Method for improving stability of water-coke slurry

A technology for water coke slurry and stability, which is applied in the field of improving the stability of water coke slurry to achieve the effects of improving stability, solving poor stability and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

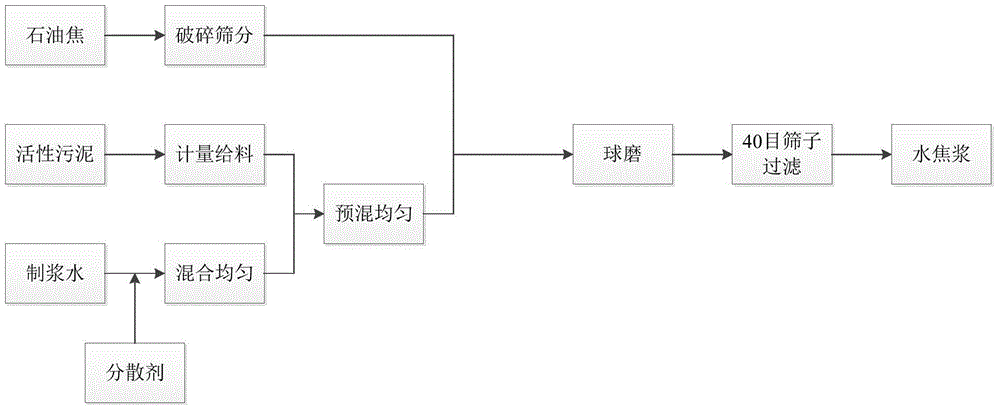

[0030] A method for improving the stability of water-coke slurry. The raw materials of water-coke slurry include 60 parts of petroleum coke, 7 parts of activated sludge, 33 parts of water, and 0.6 parts of dispersant in terms of mass parts; its operation steps are as follows :

[0031] (1) Use a sieve to sieve the petroleum coke, and keep the petroleum coke with a particle size less than 0.8mm for subsequent use;

[0032](2) Dissolving the dispersant in water, stirring evenly for subsequent use;

[0033] (3) Mix the dispersant solution in the step (2) with the activated sludge evenly, and pour it into the ball mill together with the petroleum coke treated in the step (1), and the large ball and the small ball in the ball mill The quantity ratio is 30:150, the ball milling speed is 230r / min, and the ball milling time is 30min; the large ball diameter is 20mm, and the small ball diameter is 10mm;

[0034] (4) After the ball milling is completed, filter the obtained slurry thro...

Embodiment 2

[0038] A method for improving the stability of water coke slurry. The raw materials of water coke slurry include 64 parts of petroleum coke, 24 parts of activated sludge, 12 parts of water, and 1.0 part of dispersant in terms of mass parts; its operation steps are as follows :

[0039] (1) Use a sieve to sieve the petroleum coke, and keep the petroleum coke with a particle size less than 0.8mm for subsequent use;

[0040] (2) Dissolving the dispersant in water, stirring evenly for subsequent use;

[0041] (3) Mix the dispersant solution in the step (2) with the activated sludge evenly, and pour it into the ball mill together with the petroleum coke treated in the step (1), and the large ball and the small ball in the ball mill The ratio of the quantity is 30:150, the ball milling speed is 380r / min, and the ball milling time is 50min; the diameter of the large ball is 20mm, and the diameter of the small ball is 10mm;

[0042] (4) After the ball milling is completed, filter th...

Embodiment 3

[0046] A method for improving the stability of water-coke slurry. The raw materials of water-coke slurry include 65 parts of petroleum coke, 11 parts of activated sludge, 24 parts of water, and 0.8 parts of dispersant in terms of mass parts; its operation steps are as follows :

[0047] (1) Use a sieve to sieve the petroleum coke, and keep the petroleum coke with a particle size less than 0.8mm for subsequent use;

[0048] (2) Dissolving the dispersant in water, stirring evenly for subsequent use;

[0049] (3) Mix the dispersant solution in the step (2) with the activated sludge evenly, and pour it into the ball mill together with the petroleum coke treated in the step (1), and the large ball and the small ball in the ball mill The number ratio of the ball is 30:150, the ball milling speed is 300r / min, and the ball milling time is 40min; the diameter of the large ball is 20mm, and the diameter of the small ball is 10mm;

[0050] (4) After the ball milling is completed, filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com