Patents

Literature

53results about How to "Low water separation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

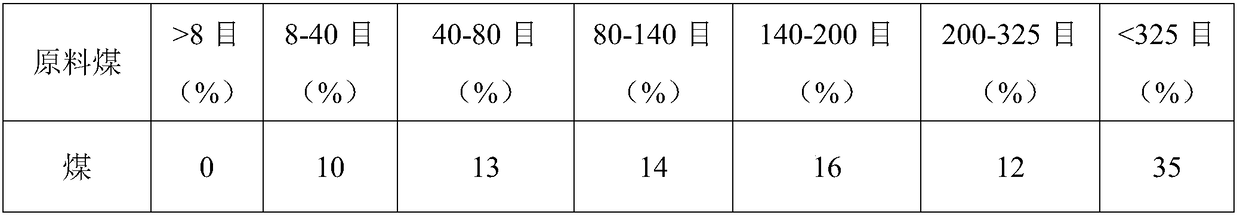

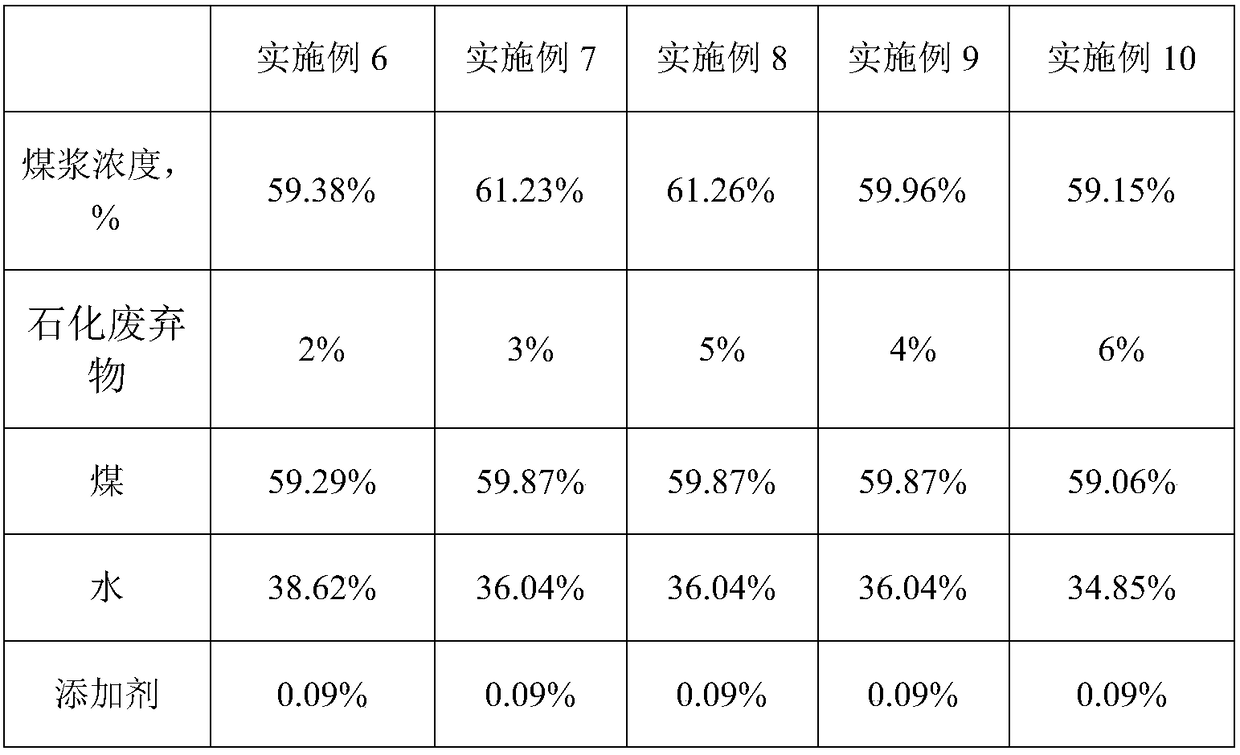

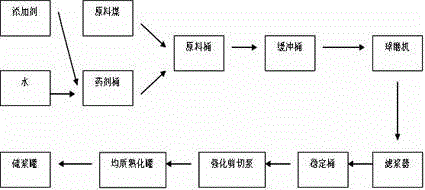

Coal-water slurry mixed with gasified coal and petrochemical waste and its pulping process

The invention discloses coal water slurry prepared by mixing gasified coal with petrochemical wastes. The coal water slurry is prepared from the following components: coal, the petrochemical wastes, additives and water, wherein the mass of the petrochemical wastes accounts for 0-6% of the total mass of the coal water slurry but not zero, and the adding amount of the additives accounts for 0-0.15% of the total mass of the dry coal but not zero. The invention also discloses a slurrying technology of the coal water slurry. The coal water slurry provided by the invention is good in fluidity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Controllable clay and cement seepage-proof reinforcement paste

The invention discloses controllable clay and cement seepage-proof reinforcement paste. The controllable clay and cement seepage-proof reinforcement paste is mainly prepared from clay raw stock, cement and water, wherein the clay raw stock is mainly obtained by stirring clay and water. A modifier is added in the controllable clay and cement seepage-proof reinforcement paste; the doping amount of the modifier is 1 to 3 percent; the modifier mainly comprises mineral additives, sulfate and bentonite in a mass ratio of a:b:c; and a:b:c is 5:(5-0):(0-5). The product has the advantages of high stability and water flow dilution resistance, controllable setting time, adjustable strength, high antiseepage performance, low cost, environment friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

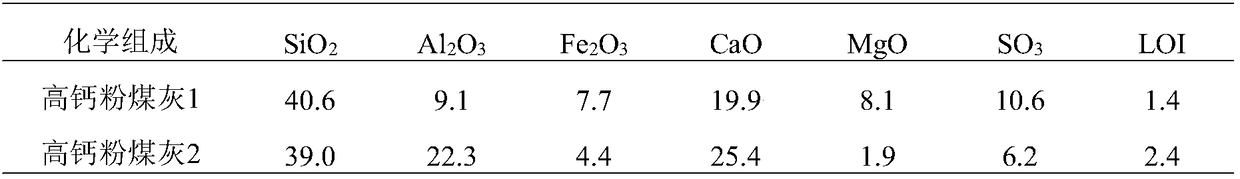

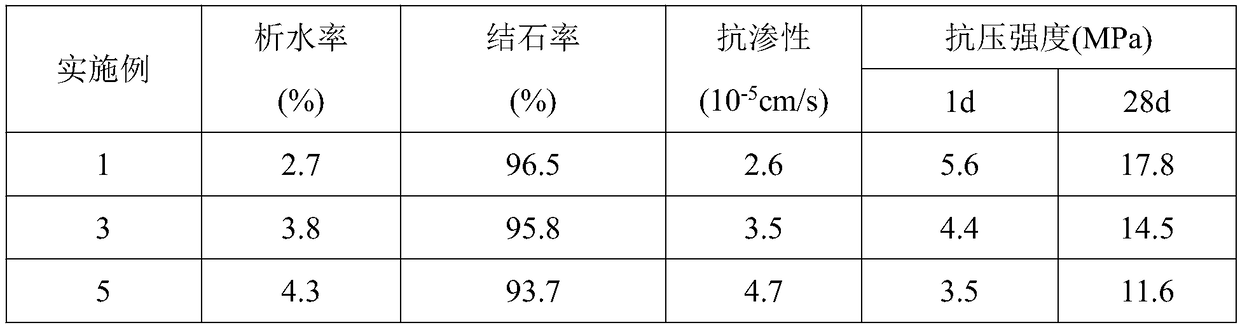

Micro-expansion grouting material and preparation method thereof

The invention discloses a micro-expansion grouting material. The micro-expansion grouting material is characterized by being prepared from the following materials in parts by mass: 30-50 parts of high-calcium flyash, 15-30 parts of calcined shale, 5-20 parts of phosphorus gypsum, 10-20 parts of ordinary silicate cement and 5-15 parts of rapidly-hardened sulphate aluminum cement. Further, additivematerials and water are added according to the times of the total parts by mass of the above materials on the basis that the total parts by mass of the materials are prepared to 100 parts. The additive materials comprise 0.5-1 part of a polycarboxylic acid water reducer, 0.1-1 part of redispersible latex powder, 0.05-0.15 part of hydroxypropyl methyl cellulose ether, 0.2-0.4 part of calcium lignosulphonate and 0.1-0.5 part of a cationic organic polymer; the water accounts for 8-10 parts. The micro-expansion grouting material has the characteristics of excellent mechanical property, micro expansion, low preparation cost, high solid waste utilization rate, green and environmental protection and high compatibility with soil.

Owner:重庆建工第七建筑工程有限责任公司 +1

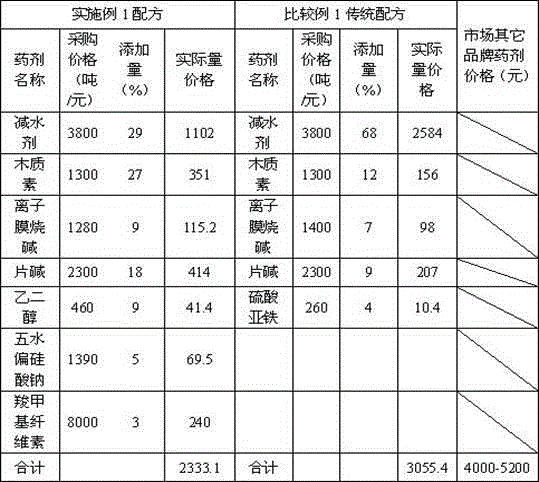

Coal water slurry additive and application thereof

ActiveCN104818063AImprove hydrophilicityIncrease electrostatic repulsionLiquid carbonaceous fuelsCelluloseCarboxymethyl cellulose

The invention discloses a coal water slurry additive which is composed of 20-40 wt% of water reducing agent, 20-35 wt% of lignosulfonate, 20-35 wt% of inorganic alkali, 2-20 wt% of ethylene glycol, 2-15 wt% of sodium metasilicate pentahydrate and 1-10 wt% of carboxymethyl cellulose. Besides, the invention also discloses application of the coal water slurry additive in preparing a coal water slurry. The coal water slurry additive can promote the disperse phase (coal particles) to be uniformly dispersed in the dispersion medium (water), and can effectively enhance the hydrophilicity of the coal and the electrostatic repulsion among the coal particles. The prepared coal water slurry has the advantages of higher coal content (or concentration), low viscosity, low bleeding rate, high flowability and high stability. Compared with the traditional formula, the coal water slurry additive can lower the slurry making cost by more than 20%.

Owner:QUFU SANRANG COAL WATER SLURRY CO LTD

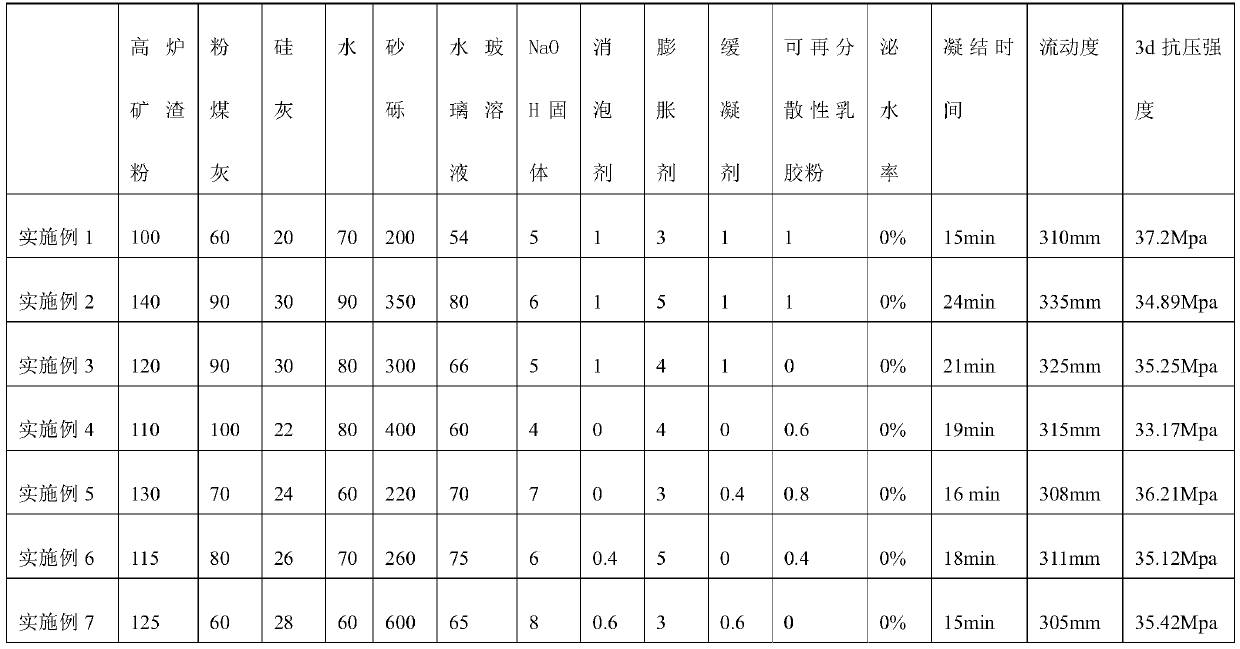

Uncemented geopolymer grouting material and preparation method thereof

he invention discloses an uncemented geopolymer grouting material and a preparation method thereof. Gravel is used as a supporting material to improve the overall strength of the material, blast furnace slag powder, fly ash and silica fume are added, and the silica ash mainly composed of SiO2 can optimize the pore structure and reduce the porosity of the system; a water glass solution and NaOH are used to dissolve and rejoin active silicon, aluminum and calcium substances in the fly ash and slag powder in order to form hydration products which are C-S-H hydrated calcium silicate and C-S-A-Hhydrated calcium aluminosilicate, and a solution composed of the water glass solution and NaOH is used to firstly react the fly ash with alumina in the slag powder in order to ensure the increase of the reinforcing material after the calcium oxide removal, so the utilization rates of the blast furnace slag powder and the fly ash are effectively improved, and the working performances of the grouting material are improved. The grouting material prepared in the invention has the advantages of good fluidity, low bleeding ratio, high concretion rate, effectiveness in utilization of the industrial wastes which are slag powder and fly ash, and realization of the purpose of changing industrial wastes into valuables.

Owner:CHANGAN UNIV

Novel green grouting superfine cement

InactiveCN102838332AConducive to turning waste into treasureReduce pollutionAluminateMicrofine cement

The invention discloses novel green grouting superfine cement. The superfine cement comprises the following minerals of superfine silicate cement, superfine aluminate cement, superfine mineral powder, superfine coal ash, a swelling agent, a water reducing agent, a retarding agent and a diluting agent. The temperature range of the superfine cement when in use is 5-60 DEG C; the compression strength of cement stone is more than 20 MPa within 24 hours, the compression strength within 3 days is more than 42 MPa, the compression strength within 7 days is more than 55 MPa, and the compression strength within 28 days is more than 65 MPa; the initial setting time of the cement is 23-208min, the final setting time is 45-223min, time is adjustable and controllable, and the cement is high in penetrating power and can penetrate through a narrow gap with a width of 15 mum; a cement slurry body with controllable setting time and controllable strength can be formed on the premise of a water-to-cement ratio ranging from (1 to 1) to (3 to 1); and the superfine cement can be applied to seepage prevention, leaking stoppage and reinforcement in excavation of projects such as water dams, mine roadways, tunnels and the like, and is a novel green blocking material.

Owner:SHANDONG JIANZHU UNIV

Indoxacarb water suspension concentrate and method for preparing same

InactiveCN104886109ANew structureUnique mechanism of actionBiocideArthropodicidesEngineeringSuspending Agents

The invention discloses indoxacarb water suspension concentrate and a method for preparing the same. The indoxacarb water suspension concentrate comprises, by weight, 10-25% of indoxacarb active compounds, 2-7% of dispersing agents, 1-7% of wetting agents, 1-5% of additional suspension concentrate, 1-8% of emulsifiers, 1-5% of thickeners, 0.5-5% of defoaming agents, 1-8% of antifreezing agents, 0.5-5% of preservatives, 0.5-5% of pH (potential of hydrogen) regulators and the balance water. The indoxacarb water suspension concentrate and the method have the advantages that the water suspension concentrate prepared by the aid of the method is free of dust, low in toxicity and safe for operators and users, optional organic solvents are omitted, and accordingly problems of flammability, explosiveness and intoxication during production can be solved; the water is used as a medium, so that environmental pollution can be reduced, and the indoxacarb water suspension concentrate is low in cost; the indoxacarb water suspension concentrate which is a pesticide preparation conforms to the high-content and environment-friendly preparation processing trend, is a pollution-free pesticide and accordingly has a broad application prospect.

