Preparation method of hydroxypropyl starch

A technology of hydroxypropyl starch and starch, applied in the field of preparation of hydroxypropyl starch, can solve the problems of instability, easy aging, poor freeze-thaw stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

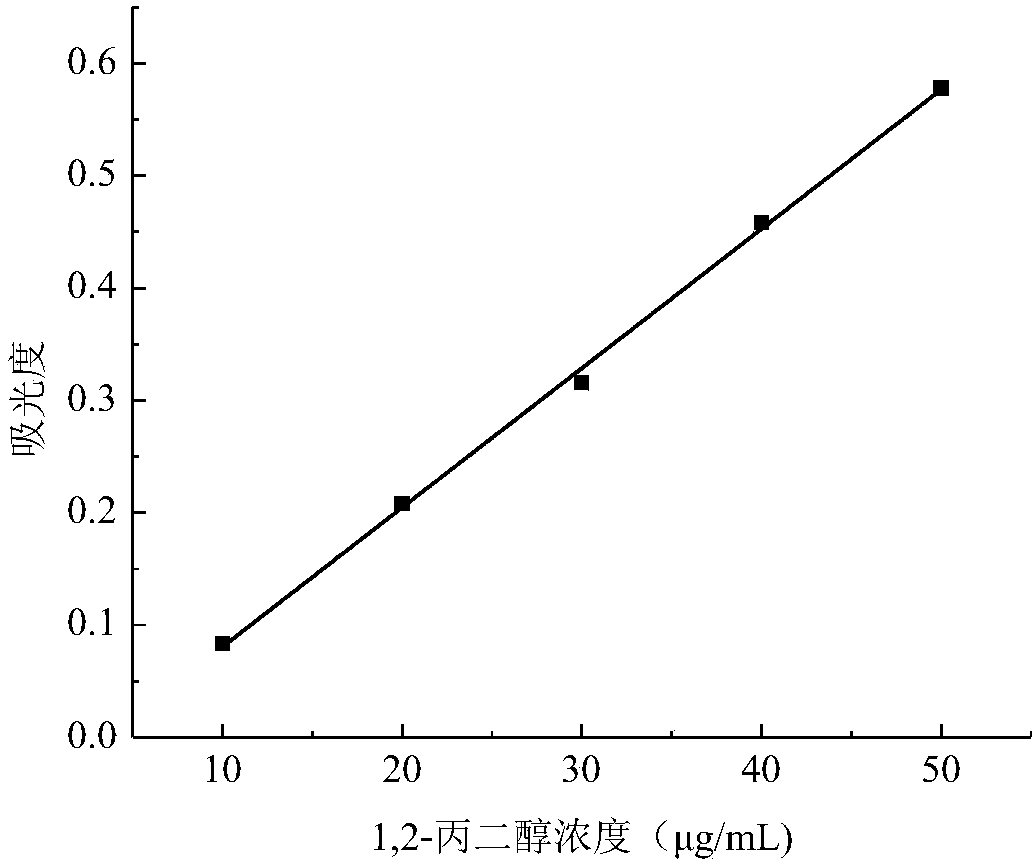

Method used

Image

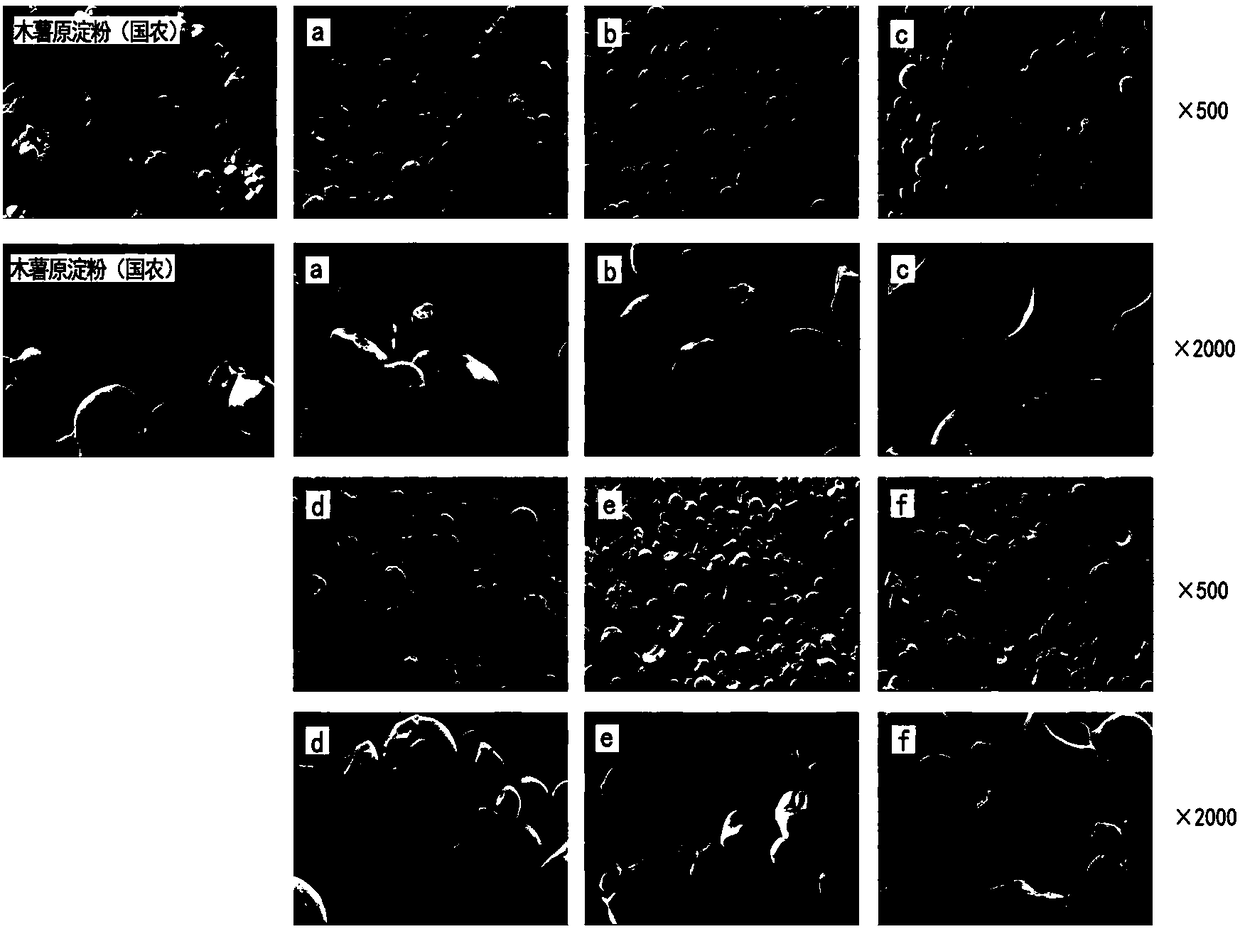

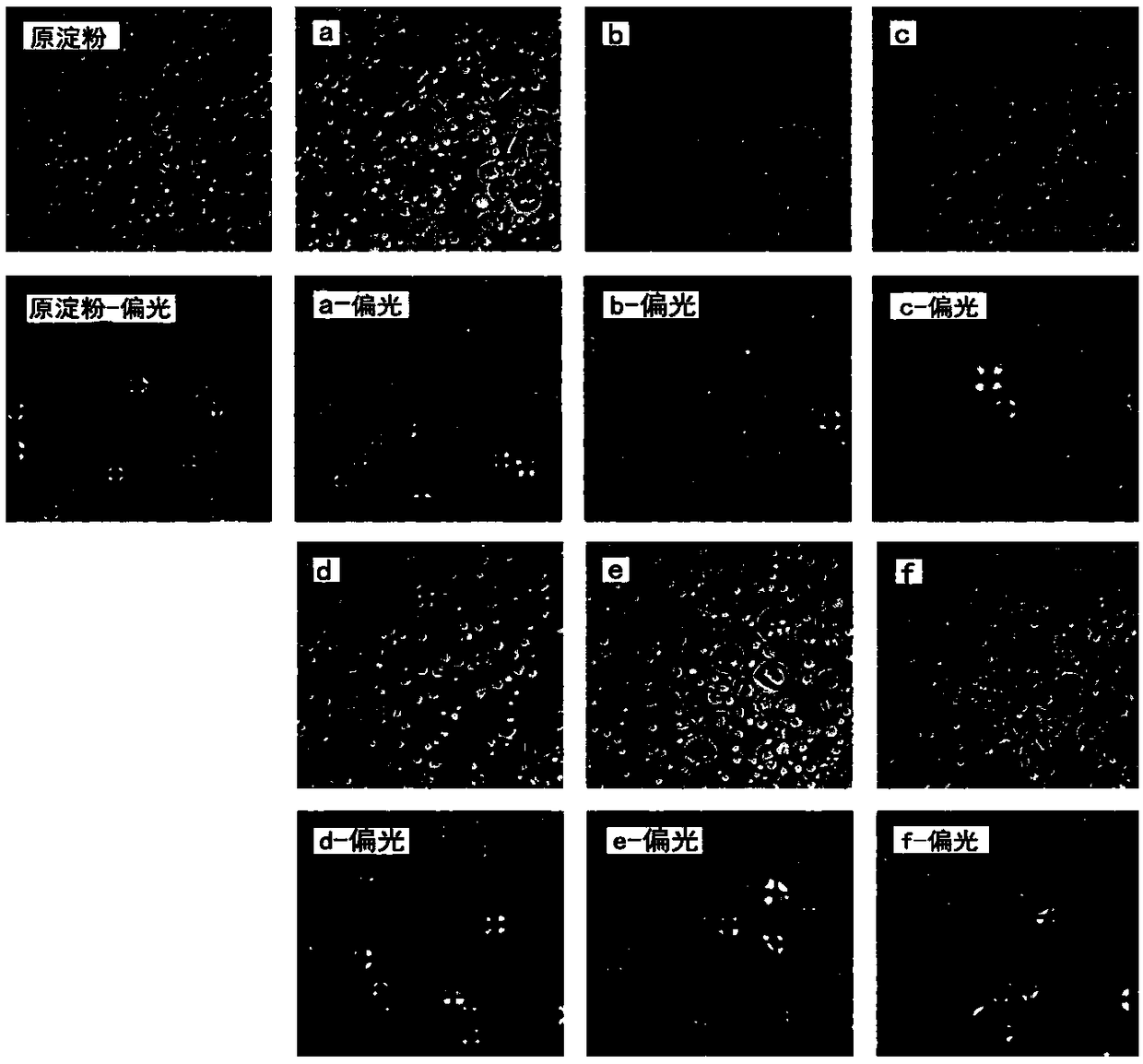

Examples

Embodiment 1

[0030] The preparation method of hydroxypropyl starch described in the present embodiment comprises the steps:

[0031] (1) Get cassava starch and add water to prepare the starch emulsion whose mass concentration is 40wt%, stir evenly for 10min to fully disperse the starch, obtain uniform starch emulsion, and add anhydrous Na 2 SO 4 , stir evenly until fully dissolved;

[0032] (2) The above-mentioned starch emulsion is heated to 35°C in a super constant temperature water bath, and under constant stirring, the pH value of the starch emulsion is adjusted to 10.5 with 3wt% sodium hydroxide solution, and at the same time, quickly add the cassava starch dry basis Amount of 8wt% propylene oxide was reacted, and the closed container was reacted for 20h;

