Preparation method for producing degradable materials by using banana stalks

A technology of banana stems and degradable materials, which is applied in fiber raw material processing, cellulose raw material pulping, textile and papermaking, etc., can solve the problems of low raw material utilization rate, long process time, high manufacturing cost, etc., and achieve the goal of increasing enterprises Economic benefits, reduced manufacturing costs, and the effect of eliminating foul odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

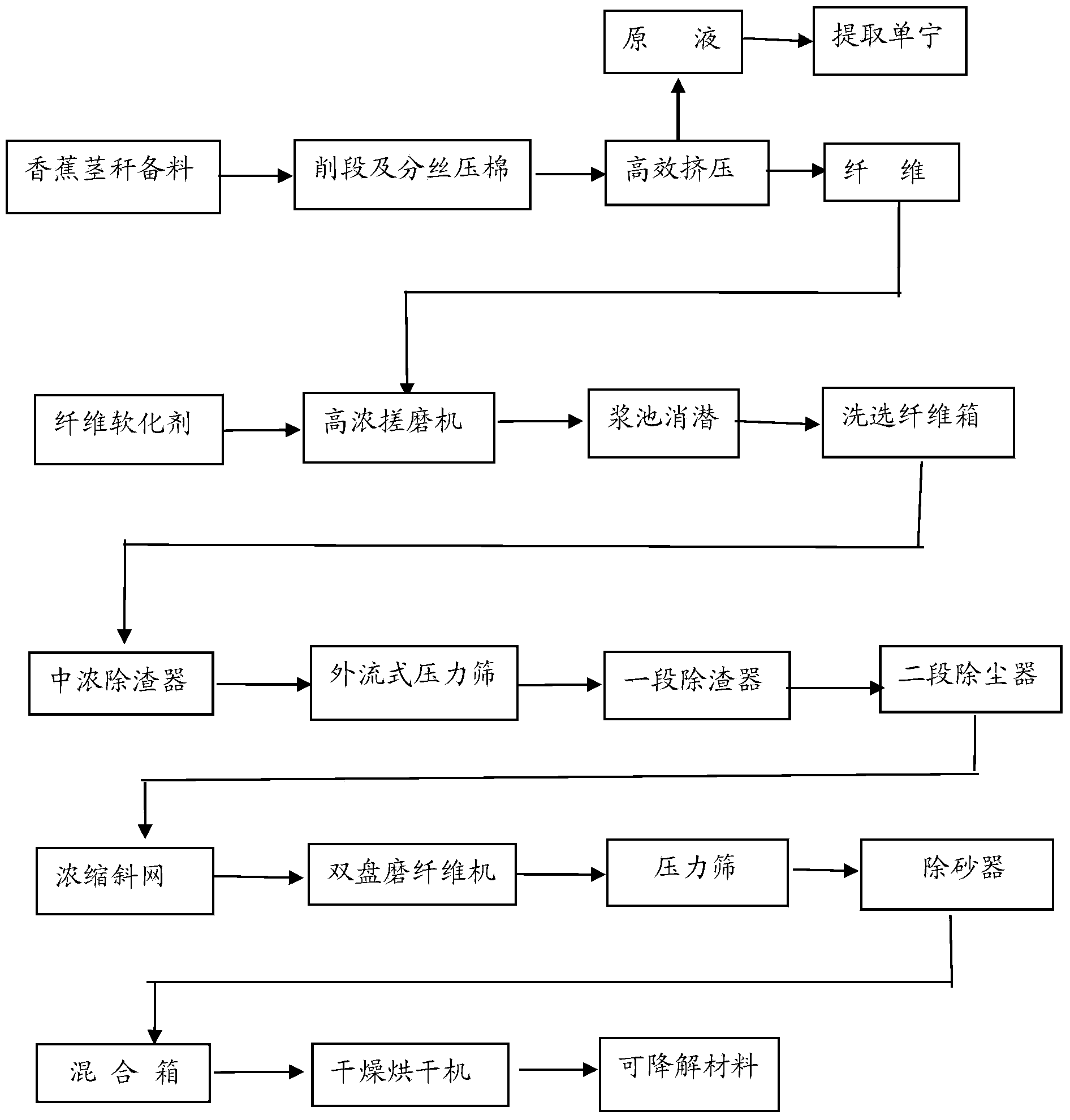

[0029] A preparation method for making degradable materials from banana stalks, the process flow chart is as follows figure 1 As shown, the following process steps are included:

[0030] (1) Prepare materials and remove impurities, cut sections, divide wires and press cotton: select 1000 kg of dry banana tree stems from the banana trees cut down by the fruit grower, and use a drum chipper to cut them into 30-50cm in length. Small pieces, and then sent to the wire splitter for wire splitting and cotton pressing.

[0031] (2) Extruded fiber: Banana stalks are efficiently extruded by an advanced extruder to separate fibers and stock solution, and the fiber is sent to a high-concentration rubbing mill to grind the fiber, and the stock solution is recovered to extract tannin for use.

[0032] (3) High-concentration milled fiber: the fiber obtained by extrusion is mixed with water to a mass fraction of 25%, the fiber softener is added to the high-concentration rubbing mill and mixe...

Embodiment 2

[0042] A preparation method for making degradable materials from banana stalks, the process flow chart is as follows figure 1 As shown, the following process steps are included:

[0043] (1) Prepare materials and remove impurities, cut sections, divide wires and press cotton: select 1000 kg of dry banana tree stems from the banana trees cut down by the fruit grower, and use a drum chipper to cut them into 30-50cm in length. Small pieces, and then sent to the wire splitter for wire splitting and cotton pressing.

[0044] (2) Extruded fiber: Banana stalks are efficiently extruded by an advanced extruder to separate fibers and stock solution, and the fiber is sent to a high-concentration rubbing mill to grind the fiber, and the stock solution is recovered to extract tannin for use.

[0045] (3) High-concentration milled fiber: the fiber obtained by extrusion is mixed with water to a mass fraction of 30%, the fiber softener is added to the high-concentration rubbing mill and mixe...

Embodiment 3

[0054] Embodiment 3 performance index

[0055] 1. The pH value of the waste water produced in Example 1 and Implementation 2 was tested, and the obtained results were 5.6 and 6.1 respectively, showing weak acidity. The process water consumption of embodiment is about 8m 3 , the wastewater discharge is only 2-3.5m 3 , while the water consumption of the traditional pulping process is 150-200m per ton of pulp 3 / ton, the displacement is 30-35m 3 , The amount of waste water is reduced by about 94%, which effectively realizes energy saving and environmental protection.

[0056] 2. Utilize the relevant indicators of the degradable material prepared in the national standard method to test the embodiment, and the obtained results are shown in Table 1.

[0057] Table 1 Performance indicators of degradable materials

[0058] project

[0059] From the data in Table 1, it can be seen that the burst index, tear index, tensile index, folding endurance, etc. of the degradabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com