Owner:ZHENGZHOU UNIV

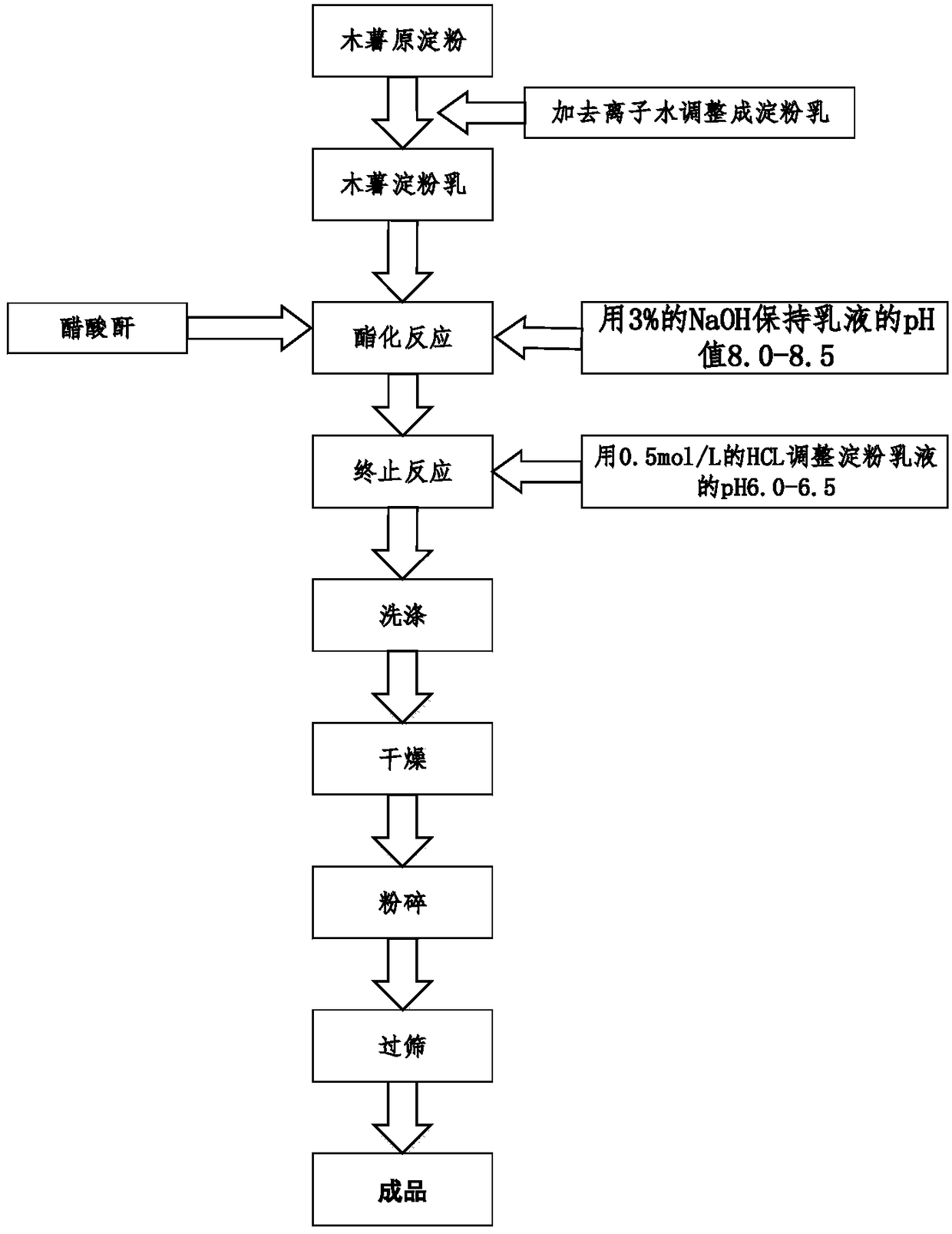

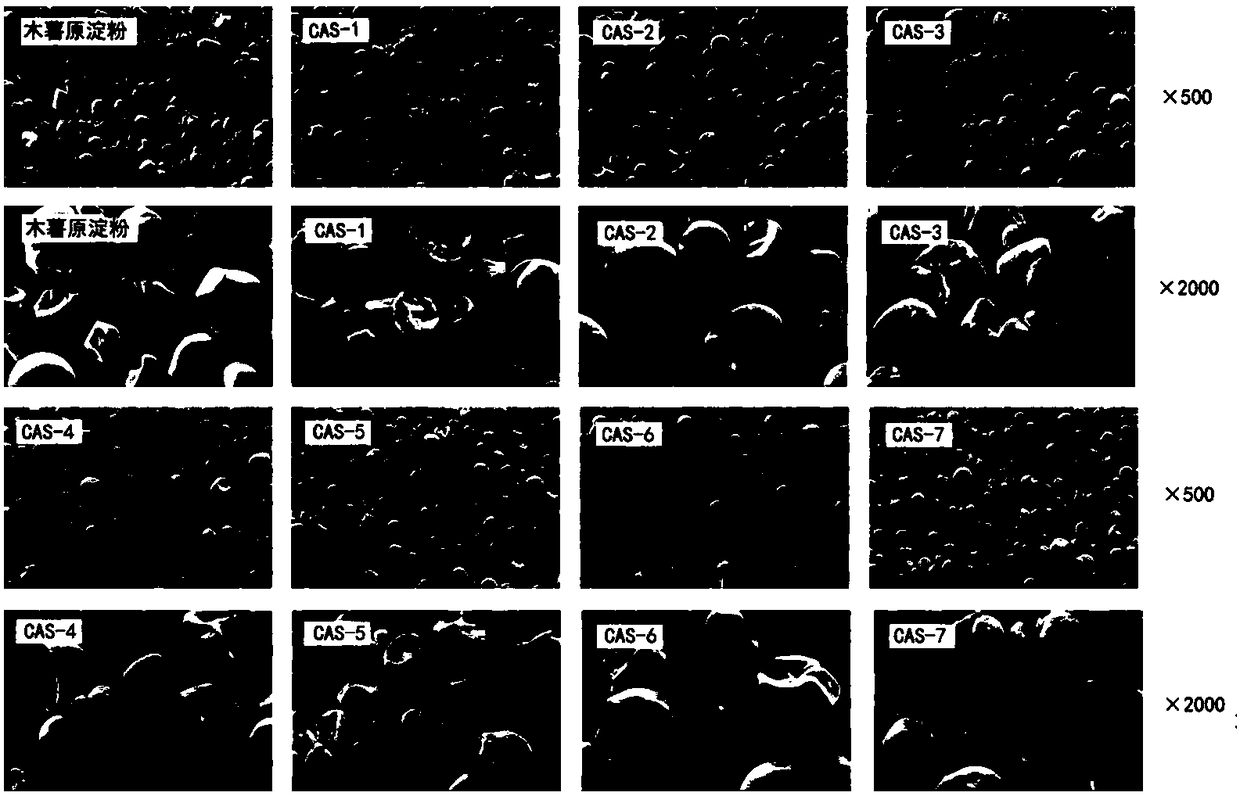

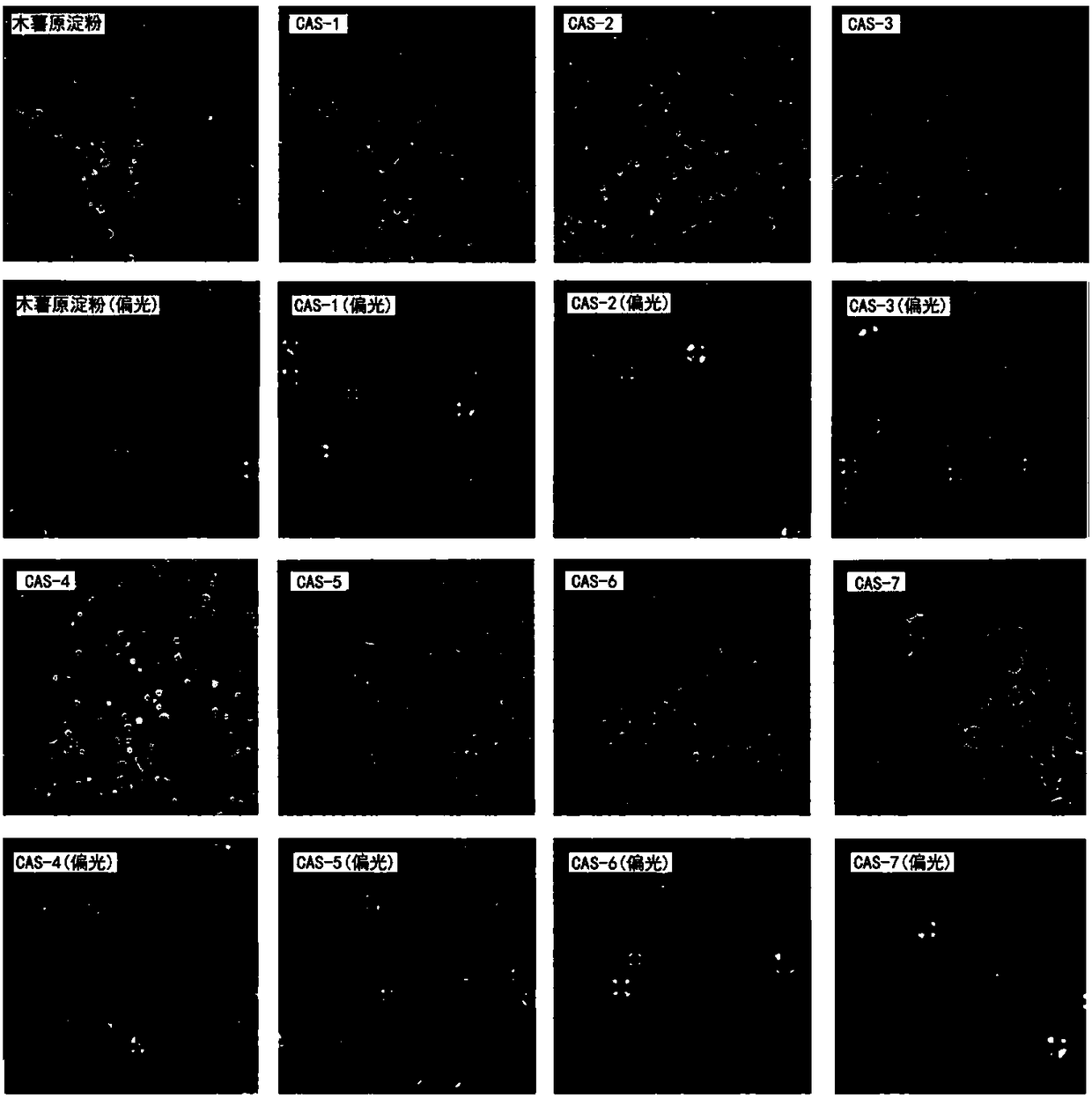

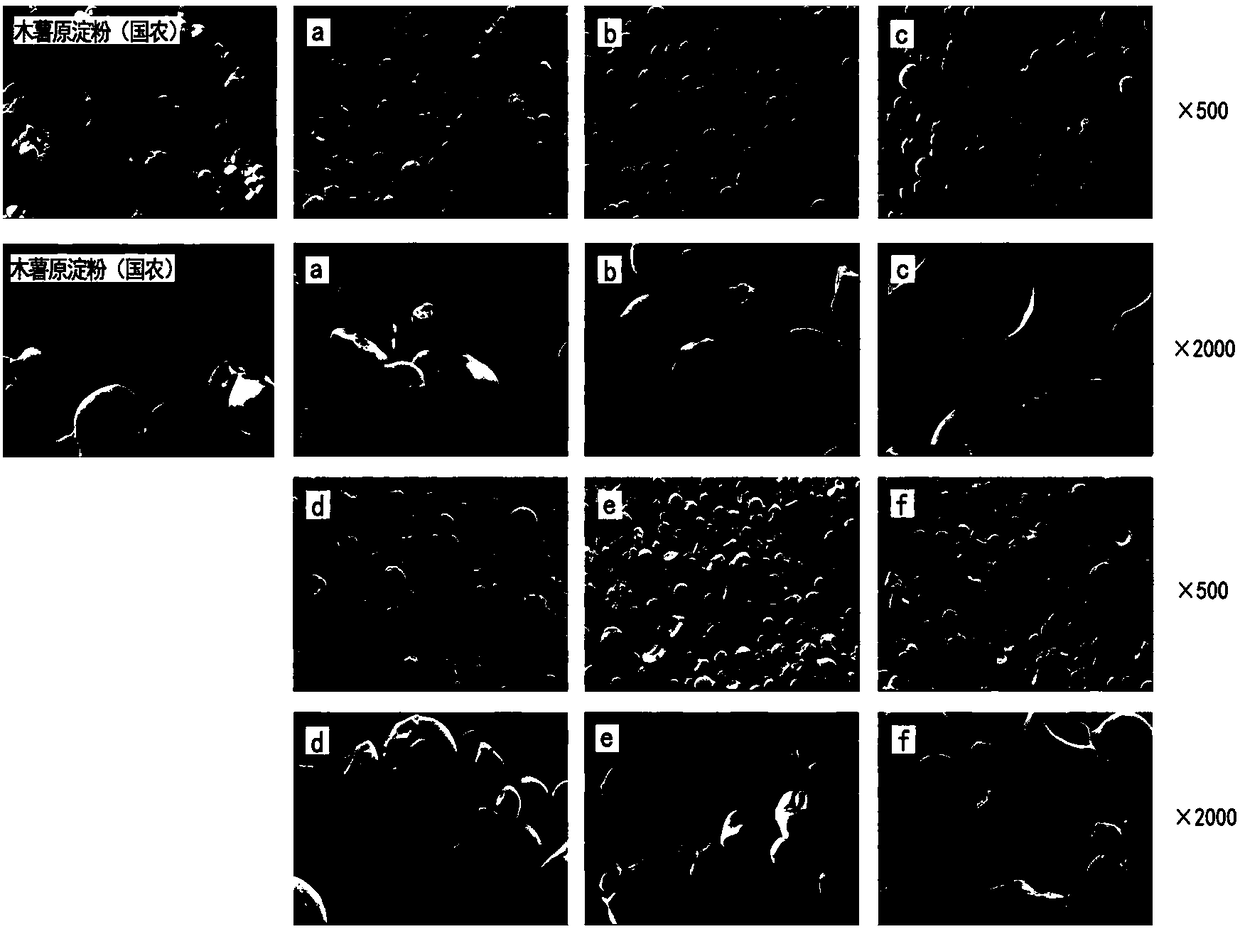

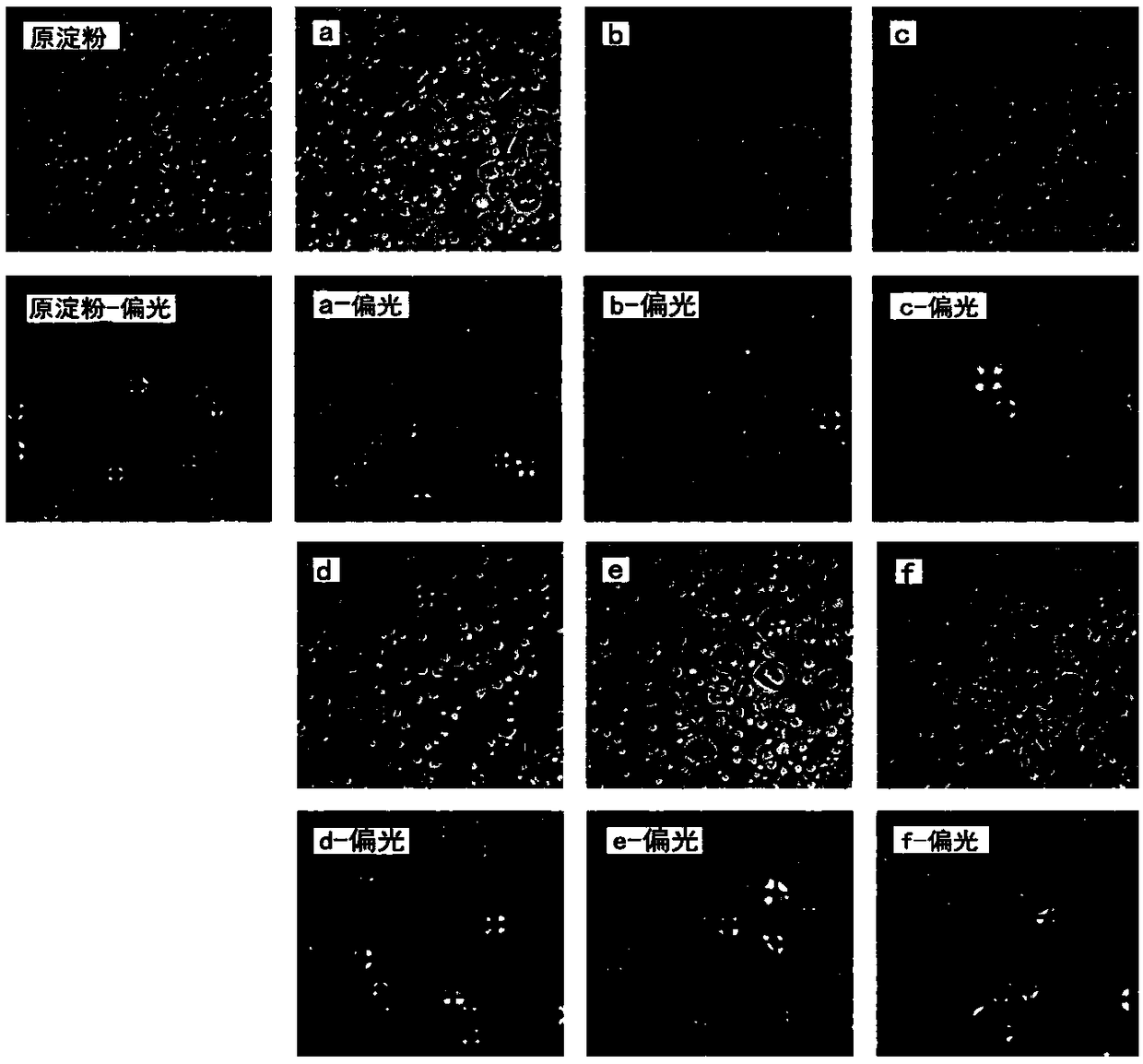

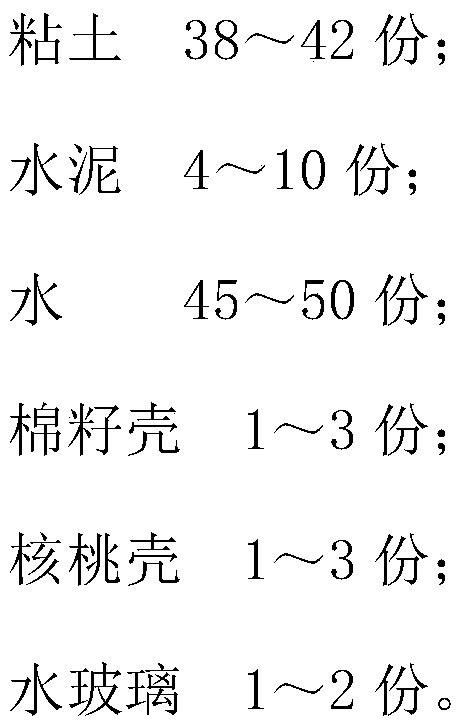

Preparation method of acetate starch

The invention belongs to the technical field of preparation of modified starch and particularly relates to a preparation method of acetate starch. The preparation method of the acetate starch comprises the following steps: taking cassava starch as a raw material and acetic anhydride as an esterification reagent and preparing tapioca acetate starch with different acetyl contents and degrees of substitution through acetylation reaction; the acetyl contents and the degrees of substitution of the obtained acetate starch meet the requirements in the market-oriented application field.

