A non-acid-soluble high-strength channeling and leakage plugging agent and its preparation method

A plugging agent and high-strength technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor acid corrosion resistance, failure of channeling and plugging measures, etc., and achieve strong acid resistance, efficient dispersion and mixing, The undemanding effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

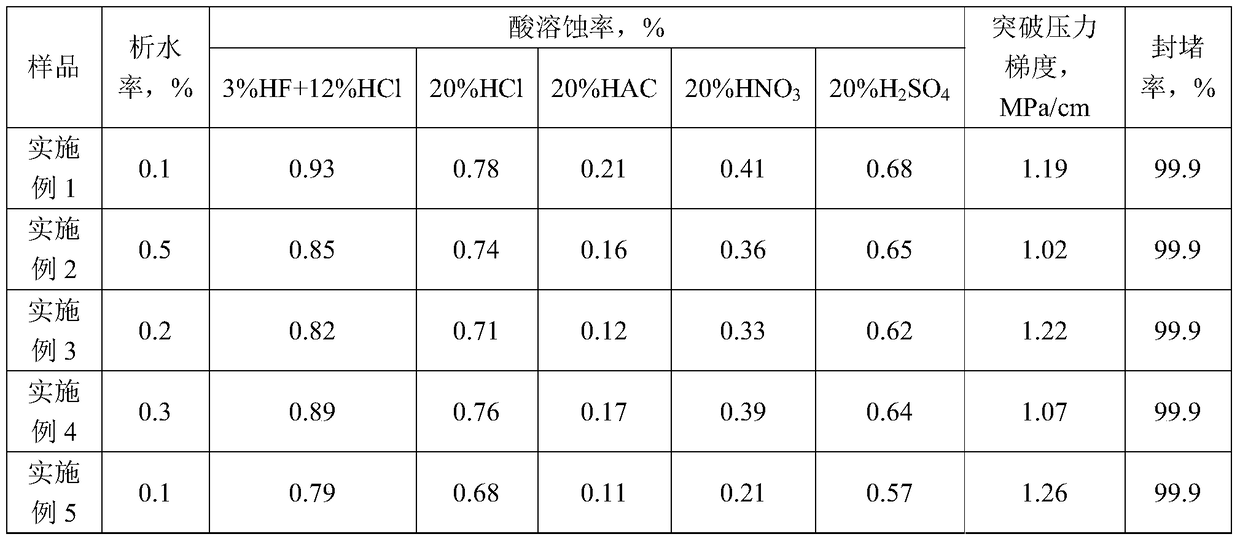

Examples

Embodiment 1

[0032] The non-acid-soluble high-strength sealing and leaking agent of this embodiment includes the following components in parts by weight: 60 parts of curing agent, 5 parts of activity enhancer, 2 parts of mutual solvent, 0.8 part of coupling agent, 1 part of furan resin, 3 parts of dispersant; the curing agent is a mixture of diabase, sodium silicate and sodium fluorosilicate in a mass ratio of 25:2:1, the silicon oxide content in diabase is more than 50%, sodium silicate The modulus is 3.0; the active enhancer is a mixture of nano-zirconia and nano-titanium oxide in a mass ratio of 3:1; the mutual solvent is furfuryl alcohol; the coupling agent is KH550; the furan resin is Furfuryl alcohol furfural type furan resin; the dispersant is calcium lignosulfonate.

[0033] The non-acid-soluble high-strength sealing and leakage plugging agent of this embodiment is composed of the following components in percentage by weight: curing agent 60%, activity enhancer 5%, mutual solvent 2...

Embodiment 2

[0037] The non-acid-soluble high-strength channeling and plugging agent of this embodiment includes the following components in parts by weight: 55 parts of curing agent, 3 parts of activity enhancer, 3 parts of mutual solvent, 1 part of coupling agent, 2 parts of furan resin, 1.5 parts of dispersant; the curing agent is a mixture of diabase, sodium silicate and sodium fluorosilicate in a mass ratio of 20:2:1, the silicon oxide content in diabase is more than 50%, and sodium silicate The modulus is 3.2; the active enhancer is a mixture of nano-zirconia and nano-titanium oxide in a mass ratio of 2:1; the mutual solvent is furfuryl alcohol; the coupling agent is KH550; the furan resin is Furfuryl alcohol furfural type furan resin; the dispersant is calcium lignosulfonate.

[0038] The non-acid-soluble high-strength sealing and plugging agent of this embodiment is composed of the following components in weight percentage: 55% curing agent, 3% active enhancer, 3% mutual solvent, 1...

Embodiment 3

[0042] The non-acid-soluble high-strength sealing and leakage plugging agent of this embodiment includes the following components in parts by weight: 60 parts of curing agent, 4 parts of activity enhancer, 2.5 parts of mutual solvent, 1 part of coupling agent, 1.5 parts of furan resin, 2.2 parts of dispersant; the curing agent is a mixture of diabase, sodium silicate and sodium fluorosilicate in a mass ratio of 23:2:1, the content of silicon oxide in diabase is more than 50%, and sodium silicate The modulus is 3.5; the active enhancer is a mixture of nano-zirconia and nano-titanium oxide in a mass ratio of 2.5:1; the mutual solvent is furfuryl alcohol; the coupling agent is KH550; the furan resin is Furfuryl alcohol furfural type furan resin; the dispersant is calcium lignosulfonate.

[0043] The non-acid-soluble high-strength channeling and plugging agent of this embodiment is composed of the following components in percentage by weight: curing agent 60%, activity enhancer 4%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com