Patents

Literature

87results about How to "Reduce pulping costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite strain microbial dry powder for bio-pulping and environment-friendly energy-saving type composite strain bio-pulping process

InactiveCN101597575ATake advantage ofReduce pollutionPretreatment with water/steamFungiYeastMicroorganism

The invention relates to composite strain microbial dry powder for bio-pulping and an environment-friendly energy-saving type composite strain bio-pulping process. The composite strain microbial dry powder for bio-pulping is characterized in that two classes of microbes of 40 to 60 portions of lipolytic yeast and 30 to 50 portions of defibering strain in portion by weight are blended to prepare the composite strain microbial dry powder for pulping. The process is environment-friendly, energy-saving and high-efficiency, can effectively improve the effect and efficiency of separating and purifying straw cellulose through joint application of multi-strain, can not only use waste straw for pulping but also carry out harmless treatment on generated wastewater and radically solves the problem of pulping pollution.

Owner:尚诚德

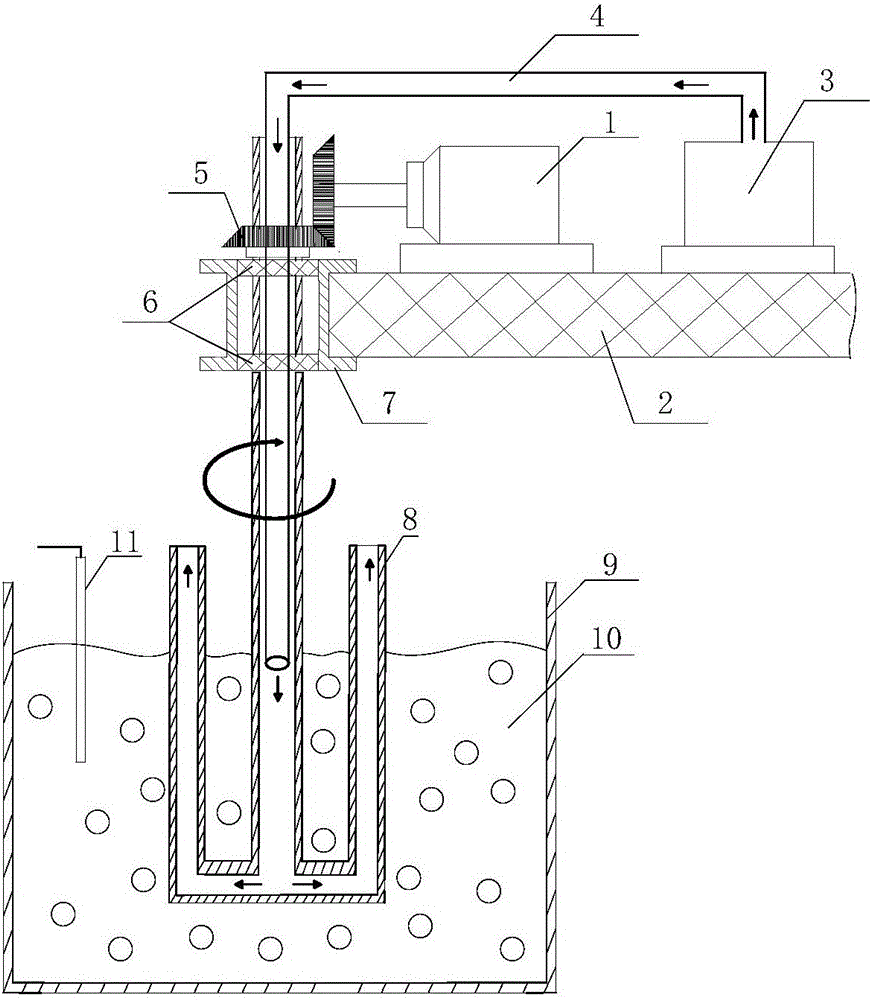

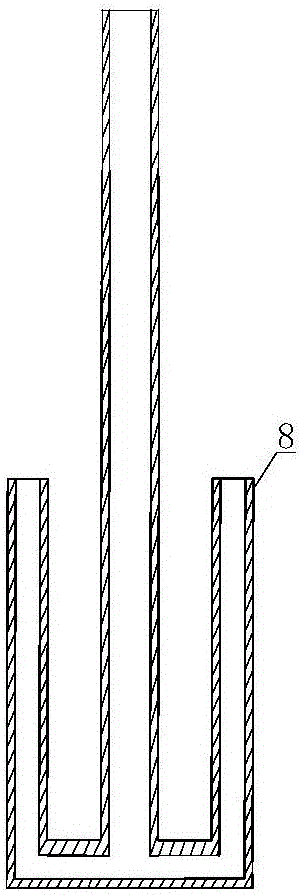

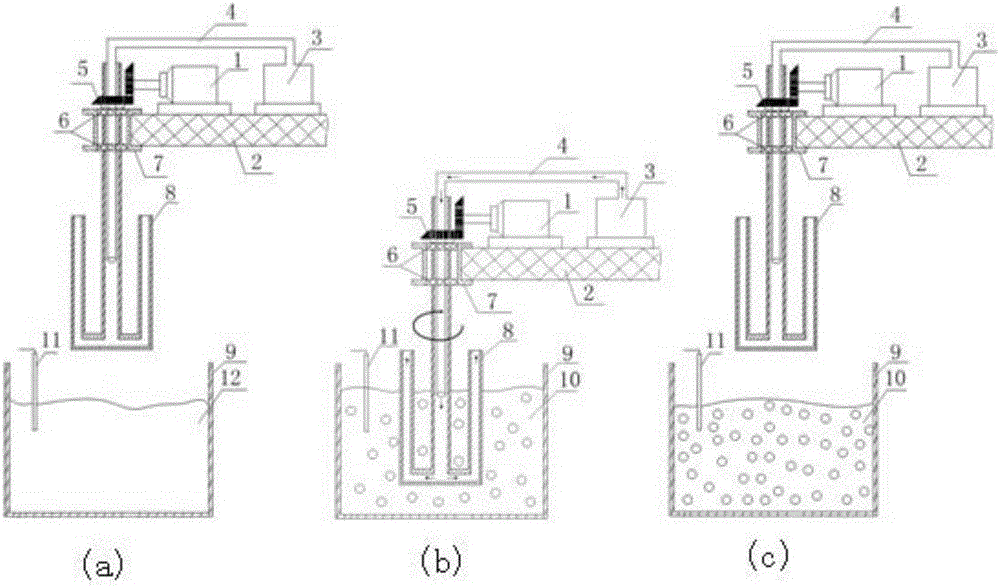

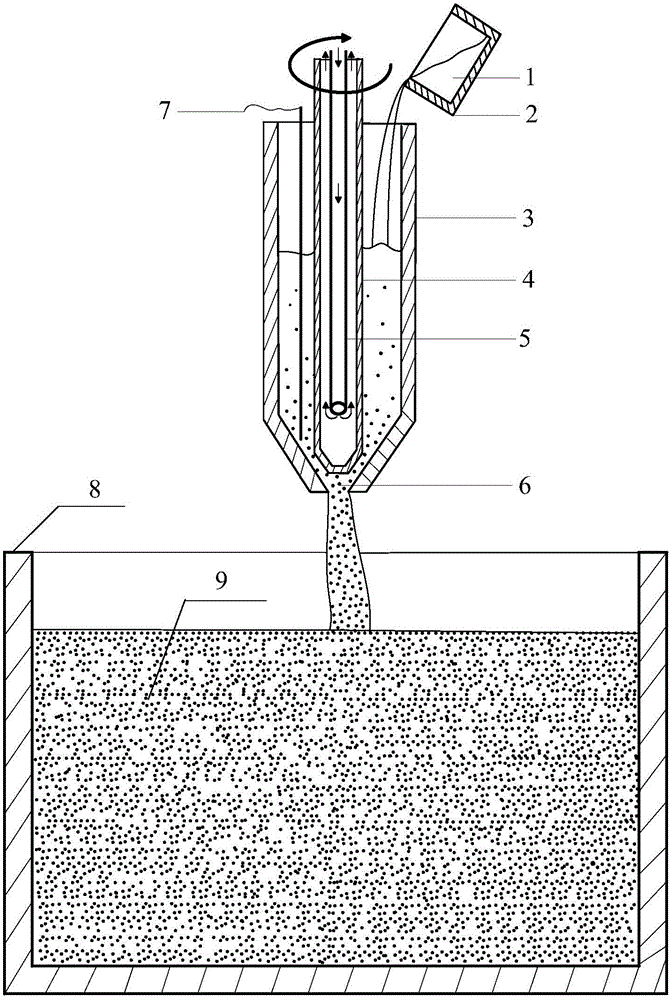

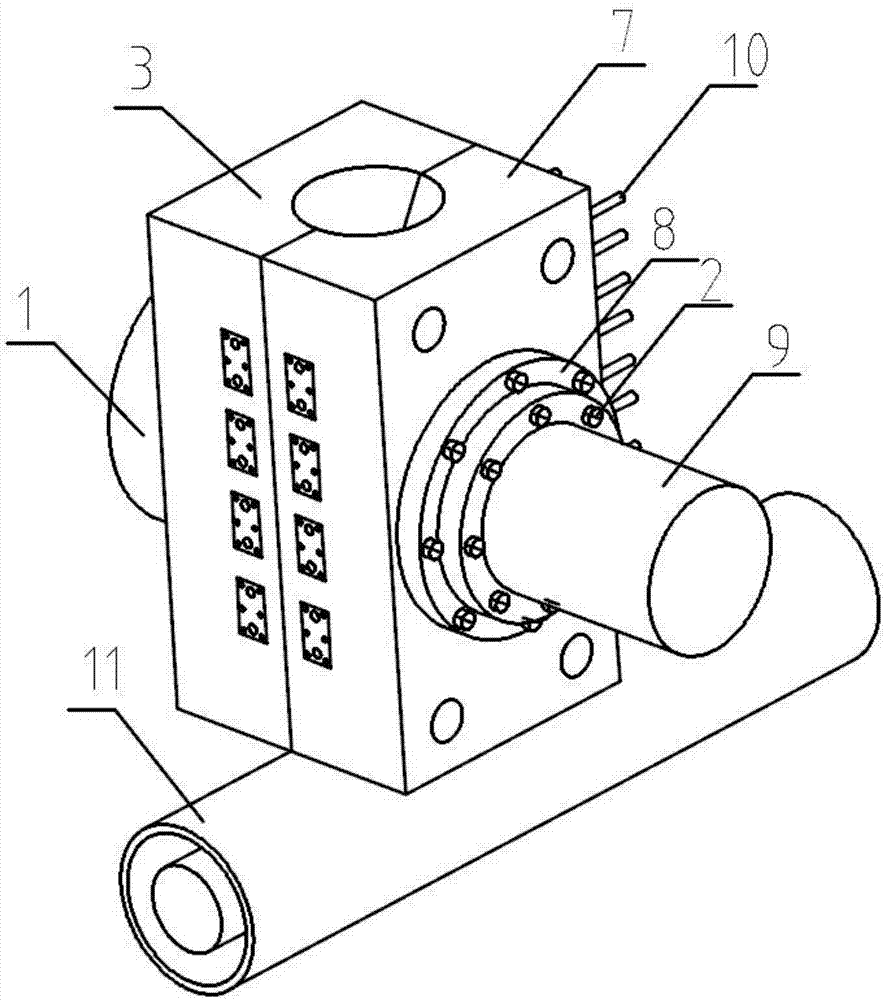

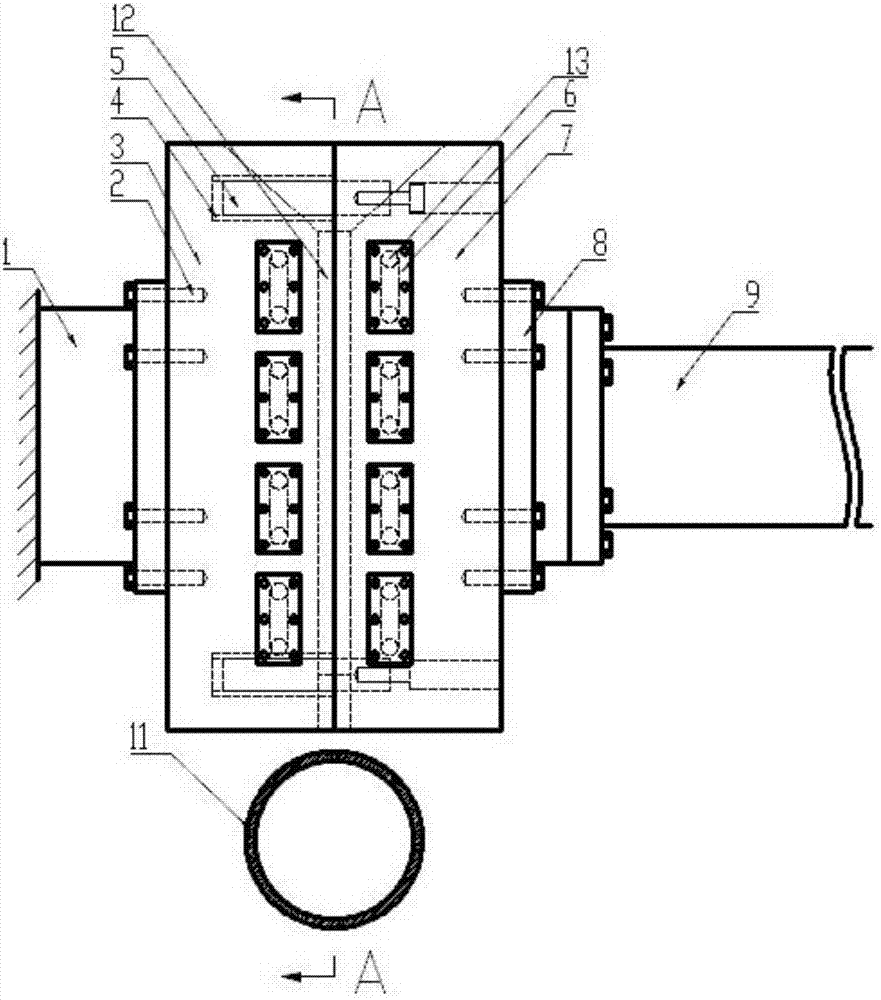

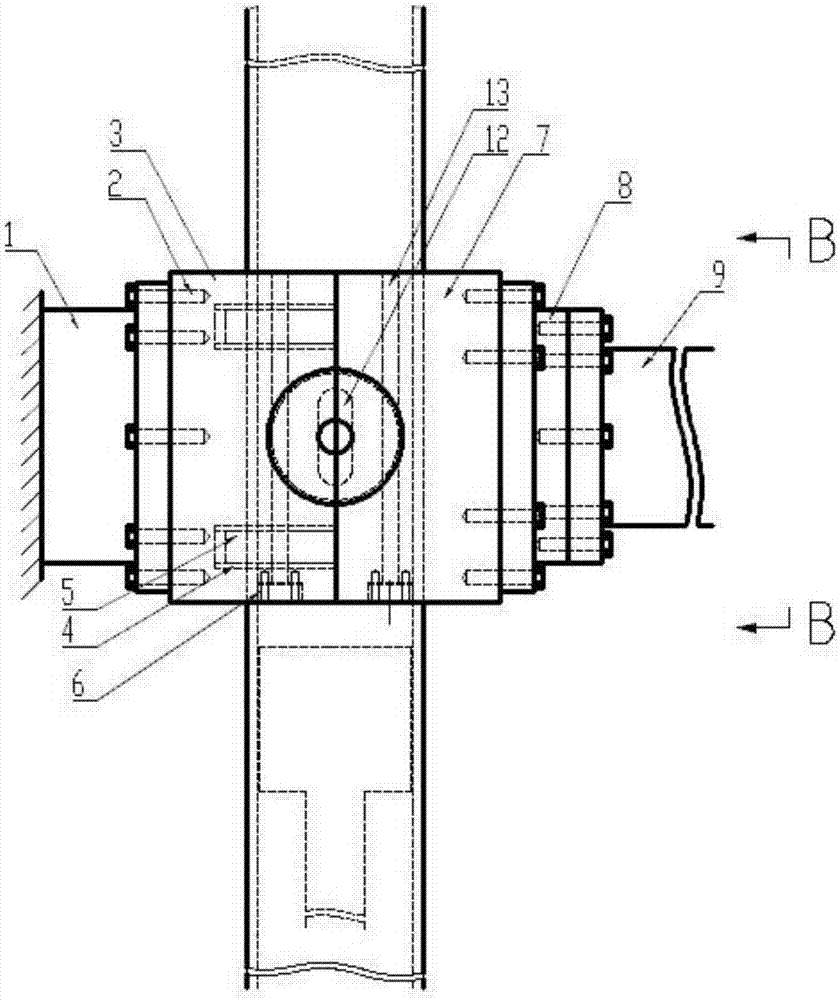

Device and method for preparing light alloy semi-solid slurry through air-cooling multi-tube stirring

The invention provides a device and method for preparing light alloy semi-solid slurry through air-cooling multi-tube stirring. The device comprises a crucible for containing light alloy melt, an air-cooling multi-tube stirring mechanism and a lifting mechanism. The air-cooling multi-tube stirring mechanism comprises a stirring mechanism body and an air supply mechanism. The stirring mechanism body is composed of a stirring motor, a multi-tube stirring rod and a bevel gear drive group which are arranged