Owner:JILIN COFCO BIOCHEM +1

Instant flavored rice-gel cakes and preparation method thereof

The present invention discloses instant flavored rice-gel cakes. The instant flavored rice-gel cakes comprise the rice-gel cakes and flavored brown sugar juice. The rice-gel cakes consist of the following raw material components in percentages by weight: 86-95% of pure water, 5-10% of rice flour, 0.01-0.20% of refined konjac flour, 0.01-0.03% of carrageenan, 0.001-0.02% of xanthan gum, and 0.1-0.9% of sodium carbonate. The flavored brown sugar juice consists of the following raw material components in percentages by weight: 20-70% of pure water, 30-80% of brown sugar, 10-30% of freshly squeezed pineapple juice, 5-20% of freshly squeezed lemon juice and 0.1-0.2% of citric acid. A preparation method of the instant flavored rice-gel cakes mainly utilizes the modern food processing technology, overcomes the technical deficiencies or defects of the related products, changes the recipe and production technology of the rice-gel cakes, and develops the pre-packaged rice-gel cake food products which are long in shelf-life, instant, same in flavor, or more unique.

Owner:蒋治江

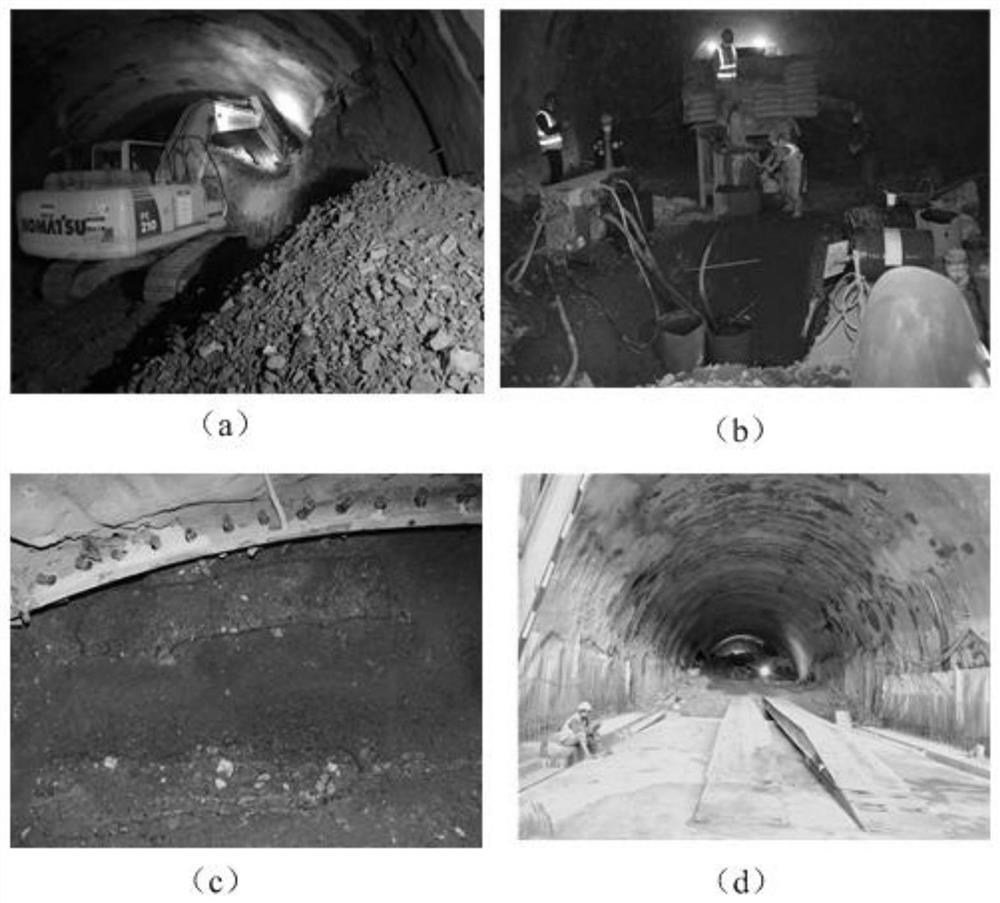

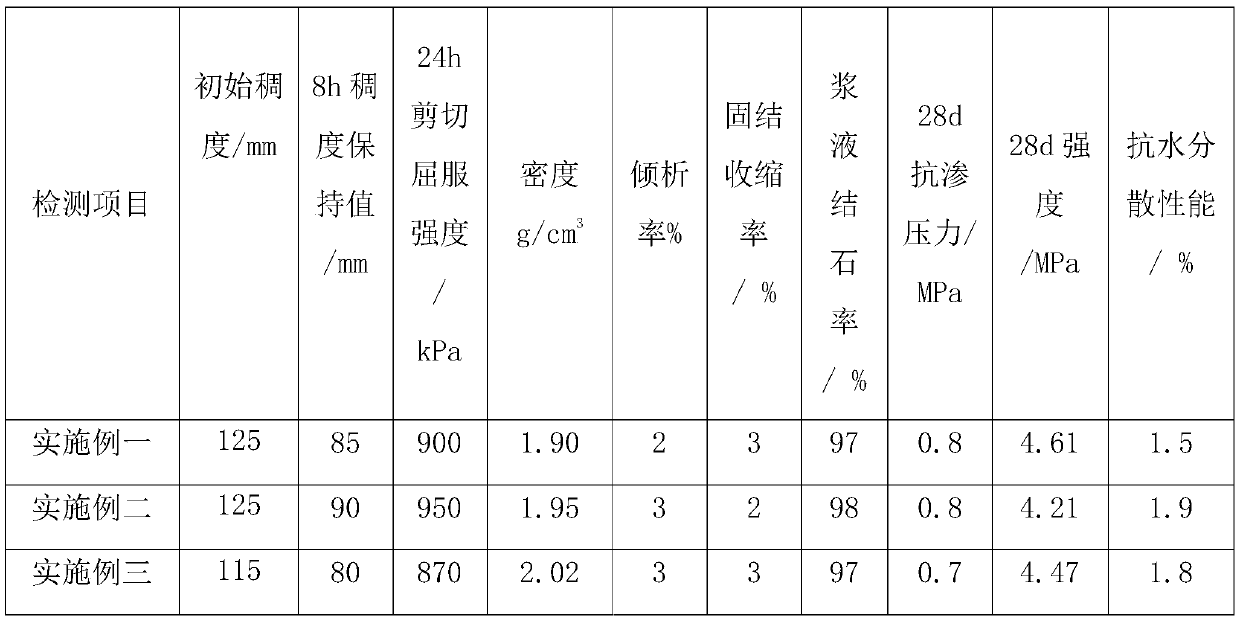

Controllable grouting material for advanced small pipe for water-rich accumulation body stratum tunnel and preparation method thereof

ActiveCN111995325AGood dispersionLow water separation rateHydro energy generationSulfonatePortland cement

The invention relates to a controllable grouting material for an advanced small pipe for a water-rich accumulation body stratum tunnel. The controllable grouting material is prepared from cement pasteand additives (polyethylene glycol, sodium hydroxide, silica sand and lignosulfonate). The preparation method comprises the following steps: uniformly mixing water and 42.5<#> ordinary Portland cement to prepare the cement paste; adding sodium hydroxide and silica sand into water, and carrying out uniform mixing and dissolving to obtain a solution A; adding a PEG-800 solid into water for dissolving to obtain a solution B; and adding the solution A, the solution B and lignosulfonate into the cement paste, and carrying out uniform mixing to obtain the controllable grouting material. According to the controllable grouting material disclosed by the invention, the problems of underwater dispersion resistance and controllability which are difficult to realize by a traditional grouting materialare solved, and the requirements of tunnel excavation for the performance such as the gelling time, the early strength and the bleeding rate of slurry are met; after grouting is finished, the water-rich accumulation body stratum reinforcing effect is good, no pollution is caused to the environment, the manufacturing cost is saved, and the construction progress requirement is met.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

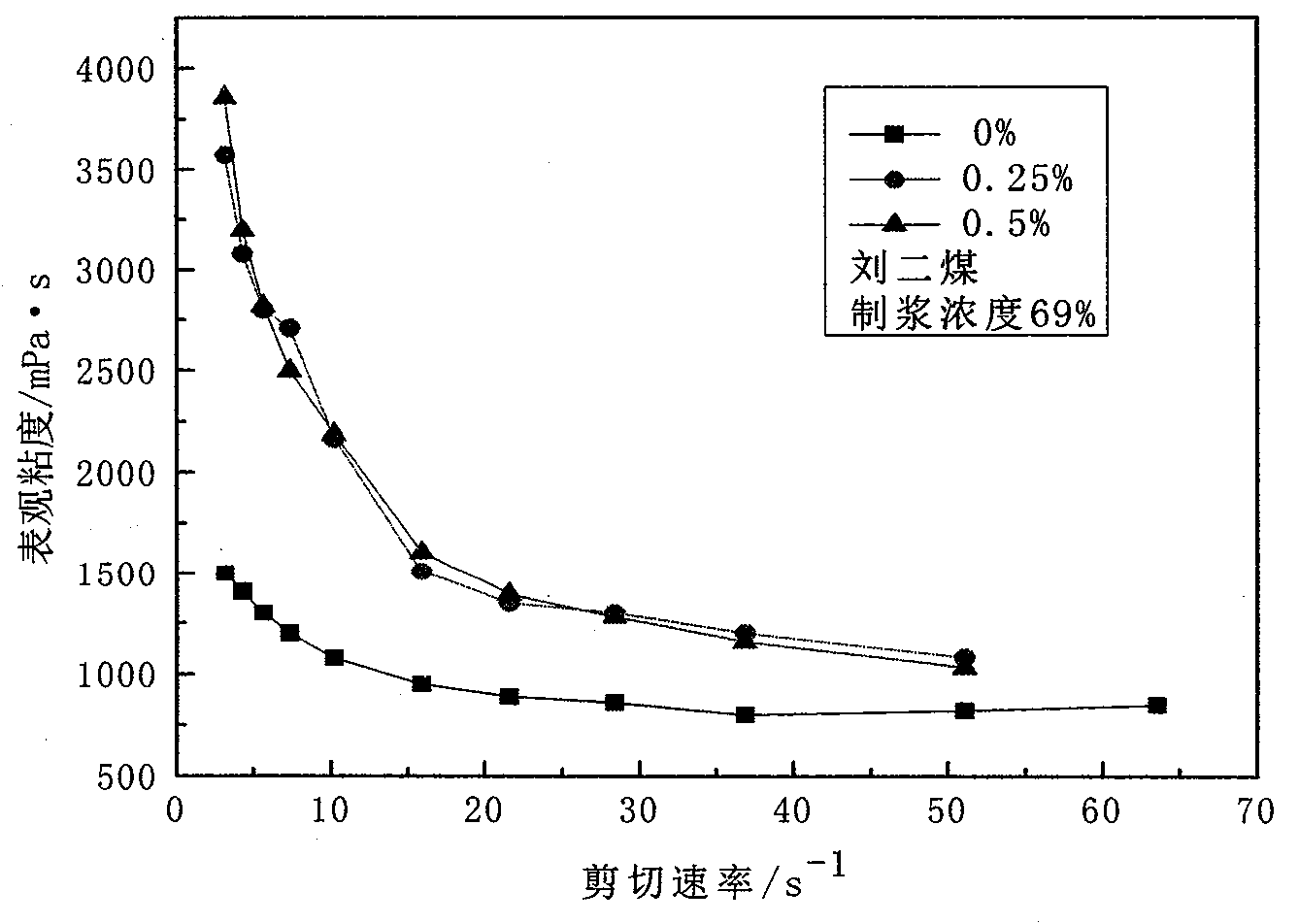

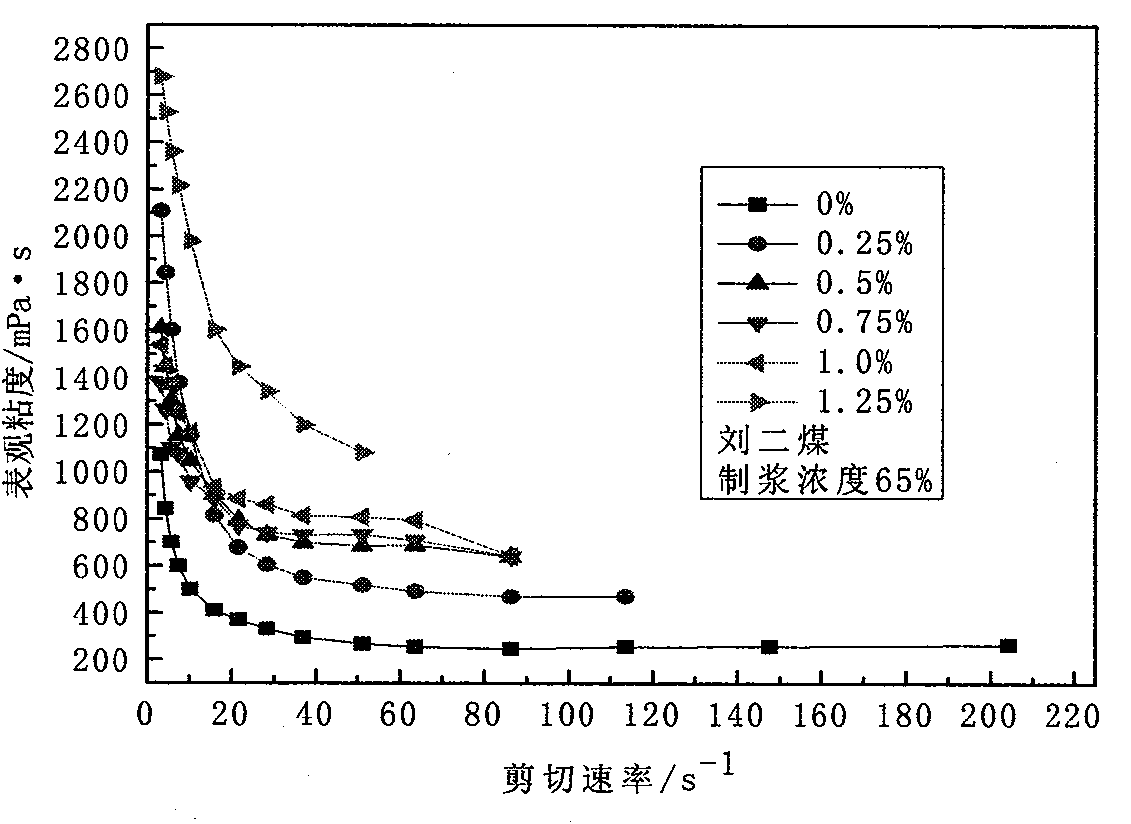

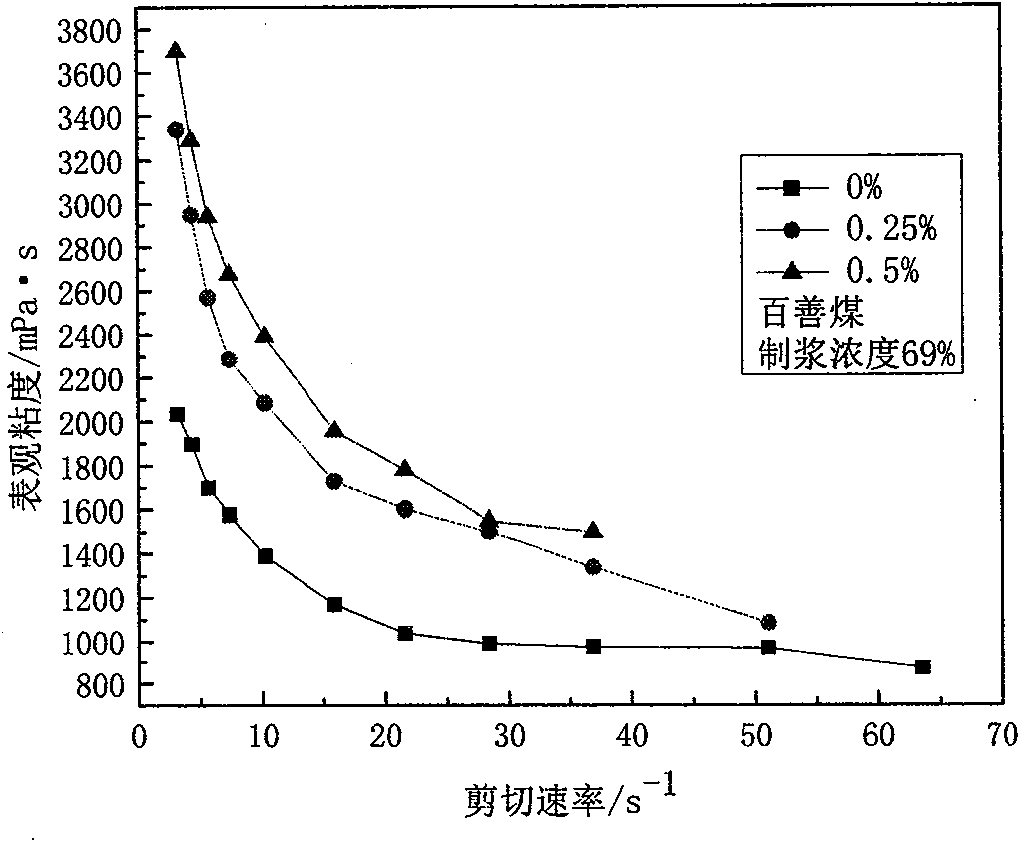

High-stability coal water slurry and preparation method thereof

InactiveCN101831329ALittle effect of viscosityLow water separation rateLiquid carbonaceous fuelsLump/pulverulent fuel preparationCoal waterCoal slurry

The invention relates to high-stability coal water slurry and a preparation method thereof. The coal water slurry contains coal powder, an additive, a stabilizer and water and has the mass concentration of 64-70 percent, wherein antibiotic fungi residues are adopted as the stabilizer, the addition of a fungi residue dry base is 0.1-1.5 percent of the total mass of a coal powder dry base and the fungi residue dry base, the addition of the additive is 1.0-2.0 percent of the mass of the coal water slurry, and the rest is water, and the antibiotic fungi residue comprises lincomycin wet bacteria residues, gentamicin wet bacteria residues and penicillin wet bacteria residues. In the preparation process of the coal water slurry, the antibiotic fungi residues are added, have less viscosity influence on the coal water slurry, but can remarkably decrease the syneresis rate of the coal water slurry and improve the stability of the coal water slurry, the slurry can be placed for a long time, and the requirements for pumping, atomizing, transporting in various modes, combusting and gasifying can be met. The method has low cost, not only can improve the stability of the coal water slurry, but also provides a new path for solving the problem of environmental pollution due to the antibiotic fungi residues.

