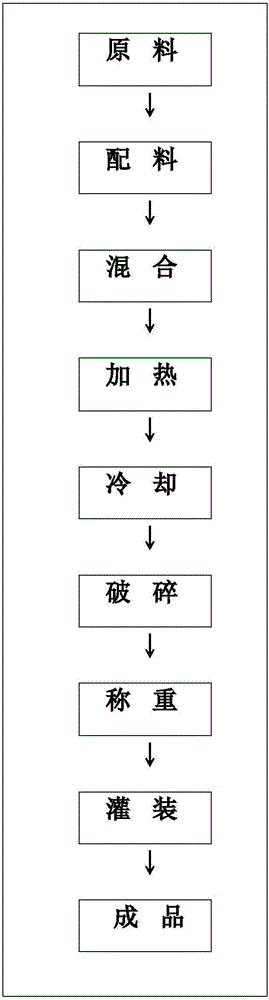

Method used

Image

Examples

Embodiment 1

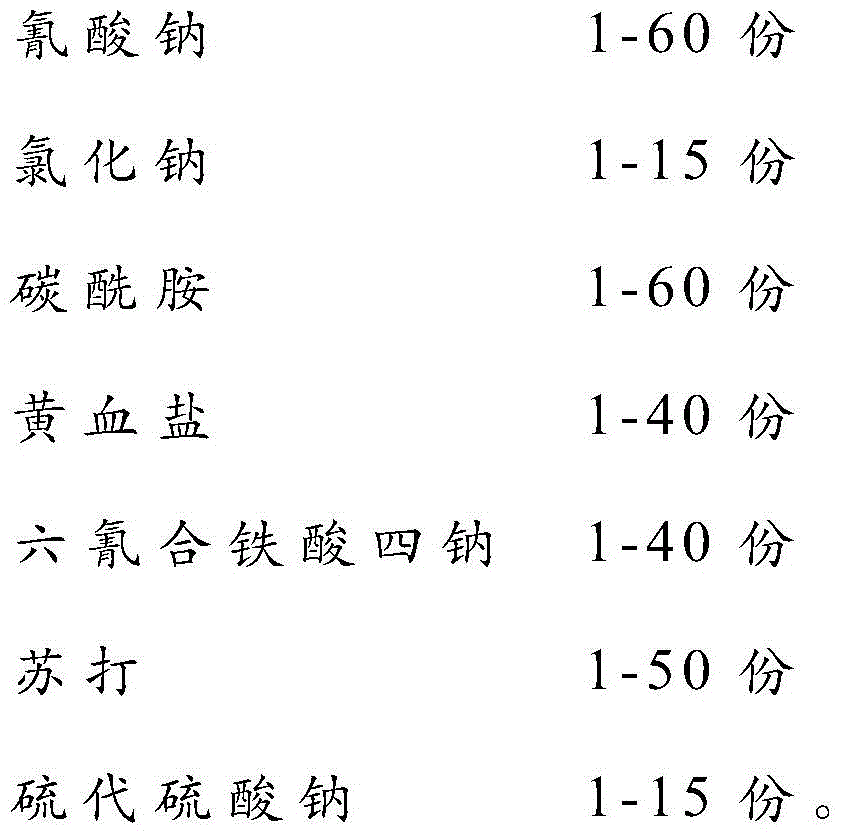

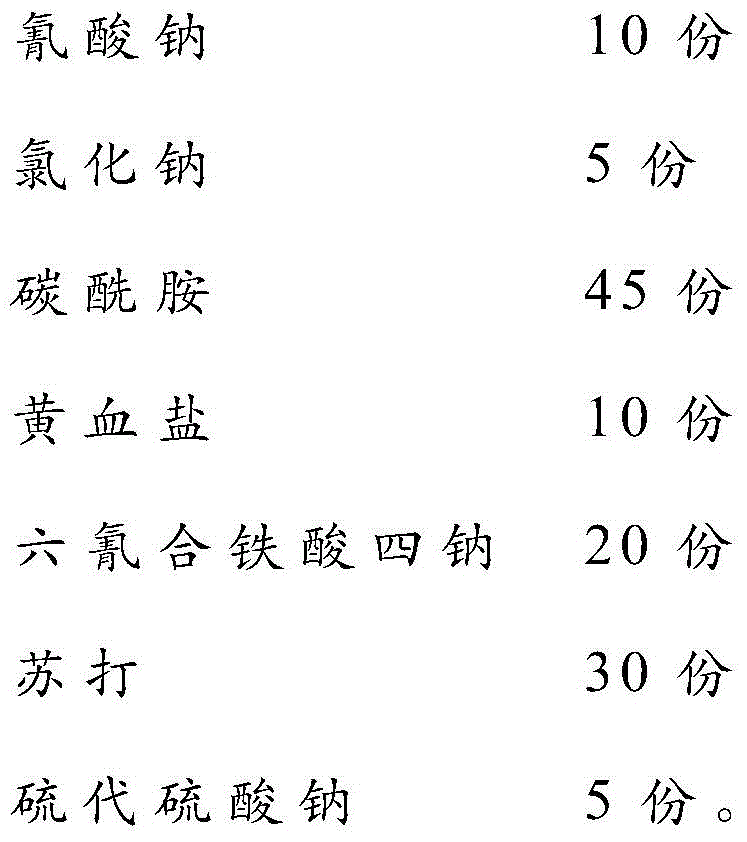

[0035] The raw material composition and parts by weight of the leaching agent are: 10 parts of sodium cyanate, 5 parts of sodium chloride, 45 parts of carbonamide, 10 parts of yellow blood salt, 20 parts of tetrasodium hexacyanoferrate, 30 parts of soda , 5 parts of sodium thiosulfate. The preparation method of the environment-friendly gold and silver leaching agent is as follows: prepare the raw materials in parts by weight, then add the raw materials into the mixing agitator and stir evenly, then add the evenly stirred raw materials into the stainless steel reaction kettle, at 600 React at a temperature of -700°C for 3.5-5.5 hours, discharge and cool, and crush to 0.5-1.5 cm with a crusher. After passing the product inspection, weigh and fill it into the environment-friendly gold and silver leaching agent.

Embodiment 2

[0037] The raw material composition and parts by weight of the leaching agent are: 50 parts of sodium cyanate, 5 parts of sodium chloride, 20 parts of carbonamide, 20 parts of yellow blood salt, 10 parts of tetrasodium hexacyanoferrate, and 10 parts of soda , 15 parts of sodium thiosulfate. The preparation method of the environment-friendly gold and silver leaching agent is specifically as follows: prepare the raw materials in parts by weight, then add the raw materials into the mixing agitator and stir evenly, then add the evenly stirred raw materials into the stainless steel reaction kettle, at 500 React at a temperature of -650°C for 5.5 hours, discharge and cool, and crush it to 1 cm with a crusher. After passing the product inspection, it is weighed and filled as the environmental-friendly gold and silver leaching agent.

Embodiment 3

[0039] The raw material composition and parts by weight of the leaching agent are: 30 parts of sodium cyanate, 10 parts of sodium chloride, 30 parts of carbonamide, 20 parts of yellow blood salt, 20 parts of tetrasodium hexacyanoferrate, 25 parts of soda , 10 parts of sodium thiosulfate. The preparation method of the environment-friendly gold and silver leaching agent is as follows: prepare the raw materials in parts by weight, then add the raw materials to the mixer and stir evenly, then add the evenly stirred raw materials to the stainless steel reaction kettle, React at a temperature of ℃ for 4.5 hours, discharge and cool, and crush it to 1 cm with a crusher. After passing the product inspection, it is weighed and filled as the environmental-friendly gold and silver leaching agent.

[0040] The method of using the leaching agent of the present invention is simple and easy to operate. During use, the original equipment does not need any technical transformation. The operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com