on a lifting platform. The multi-tube stirring rod is supported and positioned through a bearing. The air supply mechanism is composed of an air guide tube and an air supply device. One end of the air guide tube is combined with the air supply device, and the other end of the air guide tube is inserted into the multi-tube stirring rod. Multiple stirring pipes are filled with air entering the air guide tube. The device is simple in structure, convenient to use, high in efficiency, safe, reliable, wide in applicable scope in alloy and especially suitable for preparing large-volume semi-solid alloy slurry, the melt temperature, the stirring speed, the number of the stirring tubes, the inner diameter, the wall thickness, the stirring time and air ventilation quantity can be accurately controlled, and industrial application and popularization are facilitated.

Owner:UNIV OF SCI & TECH BEIJING

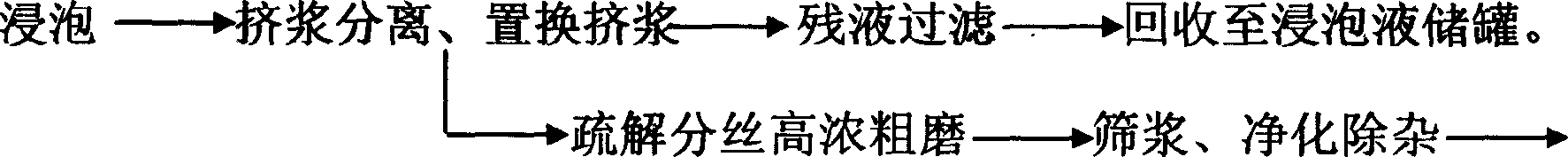

Biocatalytic clean pulping agent and application process thereof

InactiveCN1844572ANo emissionsNo pollutionPulp liquor regenerationWashing/displacing pulp-treating liquorsForeign matterProcess equipment

The invention relates to a biochemical catalysis cleaning slurry agent and relative application. Said invention is formed by: amylase, laccase, hydroxybenztriazole, calcii chloridum SL-1 slurry braise agent, sodium carbonate, and water. And the application comprises: 1, cutting raw material to be kneaded and dedusted; 2, preparing material with wet method; 3, dipping to remove lignin colloid; 4, extruding slurry to replaced and separated, dipping to filter the left liquid to be recycled; 5, rough milling and combing wire; 6, screening slurry to remove foreign matters; 7, washing slurry; 8, finish milling slurry; 9, poaching slurry; 10, washing poached slurry; 11, stepped treating and recycling used water. The invention is characterized in dipping said raw material in normal temperature and pressure. The left liquid is not discharged, but be recycled. And the pulp is poached pulp. The invention can support industrial production.