Owner:ANHUI HUAIHUA

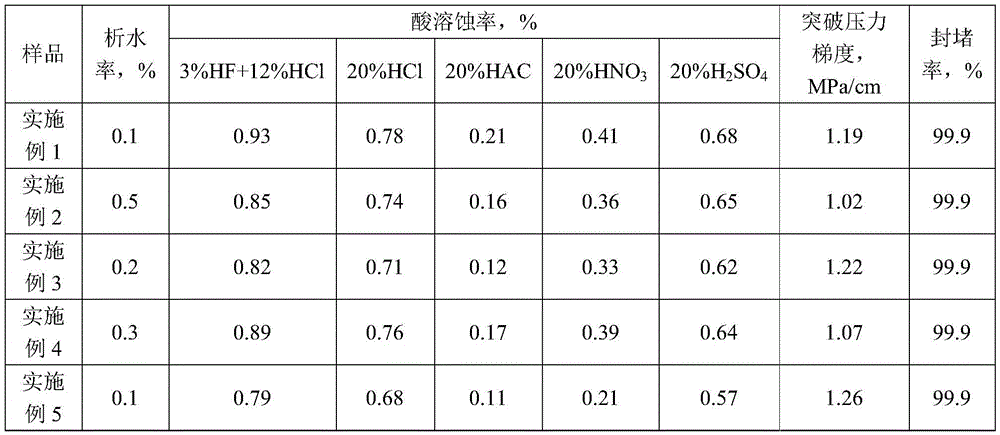

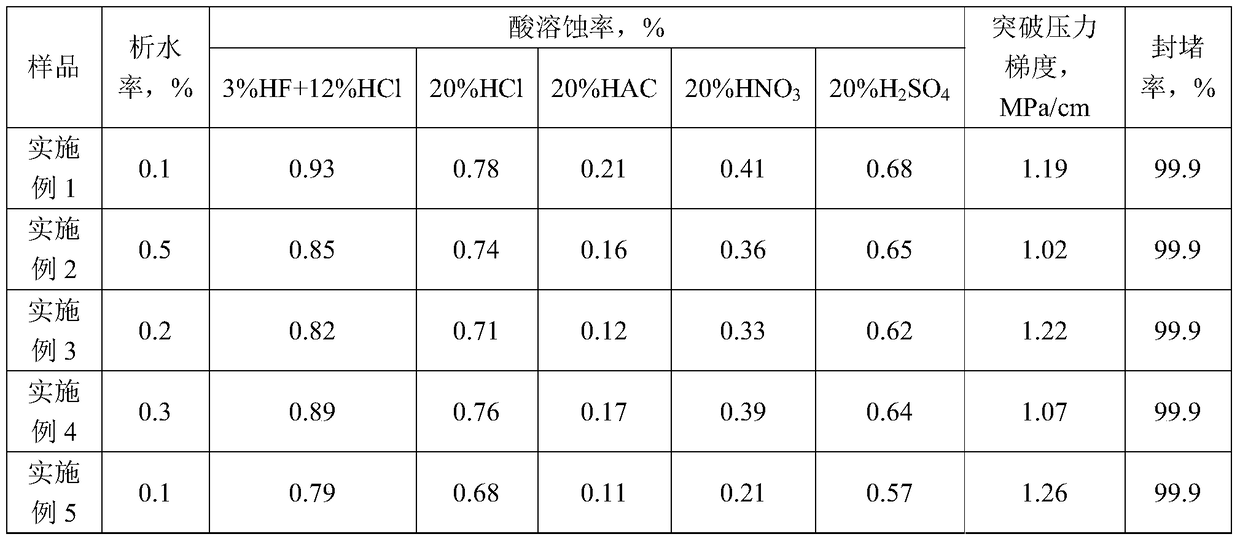

Non-acid solution high-strength plugging agent, and preparation method thereof

The invention discloses a non-acid solution high-strength plugging agent, and a preparation method thereof. The non-acid solution high-strength plugging agent is composed of, by weight, 55 to 60 parts of a curing agent, 3 to 5 parts of an activity improving agent, 2 to 3 parts of a mutual solvent, 0.8 to 1 part of a coupling agent, 1 to 2 parts of furan resin, and 1.5 to 3 parts of a dispersant. The non-acid solution high-strength plugging agent is mixed with an appropriate amount water so as to obtain a slurry; water segregation rate is less than 0.5%; breakthrough pressure gradient is larger than 1.0MPa / cm; stemming ratio is larger than 99.9%; and acid corrosion ratio is less than 1%. The non-acid solution high-strength plugging agent both possesses high strength and acid corrosion ratio, and is capable of satisfying high pressure bearing requirements of oil-water wells after plugging. Corrosion ratio of acidic mediums, such as mud acid, hydrochloric acid, nitric acid, and acetic acid, which are commonly used in oil-water well acidizing plugging removal on the non-acid solution high-strength plugging agent is low; acid resistance of the non-acid solution high-strength plugging agent is relatively high; and a technical problem that damage efficacy lose of plugged parts is easily caused by acidic fluids in oil-water well acidizing operation is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

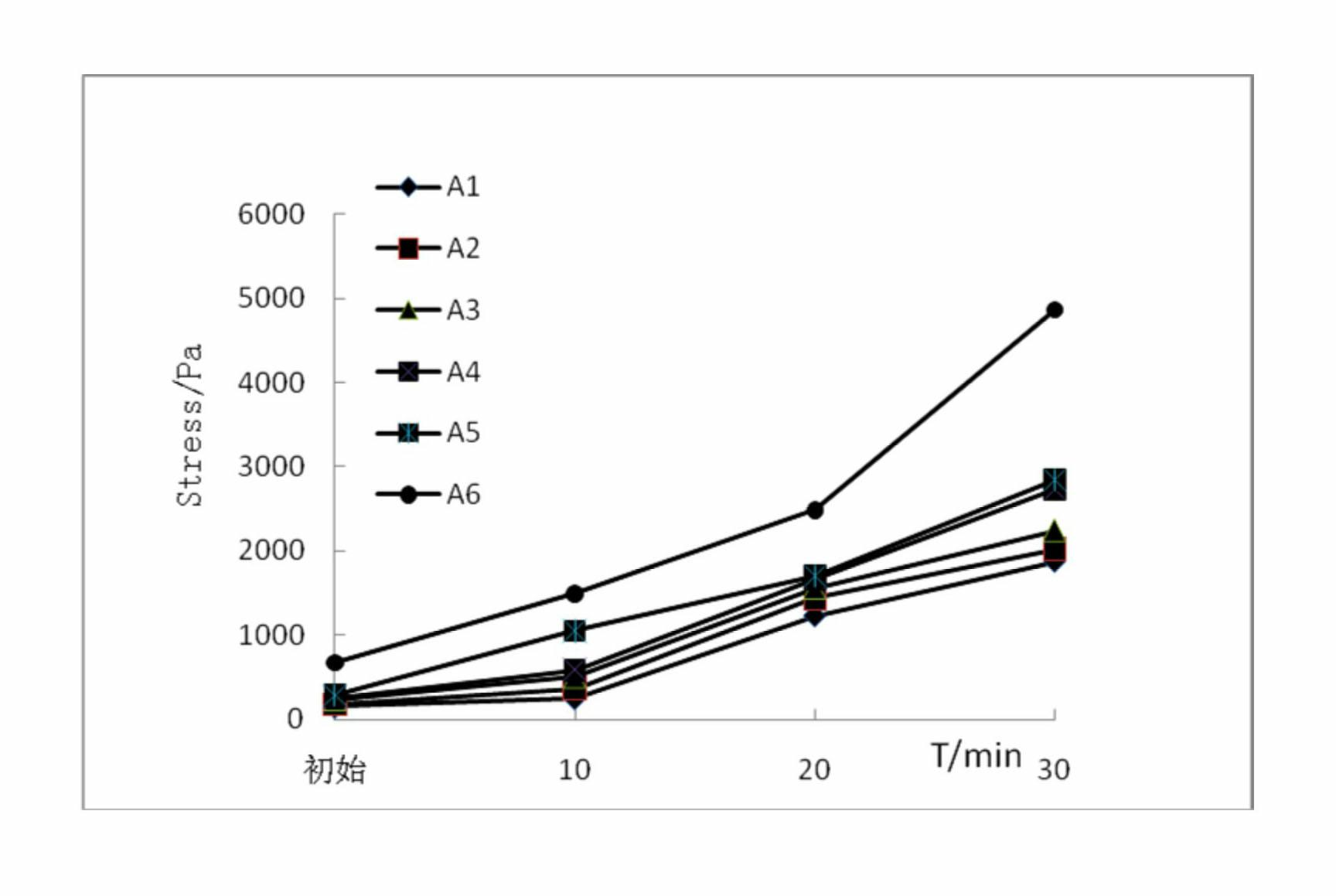

Synchronous grouting slurry for shield construction of water-rich stratum and preparation method thereof

The invention relates to synchronous grouting slurry for shield construction of a water-rich stratum and a preparation method thereof. The synchronous grouting slurry comprises a component A, a component B and a component C, wherein the raw materials of the component A comprise silicate 42.5-grade cement, II-grade fly ash, river sand and sodium bentonite, the raw materials of the component B comprise hydroxyethyl methyl cellulose and tap water, the raw material of the component C comprises nano silicon dioxide, the tap water, the ratio of the blending amount of the component B to the blending amount of the component A is 3: 5, and the ratio of the blending amount of the component C to the blending amount of the component A is 1: 2; the synchronous grouting slurry is high in early-stage shear strength, good in groutability, stable, high in stone rate, low in bleeding rate and good in dilution resistance, certain shear resistance is provided after the synchronous grouting slurry is injected, then duct pieces are inhibited from floating upwards, the effect of stabilizing the duct pieces can be achieved, and the problems of cracking and water seepage of the duct pieces are solved.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP +1

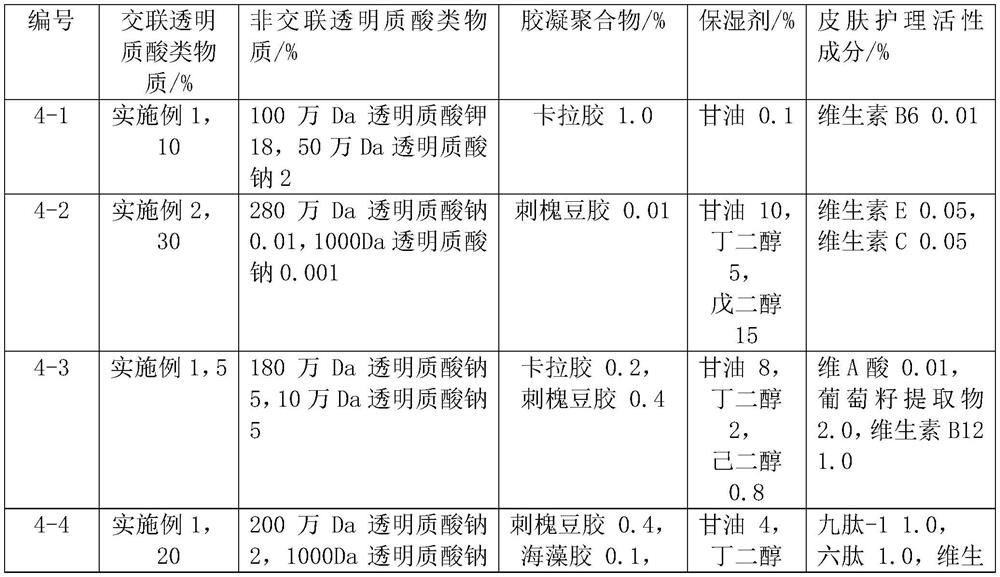

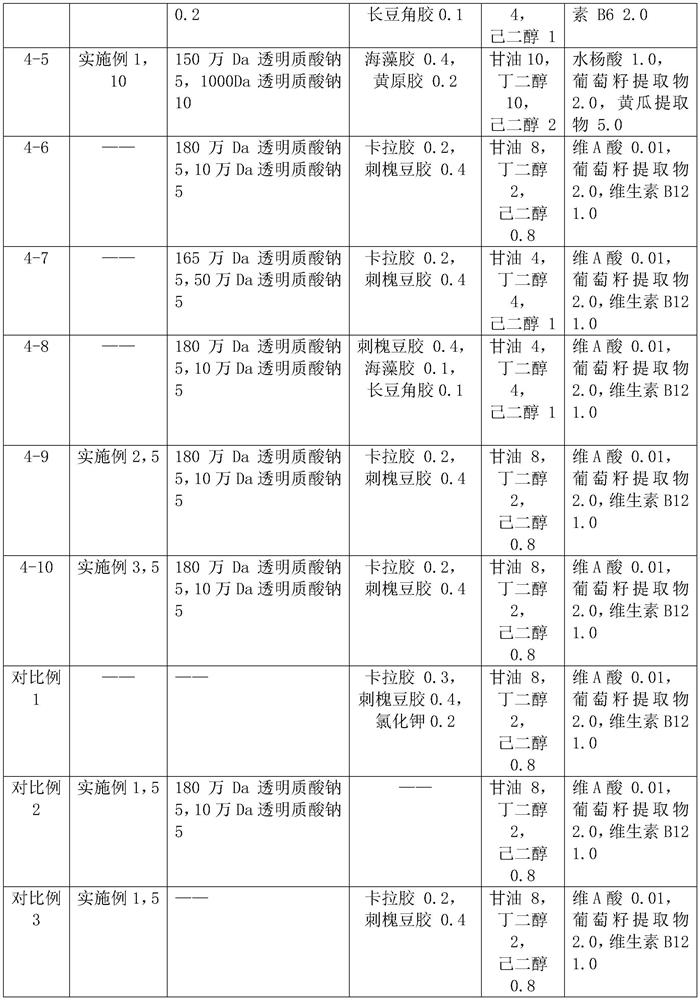

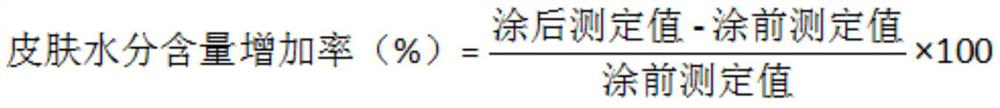

Hydrogel patch for skin care and preparation method thereof

ActiveCN112121032AImprove toughnessHigh strengthCosmetic preparationsToilet preparationsBULK ACTIVE INGREDIENTUlcer care

The invention discloses a hydrogel patch for skin care and a preparation method of the hydrogel patch. A hyaluronic acid substance serves as a main hydrogel matrix to be compounded with a small amountof gel polymers, so that the toughness and the strength of the hydrogel patch are improved. Meanwhile, the hydrogel patch is high in water locking property and low in drainage rate, has the effects of preserving moisture for a long time and promoting percutaneous absorption of active ingredients or medicines, and can be used for skin beauty care, skin trauma and ulcer care and application care ofsoft tissue sprain. Different shapes can be formed by pouring according to different use parts, including the whole face, the nose part, the eyes, the lip, the neck and the body parts such as the abdomen, the hip and the four limbs.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