[0033] (3) After the reaction is finished, add 6wt% dilute sulfuric acid dropwise through the nozzle to adjust the pH of the reaction solution to 5.5, neutralize to terminate the reaction, and then centrifuge the reaction solutio...

Embodiment 2

[0040] The preparation method of hydroxypropyl starch described in the present embodiment comprises the steps:

[0041] (1) Get cassava starch and add water to prepare the starch emulsion whose mass concentration is 40wt%, stir evenly for 10min to fully disperse the starch, obtain uniform starch emulsion, and add anhydrous Na 2 SO 4 , stir evenly until fully dissolved;

[0042](2) The above-mentioned starch emulsion is heated to 40°C in a super constant temperature water bath, under constant stirring, the pH value of the starch emulsion is adjusted to 10.5 with 3wt% sodium hydroxide solution, and at the same time, quickly add The amount of 8wt% propylene oxide was reacted, and the closed container was reacted for 20h;

[0043] (3) After the reaction is finished, add 6wt% dilute sulfuric acid dropwise through the nozzle to adjust the pH of the reaction solution to 5.5, neutralize to terminate the reaction, and then centrifuge the reaction solution to separate the solid from t...

Embodiment 3

[0046] The preparation method of hydroxypropyl starch described in the present embodiment comprises the steps:

[0047] (1) Get cassava starch and add water to prepare the starch emulsion whose mass concentration is 40wt%, stir evenly for 10min to fully disperse the starch, obtain uniform starch emulsion, and add anhydrous Na 2 SO 4 , stir evenly until fully dissolved;

[0048] (2) The above-mentioned starch emulsion is heated to 45°C in a super constant temperature water bath, and under constant stirring, the pH value of the starch emulsion is adjusted to 10.5 with 3wt% sodium hydroxide solution, and at the same time, quickly add the cassava starch dry basis The amount of 8wt% propylene oxide was reacted, and the closed container was reacted for 20h;

[0049] (3) After the reaction is finished, add 6wt% dilute sulfuric acid dropwise through the nozzle to adjust the pH of the reaction solution to 5.5, neutralize to terminate the reaction, and then centrifuge the reaction sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com