Owner:石建凯

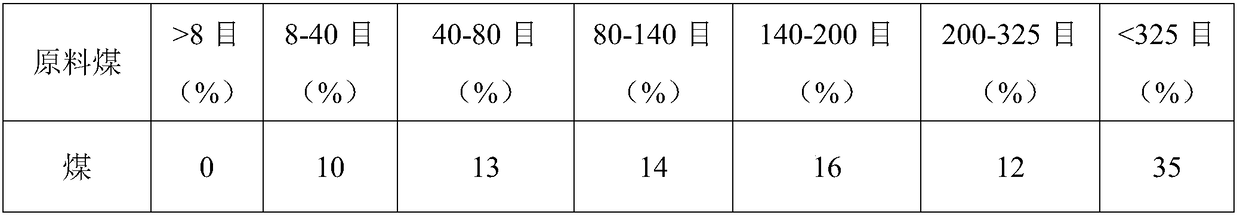

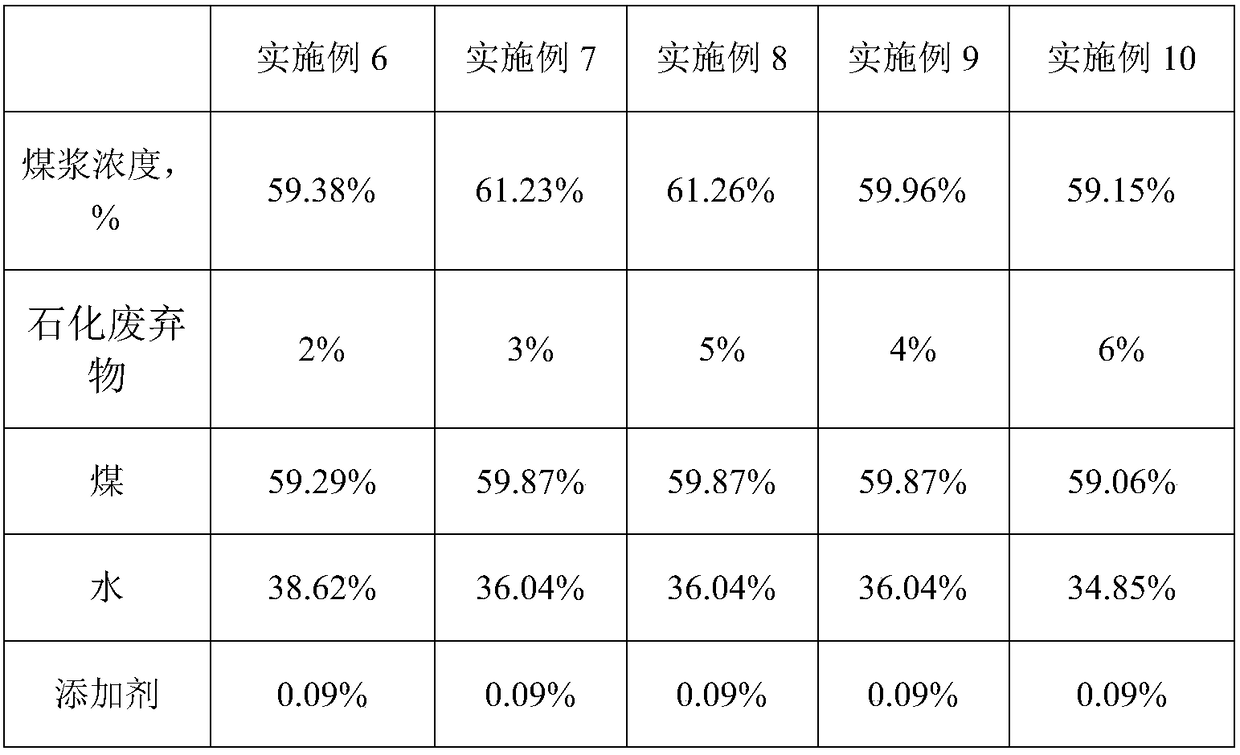

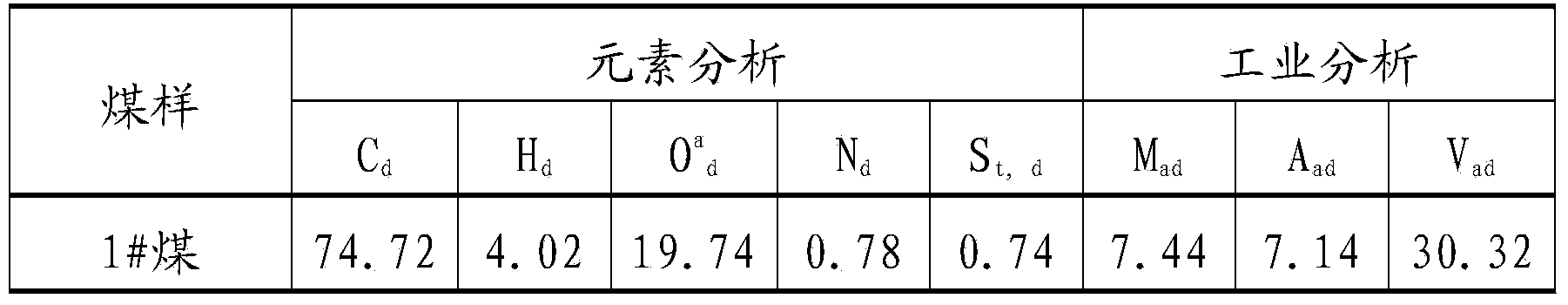

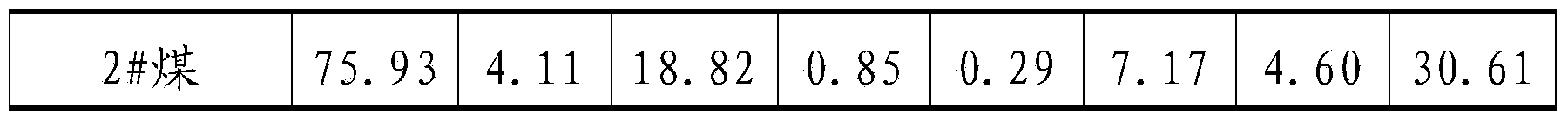

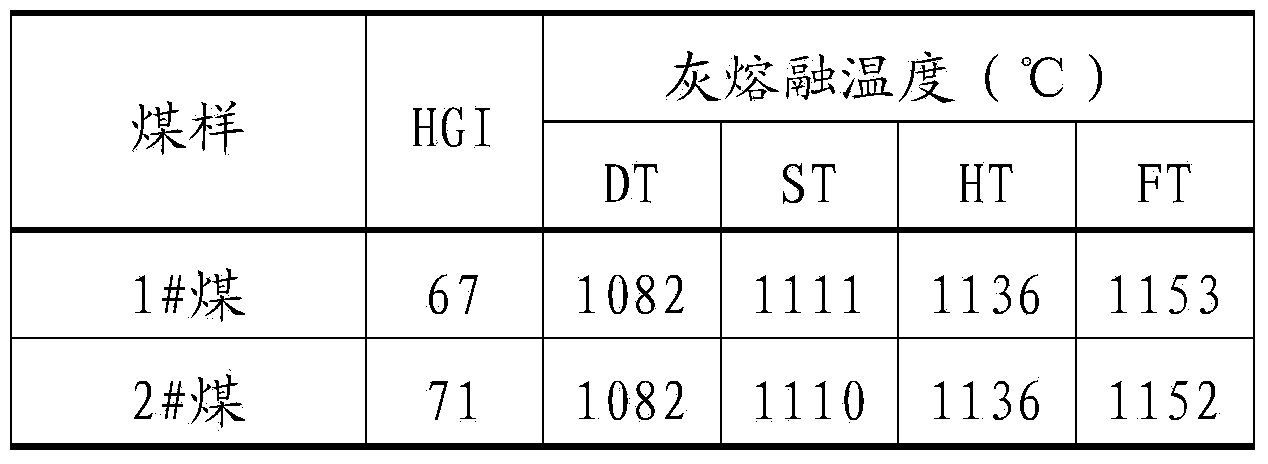

Coal-water slurry mixed with gasified coal and petrochemical waste and its pulping process

The invention discloses coal water slurry prepared by mixing gasified coal with petrochemical wastes. The coal water slurry is prepared from the following components: coal, the petrochemical wastes, additives and water, wherein the mass of the petrochemical wastes accounts for 0-6% of the total mass of the coal water slurry but not zero, and the adding amount of the additives accounts for 0-0.15% of the total mass of the dry coal but not zero. The invention also discloses a slurrying technology of the coal water slurry. The coal water slurry provided by the invention is good in fluidity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technology for producing fulvic acid fertilizer and high-strength corrugated paper by using whole cotton stalks as raw materials

ActiveCN108611912ASave resourcesIncrease productivityMachine wet endPulp beating/refining methodsHigh concentrationFiber

The invention provides a technology for producing a fulvic acid fertilizer and high-strength corrugated paper by using whole cotton stalks as raw materials. With the whole cotton stalks as the raw materials, by a weakly-acid imidized machine pulp pulping technology, through optimal combination of the cooking temperature, the cooking time and the pH value as well as high-concentration pulping and other pulping technological links, pulping red liquor rich in fulvic acid is prepared for producing the fertilizer, and high-performance pulp with a relatively light color is produced for producing thehigh-strength corrugated paper. By the technology, defects and shortcomings of a strong-alkali and strong-acid technology are avoided, differences in traits, components and structures of the whole cotton stalk raw materials are overcome, fulvic acid producing active components contained in cotton stalk cores, cotton stalk pulps, cotton boll shells and cotton stalk skins in the whole cotton stalksare effectively utilized, the advantage of combination of long and short whole cotton stalk fibers is effectively played for producing the high-strength corrugated paper, comprehensive utilization ofwhole cotton stalk resources is achieved, and a technological path for industrial and commercial utilization of the whole cotton stalk raw materials is opened up.

Owner:白博

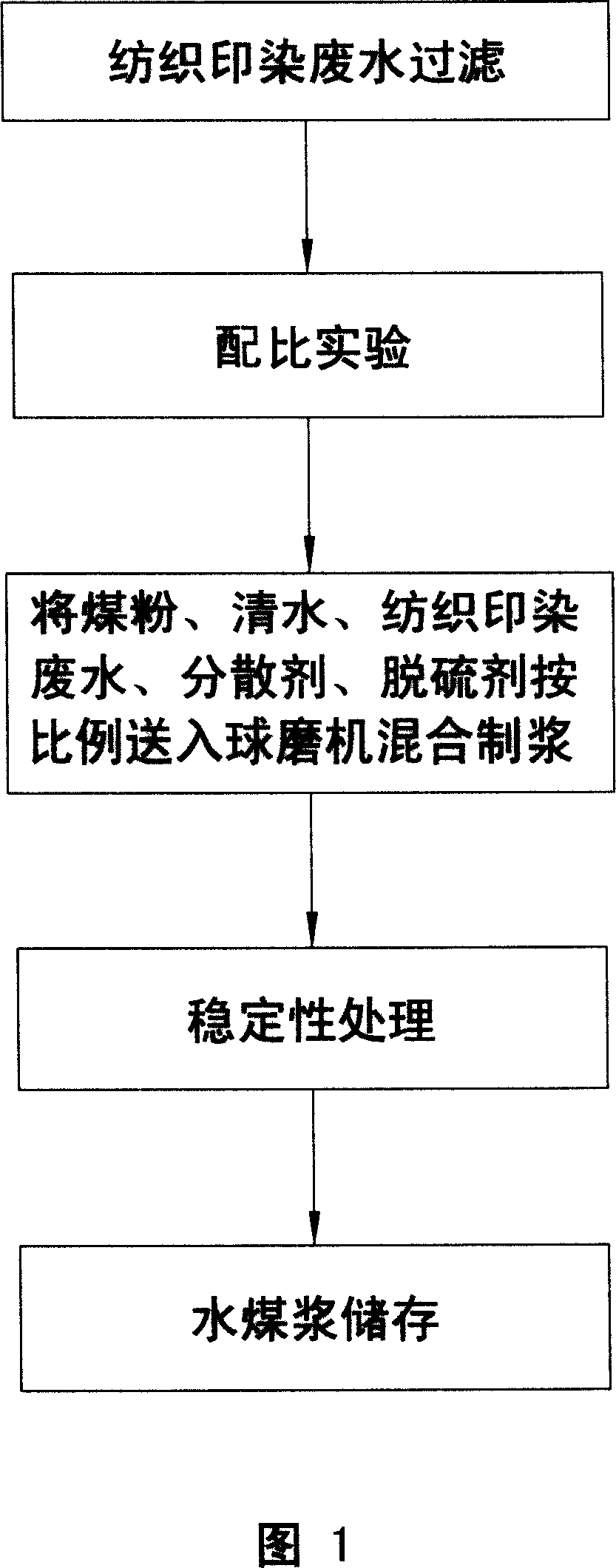

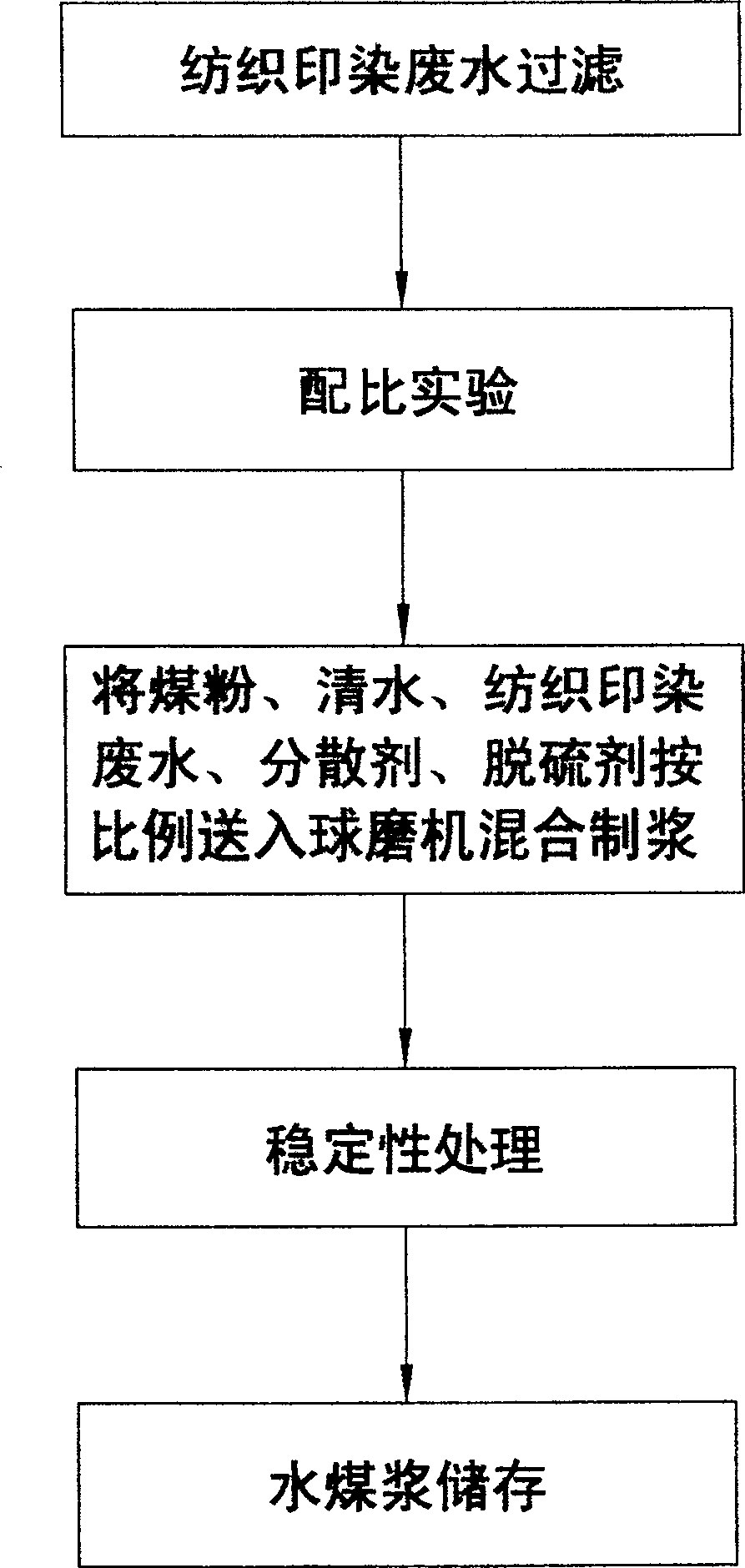

Method of treating weave printing and dyeing wastewater by slurries production technology

InactiveCN101033103AReduce pollutionReduce dosageMultistage water/sewage treatmentWater/sewage treatment by neutralisationCoal waterDyeing wastewater

This invention discloses a method for processing spinning, printing and dyeing waste water by a coal-water slurry production technology including a step of filtering spinning, printing and dyeing waste water, a step of determining the mixture ratio among desulfurizer, dispersant, clean water and waste water, a step of mixing slurrying, a step of stabilizing the slurry and a step of aging and storing coal-water slurries.