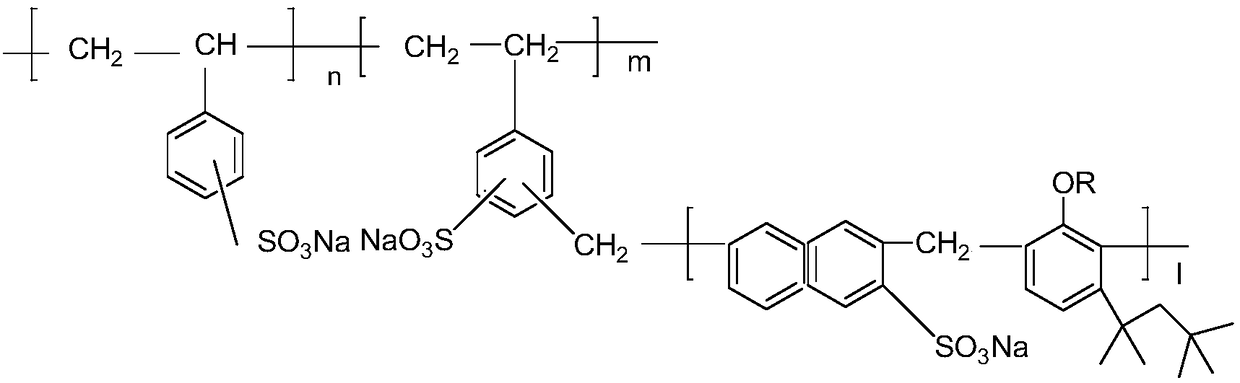

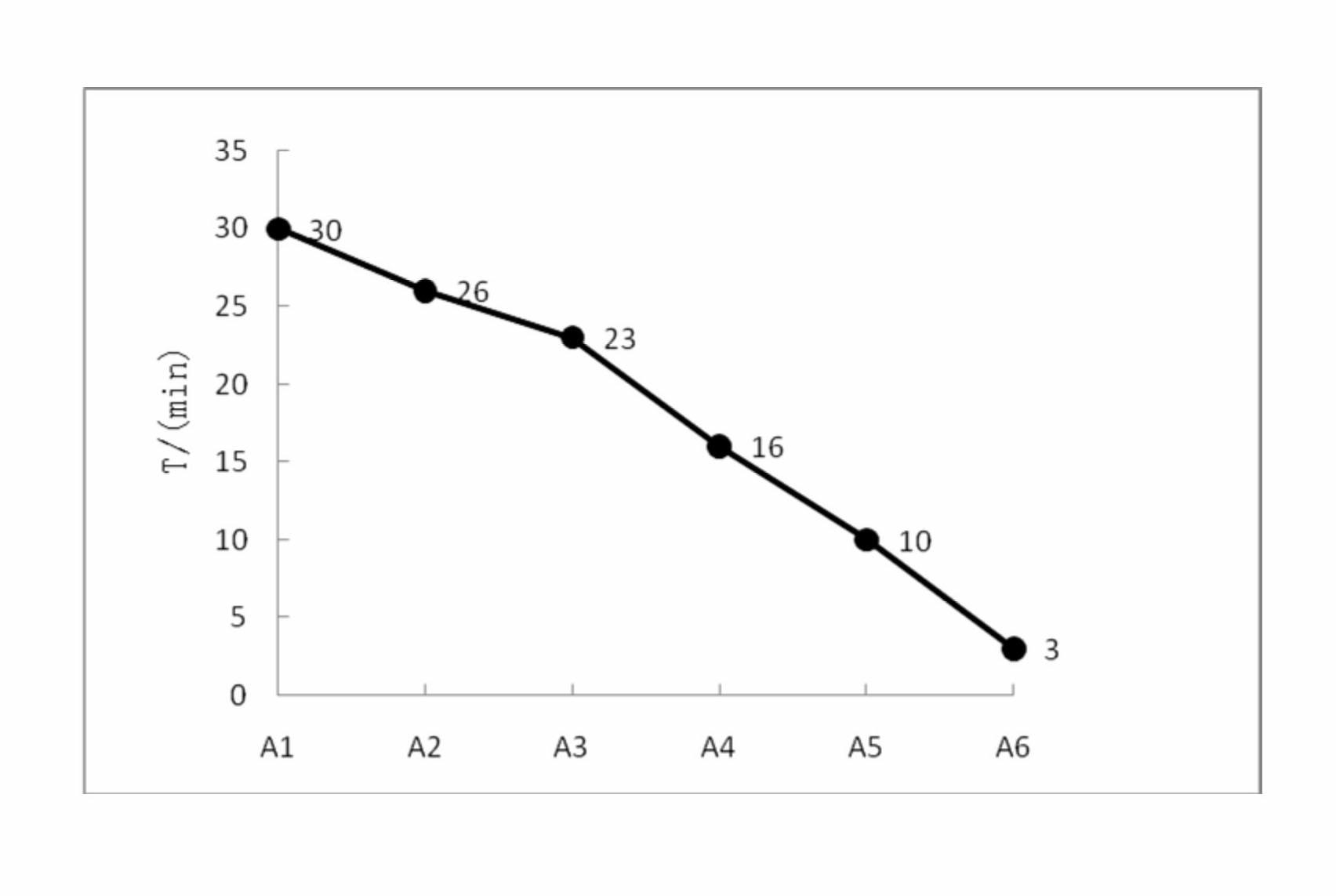

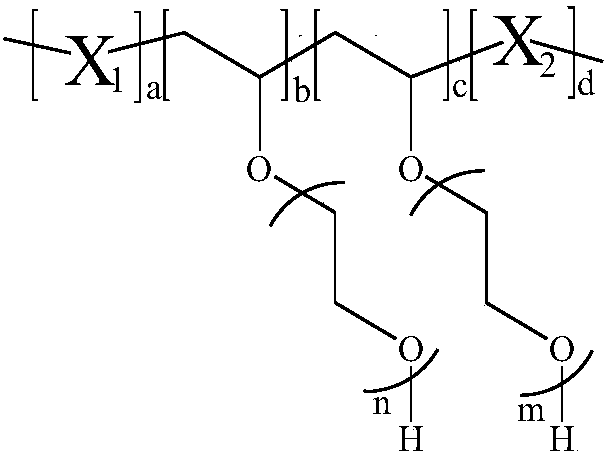

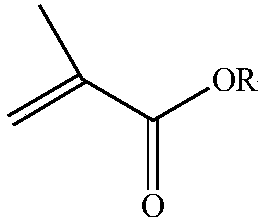

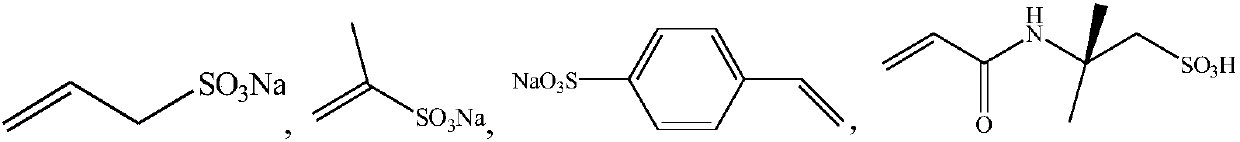

Dispersing agent containing composite long-short side chain polycarboxylate and RAFT (Reversible Addition-Fragmentation chain Transfer) synthesis method of aqueous solution thereof

InactiveCN107828061AGood dispersionLow water separation rateLiquid carbonaceous fuelsSynthesis methodsSide chain

The invention discloses a dispersing agent containing composite long-short side chain polycarboxylate and an RAFT (Reversible Addition-Fragmentation chain Transfer) synthesis method of aqueous solution thereof. The RAFT synthesis method comprises the following steps: 1) firstly synthesizing an RAFT reagent BDATT; 2) adding APEGn monomers, sulfonic monomers and water into a beaker, then mixing water and a proper amount of RAFT reagent for dissolving, adding acrylic monomers into a mixture, dripping the mixture and a water-soluble initiator solution into the beaker at a constant speed, and afterthe dripping is finished, continuously stirring to react for about 4 to 5 hours at a constant temperature; 3) uniformly dripping the APEGm aqueous solution into a reaction product from the former step, simultaneously dripping an initiator solution, stirring to react for 4 to 5 hours after the dripping is finished, and regulating pH to 7.0 after reaction is ended to obtain a dispersing agent solution containing the composite long-short side chain polycarboxylate. The dispersing agent disclosed by the invention has the advantages that the dispersing property is excellent and the storage stability of prepared water coal slurry is higher.

Owner:SHAANXI UNIV OF SCI & TECH

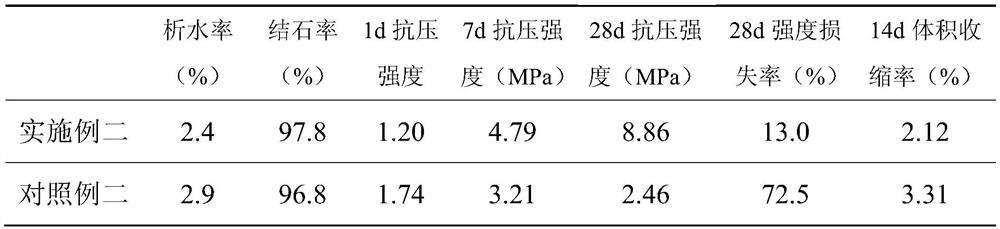

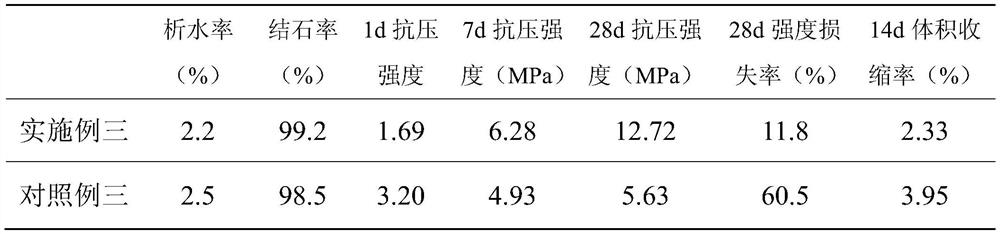

Product-stable cement-water glass double-liquid grouting material for shield synchronous grouting

PendingCN112028594AParticle dispersion increasedImprove stabilitySolid waste managementUnderground chambersPortland cementShrinkage rate

The invention discloses a product-stable cement-water glass double-liquid grouting material for shield synchronous grouting, which is composed of a liquid A and a liquid B. The product-stable cement-water glass double-liquid grouting material is characterized in that the liquid A comprises the following components: cement, fly ash, a retarder and water, wherein the cement is 42.5-grade ordinary Portland cement, the fly ash is II-grade fly ash, and the retarder is ammonium dihydrogen phosphate with the purity of more than or equal to 99.0%, the pH value of 4.0-4.5 and the clarity of less than or equal to 3; and the liquid B is water glass with the baume degree of 30-40 degrees and the modulus of 3.1-3.3. The grouting material is used for shield synchronous grouting, the gelling time is short, and the anti-floating performance of pipe pieces is good; and a reaction product is good in stability, not prone to disintegration and cracking under the natural condition of actual engineering, small in volume shrinkage rate and free of degradation of compressive strength, and a formed segmental lining structure is high in strength and good in waterproof performance.

