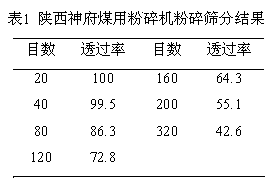

Ternary copolymer coal water slurry dispersing agent and application thereof

A technology of coal water slurry and polymer, which is applied in the field of coal chemical industry, can solve the problems of long storage time, dispersant can not meet the slurry performance requirements, etc., achieve the effect of simple preparation process, increase coal concentration and stability, and reduce viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Preparation of polyethylene glycol monoacrylate: In a 1000 mL four-neck flask, add 100 mL polyethylene glycol, 200 mL acrylic acid, 1.0 g hydroquinone and 3.0 mL concentrated sulfuric acid in sequence. Heating to 100°C under stirring, and reacting for 2 h to the end to obtain polyethylene glycol monoacrylate, adjust the pH value of the product to 7.0 for later use.

[0022] The present invention can obtain three different types of dispersants through the following three synthetic routes.

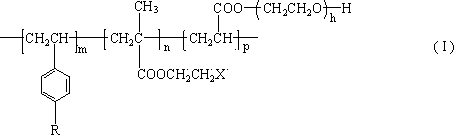

[0023] 1. Preparation of cationic dispersant

[0024] 20% composed of polyethylene glycol monoacrylate, styrene and methacryloxyethyltrimethylammonium chloride (1:2:2, 1:2:3, 1:2:4, 1:2: 5) Composition of mixed monomers, 80% water and isopropanol solution, copolymerized under the trigger of 0.5% potassium persulfate (relative to the amount of mixed monomers),

[0025] .

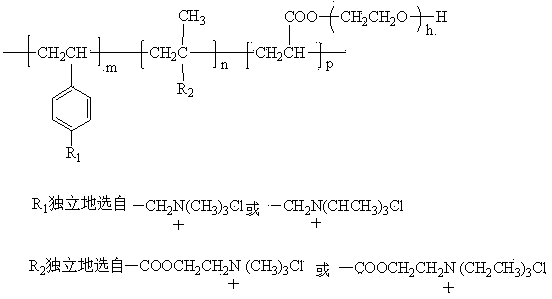

[0026] 2. Preparation of charge-enhanced cationic dispersants

[0027] 20% made of polyethylene glycol monoa...

Embodiment 1

[0035] In a 1000 mL reaction flask, add 400 mL of water and isopropanol solution (4:1, v / v), heat to 80 °C, and drop the monomer mixture (20 mL of acrylic acid polyethylene glycol mono ester, 40 mL styrene and 40 mL methacryloxyethyltrimethylammonium chloride) and 0.5 g potassium persulfate. After the dropwise addition, the reaction was continued for 3 h. After cooling to room temperature, a yellow transparent liquid is obtained, which is a cationic dispersant. The weight-average relative molecular weight distribution of the three experimental products measured by gel chromatography is from 4000 to 6000, and the dispersity is about 2.5, indicating that the preparation process is stable.

[0036] The monomer polyethylene glycol monoacrylate, styrene, methacryloyloxyethyltrimethylammonium chloride or methacryloyloxyethyltriethylammonium chloride are mixed in a mass ratio of 1~2:2~ 3: Cationic dispersants with a weight-average relative molecular weight distribution of 4,000 to ...

Embodiment 2

[0038] In a 1000 mL reaction flask, add 400 mL of water and isopropanol (4:1, v / v), heat to 80°C, and add monomers (20 mL of polyethylene glycol monoacrylate, 40 mL of chloromethylstyrene and 40 mL of methacryloyloxyethyltrimethylammonium chloride) and 0.5 g of potassium persulfate initiator. After the dropwise addition, the reaction was continued for 3h. After cooling to room temperature, 20 mL of trimethylamine was added to the reaction solution, and the reaction was continued for 2 h at room temperature to obtain a yellow transparent liquid, which was the charge-enhanced cationic dispersant. The weight-average relative molecular weight distribution of the three experimental products measured by gel chromatography is from 4500 to 6500, and the dispersity is about 2.5, indicating that the preparation process is stable.

[0039]The monomer polyethylene glycol monoacrylate, chloromethyl styrene, methacryloyloxyethyltrimethylammonium chloride or methacryloyloxyethyltriethylammo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com