Owner:珠海市金火炬清洁能源科技有限公司

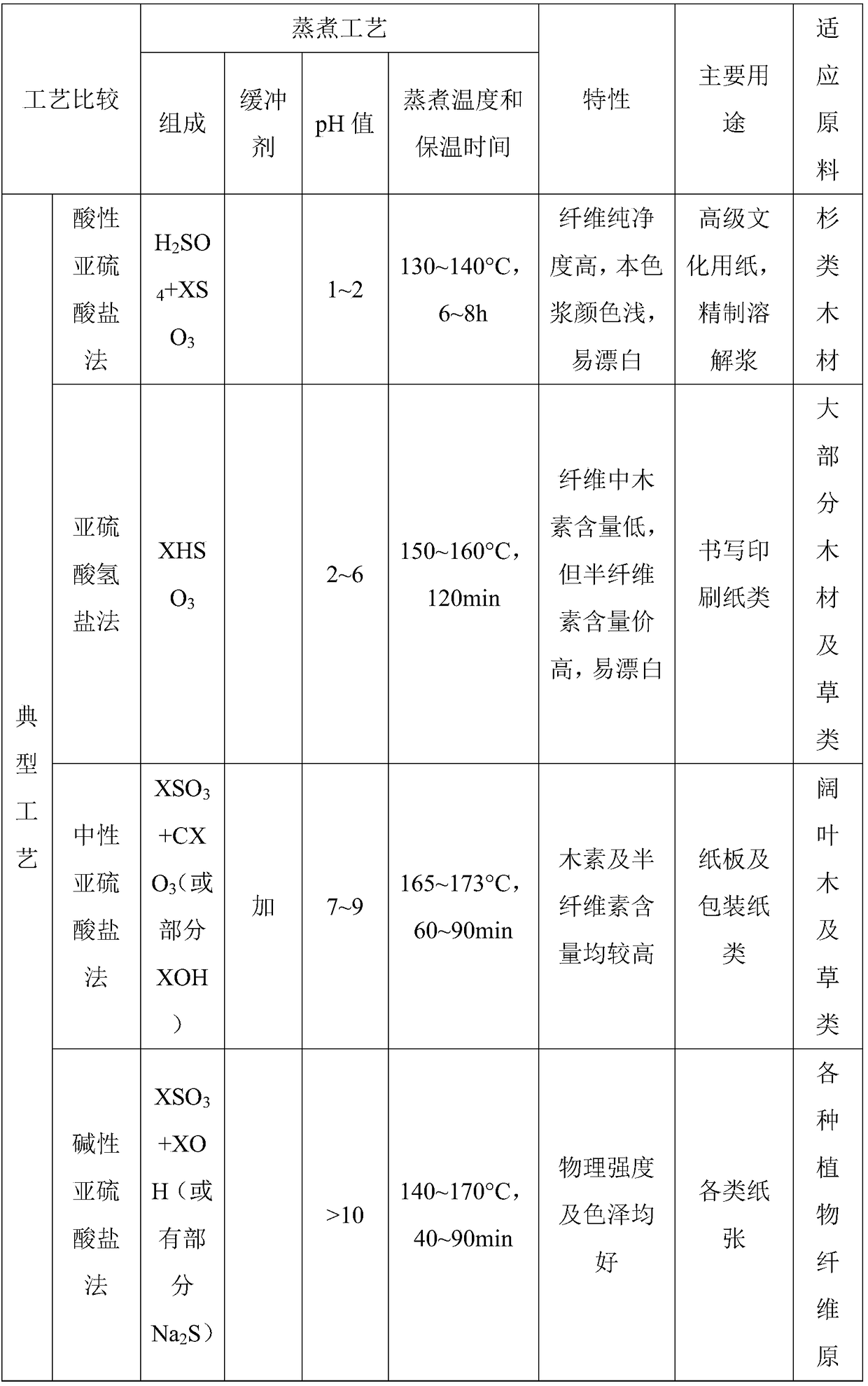

Method for producing pulp by potassium containing compound as steaming preparation with cellulose containing raw material

InactiveCN1587501AReduce pulping costsLow running costPulp liquor regenerationPulping with acid salts/anhydridesPapermakingChemistry

The present invention belongs to the field of chemical and papermaking, and is the process of producing pulp with potassium compound-containing digestion preparation for cellulose material. The production process includes the following steps: digesting cellulose material with potassium compound-containing digestion preparation to obtain mixture of paper pulp and pulp making waste liquor; extracting pulp making waste liquor and washing pulp material; concentrating pulp making waste liquor; and spray drying the concentrated waste liquor to produce organic potash fertilizer, which is further produced into re-mixed organic fertilizer with other chemical fertilizer material. The said technology can utilize papermaking waste liquor comprehensively at low cost and avoid the pollution to water.

Owner:孙玲

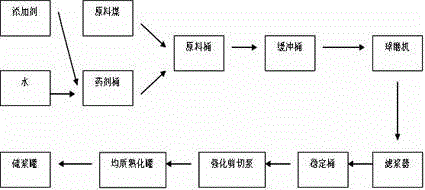

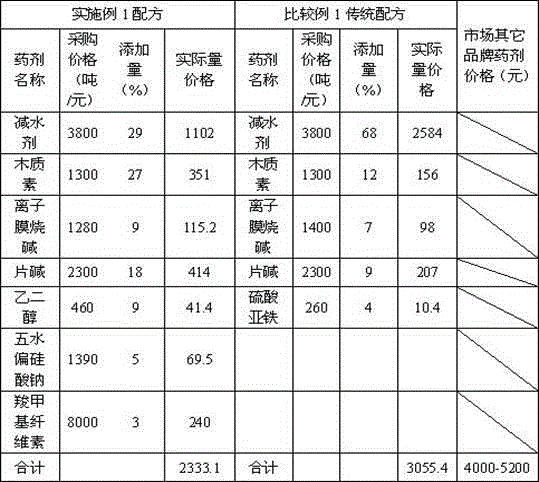

Coal water slurry additive and application thereof

ActiveCN104818063AImprove hydrophilicityIncrease electrostatic repulsionLiquid carbonaceous fuelsCelluloseCarboxymethyl cellulose

The invention discloses a coal water slurry additive which is composed of 20-40 wt% of water reducing agent, 20-35 wt% of lignosulfonate, 20-35 wt% of inorganic alkali, 2-20 wt% of ethylene glycol, 2-15 wt% of sodium metasilicate pentahydrate and 1-10 wt% of carboxymethyl cellulose. Besides, the invention also discloses application of the coal water slurry additive in preparing a coal water slurry. The coal water slurry additive can promote the disperse phase (coal particles) to be uniformly dispersed in the dispersion medium (water), and can effectively enhance the hydrophilicity of the coal and the electrostatic repulsion among the coal particles. The prepared coal water slurry has the advantages of higher coal content (or concentration), low viscosity, low bleeding rate, high flowability and high stability. Compared with the traditional formula, the coal water slurry additive can lower the slurry making cost by more than 20%.

Owner:QUFU SANRANG COAL WATER SLURRY CO LTD

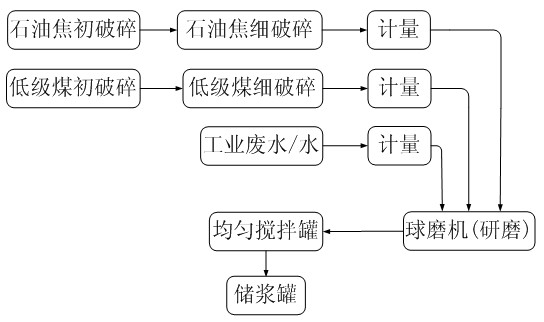

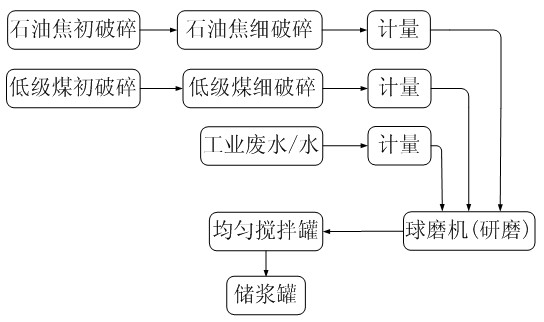

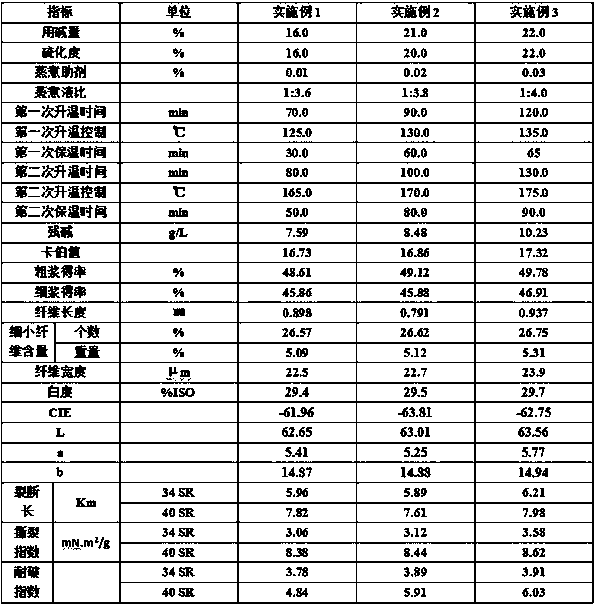

Waste water coal coke slurry and preparation method thereof

InactiveCN102181314AOvercome stabilityOvercoming burnoutLiquid carbonaceous fuelsIndustrial waste waterLower grade

The invention discloses waste water coal coke slurry and a preparation method and a use thereof. The waste water coal coke slurry comprises the following components by weight percent: 20-60% of petroleum coke, 5-40% of low-grade coal, 25-35% of industrial waste water and 0-10% of water. The waste water coal coke slurry prepared by the preparation method can fully utilize the water, organic matters and macromolecular compounds in industrial waste water, reduce the adding quantity of a dispersant and eliminate the need of adding a stabilizer; the shortcomings that water coke slurry is poor in stability and difficult to catch fire and gasify are overcome; and the complementarity of physical and chemical properties of the low-grade coal and the petroleum coke is reasonably utilized, and the shortcomings of low mixture ratio of the petroleum coke in the slurry prepared by mixing the low-grade coal with the petroleum coke and low concentration of the formed slurry are further overcome. The prepared waste water coal coke slurry has better flowability and stability, is easy to store, convey and atomize, can be used as raw material for burning or gasification, and has potential large-scale industrial application prospects.

Owner:SOUTHEAST UNIV

Kraft pulping process of camphorwood

ActiveCN110438834AQuality improvementMeet production needsPulping with inorganic basesChemical/chemomechanical pulpPaper productionSlurry

The invention discloses a kraft pulping process of camphorwood. The kraft pulping process comprises the following preparation steps that 100% camphorwood pieces are taken out for peeling, chipping andscreening operations, sent into a cooking pot for cooking operation, put into a scrubber for washing operation, sent into a pressure screen for screening operation, carried out bleaching operation byusing hydrogen peroxide, and sent into a slurry tower for storage operation. According to the kraft pulping process of the camphorwood, the purpose is that the camphorwood pieces after stewed camphorand camphor oil can be reused, process flow and process parameters can be made according to the material characteristics of camphorwood, the pulping cost is low, the pulp quality is good, and needs of high-grade paper production can be fully met.

Owner:YUEYANG FOREST & PAPER CO LTD

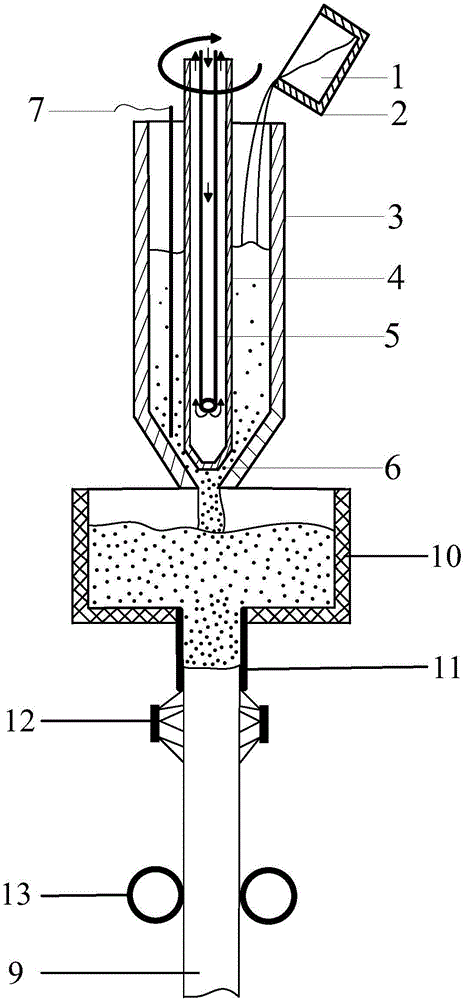

Device and method for preparing large-diameter semi-solid alloy billet

The invention provides a device and method for preparing a large-diameter semi-solid alloy billet. The device comprises a material pouring crucible used for containing molten alloy, a slurrying chamber, a stirring rod and an air duct, and the material pouring crucible is linked with the upper end of the slurrying chamber; the stirring rod is arranged in the slurrying chamber, and a cavity for containing semi-solid alloy slurry is formed between the outer wall of the stirring rod and the inner wall of the slurrying chamber; the stirring rod is of a hollow structure, and the air duct is inserted into the stirring rod; and a slurry outlet is formed in the bottom of the slurrying chamber, and the lower portion of the slurrying chamber is combined with a large-diameter collection crucible used for containing the semi-solid alloy billet. According to the device and method for preparing the large-diameter semi-solid alloy billet, strong stirring and rapid cooling of the molten alloy can be achieved by adjusting an interval between the outer wall of the stirring rod and the inner wall of the slurrying chamber, the ventilation amount in the air duct and the stirring speed of the stirring rod, the prepared semi-solid slurry directly outflows from the slurry outlet formed in the bottom of the slurrying chamber, the outflow velocity of the slurry can be precisely controlled by moving the stirring rod in the axial direction, the preparation volume of the semi-solid slurry is not limited by the size of the slurrying chamber, and the preparation efficiency of the slurry is high.

