Waste water coal coke slurry and preparation method thereof

A waste water and coke slurry technology, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problems of waste of resources, environmental pollution, etc., and achieve the effect of improving slurry forming, good fluidity, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 A wastewater coal coke slurry comprising the following components in mass fractions: 35% industrial wastewater, 20% petroleum coke, 40% low-rank coal, and 5% water.

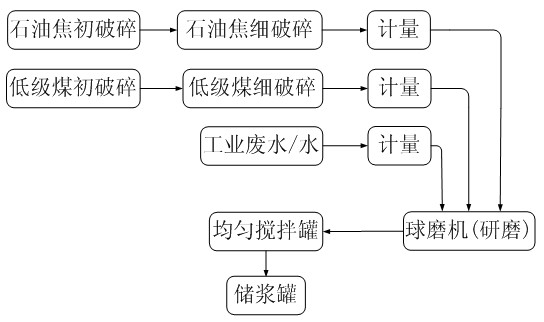

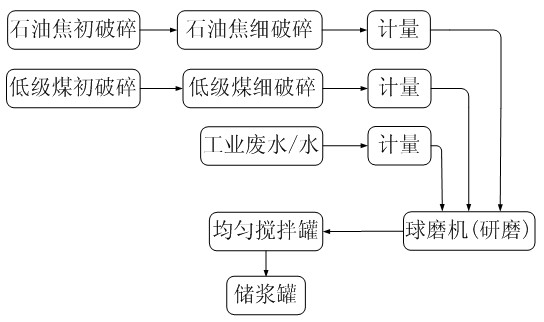

[0038] The method for preparing above-mentioned waste water coal coke slurry, as the technological process shown in accompanying drawing, its concrete steps are as follows:

[0039] (1) Carry out primary mechanical crushing of lump petroleum coke to a particle size of 8mm; then carry out secondary mechanical crushing to reach a powder with a particle size of 2mm;

[0040] (2) Perform primary mechanical crushing of lumpy low-rank coal to a particle size of 8mm; then carry out secondary mechanical crushing to achieve a powdery particle size of 2mm;

[0041] (3) Send the weighed petroleum coke powder, industrial wastewater, low-grade coal powder and water into the ball mill for continuous wet ball mill pulping;

[0042] (5) Petroleum coke powder, industrial wastewater, low-grade coal powder and wat...

Embodiment 2

[0052] A wastewater coal coke slurry comprises the following components in mass fractions: 30% industrial wastewater, 40% petroleum coke, 23% low-grade coal, and 7% water.

[0053] The method for preparing wastewater coal coke slurry, the preparation process is the same as in Example 1.

[0054] The quality index of the prepared waste water coal coke slurry is detected, and each quality index is as follows:

[0055] ① Concentration: 63±0.5% (mass);

[0056] ② The apparent viscosity is below 1000mPa.s, the fluidity is good, and it can be transported and atomized;

[0057] ③ The particle size of solid particles in the slurry is less than 0.3mm.

Embodiment 3

[0059] A wastewater coal coke slurry comprises the following components in mass fractions: 25% industrial wastewater, 60% petroleum coke, 5% low-rank coal, and 10% water.

[0060] The method for preparing wastewater coal coke slurry, the preparation process is the same as in Example 1.

[0061] The quality index of the prepared waste water coal coke slurry is detected, and each quality index is as follows:

[0062] ① Concentration: 65%±0.5% (mass);

[0063] ② The apparent viscosity is below 1200mPa.s, with good fluidity, which can be transported and atomized;

[0064] ③ The particle size of solid particles in the slurry is less than 0.3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com