Patents

Literature

156results about How to "Save pollution control costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-ecological formulation and preparation method thereof

InactiveCN101509013AIn line with the sustainable development strategySolve pollutionMicroorganism based processesWaste water treatment from food industryWastewaterVitamin B12

The invention relates to the technical field of recycling waste water produced by fermenting vitamin B12, and discloses a microbial ecological agent and a preparation method thereof. The invention more particularly relates to a microbial ecological agent product prepared by taking the waste water produced by fermenting vitamin B12 as raw material through the fermentation process of lactobacillus, microzyme and bacillus. Furthermore, the product is applied for nuisanceless agriculture; the invention develops the usage of the waste water of vitamin B12, so as to change waste into valuable and realize zero emission in the process of producing waste water by fermenting vitamin B12.

Owner:马兰 +1

Leaching method of anode material of lithium cobalt oxide waste battery

InactiveCN101928831AAvoid it happening againSave pollution control costsProcess efficiency improvementMetalMaterials science

The invention introduces a leaching method of an anode material of a lithium cobalt oxide waste battery, which comprises the following steps of: placing the anode material separated from the lithium cobalt oxide waste battery into a container which resists pressure and resists the corrosion of sulfuric acid and nitric acid, then sealing the container, pumping the sulfuric acid and the nitric acid into the container, and introducing industrial pure oxygen to leach the anode material of the lithium cobalt oxide waste battery. The leaching temperature is 20-100 DEG C, the leaching pressure is 0.05-0.5MPa, the initial concentration of the leached sulfuric acid is 1-5mol / L, the initial concentration of the nitric acid is 5-20g / L, the leaching time is 1-5 hours, stirring is carried out in the leaching process, and the stirring speed is 30-100r / min. The addition of the sulfuric acid is 101-200 percent of the theoretical consumption of the sulfuric acid for leaching all metals from the anode material added into a reaction container.

Owner:SICHUAN NORMAL UNIVERSITY

Leaching method for anode and cathode mixed materials of waste LiCoxNiyMnzO2 battery

InactiveCN101586192AReduce consumptionAvoid it happening againProcess efficiency improvementMetalMaterials science

A leaching method for the anode and cathode mixed materials of a waste LiCoxNiyMnzO2 battery provided by the invention comprises the following steps: putting the anode and cathode mixed materials separated from the waste LiCoxNiyMnzO2 battery into a pressure-resistant and nitric acid resistant container, and then sealing the container and pumping nitric acid into the container; leaching the anode and cathode mixed materials of the waste LiCoxNiyMnzO2 battery by adding industrial pure oxygen. The leaching temperature is 20-100 DEG C; the leaching pressure is 0.05-0.5MPa; the initial concentration of the leached nitric acid is 1-6mol / L; the leaching time is 1-4h; the leaching process needs stirring; and the stirring speed is 30-100r / min. The adding amount of nitric acid is 101-130% of the theoretical quantity of the nitric acid consuming by leaching all the metal out from the anode and cathode mixed materials added in a reaction vessel.

Owner:SICHUAN NORMAL UNIVERSITY

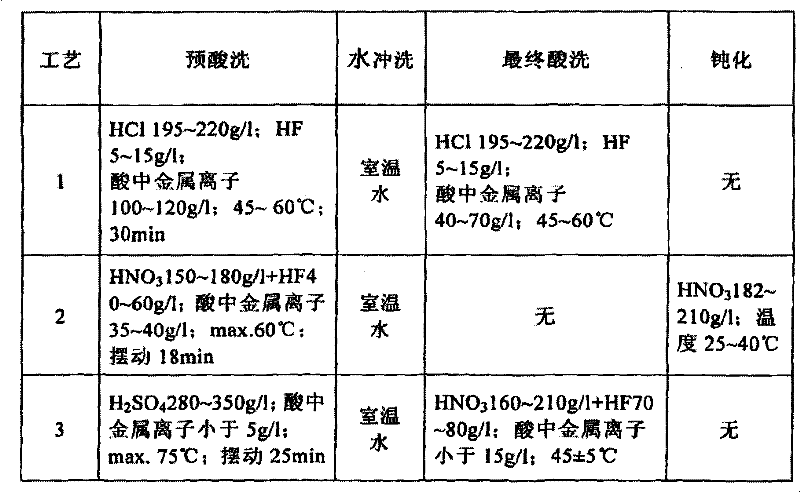

Novel stainless steel acid-washing passivation liquid

ActiveCN102653868AReduce pollutionLow running costMetallic material coating processesHydrofluoric acidAcid washing

The invention relates to a novel stainless steel acid-washing passivation liquid which comprises inorganic acid, penetrant, oxidant and corrosion inhibitor. The stainless steel acid-washing passivation liquid does not generate violent pungent odor or yellow acid mist in the application process, thereby avoiding hurting the skin, reducing the air pollution and lowering the cost. The stainless steel acid-washing passivation liquid is easy to use: the stainless steel acid-washing passivation liquid is poured into a tank, and soaks the stainless steel at normal temperature without heating; and the washing speed is about 50% higher than those of the acid-washing passivation liquid (paste) in the existing market and the acid-washing passivation liquid containing nitric acid and hydrofluoric acid, and the washing quantity is as 3.2 times or so as the like products in the market. The novel stainless steel acid-washing passivation liquid can complete oil removal, derusting, descaling and acid-washing passivation at one time. The residual liquid after use can be treated by a conventional treatment method, and can also be used for treating dyeing waste water; and the treated dyeing waste water is clear and transparent and achieves the reclamation standard. Thus, the stainless steel acid-washing passivation liquid has the advantages of environment protection and water resource saving, and can recycle water.

Owner:王福平

Application of abamectin residues in abamectin fermentation medium

InactiveCN101525642AIn line with the sustainable development strategySolve pollutionFungiBacteriaZymogenMicroorganism

The invention relates to the field of regeneration cycle utilization of antibiotic zymogen residues, provides a method using the abamectin residues as a raw material to prepare a product which is used for abamectin fermentation as a nutrient ingredient of a medium through processes of separation and concentration drying after microbes are fermented, and applies the product in the abamectin fermentation medium. The invention solves the problem of abamectin fermentation waste residues on environmental pollution, realizes regeneration cycle utilization of the waste residues, and achieves the aim of clean production.