Owner:UNIV OF SCI & TECH BEIJING

Coal water slurry prepared by utilizing waste activated carbon, organic wastewater and coal and preparation method thereof

PendingCN109135854ASolve processing problemsRealize resource utilizationLiquid carbonaceous fuelsActivated carbonCoal water

The invention discloses coal water slurry prepared by utilizing waste activated carbon, organic wastewater and coal and a preparation method thereof. The coal water slurry comprises the following components in percentage by weight: 54-60% of coal, 11-17% of waste activated carbon, 23-30% of water, 1-3% of organic wastewater, 0.5-2% of a slurry making additive and 0.05-0.15% of an ash-water dispersing agent. The coal water slurry is prepared by utilizing the waste activated carbon and the organic wastewater, so that the treatment difficulties of the waste activated carbon and the organic wastewater can be effectively solved, and the waste resource utilization can be realized at the same time. The cola water slurry is prepared by utilizing the waste activated carbon, so that the high carboncontent of the waste activated carbon can be sufficiently utilized and the dosage of slurry making coal powder is decreased. The coal water slurry is prepared by utilizing the organic wastewater, so that moisture of the organic wastewater can be sufficiently utilized and the dosage of slurry making water is decreased.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing natural color bamboo pulp

InactiveCN105256624AImprove fiber qualityRaise the ratioPulp beating/refining methodsRaw material divisionSulfite saltPotassium hydroxide

The invention discloses a method for preparing natural color bamboo pulp. The method comprises the following steps: using a rotary cutter to cut bamboo in material sections in length of 40-50 mm and diameter of 2-3 mm; sending the material sections into a digester, counting for dry weight of the material sections, adding 2-2.5% potassium hydroxide, 1.5-1.8% sodium sulfite, and 1.5-2% sodium tripolyphosphate, at temperature of 135-140 DEG C, cooking for 115-120 min, then, sending the material sections into a double-screw grinder to grind and divide, to obtain coarse pulp, then washing to obtain natural color bamboo pulp. The method is high in pulping yield, and ratio of BOD to COD of a mid-stage effluent is high, and the mid-stage effluent is readily biodegradable.

Owner:XINJIANG GUOLIYUAN INVESTMENT

Retinervus luffae fructus pulp for manufacturing viscose fiber and preparation method thereof

InactiveCN102444044AEasy plantingEasy to manageWashing/displacing pulp-treating liquorsDigestersViscoseSlurry

The invention relates to a preparation method of a retinervus luffae fructus pulp for manufacturing viscose fiber, which is characterized in that: the retinervus luffae fructus pulp for manufacturing viscose fiber is prepared by taking retinervus luffae fructus as raw material. The preparation method comprises the steps of preparation of raw materials, boiling, washing, pulp beating, desanding, bleaching, rinsing and pulping. The method specifically comprises the steps of: weighing and adding a fixed amount of pretreated retinervus luffae fructus to a boiler for boiling in alkaline liquid for a certain time; removing residual liquid upon the completion of boiling, then washing the boiled retinervus luffae fructus, pulping in a beater, desanding and bleaching the resultant pulp by chlorination, removing residual liquid and rinsing the pulp, and finally performing pulping on the pulp in a pulp machine to obtain the required retinervus luffae fructus pulp. Compared with traditional pulp-making raw materials like wood or cotton linter, the raw material in the retinervus luffae fructus pulp disclosed by the invention is easier for large-area plantation and development, has simple and convenient production process and low cost, and is an inexpensive raw material easier for large-area development.

Owner:SHANDONG UNIV OF TECH +1

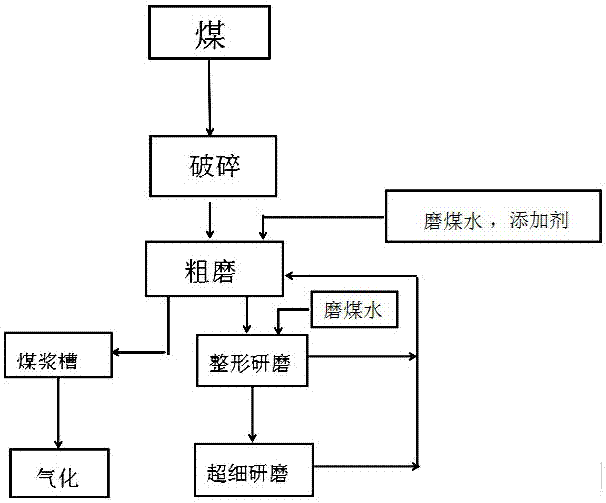

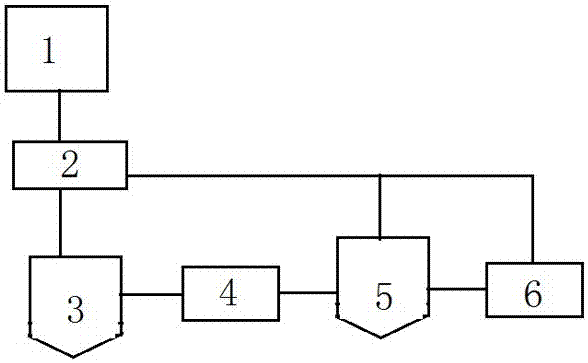

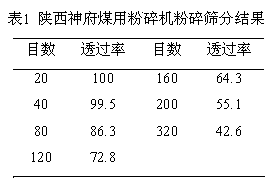

Coal slurry concentration increasing and industrial wastewater treating process and device

ActiveCN107312580AImprove liquidityReduce apparent viscosityLiquid carbonaceous fuelsGrain treatmentsIndustrial effluentEnergy consumption

The invention discloses a coal slurry concentration increasing and industrial wastewater treating process and device. The process comprises the following steps: (1) crushing coal, and then adding water and a dispersant for coarse grinding till the particle size is 50 microns or below, thus obtaining slurry 1; (2) performing shaping grinding on 25 to 35 weight percent of slurry 1 till the particle size is 20 to 30 microns, thus obtaining slurry 2, and pumping the residual slurry 1 serving as a water coal slurry product into a water coal slurry storage tank for gasification; (3) performing ultrafine grinding on 15 to 25 weight percent of the slurry 2 till the particle size is 5 to 10 microns, thus obtaining slurry 3, and conveying the residual slurry 2 and the newly obtained slurry 3 into the coarse grinding stage for coarse grinding, wherein after the coarse grinding in the step (1) and the steps (2) and (3) are repeatedly performed for multiple times, the aim of effectively increasing the concentration of the slurry 1 is fulfilled. In the concentration increasing process, used water can be replaced with industrial wastewater. According to the coal slurry concentration increasing and industrial wastewater treating process disclosed by the invention, the concentration of the coal slurry can be increased by at least 3 percent; the gasification energy consumption can be substantially reduced; the coal slurry concentration increasing and industrial wastewater treating process has the characteristics of safety, reliability, convenience in improvement and obvious economical benefits.

Owner:HUBEI YIHUA CHEMICAL INDUSTRY CO LTD

Method of treating weave printing and dyeing wastewater by slurries production technology

InactiveCN100486917CReduce pollutionReduce dosageMultistage water/sewage treatmentWater/sewage treatment by neutralisationCoal waterDyeing wastewater

This invention discloses a method for processing spinning, printing and dyeing waste water by a coal-water slurry production technology including a step of filtering spinning, printing and dyeing waste water, a step of determining the mixture ratio among desulfurizer, dispersant, clean water and waste water, a step of mixing slurrying, a step of stabilizing the slurry and a step of aging and storing coal-water slurries.

Owner:珠海市金火炬清洁能源科技有限公司

Middle-or low-pressure exposion method for making pulp with broad-leaf wood

A low-and medium-pressure blasting method for pulping the broad-leaf wood includes proportioning the alkali (1-6 wt%), Na-S compound (1-16 wt%), assistant (0-1 wt%) and broad-leaf wood (rest), stirring at ordinary temp -90 deg.C for 0-24 hr, treating at 140-220 deg.C and 0.8-2.28 MPa for 3-15 min, and sudden blasting. Its advantages are high strength, output rate, whiteness, toughness and rinsability, and low energy consumption.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for preparing high-concentration water-coal-slurry through coal with high oxygen content

ActiveCN103937568AEasy accessImprove liquidityLiquid carbonaceous fuelsHigh concentrationGranularity

The invention relates to a method for preparing high-concentration water-coal-slurry through coal with high oxygen content. The problem that high-concentration water-coal-slurry is difficultly prepared in conventional coal with high oxygen content is solved. According to the technical scheme, the method comprises the following steps: finely grinding and screening the coal with high oxygen content, grading according to a weight ratio of (4-6):(6-4) of high oxygen content coal with the granularity of 40-200 meshes to high oxygen content coal with the granularity of less than 200 meshes, adding a water-coal-slurry additive and water, uniformly stirring and mixing, and preparing the high-concentration water-coal-slurry with the concentration of over 60 percent. The method is simple in process, high in slurry property and high in concentration and is particularly suitable for preparing the high-concentration water-coal-slurry through the coal with high oxygen content.

Owner:WUHUAN ENG

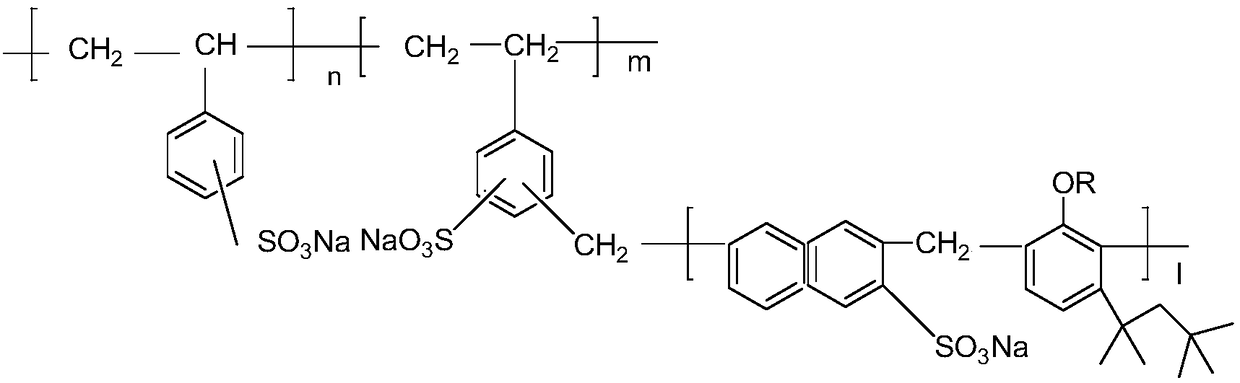

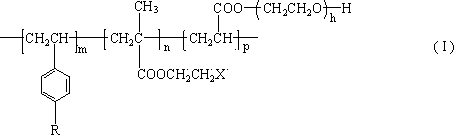

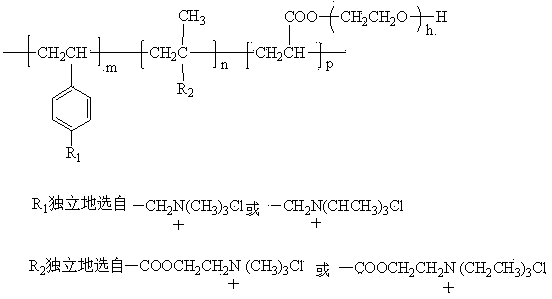

Ternary copolymer coal water slurry dispersing agent and application thereof

InactiveCN103351451AQuality improvementSimple preparation processLiquid carbonaceous fuelsCoal waterCoal particle

The invention discloses a ternary copolymer coal water slurry dispersing agent represented by a structure general formula (I), wherein m is 5-30, n is 5-30, p is 5-20, h is an integer of 4-20, R is H or the following groups, X is -N(CH3)2, -N(CH2CH3)2 or the following groups. According to the present invention, a hydrophilic three-dimensional film is formed on the surface of coal particles to produce effects of wetting and absorption on a solid-liquid interface so as to produce a dispersion effect to the system, the prepared dispersing agent has characteristics of coal concentration increase, coal stability increase and viscosity decrease, a coal water slurry preparation cost is low, and the method is suitable for industrial production.