Owner:SOUTHWEST JIAOTONG UNIV +1

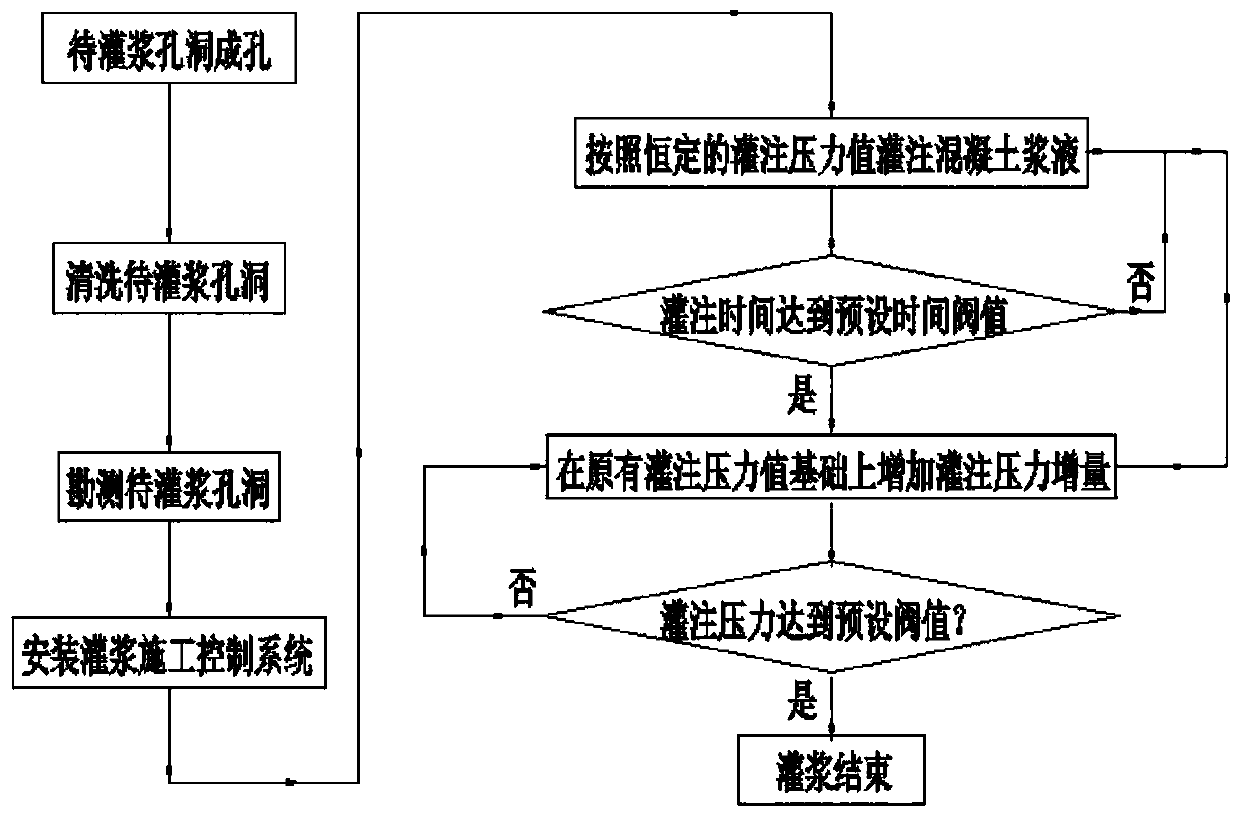

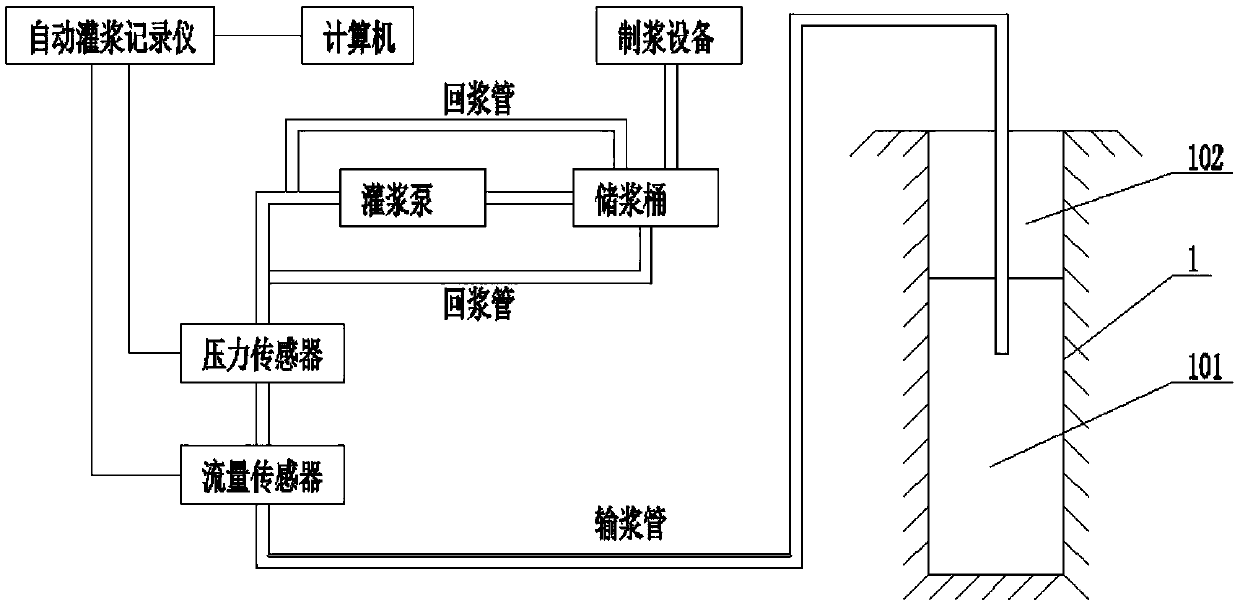

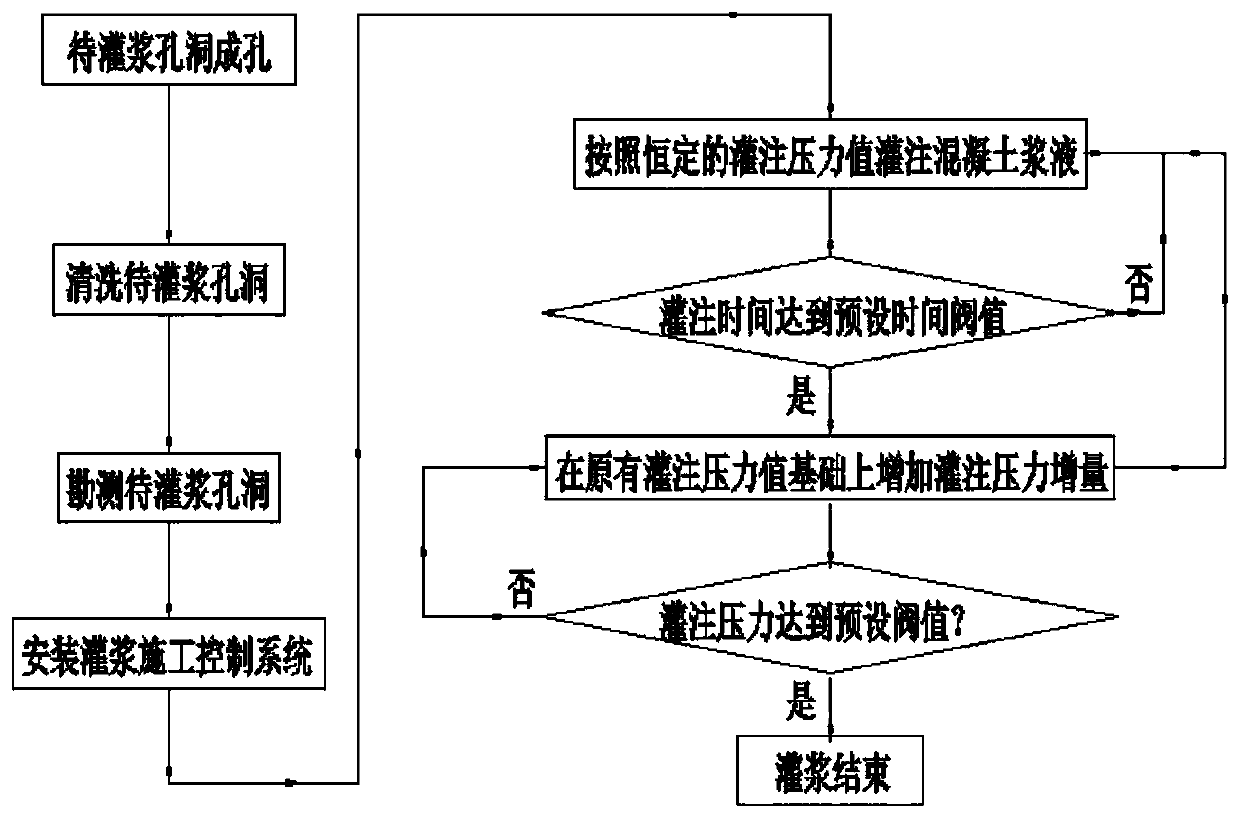

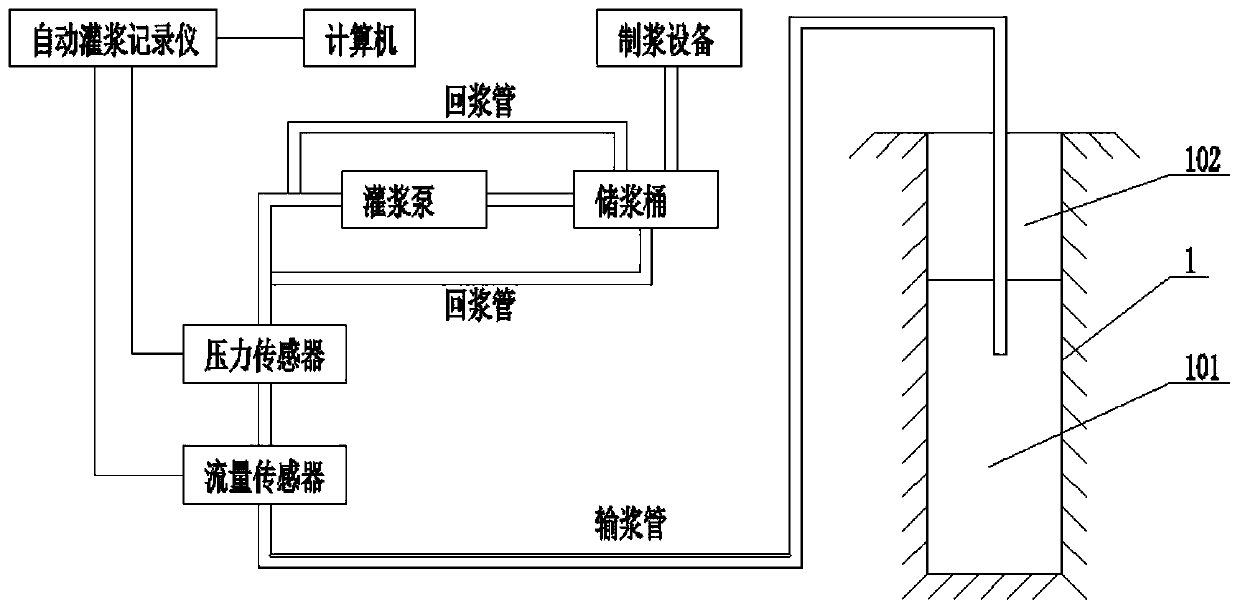

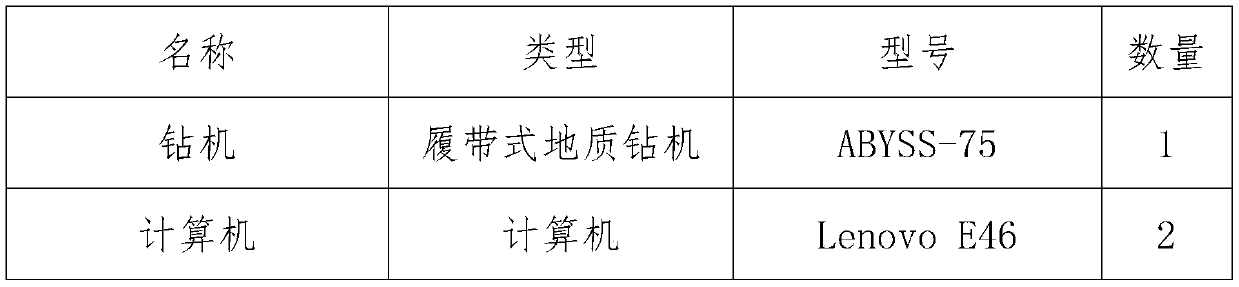

Grouting construction process using GIN grouting method

ActiveCN108678375AStable in natureLow water separation rateBuilding material handlingControl systemSurvey result

The invention relates to a grouting construction process using a GIN grouting method. The method comprises the steps of forming a hole to be grouted, cleaning the hole to be grouted, surveying the hole to be grouted, uniformly dividing a grouting section into a plurality of grouting subdivisions according to a survey result, installing a grouting construction control system, grouting the hole to be grouted through the grouting construction system, controlling the grouting pressure, when each grouting time threshold is reached, adding a grouting pressure increment on the basis of an original grouting pressure to continue grouting, and when the grouting pressure reaches the preset grouting pressure threshold, ending the grouting; by using the technical scheme of the process, the grouting strength value GIN of each grouting subdivision section is controlled by a computer, so that the grouting strength value GIN of the whole hole to be grouted in the grouting process is kept constant, anda perfusion flow rate and a perfusion pressure are always matched, the quality of the grouting construction operation is improved, and the process has the advantages that the construction process is simple, the work efficiency is high, the anti-seepage effect is good and the like.

Owner:SINOHYDRO BUREAU 9

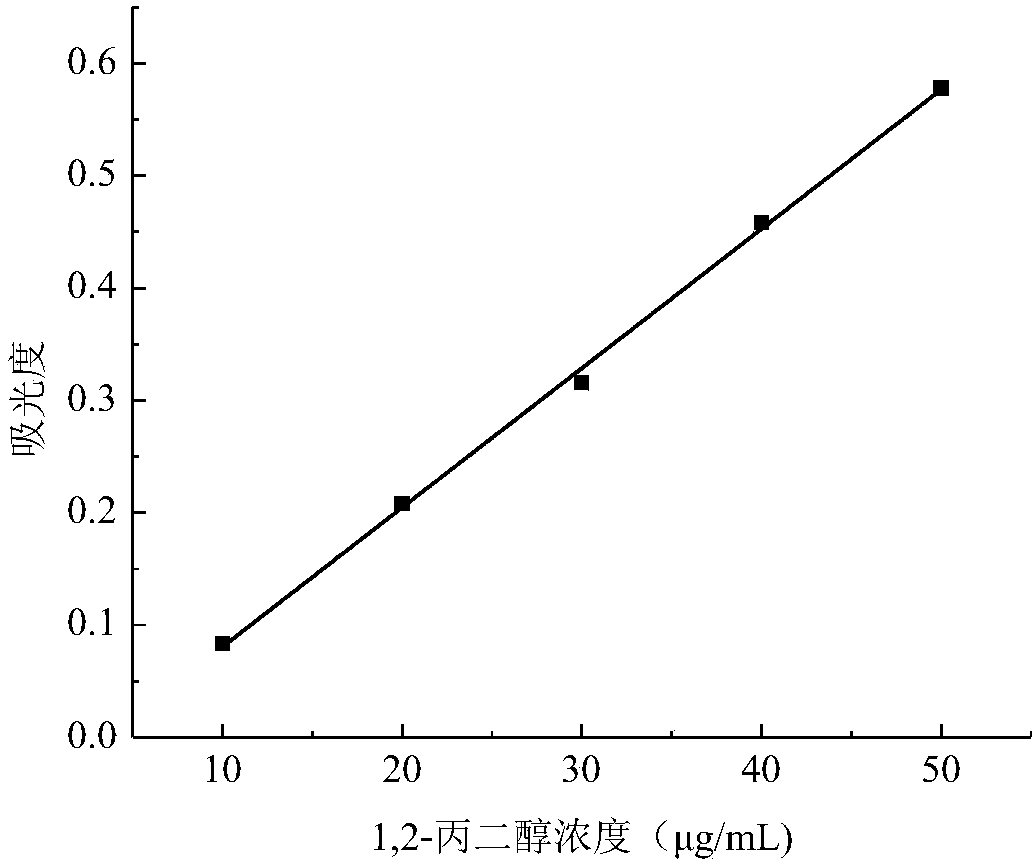

Preparation method of hydroxypropyl starch

The invention belongs to the technical field of preparation of modified starch, and particularly relates to a preparation method of hydroxypropyl starch. The preparation method of the hydroxypropyl starch provided by the invention uses tapioca starch as a raw material to react with propylene oxide under alkaline conditions to prepare tapioca hydroxypropyl starch with different hydroxypropyl contents. The hydroxypropyl content and performance of the prepared hydroxypropyl starch meet requirements in the field of market application.

Owner:JILIN COFCO BIOCHEM +1

Clay cement-aggregate mixed grouting material and preparation method thereof

The invention discloses a clay cement and aggregate mixed grouting material.The material is prepared from 38-42 parts of clay, 4-10 parts of cement, 45-50 parts of water, 1-3 parts of cottonseed hulls, 1-3 parts of walnut hulls and 1-2 parts of water glass. The invention further discloses a preparation method of theclay cement-aggregate mixed grouting material.The preparation method comprises thesteps that 1, 38-42 parts of clay is uniformly added in 45-50 parts of water, and stirring is conducted at room temperature to form mixed slurry; 2, 4-10 parts of cement is added in the mixed slurry,and stirring is conducted to form mixed slurry; 3, 1-3 parts of cottonseed hulls and 1-3 parts of walnut hulls are added in the mixed slurry, and stirring is conducted to form mixed slurry; 4, 1-2 parts of water glass is uniformly added in the mixed slurry, stirring is conducted to be uniform, and the clay cement-aggregate mixed grouting material is obtained. According to the clay cement-aggregatemixed grouting material and the preparation method thereof, the cost of coal seam floor reinforcement is lowered, and pollution is not likely to be produced.

Owner:北京大地高科地质勘查有限公司

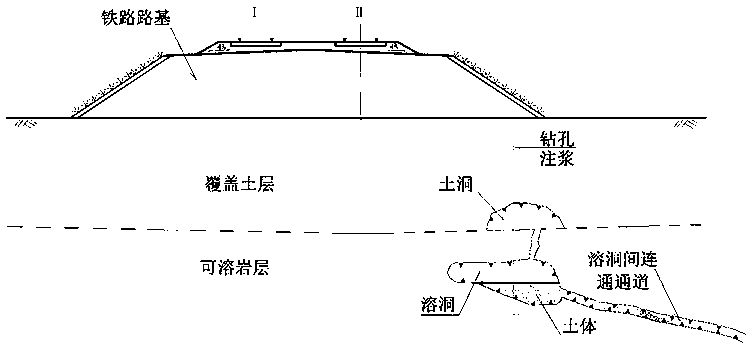

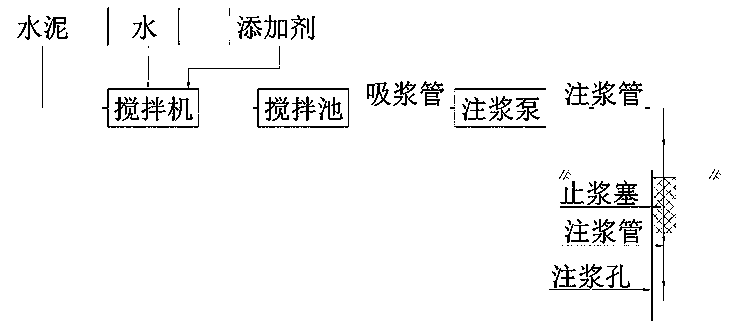

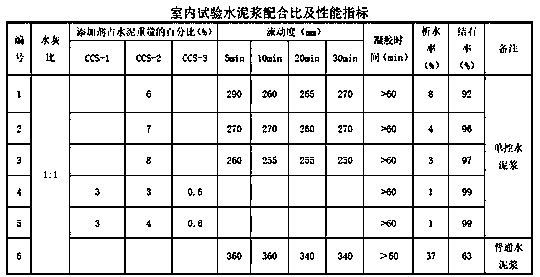

Method for controlling loss of grouting slurry for karst foundation and pollution of underground water

The invention relates to a method for controlling loss of grouting slurry for karst foundations and pollution of underground water. Additives A, B and C are added into cement slurry with the conventional water-cement ratio being 1:1, fast stirring is conducted, the controllable cement slurry is prepared, and then slow stirring is conducted at a half speed. Afterwards, the controllable cement slurry is poured into the karst foundations, when a karst cave under the foundations is about to be filled completely, a hole packer is installed at a grouting hole, pressure is applied, the controllable cement slurry continues to be pressed in till grouting of the single hole is completed, and the steps are repeated till grouting of all grouting holes in the area is completed. According to the method, initial setting time of the controllable cement slurry is shortened extremely, the diffusion radius of the cement slurry is reduced greatly, and loss of the cement slurry is controlled. The water segregation rate of the controllable cement slurry is lowered extremely, the water segregation amount of the cement slurry is reduced greatly, and pollution of the underground water due to the cement slurry is controlled. The controllable cement slurry has fluidity not smaller than 200 mm within 10-15 minutes after fully stirred, and the effect that the controllable cement slurry does not block a grouting pipeline is ensured.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