Owner:迈德金生物技术(北京)有限公司

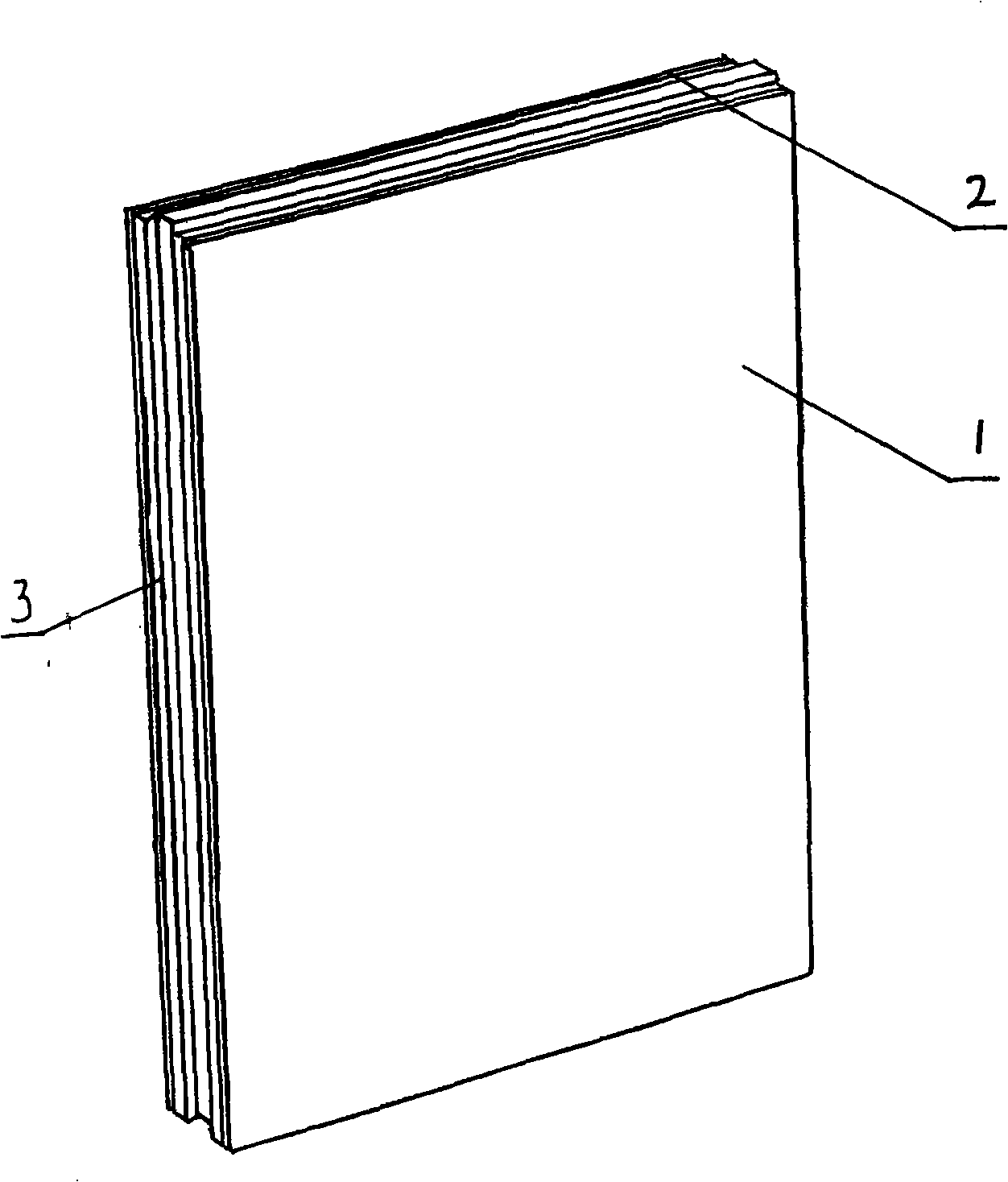

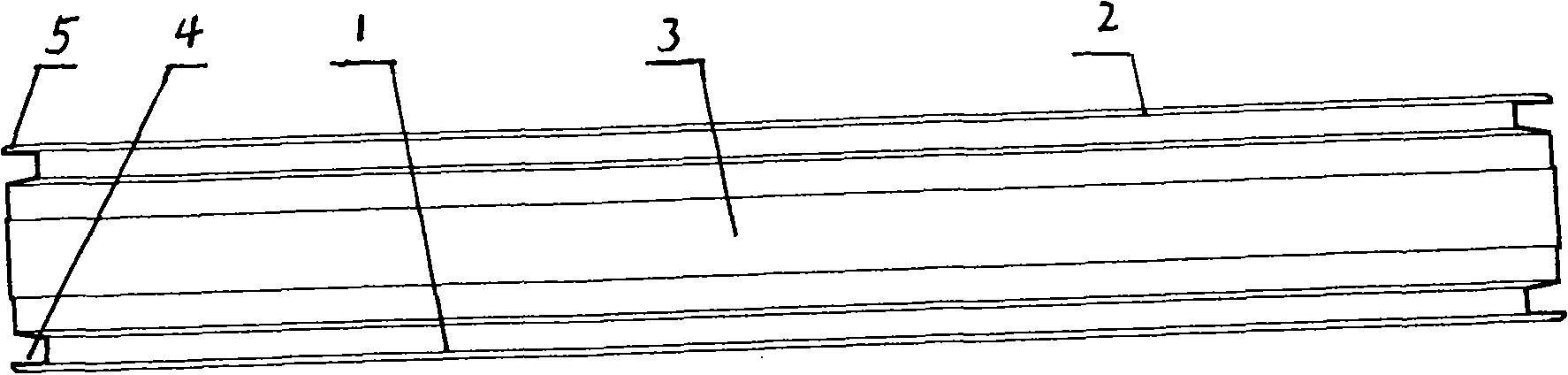

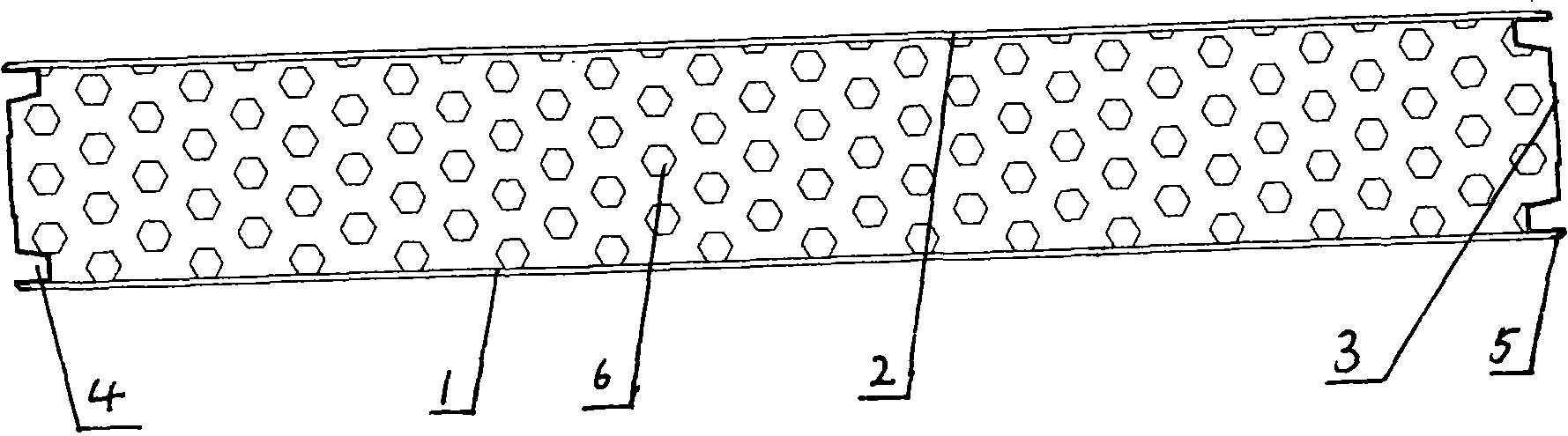

Method for preparing split joint buckled type building block composite energy-saving wall board

The invention discloses a preparation method for an assembled buckle-typed building block combination energy-saving wall plate, which is characterized in that a front panel and a rear panel are respectively inserted into panel assembly troughs which are arranged at two ends of four side plates, thus leading the front panel, the rear panel and the four side plates to be assembled together to form a whole hollow wall plate frame; subsequently, a pasty middle filling layer is injected into the hollow wall plate frame through small holes on the upper side plate by a tunnel high-pressure pouring method; after the pouring operation is completed, the solidification is carried out on a conveyor belt; subsequently, the filling layer is smoothly arranged and cured for a certain time; subsequently, the finished product is gained after the packaging is completed. The preparation method of the invention has the advantages of being directly used as screen walls, light weight, high strength, good heat preservation and sound insulation effects, good surface decoration effect, waterproofing and dust-proofing, beauty, saving decoration procedure, thus quickening the decoration progress and the construction time.