Owner:陕西省能源化工研究院

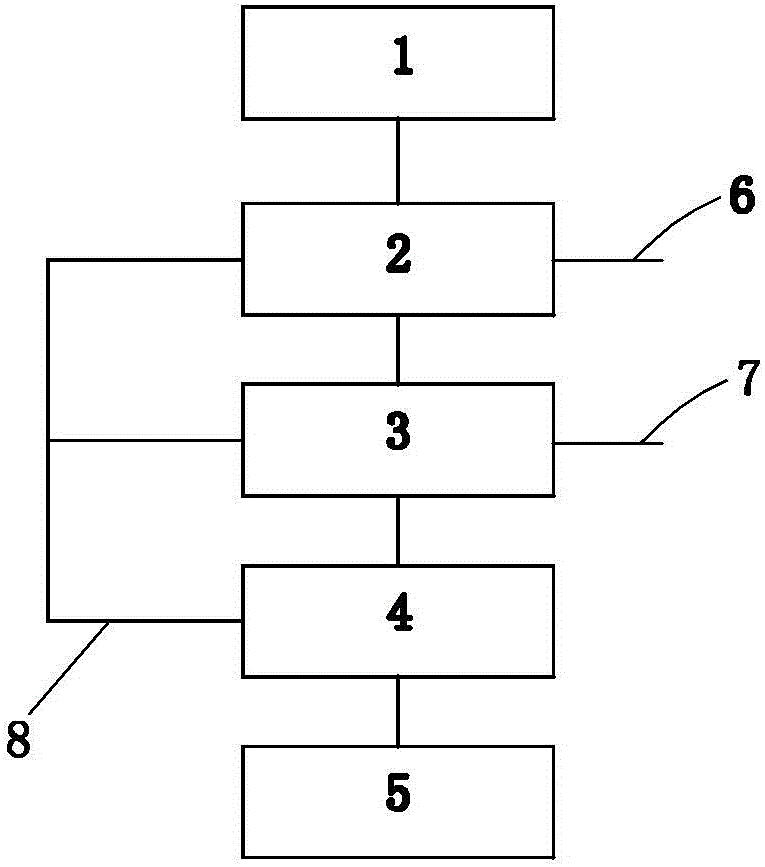

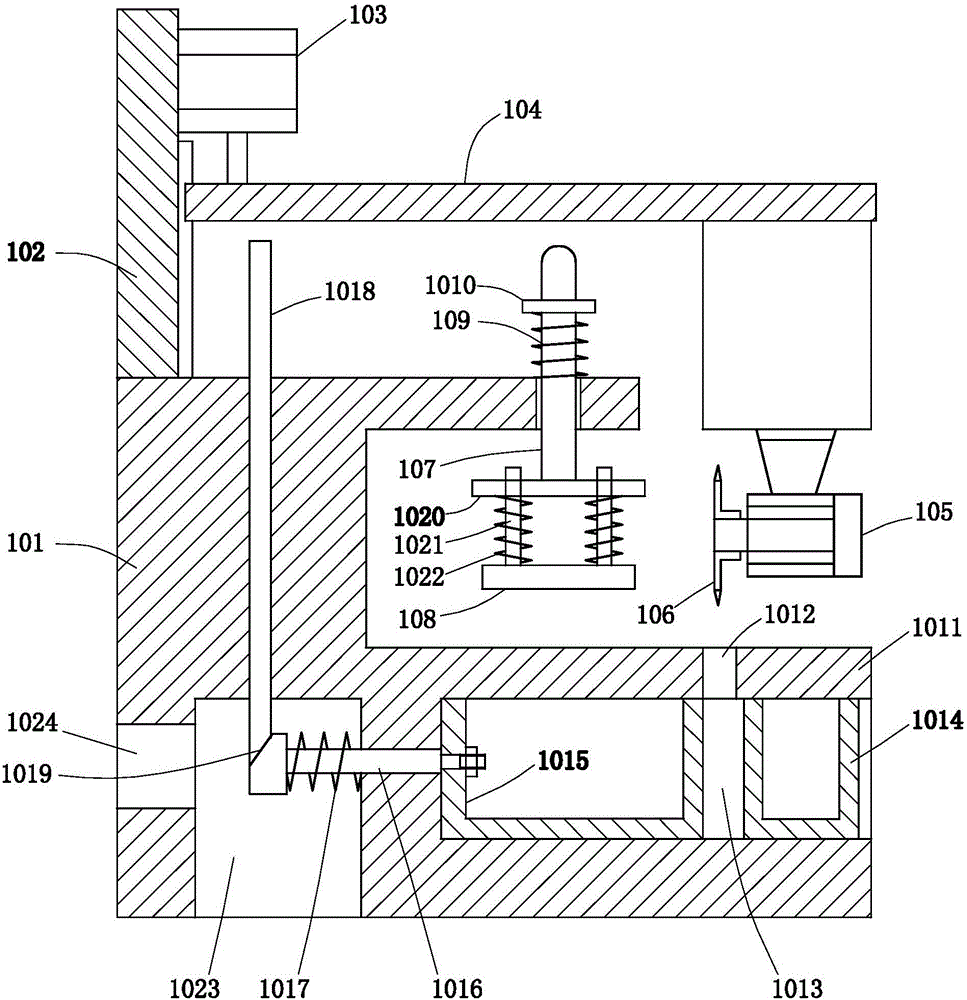

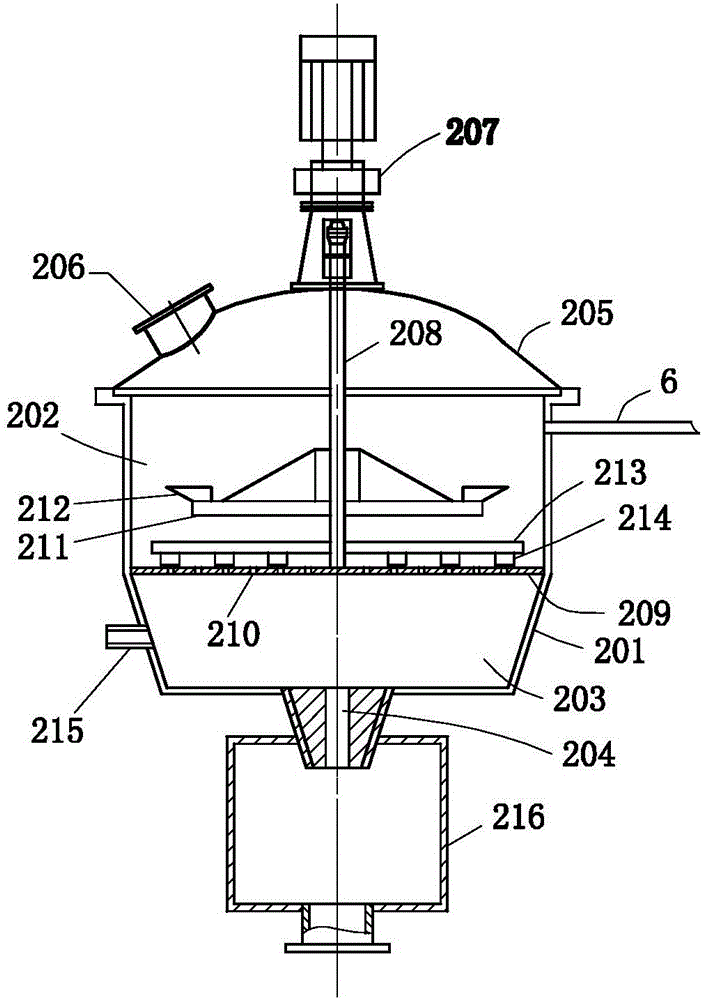

Treatment process and equipment of waste books

ActiveCN106149438AReduce power consumptionEmission reductionPaper recyclingPulp beating/refining methodsPulp and paper industryEnergy consumption

The invention discloses a treatment process and equipment of waste books and belongs to the technical field of waste paper recycling. The treatment process sequentially includes the steps, from top to bottom, of firstly, using an edge-cutting machine to cut off the edges, with glue or iron nails, of the waste books; secondly, using a hydrapulper to crush the waste books obtained after the first step, and using a ink-removing overflow pipe to discharge ink during the crushing; thirdly, using a pulping machine to make the crushed materials into pulp, performing ink removing while stirring during pulping, and discharging the removed ink through an ink discharge pipe; fourthly, using a concentrator to perform concentration; fifthly, storing the concentrated pulp in a pulp storage tank. The treatment process and equipment has the advantages that the process and equipment is simplified, energy consumption is lowered, the discharge of industrial waste liquid is reduced, the pulping efficiency and quality of the waste books are increased, and the process and equipment is widely applicable to waste paper treatment.

Owner:徐州市全鑫毛制品有限公司

Continuous cooling snake-shaped flow channel semi-solid rheo-die casting device

The invention discloses a continuous cooling snake-shaped flow channel semi-solid rheo-die casting device. The continuous cooling snake-shaped flow channel semi-solid rheo-die casting device comprises a snake-shaped flow channel fixed die and a snake-shaped flow channel moving die. The snake-shaped flow channel fixed die is matched and connected with the snake-shaped flow channel moving die through a guide post. A snake-shaped flow channel is formed at the joint between the snake-shaped flow channel fixed die and the snake-shaped flow channel moving die. The snake-shaped flow channel moving die is connected with an electric cylinder. The snake-shaped flow channel fixed die and the snake-shaped flow channel moving die are each internally provided with a plurality of cooling water channels. Each cooling water channel is of a transverse U-shaped structure. One end of each cooling water channel is provided with a water channel sealing block. According to the continuous cooling snake-shaped flow channel semi-solid rheo-die casting device, the multiple cooling water channels are formed on the periphery of the snake-shaped flow channel; water is used as a cooling medium to continuously cool the snake-shaped flow channel; in the using process, the temperature difference between the snake-shaped flow channel and an alloy solution can be kept large, and then the chilling action of the snake-shaped flow channel dies on the later part of alloy solution is maintained. Nucleation is promoted. The pulp making effect is substantially improved.