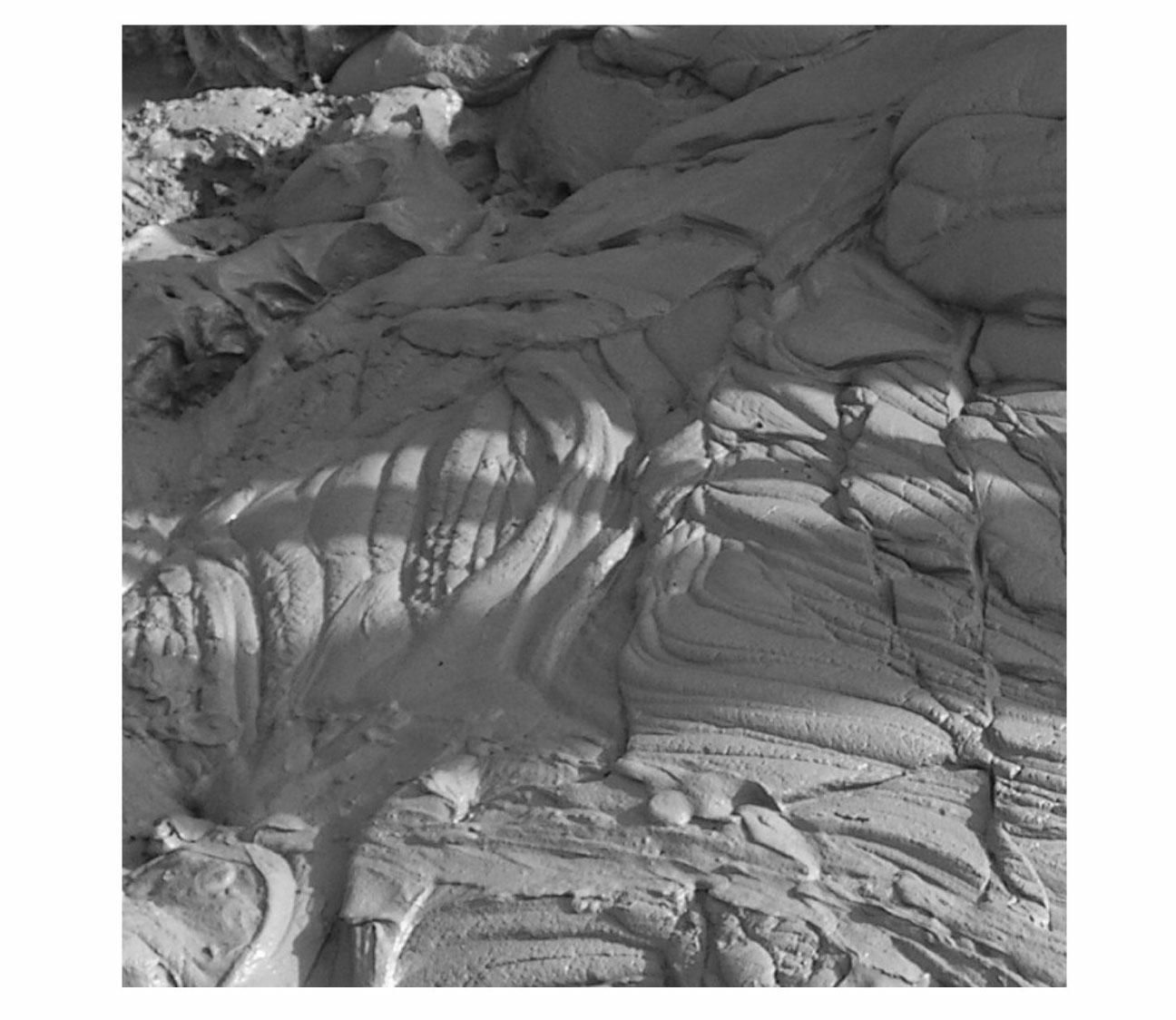

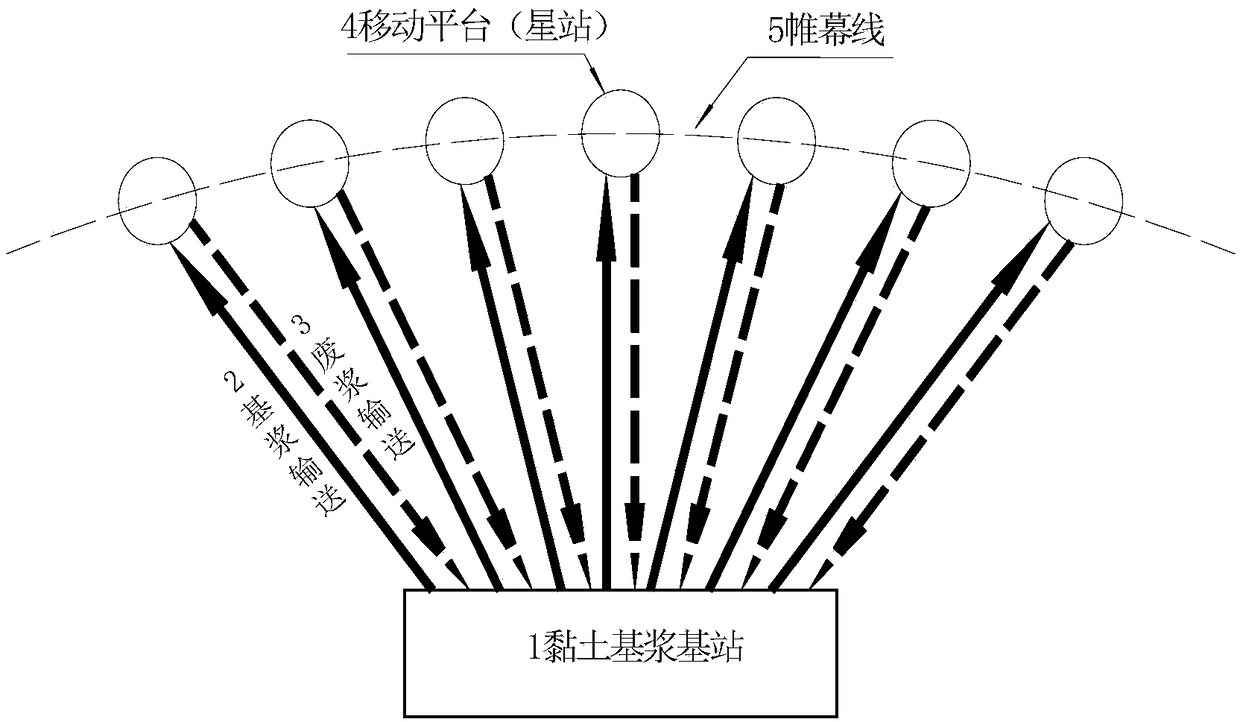

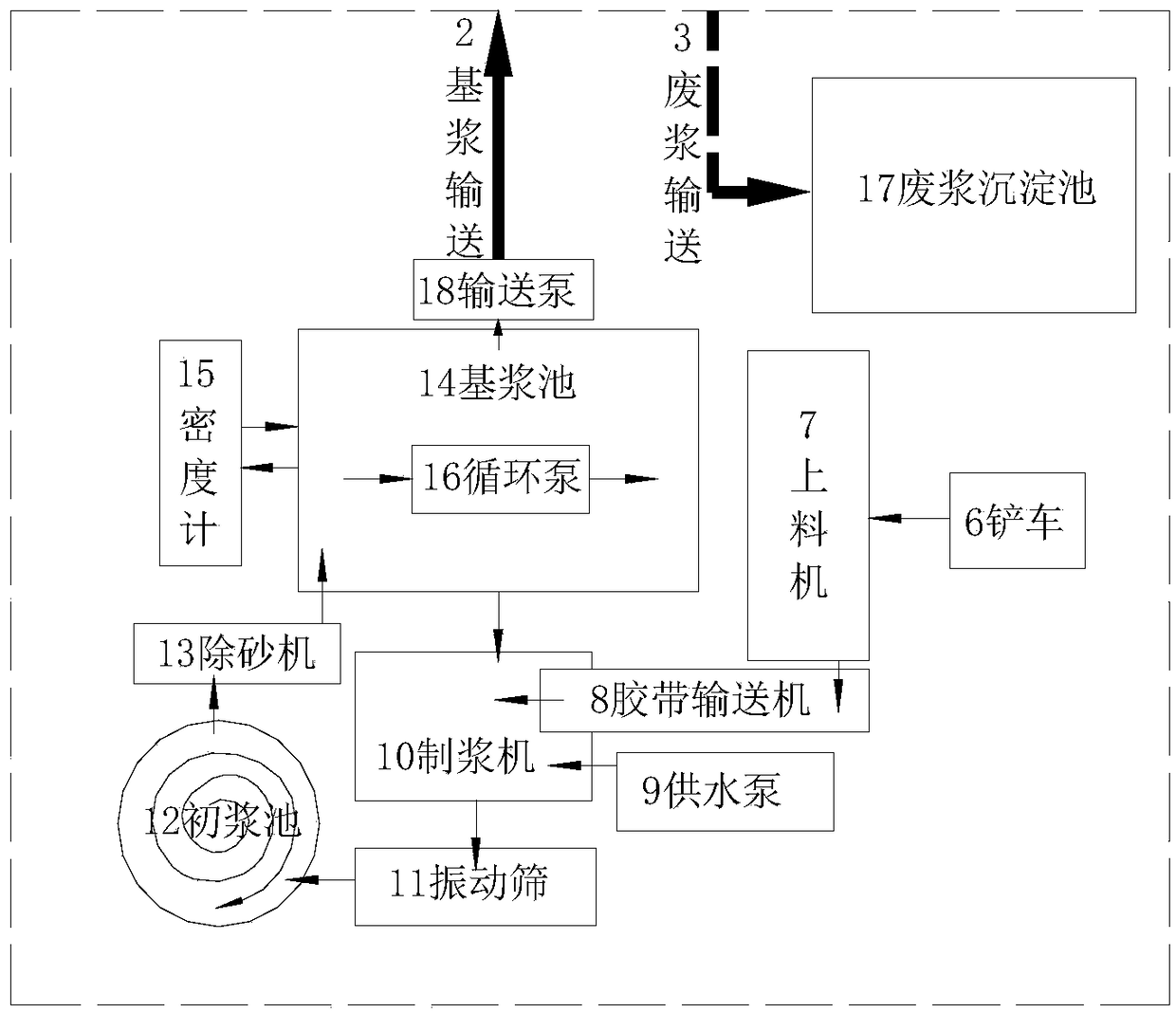

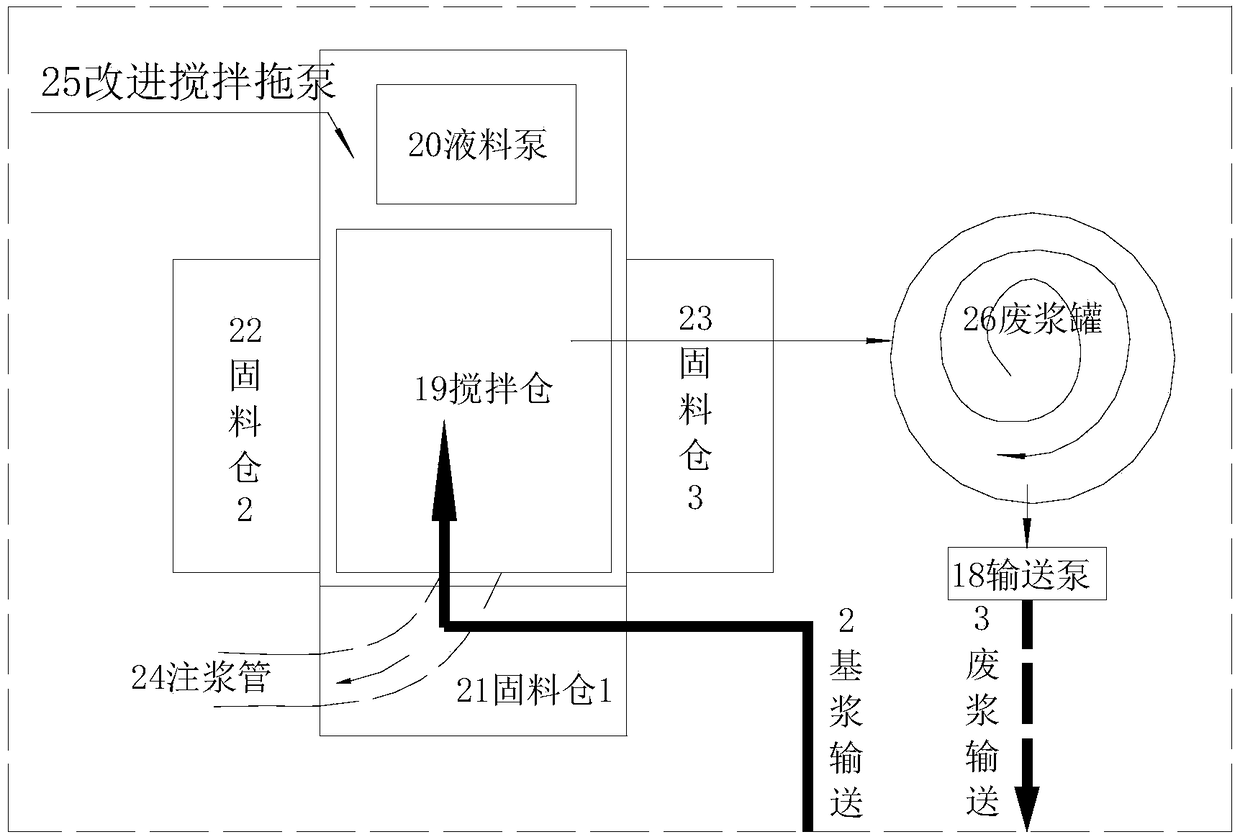

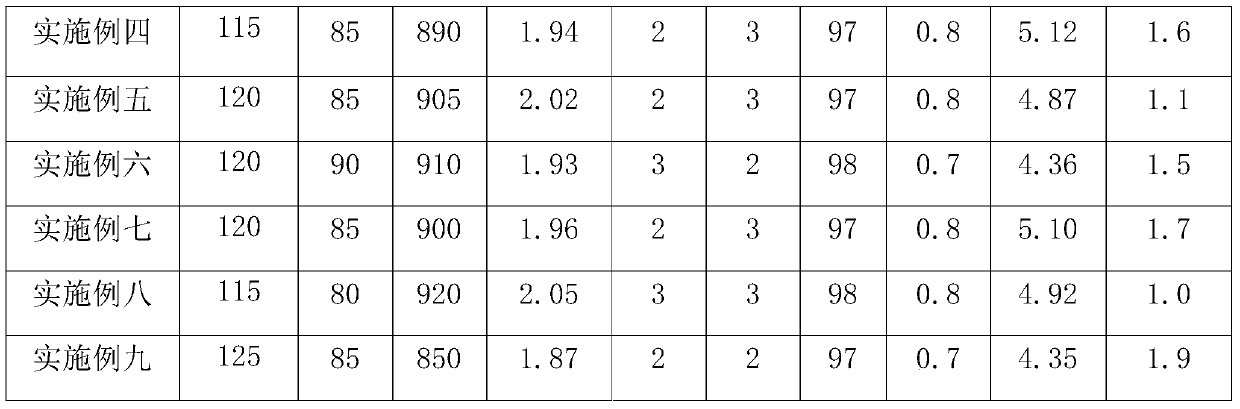

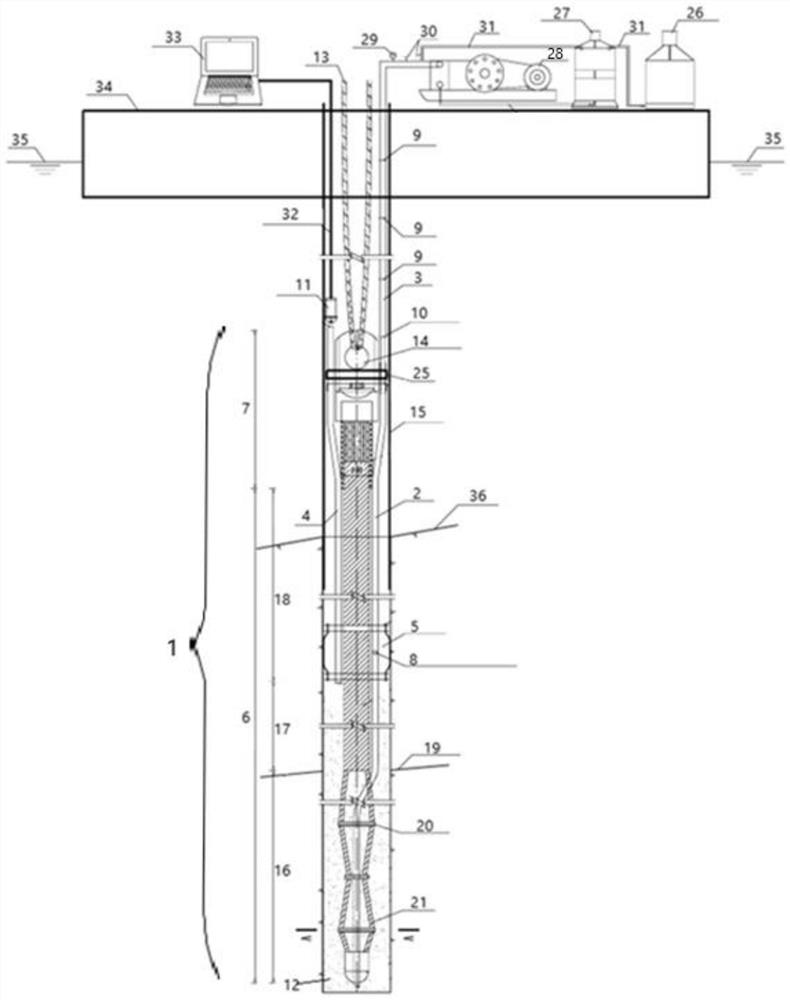

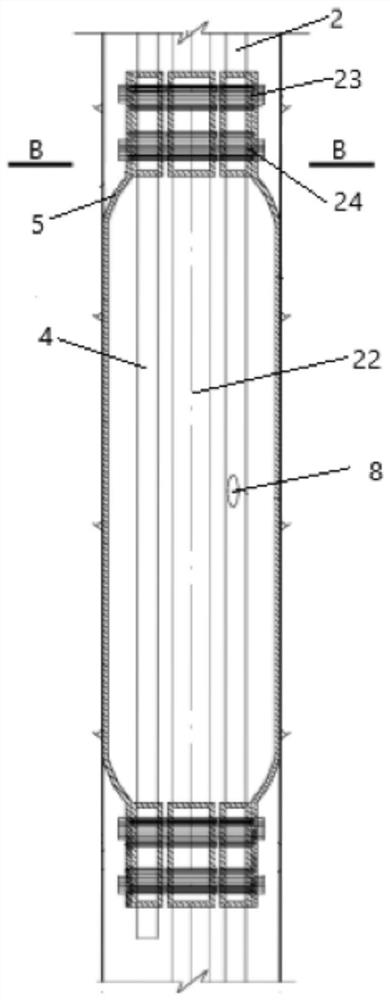

Technology and device for preparing multi-solid phase modified clay paste slurry

InactiveCN109020374ALow costLow strength erosion resistanceUnderground chambersTunnel liningEnvironmental resistanceSlurry

The invention provides a technology and a device for preparing a multi-solid phase modified clay paste slurry, and relates to the technical fields of mine grouting, and curtain grouting and water plugging of mined mines. The technology is characterized in that clay, water, a solid phase structure agent, an accelerator, a solid phase thickener and a solid phase inert natural plant reinforcement agent are stirred to prepare the paste slurry. The device used by the preparation technology comprises a clay-based slurry base station and a mobile platform, the clay-based slurry base station is provided with a transfer pump, and the transfer pump of the clay-based slurry base station pumps the qualified clay-based slurry into a stirring bin through a base slurry conveying pipeline. The paste slurry has the characteristics of high consistency, low flow rate, rapidness in setting, strong erosion resistance, low water discharging rate, excellent plugging effect on flowing water having a large flow rate, a high runoff speed and a wide water passage, obvious wall hanging effect, stable slurry performances, and good economical and environmentally-friendly properties; and the slurry preparation technology has the advantages of easiness in implementation, high efficiency, small occupied area of the device, high efficiency, and generation of large economic and environmental benefits.