Owner:朱春生

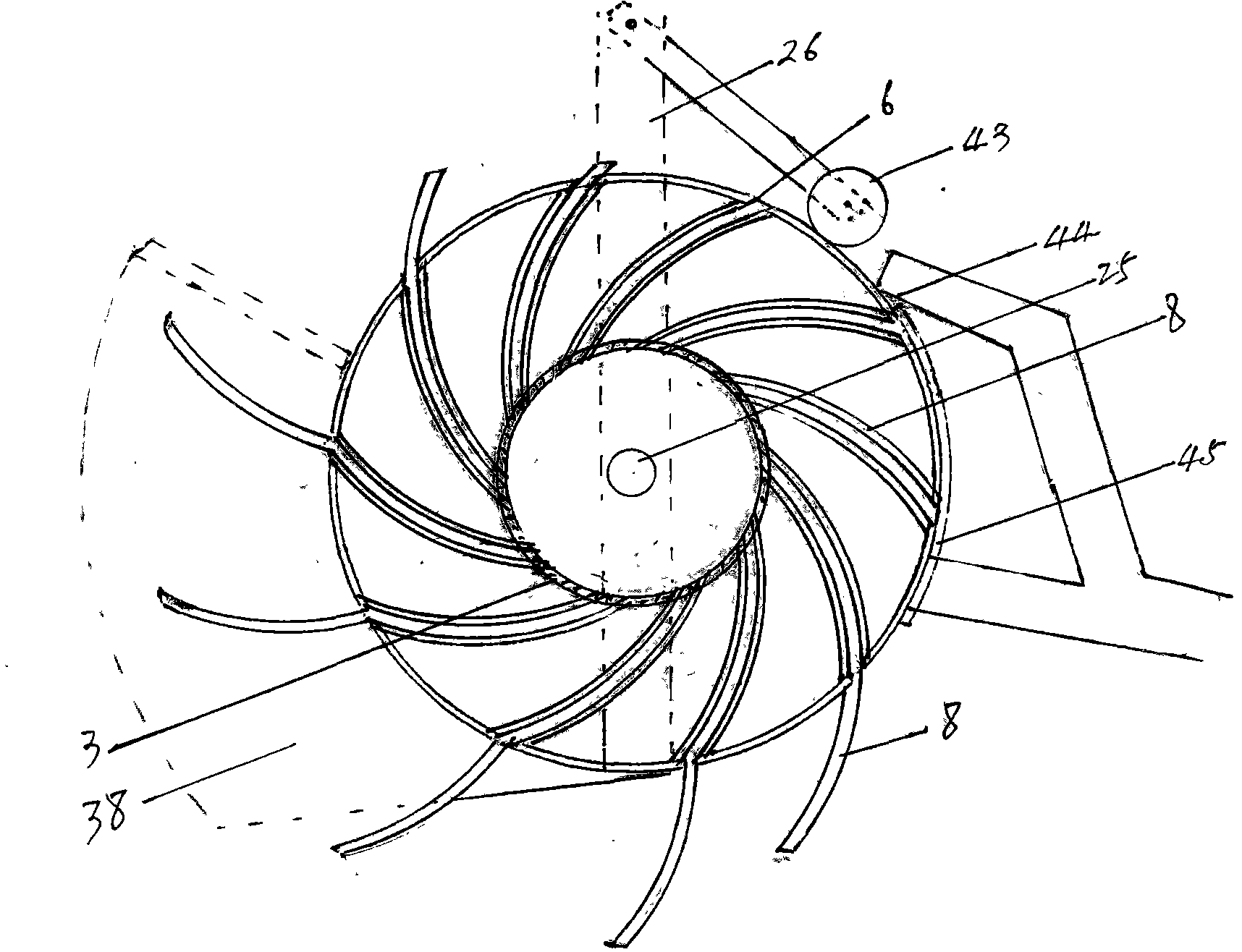

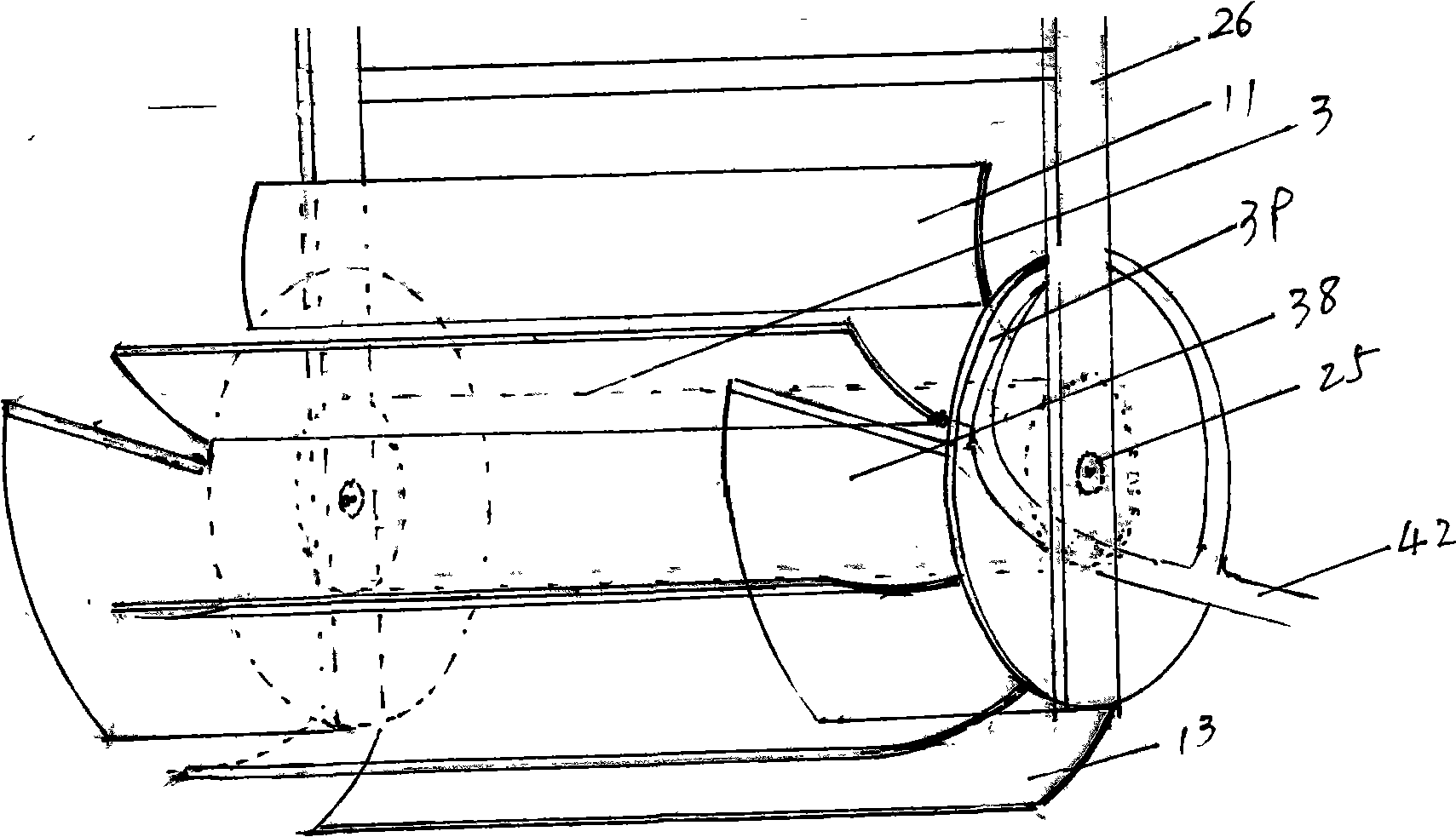

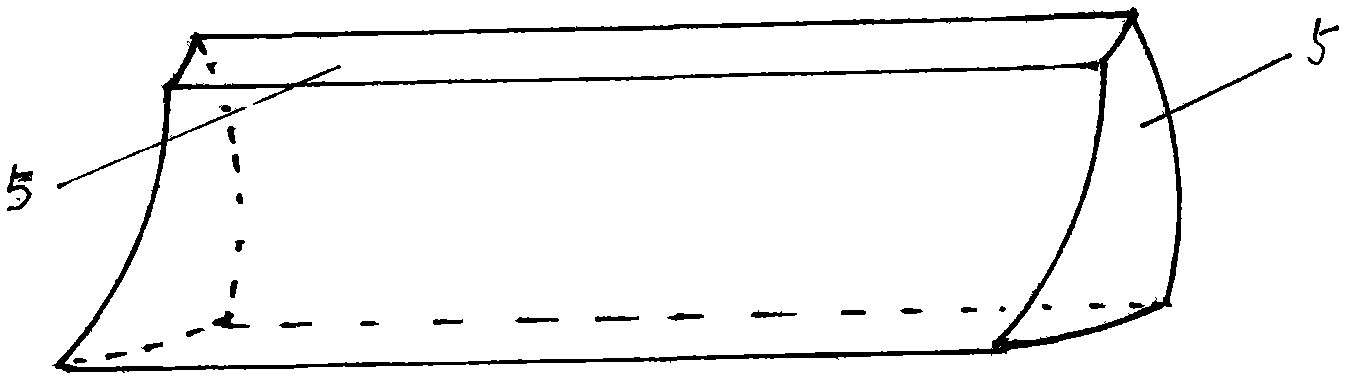

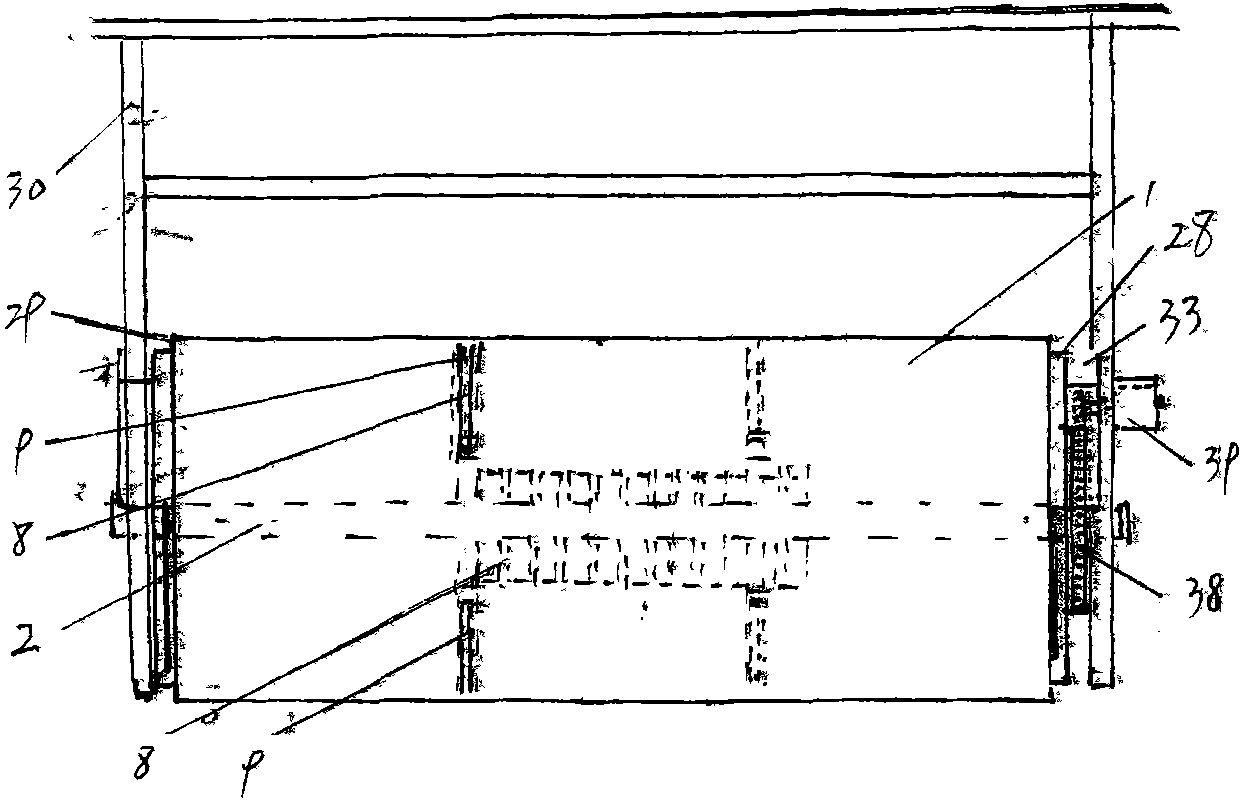

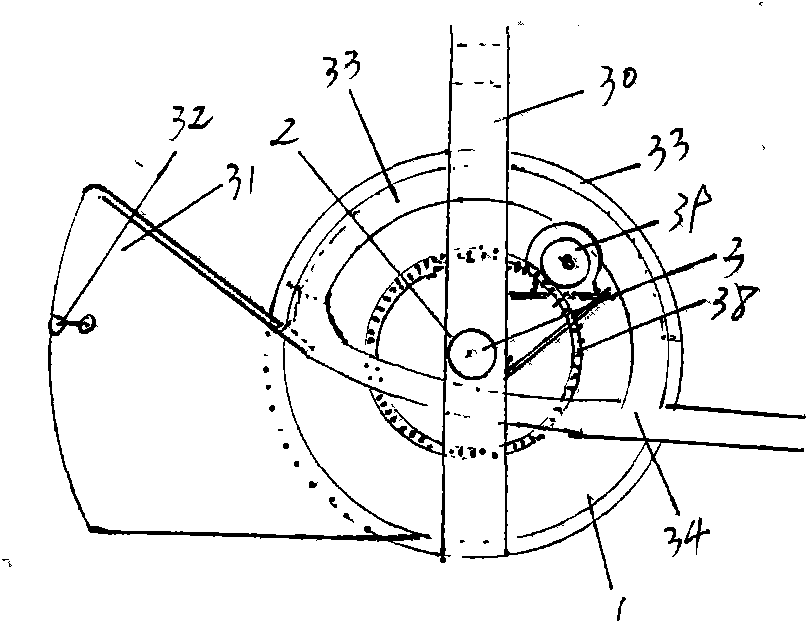

Water oil machine of arc telescopic double-layer mesh screen

InactiveCN103046520AImprove recycling efficiencySave pollution control costsWater cleaningGeneral water supply conservationPulp and paper industryOil water

Provided is a water oil machine of an arc telescopic double-layer mesh screen. The arc telescopic double-layer mesh screen utilizes a slide in a pulley-shaped carrier to be mechanically manipulated by self weight of the mesh screen. When the mesh screen is stretched through the slide, an upper layer mesh screen and a lower layer mesh screen are lifted forwards with a pulley in hole-opening state. When the mesh screen is operated to the position close to an oil layer, the upper mesh screen is pulled by a pull strip to slide one screen hole backwards. Due to the fact that a front end screen hole frame gradually changes narrower to a back end frame, the upper layer screen holes and the lower layer screen holes are gradually closed. Oil water in the arc mesh screen moves to the back end of the mesh screen with slow lifting of the mesh screen, water on the lower layer is separated from the screen holes at the back end which is not closed till the mesh screen is closed integrally, and an oil material is lifted by the mesh screen to be recycled by an oil receiving tank. The oil machine is driven by a tugboat to finish salvage recycling work of various leakage oil materials with the navigational speed as 5 kilometers per hour and the working efficiency of 15-meter-wide oil gathering face. The water oil machine finishes salvage recycling work of various leakage oil materials and prevents marine environment from severe environment.

Owner:石伟

Method for producing color and differential polyester short fibre by melting body directly spinning online adding technology

InactiveCN1944719AImprove product qualityQuality improvementMelt spinning methodsStaple fibre formationPolyesterPolymer science

The present invention relates to synthetic fiber producing technology, and is direct melt spinning and on-line adding process for producing color and differential short polyester fiber. Technologically, the process includes injecting modifying material through drying, melting, filtering and metering to the polyester melt before entering to the spinning tank; mixing with the melt homogeneously in the static mixer, and spinning the mixture. The said process makes the agglomerate permeating into the inside of fiber easily to produce color fiber and other differential fibers with high quality, high fastness, high water washing resistance, excellent wear resistance, etc.

Owner:ANXING ENVIRONMENT PROTECTION COLOR FIBER CHUZHOU

Method for lixiviating anode materials of lithium nickel waste batteries

InactiveCN101643851AAvoid it happening againSave pollution control costsProcess efficiency improvementLithiumMetal

The invention relates to a method for lixiviating anode materials of lithium nickel waste batteries. In the invention, the anode materials separated from the lithium nickel waste batteries are put ina container which resists pressure and resists corrosion of sulfuric acid and nitric acid; then the container is sealed; the sulfuric acid and the nitric acid are pumped into the container; and industrial pure oxygen is led in for lixiviating the anode materials of the lithium nickel waste batteries. The lixiviated temperature is 20 to 100 DEG C, the lixiviated pressure is 0.05 to 0.5 MPa, the initial concentration of the lixiviated sulfuric acid is 1 to 5 mol / L, the initial concentration of the nitric acid is 5 to 20 g / L, the lixiviated time is 1 to 5 hours, stirring is carried out on the lixiviated process, and the stirring speed is 30 to 100 r / min. The quality of the added sulfuric acid is 101 to 200 % of the theoretical consumption of the sulfuric acid lixiviated from all of metal of the anode materials added into the container.

Owner:SICHUAN NORMAL UNIVERSITY

Technique for producing coloured polyester filament yarn by melt direct spinning

InactiveCN101173372ARaise the gradeQuality improvementMelt spinning methodsFilament-forming treatmentAutomatic controlStatic mixer

The invention relates to a melt direct spinning technology for producing colored polyester filament, belonging to the technical field of chemical fiber production, which mainly solves the technical problem that a melt direct spinning producing method with low cost, high yield, simple technology, easy control of color difference and good color fastness of fabrics is provided. The invention is characterized in that the modified material after drying, melting, filtering and measuring are injected before the polyester melt enters a spinning box; and the modified material and the polyester melt enter the spinning box together for spinning after even mixing in a high-efficiency static mixer. The invention has the advantages of easy infiltration of master batch into fiber, good performance of the colored polyester filament product produced through the method such as high quality, good color fastness, wash resistance and abrasion resistance, simple technology, less equipment investment, easy control of material adding, convenient realization of automatic control, and avoidance of environmental pollution.

Owner:SHENGHONG GRP CO LTD

Leaching method of nickel cobalt lithium manganate waste battery positive-negative electrode mixed material

InactiveCN103757336AReduce consumptionImprove leaching rateProcess efficiency improvementManganateCorrosion

The invention provides a leaching method of a nickel cobalt lithium manganate waste battery positive-negative electrode mixed material, which comprises the following steps: adding a positive-negative electrode mixed material subjected to roasting pretreatment and separated from nickel cobalt lithium manganate waste batteries and vinasse into a pressure-resistant sulfuric-acid / nitric-acid-corrosion-resistant reaction kettle, adding a sulfuric acid-nitric acid mixed solution, and carrying out agitation leaching under sealed conditions.