Owner:GUANGDONG UNIV OF TECH

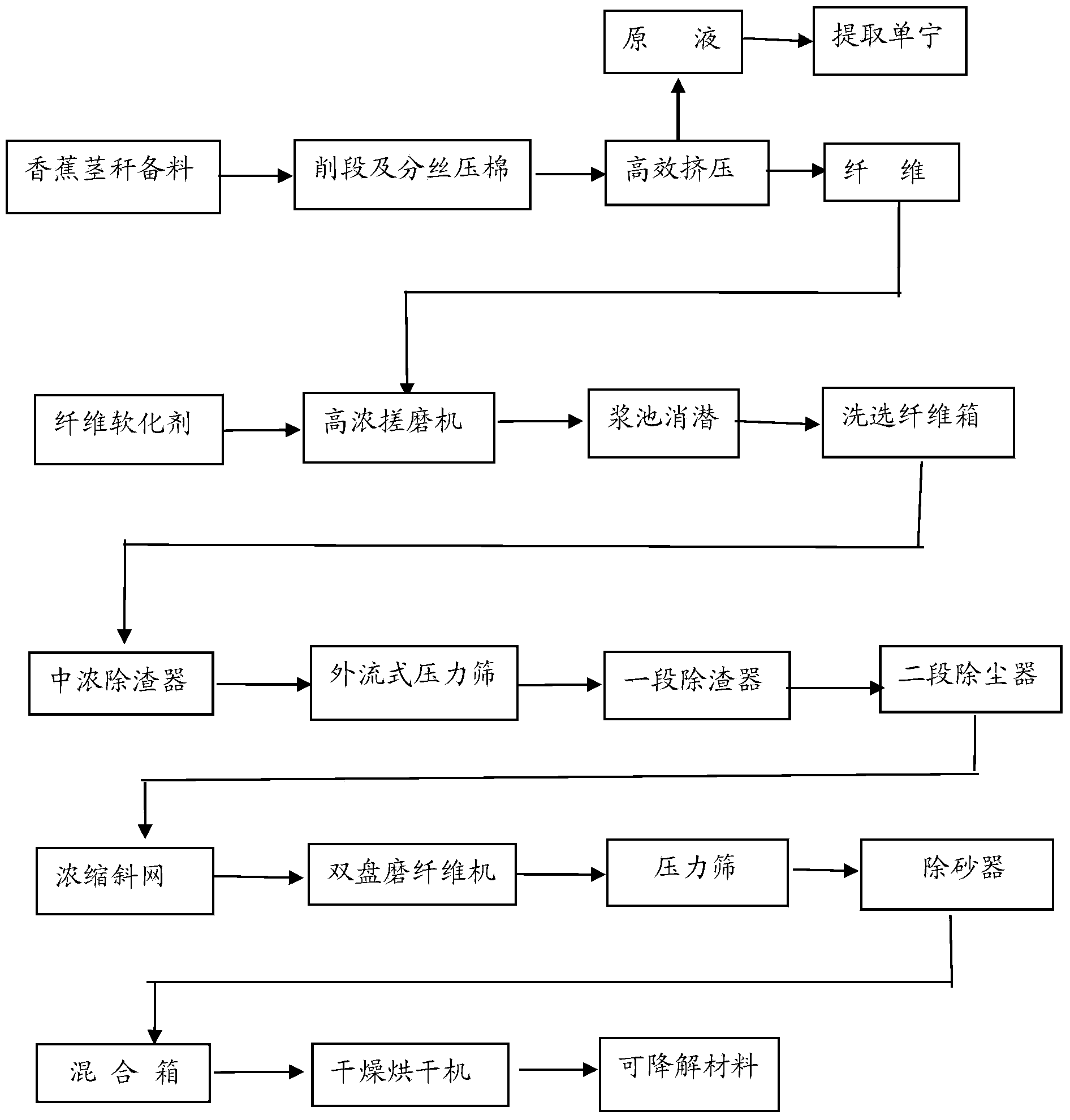

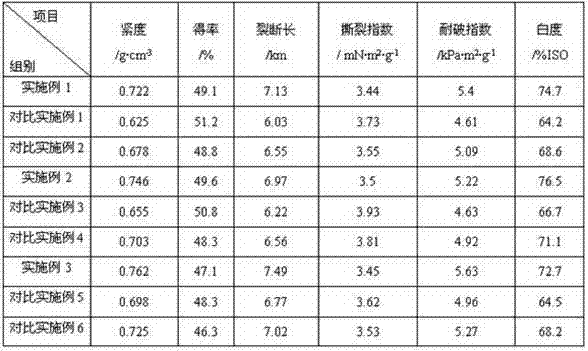

Preparation method for producing degradable materials by using banana stalks

InactiveCN104164800AReduce manufacturing costAvoid foul smellCellulose material pulpingHigh concentrationFiber

The invention discloses a preparation method for producing degradable materials by using banana stalks and belongs to the field of production of degradable materials. The preparation method of the degradable materials comprises following steps: (1) preparing materials, removing impurities, cutting the materials into sections, separating fibers and carrying out cotton pressing; (2) squeezing the fibers; (3) grinding the fibers in a high concentration manner; (4) carrying out latency in a pulp chest to obtain fiber pulp; (5) washing the fiber pulp; (6) modifying; and (7) drying. The banana stalks and cationic starch used in the preparation method are completely biodegradable materials; other added auxiliary materials are inorganic chemical products; the prepared products are completely degradable and environment-friendly products; all the indexes, such as burst index, tearing index and tensile strength, meet the standards in China. The preparation method for producing the degradable materials by using the banana stalks is free of steps of heating, coking and soaking with alkali, simple in production process, capable of quickly softening the fibers, low in cost and free of pollution.

Owner:南宁市美意环保工程有限责任公司 +2

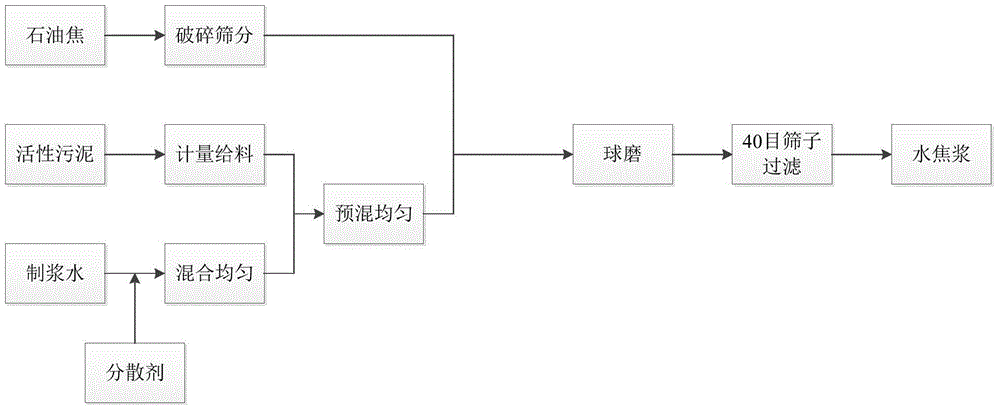

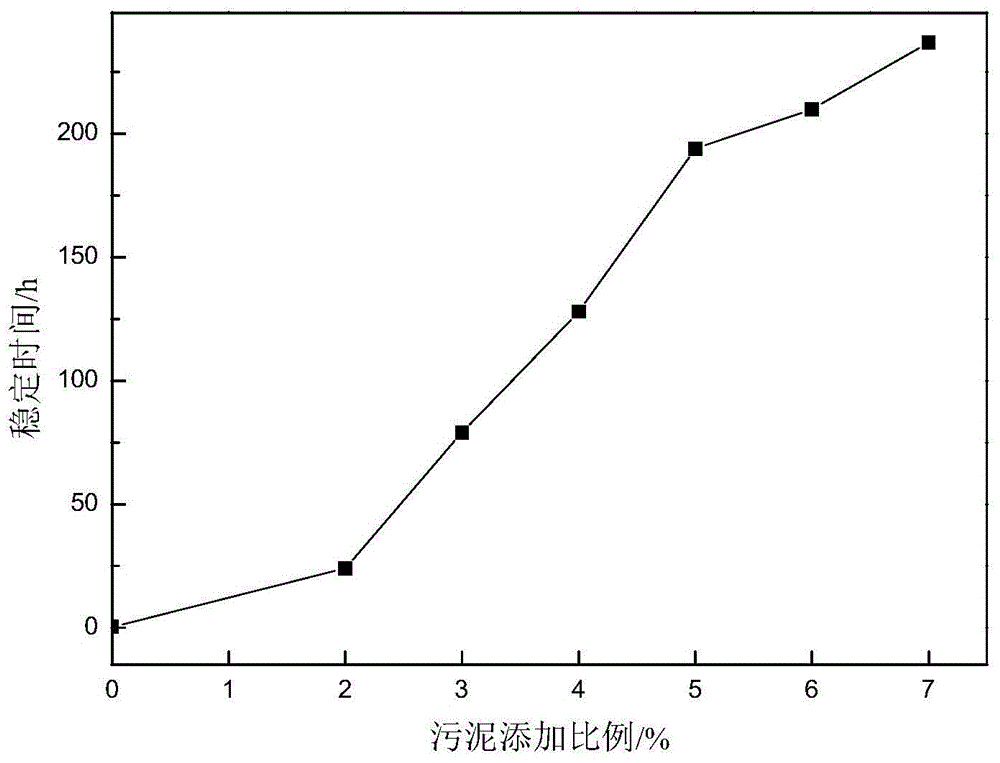

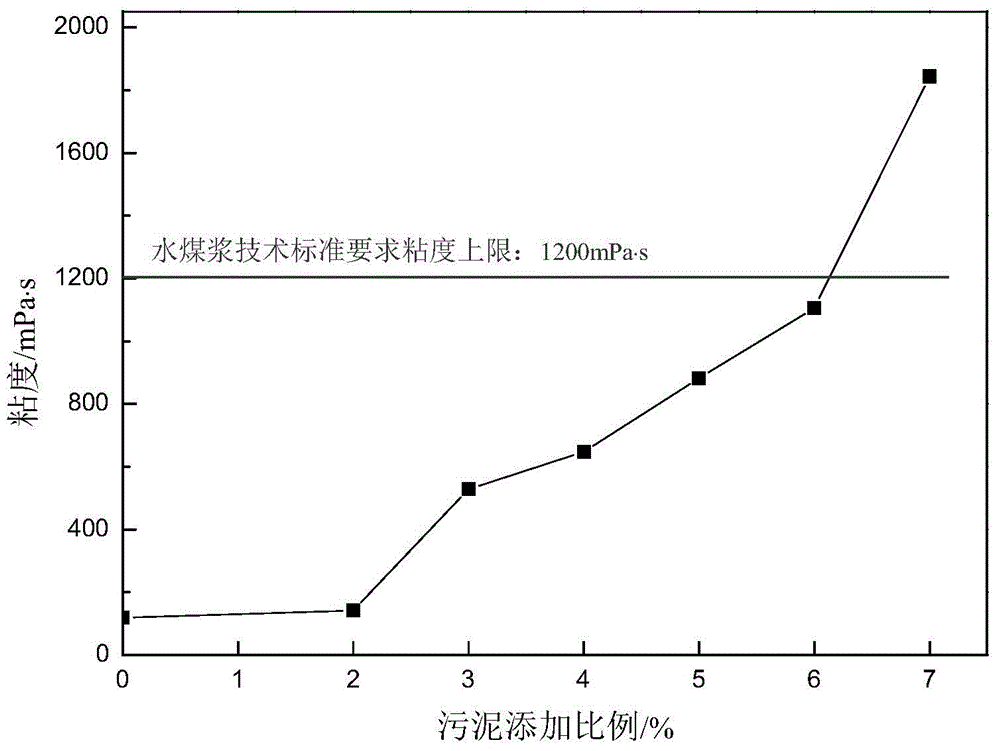

Method for improving stability of water-coke slurry

The invention relates to a method for improving stability of water-coke slurry. The water-coke slurry is prepared from the raw materials, including petroleum coke, activated sludge, water and a dispersing agent. The method comprises the steps of (1) sieving petroleum coke through a sieve, and remaining petroleum coke of which the particle size is less than 0.8mm; (2) dissolving the dispersing agent into water, and uniformly agitating for later use; (3) integrally uniformly mixing the dispersing agent solution obtained in step (2) and activated sludge, pouring into a ball mill tank together with the petroleum coke processed in step (1), wherein the quantity ratio of large balls to small balls in the ball mill tank is 30: 150; a ball mill rotates at the speed of 230 to 380r / min; the ball milling costs 30 to 50 minutes; (4) filtering the slurry obtained by ball milling through a sieve with 40 meshes so as to remove impurities and large particles and obtain water-coke slurry. According to the method, the activated sludge is doped into the water-coke slurry to greatly improve the stability of the water-coke slurry, so that the problem of poor stability of the water-coke slurry can be completely solved; meanwhile, a new treatment way is provided to the activated sludge of a melting plant, and the sludge treatment cost of the melting plant can be reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Clean pulp preparation process for high-whiteness and high-strength chemical straw pulp

ActiveCN102363927AHigh whitenessHigh strengthCellulose material pulpingBlack liquorMetal ion sequestering