Owner:NORTH CHINA ENG INVESTIGATION INST

A non-acid-soluble high-strength channeling and leakage plugging agent and its preparation method

Owner:CHINA PETROLEUM & CHEM CORP +1

High waterproof synchronous grouting grout for subsea shield tunnel

The invention provides a high-waterproofness synchronous grouting slurry for submarine shield tunnels. The high-waterproofness synchronous grouting slurry comprises the following components as raw materials in percent by weight: 7.0-9.5% of a cementing material, 14.5-17.5% of ground limestone powder, 2.6-4.2% of sodium-based bentonite, 55-60% of river sand, a waterproofing agent of which the usingamount is 3.0% of that of the cementing material, a water reducing agent of which the using amount is 1.0% of that of the cementing material, hydroxypropyl methyl cellulose of which the using amountis 0.5% of that of the cementing material, polyacrylamide of which the using amount is 0.1% of that of the cementing material, an air entraining agent of which the using amount is 0.03% of that of thecementing material, and the balance of water, wherein the cementing material comprises cement and slaked lime according to a mass ratio of (4.0-5.5):(3.0-4.0). The high-waterproofness synchronous grouting slurry provided by the invention has relatively high waterproofness, relatively high early shear strength and strong seawater seepage resistance, and can provide certain shear resistance, so that the problems of floating of duct pieces and cracking-caused water seepage can be effectively solved and a role in stabilizing the duct piece is played.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Deepwater ground anchor grouting method

The invention discloses a deepwater ground anchor grouting method. The deepwater ground anchor grouting method comprises the following steps that S1, a water-proof casing pipe is installed in an anchor hole, a grout inlet pipe and a grout return pipe are fixed to a cable body, a grout stopping bag is installed on the cable body, an outlet of the grout inlet pipe is close to the bottom of the anchor hole, a lower opening of the grout return pipe is located below the grout stopping bag, an upper opening of the grout return pipe is located above a cable joint, and an underwater detector is installed over the upper opening of the grout return pipe; S2, an anchor cable is placed in the water-proof casing pipe and placed in the anchor hole; S3, grouting grout prepared on site is injected into the anchor hole through the grout inlet pipe; and S4, when the underwater detector monitors that grout starts to return from the upper opening of the grout return pipe, the theoretical grouting amount which is 0.6-1.4 times that of the grout is injected continuously, and the theoretical grouting amount is the theoretical grout amount needed for filling the anchor hole. According to the deepwater ground anchor grouting method, the requirements that an underwater anchoring grouting solidified body is early in strength, high in strength, micro-expanded, good in groutability, free of corrosion to steel strands and the like can be met while the compactness of the grout is guaranteed.

Owner:POWERCHINA ZHONGNAN ENG +1

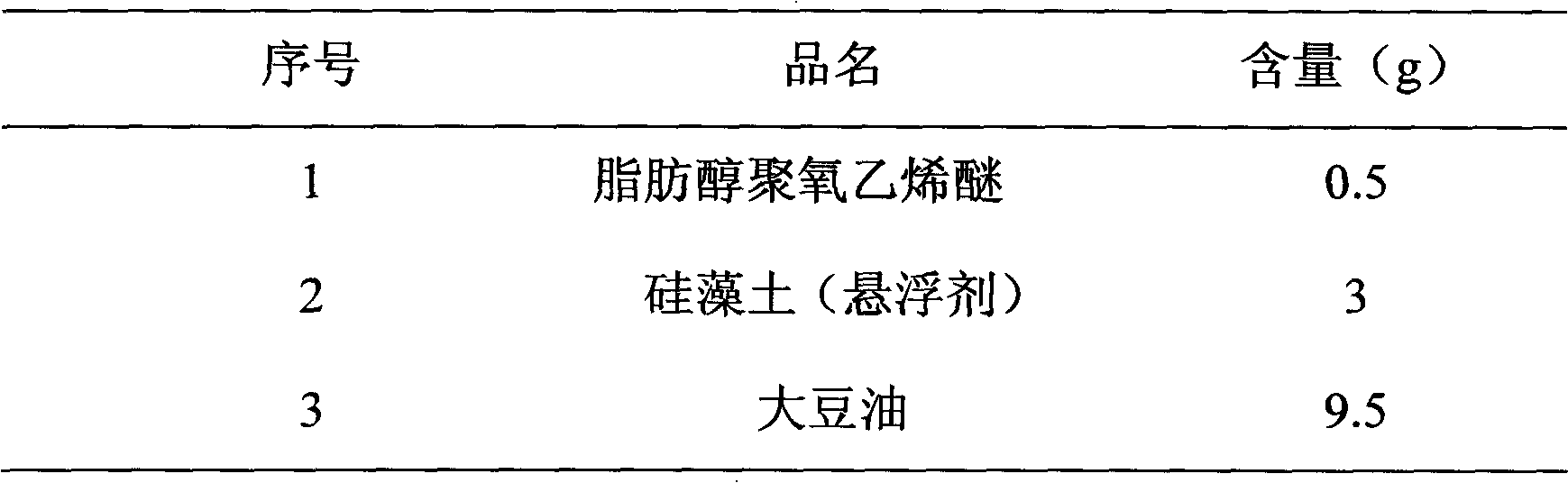

Cyhalothrin water emulsion and method for preparing same

InactiveCN101790991AGood liquidityLow water separation rateBiocideAnimal repellantsEmulsionSOYBEAN SEED OIL

The invention provides cyhalothrin water emulsion comprising the following components by mass percent: 8-10 percent of cyhalothrin, 8-15 percent of vegetable oil, 2-4 percent of lauric acid diethanolamide, 0.6-1.5 percent of mixture of acrylic acid and acrylic ester, 3-5 percent of diatomaceous earth and 2-4 percent of the low-HLB (hydrophile-lipophile balance) surfactant. According to the inverse suspended emulsion polymerization theory, the raw medicament is dissolved in the soybean oil so as to be suspended and emulsified directly to be more environmental friendly. The cyhalothrin water emulsion has good dispersity and high dilution stability, physical and chemical heat storage stability and cold storage stability.

Owner:GUANGZHOU UNIVERSITY

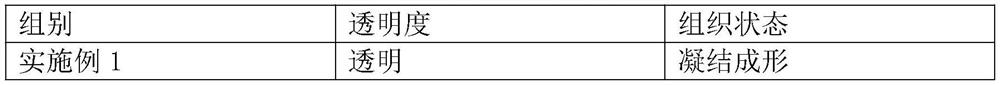

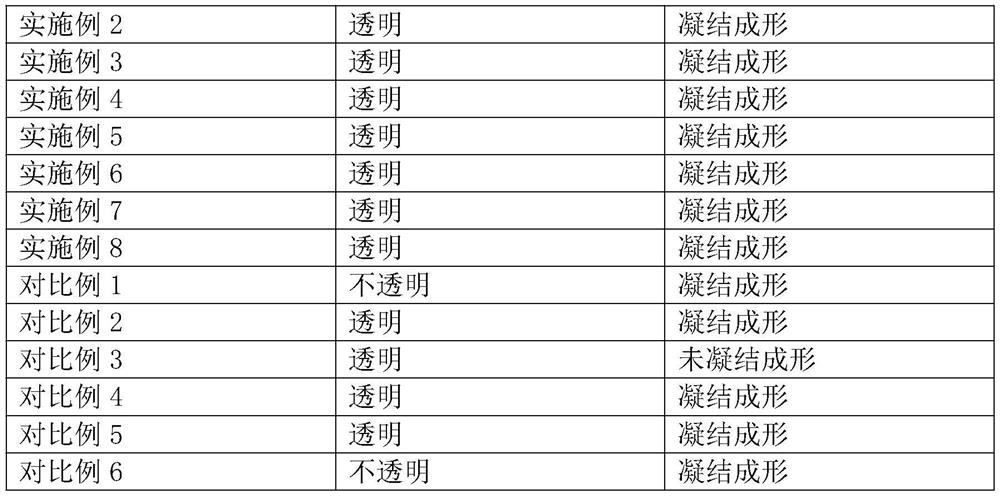

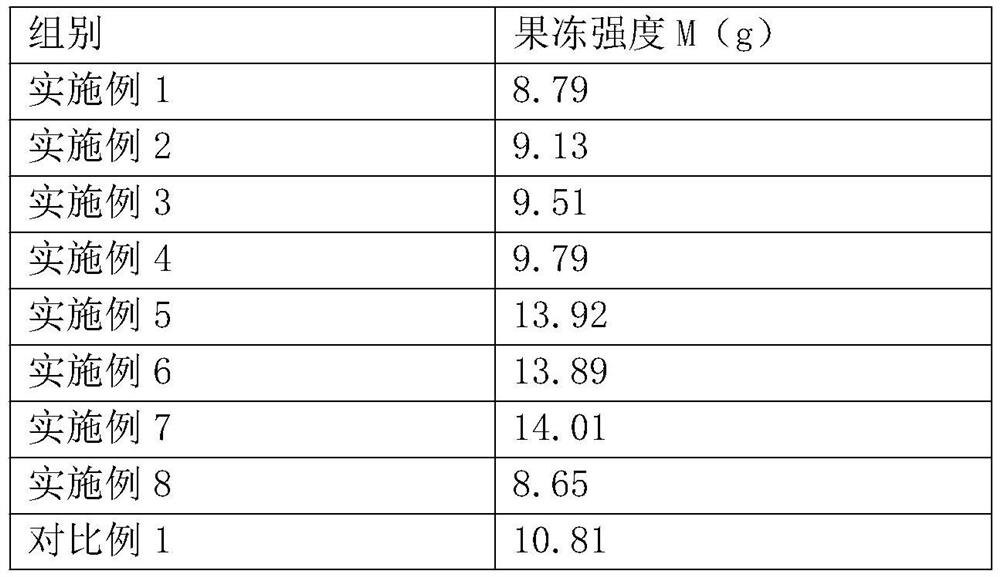

Hyaluronic acid jelly and preparation method thereof

ActiveCN112335863ASolve the problem of easy water analysisDoes not affect blood sugarInorganic compound food ingredientsFood ingredient as gelling agentCarrageenanMedicine

The invention discloses hyaluronic acid jelly. The hyaluronic acid jelly is characterized in that the hyaluronic acid jelly is of a three-dimensional reticular gel structure and comprises kappa-carrageenan, KCl, xylitol, hyaluronic acid or salt thereof. The sugar-free jelly containing hyaluronic acid disclosed by the invention can solve the problem of jelly bleeding, and besides, can meet the requirements of people for low sugar and even no sugar.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

Fresh wet konjac rice and preparation method thereof

PendingCN113768108ARich varietyHigh nutritional valueFood thermal treatmentFood ingredientsBiotechnologyCalcium biphosphate

The invention relates to the technical field of food processing and discloses fresh wet konjac rice. The fresh wet konjac rice is prepared from raw materials in parts by weight as follows: 6-6.5 parts of konjac powder, 4-4.5 parts of soy isolate protein, 50-60 parts of water, 0.6-3 parts of a calcium hydroxide solution and 4-6 parts of a calcium hydrophosphate solution. The invention further discloses a method for preparing the fresh wet konjac rice. The method comprises steps as follows: the konjac powder, the soy isolate protein and water are mixed and stirred uniformly, and a blended solution is obtained; the blended solution is left to stand for swelling, and konjac-soy isolate protein gel is obtained; and the calcium hydroxide solution, the calcium hydrophosphate solution and the konjac-soy isolate protein gel are mixed uniformly, and composite gel is obtained; the composite gel is subjected to extrusion, heat setting, curing and rinsing sequentially, and the fresh wet konjac rice is obtained. According to the fresh wet konjac rice and the preparation method thereof, the variety of konjac food can be enriched, the nutritional value of the konjac food is increased, and the obtained fresh wet konjac rice has uniform texture, good elasticity and toughness and low water separation rate.

Owner:SICHUAN ACAD OF FOOD & FERMENTATION INDS

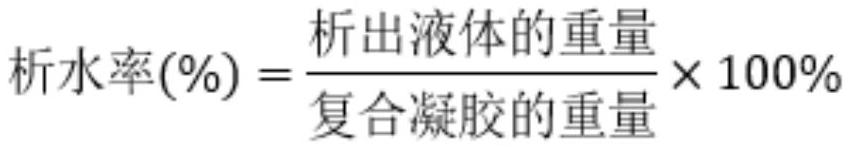

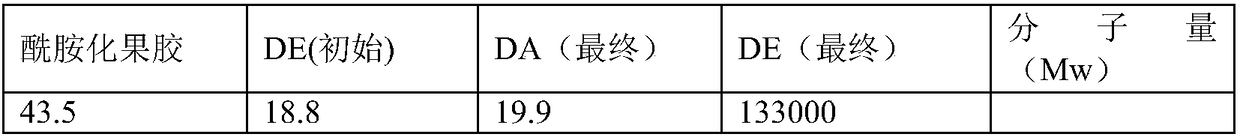

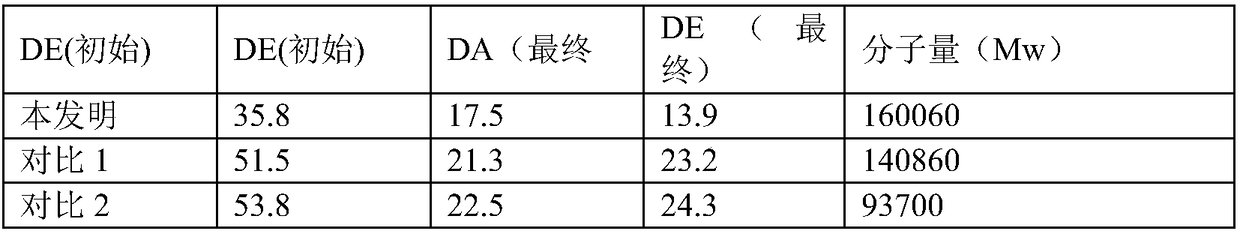

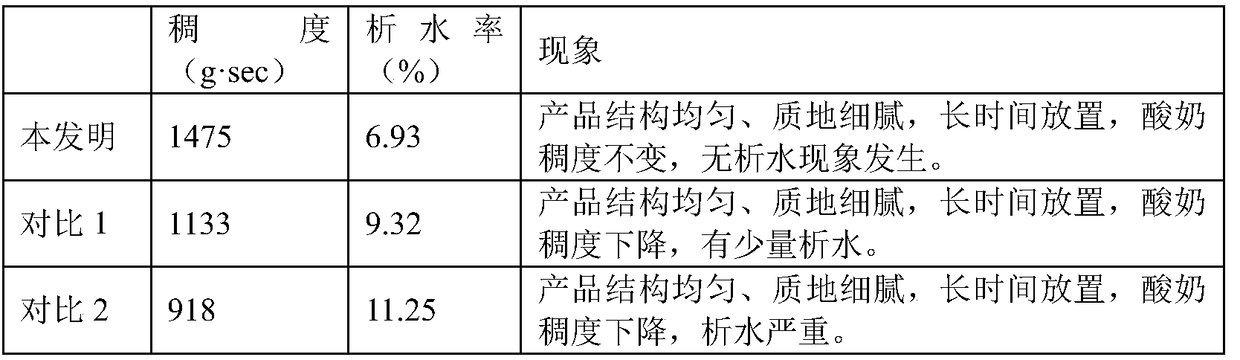

Preparation method of amidated pectin

The invention relates to a preparation method of amidated pectin. The preparation method comprises the steps that dried orange peel is dried and crushed, a mild extraction method is adopted to preparea pectin solution, plant pectin methylesterase is used for enzymolysis of a pectin clear solution, and finally, powder initial pectin is obtained; amidation reaction is carried out on the powder initial pectin to obtain the amidated pectin. The obtained amidated pectin has a high molecular weight and a controllable block structure so as to meet requirement standards of European Union (EU) for quality of the amidated pectin. When the amidated pectin is applied to yogurt, the consistency of the yogurt can be remarkably increased; when the yogurt is placed for a long time, the consistency of theyogurt is not reduced, and the water separation phenomenon is avoided. Besides, the prepared amidated pectin can be used for remarkably changing intestinal flora and promoting the growth of intestinal probiotics.

Owner:YANTAI ANDRE PECTIN

A kind of grouting construction technology using gin grouting method

ActiveCN108678375BStable in natureLow water separation rateBuilding material handlingControl systemArchitectural engineering

The invention relates to a grouting construction process using a GIN grouting method. The method comprises the steps of forming a hole to be grouted, cleaning the hole to be grouted, surveying the hole to be grouted, uniformly dividing a grouting section into a plurality of grouting subdivisions according to a survey result, installing a grouting construction control system, grouting the hole to be grouted through the grouting construction system, controlling the grouting pressure, when each grouting time threshold is reached, adding a grouting pressure increment on the basis of an original grouting pressure to continue grouting, and when the grouting pressure reaches the preset grouting pressure threshold, ending the grouting; by using the technical scheme of the process, the grouting strength value GIN of each grouting subdivision section is controlled by a computer, so that the grouting strength value GIN of the whole hole to be grouted in the grouting process is kept constant, anda perfusion flow rate and a perfusion pressure are always matched, the quality of the grouting construction operation is improved, and the process has the advantages that the construction process is simple, the work efficiency is high, the anti-seepage effect is good and the like.

Owner:SINOHYDRO BUREAU 9

Preparation method of karst foundation grouting single-control cement grout

The invention relates to a preparation method of a karst foundation grouting single-control cement grout. According to a technical index of a water bleeding rate not higher than 5%, the preparation method comprises mixing coagulation accelerator, water-retaining agent and water reducer into cement slurry to prepare the karst foundation grouting single-control cement grout. The dosage of components, especially additives, in the prepared karst foundation grouting single-control cement grout is determined according to the technical index of the water bleeding rate, so that the karst foundation grouting single-control cement grout has the advantages of being low in water bleeding rate, high in concretion rate and simple in construction process, is applicable to grouting karst foundations withpoor grouting treatment connectivity and easy loss of large amount of slurry and further has a broad application prospect in karst foundation processing.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com