Owner:SICHUAN NORMAL UNIVERSITY

Depilating composition for less thiolase process and the piling depilation method therewith

InactiveCN1526288AReduce sulfide pollutionReduce COD and BOD5Slaughtering accessoriesDepilationsChemistry

The depilating composition for less thiolase process and the piling depilation method therewith features that leather blank in 100 portions, proteinase in 0.1-0.6 portion, sodium sulphide in 0.1-0.8 portion, sodium chloride in 0.1-3 portions, surfactant 0.1-1 portion and hydrogen peroxide in 0-5 portions are dissolved or dispersed in water of 7-15 portions while adding rice bran in 1-4 portions and kaolin in 0.5-3 portions to form paste mixture; and the leather blank is then brushed manually to make the mixture adhered onto the inside of the leather blank, piled with inside to inside in hot room at 15-35 deg.c for 20-30 hr, and depilated manually after the hair becomes loose. The said depilating process has high depilating effect, and can produce soft plumpy and light-colored leather with high strength. In addition, the said process has less sulfide pollution and its effluent has low COD and low BOD5.

Owner:SICHUAN UNIV

Microbial fertilizer and preparation method thereof

InactiveCN101525253AIn line with the sustainable development strategySolve pollutionClimate change adaptationSewage/sludge fertilisersBiotechnologyPesticide residue

The invention relates to the technical field of treatment and comprehensive utilization of animal slaughter industrial wastewater, finds new application of blood wastewater, and provides a microbial fertilizer which is manufactured by taking blood wastewater as a raw material and selecting lactobacillus and bacillus through fermentation. The microbial fertilizer has the advantages of pesticide residues degradation, and can be used for producing nuisanceless agricultural products.

Owner:迈德金生物技术(北京)有限公司

Leaching method of nickel cobalt lithium manganate waste battery positive-negative electrode mixed material

InactiveCN103757354AReduce consumptionImprove leaching rateProcess efficiency improvementManganateMaterials science

The invention provides a leaching method of a nickel cobalt lithium manganate waste battery positive electrode material, which comprises the following steps: putting a positive-negative electrode mixed material subjected to roasting pretreatment separated from nickel cobalt lithium manganate waste batteries into a pressure-resistant sulfuric-acid-corrosion-resistant container, pumping sulfuric acid into the container, sealing the container, pumping a Na2SO3 solution into the container by using a filling pump, closing the Na2SO3 solution inlet valve, and leaching.

Owner:SICHUAN NORMAL UNIVERSITY

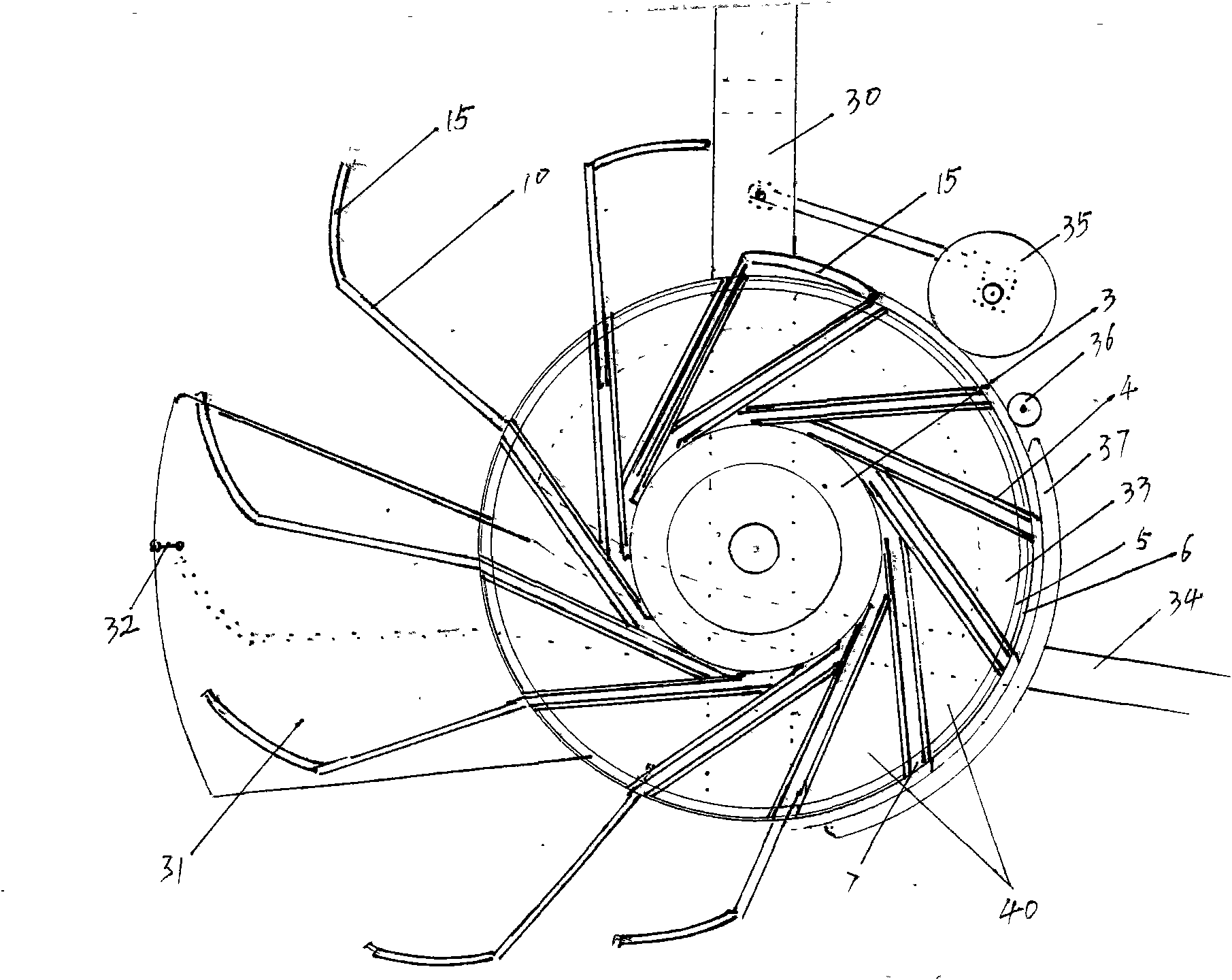

Overwater oil fishing machine of barrel-shaped telescopic opening/closing mesh sieve

InactiveCN102373696AAvoid pollutionImprove efficiencyWater cleaningGeneral water supply conservationBarrel ShapedEngineering

The invention discloses a machine capable of quickly fishing and recycling various kinds of leaked oil on water, namely an overwater oil fishing machine of a barrel-shaped telescopic opening / closing mesh sieve. A mesh sieve box frame of the oil fishing machine is arranged in a slideway in a barrel-shaped carrier; when a slideway port faces downwards with the barrel rotation, the mesh sieve box frame extends out of the slideway port under self gravity; and when the slideway port faces upwards with the barrel rotation, the mesh sieve box frame retracts from the slideway port under self gravity. In the invention, the fishing action of the mesh sieve is controlled by mechanical operation; and according to the technology of controlling the opening / closing of mesh sieve holes by use of a mechanical or specific gravity sensing device, the mesh sieve can quickly separate sea water from the floating oil with different viscosities so as to fish the oil. Under the pushing or traction of a tugboat, the oil fishing machine has a working efficiency of delivering an opening / closing mesh sieve of about 3 square meters out of water per 3 seconds or so at a working speed of about 3-5 km / h on an oil gathering surface of about 15 m wide of an oil boom, and the working efficiency is much higher than that of the existing fishing technology. Through the invention, various kinds of leaked oil can be recycled so as to protect the ocean environment from serious pollution.