Owner:QILU UNIV OF TECH

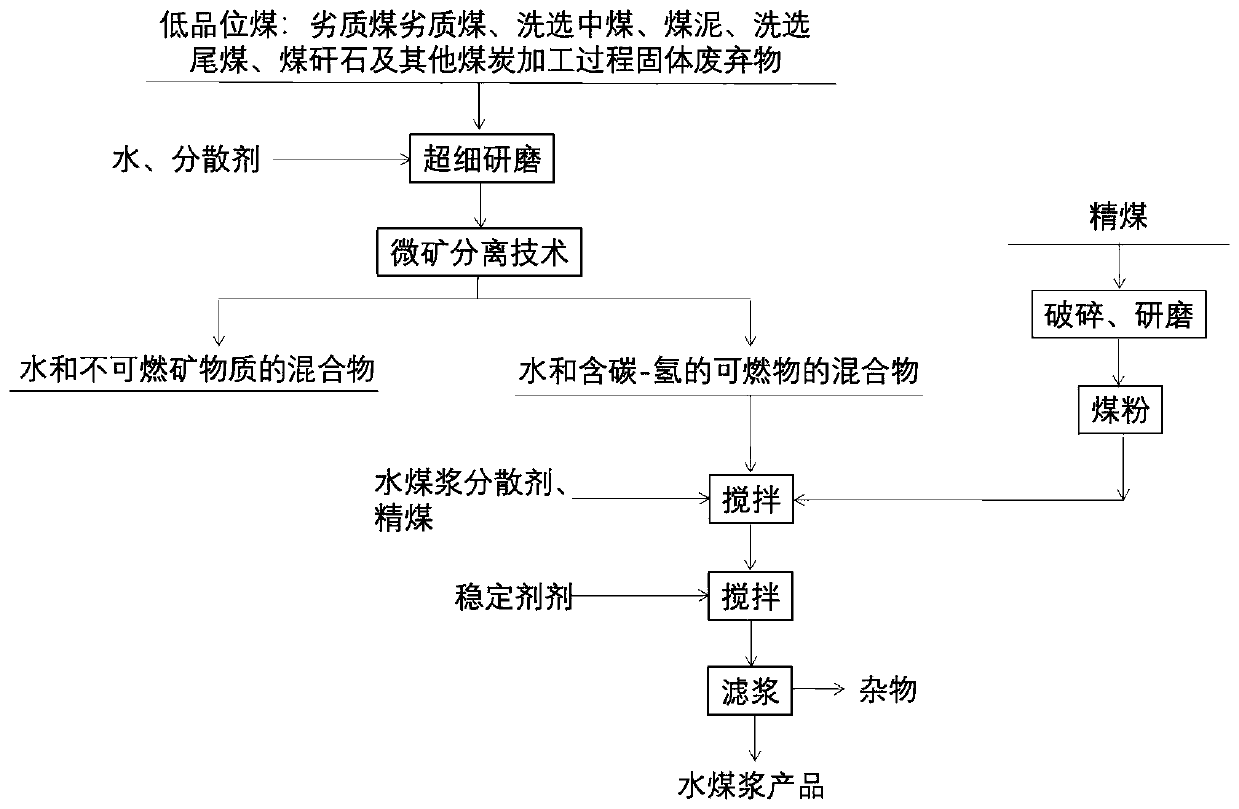

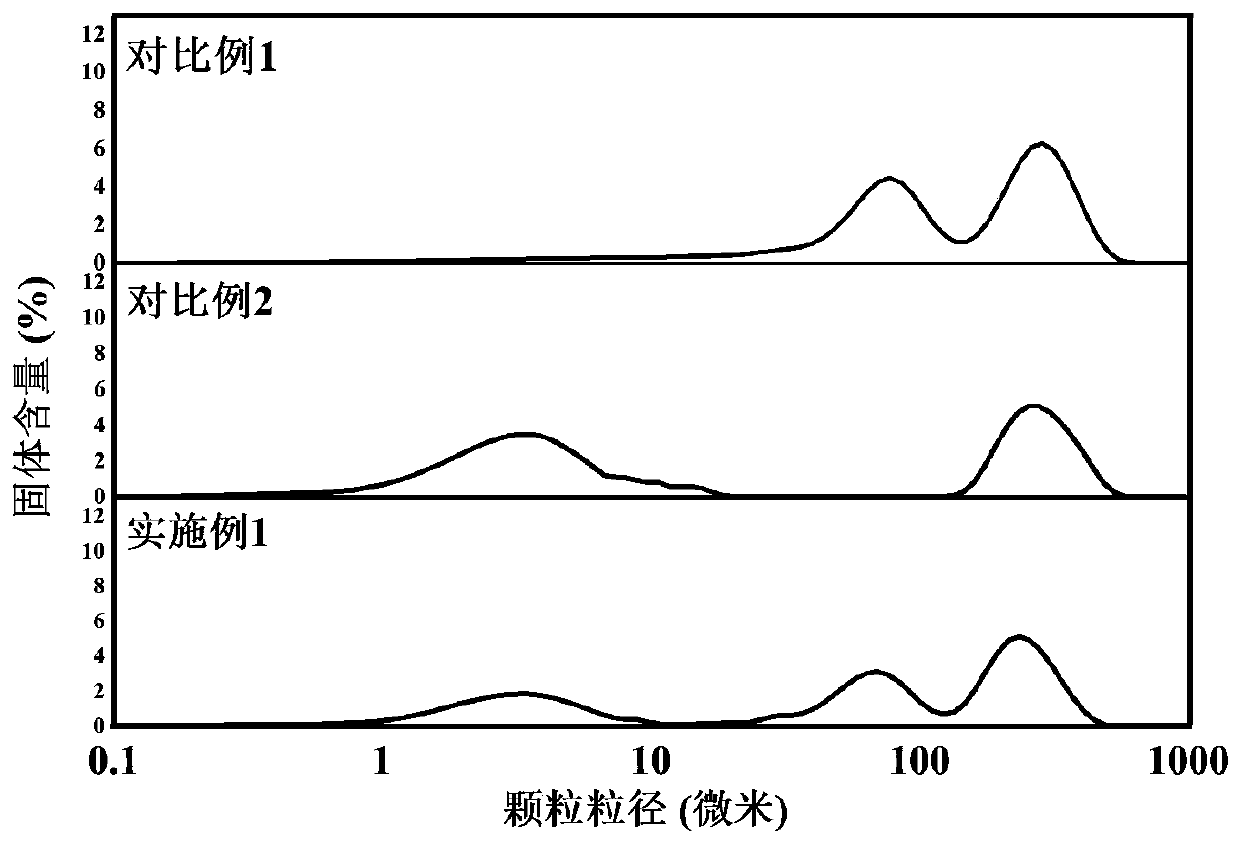

High-concentration coal water slurry and preparation method and application thereof

PendingCN111534342AIncrease the scope of applicationImprove stacking efficiency and concentrationLiquid carbonaceous fuelsCoal waterMineralogy

The invention discloses high-concentration coal water slurry and a preparation method thereof. The concentration of the high-concentration coal water slurry is 63-75wt%, and the mass ratio of dry basis coarse particle pulverized coal to medium particle pulverized coal to fine particle pulverized coal to additive in the coal slurry is (10-60): (10-50): (5-50): (0.5-5). The low-ash coal slurry withthe solid content of 10%-35% and the ash content of 1%-10% is prepared by taking inferior low-quality coal as a raw material through a micro-ore separation technology. The low-ash coal slurry is usedas a medium-particle coal slurry raw material and a fine-particle coal slurry raw material, and coarse-particle pulverized coal which is obtained by grinding clean coal and has the particle size of 150-500 microns is added into the low-ash coal slurry, high-concentration coal water slurry is prepared by adjusting particle size distribution of pulverized coal to be in three-peak distribution, the concentration range of the high-concentration coal water slurry is 63-75 wt%, the apparent viscosity of the high-concentration coal water slurry is 850-1300 mPa.s, the fluidity of the high-concentration coal water slurry is B or above, and the stability of the high-concentration coal water slurry is in level B or above. Low-ash coal slurry obtained by upgrading low-quality coal through a micro-mineral separation technology does not need to be subjected to filter-pressing dehydration treatment, re-crushing and re-dispersing of filter-pressing clean coal filter cakes do not need to be considered,and the cost can be greatly saved by directly pulping the low-ash coal slurry through micro-mineral separation.

Owner:SHENZHEN REVELATION TECH CO LTD

Biomass water-coal-slurry prepared by using livestock breeding wastes

The invention discloses biomass water-coal-slurry prepared by using livestock breeding wastes. The biomass water-coal-slurry is prepared by the following steps: uniformly mixing coal powder, the livestock breeding wastes and water; and adjusting the pH value to 7-9 by sodium hydroxide, wherein the mass ratio of solid matters in the livestock breeding wastes to dry base coal in coal powder is (0.15-1.5) to 100. By replacing additives and part of coal by means of the livestock breeding wastes, the livestock breeding wastes are used as resources, and meanwhile, the use level of coal and water in the pulping process is reduced. The biomass water-coal-slurry has the characteristics of low cost, simple process and environment friendliness. The mass percentage concentration of the obtained biomass water-coal-slurry is not less than 60% and the biomass water-coal-slurry meets the industrial requirements in size distribution, viscosity, pH value and stability.

Owner:XIAN UNVERSITY OF ARTS & SCI +1

Paper-making pulping method

InactiveCN101736626AImprove pulping efficiencyReduce pulping costsPulp bleachingFinely-divided material pretreatmentManufacturing technologySteam cooking

The invention discloses a paper-making pulping method which belongs to the technical fields of paper-making process and manufacture. The method comprises the processes of grass cutting, steam cooking and screening, wherein biological fermentation and bleaching processes are carried out before steam cooking, and the bleaching process refers to immersing in bleaching liquid for 2 to 5 days. The process of the invention is reasonable and feasible, the operation is simple and convenient, the paper-making pulp manufactured by the process does not need disinfection, and the pulping cost is low; the stock solution is convenient for processing, the cod index of disposed water is less than 300, and the disposed water does not pollute the environment or even underground water.

Owner:QUANZHOU HUAXIANG PAPER IND

Physical waste paper deinking technology

InactiveCN103132357AHigh whitenessHigh yieldPaper recyclingWaste paper working-upDeinkingSingle fiber

The invention relates to a physical waste paper deinking technology. The technology comprises the following steps: 1, shredding: shredding waste paper with a shredder to form fragments; 2, fluffing: fluffing the waste paper fragments by a fluffer to form semi-fibers or fibers; 3, defibrination: defibering the fluffed semi-fibers or fibers by a defibrination machine to form single fibers; 4, washing: washing fiber raw materials; and 5, water precipitation reuse: allowing washing water to flow to a precipitating pool and naturally settle to form clear water, and reusing the clear water in above defibrination and washing operations. The technology allows the clean and effective deinking process of various books, newspaper, double-sided thick-ink posters, static duplicating paper and the like to be completed through a physical method without various chemicals comprising a deinking agent, an enzyme or the like, the deinking degree reaches 98%, and the paper pulp obtained after washing has a good whiteness and a high yield; and the pulp preparation cost is low, the washing water can naturally settle to form the clear water without adding any water treatment medicines, and the water reuse has no influences on deinking, so sewage-free discharge is completely reached.

Owner:刘长如 +1

Method of preparing semi-chemical pulp with broadleaf wood slab

ActiveCN108221470AHigh strengthTake advantage ofPulp beating methodsPaper/cardboardBlack liquorAlcohol

The invention belongs to the technical field of pulping and papermaking and particularly relates to a method of preparing semi-chemical pulp with broadleaf wood slab. In the method, the broadleaf woodslab is used as a raw material and is pre-treated with alcohol; then through two-stage defibrination, washing and sieving, high-performance semi-chemical pulp is produced. In the method, the broadleaf wood slab, as the raw material, has abundant sources and is low in cost. With the alcohol as a main solvent for treating the broadleaf wood slab, alkali use amount is reduced, and cost of treating pulping black liquor is saved.

Owner:QILU UNIV OF TECH

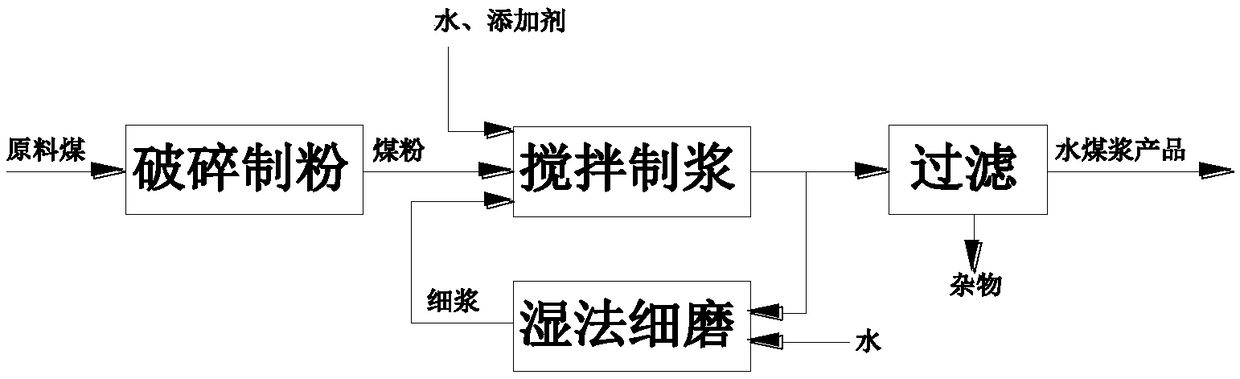

Method for preparing high-concentration coal water slurry by means of fine crushing and little grinding

ActiveCN109135853AIncrease concentrationLow viscosityLiquid carbonaceous fuelsHigh concentrationCoal water

The invention discloses a method for preparing high-concentration coal water slurry by means of fine crushing and little grinding. The method includes steps of (1), mixing and stirring fine coal powder, water and additives with one another in mixing and stirring tanks to obtain slurry; (2), finely grinding the slurry by the aid of wet processes to obtain fine slurry A, feeding the fine slurry A back into the mixing and stirring tanks, mixing and stirring the fine slurry A, the fine coal powder, the water and the additives with one another to obtain finished coal water slurry, diluting a part of the finished coal water slurry by water and then finely grinding the diluted finished coal water slurry by the aid of wet processes to obtain fine slurry B, feeding the fine slurry B back into the mixing and stirring tanks in a circulation manner and carrying out mixing and stirring steps. The method has the advantages that the high-concentration coal water slurry is prepared by means of fine crushing and little grinding, the conventional single-rod / ball mill ore grinding slurry production can be replaced, slurry production energy consumption can be saved by 40-65%, accordingly, the slurry production cost can be obviously reduced, and the high-concentration coal water slurry is high in concentration, low in viscosity and good in flowability and stability.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com