Lithium-sulfur rechargeable battery

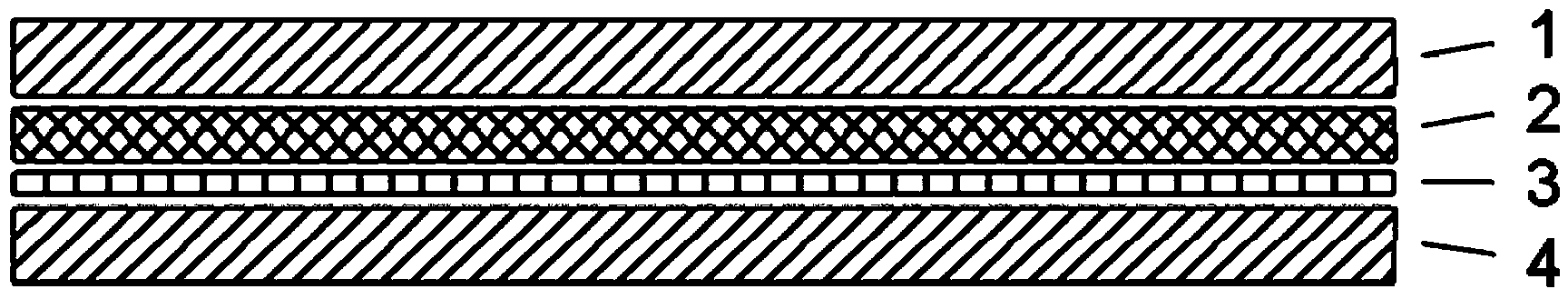

A lithium-sulfur secondary battery and graphene layer technology, applied in the field of electrochemistry, can solve problems such as poor stability or capacity characteristics, and achieve overcoming poor battery performance stability, inhibiting side reactions, and inhibiting polysulfide migration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the graphene material with a thickness of 0.8 nanometers directly grown by chemical vapor deposition is used as an intermediate layer alone, and it is attached to one side of the positive electrode material of a polyethylene diaphragm, wherein the oxygen content of the graphene material is 0%. The intermediate layer is used in a lithium-sulfur secondary battery to realize electronic insulation and lithium ion selective permeability at the same time, so that lithium ions migrate smoothly in the system, while polysulfide anions are confined to the positive electrode side. At the same time, the sulfur / activated carbon composite material is used as the positive electrode, the lithium metal sheet is used as the negative electrode, and the 1,3-dioxane and 1,2-dimethoxyethane solution of lithium bis(trifluoromethylsulfonyl)imide are used as the The electrolyte is used to make lithium-sulfur secondary batteries. At a charge-discharge rate of 0.01C, the initial cap...

Embodiment 2

[0020] Embodiment 2: graphene oxide is separately formed into an intermediate layer with a thickness of 500 nanometers, wherein the oxygen content of the graphene material is 50%. The intermediate layer realizes electronic insulation and cation selective permeability at the same time, so that lithium ions migrate smoothly in the system, while polysulfide anions are partially confined on the positive electrode side. At the same time, the sulfur / carbon black composite material in the aluminum foam network is used as the positive electrode, the graphene oxide intermediate layer is attached to the surface of the positive electrode material, the metal lithium sheet is used as the negative electrode, and the 1,3-dioxane of tetraethylammonium tetrafluoroborate is used as the positive electrode. , 1,2-dimethoxyethane solution as electrolyte to make lithium-sulfur secondary battery. At a charge-discharge rate of 0.4C, the initial capacity of the battery using the ion-selective diaphrag...

Embodiment 3

[0021] Embodiment 3: Graphene oxide and foam metal nickel framework are used to form an intermediate layer with a thickness of 1000 microns to limit the diffusion of polysulfides. At the same time, the sulfur / mesoporous carbon composite material is used as the positive electrode, the metal lithium sheet is used as the negative electrode, and the ethylene glycol dimethyl ether solution of lithium bis(trifluoromethylsulfonyl)imide and lithium nitrate is used as the electrolyte to make a lithium-sulfur secondary battery. , the interlayer is located between the separator and the negative electrode of the battery. At a charge-discharge rate of 1.5C, the initial capacity of the battery using the ion-selective diaphragm reaches 863mAh / g, and the decay rate of the first 100 cycles is about 0.05%, which is much lower than that of the lithium-sulfur battery using the ordinary diaphragm (about 0.30%) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com