Owner:石伟

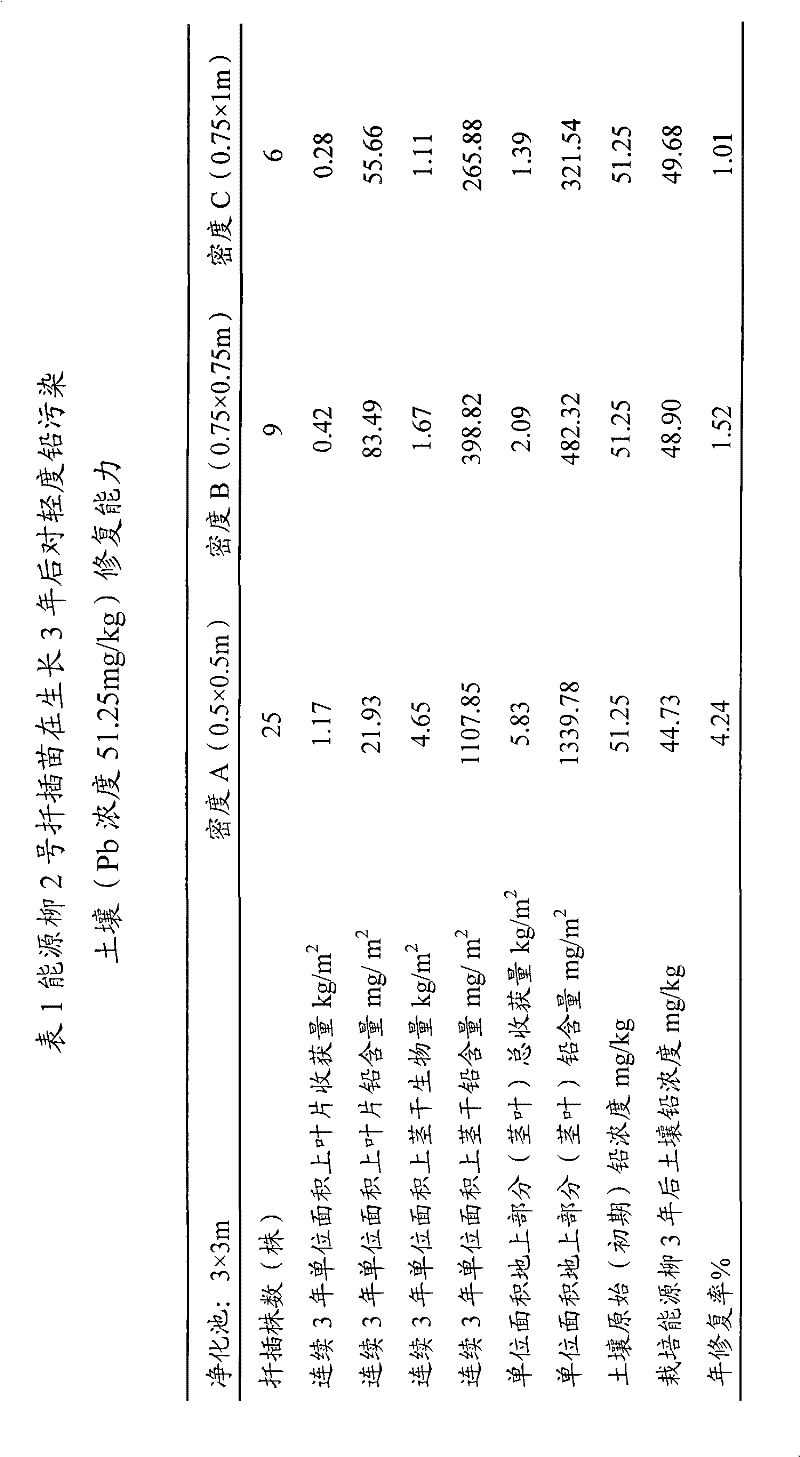

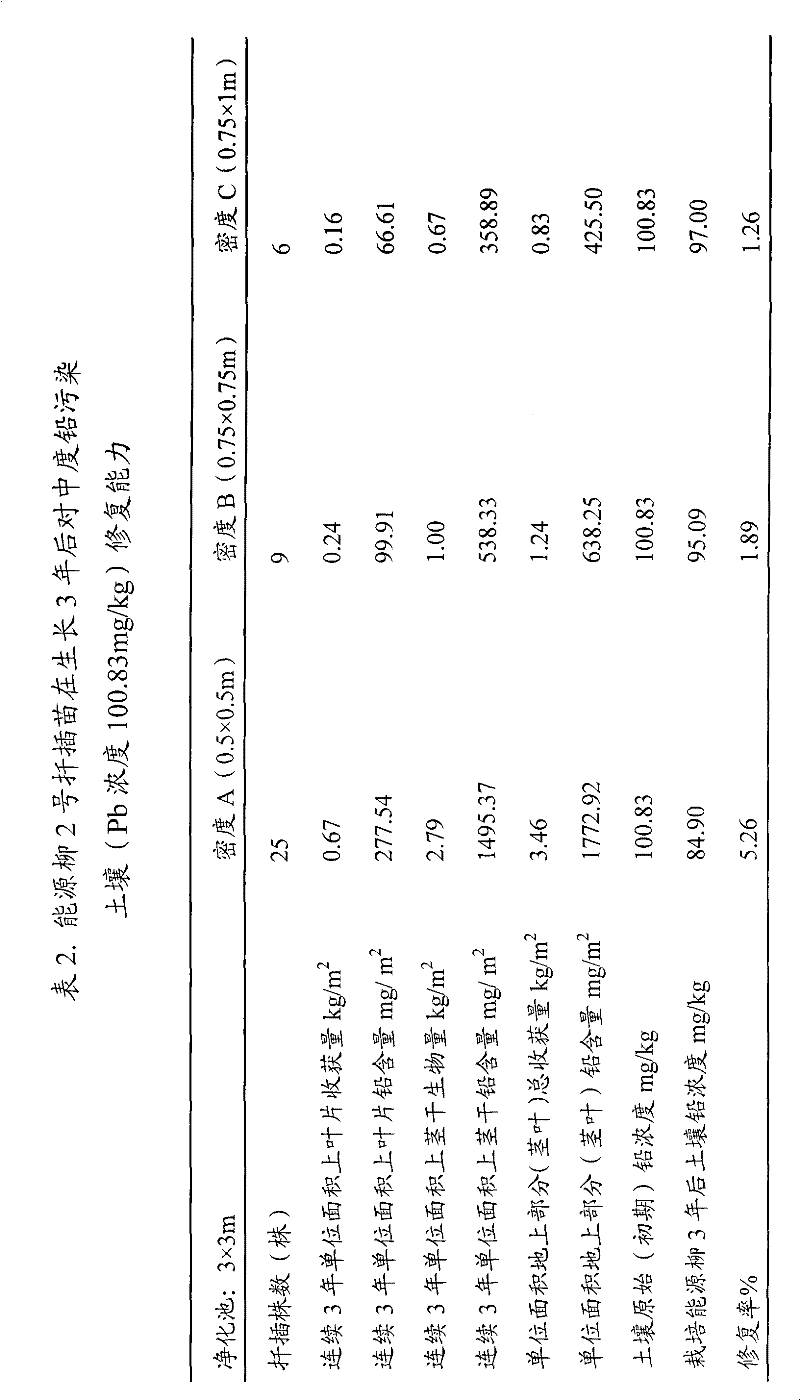

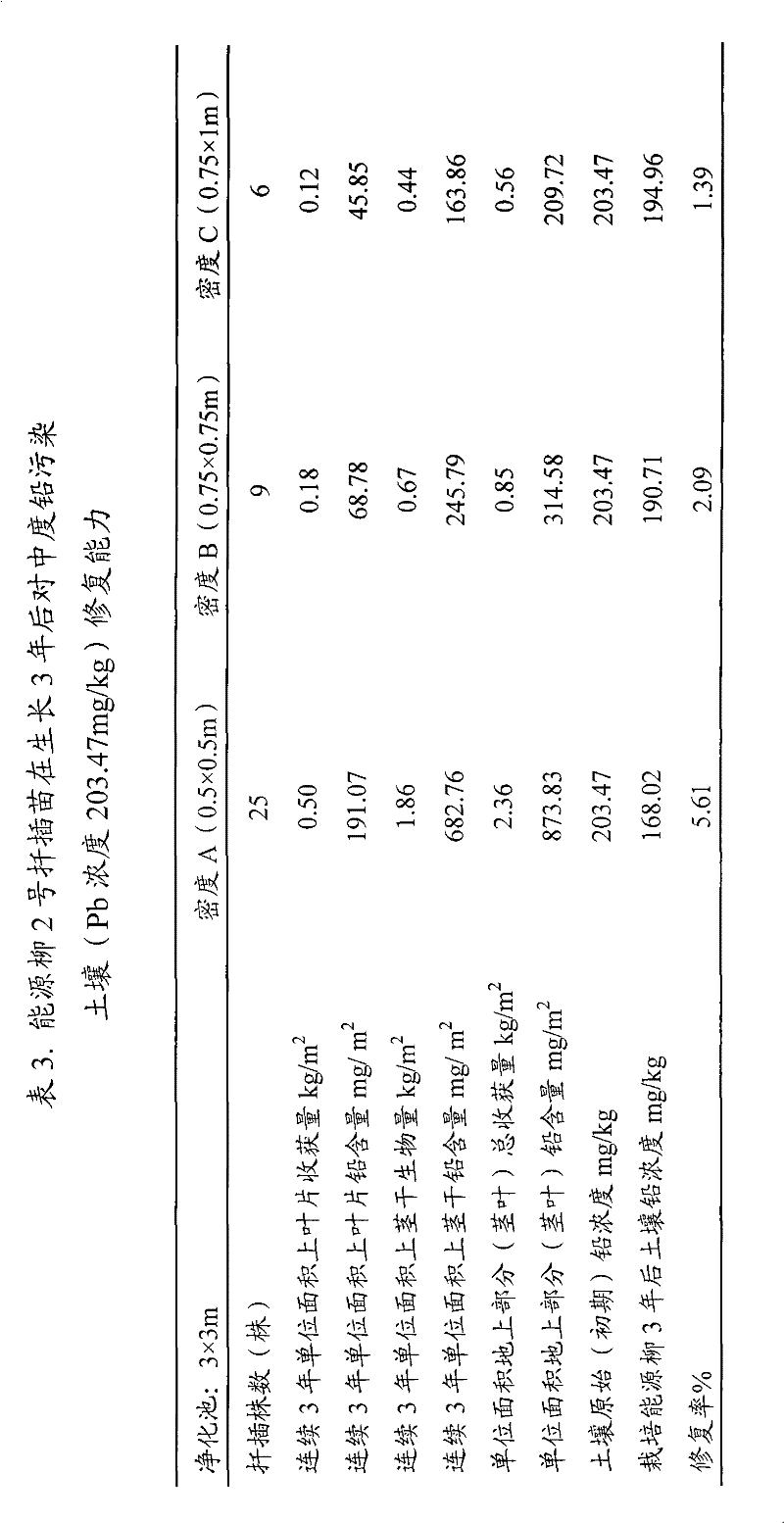

Method for remedying lead-polluted soil by utilizing Salix dascladus

InactiveCN102124886AImprove purification efficiencyCause secondary pollutionContaminated soil reclamationHorticultureEcological environmentSoil fertility

The invention relates to a method for remedying lead-polluted soil by utilizing Sweden Salix dascladus. The method comprises the steps of: selecting a Salix dascladus branch of one year old Salix dascladus tree space with a diameter of 1.5-2.0cm and a length of 15-20cm and carrying out cuttage according to a planting space of 0.5-0.75m and a row space of 0.5-1m in the lead-polluted soil; covering by utilizing polyethylene mulching film and watering; and after three years of the cuttage and growth, cutting the aboveground part of the Sweden Salix dascladus and preserving a stump height of 5-10cm when cutting to ensure that the preserved stump can keep on producing branches. By means of the method provided by the invention, the lead pollution problem of the soil can be continuously solved and the annual purification rate of the lead-polluted soil can be up to 1.01-5.61%. Compared with herbaceous plants, the Salix dascladus can enhance the lead purification capacity of the soil by 3-5 times; and the growth of the Salix dascladus is exuberant and the biomass can be up to 7-10t / hm<2> / year. According to the method, the advantages of low energy consumption and low cost in lead pollution abatement are provided, the ecological environment is not destroyed and the soil fertility can be rapidly recovered, therefore, the method provided by the invention can be widely popularized and applied.

Owner:TIANJIN NORMAL UNIVERSITY

Leaching method for anode material of waste LiCoO battery

InactiveCN101586189AReduce consumptionAvoid it happening againProcess efficiency improvementMaterials scienceMetal

A leaching method for the anode material of a waste LiCoO battery provided by the invention comprises the following steps: putting the anode material separated from the waste LiCoO battery into a pressure-resistant and nitric acid resistant container, and then sealing the container and pumping nitric acid into the container; leaching the anode material of the waste LiCoO battery by adding industrial pure oxygen. The leaching temperature is 20-100 DEG C; the leaching pressure is 0.05-0.5MPa; the initial concentration of the leached nitric acid is 1-6mol / L; the leaching time is 1-4h; the leaching process needs stirring; and the stirring speed is 30-100r / min. The adding amount of nitric acid is 101-130% of the theoretical quantity of the nitric acid consuming by leaching all the metal out from the anode material added in a reaction vessel.

Owner:SICHUAN NORMAL UNIVERSITY

Leaching method of nickel cobalt lithium manganate waste battery positive-negative electrode mixed material

InactiveCN103757330AReduce consumptionImprove leaching rateProcess efficiency improvementManganateEngineering

The invention provides a leaching method of a nickel cobalt lithium manganate waste battery positive-negative electrode mixed material, which comprises the following steps: adding a positive-negative electrode mixed material subjected to roasting pretreatment and separated from nickel cobalt lithium manganate waste batteries and pasture powder into a pressure-resistant sulfuric-acid / nitric-acid-corrosion-resistant reaction kettle, adding a sulfuric acid-nitric acid mixed solution, and carrying out agitation leaching under sealed conditions.

