Coal-water slurry mixed with gasified coal and petrochemical waste and its pulping process

A waste, coal-water slurry technology, applied in the petroleum industry, fuels, liquid carbon-containing fuels, etc., can solve the problems of unreported industrial application of high-concentration coal-water slurry, abnormal shutdown, coal slurry precipitation, etc. The effect of reducing cost, reducing pulping cost, and high concentration of coal slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

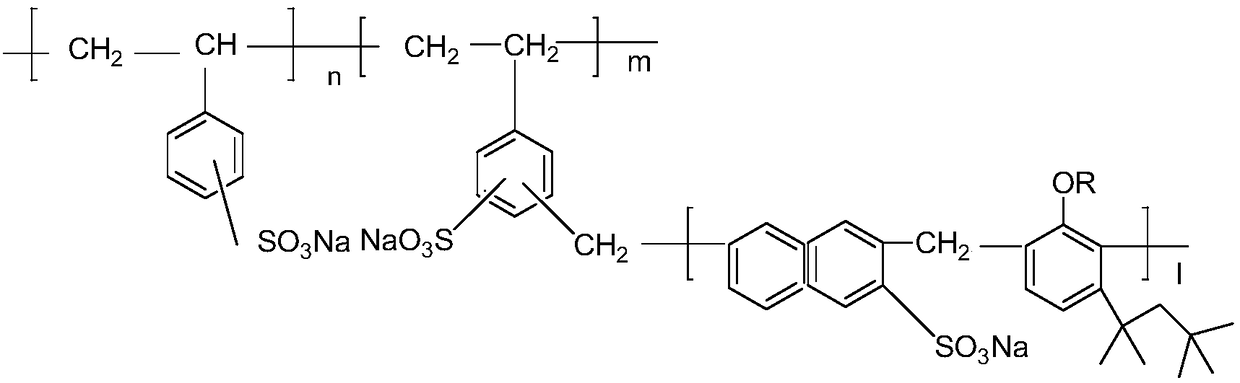

[0030] Get the water that is 8.6% of naphthalene, 14% of sulfuric acid, 37% of liquid caustic, 11% of formaldehyde, 5% of styrene, 3% of octylphenol and 21.4% of water by mass percentage, put naphthalene at 160-165 ℃ Dissolve naphthalene under low temperature; then carry out sulfonation reaction with sulfuric acid to generate β-naphthalenesulfonic acid; conduct condensation reaction with formaldehyde, styrene and octylphenol on the obtained β-naphthalenesulfonic acid at 105-110°C; then lower the temperature Cool, put concentrated sulfuric acid at 70-80°C for secondary reaction; then continue to cool down, add liquid caustic soda at 40-50°C for hydrolysis reaction to obtain methylene naphthalenesulfonate-styrenesulfonate-octyl Based phenate polymer water agent.

[0031] Components in mass percent: 60% of methylene naphthalene sulfonate-styrene sulfonate-octyl phenoxide polymer, 4% of sodium carbonate, 5% of carboxymethyl cellulose, 1% Dioctyl sulfosuccinate sodium penetrant an...

Embodiment 2

[0033] Get the water that is 8.6% of naphthalene, 14% of sulfuric acid, 37% of liquid caustic, 11% of formaldehyde, 5% of styrene, 3% of octylphenol and 21.4% of water by mass percentage, put naphthalene at 160-165 ℃ Dissolve naphthalene under low temperature; then carry out sulfonation reaction with sulfuric acid to generate β-naphthalenesulfonic acid; conduct condensation reaction with formaldehyde, styrene and octylphenol on the obtained β-naphthalenesulfonic acid at 105-110°C; then lower the temperature Cool, put concentrated sulfuric acid at 70-80°C for secondary reaction; then continue to cool down, add liquid caustic soda at 40-50°C for hydrolysis reaction to obtain methylene naphthalenesulfonate-styrenesulfonate-octyl Based phenate polymer water agent.

[0034] Components in mass percent: 56% of methylene naphthalene sulfonate-styrene sulfonate-octylphenate polymer, 6% of sodium carbonate, 8% of carboxymethyl cellulose, 5% Dioctyl sulfosuccinate sodium penetrant and 2...

Embodiment 3

[0036] Get the water that is 8.6% of naphthalene, 14% of sulfuric acid, 37% of liquid caustic, 11% of formaldehyde, 5% of styrene, 3% of octylphenol and 21.4% of water by mass percentage, put naphthalene at 160-165 ℃ Dissolve naphthalene under low temperature; then carry out sulfonation reaction with sulfuric acid to generate β-naphthalenesulfonic acid; conduct condensation reaction with formaldehyde, styrene and octylphenol on the obtained β-naphthalenesulfonic acid at 105-110°C; then lower the temperature Cool, put concentrated sulfuric acid at 70-80°C for secondary reaction; then continue to cool down, add liquid caustic soda at 40-50°C for hydrolysis reaction to obtain methylene naphthalenesulfonate-styrenesulfonate-octyl Based phenate polymer water agent.

[0037] Components in mass percent: 62% of methylene naphthalene sulfonate-styrene sulfonate-octylphenate polymer, 5% of sodium carbonate, 8% of carboxymethyl cellulose, 5% Dioctyl sulfosuccinate sodium penetrant and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com