Device and method used for restoring sludge polluted by heavy metals

A heavy metal and heavy metal precipitation technology, applied in the field of electrochemistry, can solve the problems of low treatment rate, secondary pollution, large engineering workload, etc., and achieve the effect of high repair efficiency, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

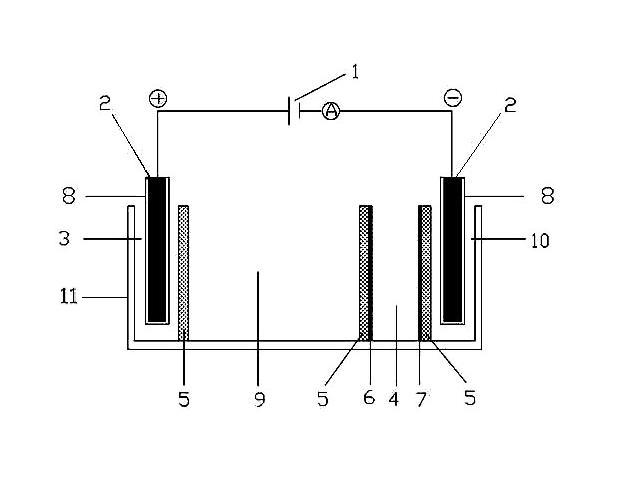

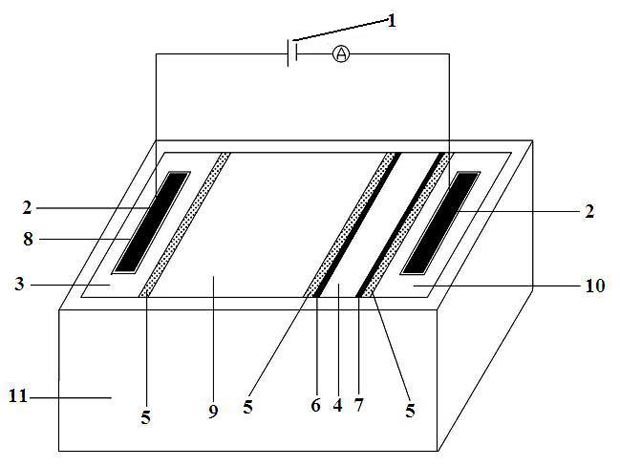

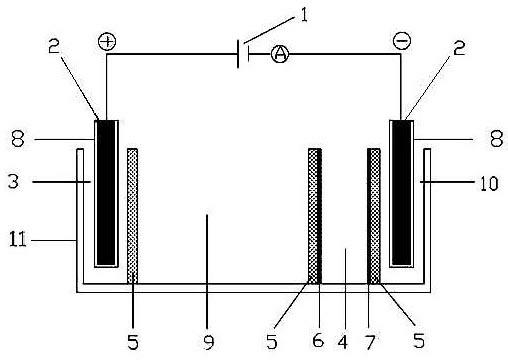

[0035] Embodiment 1: The device for repairing heavy metal polluted sludge

[0036] Devices for remediation of heavy metal contaminated sludge, such as figure 1and 2 As shown, the device is an electrolytic cell 11, and three baffles 5 are sequentially arranged in the electrolytic cell 11, and the baffles 5 divide the electrolytic cell in sequence into: an anolyte pool 3, a sludge treatment chamber 9, a heavy metal Sedimentation tank 4, catholyte pool 10, two graphite electrodes 2 connected to power supply 1 are respectively inserted into anolyte pool 3 and catholyte pool 10, the heavy metal sedimentation pool 4 is in phase with sludge treatment chamber 9 A cation selective permeable membrane 6 is provided on the inner side of the adjacent side, and an anion selective permeable membrane 7 is provided on the opposite side of the heavy metal precipitation tank 4 to the cation selective permeable membrane 6 . The surface of the two graphite electrodes 2 is coated with an electrod...

Embodiment 2

[0038] Embodiment 2 adopts the device in embodiment 1 to repair the process of the sludge polluted by heavy metals

[0039] The sludge polluted by heavy metals is collected and sieved through a sieve with a diameter of 2mm to remove impurities and residues.

[0040] Add water to the sieved silt, according to the ratio of water to soil 3:1, make the silt in a supersaturated state, which can increase the conductivity of the silt.

[0041] Put the prepared sludge into the sludge treatment chamber 9, and add 0.025mol / L of H to the anolyte pool 3 2 SO 4 Solution is used as electrolyte, in heavy metal precipitation tank 4 and catholyte tank 10, add 0.025mol / LNa respectively 2 SO 4 Solution is used as the electrolyte, and then a graphite electrode 2 connected to the power supply 1 is respectively inserted in the anolyte pool 3 and the catholyte pool 10, and the DC power supply is switched on, and a constant DC voltage of 25V is desirable. During the power-on process, the electrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com