Owner:SICHUAN NORMAL UNIVERSITY

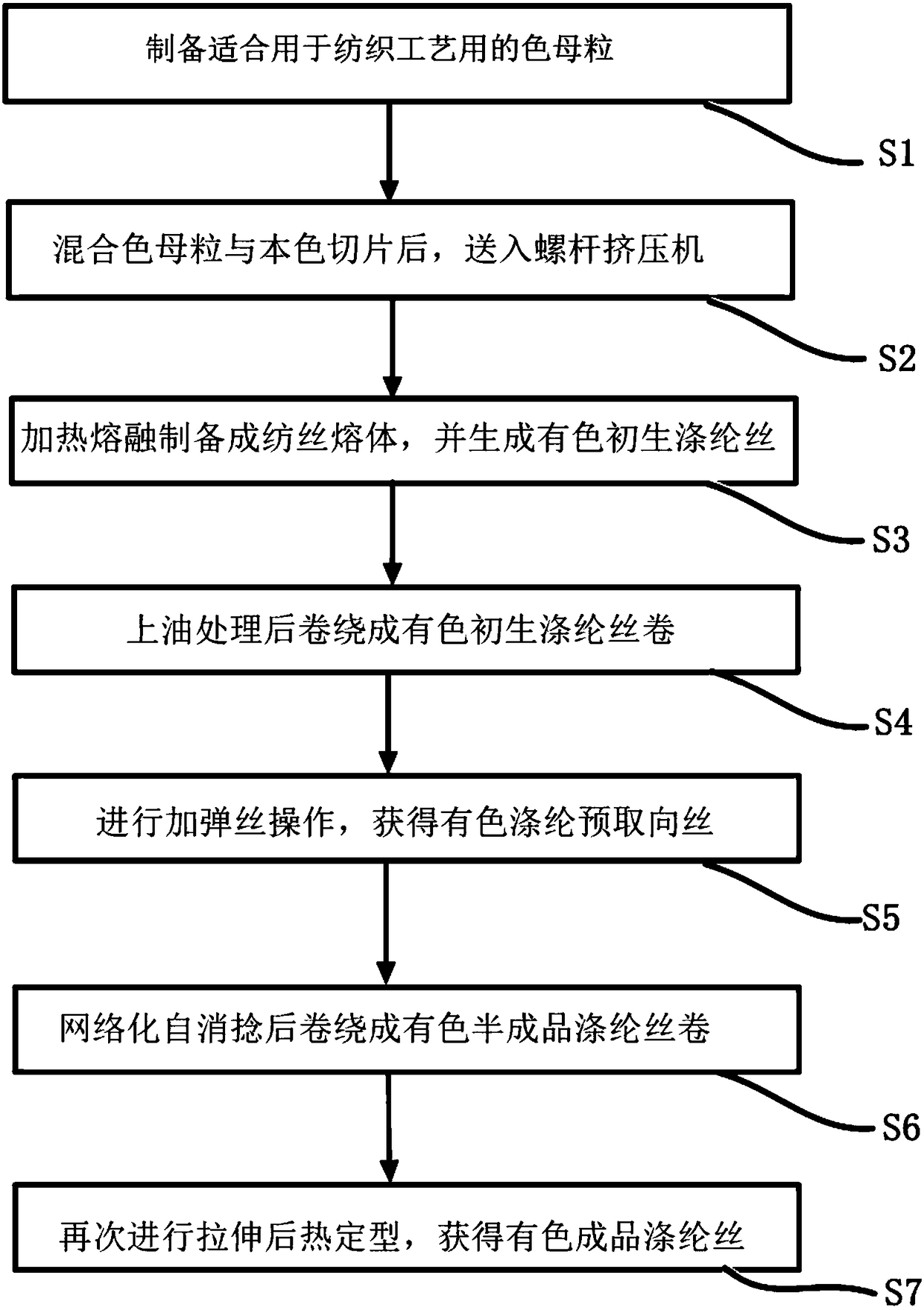

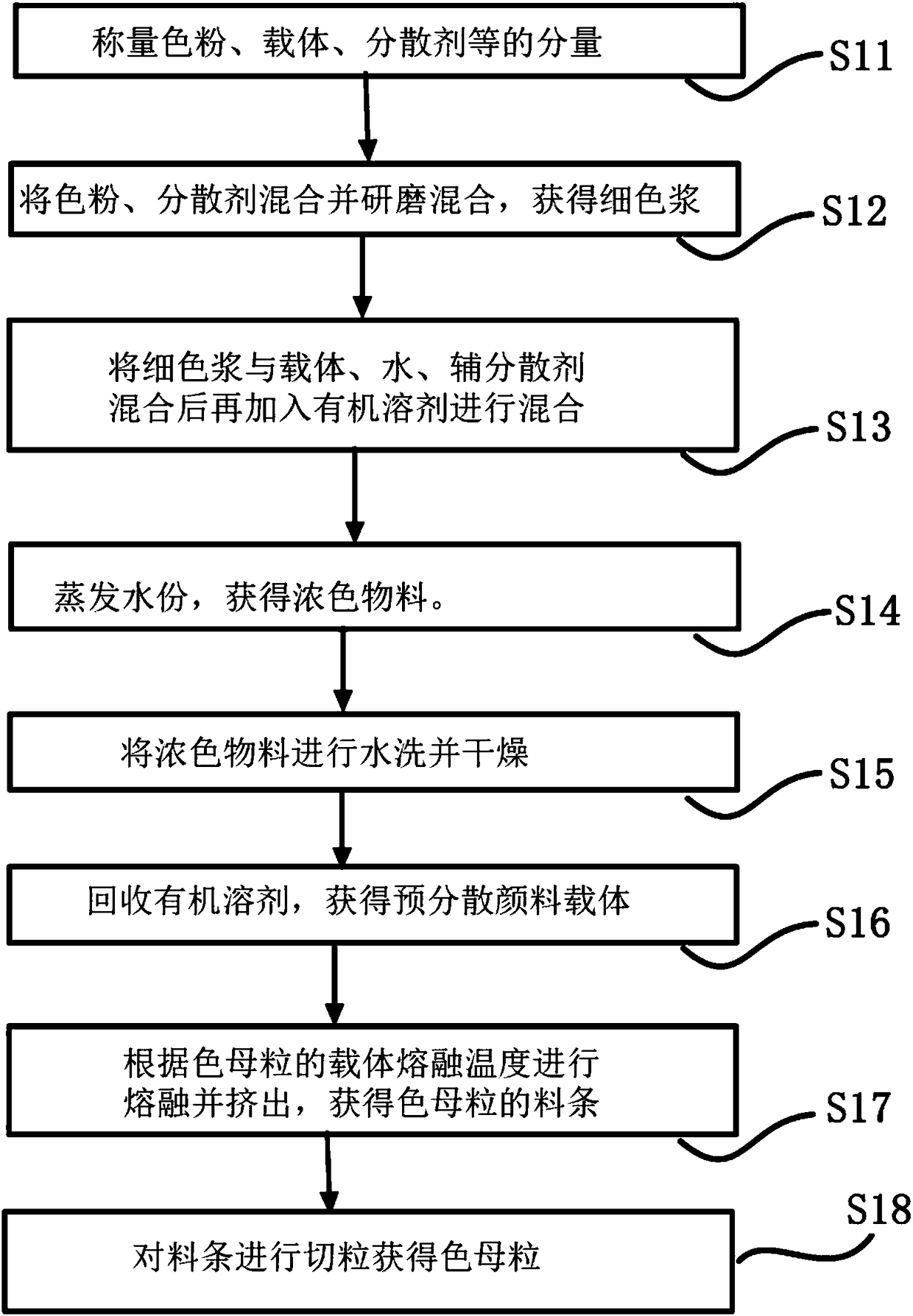

Preparation method of colored polyester yarn

ActiveCN108486659AUniform dyeingSmall color differenceFilament forming substance formingSpinning head liquid feederYarnPolyester

The invention relates to a preparation method of colored polyester yarn. The preparation method comprises the steps that color master batch and natural-color slices are evenly mixed in proportion, areconveyed into a screw extruder and are heated and melted in the screw extruder to be prepared into a spinning melt, the mixture is sprayed out of spinneret orifices and cooled to form colored primarypolyester yarn, and the colored primary polyester yarn is subjected to oiling and wound into a colored primary polyester yarn roll; then, the draw texturing yarn operation is carried out to obtain colored polyester pre-oriented yarn; the colored polyester pre-oriented yarn is subjected to networked self-detwisting to be processed into a colored polyester yarn semi-finished product, and the colored polyester yarn semi-finished product is wound into a colored polyester yarn semi-finished product roll; the colored polyester yarn semi-finished product is drawn again, the re-drawn colored polyester yarn semi-finished product is subjected to heat setting processing at the temperature of 170-210 DEG C, and the colored polyester yarn is obtained. Meanwhile, the invention further relates to a preparation method of the color master batch and the colored polyester yarn.

Owner:江苏苏美达纺织有限公司

Method for leaching positive-negative pole material mixture of waste lithium nickel cobalt manganese oxide battery

InactiveCN103757321AReduce consumptionImprove leaching rateProcess efficiency improvementPhysical chemistryManganese oxide

The invention discloses a method for leaching a positive-negative pole material mixture of a waste lithium nickel cobalt manganese oxide battery. The method comprises the steps of adding the positive-negative pole material mixture which is separated from the manganese waste lithium cobalt oxide battery and is subjected to roasting pretreatment, and napier grass powder into a reaction kettle which is resistant to pressure and the corrosion of sulfuric acid and nitric acid, adding a mixed solution of sulfuric acid and nitric acid, and leaching while stirring under closed conditions.

Owner:SICHUAN NORMAL UNIVERSITY

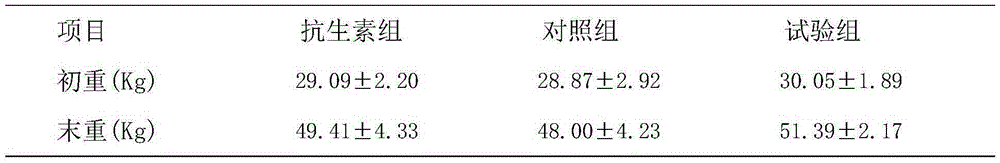

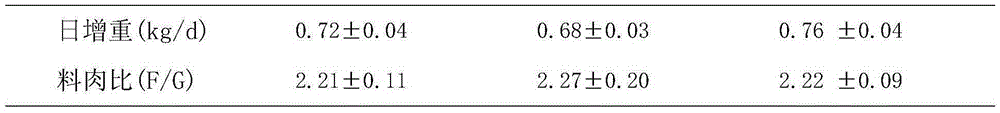

Preparation method of feed micro-ecologic agent produced by using citrus peels

InactiveCN105285326ASolve pollutionSave pollution control costsAnimal feeding stuffYeastBacillus subtilis

The present invention discloses a preparation method of a feed micro-ecologic agent produced by using citrus peels and a product thereof. The preparation method: Lactobacillus delbrueckii (Preservation No., CCTCC M 207096), Bacillus subtilis (Preservation No., CCTCC M 207097), Saccharomyces paradoxus (Preservation No., CCTCC M 207098) are inoculated to the corresponding liquid culture medium and cultured at a constant temperature of 37 DEG C for 18-24 hours, then the prepared bacteria solution is mixed in a certain proportion, the mixture is inoculated into sterilized solid state fermentation medium with the citrus peel as the main raw material and fermented at 30-40 DEG C for 36-48 hours, the fermented mixture is dried at a low temperature of 50-55 DEG C, and the dried mixture is crushed, thereby obtaining the feed micro-ecologic agent. Production technology of the feed micro-ecologic agent has the advantages of low investment, low energy consumption, no waste water pollution, etc., and opens up a new way for the utilization of the citrus peels at the same time.

Owner:HUNAN AGRICULTURAL UNIV

Leaching method of nickel cobalt lithium manganate waste battery positive-negative electrode mixed material

InactiveCN103757410AIncrease profitSimple equipmentProcess efficiency improvementSulfuric acidManganate

The invention provides a leaching method of a nickel cobalt lithium manganate waste battery positive-negative electrode mixed material, which comprises the following steps: putting a positive-negative electrode mixed material separated from nickel cobalt lithium manganate waste batteries and ground pyrolusite into a pressure-resistant sulfuric-acid / nitric-acid-corrosion-resistant container, pumping sulfuric acid and nitric acid into the container, sealing the container, and leaching the nickel cobalt lithium manganate waste battery positive-negative electrode mixed material.

Owner:SICHUAN NORMAL UNIVERSITY

Method and device for cooling high-temperature calcined coke of carbon rotary kiln

The invention discloses a production process of a carbon calcined rotary kiln in the field of carbon production and in particular relates to a method and a device for cooling high-temperature calcined coke of a carbon rotary kiln. The method for the cooling high-temperature calcined coke of the carbon rotary kiln comprises the following steps of: guiding the high-temperature calcined coke into a cooling jacket after passing through a launder at the bottom of a rotary kiln head; and after continuously discharging downwards, guiding the high-temperature calcined coke into discharge equipment for discharging from the cooling jacket. The method and the device solve the problems of poor cooling effect, oxidation of high-temperature materials, waste of cooling water resource, severe operating environment condition, serious water pollution, high cost of a cooling water circulation and processing system and waste of heat carried by the high-temperature calcined coke in the process of calcining petroleum coke.

Owner:中铝国际技术发展有限公司

Production method for zero-discharge yarn-dyed and woven fabric

InactiveCN102517756AEliminate emissionsReduce consumptionMercerising of yarns/threads/filamentsWoven fabricsYarnWastewater

The invention discloses a production method for a zero-discharge yarn-dyed and woven fabric and belongs to the field of textiles. The production method comprises the following steps of: preparing chemical fiber synthetic fibers or regenerated cellulose fibers by applying a color master-batch coloring mode; preparing blended colored yarns by blending the prepared chemical fiber synthetic fibers or regenerated cellulose fibers with cotton fibers according to the required color; finishing the blended yarns by adopting a zero-discharge mercerized finish method; and weaving on a weaving machine by adopting a non-slurry woven fabric weaving method and then finishing to obtain the zero-discharge yarn-dyed and woven fabric. Due to the use of the method, the production method of the complete zero-discharge environment-friendly yarn-dyed fabric can be obtained. Wastewater discharge can be completely avoided and the pollution to water is avoided.

Owner:WUXI NON SIZING TECH

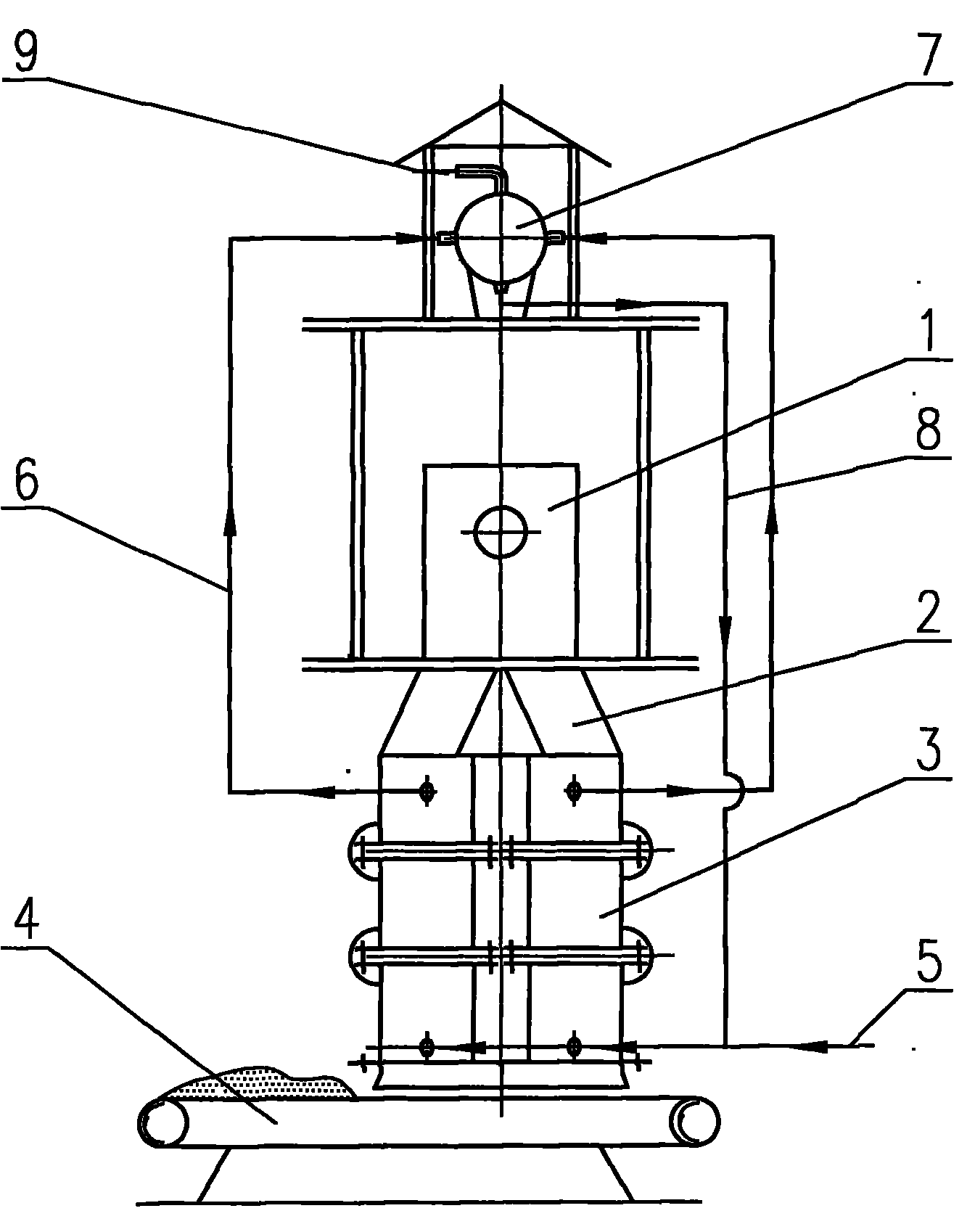

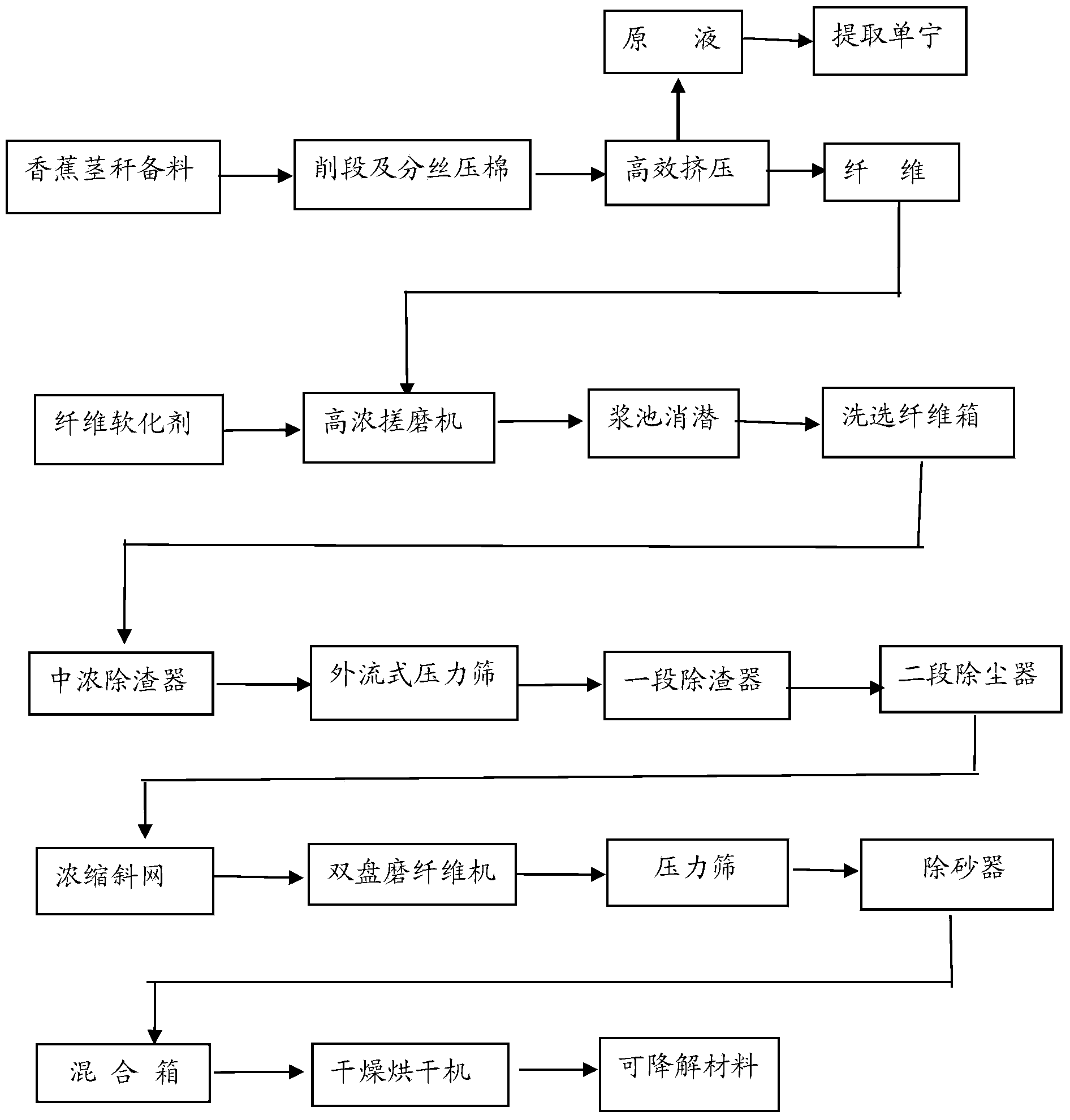

Preparation method for producing degradable materials by using banana stalks

InactiveCN104164800AReduce manufacturing costAvoid foul smellCellulose material pulpingHigh concentrationFiber

The invention discloses a preparation method for producing degradable materials by using banana stalks and belongs to the field of production of degradable materials. The preparation method of the degradable materials comprises following steps: (1) preparing materials, removing impurities, cutting the materials into sections, separating fibers and carrying out cotton pressing; (2) squeezing the fibers; (3) grinding the fibers in a high concentration manner; (4) carrying out latency in a pulp chest to obtain fiber pulp; (5) washing the fiber pulp; (6) modifying; and (7) drying. The banana stalks and cationic starch used in the preparation method are completely biodegradable materials; other added auxiliary materials are inorganic chemical products; the prepared products are completely degradable and environment-friendly products; all the indexes, such as burst index, tearing index and tensile strength, meet the standards in China. The preparation method for producing the degradable materials by using the banana stalks is free of steps of heating, coking and soaking with alkali, simple in production process, capable of quickly softening the fibers, low in cost and free of pollution.

Owner:南宁市美意环保工程有限责任公司 +2

Low-aluminum silicon-barium-calcium alloy and production process thereof

The invention relates to a low-aluminum silicon-barium-calcium alloy and a production process thereof, relating to the field of steel-making deoxidizing agents. At present, silicon-barium alloy, silicon-calcium alloy and ferrosilicon alloy are commonly and respectively added during steel making. As a result, high-content of impurities such as sulfur, phosphorus, and the like exists in a steel material, and the aluminum content is also over 2 percent, so that the quality of the steel material is severely affected; besides, the production cost is high, the process is complex, and the labor intensity is great. The invention adopts a compound refining method to produce the low-aluminum silicon-barium-calcium alloy, comprising the steps of adding and melting scrap iron, melting the silicon-barium alloy till ebullition, adding silicon-calcium alloy, adding dealuminzation powder, keeping the ebullition for 10-20 min, and finally casting and forming to obtain a finished deoxidizing agent. The invention has the advantages of low content of harmful elements, few impurities, capability of meeting the requirements on special good-quality steel materials, low cost, simple process and low construction investment.

Owner:王玉清

Microecological preparation and preparation method thereof

InactiveCN101525632ASave pollution control costsPrevent bowel diseaseAnimal feeding stuffMicroorganism based processesChemistryAnimal slaughter

The invention relates to the technical field of treatment and comprehensive utilization of animal slaughter industrial wastewater, finds new application of blood wastewater and provides an animal-used microecological preparation which is prepared by taking blood wastewater as a raw material and selecting safe microbe. The animal-used microecological preparation is used in the field of livestock breeding, thereby solving the problem of environment pollution by blood wastewater and changing the waste into valuable and achieving the aim of clean production.

Owner:迈德金生物技术(北京)有限公司

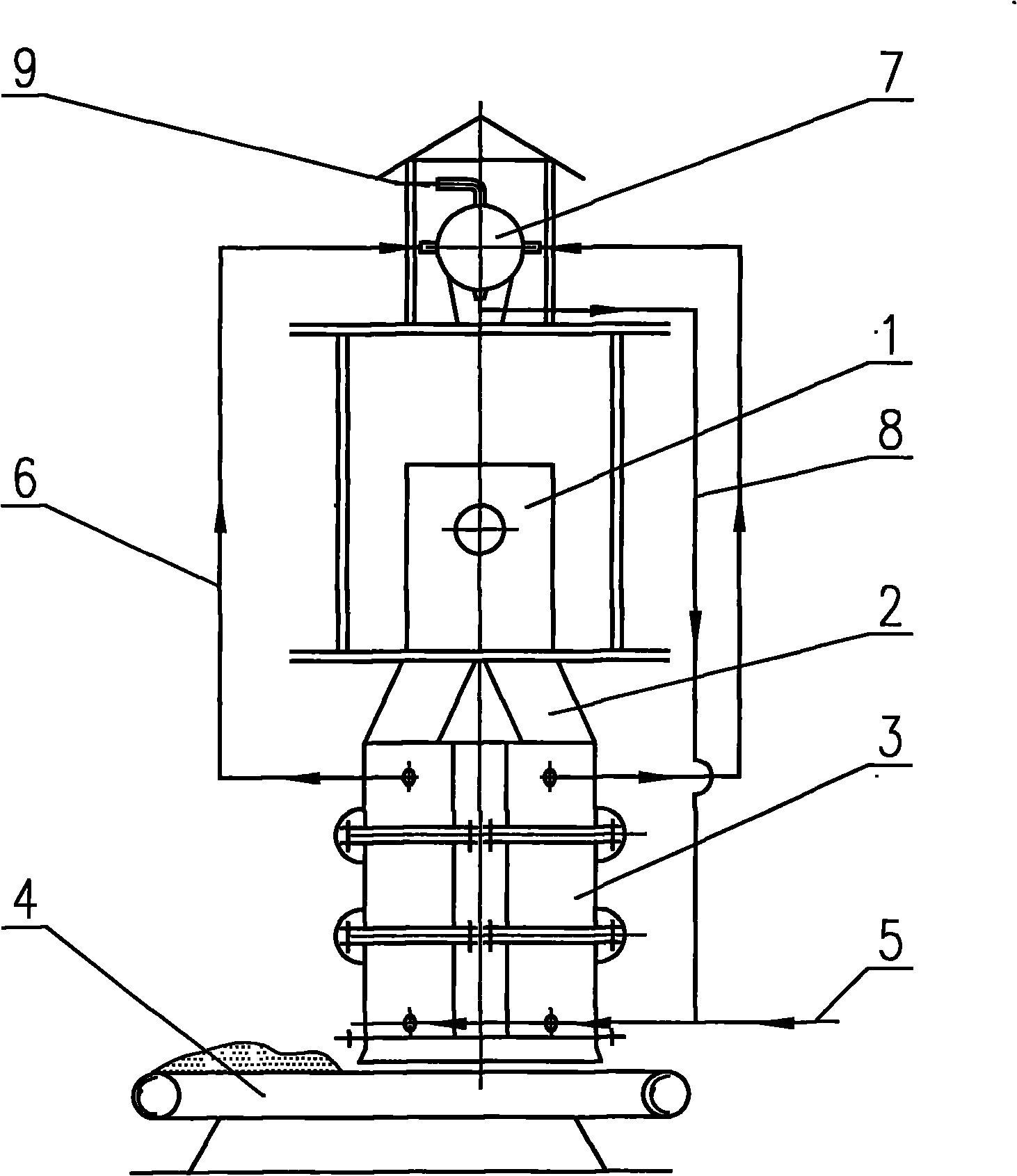

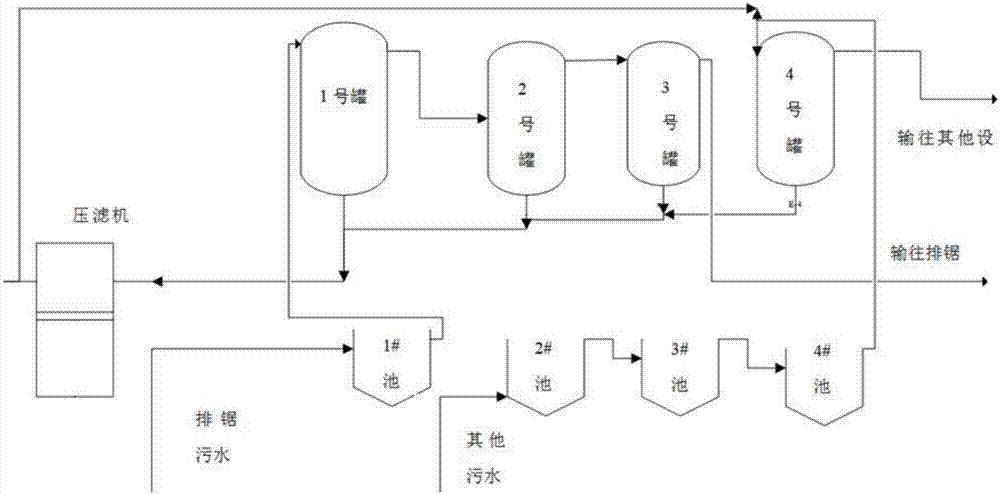

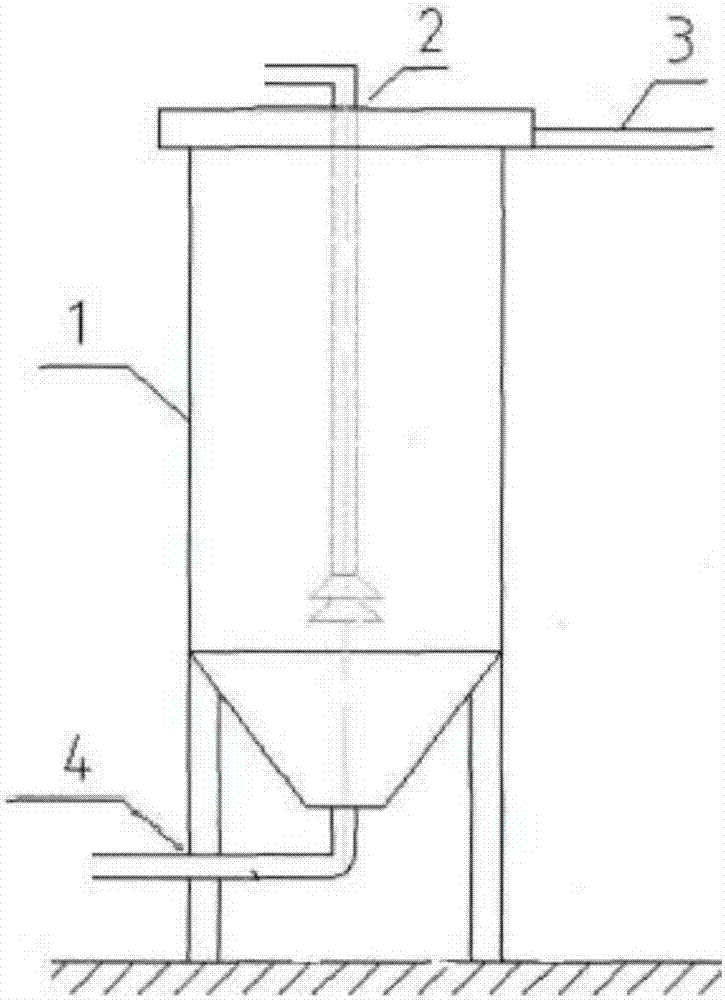

Marble sewage treatment production line

InactiveCN107352592ASave pollution control costsTreatment involving filtrationTreatment involving sedimentationSuspended particlesProduction line

The invention discloses a marble sewage treatment production line and belongs to the technical field of stone processing. By means of dead weight of suspended particles in sewage, a treatment system follows the principle of mass sedimentation and adopts a treatment way combining vertical-flow sedimentation in tanks and horizontal-flow sedimentation in water pools, so that the suspended particles settle to the bottoms of the water tanks, and sludge-water layering and sewage purification are realized. Marble sewage produced in a gang saw workshop and a kerb workshop is treated with vertical-flow sedimentation, for example, about 1 million m<3> of stone sewage can be treated every year and 78.34% is recycled, then 0.7834 million m<3> of tap water can be saved, in terms of 2.5 yuan saved for each ton, 0.7981 million yuan can be increased each year by the sewage system, and pollution treatment cost caused by massive sewage emission is saved.

Owner:贵州紫云玉腾石业有限公司

Leaching method for anode material of waste LiNiO2 battery

InactiveCN101586193AReduce nitric acid consumptionAvoid the production of pollutant nitrogen oxidesProcess efficiency improvementAnodeMetal

A leaching method for the anode material of waste LiNiO2 battery provided by the invention comprises the following steps: putting the anode material separated from the waste LiNiO2 battery into a pressure-resistant and nitric acid resistant container, and then sealing the container and pumping nitric acid into the container; leaching the anode material of the waste LiNiO2 battery by adding industrial pure oxygen. The leaching temperature is 20-100 DEG C; the leaching pressure is 0.05-0.5MPa; the initial concentration of the leached nitric acid is 1-6mol / L; the leaching time is 1-4h; the leaching process needs stirring; and the stirring speed is 30-100r / min. The adding amount of nitric acid is 101-130% of the theoretical quantity of the nitric acid consuming by leaching all the metal out from the anode material added in a reaction vessel.

Owner:SICHUAN NORMAL UNIVERSITY

Leaching method of lithium iron phosphate waste battery positive electrode material

InactiveCN103757388AImprove leaching rateQuick responseProcess efficiency improvementLithium iron phosphateEnvironmental engineering

The invention provides a leaching method of a lithium iron phosphate waste battery positive electrode material, which comprises the following steps: putting a positive-negative electrode mixed material subjected to roasting pretreatment separated from lithium iron phosphate waste batteries into a pressure-resistant sulfuric-acid-corrosion-resistant container, pumping sulfuric acid into the container, sealing the container, and introducing SO2 to perform leaching.

Owner:SICHUAN NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com